A Review of Research on Improving Wear Resistance of Titanium Alloys

Abstract

:1. Introduction

2. Surface Modification Technology of Titanium Alloy

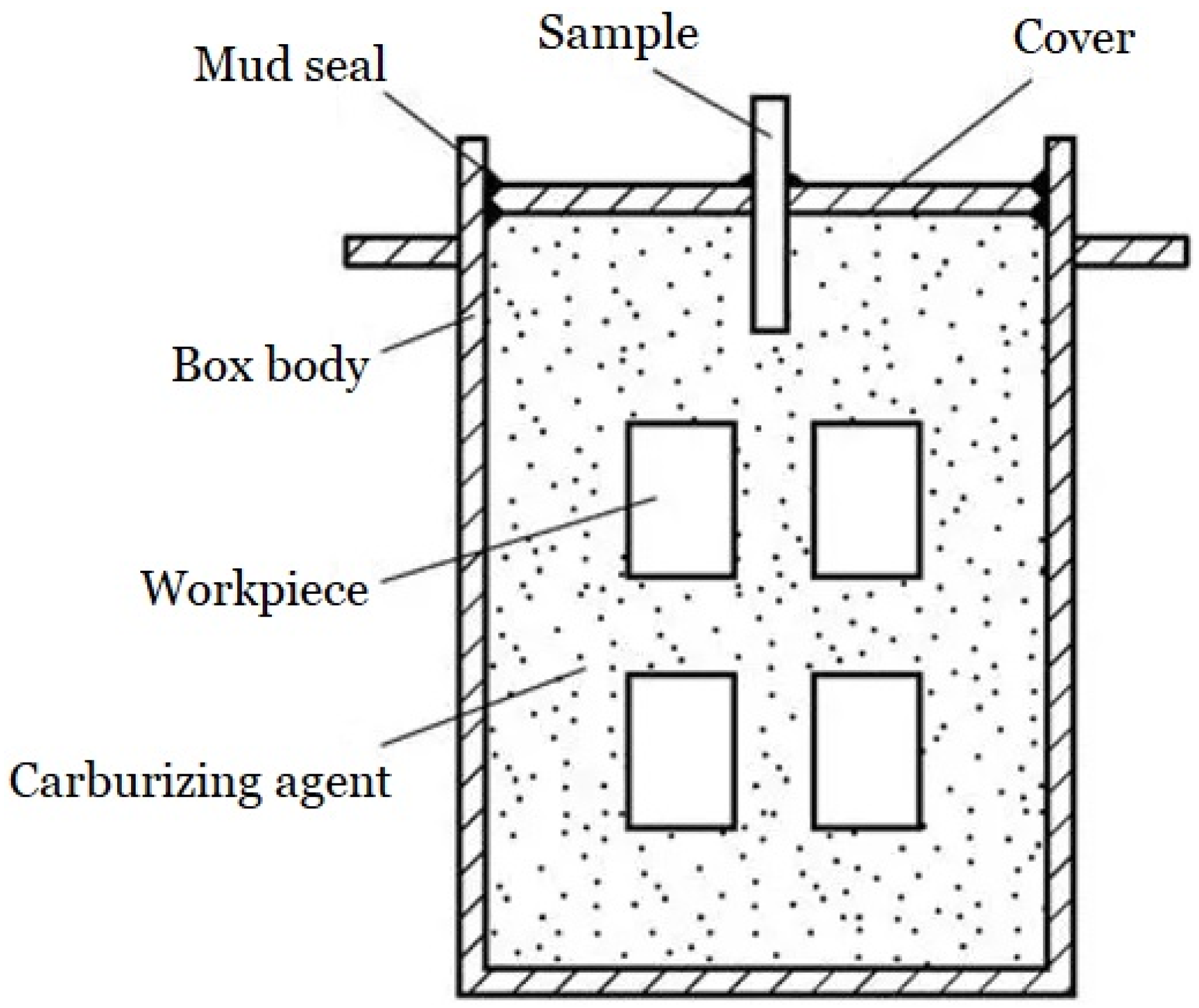

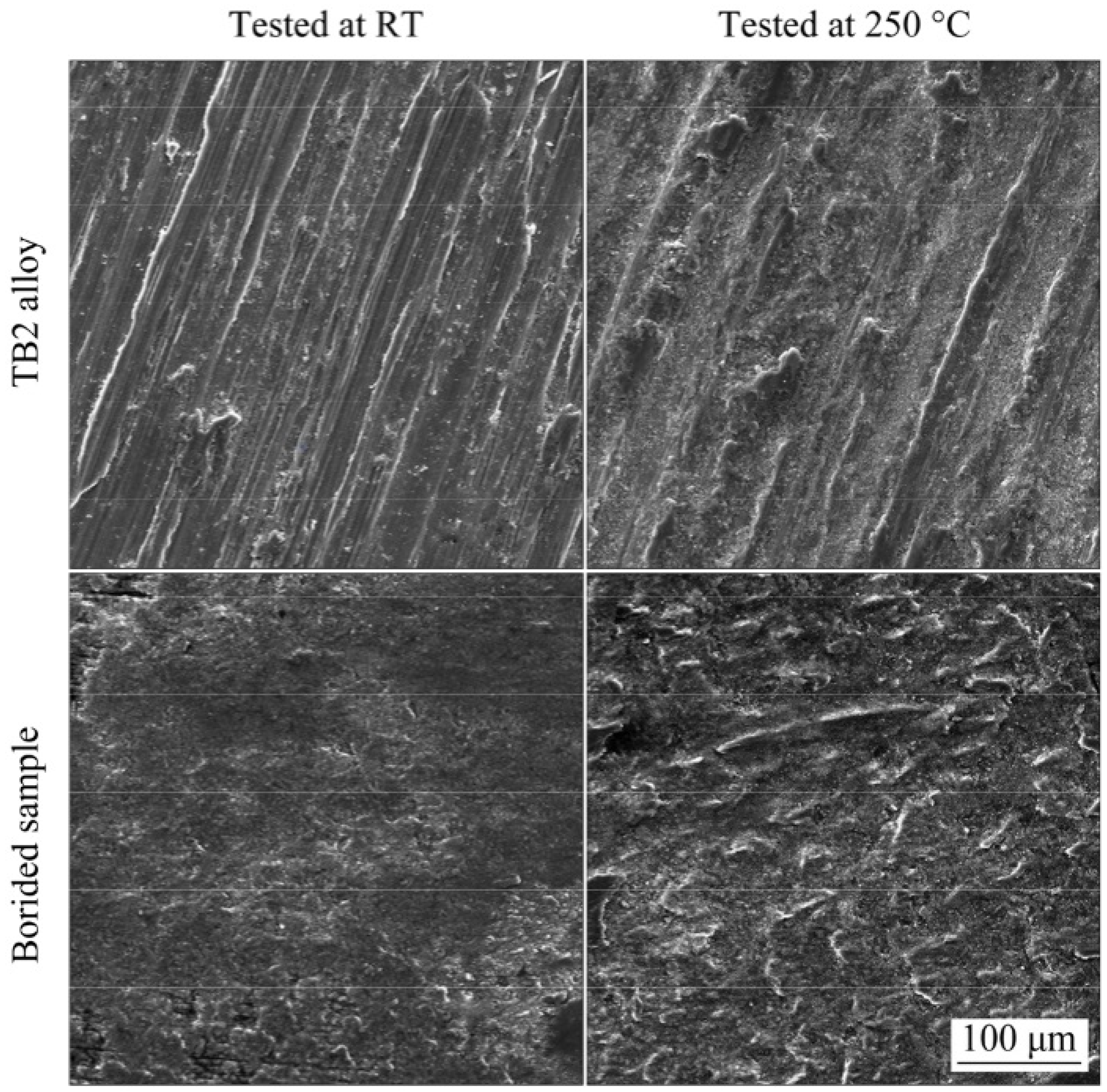

2.1. Surface Carburizing/Nitrogen/Boron Technology

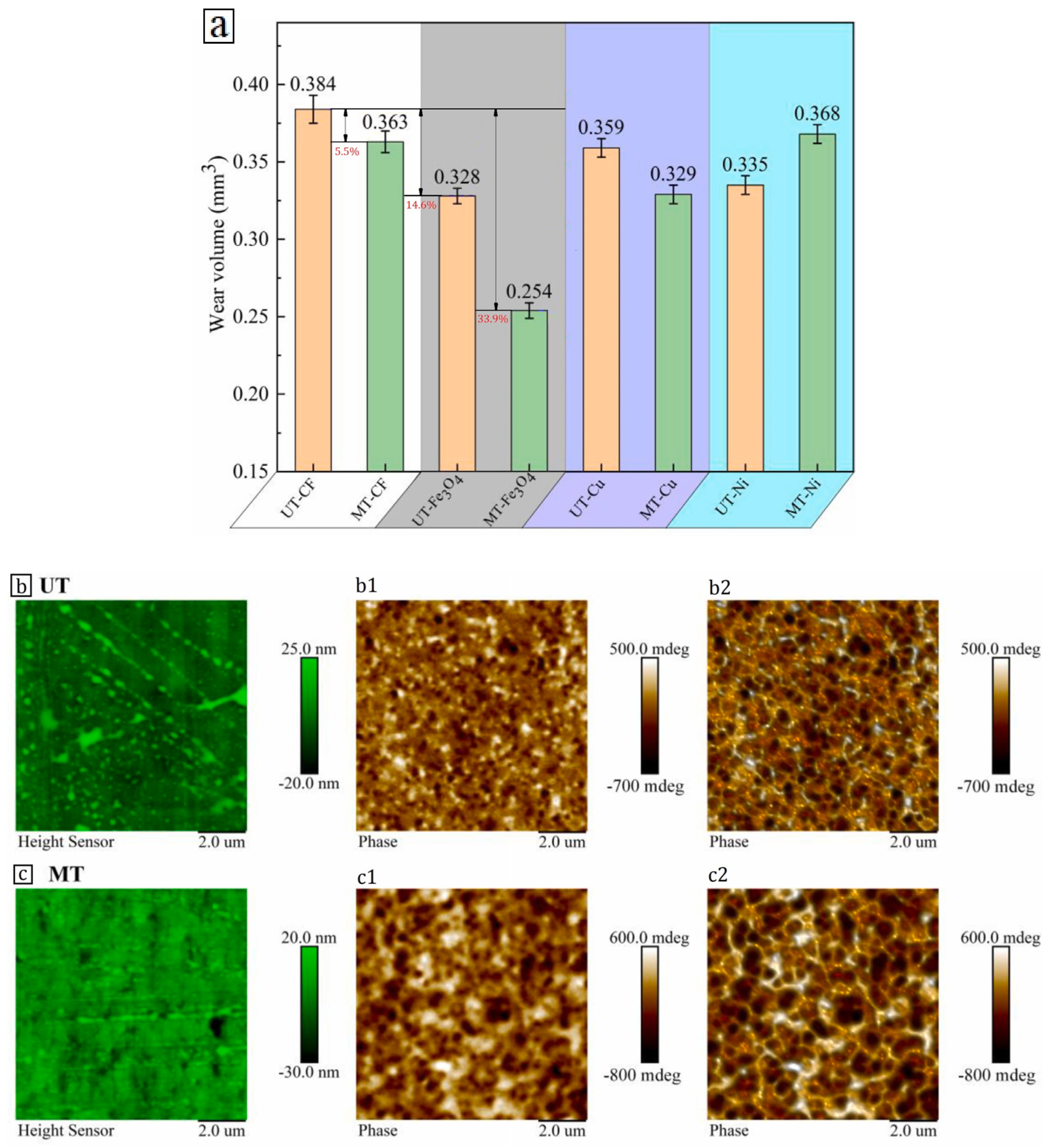

2.2. Pulse Magnetic Field Treatment

2.3. Laser Cladding Technology

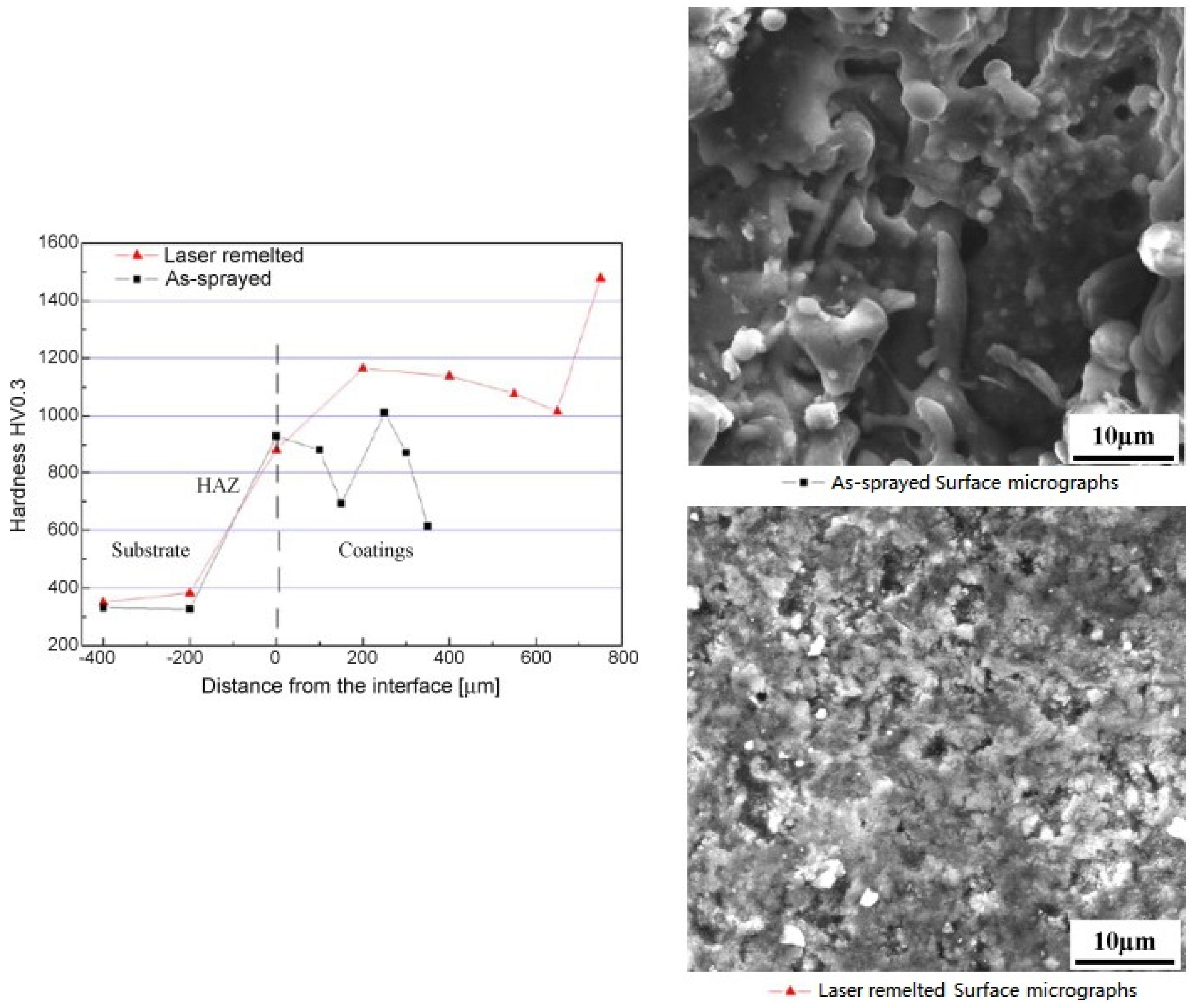

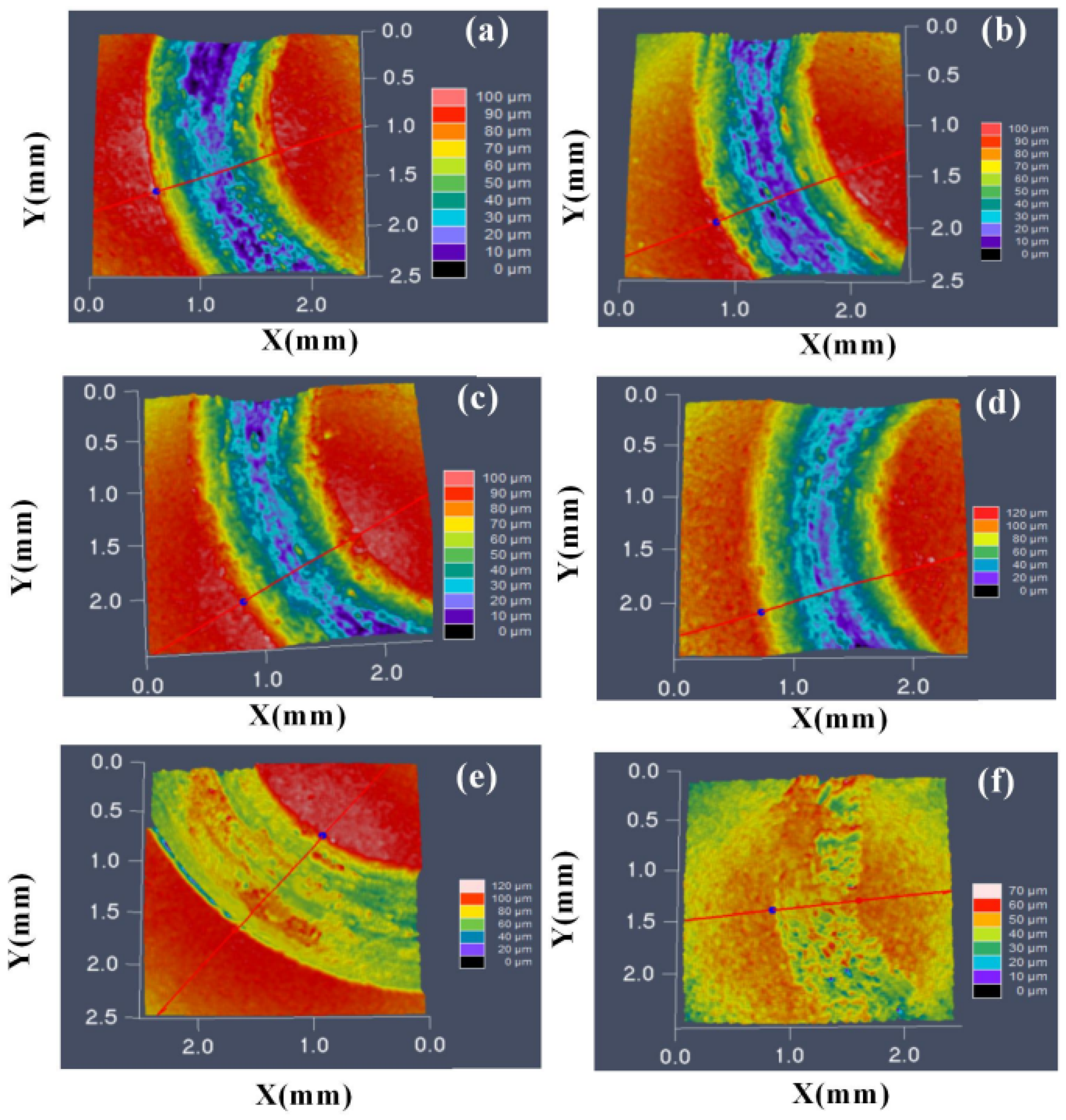

2.4. Plasma Spraying Technology

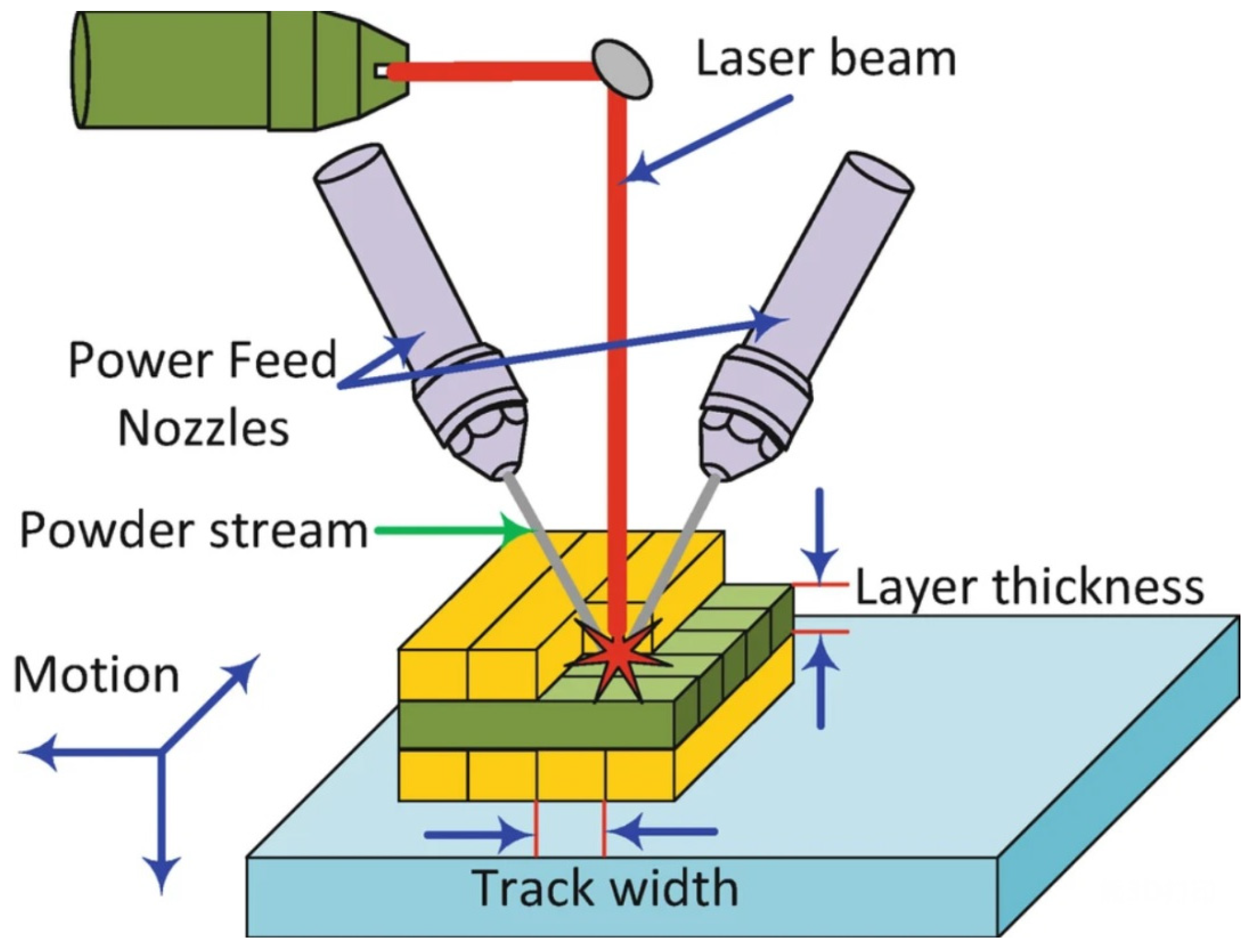

2.5. Additive Manufacturing Technology

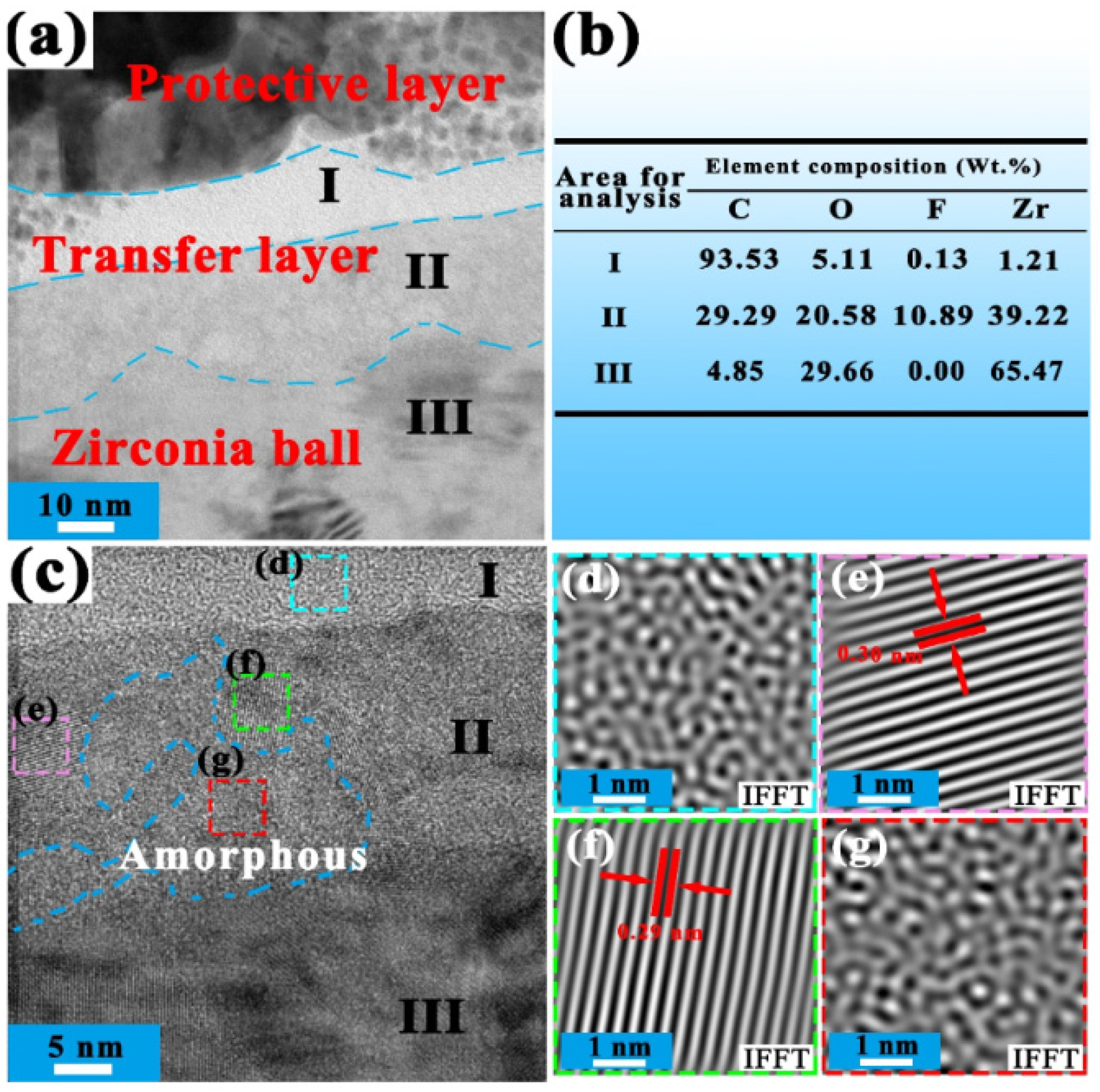

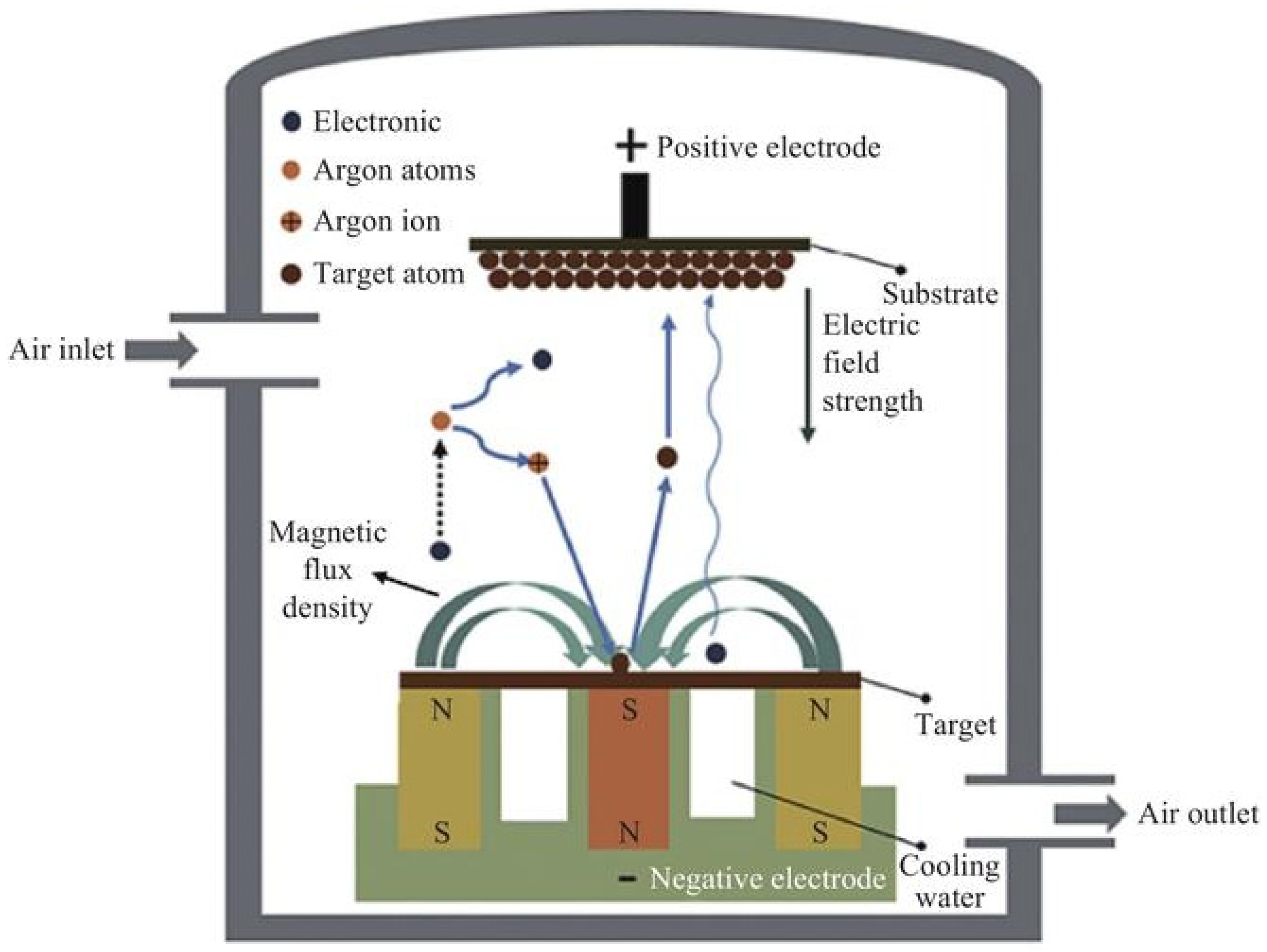

2.6. Magnetron Sputtering Technology

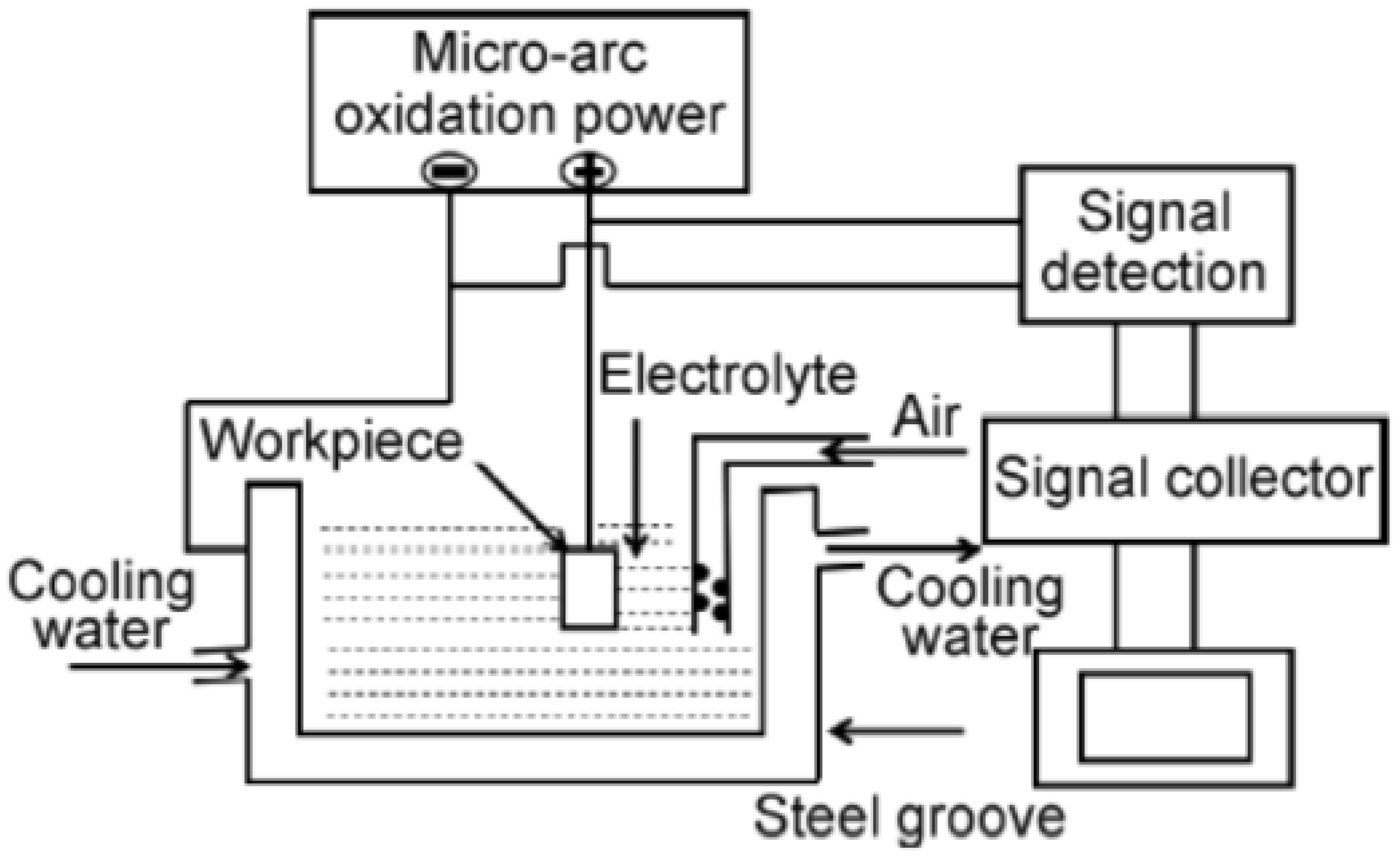

2.7. Micro Arc Oxidation Technology

3. Conclusions

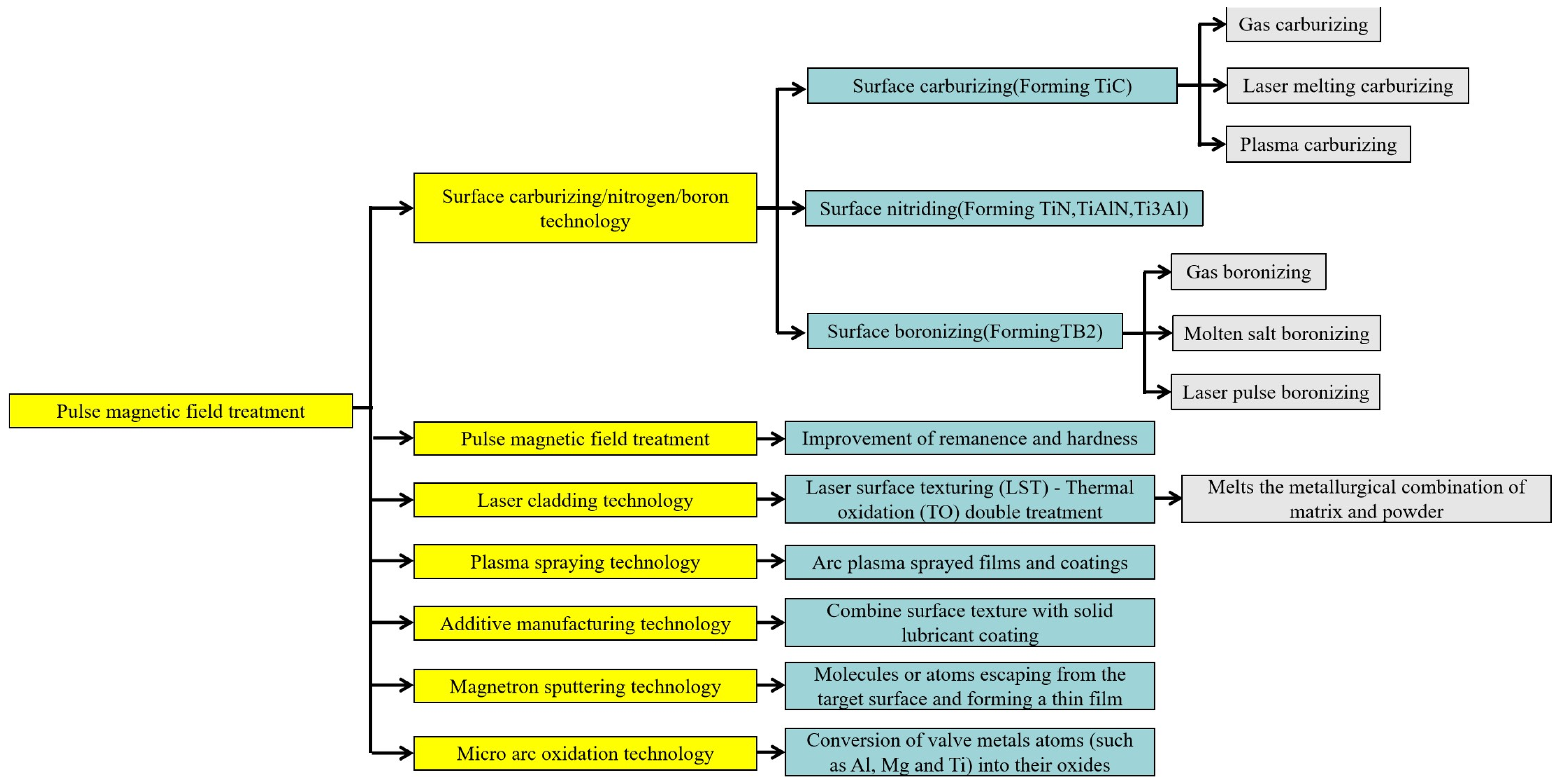

