Impact of Interfacial Transition Zone on Concrete Mechanical Properties: A Comparative Analysis of Multiphase Inclusion Theory and Numerical Simulations

Abstract

:1. Introduction

2. Theoretical Model of Multiphase Inclusions

2.1. Theoretical Basis of Multiphase Inclusions

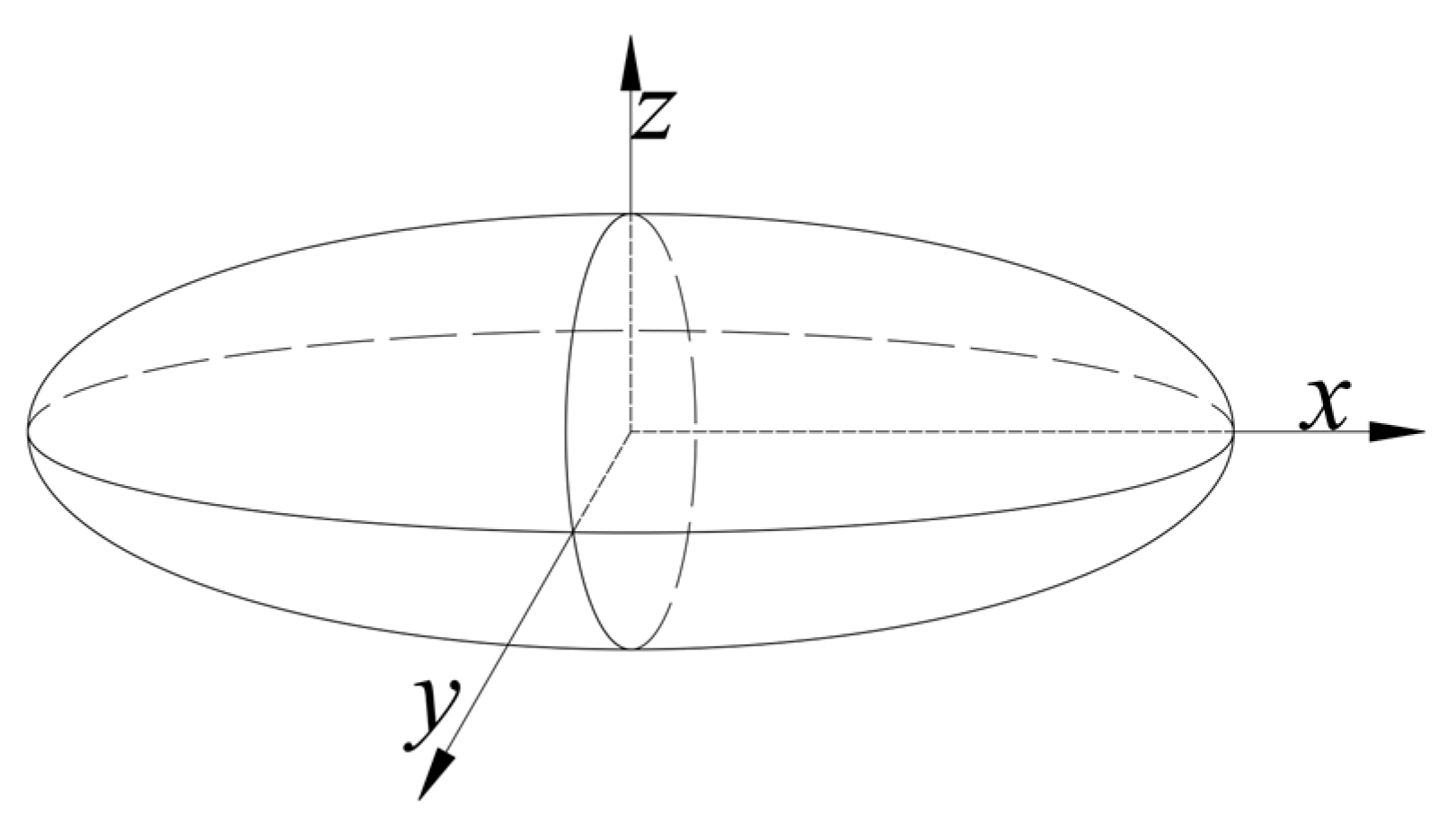

2.1.1. Eshelby’s Theory

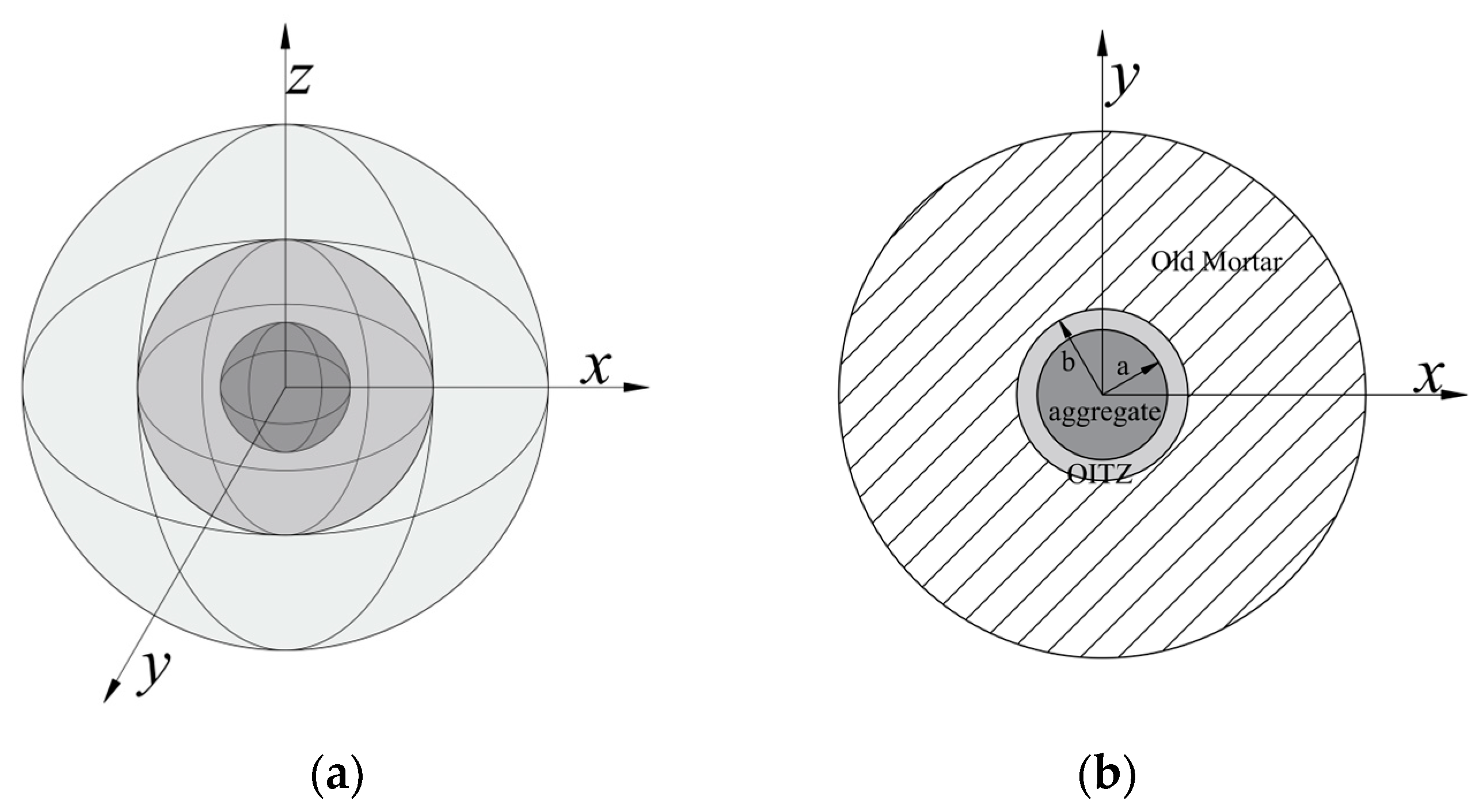

2.1.2. Three-Phase Sphere Model

