Analysis of Wear Vibration Behavior of Micro-Textured Coated Cemented Carbide Considering High-Order Scale

Abstract

1. Introduction

2. Friction and Wear Test

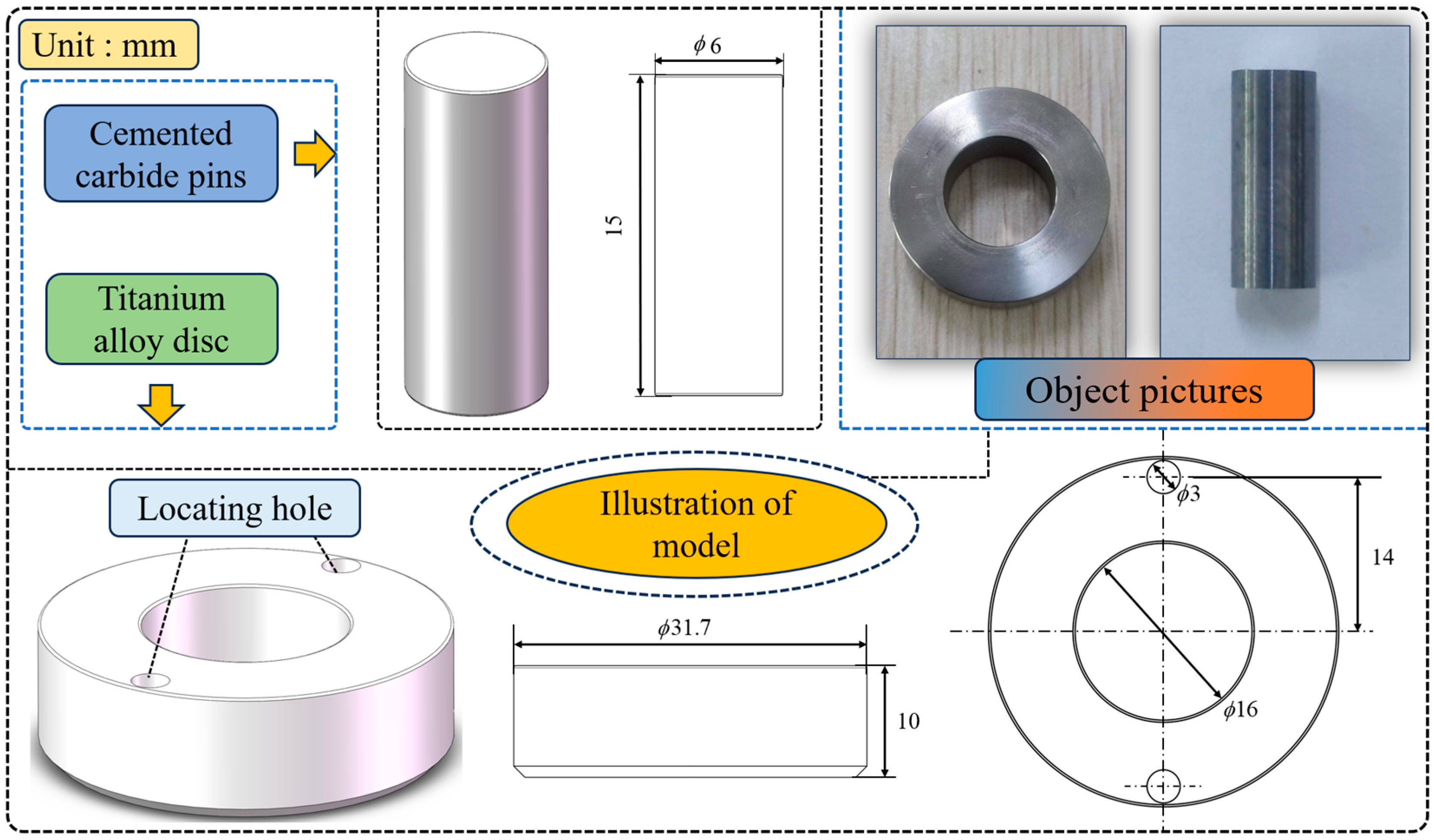

2.1. Workpiece Material Selection

2.2. Test Design

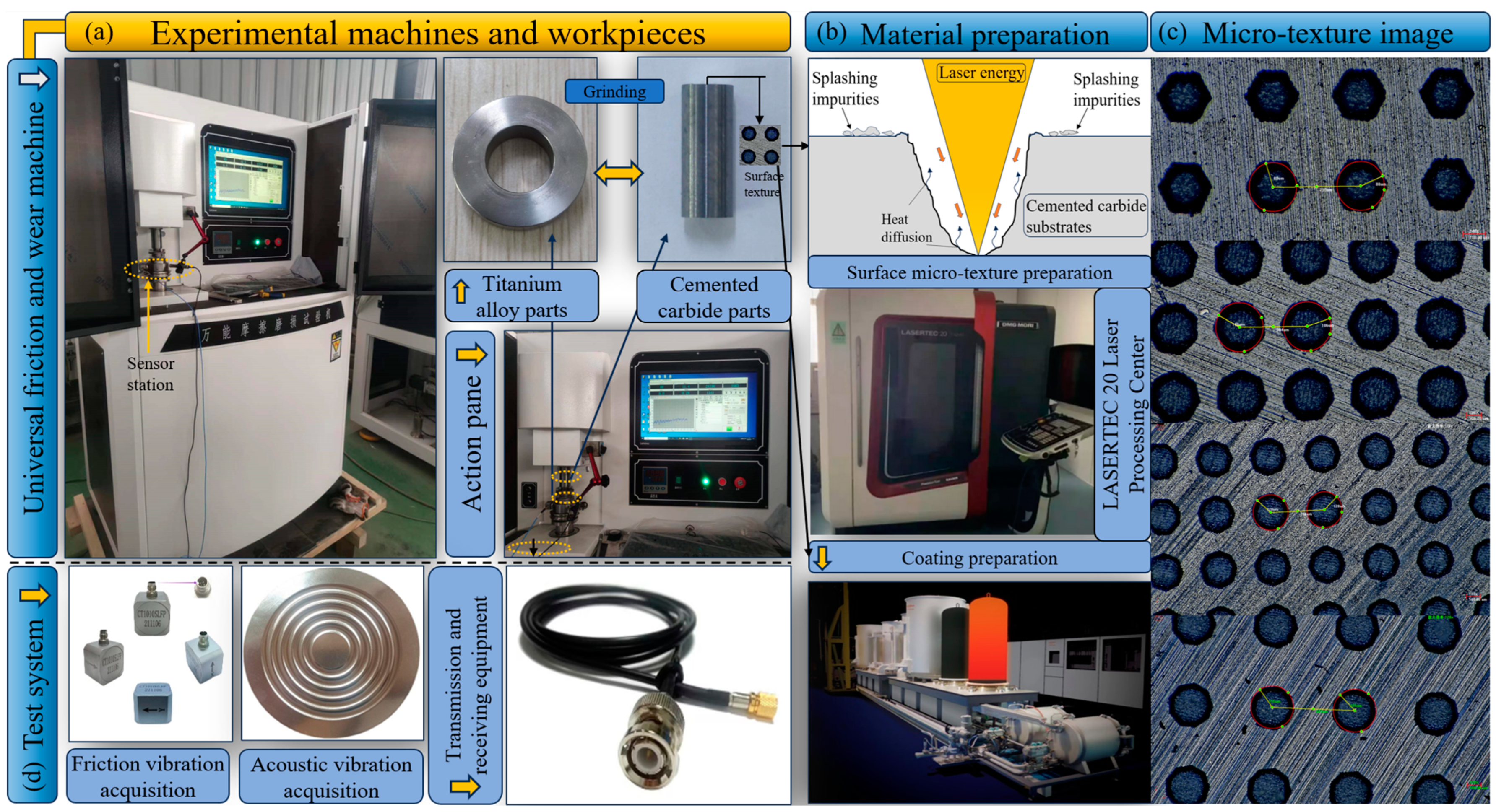

2.3. Test Platform Building

3. Analysis Method

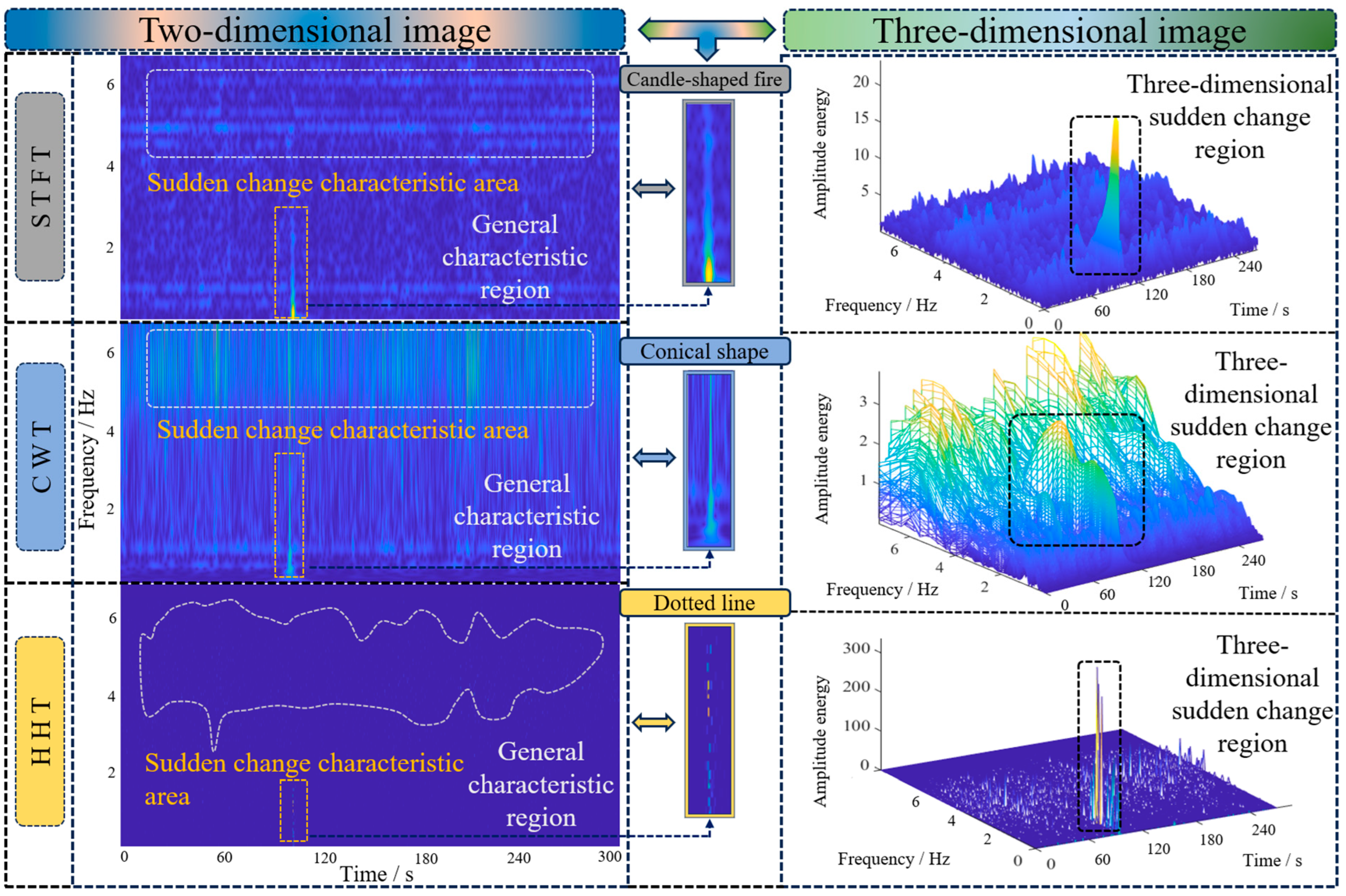

3.1. Comparison of Signal Analysis Methods