- Titanium alloys play a crucial role in the petroleum industry, especially in oil well tubing materials, because of their outstanding specific strength, toughness, corrosion resistance, and fatigue resistance. There is a need to enhance and advance the surface modification technology of titanium alloys, and to obtain more extensive applications and better economic benefits, increasing innovation is needed. This work reviews and summarizes the current methods for improving the wear resistance of titanium alloys through surface treatment, as shown in Figure 15. Table 2 provides a comprehensive comparison of the various methods. Through the review of this article, some conclusions can be summarized as follows.

- In terms of economic benefits and the ease of use of equipment, the methods of pulse magnetic field treatment and additive manufacturing technology are relatively cheaper and more economical and the equipment preparation time is shorter.

- Plasma spraying technology and laser cladding technology can form multiple coatings, but the roughness of the coating formed by plasma spraying technology is relatively high.

- Additive manufacturing technology and micro arc oxidation technology are relatively environmentally friendly and cause less environmental pollution.

4. Areas for Further Research

- (1)

- Micro arc oxidation is expected to remain the preferred method for improving the wear resistance of titanium alloys in the near future, due to its consideration of environmental protection, economic costs, and other factors. This technology also holds great potential for further development.

- (2)

- With further research on the preparation technology of wear-resistant micro arc oxidation films and the gradual improvement of the relevant theoretical