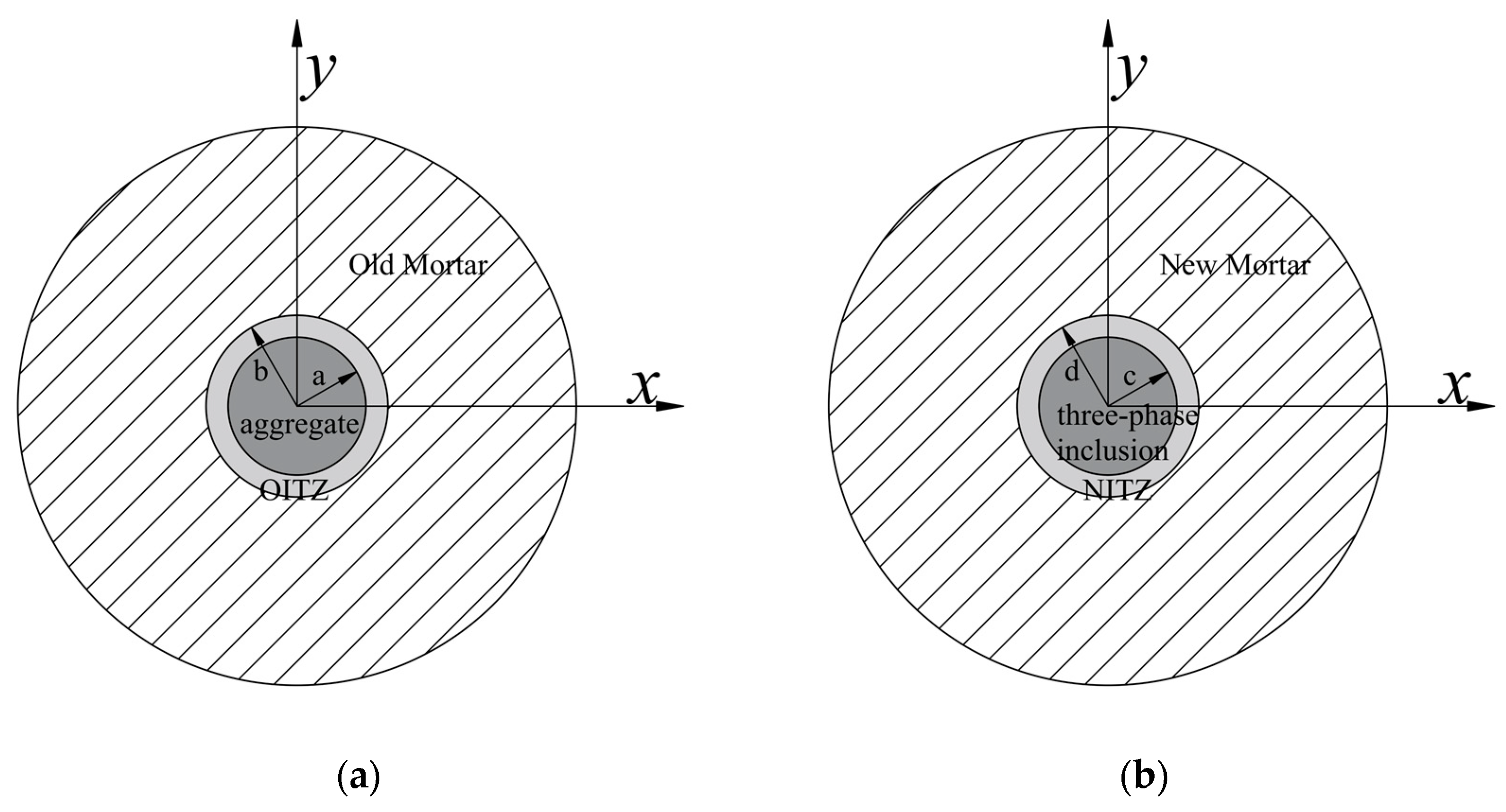

2.1.3. Superimposed Three-Phase Sphere and Mori–Tanaka Method

2.2. Material Mechanical Performance Testing

2.3. Theoretical Calculation Example of RC

2.3.1. Simplified RC

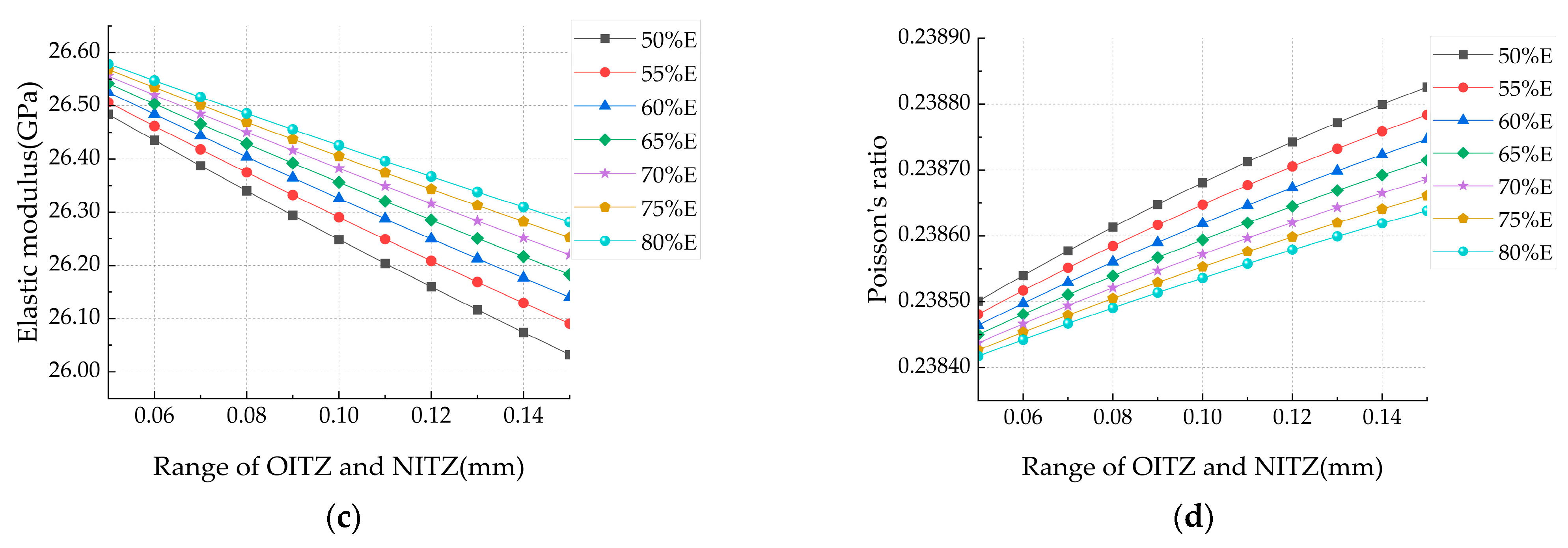

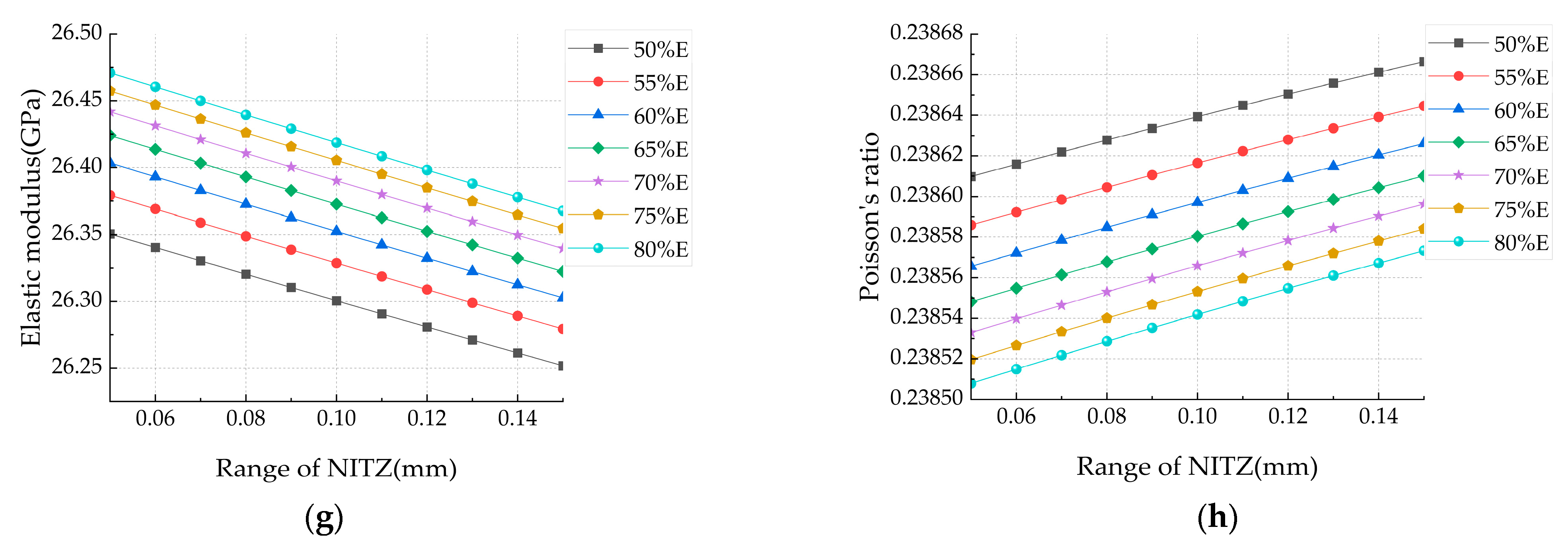

2.3.2. Theoretical Examples

3. Numerical Simulation

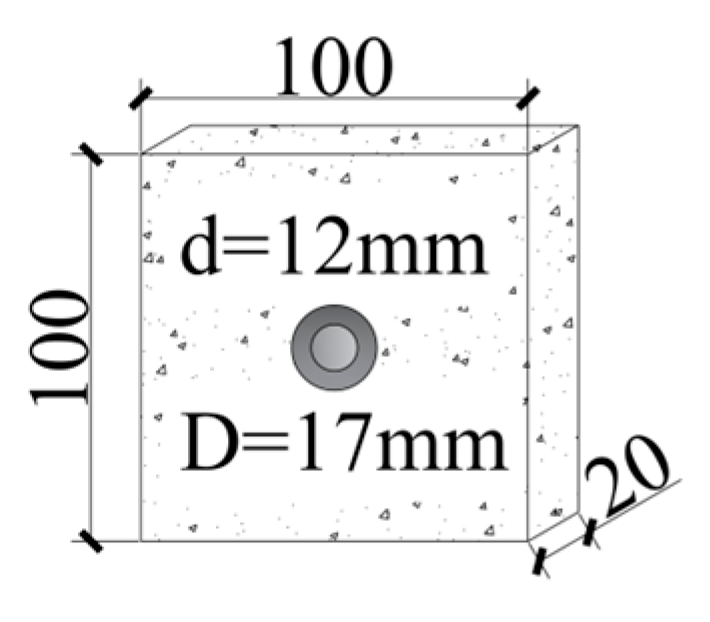