3.1.1. STFT Time-Frequency Domain Signal Analysis

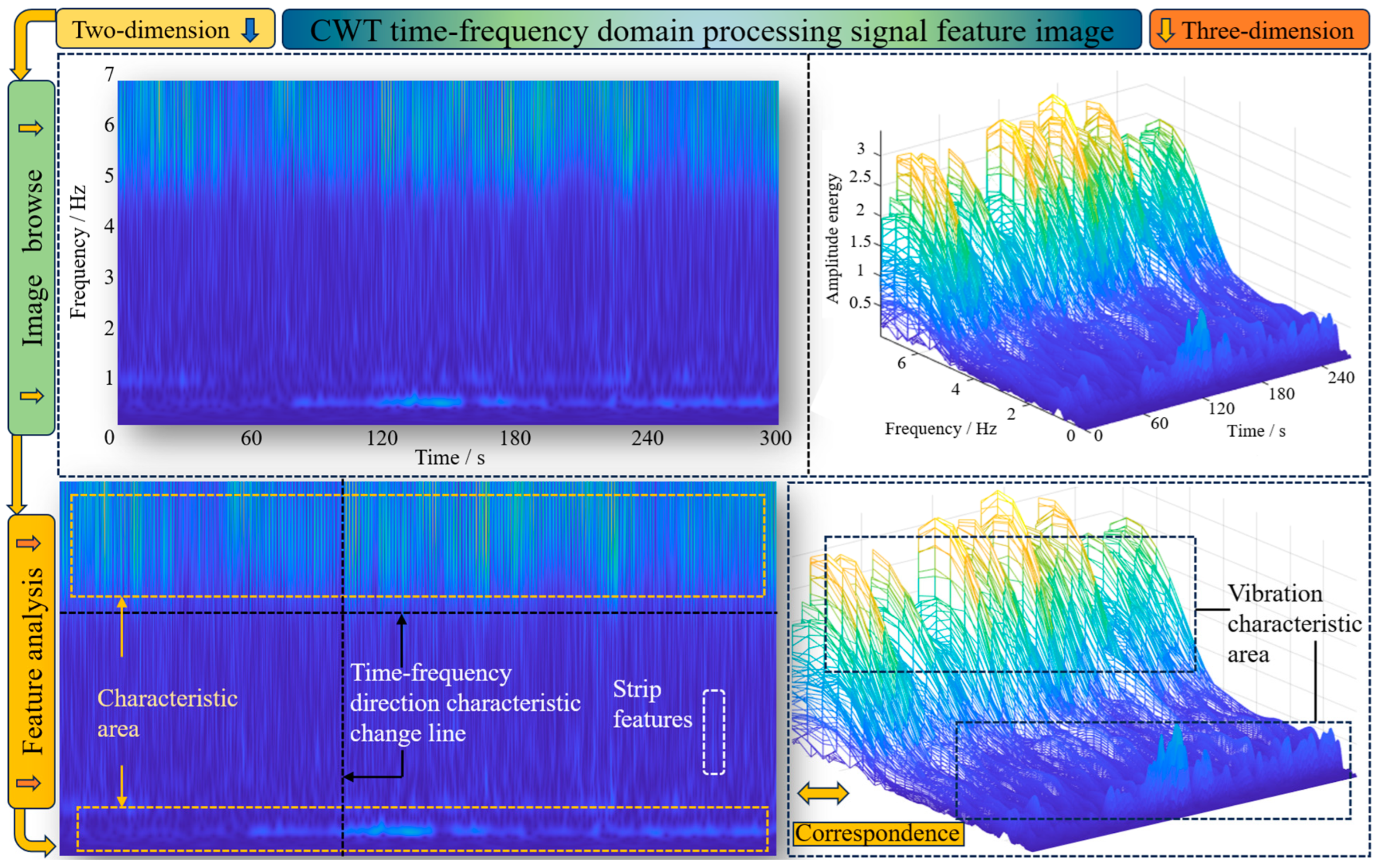

3.1.2. CWT Time-Frequency Domain Signal Analysis

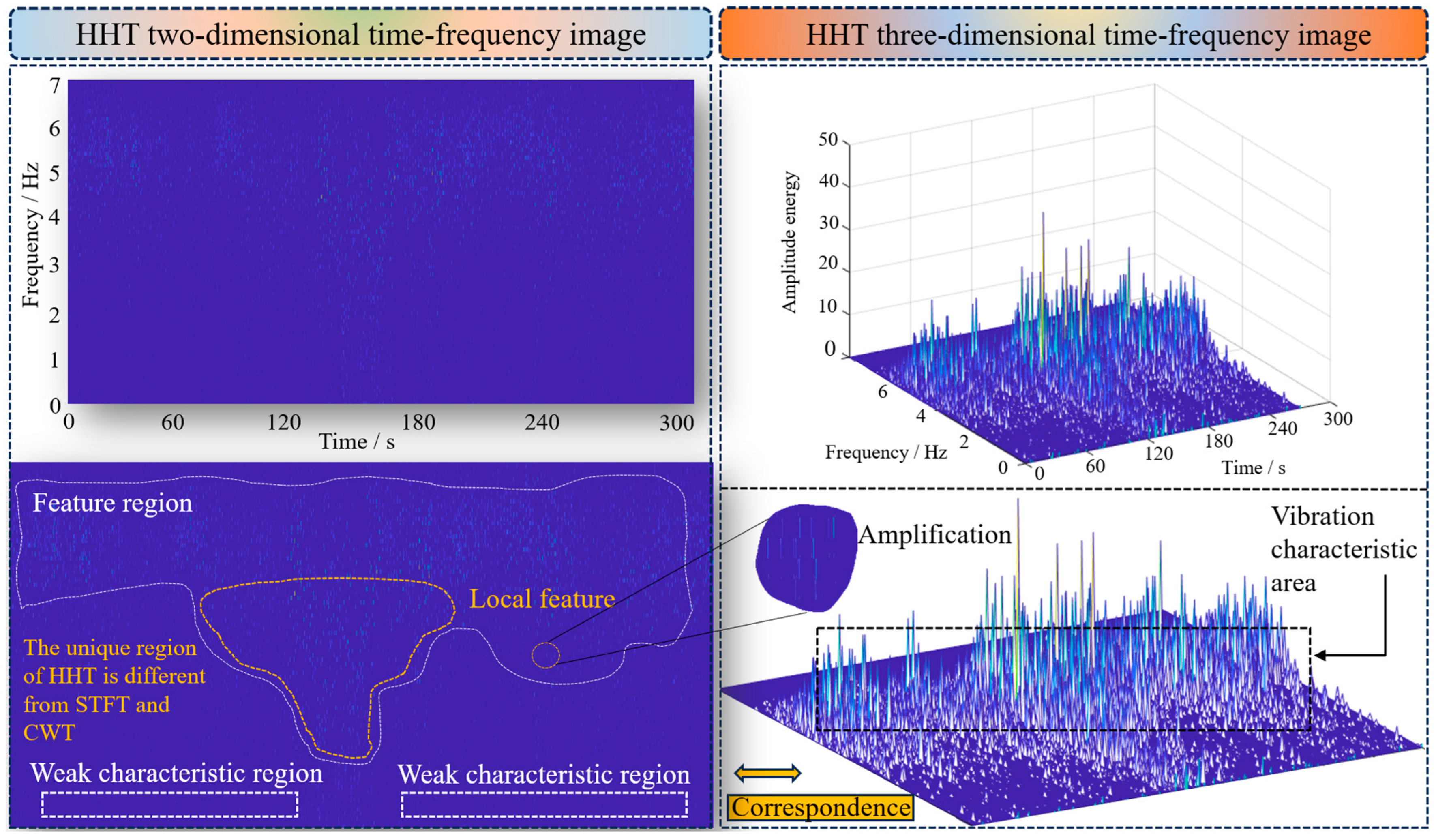

3.1.3. HHT Time-Frequency Domain Signal Analysis

3.1.4. Selection of Time-Frequency Analysis Method for Test Signal

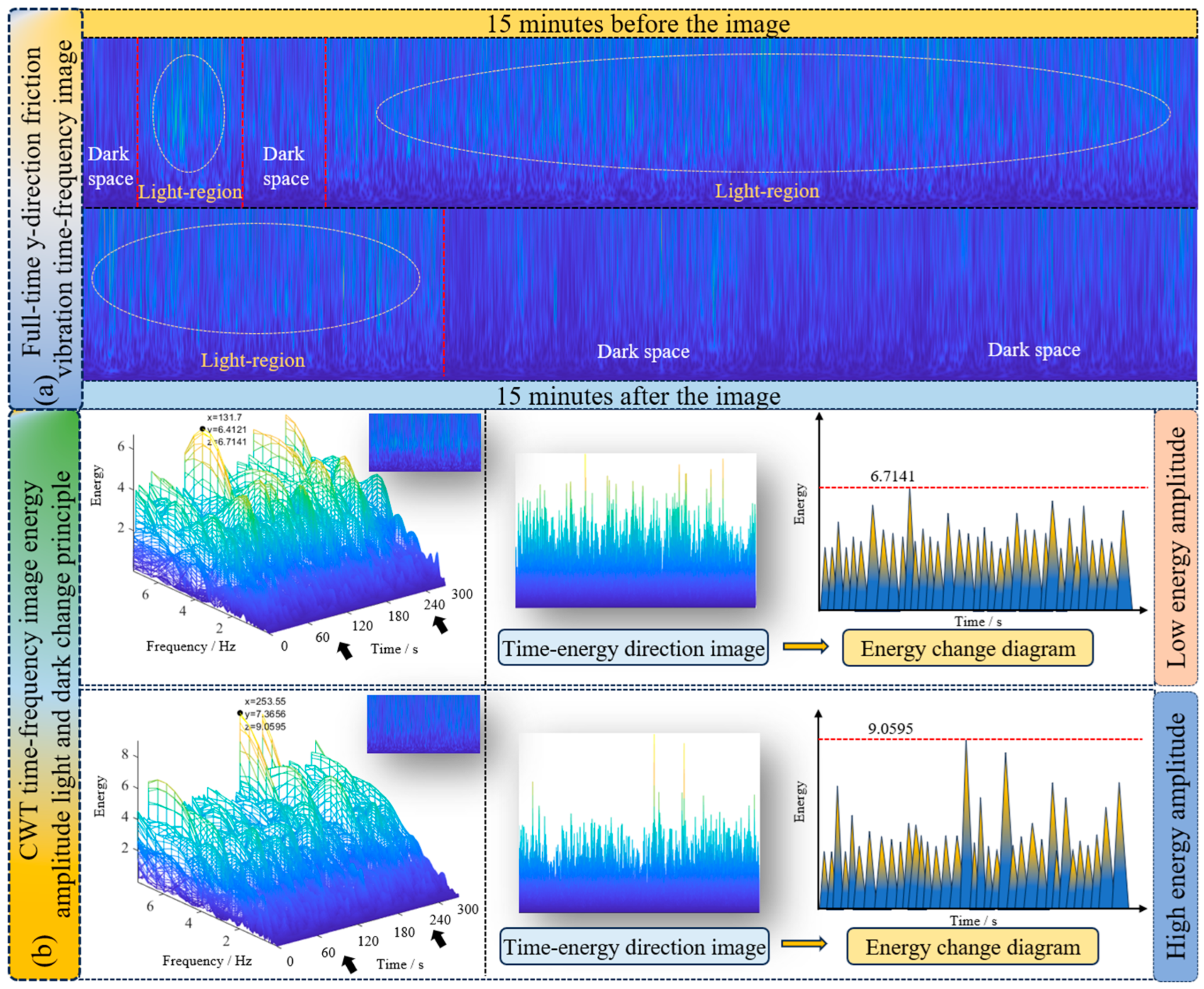

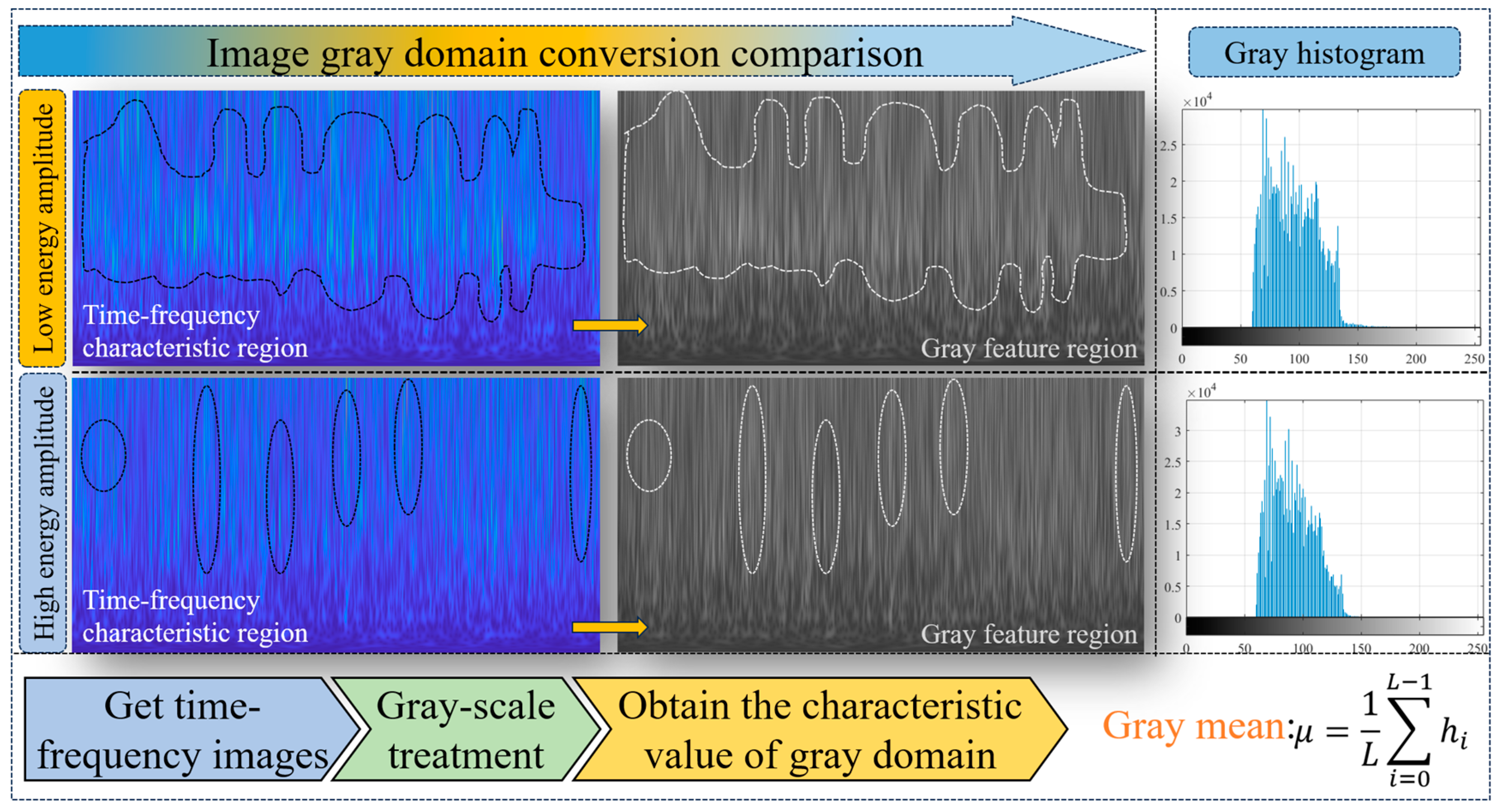

3.2. Research on Signal CWT-Grayscale Analysis Method