basis, it is believed that micro arc oxidation coatings with controllable friction properties and a good comprehensive performance can be designed and developed at a certain energy, so as to broaden the application range of titanium alloys and promote their industrial application in more fields.

Funding

Conflicts of Interest

References

- Lu, N.Y.; Fan, J.C.; Liu, D.; Liu, S.J.; Wen, M.; Liang, Z.W. Simulation study on leakage acoustic source characteristics of gas well tubing and casing. China Pet. Mach. 2017, 45, 79–82. [Google Scholar]

- Lin, N.M.; Liu, Q.; Zou, J.J.; Li, D.L.; Yuan, S.; Wang, Z.H.; Tang, B. Surface damage mitigation of Ti6Al4V alloy via thermal oxidation for oil and gas exploitation application: Characterization of the microstructure and evaluation of the surface performance. RSC Adv. 2017, 7, 13517–13535. [Google Scholar] [CrossRef]

- Wang, Y.M.; Jiang, B.L.; Lei, T.Q.; Guo, L.X. Microarc oxidation coatings formed on Ti6Al4V in Na2SiO3 system solution: Microstructure, mechanical and tribological properties. Surf. Coat. Technol. 2006, 201, 82–89. [Google Scholar] [CrossRef]

- Budinski, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Yerokhin, A.L.; Leyland, A.; Matthews, A. Kinetic aspects of aluminium titanate layer formation on titanium alloys by plasma electrolytic oxidation. Appl. Surf. Sci. 2002, 200, 172–184. [Google Scholar] [CrossRef]

- Liu, Q.; Song, S.Y.; Li, D.J.; Bai, Q. Research and development of titanium alloy OCTG application in energy industry. Oil Field Equip. 2014, 43, 88–94. [Google Scholar]

- Wu, X.Y.; Zhang, H.; Xu, X.J.; Zhang, Z.S.; Guo, S.J. Application of titanium alloy in oil & gas exploration and development. Petrochem. Ind. Appl. 2016, 35, 105–113. [Google Scholar]

