Abstract

As an important part of human cultural heritage, earthen sites are subject to damage caused by a variety of environmental factors, such as cracking, weathering, and flooding. Due to the low mechanical strength of earthen site materials, especially in humid environments, they are susceptible to hazards like moisture penetration, freeze–thaw cycles, and biological invasion. Superhydrophobic coatings show promising potential in the protection of earthen sites, with key properties that include waterproof performance, breathability, robustness, and transparency. By exploring various material systems and preparation methods, the current state of research on the protection of building materials with superhydrophobic materials has been demonstrated, highlighting advantages in the corrosion resistance, self-cleaning, frost prevention, anti-scaling, and other aspects. At the same time, it also points out the challenges faced in the practical application of earthen site protection and the prospects for future research. These include enhancing the bonding strength between the coating and soil particles, improving durability and breathability, and developing large-scale, low-cost, and efficient coating construction techniques.

1. Introduction

Earthen sites refer to the remains and artifacts left by human activities that are built with earth as the main material, including houses, rammed earth foundations, city walls, cellars, kilns, granaries, and earth-structured tombs. Earthen sites often possess significant cultural and historical value, revealing important information about past civilizations, architectural techniques, and social structures. These sites can provide insights into the lifestyles, beliefs, and evolution of human societies over time, serving as precious artifacts for our understanding of the development of human civilization.

However, as immovable cultural relics, the preservation environment for earthen sites is generally quite harsh. At present, the vast majority of earthen sites are experiencing various forms of deterioration, including cracking, surface weathering, soil pulverization, vegetation erosion, water-related disasters, and destruction from human activities, all of which they urgently require protection from [1]. The synergistic effects of destructive factors in the environment can rapidly alter the appearance of earthen sites, resulting in irreversible losses. For instance, the No.1 Pit of the Terracotta Army and the Armor Pit at the Mausoleum of Emperor Qin Shihuang both experienced varying degrees of weathering after excavation [2].

Earthen sites are widely distributed and cover large areas, with diverse construction techniques and building materials. Their preservation environments range from arid to humid, presenting many challenges for the protection of these sites. Starting from the 1960s, researchers began to attempt the chemical reinforcement of earthen sites. However, due to toxicity and the susceptibility of curing to environmental influences, there have been very few practical applications. An analysis indicates that the main issues in the protection of earthen sites currently include insufficient preventive conservation and immature protective technologies [3]. Therefore, to protect the large number of earthen sites that are on the brink of destruction and to promote the development of cultural heritage protection theory and practical application technology, it is necessary to integrate the materials science and engineering disciplines. The goal is to find surface sealing technologies for earthen sites that meet both protection and display needs, are compatible with earthen sites, are convenient for construction and maintenance, and have a long lifespan. In particular, superhydrophobic coatings with self-cleaning properties hold great promise for the protection of earthen sites.

2. Material Properties and Surface Damage Mechanisms of Earthen Sites

2.1. Characteristics of Earthen Site Materials and Construction

Rammed earth, as one of the main building materials in ancient times, was used to construct walls or structures of buildings by compacting soil or clay through various techniques. Rammed earth constructions are commonly found across many ancient civilizations and traditional architectures, offering certain levels of durability and environmental protection characteristics. The compressive strength of earthen materials is usually only 0.4–2.3 MPa, which is one to two orders of magnitude lower than that of concrete and stone [4], leading to a weaker resistance against rain, sunlight, wind, and earthquakes, which becomes a challenge in the protection of earthen sites

From a geographical distribution perspective, earthen site building materials reflect the characteristic of using local resources. Taking the World Cultural Heritage site “Silk Roads: the Routes Network of Chang’an–Tianshan Corridor” as an example, due to the genetic differentiation of Quaternary sediments, there are significant differences in the proportions of gravel, sandy soil, clay, and silt in the earthen site building materials located in areas south and north of the Tianshan Mountains, the Hexi Corridor, the Guanzhong Plain, and the North China Plain. On the other hand, when viewed from the historical developmental period, the era characteristics of earthen site construction techniques are also quite distinct. Regions at different stages of development exhibit a variety of construction techniques such as earth pits, mud mounds, rammed earth paneling, adobe construction, and wet mud stacking [4]. Therefore, the protection of earthen sites must consider the different basic physical and mechanical properties caused by the different composition and particle size distribution of soil materials.

2.2. The Impact of Climate and Environment on the Damage of Earthen Sites

Around the world, there is a very rich resource of earthen sites, which are distributed in different climatic environments, encompassing arid (extremely arid, arid, and semi-arid), humid (semi-humid and humid), and wet (moist and overly moist) conditions. The amount of precipitation varies across different regions; for instance, the earthen site of the ancient city of Jiaohe in Xinjiang, China, receives 16 mm of rainfall, whereas the earthen site of the Liangzhu ancient city in Zhejiang receives 1800 mm. Consequently, under the influence factors such as different climate zones, building materials, and construction techniques, the deterioration characteristics of earthen sites also differ.

In arid environments, the main forms of deterioration for earthen sites include shrinkage cracking [5], surface spalling [6], and aeolian sand erosion [7]. In humid environments, earthen sites face more complex environmental erosion, as shown in Table 1. The rise in groundwater levels can easily lead to soil softening, shrinkage, and cracking [8]. Earthen sites in humid environments are also susceptible to biological invasions, such as by birds, insects, plants, and micro-organisms, which can change the soil properties, leading to surface erosion and changes in the pore structure. Additionally, the deposition of soluble salts due to rainfall is also a major form of damage to earthen sites in humid environments, resulting in the appearance of crystalline particles on the soil surface [9]. Therefore, for earthen sites in humid environments, it is especially necessary to use hydrophobic sealing materials to protect the surface.

Table 1.

Main damage types in earthen sites within moisture environment [10,11,12,13,14].

3. Technical Requirements and Main Systems of Protective Coatings for Earthen Sites

The factors influencing the weathering of earthen sites are very complex. Internal factors include the size, shape, composition, arrangement, and bonding state of solid particles, while external factors encompass rainwater, surface water, groundwater, alternating wet and dry conditions, and fluctuations in temperature. The genuine international efforts to protect earthen sites began in the 1960s, but, to date, there are relatively few anti-weathering protection projects for earthen sites worldwide, and the research on materials for the surface reinforcement of earthen sites remains a global challenge.

A notable representative in the field of earthen site protection is the Dunhuang Academy in China. After more than 30 years of unremitting efforts, they have addressed the protection issues of numerous earthen sites in arid environments, such as the Great Wall, Yumen Pass, Jiaohe Ancient City, Beiting Ancient City, and the Western Xia Mausoleum [4,5,15,16]. They have established a foundational theory for earthen site protection, invented a series of protective reinforcement materials, developed a complete set of specialized protection technologies and equipment, and advanced the scientific and standardized approach to earthen site protection. A large number of valuable earthen sites along the Silk Road have been successfully protected.

In contrast to arid environments, due to the abundance of rainfall and shallow groundwater levels in humid environments, an effective protective reinforcement system for the surface of earthen sites has not yet been formed to this day.

According to the principles of “preserving the original appearance” and “repairing the old as old” as stipulated in cultural heritage protection regulations, there are stringent requirements for the protective materials that can be applied to the surfaces of earthen sites. This is also one of the key difficulties in the research of protective coatings for earthen sites. Typically, when selecting or developing materials for earthen site protection, the following technical requirements must be met:

(1) The surface sealing material must be colorless and non-glare, and it must not alter the original appearance of the earthen site after curing.

(2) The selected or developed coating slurry should have strong fluidity, minimal shrinkage, good wettability, strong permeability, and a moderate binding force. The protective coating should have a high mechanical strength (bending and compressive) to effectively resist erosion by wind.

(3) The material must have good water resistance, especially for the protection of earthen sites in humid areas. After curing, the coating should have good breathability and dust resistance. The material should have good weather resistance (resistance to CO2, light exposure, temperature and humidity changes, acid and alkali, and freeze–thaw cycles), and should have properties that prevent mold, pest infestation, vegetation, and microbial growth.

(4) After the material ages, it should have no impact on the earthen site itself, and it should be possible to reinforce it again, possessing reversibility or reprocessability. The coating should be non-toxic and non-flammable to reduce pollution and avoid fire hazards.

(5) The material should be inexpensive, and the construction process should be simple. It should cure at room temperature with a moderate curing period, facilitating construction.

Based on the above requirements, the development of weatherproof materials for earthen sites has always been the focus and difficulty in the research of earthen site protection. Cultural heritage conservationists have tried a variety of materials, the advantages and disadvantages of which are shown in Table 2.

Table 2.

Advantages and disadvantages of weatherproof materials for common earthen sites.

These materials all have more or less some issues in practical engineering applications and still require further improvement and exploration. Currently, the most widely used materials are still inorganic materials represented by lime and high-modulus potassium silicate solutions [5,22], but they have the drawbacks of low initial strength, poor water resistance, and shrinkage cracking.

In recent years, more and more scholars have turned their attention to organic polymer reinforcement materials. Polyacrylamide series materials modified by different methods are quite effective in the curing of soil [23,24]. Lignin, a natural polymer material from the plant kingdom, has also been studied for soil reinforcement [25]. For earthen sites, the SH material developed by Lanzhou University has also achieved good aging resistance, salt resistance, and alkali resistance in reinforcing the site soil [26,27]. The research on these materials often focuses on improving the curing properties, but enhancing water resistance and weather resistance will be important directions for the future protection of earthen sites.

