Abstract

In this investigation, a duplex surface modification of M2 high-speed steel (HSS) was demonstrated, including electron beam treatment (EBT) followed by a tungsten nitride (WN) coating deposition. The influence of the EBT of the substrate on the functional properties of the film was also studied. The phase composition of the EBT sample consists of Fe (the main element in the M2 HSS), as well as MC and M6C carbides, while the phase composition of the EBT + WN sample consists of the α’-Fe, M6C, and WN phases. The depth of the treated zone is about 20 μm, and the thickness of the WN coating is about 300 nm in all cases. The hardness of the coating deposited on the EBT substrate is 12.4 GPa, while that of the WN film deposited on the untreated substrate is 8.8 GPa. The application of the electron beam treatment procedure and deposition of WN film leads to an improvement in the tribological properties where the coefficient of friction decreases from 0.81 to 0.66. However, the same coating deposited on untreated substrate exhibits even less friction coefficient values of 0.54. The applied modification technique suggests that this is a viable method for improving the mechanical and tribological properties of the surface of tool steels and, thus, their longevity and applicability.

1. Introduction

High-speed steel (HSS) is a subset of tool steels widely used for the fabrication of cutting tools. The main use of those steels continues to be in the manufacturing of various cutting tools: drills, taps, milling cutters, tool bits, saw blades, router bits, etc. The service life of the cutting tools is of significant importance for improving productivity and, therefore, is an important economic factor [1,2,3].

The wear of cutting tools can be divided into four main groups: abrasive, adhesive, diffusion, and fatigue wear [4]. One of the main problems in the modern engineering industry is maintaining a sufficiently high wear resistance of cutting tools that work in environments with abrasive wear and various load conditions [5]. The durability of such tools largely depends on the properties of their surface to ensure the improvement of their functional characteristics. This is a significant factor influencing the development of methods of surface treatment of various metals and their alloys, such as surface modification with high energy flows [6,7,8], thin films and coatings deposition [9,10,11], ion implantation [12,13,14], and others. Many researchers are working on obtaining new materials and technologies to overcome this problem [1,15,16]. The authors of [7] discussed the effect of electron beam modification on the morphology of the fine structure of the surface layer of M2 steel. After the modification procedure, no phase transformations were observed. A multi-phase structure of the steel, namely α-phase, γ-phase (residual austenite), and a carbide phase was detected. However, EBT led to an increase in the volume fraction of lamellar martensite by 10%, as well as an increase in the internal stresses in the α’-martensite phase. Also, the presence of bending extinction contours in all M6C carbide particles was observed. The authors of [11] investigated the possibility of improvement in the mechanical and tribological properties of high-speed steel, cemented carbide, and TiCN-based cermet substrates by the deposition of a TiN film. Their results showed that the coating deposited on the high-speed steel exhibited the highest hardness, while no significant difference in Young’s modulus was observed. The coating deposited on the TiCN-based cermet substrate showed the best wear resistance. Nevertheless, in all cases, the deposition of the TiN film led to a significant improvement in the functional properties. The authors of [12] investigated the effect of nitrogen ion implantation on the mechanical and chemical properties of M50 steel. Their results showed the relationship between the microhardness of the samples and the energy of the ions. The increase of the energy of the last leads to a direct increase in the microhardness.

Accelerated particle beams (such as electron, photon, and ion beams) are the basis of the creation and development of new methods of surface treatment [17,18,19]. Processing the surface of metal alloys by accelerated electrons is accompanied by a transfer of their kinetic energy to heat, which is distributed from the surface to the bottom of the modified zone [20,21]. During these processes, due to the rapid heating and cooling of the materials, changes in their microstructure, chemical composition, phase composition, texture changes, and others are common occurrences. This is a major factor in significantly improving a number of properties, such as mechanical, tribological, and others [22,23,24]. The correct selection of the technological conditions during treatment with a scanning electron beam is essential to obtain materials with appropriate structures and properties depending on their specific applications. On the other hand, the PVD (physical vapor deposition) methods and techniques, particularly direct current magnetron sputtering (DCMS), for thin film deposition present a number of advantages, such as very high reproducibility rate, good control of the technological conditions during the deposition process and the corresponding structure and properties of the film, etc. These techniques are based on the bombardment of a target material by energetic ions [25].

Applying two or more methods to modify the surfaces of materials is of interest to a number of researchers [26]. The application of this approach combines the benefits of the two or more technologies, which should be considered as an important advantage of this strategy and the overall efficiency should be much greater in comparison with the single surface treatment technique. For example, in [27], plasma nitriding and subsequent electron beam treatment (PN + EBT) were combined on samples of 40X steel. It was found that the resulting hardness increased by a factor of three compared to the base material. The application of this combined method increased the steel’s resistance to abrasive wear by a factor of two compared to the plasma nitriding method. In [28], a combined method consisting of electron beam treatment (EBT), plasma nitriding (PN), and CrN-based PVD coating was implemented. The treated samples showed a significant increase in the hardness and a decrease in the coefficient of friction compared to the untreated material.

In previous work, a combined treatment, including WN deposition and subsequent electron beam modification of the already deposited tungsten nitride coating, was applied on R18 high-speed steel [8]. The results showed that the surface electron-beam treatment led to the refinement of the microstructure in both cases (with and without WN coating). The microhardness in the case of EBT without nitride coating was 720 HV (280 HV higher than that of the starting material). EBT of the high-speed R18 steel with a tungsten nitride coating exhibited an even higher microhardness, with a value of 880 HV (about twice higher than that of the R18 steel).

Electron beam surface treatment is a promising technology for improving the properties of metallic materials and their alloys. It is also well known that the deposition of WN coatings leads to an enhancement of the functional characteristics of metals and alloys [29,30]. As reported previously by the authors of [8], the modification of an R18 high-speed steel by the deposition of a WN coating, which is further modified by a scanning electron beam, has led to a significant improvement in the microhardness. However, studies on combined surface modification by the application of preliminary electron beam treatment and subsequent deposition of a WN coating on the functional properties of high-speed steels (M2 HSS), at this time, are lacking in the scientific literature. The application of the preliminary surface treatment procedure by a scanning electron beam followed by the deposition of the WN coating is expected to form a gradient structure from the surface to the bulk material which could have some advantages from a practical point of view. Therefore, the aim of this paper is to investigate the possibilities of a combined surface modification of M2 high-speed steel, including preliminary electron-beam surface treatment (EBT) followed by a tungsten nitride (WN) coating deposition. The results obtained in this study provide new information on the functional characteristics of M2 high-speed steel processed with combined surface modification.