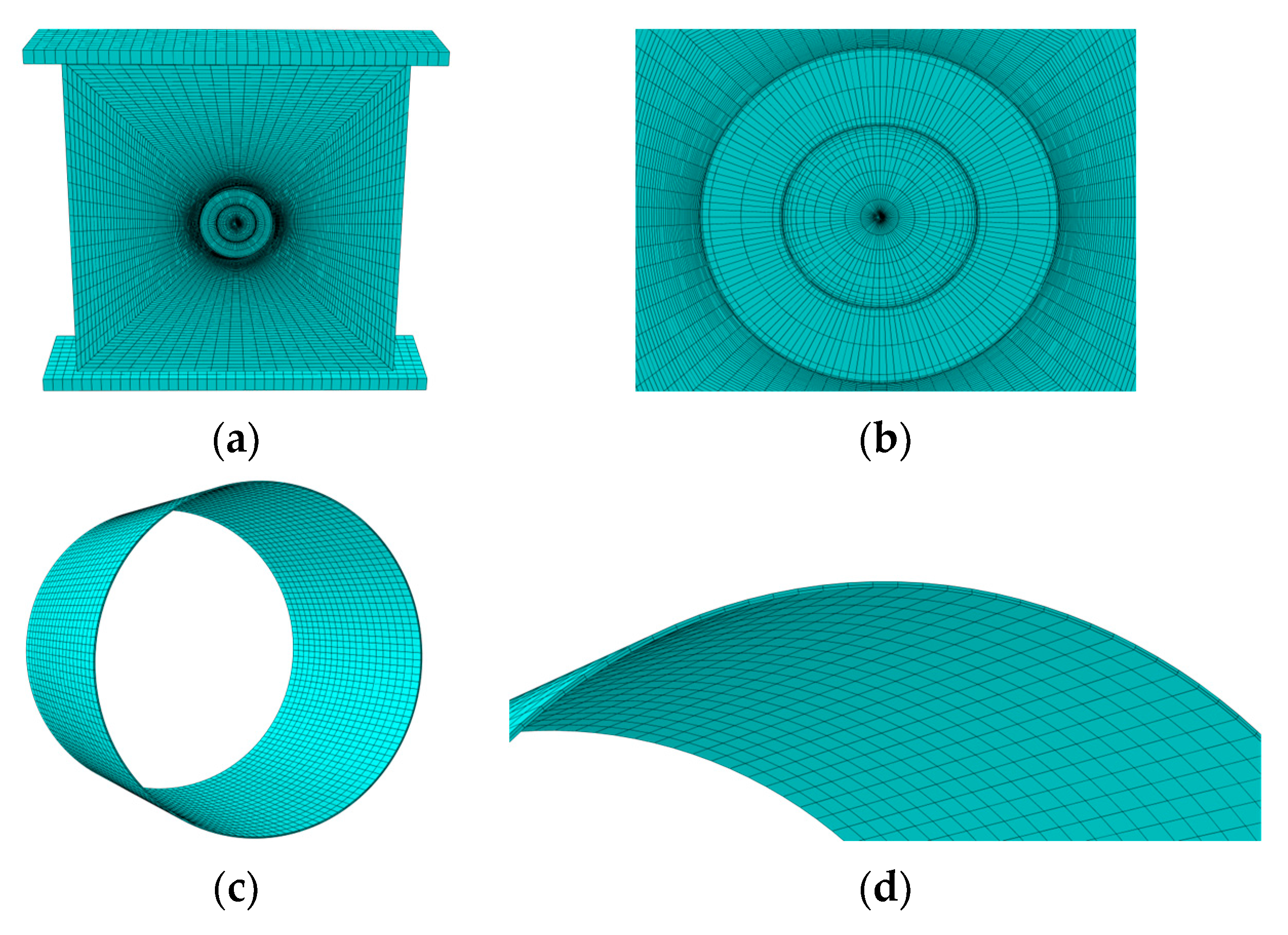

3.1. Model Establishment

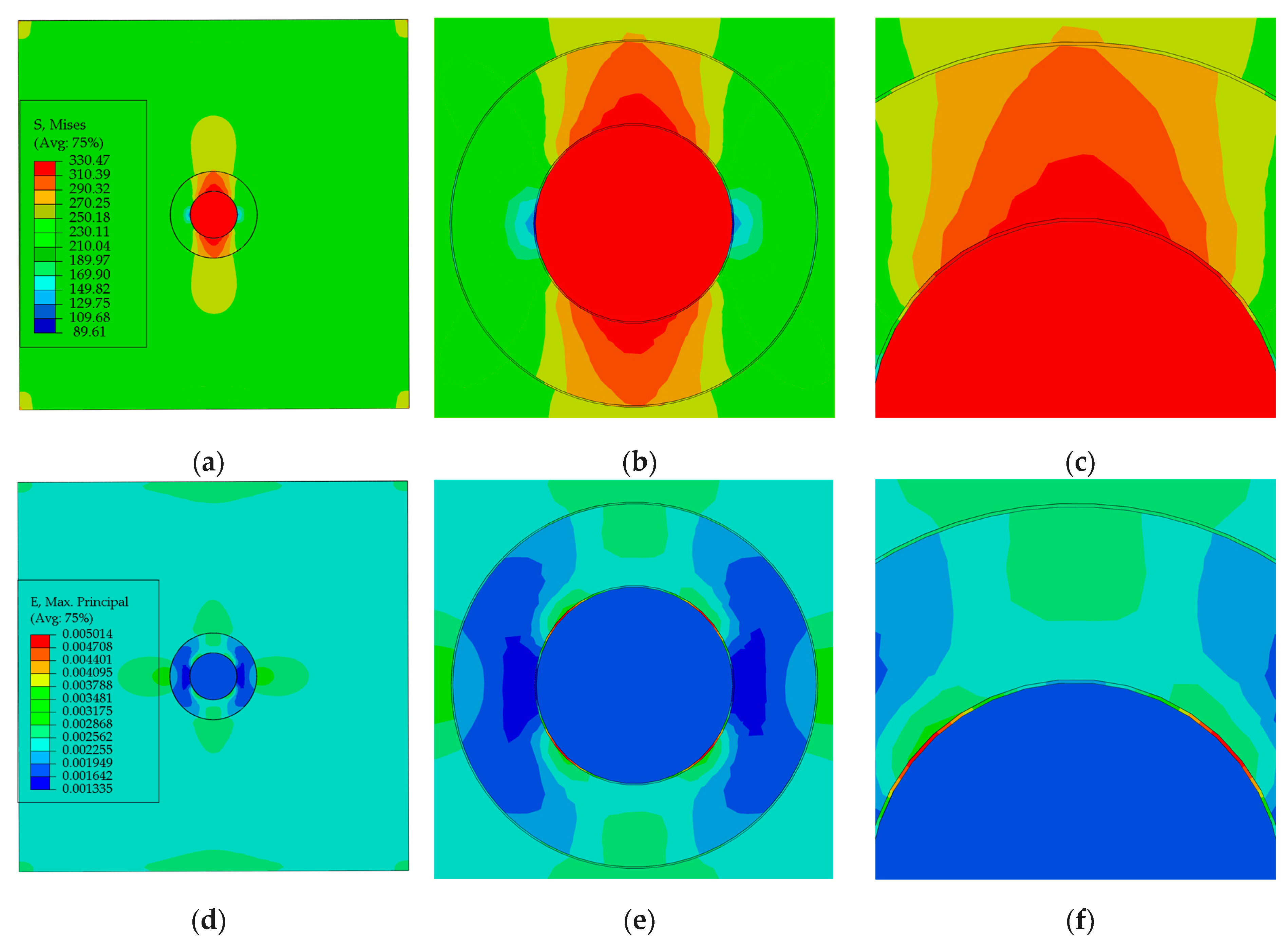

3.2. Stress Distribution Morphology and Analysis

4. Discussion

Comparison of Theoretical Analysis and Numerical Simulation Results

5. Conclusions

- (1)

- This research is centered on the multiphase inclusion theory, which helps minimize errors stemming from simplified assumptions by utilizing precise theoretical calculations. RC is considered a multiphase composite material and details the interactions between different phases and their impacts on the overall properties of the material. The ITZ layer in the model plays a pivotal role in the mesoscale, significantly influencing the mechanical properties of the concrete. To accurately capture the characteristics of the recycled aggregate concrete, various mesoscale parameters are introduced, including different ITZ thicknesses and mechanical parameters, to predict the elastic modulus and Poisson’s ratio of RC. Based on the comparison of different ITZs in theory, it is suggested that the old mortar attached to RA should be removed as much as possible in practical application. In this way, the existence of OITZ is reduced to enhance the mechanical properties of RC.