4. The Main Protective Effect of Superhydrophobic Coatings on Earthen Sites

The discovery of superhydrophobic materials has provided solutions to many challenges in the field of materials science. By reducing surface energy and constructing micro-/nanostructures, it is possible to achieve a water contact angle of over 150°. At this point, water droplets will roll off the surface of the material without wetting it, giving superhydrophobic materials advantages such as corrosion resistance, self-cleaning, anti-freezing, anti-scaling, and anti-fogging properties. Over the past 20 years, superhydrophobic materials have always been one of the hottest research directions in material science [28], and they hold immense potential for application in fields such as construction, transportation, energy, and healthcare. Through the efforts of many scholars, a variety of material systems and preparation methods have been developed [29], such as using carbon nanotubes [30], graphene [31], silica [32], metal oxides [33], and organic clay [34]. The comprehensive performance of superhydrophobic coatings in engineering applications can be effectively evaluated through methods such as Structural Equation Modeling (SEM) [35].

The wettability of the surface of earthen sites has a significant impact on their ability to resist environmental erosion [36]. It is necessary to choose the right materials and preparation processes to overcome the effects of various harmful environmental factors, such as sunlight, rain, wind-blown sand, temperature and humidity changes, soluble salts, settling dust, and mold. Superhydrophobic materials have excellent application prospects in the field of earthen site protection, mainly reflected in the following aspects.

4.1. Water-Repellent Properties of Superhydrophobic Coatings

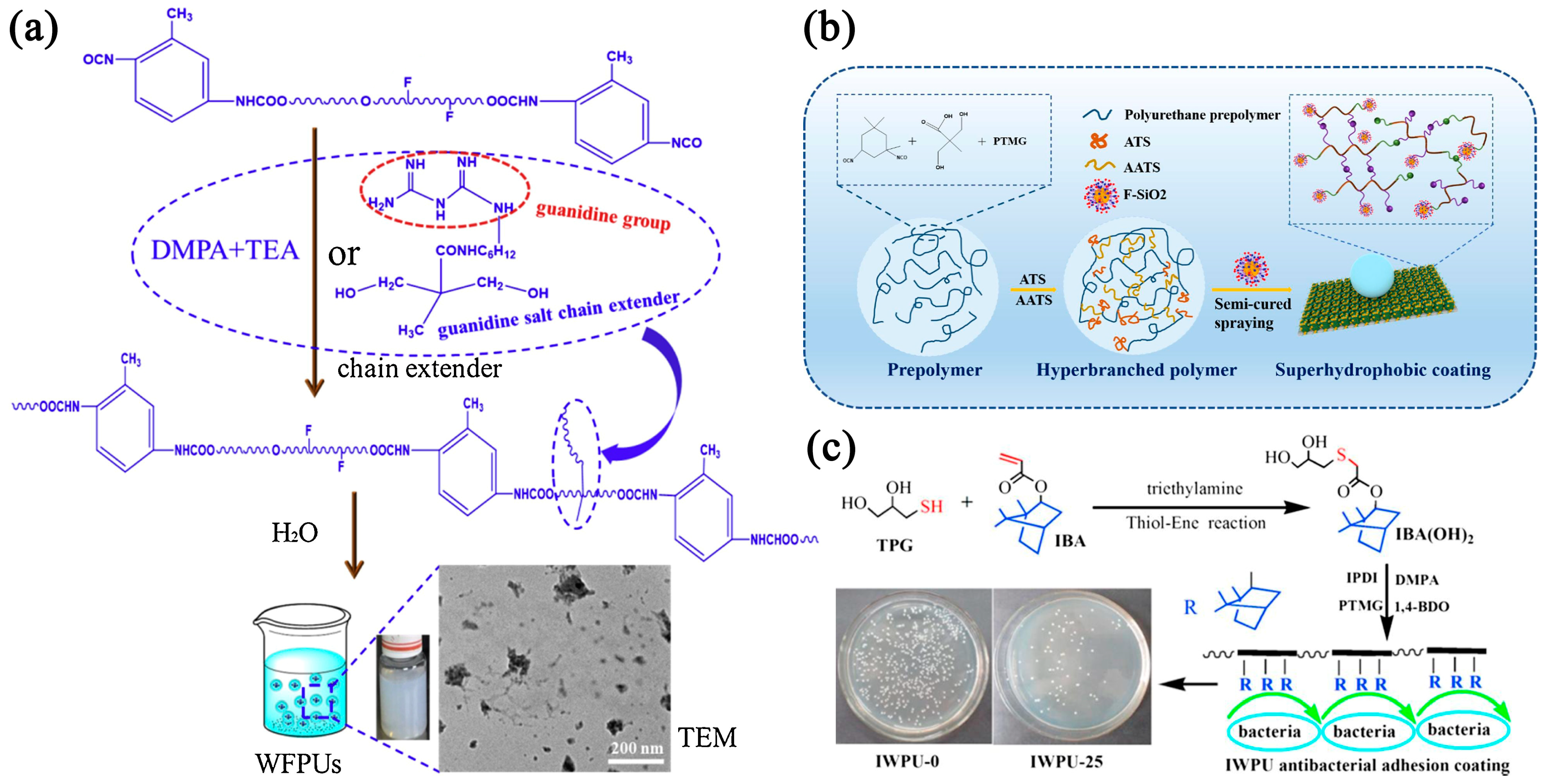

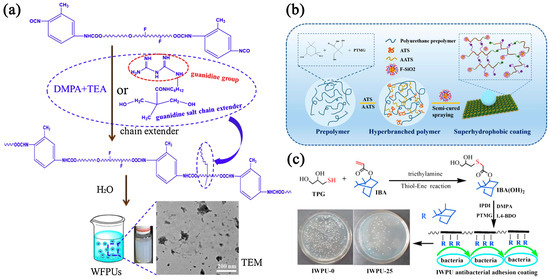

In recent years, significant progress has been made in the research of the waterproof properties of superhydrophobic coatings. Simple methods such as spraying can be used to prepare eco-friendly and high-performance superhydrophobic coatings [37,38,39]. Among them, waterborne polyurethane (WPU) superhydrophobic coatings have attracted widespread attention due to their environmental-friendliness and cost-effectiveness [40]. Their waterproof properties can be enhanced by improving the structure and composition of the coating. Zhao and Jia prepared a new type of superhydrophobic waterborne polyurethane (WFPU) coating containing guanidine groups [41]. As shown in Figure 1a, the guanidine groups and carbonyl groups in the coating quickly cross-link through hydrogen bonding, which improves the hydrophobicity and durability.

Figure 1.

Introducing different functional groups into waterborne polyurethane coatings: (a) guanidine groups [41]; (b) silane groups [42]; and (c) isobornyl acrylate [43].

Zhao et al. combined a silane-modified hyperbranched waterborne polyurethane (Si-HBPU) with fluorinated silica nanoparticles (F-SiO2), as shown in Figure 1b, to design an environmentally friendly, robust, and superhydrophobic composite coating [42]. The Si-HBPU covalently bonds with the F-SiO2 nanoparticles because the Si-HBPU has many polar groups (such as Si-OH). These polar groups react chemically with the hydroxyl groups on the substrate surface and the F-SiO2 nanoparticles through silanol groups, forming a stable siloxane cross-linked network. The resulting superhydrophobic coating exhibits a water contact angle of approximately 163° and a sliding angle of approximately 3°, and it maintains its superhydrophobicity after 140 cycles of sandpaper abrasion. More importantly, the obtained coating has excellent anti-icing/de-icing performance: at −20 °C, the time for water to freeze can be delayed to 2205 s, and the ice adhesion force is significantly lower than that of the pure copolymer coating (~21.2 kPa). These remarkable properties can promote the development of large-scale operations and practical applications for the protection of earthen sites.

Additionally, researchers have also focused on the functionalization of waterborne polyurethane coatings. For example, the introduction of isobornyl acrylate, as shown in Figure 1c, has significantly enhanced the hydrophobicity and resistance to antibacterial adhesion of the polyurethane coating, demonstrating the multifunctionality and potential of these materials in various fields [43].