2. Materials and Methods

In this investigation, M2 high-speed steel with dimensions of 30 × 30 × 4 mm was used. The base material was previously subjected to a thermal quenching procedure, and its chemical composition is presented in Table 1.

Table 1.

Chemical composition of M2 high-speed steel.

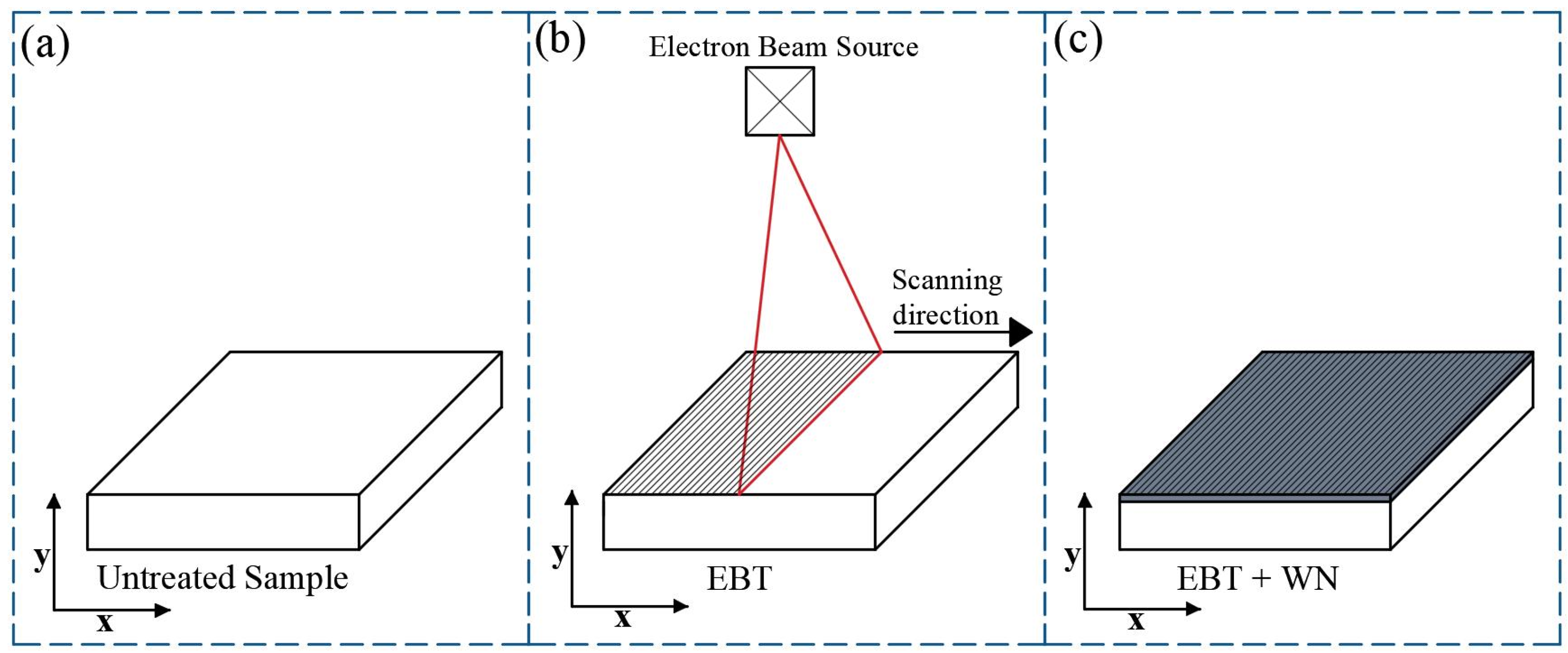

Figure 1 presents a schematical representation of the duplex surface treatment procedure performed on the samples. Figure 1a depicts the untreated sample. Figure 1b depicts the electron beam surface treated one, and Figure 1c depicts the electron beam surface treated substrate with an applied WN coating atop its surface. Initially, all specimens’ surfaces were mechanically polished with grinding papers (from 240 to 2500) and ultrasonically cleaned in water. The electron beam treatment was carried out using an Evobeam Cube 400 machine (Evobeam GmbH, Nieder-Olm, Germany). During the EBT process, the following technological conditions were applied—accelerating voltage—60 kV; scanning speed—40 mm/s; electron beam scanning frequency—200 Hz. The heat input was varied by the beam current (Ib): 20 mA, 30 mA, and 40 mA. The beam deflection geometry was in the form of a line with an oscillation amplitude of 16 mm. The selection of the discussed technological conditions is based on systematical optimization and the parameters presented above were considered as the most representative. The use of a beam current lower than 20 mA leads to insufficient heat input and the transformation in the structure and functional properties will not occur. At the same time, values of the beam current higher than 40 mA will lead to a significant melting and modification of the surface morphology and topography of the samples. This is accompanied by accelerated melting and evaporation processes. The hardness of the M2 substrates without and with the EBT process was measured and the specimen with the highest hardness was selected for further investigations.

Figure 1.

Schematic of the duplex surface treatment where (a) is the untreated sample, (b) is the EBT one, and (c) is the WN-coated EBT one.

The tungsten nitride (WN) coating was deposited via direct current magnetron sputtering (DCMS) on the electron-beam treated M2 HSS surface. During the deposition, the working pressure was 1.2 × 10−1 Pa; the substrate temperature was 350 °C, and the deposition time was 60 min. In order to understand the influence of each technological procedure, as well as the impact on the resultant structure and properties of the combined method, the following specimens were considered in this paper, namely raw M2 steel, M2 steel subjected to EBT under different technological conditions, M2 steel subjected to EBT under the best technological condition followed by subsequent deposition of a WN coating, and M2 steel covered with WN coating without the application of the EBT. In both cases, the thicknesses of the deposited coatings are about 300 nm.

X-ray diffraction (XRD, Philips, PW1050, Amsterdam, The Netherlands) experiments were performed for investigation of the phase composition of the obtained specimens. The measurements were performed in a symmetrical Bragg–Brentano geometry by CuKα radiation within the range of 30° to 90° at 2θ scale.

The microstructure and chemical composition of the obtained specimens were studied via scanning electron microscopy (SEM-LYRA I XMU (Tescan), Brno, Czech Republic) equipped with energy-dispersive X-ray spectroscopy (EDX) microanalyzer. During the measurements, secondary electrons mode was used.