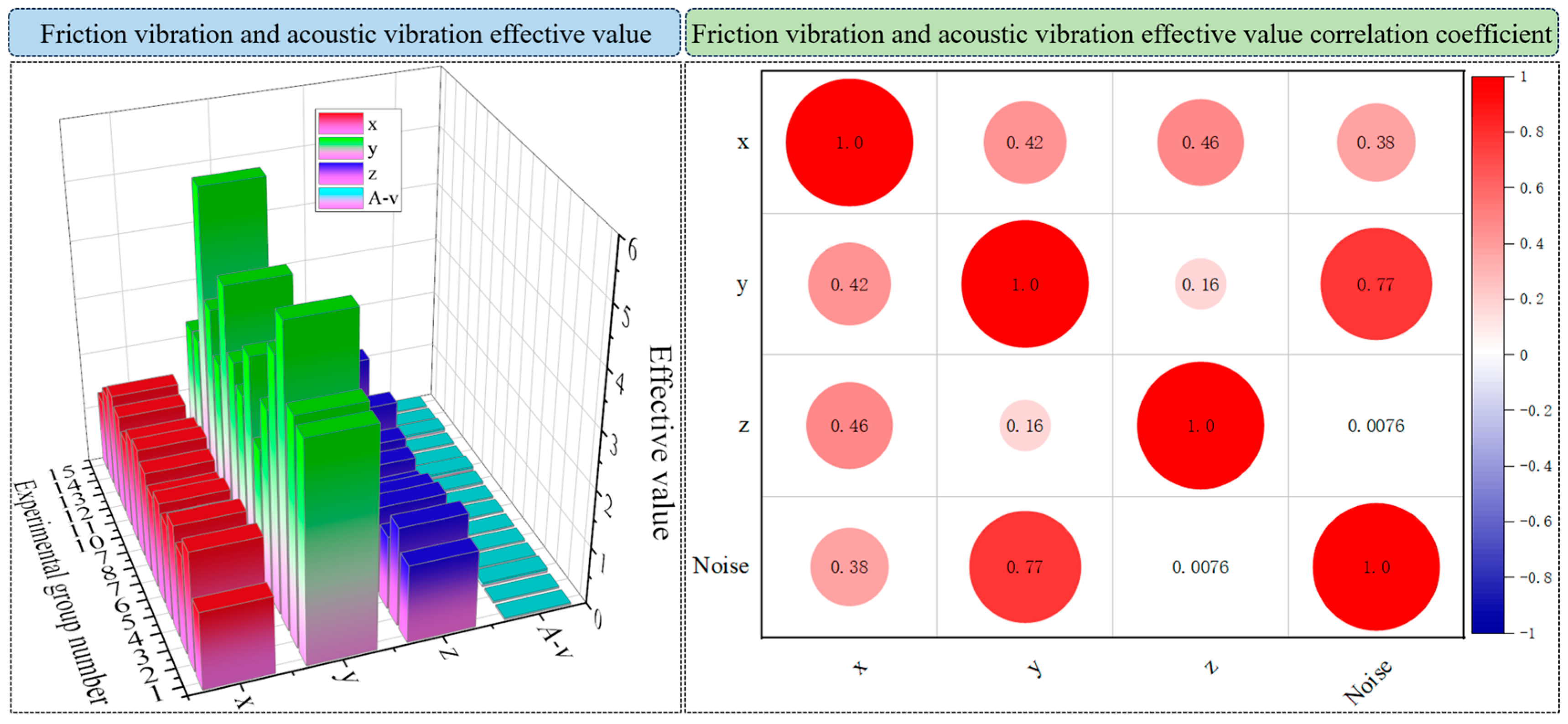

3.2.1. Time-Frequency Image Feature Analysis

- (a)

- The characteristic regions of the friction vibration signal in the x direction are mainly distributed in the high frequency band, and there are weak characteristics in the low frequency band;

- (b)

- The characteristics of the friction vibration signal in the y direction are almost covered with the whole image; The friction vibration characteristics in the z direction are mainly distributed in the high frequency band, but the distribution is more divergent and fuzzy;

- (c)

- The characteristics of the acoustic vibration signal are distributed in the middle and high frequency regions in two sections, showing a divergent trend;

- (d)

- The acoustic vibration is relatively weak compared with the friction vibration, but the characteristics are distinct.