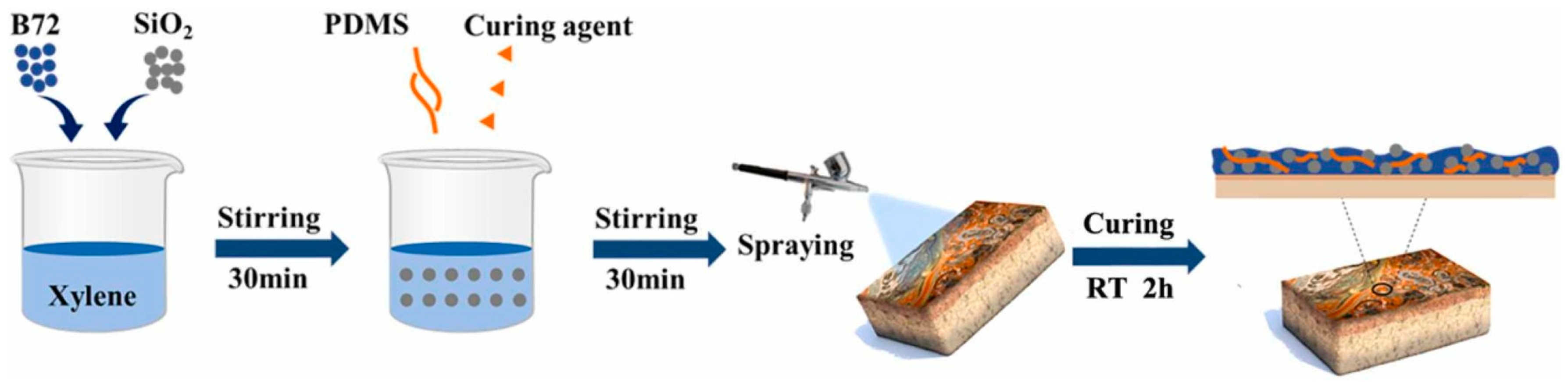

Silica-based additives often enable coatings to have better acid and alkali resistance, which can enhance the weathering resistance and self-cleaning properties of superhydrophobic coatings in humid environments [29], as well as prevent freeze–thaw cycle damage caused by water infiltration into the soil [44]. Zhou et al. used a semi-transparent and superhydrophobic coating composed of acrylic resin (Paraloid B72), nanosilica, and polydimethylsiloxane (PDMS) to protect murals [45], as shown in Figure 2. The composite coating produced by this method exhibits excellent hydrophobicity, with a contact angle of 165.5° and a rolling angle of approximately 7°. After the application of this superhydrophobic coating, the water absorption rate of the murals significantly decreased from around 53% to about 5%. The coating is capable of withstanding fatigue from high and low temperatures, ultraviolet radiation, and mechanical impact, but the main issue is that the visible light transmittance is only around 60%.

Figure 2.

Fabrication procedures for the superhydrophobic coating on the mural craft [45].

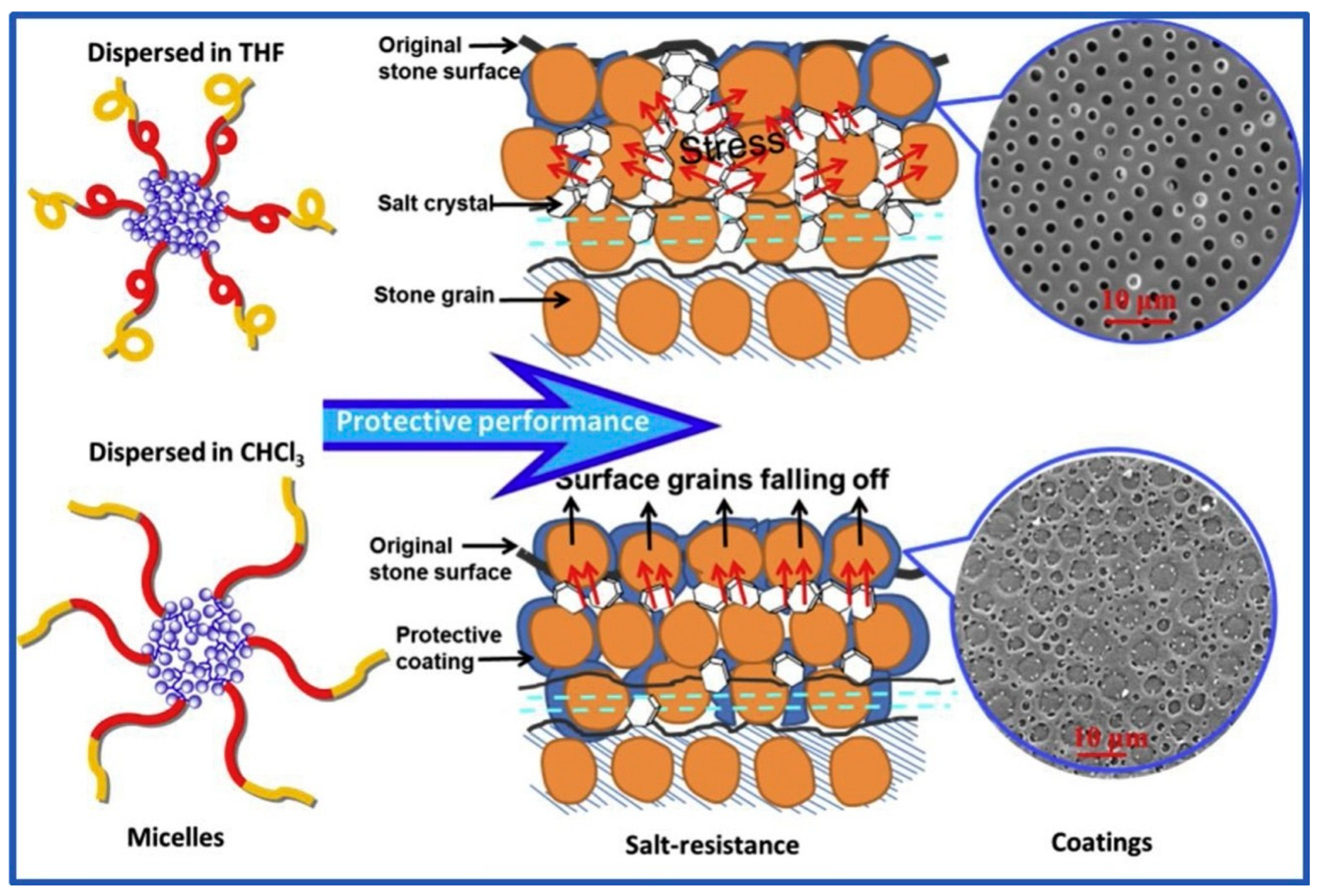

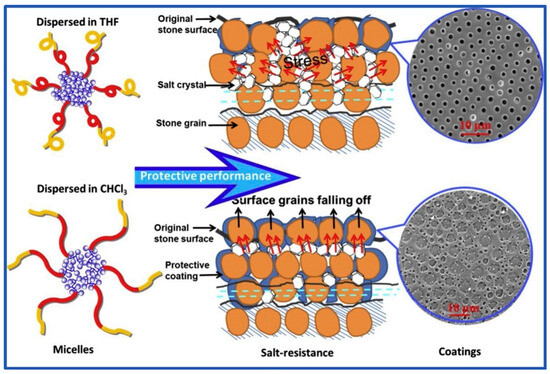

Recently, polyhedral oligomeric silsesquioxane (POSS) has emerged as an ideal nanoscale inorganic particle that can be incorporated into epoxy resin or polyurethane to produce reinforced organic–inorganic hybrid superhydrophobic coatings. These coatings exhibit good thermal stability and mechanical strength, making them suitable for the conservation of bronze or iron artifacts [46,47]. Jia et al. fabricated superhydrophobic coatings from POSS-based poly methylmethacrylate hybrids and investigated their protective performance on sandstone surfaces [48], which has certain implications for the protection of earthen sites. The study results indicate that the combination of POSS with the flexible polydimethylsiloxane (PDMS) exhibits the best mechanical strength, water repellency, and salt resistance. It was also found that the use of tetrahydrofuran (THF) or chloroform (CHCl3) as dispersants significantly affects the coating’s adhesion strength, mechanical strength, and surface wettability, which, in turn, impacts the protective performance on sandstone, as shown in Figure 3.

Figure 3.

The sandstones protected by POSS-based hybrids dispersed in THF and CHCl3 [48].

4.2. Breathability of Superhydrophobic Coatings

The breathability of superhydrophobic coatings can impact the structural stability of the soil within earthen sites. Good breathability can help the soil maintain its natural humidity and ventilation, preventing the accumulation of moisture and oxygen deficiency, reducing the growth of mold and bacteria in damp environments, lowering the risk of the coating flaking and cracking, and extending the service life of the coating.

However, past research has rarely focused on the breathability of superhydrophobic coatings. It is possible to create porous superhydrophobic coatings with a certain amount of breathability using silica networks [49]. Facio et al. constructed a hydrophobic sealant coating on stone buildings by spraying a sol containing siloxane oligomers, silica nanoparticles, and surfactants [50]. The study found that this coating not only does not alter the original texture and breathability (water vapor transference across the pore structure) of the stone surface but also possesses a high mechanical strength and self-cleaning properties.