The nanoindentation (Hysitron TI 980 instrument, Bruker, Billerica, MA, USA) experiments were performed to study the hardness and Young’s modulus of the obtained specimens. Nanoindentation tests were made in a load control mode by force of 5 N. Every single experiment consisted of 7 lines with 7 indentations (a total number of 49 indentations) and a spacing of 10 µm.

The wear of the samples was also studied by means of coefficient of friction (COF) experiments. The tests were performed on a micro-tribotester (UMT-2, Brucker, Beverly Hills, CA, USA) using a Cr-coated steel sliding ball. The performed tests were of the type ball-on-flat. The applied force was 2 N in all considered cases, with a test time of 900 s.

3. Results and Discussion

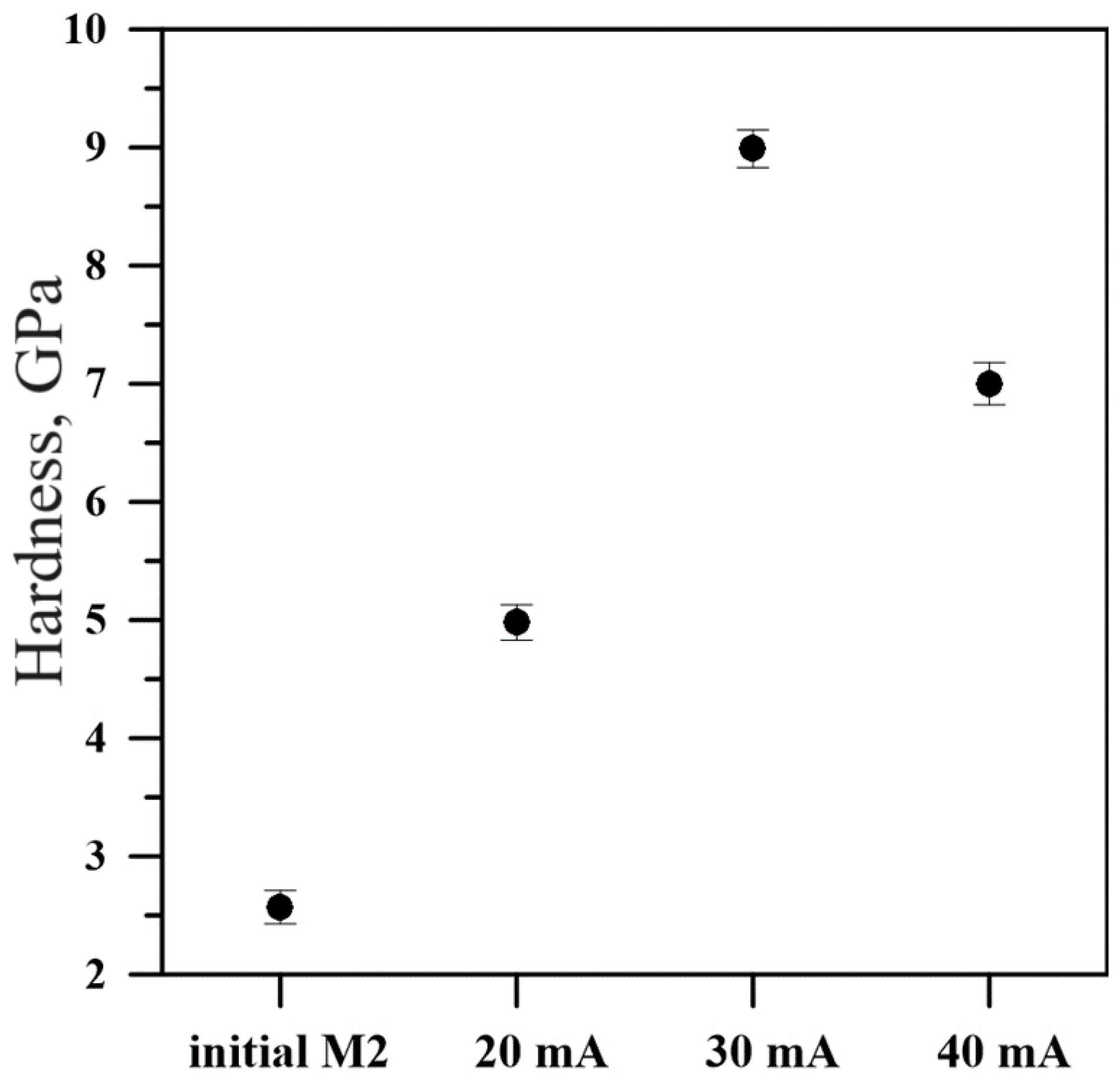

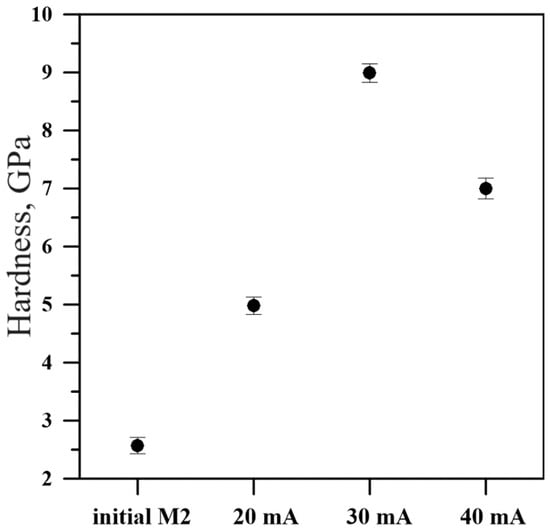

The hardness values of the M2 substrate without surface treatment and with treatment via different electron beam currents are presented in Figure 2. It is obvious that in all cases, the values increase due to the phase transformation, M2C + matrix → M6C + MC + matrix [8,31], as well as the formation of a finer microstructure which is typical for the electron beam surface modification processes. The measured value of the specimen subjected to the electron beam surface modification using a beam current of 20 mA is about 5 GPa, or about two times higher than the base material. Increasing the beam current to 30 mA has also led to an increase in the hardness of the modified steel, up to 9 GPa, or more than three times that of the substrate. Further increase of the beam current to 40 mA led to a decrease of the investigated mechanical characteristic, where the measured values are about 7 GPa, which is more than 2.5 times higher than that of the initial M2 steel. It is obvious that increasing the beam current from 20 to 30 mA leads to an increase in the hardness, which could be attributed to the higher cooling rate in the latter case. The cooling rate is essential for the resultant microstructure and corresponding functional properties (microhardness in the present case), where a higher cooling rate corresponds to higher hardness. However, a further increase in the current of the electron beam leads to a decrease in the discussed mechanical characteristic. This decrease in the hardness of the modified zone at the highest value of the beam current could be attributed to the lowering of the cooling rate. The application of the aforementioned technological conditions with the highest values of the current of the electron beam probably led to the formation of a melted zone on the top of the specimen where the liquid mixing convective processes within it become predominant, leading to the lowering of the thermal cycle gradient. Similar effects were observed by the authors of [32,33]. The results obtained for the hardness of the surface-modified M2 tool steel show that the highest value was obtained at a beam current of 30 mA, and therefore, this specimen has been selected as a substrate for the WN coating deposition.