3.2.2. Selection of Friction Vibration Analysis

3.3. Time-Frequency Image Analysis Based on Gray Algorithm

3.3.1. Analysis of Light and Dark Characteristics of Time-Frequency Images

3.3.2. Numerical Analysis of Gray Feature of Time-Frequency Image

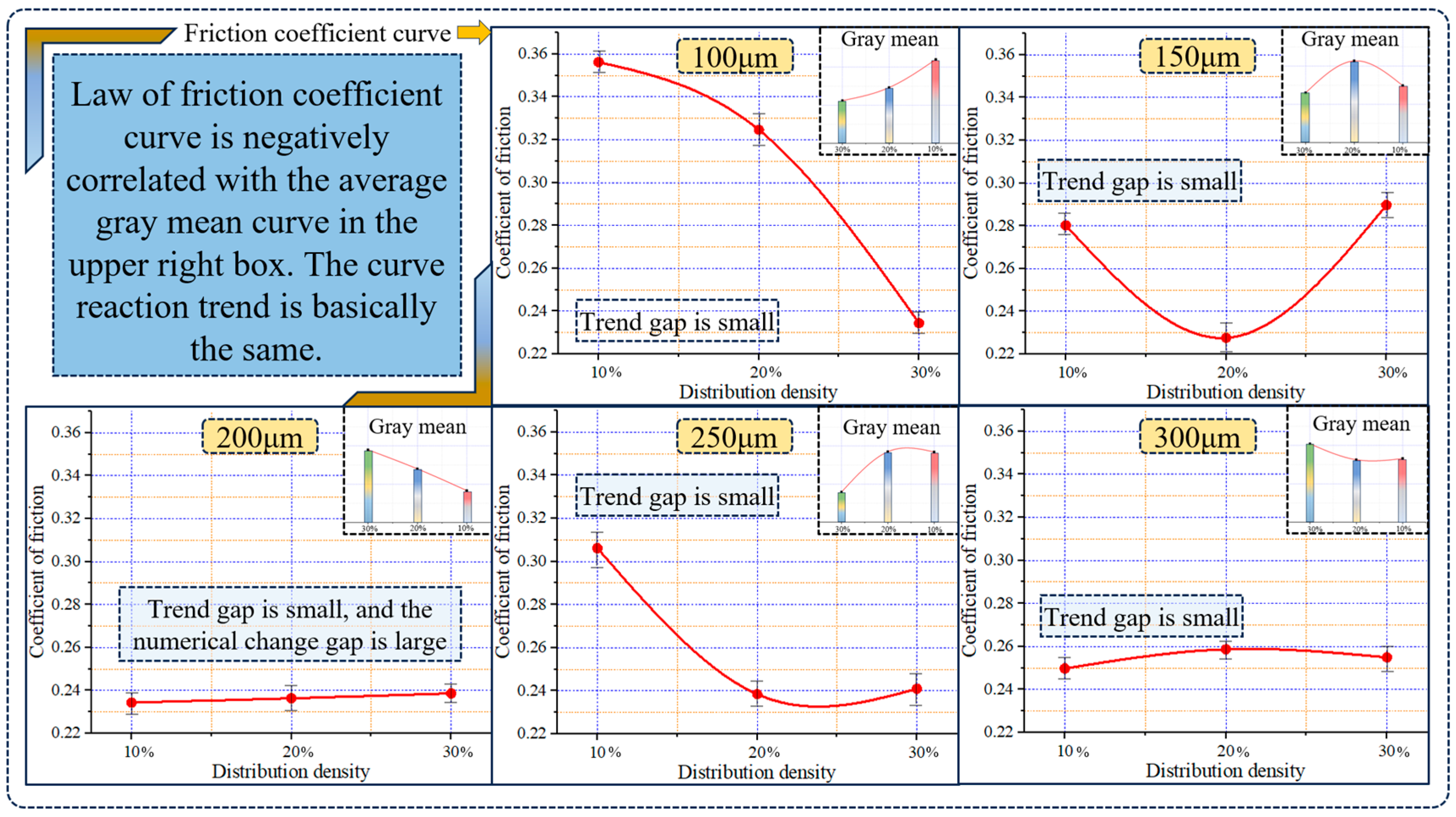

4. Test Result Analysis