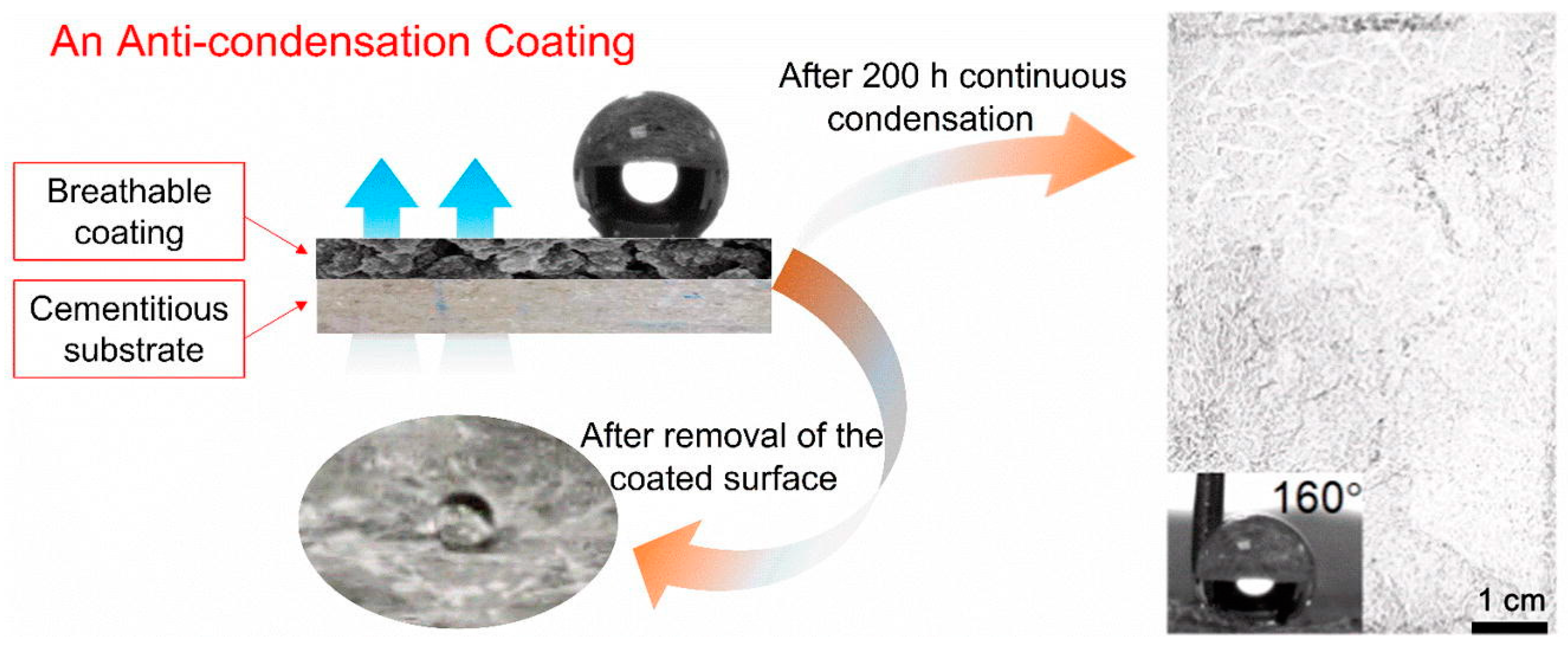

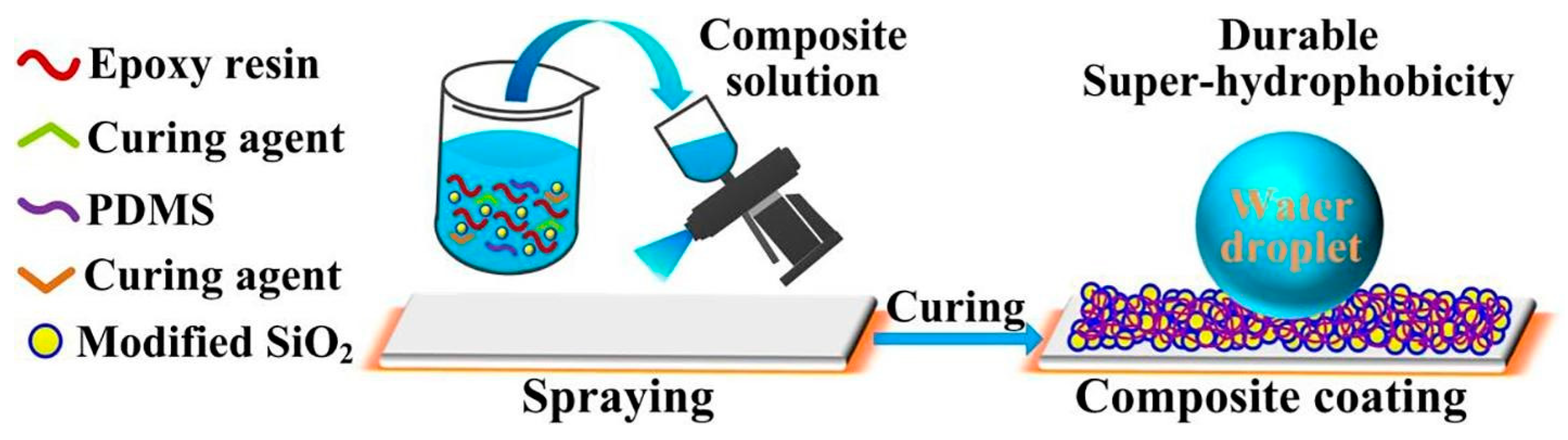

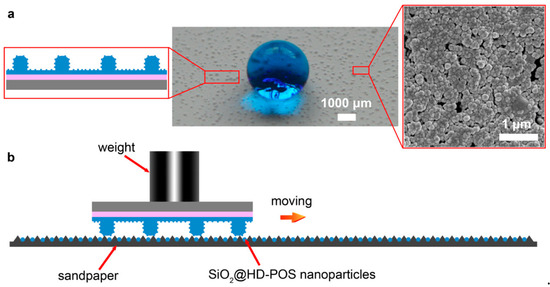

Wu et al. developed a breathable superhydrophobic coating that can be processed on a large scale at room temperature using bio-epoxy, PDMS, SiO2, etc. [51], as shown in Figure 4. The coating demonstrates good adhesion to cementitious substrates, and, even after the removal of the coated surface, the coated area maintains superhydrophobicity. This indicates that such superhydrophobic coatings have potential practical applications in reducing the risks of structural expansion, cracking, scaling, and fragmentation for earthen sites.

Figure 4.

A breathable anti-condensation coating with robust superhydrophobicity has been developed by a simple, low-cost, and scalable method [51].

4.3. Durability of Superhydrophobic Coatings

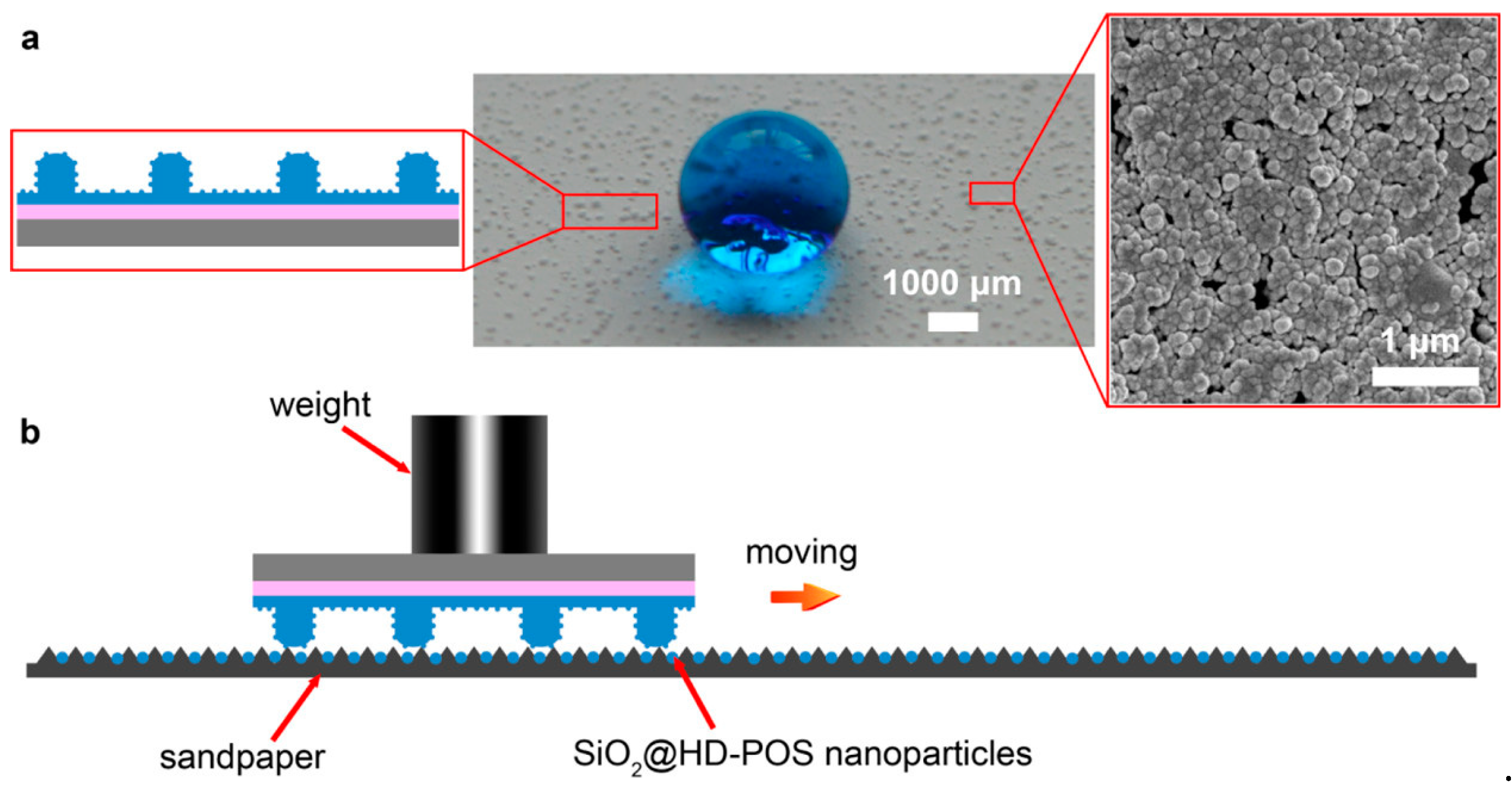

The superhydrophobic coatings on the surfaces of earthen sites need to be capable of large-scale production and possess good durability to reduce the frequency of maintenance. Currently, various high-durability superhydrophobic systems have been developed across different industries. Fluorine-free polymer coatings with added SiO2 nanoparticles have significant advantages in terms of durability and self-healing. Li et al. firmly bonded SiO2 nanoparticles to the surface through a polymer [52], creating a unique hierarchical macro-/nanostructure (Figure 5a). The superhydrophobic coating surface has many large protuberances, which contribute to its macroscopic roughness. During the wear or tape-peeling process, these protrusions can prevent the nano-scale roughness of the coating from coming into direct contact with sandpaper or the tape, effectively reducing the mechanical wear of the coating (Figure 5b).