Figure 2.

The hardness of the initial M2 steel and M2 treated steel via different electron beam current values.

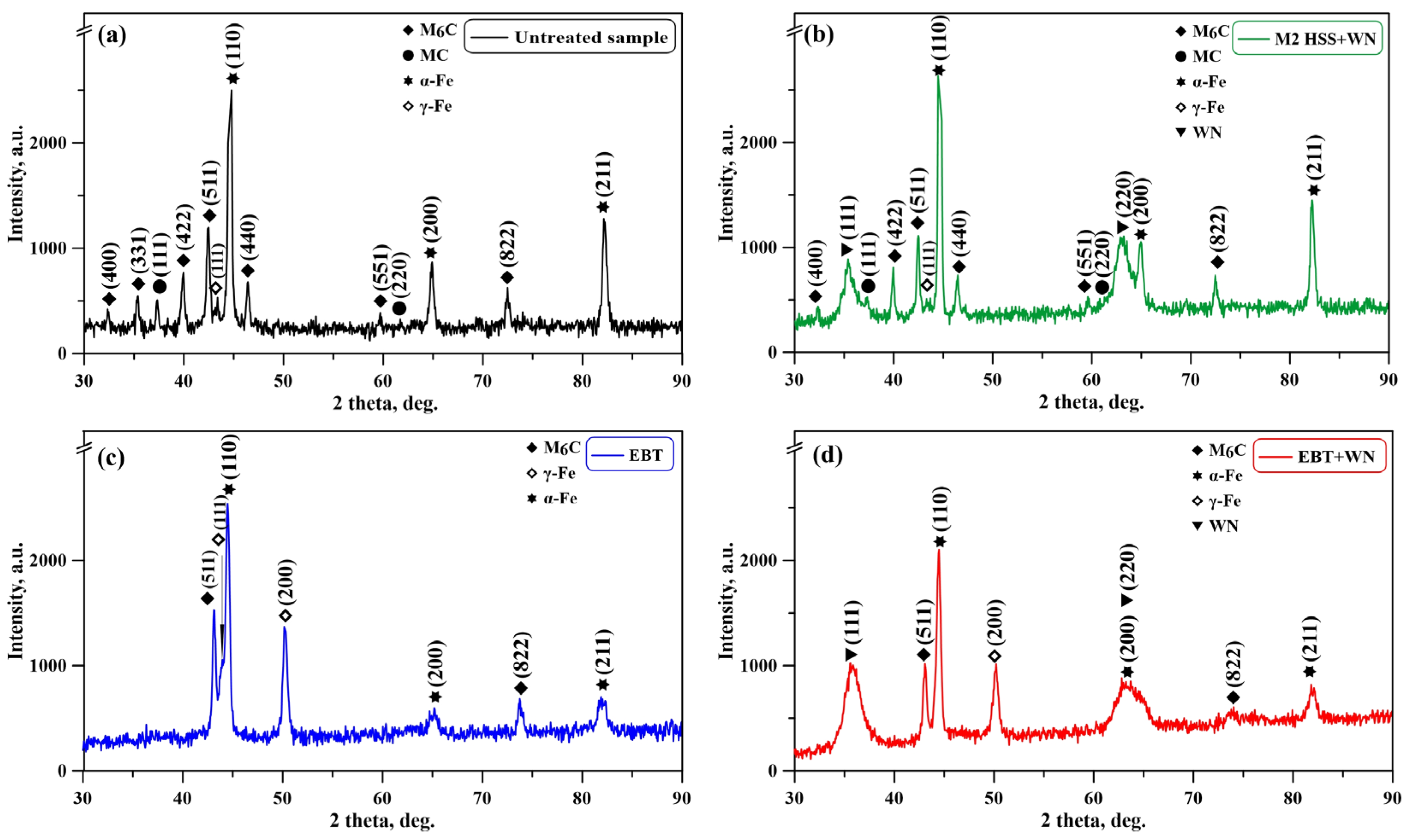

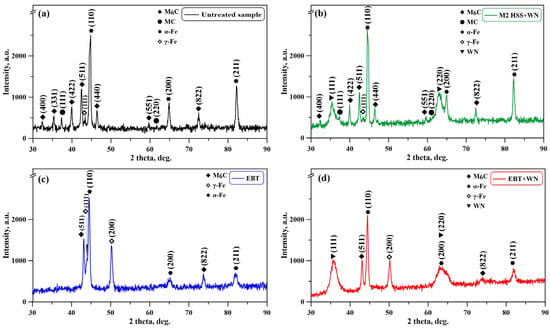

Figure 3 shows the obtained XRD patterns of investigated samples. Figure 3a presents the phase composition of the untreated sample. The pattern corresponding to the WN film deposited on untreated steel substrate is presented in Figure 3b. X-ray diffraction pattern of the electron-beam treated M2 sample with a beam current of 30 mA is presented in Figure 3c. The XRD pattern of the specimen subjected to the electron-beam treatment procedure and subsequent WN coating deposition is shown in Figure 3d. No amorphous-like halos can be seen in all cases which is a confirmation that the considered samples are crystalline and no amorphous-like structures exist. The M2 HSS substrate is a multi-phase material including the α’-Fe and γ-Fe phases, which are the main phases in the steel, as well as M6C and MC carbides. The main phase is α’-Fe, as a result of the martensitic γ → α’ transformation and subsequent self-hardening due to the standard heat treatment of the initial material. The other phase, γ-Fe, is in the form of residual austenite as a result of incomplete martensitic transformation during the hardening of the steel during its manufacturing [34]. The main carbide phase present in the structure of the M2 steel is in the form of carbide particles of the type M6C–(Fe, W, Mo)6C; it has complex crystal lattices on the basis of fcc (face-centered cubic). Studying the untreated sample, a small amount of MC (VC) carbides have been detected, in addition to the α’-Fe, γ-Fe, and M6C phases. MC carbide particles are located in the structure of the martensitic phase (α′-phase), mainly residing in defect regions in the crystal structure of steel [7]. After the application of the electron beam treatment, the phase of MC carbides disappears. At the same time, the intensities of the diffraction maxima corresponding to the (400), (331), (422), (440), and (551) crystallographic planes of the M6C phase disappear. On the other hand, a new diffraction maximum at around 50°, corresponding to the (200) crystallographic plane of the γ-Fe phase, was registered. All these features can be attributed to reorientations in the micro-volumes with respect to surface modification by the scanning electron beam, which is typical for the electron beam procedure due to highly non-equilibrium conditions [35]. The pattern of the sample corresponding to the deposited WN coating on the untreated steel substrate exhibits diffraction maxima of α- and γ- Fe, as well as M6C and MC carbides coming from the substrate and already registered also at the diffractogram of untreated steel (Figure 3a). In addition to these diffraction maxima, peaks corresponding to the WN coating also appear, which is proof of the successful deposition of the film. Following the WN coating deposition on the electron beam treated substrate, diffraction maxima belonging to the WN phase are seen, along with the peaks of alpha and gamma iron, as well as M6C carbides, indicating the successful deposition of the coating on the surface of the sample on the electron beam surface modified M2 HSS substrate. In both cases (i.e., the WN coating deposition on untreated and EBT substrate), the phase composition of the film remains unchanged, meaning that the treatment procedure does not influence the discussed structural parameter of the coating.

Figure 3.

XRD patterns of (a) base material; (b) untreated M2 steel with deposited WN film; (c) electron-beam treated M2 steel; (d) electron-beam treated M2 steel with deposited WN coating.