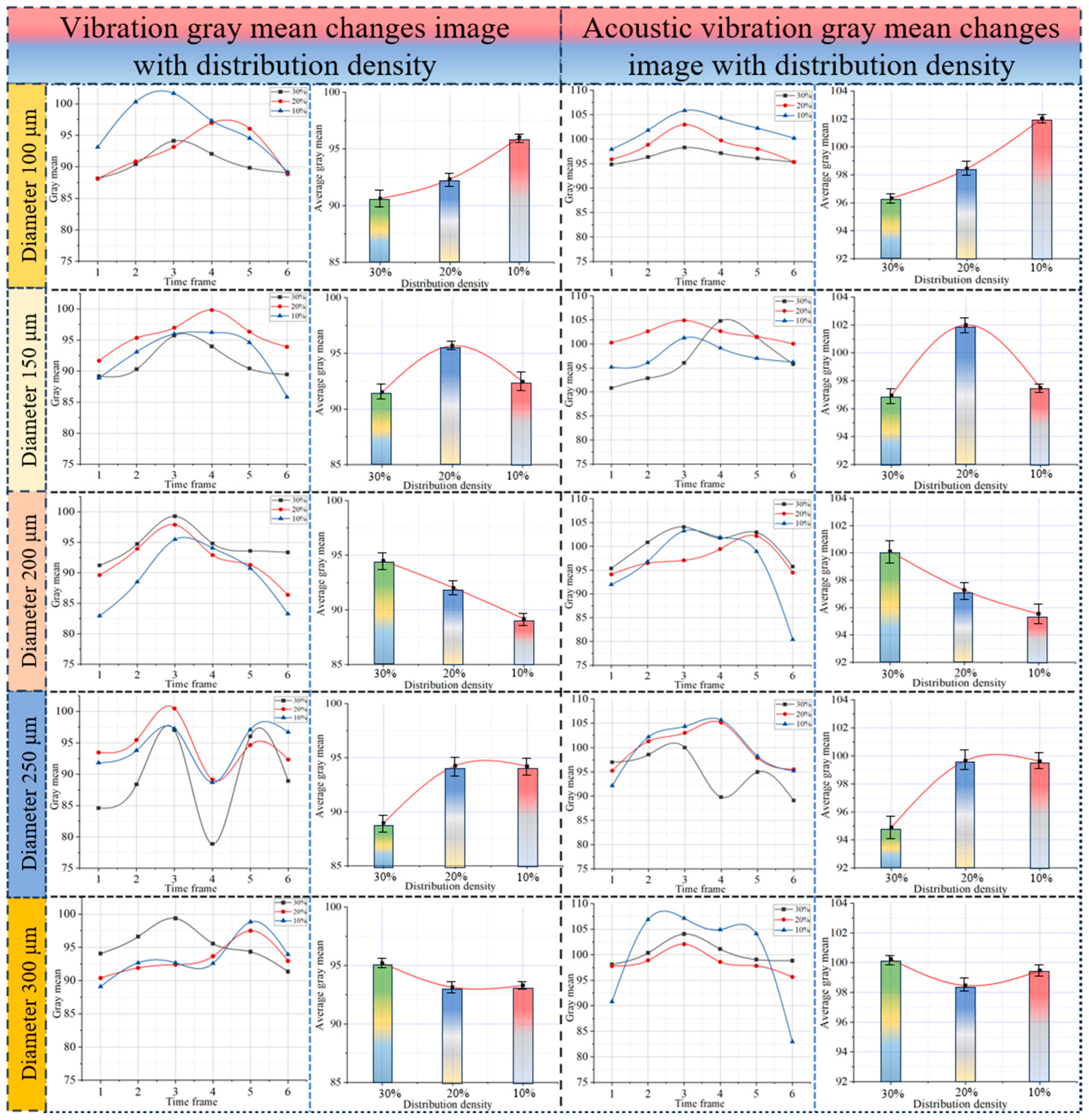

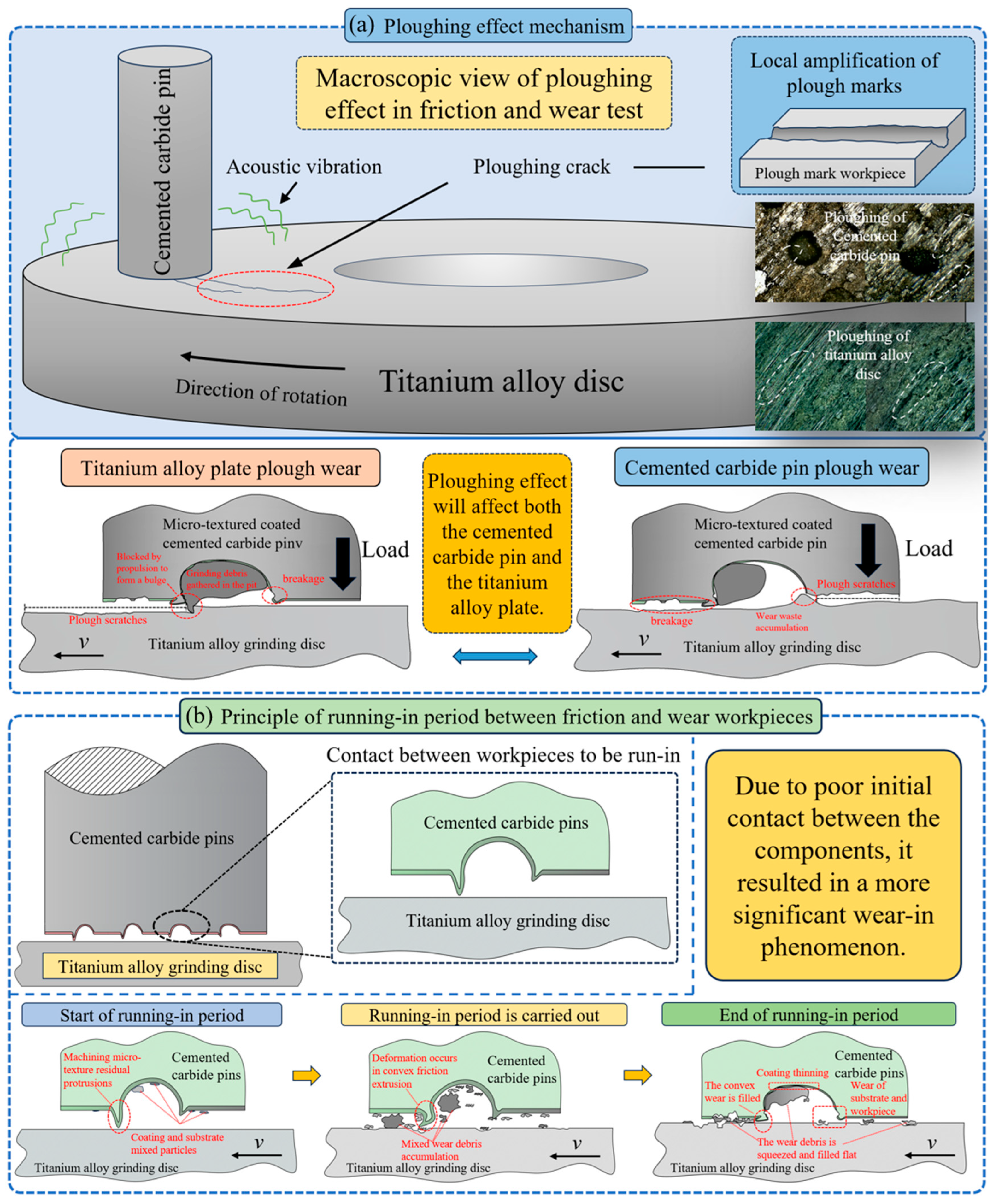

4.1. Analysis of Friction Vibration and Acoustic Vibration Data Change Mechanism

- (1)

- Gray mean time change image analysis:

- (2)

- Mechanism analysis of the group average gray mean change image in the friction and wear test:

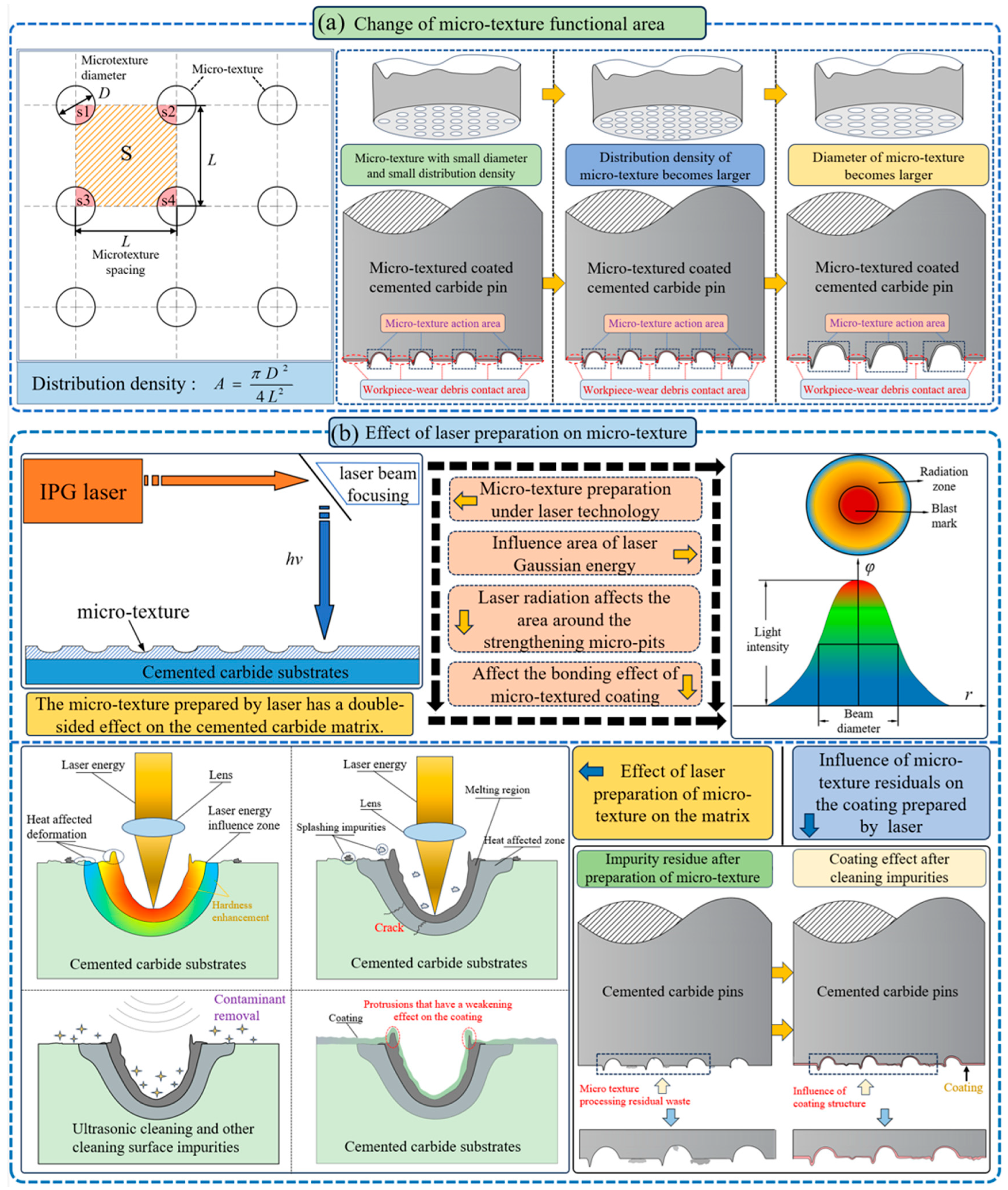

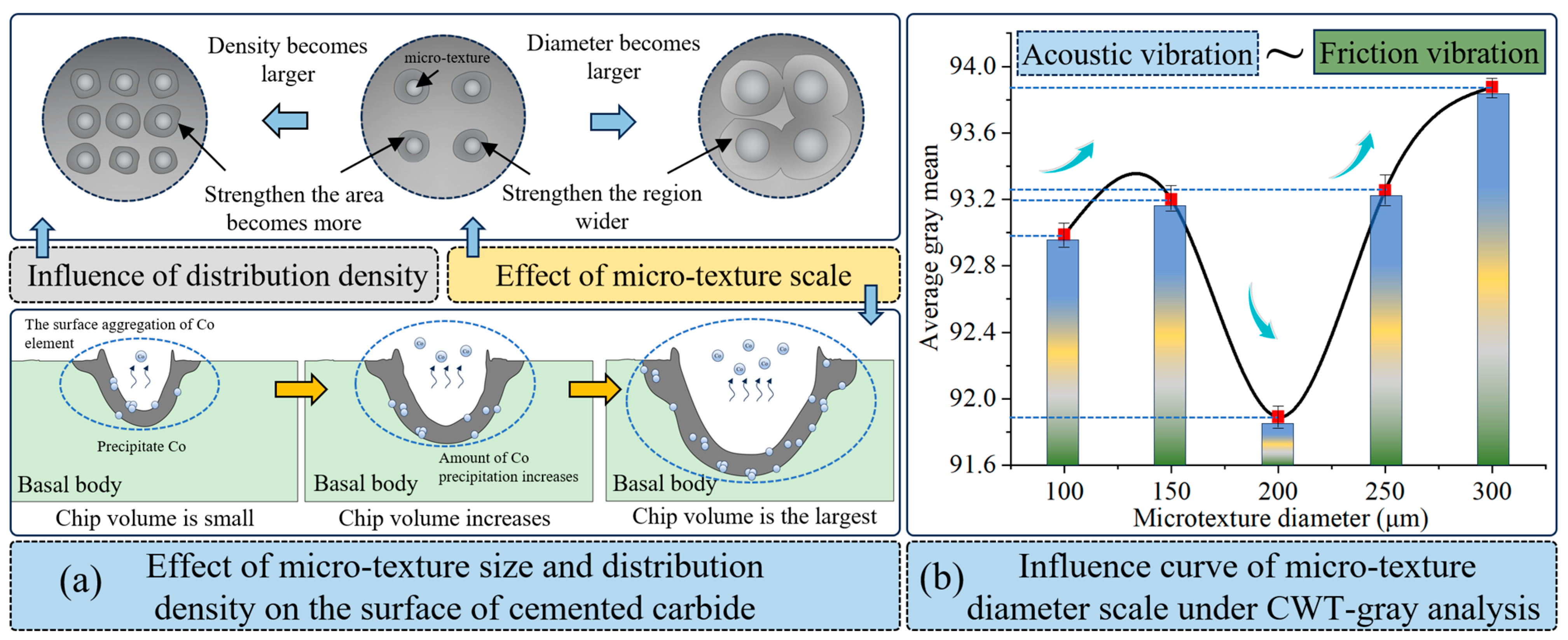

4.2. Comparison of Advantages and Disadvantages between High-Order Micro-Texture and Traditional Size

4.2.1. CWT-Grayscale Analysis Verification

4.2.2. Comparison of Advantages and Disadvantages of Micro-Texture Magnitude

4.3. Analysis of Friction Vibration and Acoustic Vibration Stable Period

5. Conclusions

- (1)

- For the frictional vibration and acoustic vibration signals with large amounts of data and continuous changes, the time-frequency characteristics obtained by CWT analysis are clearer and more comprehensive.

- (2)

- The size expansion of micro-texture helps to improve its chip-holding function, especially in the sizes of 100–150 μm and 250–300 μm. It can effectively expand the laser Marangoni effect strengthening area. Reduce the contact between the wear debris and the workpiece, and reduce the influence of friction vibration and acoustic vibration. The synergistic effect of surface texture and coating of cemented carbide is improved, and the wear resistance is improved.

- (3)

- Compared with the modification effect of traditional-scale micro-textured AlCrN coating, it is found that when the size of the micro-texture is increased, the friction vibration stability is increased by 1.58%, the acoustic vibration stability is increased by 4.47%, the friction stability is increased by 13.16%, and the friction and wear performance are improved.

- (4)

- The variation of friction vibration and acoustic vibration obtained by friction and wear tests is basically the same. The variation curves of friction vibration and acoustic vibration under CWT-grayscale analysis show that the stable period of high-order textured coating is 10–25 min. The best action period is 15–20 min.