Figure 5.

Schematic illustrations of (a) micro-/nanostructure of the superhydrophobic coating, and (b) nanoparticles acting as the solid lubricants in the abrasion against sandpaper [52].

Li et al. demonstrated a method to fabricate a robust superhydrophobic coating on the surface of magnesium alloy by spraying a fluorine-free suspension (Figure 6) [53]. The superhydrophobic coating was capable of withstanding harsh environments such as extreme temperatures, ultraviolet radiation, and chemical corrosion. Electrochemical measurements indicated that the corrosion current of the superhydrophobic coating had been reduced by approximately two orders of magnitude. Furthermore, the coating exhibited a superior self-healing ability against O2 plasma etching. The durability and robustness of such superhydrophobic coatings were seen to hold potential for practical applications under adverse conditions.

Figure 6.

Schematic illustration of the durable super-hydrophobic coating fabricating process [53].

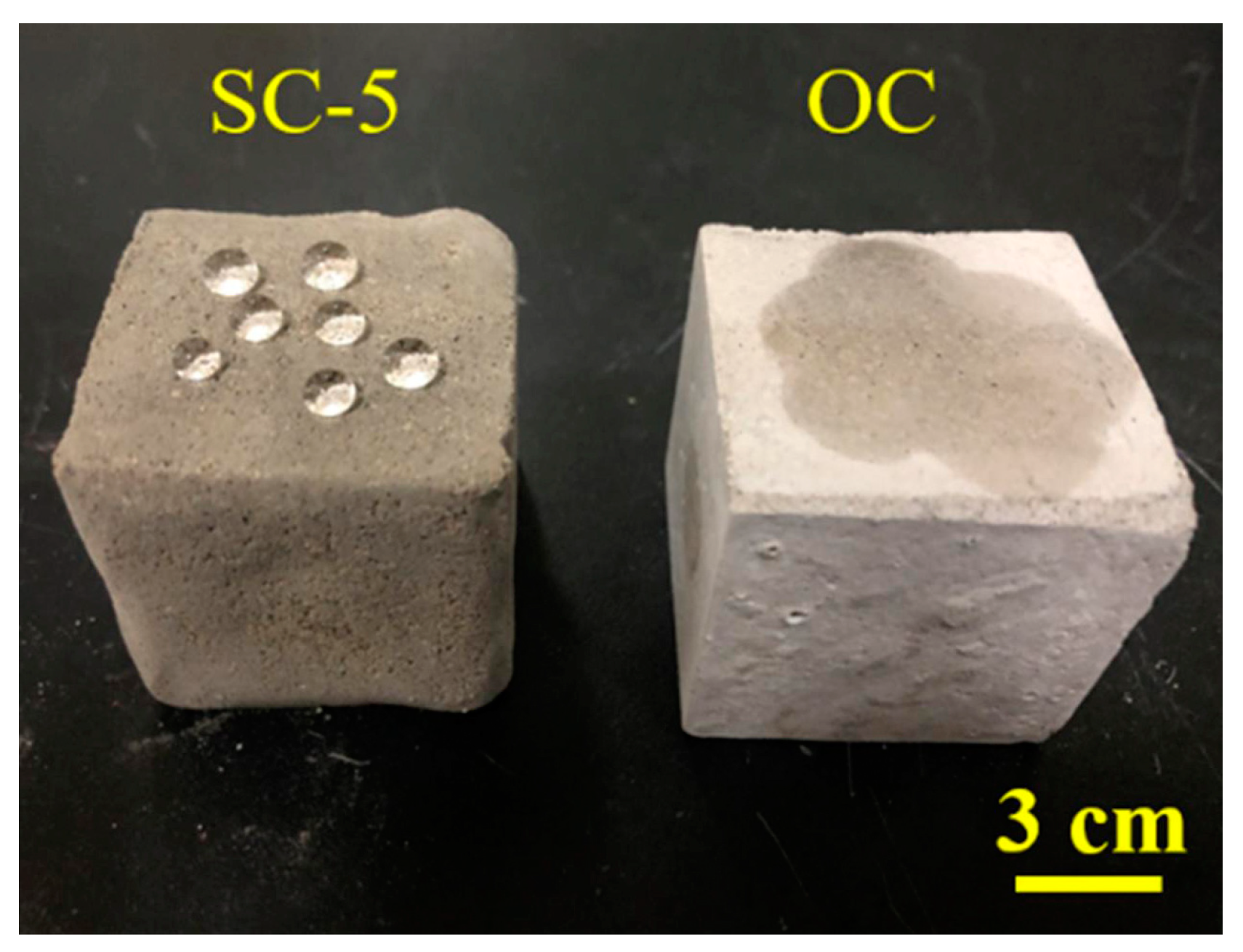

For building materials, silica-based water repellents also play a vital role in enhancing the corrosion resistance of superhydrophobic coatings. For example, Xiang et al. successfully applied a superhydrophobic surface treatment to concrete by adding a fluoroalkylsilane, achieving a maximum water contact angle greater than 154° and a sliding angle of 4° [54]. As shown in Figure 7, water droplets on the superhydrophobic sample (SC-5) appeared spherical and vivid in color. In contrast, droplets on the original sample (OC) quickly spread and wetted the surface. Additionally, the prepared superhydrophobic concrete demonstrated excellent anti-penetration performance, with an absorption rate of only about 1 wt% after being soaked in water for 48 h. Moreover, it showed minimal corrosion even after being soaked for 14 days.

Figure 7.

The optical image water droplets on the superhydrophobic (SC-5) and original (OC) surface [54].

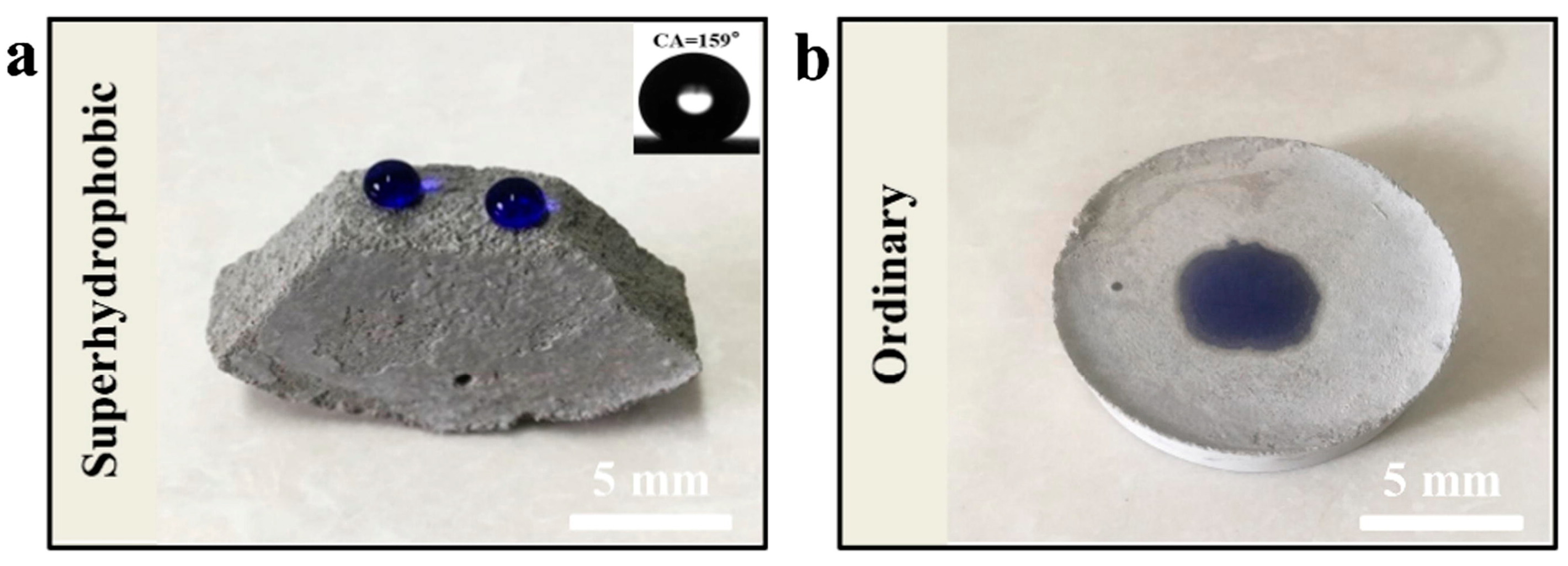

Wang et al. proposed an all-dimensional superhydrophobic mortar [55], and the blocks of this mortar demonstrated excellent water resistance as shown in Figure 8. Compared to ordinary mortar, the water absorption rate of the developed superhydrophobic mortar decreased by 13.5%, which signifies its superior waterproofing properties. The blocks of this mortar exhibit superhydrophobic characteristics both on the surface and internally, and they showed almost no change after 220 freeze–thaw cycles. This all-dimensional, highly durable superhydrophobic mortar has the potential to be applied in the reinforcement and restoration of earthen sites.