- (2)

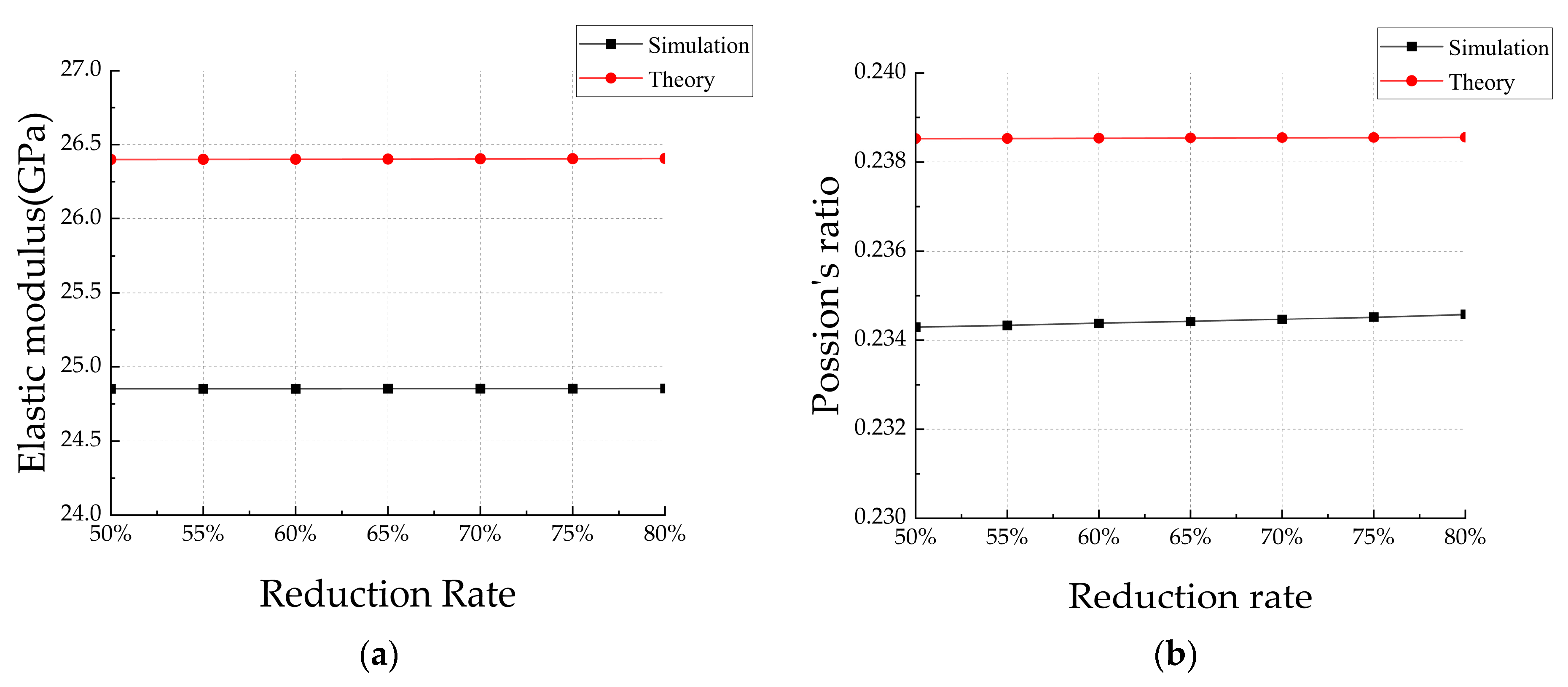

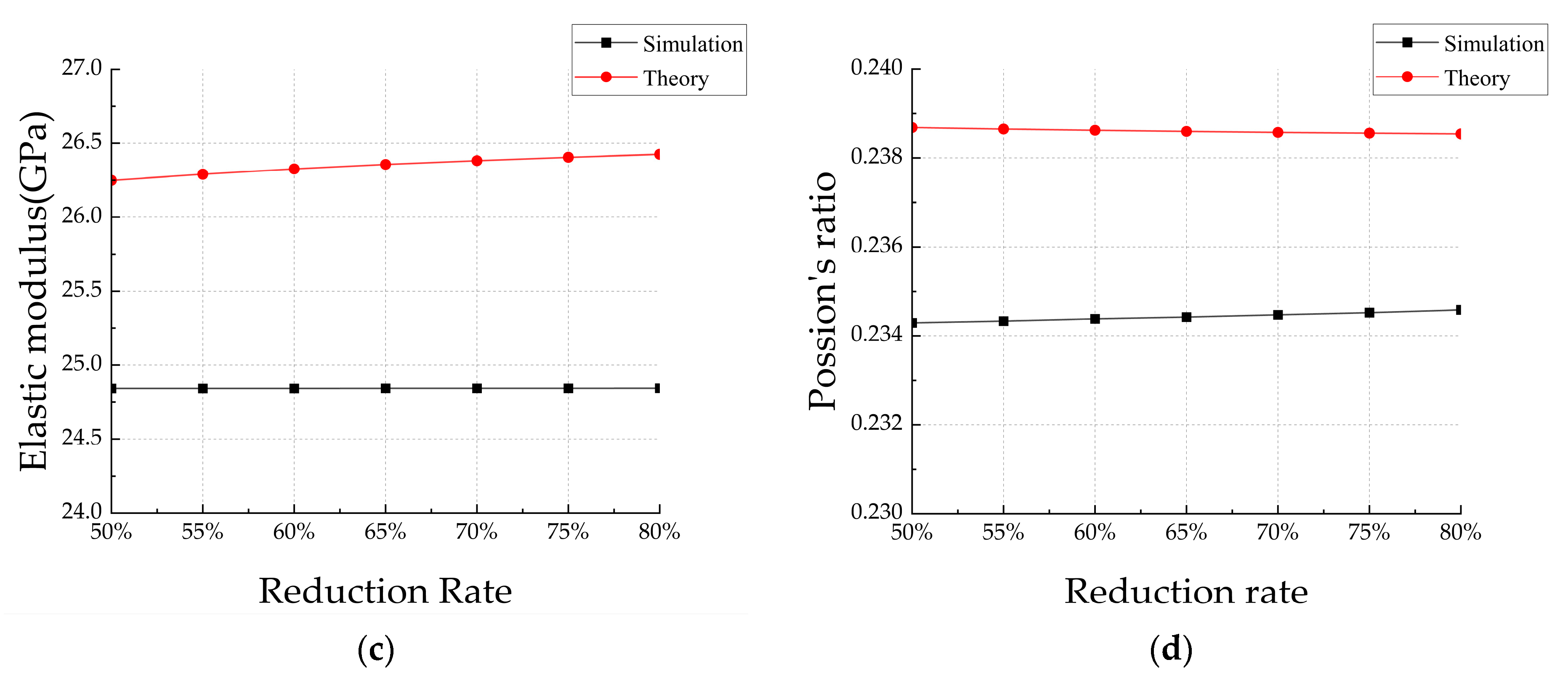

- Theoretical predictions are validated using the finite element method, maintaining consistency in parameters such as ITZ thickness. The results demonstrated that under identical conditions, the elastic modulus of RC is 26.4059 GPa, and the Poisson’s ratio is 0.2386. They closely align with those from the finite element simulation, which recorded an elastic modulus of 24.8542 GPa and a Poisson’s ratio of 0.2345, with errors controlled within 6.24% and 1.75%. This precision confirms the efficacy of multiphase inclusion theory in predicting the mechanical properties of composite materials and highlights the reliability of the inclusion theoretical model.

- (3)

- This study provides a scientific basis for the material design and performance optimization of RC, highlighting the significant value and application potential of theoretical research in the field of building materials. Future research will delve into the relationship between the mesoscale and macroscale properties of RC. By enhancing the theory of multiphase inclusions and improving the transition from microscale to macroscale analyses, we aim to extend this study beyond the elastic stage. The multiphase inclusion theory provides a detailed and accurate framework for predicting and optimizing the mechanical properties of recycled concrete. Although it has great potential for further computational research, it is clear that its updating requires complex models and hypotheses, as well as experimental verification of them. This approach will enable researchers to predict material strength and deepen the understanding of phase compatibility. Additionally, methods to enhance the strength of ITZ through the use of nanoscale materials continue to emerge in the future, and relying solely on microscopic experiments is not enough to fully demonstrate the macroscopic mechanical properties of materials, ongoing research on multiphase inclusion theory is expected to guide the selection of concrete materials and the optimization of ITZ layers in practical applications, enhancing the utilization efficiency of recycled materials in concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, J.; Li, L.; Shen, L.; Poon, C.S. Compressive Behaviour of Recycled Aggregate Concrete under Impact Loading. Cem. Concr. Res. 2015, 71, 46–55. [Google Scholar] [CrossRef]