- (5)

- The treatment method of high-order micro-texture synergistic coating can provide a good modification reference for metal surface modification, especially for cutting tools, reduce contact vibration, and enhance tool wear resistance and oxidation resistance. The idea of size expansion can also provide a reference for the development of other directions based on size parameter strengthening modifications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Yu, X.; Yue, X.; Han, S. Effect of tool micro-texture on cutting performance of 6061 aluminum alloy. Ordnance Mater. Sci. Eng. 2023, 46, 24–28. [Google Scholar]

- Liu, T.; Li, J.; Lu, X.; Jiang, Z. Effect of Surface Texture Parameters on Triblogical Properties of Steel Ball and Steel Disk under Poor Oil Lubrication. Lubr. Eng. 2023, 48, 74–80. [Google Scholar]

- Georg, S.; Hauke, S.; Robert, T.; Hermann, S. Experimental investigations on the friction behavior of partially femtosecond laser-textured journal bearing shells. Tribol. Int. 2023, 188, 108764. [Google Scholar]

- Wu, X.; Zhan, J.; Mei, S. Optimization of Micro-Texturing Process Parameters of TiAlN Coated Cutting Tools by Femtosecond Laser. Materials 2022, 15, 6519. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Wang, W.; Cong, J.; Yuan, W.; Guo, Q. Research on composite friction modification method of GCr15 surface coating and texture. Mod. Manuf. Eng. 2023, 5, 1–5. [Google Scholar]

- Zhang, K.; Zhang, C.; Li, H.; Dong, B.; Guo, X. Study on the substrate surface micro-texturing/carburizing regulating the film-substrate adhesion and wear behavior of DLC coatings. Diam. Relat. Mater. 2022, 130, 109535. [Google Scholar] [CrossRef]

- Liu, M.; Wang, D.; Li, J.; Zhu, Z.; Mo, J. Characteristics of the tribological wear, vibration and sgueal noise of brake disc surfaces with grooves. J. Vib. Shock 2018, 37, 236–240. [Google Scholar]

- Xu, H.; Lv, X.; Wang, X.; Feng, J.; Liu, X.; Peng, J.; Wu, H. Electrochemically assisted laser surface microtexture preparation and tribological properties research. J. Manuf. Process. 2024, 122, 54–64. [Google Scholar] [CrossRef]

- Rajurkar, A.; Chinchanikar, S. Investigations on homothetic and hybrid micro-textured tools during turning Inconel-718. Mater. Manuf. Process. 2024, 39, 529–545. [Google Scholar] [CrossRef]

- Wang, H.; Wang, B.; Zhou, F.; Guo, K.; Liu, Y.; Lin, H. Effect of laser surface texturing on friction performance and surface damage of silicon nitride ceramic. J. Asian Ceram. Soc. 2024, 12, 184–193. [Google Scholar] [CrossRef]

- Bondarev, A.; Simonovic, K.; Vitu, T.; Kožmín, P.; Syrovatka, Š. Textured coating or coated texture: Femtosecond laser texturing of aC: H/WC coatings for dry friction applications. Surf. Coat. Technol. 2023, 469, 129808. [Google Scholar] [CrossRef]

- Fan, Q.; Lin, J.; Wang, T. The Latest Research Progress of Tool Coating Materials. Surf. Technol. 2022, 51, 1–19+28. [Google Scholar]

- Ma, Z. Research on Vibration Signal Feature Extraction METHOD Based on Time-Frequency Analysis and Convolutional Neural Network. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2020. [Google Scholar]

- Su, Y.; Mao, H. Fault diagnosis of scroll compressor based on wavelet transform and CNN. China Meas. Test 2023, 49, 92–97. [Google Scholar]

- Liu, Z.; Bai, Y.; Li, S.; Jia, X. Diesel engine fault diagnosis method based on wavelet time-frequencyDiagram and Swin Transformer. Syst. Eng. Electron. 2023, 45, 2986–2998. [Google Scholar]

- Wang, S.; Zhao, W.; Zhang, G.; Xu, H.; Du, Y. Identification of structural parameters from free vibration data using Gabor wavelet transform. Mech. Syst. Signal Process. 2021, 147, 107122. [Google Scholar] [CrossRef]

- Tong, X.; Li, X. Study on noise behavior of micro-textured composite coated cemented carbide surface grinding titanium alloy based on HHT analysis. J. Vib. Control. 2023. [Google Scholar] [CrossRef]

- Sun, M.; Yang, J.; Wu, L. Time-Frequency Analysis of Noisy Vibration Signal Based on Improved Hilbert-Huang Transform. J. Shanghai Jiaotong Univ. 2023, 57, 1648–1656. [Google Scholar] [CrossRef]

- Tong, X.; Han, P.; Yang, S. Study of the friction behavior of AlCrN coated micro-textured surfaces. Tribol. Int. 2023, 177, 107985. [Google Scholar] [CrossRef]

- Fu, K. Research on Feature Extraction Methods and Its Application to Nonstationary Signal Based on HHT. Master’s Thesis, Chongqing University, Chongqing, China, 2015. [Google Scholar]

- Wang, W.; Xu, Q.; Yang, M. Method of system fault diagnosis basedon opticalgray-image recognition. Chin. J. Quantum Electron. 2019, 36, 699–704. [Google Scholar]

- Tong, X.; Wang, S. STFT—Based surface vibration analysis method for textured coated cemented carbide. Chin. J. Sci. Instrum. 2023, 44, 284–295. [Google Scholar]

- Su, S. Research on Micro-Texture Distribution Design and Anti-Wear and Anti-Friction Mechanism of Ball-End Milling Cutter. Master’s Thesis, Harbin University of Science and Technology, Harbin, China, 2021. [Google Scholar]

| YG8 | Ti6Al4V | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| WC | Co | Al | V | Ti | O | C | H | N | Fe | other |

| 92 | 8 | 5.50~6.50 | 3.50~4.50 | margin | 0.20 | 0.08 | 0.015 | 0.05 | 0.30 | 0.40 |

| Physical Property | YG8 | Ti6Al4V |

|---|---|---|

| Density (kg/m3) | 14,600 | 4400 |

| Elastic modulus (GPa) | 510 | 110 |

| Hardness (HRC) | 71 | 33 |

| Tensile strength (MPa) | 1500 | 539 |

| Average Gray Mean of the Whole Group | Traditional Size | High-Order Size |

|---|---|---|

| Friction vibration | 91.59 | 93.04 |

| Standard deviation | 1.84 | 1.89 |

| Acoustic vibration | 94.35 | 98.57 |

| Standard deviation | 2.28 | 2.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, X.; Wang, S. Analysis of Wear Vibration Behavior of Micro-Textured Coated Cemented Carbide Considering High-Order Scale. Coatings 2024, 14, 791. https://doi.org/10.3390/coatings14070791

Tong X, Wang S. Analysis of Wear Vibration Behavior of Micro-Textured Coated Cemented Carbide Considering High-Order Scale. Coatings. 2024; 14(7):791. https://doi.org/10.3390/coatings14070791

Chicago/Turabian StyleTong, Xin, and Shoumeng Wang. 2024. "Analysis of Wear Vibration Behavior of Micro-Textured Coated Cemented Carbide Considering High-Order Scale" Coatings 14, no. 7: 791. https://doi.org/10.3390/coatings14070791

APA StyleTong, X., & Wang, S. (2024). Analysis of Wear Vibration Behavior of Micro-Textured Coated Cemented Carbide Considering High-Order Scale. Coatings, 14(7), 791. https://doi.org/10.3390/coatings14070791