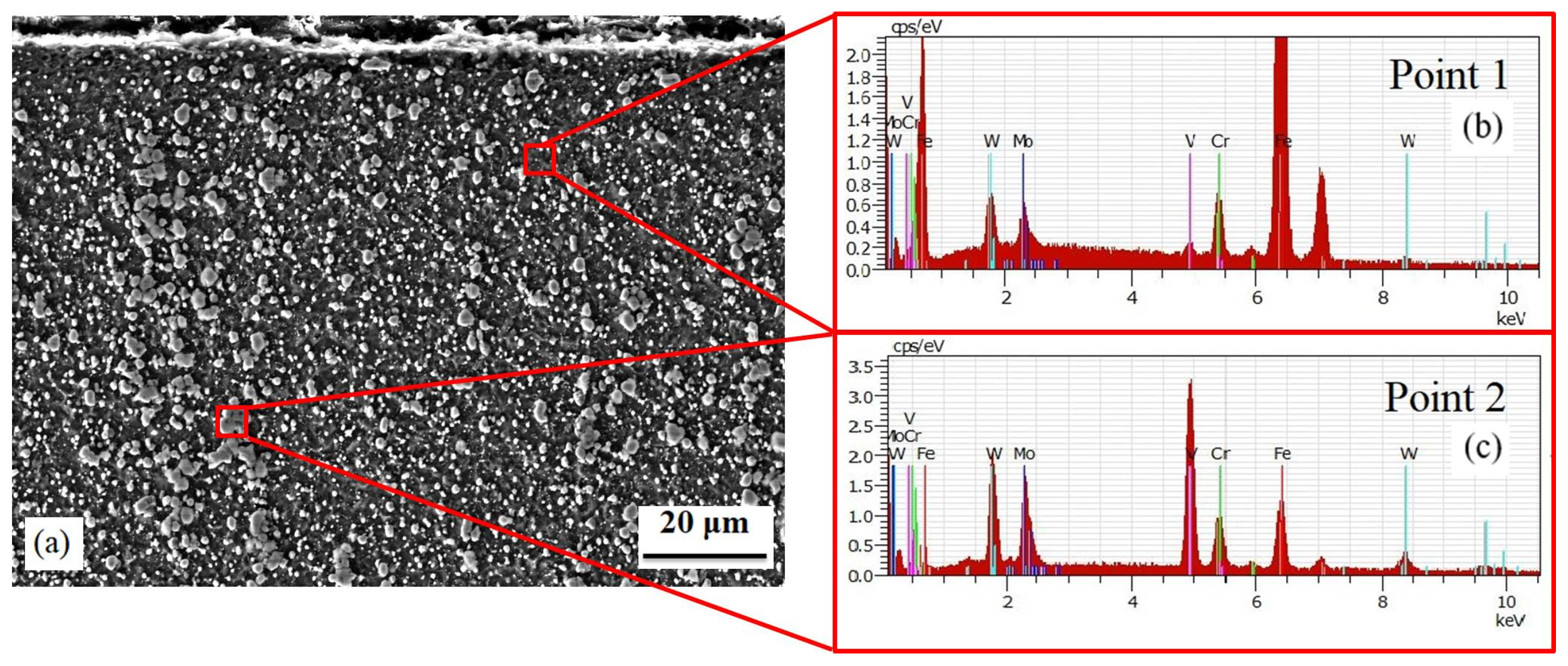

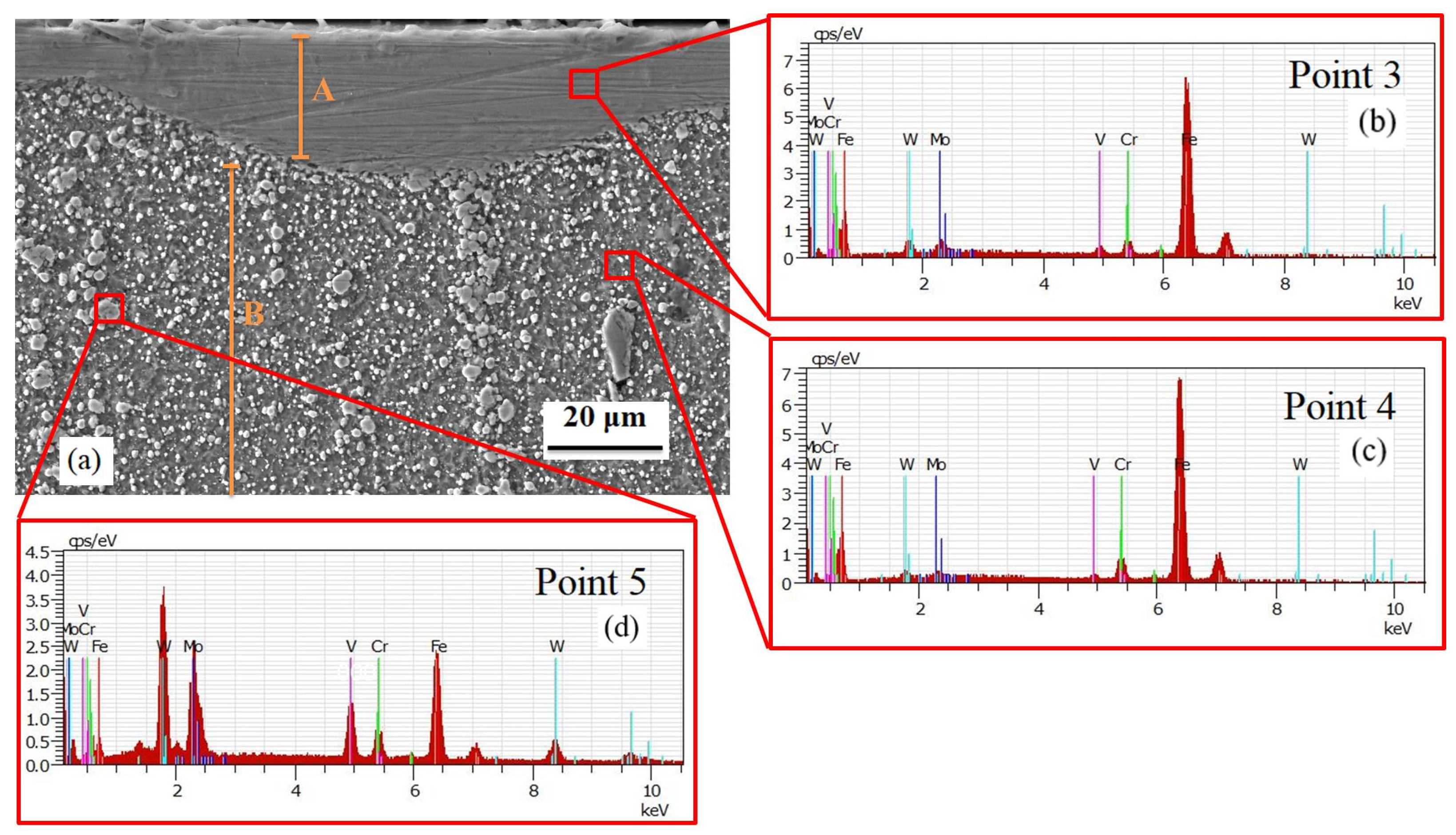

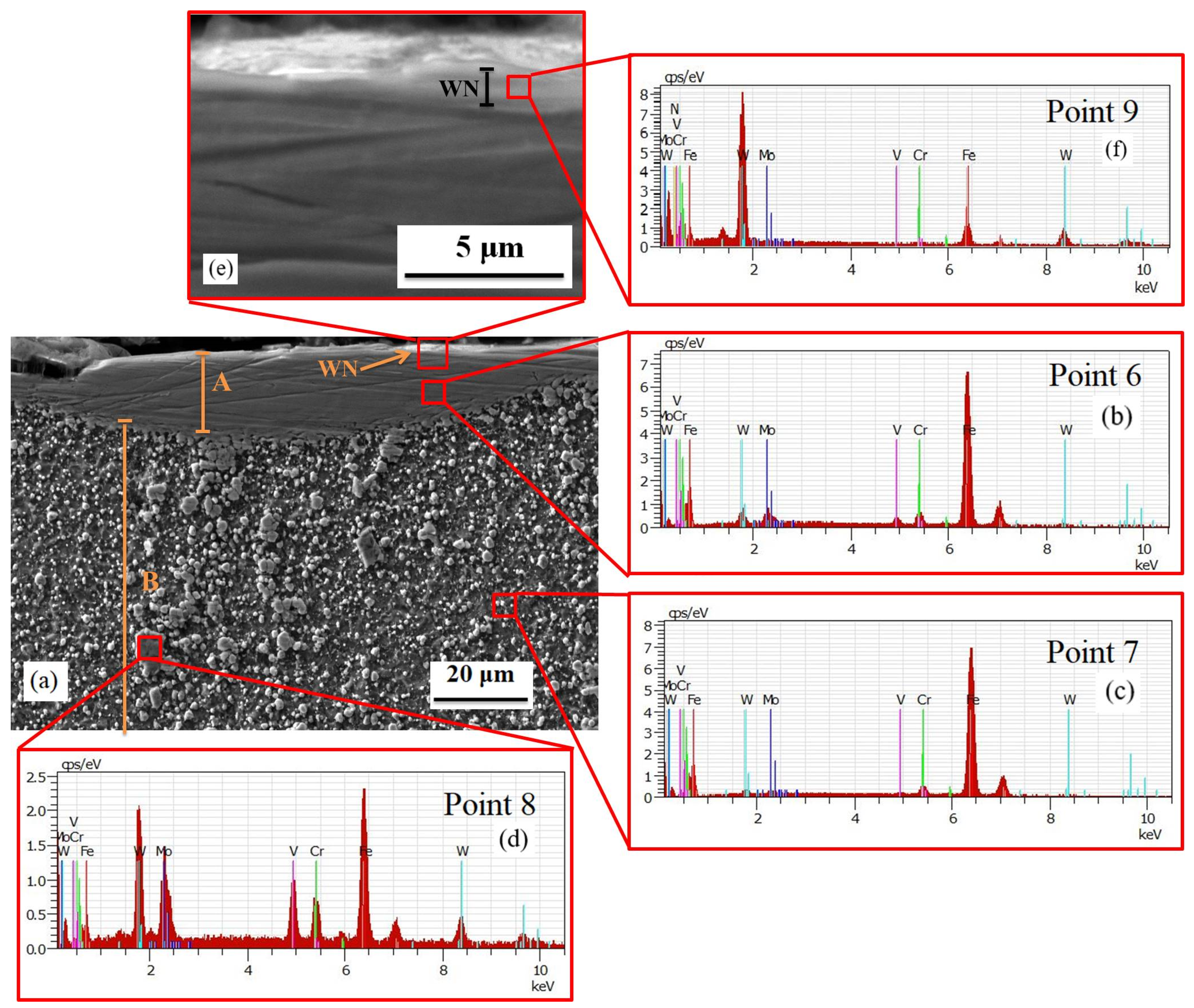

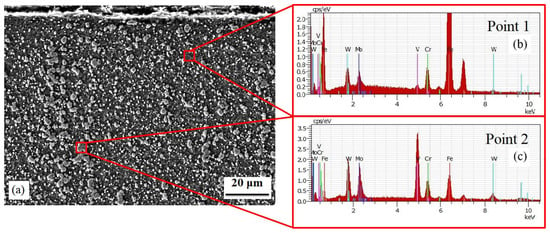

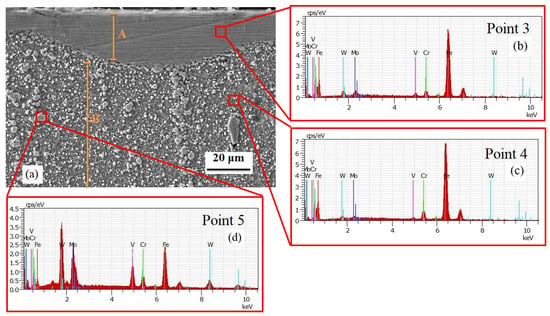

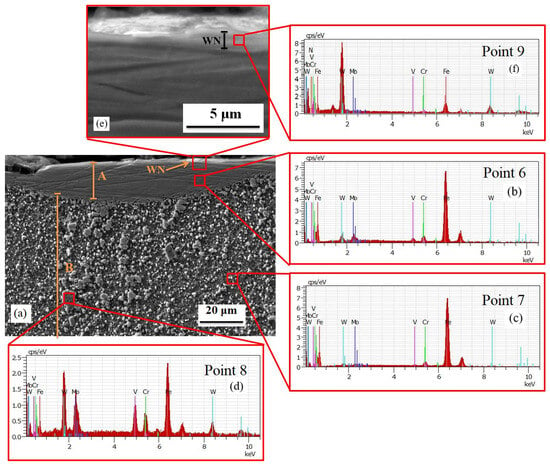

The experimentally obtained cross-sectional SEM micrographs of the untreated, the EBT, and the EBT + WN samples are presented in Figure 4, Figure 5 and Figure 6, respectively. The chemical composition of the obtained samples was investigated by energy-dispersive X-ray spectroscopy (EDS), and the results are summarized in Table 2, Table 3 and Table 4. Figure 4a presents the microstructure of the untreated sample. The SEM micrographs of the electron-beam-treated M2 steel and electron-beam-treated M2 steel with deposited WN coating are shown in Figure 5a and Figure 6a, respectively. The modified area is marked as area A, and the M2 substrate is noted as B. A