- Zhao, H.; Wang, B.T.; Du, C.Y.; Wang, S.R.; Meng, F.L.; Zhang, X. Research progress of surface modification technology of TC4 titanium alloy. J. Shenyang Ligong Univ. 2017, 2, 74–77. [Google Scholar]

- Liu, W.; Blawert, C.; Zheludkevich, M.L.; Lin, Y.; Talha, M.; Shi, Y.; Chen, L. Effects of graphene nanosheets on the ceramic coatings formed on Ti6Al4V alloy drill pipe by plasma electrolytic oxidation. J. Alloys Compd. 2019, 789, 996–1007. [Google Scholar] [CrossRef]

- Prabu, S.S.; Prathiba, S.; Asokan, M.A.; Akhil, V.S. Effect of titanium on dry sliding wear behavior of hot forged P/M low alloy steels. Mater. Today Proc. 2020, 22, 1380–1389. [Google Scholar] [CrossRef]

- Dong, Z.H.; Zhang, W.; Kang, H.W.; Xie, Y.J.; Ebrahimnia, M.; Peng, X. Surface hardening of laser melting deposited 12CrNi2 alloy steel by enhanced plasma carburizing via hollow cathode discharge. Surf. Coat. Technol. 2020, 397, 125976. [Google Scholar] [CrossRef]

- Yang, Y.H.; Wang, M.Q.; Chen, J.C.; Dong, H. Microstructure and Mechanical Properties of Gear Steels After High Temperature Carburization. J. Iron Steel Res. 2013, 20, 140–145. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, W.; Sun, W.; Li, Z.J.; Liu, Z. Preparation of Metakaolin Based Geopolymer and Its Three-dimensional Pore Structural Characterization. J. Wuhan Univ. Technol.-Mater. 2015, 30, 550–555. [Google Scholar] [CrossRef]

- Guo, L.N.; Chen, J.; Pan, J.D. Double Glow Plasma Hydrogen-Free Carburizing on the Surface of Purity Titanium. Adv. Mater. Res. 2011, 314–316, 108–111. [Google Scholar] [CrossRef]

- Jiang, Y.; Wu, Q.; Wang, Y.F.; Zhao, J.X.; Gong, J.M. Suppression of hydrogen absorption into 304L austenitic stainless steel by surface low temperature gas carburizing treatment. Int. J. Hydrogen Energy 2019, 44, 24054–24064. [Google Scholar] [CrossRef]

- Dewan, M.A.R.; Zhang, G.; Ostrovski, O. Carbothermal Reduction of Titania in Different Gas Atmospheres. Metall. Mater. Trans. B 2009, 40, 62–69. [Google Scholar] [CrossRef]

- Kusmanov, S.A.; Tambovskii, I.V.; Kusmanova, I.A.; Belkin, P.N. Improving the Wear Resistance of VT22 Titanium Alloy by Anodic Plasma Electrolytic Boriding. Surf. Eng. Appl. Electrochem. 2021, 57, 419–424. [Google Scholar] [CrossRef]

- Liu, Z.; Peng, Y.W.; Chen, C.M.; Gong, J.M.; Jiang, Y. Effect of surface nanocrystallization on low-temperature gas carburization for AISI 316L austenitic stainless steel. Int. J. Press. Vessel. Pip. 2020, 182, 104053. [Google Scholar] [CrossRef]

- Yang, C.; Liu, J.; Ma, Y.Q.; Hong, L.; Wang, H. Microstructure and Wear Resistance of Low Pressure Nitrided Layer on TC4 Titanium Alloy Surface. Mater. Mech. Eng. 2016, 40, 98–101. [Google Scholar]

- Peng, M.J.; Duan, Y.H.; Ma, L.S.; Shu, B.P. Characteristics of surface layers on Ti6Al4V alloy borided with CeO2 near the transition temperature. J. Alloys Compd. 2018, 769, 1–9. [Google Scholar] [CrossRef]

- Makuch, N. Influence of nickel silicides presence on hardness, elastic modulus and fracture toughness of gas-borided layer produced on Nisil-alloy. Trans. Nonferrous Met. Soc. China 2021, 31, 764–778. [Google Scholar] [CrossRef]

- Ma, L.S.; Duan, Y.H.; Li, P. Microstructure, growth kinetics and some mechanical properties of boride layers produced on pure titanium by molten-salt boriding. J. Mater. Eng. Perform. 2017, 26, 4544–4555. [Google Scholar] [CrossRef]

- Makuch, N.; Dziarski, P.; Kulka, M.; Piasecki, A.; Tulinski, M.; Majchrowski, R. Influence of niobium and molybdenum addition on microstructure and wear behavior of laser-borided layers produced on Nimonic 80A-alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 322–337. [Google Scholar] [CrossRef]

- Atar, E.; Kayali, E.S.; Cimenoglu, H. Characteristics and wear performance of borided Ti6Al4V alloy. Surf. Coat. Technol. 2008, 202, 4583–4590. [Google Scholar] [CrossRef]

- Si, J.Y.; Wu, X.L.; Xia, K.N.; Zhang, J. Equal channel angular extrusion of TB2 alloy under different die designs by finite element method. Rare Met. Mater. Eng. 2014, 43, 1577–1581. [Google Scholar] [CrossRef]

- Wang, Z.M.; Chen, Z.Y.; Zhan, C.K.; Kuang, L.J.; Shao, J.B.; Wang, R.K.; Liu, C.M. Quasi-static and dynamic forced shear deformation behaviors of Ti-5Mo-5V-8Cr-3Al alloy. Mater. Sci. Eng. A 2017, 691, 51–59. [Google Scholar] [CrossRef]

- Li, P.; Liu, D.; Bao, W.Z.; Ma, L.S.; Duan, Y.H. Surface characterization and diffusion model of pack borided TB2 titanium alloy. Ceram. Int. 2018, 44, 18429–18437. [Google Scholar] [CrossRef]

- Huang, Y.G.; Chen, J.R.; Zhang, X.H.; Wang, H.Q.; Fang, Z.; Li, Q.Y. Effects of La2O3 on electrolytic boronising of titanium. Surf. Eng. 2015, 31, 570–574. [Google Scholar] [CrossRef]

- Zhu, Y.S.; Yin, Y.X.; Wu, J.; Liu, Y.F.; Lu, W.Z.; Zuo, D.W.; Xiao, H.P.; Cao, D.W.; Ko, T.J. Effect of RE on accelerating the kinetics of boride layer growth on titanium alloy. J. Alloys Compd. 2020, 844, 156091. [Google Scholar] [CrossRef]

- Duan, Y.H.; Liu, D.; He, B.L.; Ma, L.S.; Hu, Y.Y.; Li, X.Q. Experimental investigations of TB2 alloy by pack boriding with rare-earth oxides. Philos. Mag. Lett. 2019, 98, 521–526. [Google Scholar] [CrossRef]

- Qu, D.Y.; Liu, D.; Wang, X.Y.; Duan, Y.H.; Peng, M.J. Corrosion and wear properties of TB2 titanium alloy borided by pack boriding with La2O3. Trans. Nonferrous Met. Soc. China 2022, 32, 868–881. [Google Scholar] [CrossRef]

- Bloyce, A.; Qi, P.Y.; Dong, H.; Bell, T. Surface modification of titanium alloys for combined improvements in corrosion and wear resistance. Surf. Coat. Technol. 1998, 107, 125–132. [Google Scholar] [CrossRef]

- Yang, Y.F.; Qin, Y.; Yang, Y.; Wu, M.X.; Yang, G. Enhancing the wear resistance of a cemented carbide/titanium alloy under magnetofluid lubrication via the magnetic response. Wear Int. J. Sci. Technol. Frict. Lubr. Wear 2022, 500–501, 204370. [Google Scholar] [CrossRef]

- Awasthi, S.; Gaur, J.K.; Bobji, M.S. Advanced ferrogels with high magnetic response and wear resistance using carbon nanotubes. J. Alloys Compd. Interdiscip. J. Mater. Sci. Solid-State Chem. Phys. 2020, 848, 156259. [Google Scholar] [CrossRef]

- Jin, J.; Duan, H.J.; Li, X.H. The influence of plasma nitriding on microstructure and properties of CrN and CrNiN coatings on Ti6Al4V by magnetron sputtering. Vacuum 2016, 136, 112–120. [Google Scholar] [CrossRef]