Figure 8.

Wettability of the (a) superhydrophobic mortar and (b) ordinary mortar [55].

Additionally, some studies have explored the enhancement of the durability and mechanical strength of superhydrophobic coatings through the use of materials such as graphene, to address the limitations of traditional coatings in terms of service life [28,31,56]. However, the transparency of such coatings is often difficult to achieve to a level that meets the requirements for the protection of earthen sites.

4.4. Transparency of Superhydrophobic Coatings

For cultural heritage conservation, the transparency of protective coatings is one of the important performance indicators. However, the rough surface structure of superhydrophobic coatings can increase light scattering, leading to reduced light transmission. Currently, systems such as silica/fluoropolymer [57] and siloxane polymers [58] can achieve highly transparent superhydrophobic materials. Aslanidou et al. [59] applied a coating containing alkoxysilane and organic fluoropolymer with SiO2 nanoparticles to white marble and sandstone. The composite coating exhibited superhydrophobic and superoleophobic properties, with minimal optical impact on the color of both types of stone, but it slightly reduced the breathability of the marble and sandstone.

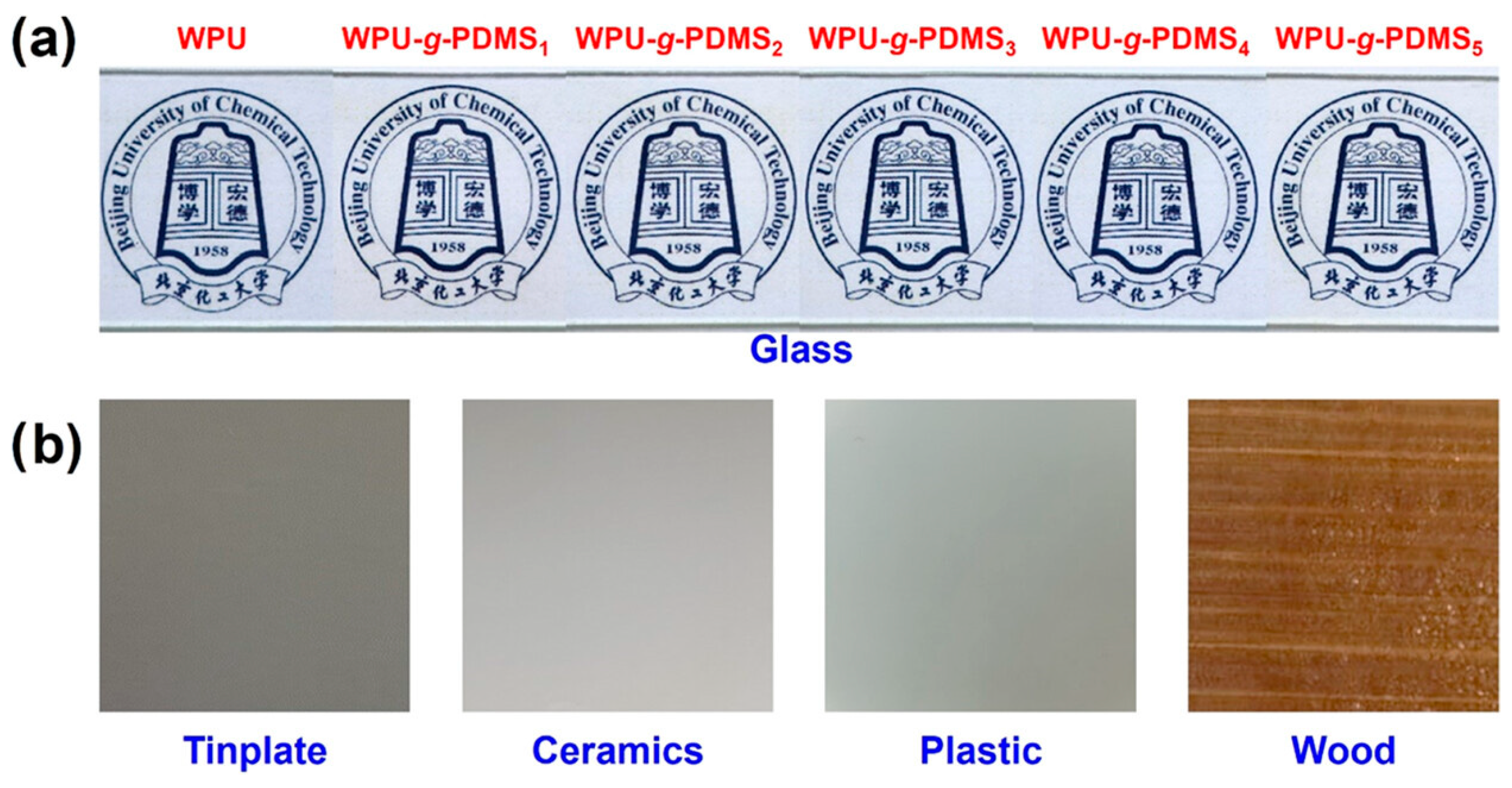

Ha et al. obtained a superhydrophobic coating by doping a Waterborne polyurethane (WPU) with monocarbinol-terminated PDMS [60]. The domain size of microphase-separated PDMS was smaller than the wavelength of visible light, effectively preventing light scattering. As can be seen in Figure 9, all of the WPU-g-PDMSx coatings exhibit excellent transparency, with a transmittance higher than 95.0% at 500 nm.

Figure 9.

(a) Optical photos of WPU and WPU-g-PDMSx (x = 1, 2, 3, 4, and 5) coatings on the glass slides. (b) Optical photos of WPU-g-PDMS2 coatings on different substrates, including tinplate, ceramics, plastic, and wood substrates [60].

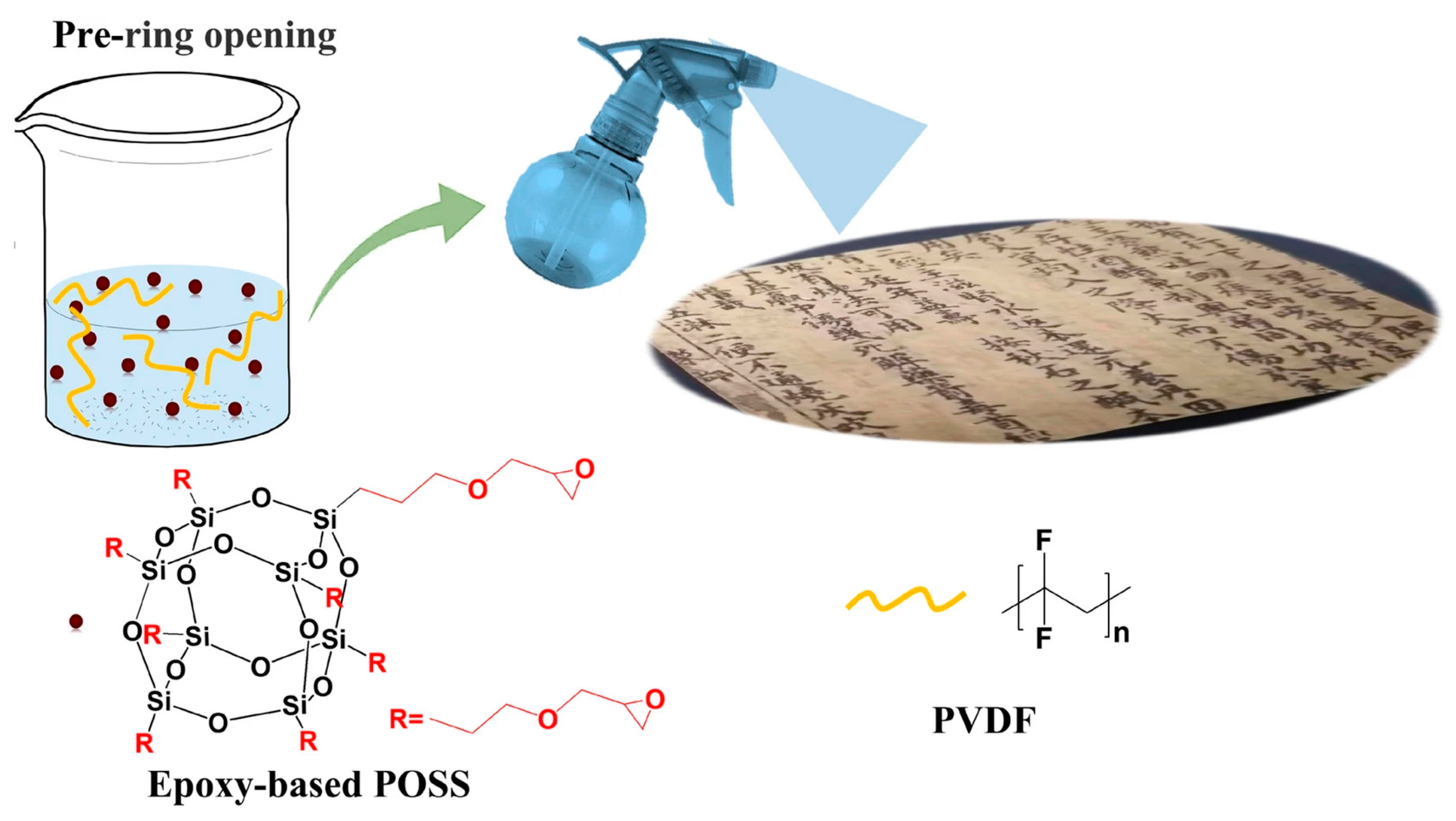

Lan et al. fabricated in situ a POSS/PVDF composite coating on the surface of ancient-book paper materials, achieving the application of superhydrophobic coatings for the protection of ancient paper [61]. The paper co-modified with POSS/PVDF exhibited strong surface anti-fouling properties (resistant to ink contamination) and ensured good transparency and readability, as depicted in Figure 10. This study provides an important reference for the application of simple and efficient transparent hydrophobic coatings to the surface protection of cultural relics.