uniform distribution of the carbide particles in the iron matrix is observed when observing the untreated sample. This is confirmed by the obtained results of the EDS presented in Table 2. In point 1, nearly 84 wt% of Fe was registered, corresponding to the iron matrix, while in point 2, 18 wt% of Fe was registered, along with 30 wt% W, 18 wt% Mo, and 26 wt% V, corresponding to the M6C and MC phases. On the other hand, during the electron beam treatment process, a high-temperature gradient exists, leading to the finer structure of the modified area (zone A). The average thickness of this zone regarding both the EBT and EBT + WN samples is about 20 μm. No significant change in the distribution of chemical elements between the matrix of the high-speed steel (point 1 from Table 2) and the modified zone of the EBT specimen (point 3 from Table 3). The deposited WN layer atop the surface treated sample has a thickness of about 300 nm. The obtained results showed a good agreement between the data from the X-ray diffraction analysis and the study of the microstructure and chemical composition of the samples.

Figure 4.

Cross-sectional SEM micrograph of initial material (a); chemical composition of points 1 (b) and 2 (c).

Figure 5.

Cross-sectional SEM micrograph of electron-beam treated steel (a); chemical composition of points 3 (b), 4 (c), and 5 (d).

Figure 6.

Cross-sectional SEM micrograph of electron-beam treated steel with deposited WN coating (a); chemical composition of points 6 (b), 7 (c), and 8 (d); SEM image of WN coating at higher magnification (e); chemical composition of point 9 (f).

Table 2.

The chemical composition of each point is marked in Figure 4.

Table 3.

The chemical composition of each point is marked in Figure 5.

Table 4.

The chemical composition of each point is marked in Figure 6.