- Tang, Y.; Xiao, J.; Zhang, H.; Duan, Z.; Xia, B. Mechanical Properties and Uniaxial Compressive Stress-Strain Behavior of Fully Recycled Aggregate Concrete. Constr. Build. Mater. 2022, 323, 126546. [Google Scholar] [CrossRef]

- Luo, Z.; Li, W.; Wang, K.; Shah, S.P. Research Progress in Advanced Nanomechanical Characterization of Cement-Based Materials. Cem. Concr. Compos. 2018, 94, 277–295. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Liu, Q. Meso-Level Numerical Simulation on Mechanical Properties of Modeled Recycled Concrete under Uniaxial Compression. Tongji Daxue Xuebao/J. Tongji Univ. 2011, 39, 791–797. [Google Scholar] [CrossRef]

- Maso, J.C. Interfacial Transition Zone in Concrete: State-of-the-Art Report; E & FN Spon: London, UK, 1996; ISBN 978-0-203-62725-9. [Google Scholar]

- Rahmadiawan, D.; Shi, S.; Abral, H.; Ilham, M.K.; Sugiarti, E.; Muslimin, A.N.; Ilyas, R.A.; Lapisa, R.; Putra, N.S.D. Comparative Analysis of the Influence of Different Preparation Methods on the Properties of TEMPO-Oxidized Bacterial Cellulose Powder Films. J. Nat. Fibers 2024, 21, 2301386. [Google Scholar] [CrossRef]

- Jean, B.; Liu, H.; Zhu, X.; Wang, X.; Yan, X.; Ma, T. Enhancing the Mechanical and Durability Properties of Fully Recycled Aggregate Concrete Using Carbonated Recycled Fine Aggregates. Materials 2024, 17, 1715. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y.; Pei, Z. Investigation of Mechanical Properties of Ultra-High-Performance Polyethylene-Fiber-Reinforced Recycled-Brick-Aggregate Concrete. Polymers 2023, 15, 4573. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.Z.; Odler, I. The Interfacial Zone between Marble and Tricalcium Silicate Paste. Cem. Concr. Res. 1987, 17, 784–792. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Nemati, K.M. The Percolation of Pore Space in the Cement Paste/Aggregate Interfacial Zone of Concrete. Cem. Concr. Res. 1996, 26, 35–40. [Google Scholar] [CrossRef]

- Vargas, P.; Restrepo-Baena, O.; Tobón, J.I. Microstructural Analysis of Interfacial Transition Zone (ITZ) and Its Impact on the Compressive Strength of Lightweight Concretes. Constr. Build. Mater. 2017, 137, 381–389. [Google Scholar] [CrossRef]