Figure 10.

Achieving surface hydrophobic and moisture-proof properties of ancient-book paper by in situ protection of epoxy-based POSS/PVDF composite coating [61].

5. Summary and Outlook

Overall, superhydrophobic coatings play a crucial role in the protection of earthen sites by effectively preventing water ingress and minimizing the impact of moisture-related damage, thereby aiding in the conservation and preservation of these valuable cultural heritages. However, there are several issues in practical applications, including unclear relationships between the deterioration characteristics of sites and their existing protective coatings, insufficient stability of coatings under harsh environmental conditions, and a lack of quality evaluation standards for protective coatings for earthen sites.

The main challenges faced in the research of superhydrophobic protective coatings for the surfaces of earthen sites are as follows:

(1) Further enhancing the adhesion between the coating material and soil particles to strengthen the consolidation effect on earthen sites;

(2) Improving the durability and breathability of the coatings to withstand aging, discoloration, or cracking when exposed to the natural environment over the long term. Protective coatings need to adapt to harsh environments under the coupled action of soil–water–gas–heat without affecting the ventilation and humidity regulation inside the earthen sites, ensuring stable protective effects;

(3) Achieving the large-scale, low-cost, and efficient construction of superhydrophobic coatings on the surfaces of earthen sites;

(4) Meeting the reversibility or reprocessability principles required for cultural heritage protection. This means that the chemical composition of the surface coating should not have adverse effects on the earthen sites, and it should be possible to remove the coating reversibly without affecting the cultural relics when necessary, or it should not interfere with the reapplication of protective coatings.

Author Contributions

Writing—original draft preparation, Q.L. and Y.L.; writing—review and editing, R.Z.; supervision, R.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Matera, F.; Moss, E. Temporary site protection for earthen walls and murals at Çata1höyük, Turkey. Conserv. Manag. Archaeol. Sites 2004, 6, 213–227. [Google Scholar] [CrossRef]

- Lei, Y. Study on the weathering of the emperor Qin’S Terracotta. Sci. Conserv. Archaeol. 2004, 16, 36–42. [Google Scholar]

- Correia, M.R.A.R. Conservation in Earthen Heritage: Assessment and Significance of Failure, Criteria, Conservation Theory, and Strategies; Cambridge Scholars Publishing: Newcastle upon Tyne, UK, 2016. [Google Scholar]

- Guo, Q.; Wang, Y.; Chen, W.; Pei, Q.; Sun, M.; Yang, S.; Zhang, J.; Du, Y. Key Issues and Research Progress on the Deterioration Processes and Protection Technology of Earthen Sites under Multi-Field Coupling. Coatings 2022, 12, 1677. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; Sun, M.; Chen, W.; Guo, Q.; Zhang, H. Conservation of Jiaohe ancient earthen site in China. J. Rock. Mech. Geotech. Eng. 2011, 3, 270–281. [Google Scholar] [CrossRef]

- Du, Y.; Dong, W.; Cui, K.; Chen, W.; Yang, W. Research progress on the development mechanism and exploratory protection of the scaling off on earthen sites in NW China. Sci. China Technol. Sci. 2023, 66, 2183–2196. [Google Scholar] [CrossRef]

- Guo, Q.; Huang, J.; Pei, Q.; Zhang, B.; Zhan, H.; Zhang, H.; Richards, J.; Viles, H. Erosion Model for Wind-Blown Sand Flow at Earthen Sites in Arid Environment, Northwest China. Int. J. Archit. Herit. 2023, 1–16. [Google Scholar] [CrossRef]

- Pan, C.; Chen, K.; Chen, D.; Xi, S.; Geng, J.; Zhu, D. Research progress on in-situ protection status and technology of earthen sites in moisty environment. Constr. Build. Mater. 2020, 253, 119219. [Google Scholar] [CrossRef]

- Xu, W.; Chang, B.; Zhang, Y.; Gu, Z.; Yu, C.W.; Luo, X. Study on Barriers of Water Salt Transfers in Earthen Sites by Plastic-Coated Sand. Atmosphere 2023, 14, 236. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, M.; Wang, X.; Guo, Q. Status and Countermeasures of Conservation of Earthen Monuments in Moist Circumstances. Dunhuang Res. 2011, 6, 70–75. [Google Scholar]

- Jambhekar, V.A.; Helmig, R.; Schröder, N.; Shokri, N. Free-Flow–Porous-Media Coupling for Evaporation-Driven Transport and Precipitation of Salt in Soil. Transport Porous Med. 2015, 110, 251–280. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, S.; Zhang, B.; Wu, J. Investigation and research on relics diseases of the earthen site of Kuahuqiao Site Museum. Sci. Conserv. Archaeol. 2018, 30, 53–62. [Google Scholar]

- Schulz, W.; Smith, J.B.; Wang, G.; Jiang, Y.; Roering, J.J. Clayey landslide initiation and acceleration strongly modulated by soil swelling. Geophys. Res. Lett. 2018, 45, 1888–1896. [Google Scholar] [CrossRef]

- Dong, M.; Hu, H.; Guo, Q.; Gong, X.; Azzam, R.; Kong, M. Correlation of Environmental Parameters and the Water Saturation Induced Deterioration of Earthen Archaeological Sites: The Case of World Heritage Liangzhu City, China. Heritage 2021, 4, 387–400. [Google Scholar] [CrossRef]

- Wang, T.; Guo, Q.; Pei, Q.; Chen, W.; Wang, Y.; Zhang, B.; Yu, J. Destruction or protection? Experimental studies on the mechanism of biological soil crusts on the surfaces of earthen sites. Catena 2023, 227, 107096. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, B.; Pei, Q.; Guo, Q.; Chen, W.; Li, F. Experimental studies on sacrificial layer in conservation of earthen sites. J. Cult. Herit. 2020, 41, 74–83. [Google Scholar] [CrossRef]

- Han, X.; Rong, B.; Huang, X.; Luo, H. Bridged siloxanes as novel potential hybrid consolidants for ancient Qin terracotta. Prog. Org. Coat. 2016, 101, 416–422. [Google Scholar] [CrossRef]

- Liu, S.; Wang, R.; Yu, J.; Peng, X.; Cai, Y.; Tu, B. Effectiveness of the anti-erosion of an MICP coating on the surfaces of ancient clay roof tiles. Constr. Build. Mater. 2020, 243, 118202. [Google Scholar] [CrossRef]

- Dong, J.; Liu, X. Application of improved enzyme induced calcium carbonate precipitation (EICP) technology in surface protection of earthen sites. J. Cult. Herit. 2022, 54, 146–154. [Google Scholar] [CrossRef]

- Pei, Q.Q.; Wang, X.D.; Zhao, L.Y.; Zhang, B.; Guo, Q.L. A sticky rice paste preparation method for reinforcing earthen heritage sites. J. Cult. Herit. 2020, 44, 98–109. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Li, L.; Shao, M.; Wang, S.; Li, Z. Preservation of earthen heritage sites on the Silk Road, northwest China from the impact of the environment. Environ. Earth Sci. 2011, 64, 1625–1639. [Google Scholar] [CrossRef]

- Bishop, M.D.; Kim, S.; Palomino, A.M.; Lee, J. Deformation of “tunable” clay–polymer composites. Appl. Clay Sci. 2014, 101, 265–271. [Google Scholar] [CrossRef]

- Lei, H.; Xu, Y.; Li, X.; Liu, G.; Jin, Y. Experimental study on consolidation characteristics of polyacrylamide-modified lime-stabilized dredger fill. Chin. J. Geotech. Eng. 2017, 39, 107–111. [Google Scholar]

- Vinod, J.S.; Indraratna, B.; Al Mahamud, M.A. Stabilisation of an erodible soil using a chemical admixture. Proc. Inst. Civ. Eng. Ground Improv. 2010, 163, 43–51. [Google Scholar] [CrossRef]

- He, F.; Lu, R.; Su, H.; Zhou, J.; Zhang, J.; Wang, N. Durability test and reinforced mechanism on adding SH materials into soil of archaeological sites. Rock Soil Mech. 2019, 40, 297–307. [Google Scholar]

- Chen, W.W.; Zhang, Q.Y.; Liu, H.W.; Guo, Z.Q. Feasibility of protecting earthen sites by infiltration of modified polyvinyl alcohol. Constr. Build. Mater. 2019, 204, 410–418. [Google Scholar] [CrossRef]

- Ashok Kumar, S.S.; Bashir, S.; Ramesh, K.; Ramesh, S. A comprehensive review: Super hydrophobic graphene nanocomposite coatings for underwater and wet applications to enhance corrosion resistance. FlatChem 2022, 31, 100326. [Google Scholar] [CrossRef]