- Trivedi, P.; Gupta, P.; Srivastava, S.; Jayaganthan, R.; Chandra, R.; Roy, P. Characterization and in vitro biocompatibility study of Ti-Si-N nanocomposite coatings developed by using physical vapor deposition. Appl. Surf. Sci. A J. Devoted Prop. Interfaces Relat. Synth. Behav. Mater. 2014, 293, 143–150. [Google Scholar] [CrossRef]

- Yuan, S.; Lin, N.M.; Zou, J.J.; Lin, X.Z.; Liu, Z.Q.; Yu, Y.; Wang, Z.X.; Zeng, Q.F.; Chen, W.G.; Tian, L.H.; et al. In-Situ fabrication of gradient titanium oxide ceramic coating on laser surface textured Ti6Al4V alloy with improved mechanical property and wear performance. Vacuum 2020, 176, 109327. [Google Scholar] [CrossRef]

- Yang, H.L.; Zheng, Y.; Wang, Y. Bio-tribology properties of imitation shark skin morphology on Ti6A14V surface. Hot Work. Technol. 2016, 45, 119–122. [Google Scholar]

- Kashyap, V.; Ramkumar, P. Feasibility study of micro-groove cross hatched surface texturing on Ti6Al4V for improved biotribological performance in metal-onpolymer hip implant. Tribol. Mater. Surf. Interfaces 2019, 13, 150–160. [Google Scholar] [CrossRef]

- Wang, D.W.; Mo, J.L.; Zhu, Z.Y.; Ouyang, H.; Zhu, M.H.; Zhou, Z.R. Debris trapping and space-varying contact via surface texturing for enhanced noise performance. Wear 2018, 396–397, 86–97. [Google Scholar] [CrossRef]

- Li, X.L.; Yue, W.; Huang, F.; Kang, J.J.; Zhu, L.N.; Tian, B. Tribological behaviour of textured titanium under abrasive wear. Surf. Eng. 2018, 35, 378–386. [Google Scholar] [CrossRef]

- Wu, Z.; Xing, Y.Q.; Huang, P.; Liu, L. Tribological properties of dimple-textured titanium alloys under dry sliding contact. Surf. Coat. Technol. 2017, 309, 21–28. [Google Scholar] [CrossRef]

- Zhang, H.; Qin, L.G.; Hua, M.; Dong, G.N.; Chin, K.S. A tribological study of the petaloid surface texturing for Co-Cr-Mo alloy artificial joints. Appl. Surf. Sci. 2015, 332, 557–564. [Google Scholar] [CrossRef]

- Koszela, W.; Pawlus, P.; Reizer, R.; Liskiewicz, T. The combined effect of surface texturing and DLC coating on the functional properties of internal combustion engines. Tribol. Int. 2018, 127, 470–477. [Google Scholar] [CrossRef]

- Yuan, S.; Lin, N.M.; Zou, J.J.; Liu, Z.Q.; Wang, Z.X.; Tian, L.H.; Qin, L.; Zhang, H.X.; Wang, Z.H.; Tang, B.; et al. Effect of laser surface texturing(LST) on tribological behavior of double glow plasma surface zirconizing coating on Ti6Al4V alloy. Surf. Coat. Technol. 2019, 368, 97–109. [Google Scholar] [CrossRef]

- Wu, C.; Yang, K.; Chen, Y.; Ni, J.; Yao, L.D.; Li, X.L. Investigation of friction and vibration performance of lithium complex grease containing nano-particles on rolling bearing. Tribol. Int. 2021, 155, 45–48. [Google Scholar] [CrossRef]

- Jiang, C.P.; Zhang, J.; Chen, Y.N.; Hou, Z.M.; Zhao, Q.Y.; Li, Y.; Zhu, L.X.; Zhang, F.Y.; Zhao, Y.Q. On enhancing wear resistance of titanium alloys by laser cladded WC-Co composite coatings. Int. J. Refract. Met. Hard Mater. 2022, 107, 105902. [Google Scholar] [CrossRef]

- Wang, K.P.; Wu, H.C.; Wang, H.D.; Liu, Y.H. Superior extreme pressure properties of different layer LDH nanoplatelets used as boundary lubricants. Appl. Surf. Sci. 2020, 530, 15–23. [Google Scholar] [CrossRef]

- Fan, S.G.; Gao, C.P.; Yang, G.B.; Zhang, Y.J.; Zhang, C.L.; Song, N.N.; Zhang, S.M.; Zhang, P.Y.; Zhang, Z.J.; Ke, S.J. Enhancing wear-resistance of Cu nanowires filled polyetheretherketone-based composites under water lubrication conditions via magnetic response to tribofilm. Tribol. Int. 2021, 153, 106601. [Google Scholar] [CrossRef]

- Ni, J.; Cui, Z.; Wu, C.; Sun, J.B.; Zhou, J.H. Evaluation of MQL broaching AISI 1045 steel with sesame oil containing nano-particles under best concentration. J. Clean. Prod. 2021, 320, 443–456. [Google Scholar] [CrossRef]

- Kossman, S.; Coorevits, T.; Iost, A.; Chicot, D. A new approach of the Oliver and Pharr model to fit the unloading curve from instrumented indentation testing. J. Mater. Res. 2017, 32, 2230–2240. [Google Scholar] [CrossRef]

- Wu, B.; Song, H.; Zhang, Q.Q.; Hu, X.G. Controllable synthesis and friction reduction of ZnFe2O4@C microspheres with diverse core-shell architectures. Tribol. Int. 2021, 153, 106614. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, Y.; Shan, J.; Wu, A.; Tang, X. Evolution behavior of liquid film in the heataffected zone of laser cladding non-weldable nickel-based superalloy. J. Alloys Compd. 2021, 863, 158463. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.G.; Tian, W.; Yang, Y. Laser surface remelting of plasma sprayed nanostructured Al2O3-13wt%TiO2 coatings on titanium alloy. J. Alloys Compd. 2010, 503, 127–132. [Google Scholar] [CrossRef]

- Yu, G.; Li, Z.; Li, S.; Zhang, Q.; Hua, Y.; Liu, H.; Zhao, X.; Dhaidhai, D.T.; Li, W.; Wang, X. The select of internal architecture for porous Ti alloy scaffold: A compromise between mechanical properties and permeability. Mater. Des. 2020, 192, 108754. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Zhao, Y.; Mei, H.; Chang, P.; Yang, Y.; Huang, W.; Liu, Y.; Cheng, L.; Zhang, L. 3DPrinted Topological MoS2/MoSe2 Heterostructures for Macroscale Superlubricity. ACS Appl. Mater. Interfaces 2021, 13, 34984–34995. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Shi, X.; Xue, Y.; Zhang, K.; Wu, C. Optimization of bionic textured parameter to improve the tribological performance of AISI 4140 self-lubricating composite through response surface methodology. Tribol. Int. 2021, 161, 107104. [Google Scholar] [CrossRef]

- Li, S.; An, Y.; Zhao, X.; Zhou, H.; Chen, J.; Hou, G. Bioinspired Smart Coating with Superior Tribological Performance. ACS Appl. Mater. Interfaces 2017, 9, 16745–16749. [Google Scholar] [CrossRef]

- Harris, K.L.; Pitenis, A.A.; Sawyer, W.G.; Krick, B.A.; Blackman, G.S.; Kasprzak, D.J.; Junk, C.P. PTFE Tribology and the Role of Mechanochemistry in the Development of Protective Surface Films. Macromolecules 2015, 48, 3739–3745. [Google Scholar] [CrossRef]

- Zuo, Z.; Jin, X.; Li, C.; Zhang, Z.; Yang, Y. Chemisorption mechanism of defluorinated fluorine on bcc Fe surface during formation of PTFE transfer film. Appl. Surf. Sci. 2021, 567, 150777. [Google Scholar] [CrossRef]

- Xu, F.; Gong, D. Improved the elevated temperature mechanical properties of Al-Si alloy deposited with Al-Si coating by magnetron sputtering. Vacuum 2018, 150, 1–7. [Google Scholar] [CrossRef]

- Wu, B.H.; Leng, Y.X.; Huang, N.; Yang, W.M.; Li, X.Y. The plasma characteristics in high power pulsed impulsed magnetron sputtering (hipims) and its effect on films properties. Surf. Technol. 2018, 47, 245–255. [Google Scholar]

- Khrushchov, M.M.; Levin, I.S.; Reilyanu, M.D.; Obraztsova, E.A.; Atamanov, M.V. Structure and tribological behavior of chromium-carbon coatings obtained by magnetron sputtering. Phys. Met. Metallogr. 2019, 120, 204–209. [Google Scholar] [CrossRef]