- Thomas, T.C.H.; Floyd, O.S. Tensile Bond Strength between Aggregate and Cement Paste or Mortar. ACI J. Proc. 1963, 60, 465–486. [Google Scholar] [CrossRef]

- Qiu, H.; Zhu, Z.; Wang, M.; Wang, F.; Luo, C.; Wan, D. Study of the Failure Properties and Tensile Strength of Rock-Mortar Interface Transition Zone Using Bi-Material Brazilian Discs. Constr. Build. Mater. 2020, 236, 117551. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Corr, D.J.; Shah, S.P. Effects of Interfacial Transition Zones on the Stress–Strain Behavior of Modeled Recycled Aggregate Concrete. Cem. Concr. Res. 2013, 52, 82–99. [Google Scholar] [CrossRef]

- Du, X.; Jin, L.; Ma, G. Macroscopic Effective Mechanical Properties of Porous Dry Concrete. Cem. Concr. Res. 2013, 44, 87–96. [Google Scholar] [CrossRef]

- Lin, F.; Meyer, C. Micromechanics Model for the Effective Elastic Properties of Hardened Cement Pastes. Fuhe Cailiao Xuebao/Acta Mater. Compos. Sin. 2007, 24, 184–189. [Google Scholar] [CrossRef]

- Thermal and Acoustic Performance in Textile Fibre-Reinforced Concrete: An Analytical Review—All Databases. Available online: https://webofscience.clarivate.cn/wos/alldb/full-record/INSPEC:12015501 (accessed on 17 April 2024).

- Li, G.; Zhao, Y.; Pang, S.-S. Four-Phase Sphere Modeling of Effective Bulk Modulus of Concrete. Cem. Concr. Res. 1999, 29, 839–845. [Google Scholar] [CrossRef]

- Eshelby, J.D. The Determination of the Elastic Field of an Ellipsoidal Inclusion, and Related Problems. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1957, 241, 376–396. [Google Scholar]

- Shi, C.; Fan, H.; Li, S. Interphase Model for Effective Moduli of Nanoparticle-Reinforced Composites. J. Eng. Mech. 2015, 141, 04015052. [Google Scholar] [CrossRef]

- Christensen, R.M.; Lo, K.H. Solutions for Effective Shear Properties in Three Phase Sphere and Cylinder Models. J. Mech. Phys. Solids 1979, 27, 315–330. [Google Scholar] [CrossRef]

- Benveniste, Y. A New Approach to the Application of Mori-Tanaka’s Theory in Composite Materials. Mech. Mater. 1987, 6, 147–157. [Google Scholar] [CrossRef]

- Boucher, S. On the Effective Moduli of Isotropic Two-Phase Elastic Composites. J. Compos. Mater. 1974, 8, 82–89. [Google Scholar] [CrossRef]

- The Interfacial Transition Zone (ITZ) between Cement Paste and Aggregate in Concrete|Interface Science. Available online: https://link.springer.com/article/10.1023/B:INTS.0000042339.92990.4c (accessed on 18 April 2024).

- Crack Propagation in Recycled Aggregate Concrete under Uniaxial Compressive Loading. ACI Mater. J. 2012, 109, 451–462. [CrossRef]

- Liu, Q.; Xiao, J.; Poon, C.S.; Li, L. Investigation on Modeled Recycled Concrete Prepared with Recycled Concrete Aggregate and Recycled Brick Aggregate. Jianzhu Jiegou Xuebao/J. Build. Struct. 2020, 41, 133–140. [Google Scholar] [CrossRef]

- Liu, Q.; Xiao, J.; Zhi, X.; Wang, Z. Damage Evolution Study of Modeled Recycled Concrete Based on Orientation of Recycled Aggregate. Tongji Daxue Xuebao/J. Tongji Univ. 2020, 48, 1417–1424. [Google Scholar]

| Material Type | Density (kg/m−3) | Elastic Modulus (GPa) | Compressive Strength (MPa) | Poisson’s Ratio |

|---|---|---|---|---|

| NA | 2560 | 75.0 | 170.1 | 0.360 |

| OM | 2209 | 23.0 | 29.60 | 0.176 |

| NM | 2180 | 24.0 | 33.32 | 0.238 |

| OITZ | 1657 | 17.3 | — | 0.132 |

| NITZ | 1635 | 18 | — | 0.179 |

| Material Type | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|

| NA | 75.0 | 0.360 |

| OM | 23.0 | 0.176 |

| NM | 24.0 | 0.238 |

| OITZ | 17.3 | 0.132 |

| NITZ | 18 | 0.179 |

| Result Type * | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|

| RC theoretical results | 26.4059 | 0.2386 |

| RC simulation results | 24.8542 | 0.2345 |

| Absolute value of error rate (%) | 6.24% | 1.75% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Jin, C.; Li, X. Impact of Interfacial Transition Zone on Concrete Mechanical Properties: A Comparative Analysis of Multiphase Inclusion Theory and Numerical Simulations. Coatings 2024, 14, 698. https://doi.org/10.3390/coatings14060698

Liu Q, Jin C, Li X. Impact of Interfacial Transition Zone on Concrete Mechanical Properties: A Comparative Analysis of Multiphase Inclusion Theory and Numerical Simulations. Coatings. 2024; 14(6):698. https://doi.org/10.3390/coatings14060698

Chicago/Turabian StyleLiu, Qiong, Congkai Jin, and Xiujun Li. 2024. "Impact of Interfacial Transition Zone on Concrete Mechanical Properties: A Comparative Analysis of Multiphase Inclusion Theory and Numerical Simulations" Coatings 14, no. 6: 698. https://doi.org/10.3390/coatings14060698