- Das, S.; Kumar, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. A review on superhydrophobic polymer nanocoatings: Recent development and applications. Ind. Eng. Chem. Res. 2018, 57, 2727–2745. [Google Scholar] [CrossRef]

- Gu, J.; Xiao, P.; Chen, J.; Liu, F.; Huang, Y.; Li, G.; Zhang, J.; Chen, T. Robust preparation of superhydrophobic polymer/carbon nanotube hybrid membranes for highly effective removal of oils and separation of water-in-oil emulsions. J. Mater. Chem. A 2014, 2, 15268–15272. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, L.; Sun, W.; Li, S.; Zhu, T.; Liu, W.; Liu, G. Superhydrophobic epoxy coating modified by fluorographene used for anti-corrosion and self-cleaning. Appl. Surf. Sci. 2017, 401, 146–155. [Google Scholar] [CrossRef]

- Junaidi, M.; Azaman, S.H.; Ahmad, N.; Leo, C.P.; Lim, G.W.; Chan, D.; Yee, H.M. Superhydrophobic coating of silica with photoluminescence properties synthesized from rice husk ash. Prog. Org. Coat. 2017, 111, 29–37. [Google Scholar] [CrossRef]

- Steele, A.; Bayer, I.; Loth, E. Inherently superoleophobic nanocomposite coatings by spray atomization. Nano Lett. 2008, 9, 501–505. [Google Scholar] [CrossRef]

- Bayer, I.S.; Steele, A.; Martorana, P.J.; Loth, E. Fabrication of superhydrophobic polyurethane/organoclay nano-structured composites from cyclomethicone-in-water emulsions. Appl. Surf. Sci. 2010, 257, 823–826. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Skrzypkowski, K.; Ghumman, A.S.M. Evaluation of Success of Superhydrophobic Coatings in the Oil and Gas Construction Industry Using Structural Equation Modeling. Coatings 2023, 13, 526. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, W.; Zhang, J. Wettability of earthen sites protected by PVA solution with a high degree of alcoholysis. Catena 2021, 196, 104929. [Google Scholar] [CrossRef]

- Bayer, I.S. Superhydrophobic Coatings from Ecofriendly Materials and Processes: A Review. Adv. Mater. Interfaces 2020, 7, 2000095. [Google Scholar] [CrossRef]

- Sbardella, F.; Pronti, L.; Santarelli, M.L.; Asua Gonzàlez, J.M.; Bracciale, M.P. Waterborne Acrylate-Based Hybrid Coatings with Enhanced Resistance Properties on Stone Surfaces. Coatings 2018, 8, 283. [Google Scholar] [CrossRef]

- Feng, K.; Hung, G.; Liu, J.; Li, M.; Zhou, C.; Liu, M. Fabrication of high performance superhydrophobic coatings by spray-coating of polysiloxane modified halloysite nanotubes. Chem. Eng. J. 2018, 331, 744–754. [Google Scholar] [CrossRef]

- Wang, F.; Feng, L.; Li, G.; Zhai, Z.; Ma, H.; Deng, B.; Zhang, S. Fabrication and Properties of Superhydrophobic Waterborne Polyurethane Composites with Micro-Rough Surface Structure Using Electrostatic Spraying. Polymers 2019, 11, 1748. [Google Scholar] [CrossRef]

- Zhao, B.; Jia, R. Preparation of super-hydrophobic films based on waterborne polyurethane and their hydrophobicity characteristics. Prog. Org. Coat. 2019, 135, 440–448. [Google Scholar] [CrossRef]

- Zhao, Y.; Hao, T.; Wu, W.; Meng, Y.; Cao, X.; Zhang, Q.; She, W.; You, J.; Shi, D.; Jiang, T. A novel moisture-controlled siloxane-modified hyperbranched waterborne polyurethane for durable superhydrophobic coatings. Appl. Surf. Sci. 2022, 587, 152446. [Google Scholar] [CrossRef]

- Wu, J.; Wang, C.; Mu, C.; Lin, W. A waterborne polyurethane coating functionalized by isobornyl with enhanced antibacterial adhesion and hydrophobic property. Eur. Polym. J. 2018, 108, 498–506. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, W.; Fan, W. Protecting earthen sites by soil hydrophobicity under freeze–thaw and dry–wet cycles. Constr. Build. Mater. 2020, 262, 120089. [Google Scholar] [CrossRef]

- Zhou, X.; He, W.; Ou, J.; Hu, Y.; Wang, F.; Fang, X.; Li, W.; Amirfazli, A. Translucent superhydrophobic coating for murals protection. Colloids Surf. A Physicochem. Eng. Asp. 2024, 689, 133750. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Chen, H.; Li, J.; Wang, X.; Zhu, J. Application of epoxy resin in cultural relics protection. Chinese Chem. Lett. 2024, 35, 109194. [Google Scholar] [CrossRef]

- Wang, Y.; An, Q.; Yang, B. Synthesis of UV-curable polyurethane acrylate modified with polyhedral oligomeric silsesquioxane and fluorine for iron cultural relic protection coating. Prog. Org. Coat. 2019, 136, 105235. [Google Scholar] [CrossRef]

- Jia, M.; He, L.; Liang, J.; Pan, A.; Zhao, L.; Simon, S. Dispersant effect on coatings of POSS-based poly methylmethacrylate hybrids and their protective performance to sandstones. Prog. Org. Coat. 2019, 132, 388–398. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Z.; Wang, M.; Men, X.; Xue, Q. Environmentally safe, substrate-independent and repairable nanoporous coatings: Large-scale preparation, high transparency and antifouling properties. J. Mater. Chem. A 2017, 5, 20277–20288. [Google Scholar] [CrossRef]

- Facio, D.S.; Ordoñez, J.A.; Gil, M.L.A.; Carrascosa, L.A.M.; Mosquera, M.J. New Consolidant-Hydrophobic Treatment by Combining SiO2 Composite and Fluorinated Alkoxysilane: Application on Decayed Biocalcareous Stone from an 18th Century Cathedral. Coatings 2018, 8, 170. [Google Scholar] [CrossRef]

- Wu, X.; Yang, F.; Lu, G.; Zhao, X.; Chen, Z.; Qian, S. A breathable and environmentally friendly superhydrophobic coating for anti-condensation applications. Chem. Eng. J. 2021, 412, 128725. [Google Scholar] [CrossRef]

- Li, Y.; Li, B.; Zhao, X.; Tian, N.; Zhang, J. Totally Waterborne, Nonfluorinated, Mechanically Robust, and Self-Healing Superhydrophobic Coatings for Actual Anti-Icing. ACS Appl. Mater. Interfaces 2018, 10, 39391–39399. [Google Scholar] [CrossRef]

- Li, D.; Wang, H.; Liu, Y.; Wei, D.; Zhao, Z. Large-scale fabrication of durable and robust super-hydrophobic spray coatings with excellent repairable and anti-corrosion performance. Chem. Eng. J. 2019, 367, 169–179. [Google Scholar] [CrossRef]

- Xiang, T.; Liu, J.; Lv, Z.; Wei, F.; Liu, Q.; Zhang, Y.; Ren, H.; Zhou, S.; Chen, D. The effect of silicon-based waterproof agent on the wettability of superhydrophobic concrete and enhanced corrosion resistance. Constr. Build. Mater. 2021, 313, 125482. [Google Scholar] [CrossRef]

- Wang, W.; Wang, S.; Yao, D.; Wang, X.; Yu, X.; Zhang, Y. Fabrication of all-dimensional superhydrophobic mortar with enhanced waterproof ability and freeze-thaw resistance. Constr. Build. Mater. 2020, 238, 117626. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Z.; Li, Y.; Wang, C.; Zhu, Y.; Wang, H.; Wang, J. Robust superhydrophobic epoxy composite coating prepared by dual interfacial enhancement. Chem. Eng. J. 2019, 371, 276–285. [Google Scholar] [CrossRef]

- Lee, S.G.; Ham, D.S.; Lee, D.Y.; Bong, H.; Cho, K. Transparent superhydrophobic/translucent superamphiphobic coatings based on silica–fluoropolymer hybrid nanoparticles. Langmuir 2013, 29, 15051–15057. [Google Scholar] [CrossRef]

- Cho, E.; Chang-Jian, C.; Chen, H.; Chuang, K.; Zheng, J.; Hsiao, Y.; Lee, K.; Huang, J. Robust multifunctional superhydrophobic coatings with enhanced water/oil separation, self-cleaning, anti-corrosion, and anti-biological adhesion. Chem. Eng. J. 2017, 314, 347–357. [Google Scholar] [CrossRef]

- Aslanidou, D.; Karapanagiotis, I.; Lampakis, D. Waterborne Superhydrophobic and Superoleophobic Coatings for the Protection of Marble and Sandstone. Materials 2018, 11, 585. [Google Scholar] [CrossRef]

- Ha, Z.; Lei, L.; Zhou, M.; Xia, Y.; Chen, X.; Mao, P.; Fan, B.; Shi, S. Bio-Based Waterborne Polyurethane Coatings with High Transparency, Antismudge and Anticorrosive Properties. ACS Appl. Mater. Interfaces 2023, 15, 7427–7441. [Google Scholar] [CrossRef]

- Lan, Z.; Duan, W. Achieving surface hydrophobic and moisture-proof properties of ancient-book paper by in-situ protection of epoxy-based POSS/PVDF composite coating. Bull. Mater. Sci. 2023, 46, 73. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).