- Kang, S.H.; Tu, W.B.; Han, J.X.; Li, Z.; Cheng, Y.L. A significant improvement of the wear resistance of Ti-6Al-4V alloy by a combined method of magnetron sputtering and plasma electrolytic oxidation (PEO). Surf. Coat. Technol. 2019, 358, 879–890. [Google Scholar] [CrossRef]

- Chi, G.F.; Yi, D.Q.; Liu, H.Q. Effect of roughness on electrochemical and pitting corrosion of Ti-6Al-4V alloy in 12 wt.% HCl solution at 35 °C. J. Mater. Res. Technol. 2020, 9, 1162–1174. [Google Scholar] [CrossRef]

- Cheng, Z.H.; Yang, W.; Xu, D.P.; Wu, S.K.; Yao, X.F.; Lv, Y.K.; Chen, J. Improvement of high temperature oxidation resistance of micro arc oxidation coated AlTiNbMo0.5Ta0.5Zr high entropy alloy. Mater. Lett. 2020, 262, 127192. [Google Scholar] [CrossRef]

- Correa, D.R.N.; Rocha, L.A.; Ribeiro, A.R.; Gemini-Piperni, S.; Archanjo, B.S.; Achete, C.A.; Werckmann, J.; Afonso, C.R.M.; Shimabukuro, M.; Doi, H.; et al. Growth mechanisms of Ca- and P-richMAO films in Ti-15Zr-xMo alloys for osseointegrative implants. Surf. Coat. Technol. 2018, 344, 373–382. [Google Scholar] [CrossRef]

- Guo, Q.; Xu, D.; Yang, W.; Guo, Y.; Yang, Z.; Li, J.; Gao, P. Synthesis, corrosion, and wear resistance of a black microarc oxidation coating on pure titanium. Surf. Coat. Technol. 2020, 386, 125454. [Google Scholar] [CrossRef]

- Aliofkhazraei, M.; Rouhaghdam, A.S. Wear and coating removal mechanism of alumina/titania nanocomposite layer fabricated by plasma electrolysis. Surf. Coat. Technol. 2011, 205, S57–S62. [Google Scholar] [CrossRef]

- Qi, Y.M.; Peng, Z.J.; Liang, J. Fabrication and wear resistance of hard micro arc oxidation coatings on Ti alloys. Surf. Technol. 2019, 48, 81–88. [Google Scholar]

- Chen, L.; Wei, K.; Yao, Q.; Tao, L.; Bei, C.; Liao, B.; Xue, W. Characterization of plasma electrolytic oxidation film on biomedical high niobiumcontaining β-titanium alloy. Surf. Coat. Technol. 2018, 352, 295–301. [Google Scholar] [CrossRef]

- Li, Q.B.; Yang, W.B.; Liu, C.C.; Wang, D.A.; Liang, J. Correlations between the growth mechanism and properties of micro-arc oxidation coatings on titanium alloy: Effects of electrolytes. Surf. Coat. Technol. 2017, 316, 162–170. [Google Scholar] [CrossRef]

- Yerokhin, A.L.; Nie, X.; Leyland, A.; Matthews, A. Characterization of oxide films produced by plasma electrolytic oxidation of a Ti-6Al-4V alloy. Surf. Coat. Technol. 2000, 130, 195–206. [Google Scholar] [CrossRef]

- Quintero, D.; Galvis, Q.; Calderon, J.A.; Gomez, M.A.; Castano, J.G.; Echeverria, F.; Habazaki, H. Control of the physical properties of anodic coatings obtained by plasma electrolytic oxidation on Ti6Al4V alloy. Surf. Coat. Technol. 2015, 283, 210222. [Google Scholar] [CrossRef]

- Lan, N.; Yang, W.; Gao, W.; Guo, P.; Zhao, C.; Chen, J. Characterization of ta-C film on micro arc oxidation coated titanium alloy in simulated seawater. Diam. Relat. Mater. 2021, 117, 108483. [Google Scholar] [CrossRef]

| Material Type | Material Grade | Yield Strength/MPa | Tensile Strength/kN | Gravity/N | Strength to Gravity Ratio |

|---|---|---|---|---|---|

| Steel | UD-165(VM-150) | 1137 | 4591 | 5039 | 901 |

| Steel | V-150 | 1034 | 4174 | 5039 | 819 |

| Steel | Z-140 | 965 | 895 | 5039 | 765 |

| Steel | S-135 | 931 | 3756 | 5039 | 737 |

| Aluminum alloy | Al-Zn-MgI | 325 | 1778 | 3189 | 557 |

| Aluminum alloy | Al-Zn-MgII | 480 | 2626 | 3189 | 823 |

| Aluminum alloy | Al-Cu-Mg-Si-FeIII | 340 | 1860 | 3189 | 583 |

| Aluminum alloy | Al-Zn-MgIV | 350 | 1914 | 3189 | 600 |

| Titanium alloy | Ti6Al4V | 951 | 3825 | 3130 | 1213 |

| Comparison Content | Surface Carburizing/Nitrogen/Boron Technology | Pulse Magnetic Field Treatment | Laser Cladding Technology | Plasma Spraying Technology | Additive Manufacturing Technology | Magnetron Sputtering Technology | Micro Arc Oxidation |

|---|---|---|---|---|---|---|---|

| Equipment and process | Expensive equipment and complex process | Simple equipment and complex process | Complex equipment and process | Expensive equipment and simple process | Simple equipment and process | Expensive equipment and complex process | Simple equipment and process |

| Base material | Metallic materials | Metallic materials | Metals, ceramics and composites | Metal, ceramic and organic materials | Metallic materials | Metallic materials | Metallic materials |

| Matrix temperature | 800 °C | 900 °C | Lower | 100~260 °C | 500 °C | 40~50 °C | <300 °C |

| Preparation time | A few hours | A few minutes | A few minutes | A few minutes to ten minutes | A few seconds | About 4 h | A few minutes to ten minutes |

| Coating thickness | Thin, 20~30 μm | 5 mm | 0.5~2.0 mm | Dozens to hundreds of microns | 0.1 mm | About 6 nm | Thin, more than ten microns |

| Microhardness of coating | High | High | Very high | Higher | High | High | High |

| Coating roughness | Lower | Low | Low | Higher | Low | Low | Low |

| Substrate suitability | Suitable for simple small size parts | Final parts | Alloy powder | Simple parts with wide size range | Highly complex and functional parts | Precision instrument | Suitable for complex parts |

| Type of coating | Single | Single | Variety | Variety | Single | Single | Single |

| Working environment | Vacuum state, environment-friendly | Vacuum state, environment-friendly | Vacuum state, environment-friendly | Inert gas protection, loud noise | No pollution to the environment | Vacuum state | No pollution to the environment |

| Preparation cost | High, suitable for small-scale production | Low, suitable for mass production | Low, widely used | Low, suitable for mass production | High, suitable for small-scale production | Low, suitable for mass production | Low, suitable for mass production |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Zhang, H.; Wang, B.; Huang, J.; Zhou, M.; Wang, L.; Xi, Y.; Jia, H.; Xu, S.; Liu, H.; et al. A Review of Research on Improving Wear Resistance of Titanium Alloys. Coatings 2024, 14, 786. https://doi.org/10.3390/coatings14070786

Chen Y, Zhang H, Wang B, Huang J, Zhou M, Wang L, Xi Y, Jia H, Xu S, Liu H, et al. A Review of Research on Improving Wear Resistance of Titanium Alloys. Coatings. 2024; 14(7):786. https://doi.org/10.3390/coatings14070786

Chicago/Turabian StyleChen, Yazhou, Honggang Zhang, Bitao Wang, Jianyong Huang, Meihong Zhou, Lei Wang, Yuntao Xi, Hongmin Jia, Shanna Xu, Haitao Liu, and et al. 2024. "A Review of Research on Improving Wear Resistance of Titanium Alloys" Coatings 14, no. 7: 786. https://doi.org/10.3390/coatings14070786

APA StyleChen, Y., Zhang, H., Wang, B., Huang, J., Zhou, M., Wang, L., Xi, Y., Jia, H., Xu, S., Liu, H., Wen, L., Xiao, X., Liu, R., & Ji, J. (2024). A Review of Research on Improving Wear Resistance of Titanium Alloys. Coatings, 14(7), 786. https://doi.org/10.3390/coatings14070786