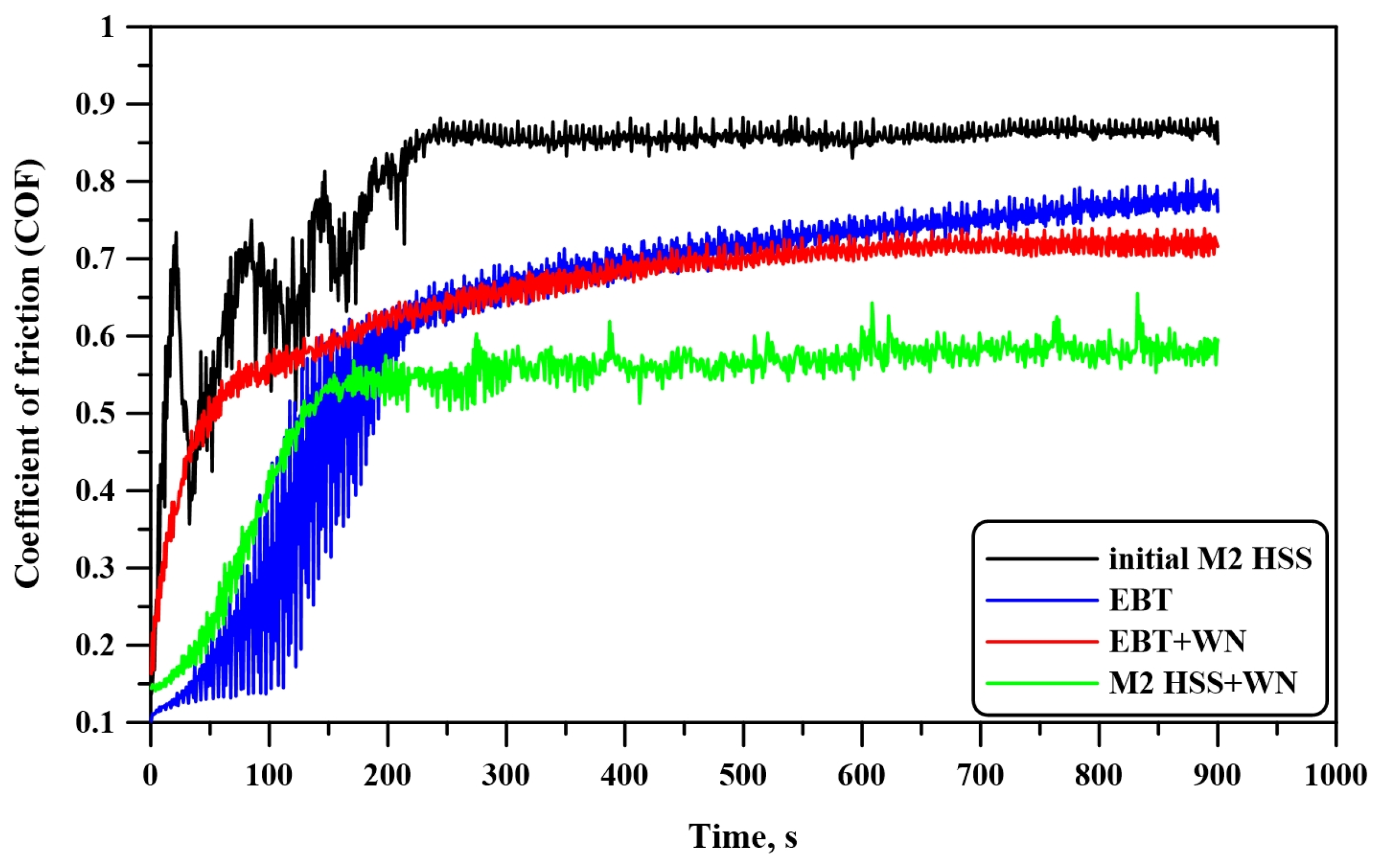

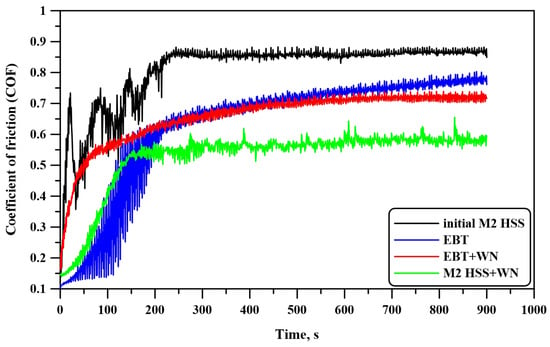

The coefficients of friction results of the investigated samples are presented in Table 5. The untreated sample exhibited a COF of 0.81. It was found that the deposition of WN coating on the already modified surface of the M2 HSS substrate leads to a reduction of the coefficient of friction where the obtained value is 0.66. Therefore, it can be concluded that with the surface modification (i.e., the EBT of the steel substrate followed by a WN film deposition), the coefficient of friction was reduced. Considering the specimen consisting of WN coating without the modification of the surface substrate by a scanning electron beam leads to an even lower friction coefficient, where the measured value is 0.54. Coatings and surface structures with low coefficient of friction should have high wear resistance and good adhesion to the base material. This effect is much more pronounced in the case of the deposition of WN coating without the electron-beam surface modification of the substrate. It is important to note that the metal-nitride coatings are characterized by a lower coefficient of friction and better wear properties in comparison with the high-speed steels, which can be considered as a reason for the lower COF in the case of WN coatings deposited on M2 HSS. Following the results summarized in Table 5, the COF of the WN-coated and EBT sample is higher than that of the sample to which just a coating was applied. It is important to note that the coefficient of friction and wear properties depend not only on the structure of the investigated surfaces but also on other important parameters, such as surface roughness. Higher values of the surface roughness correspond to higher values of the coefficient of friction and worse wear properties. At the same time, it is known that the preliminary surface modification of the substrate by a scanning electron beam leads to an increase in the roughness [23,33]. This could be a reason for the higher value of the COF of the sample with the duplex surface treatment. It is important to note that the results obtained for the COF are comparable with those of other metal-nitride coatings, where it was shown that the COF of TiN, TiCN, and TiAlN ranged from 0.5 to 0.7 [36].

Table 5.

Mechanical properties of the investigated samples.

For a better understanding of the friction and wear behavior of the M2 HSS substrate as well as that of the EBT and EBT and WN coated samples, the evolution of the COF as a function of the sliding time was investigated, and the results are presented in Figure 7. The COF of the steel substrate in the beginning (i.e., up to the 250th second) increases gradually from 0.1 to about 0.9, where some fluctuations can be observed. These fluctuations could be attributed to the microstructure of the M2 steel substrate consisting of MC and M6C carbides randomly distributed within the base Fe matrix. The M2 HSS sample subjected to EBT shows an increase of the COF from 0.1 to about 0.6 at the initial stages of friction (up to the 250th second). After 900th seconds no substantial increase of the COF was noticed. The last exhibited a value of 0.75. This stable behavior of the electron-beam-modified M2 HSS sample could be attributed to the homogeneous microstructure on the surface after the application of the EBT procedure. The coefficient of friction of the specimen subjected to the EBT and subsequent deposition of the WN coating started from 0.15 and gradually increased to about 0.55 at the initial stages of the friction experiment (up to the 50th second). After that, the COF curve is also very flat, and the maximum measured value was 0.7 at the end of the friction test (i.e., at the 900th second). No fluctuations were observed. The absence of fluctuations could be attributed to the improved adhesion between the coating and the substrate due to the EBT procedure. Also, it is important to note that the increase of the COF from the beginning to the end of the experiment in the case of the electron beam treated and coated sample is much more rapid, without any fluctuations, compared to the just electron beam treated substrate. In the last, some fluctuations were observed, and the curve was much flatter. This means that the applied coating could have potentially improved the surface roughness of the sample, thus the COF value. Considering the friction coefficient evolution of the specimen subjected to the deposition of the WN coating without the EBT of the surface of the substrate, it started from 0.15 and increased to about 0.55 at the 150th second. After that, the COF represents a stable behavior, and no increase in the measured values can be observed until the end of the experiment. However, some fluctuations were observed, which can be considered as a drawback since they occurred due to the bad adhesion between the coating and the substrate.

Figure 7.

Friction coefficient of initial M2 HSS and WN coating deposited on the electron beam treated and untreated M2 steel substrate.

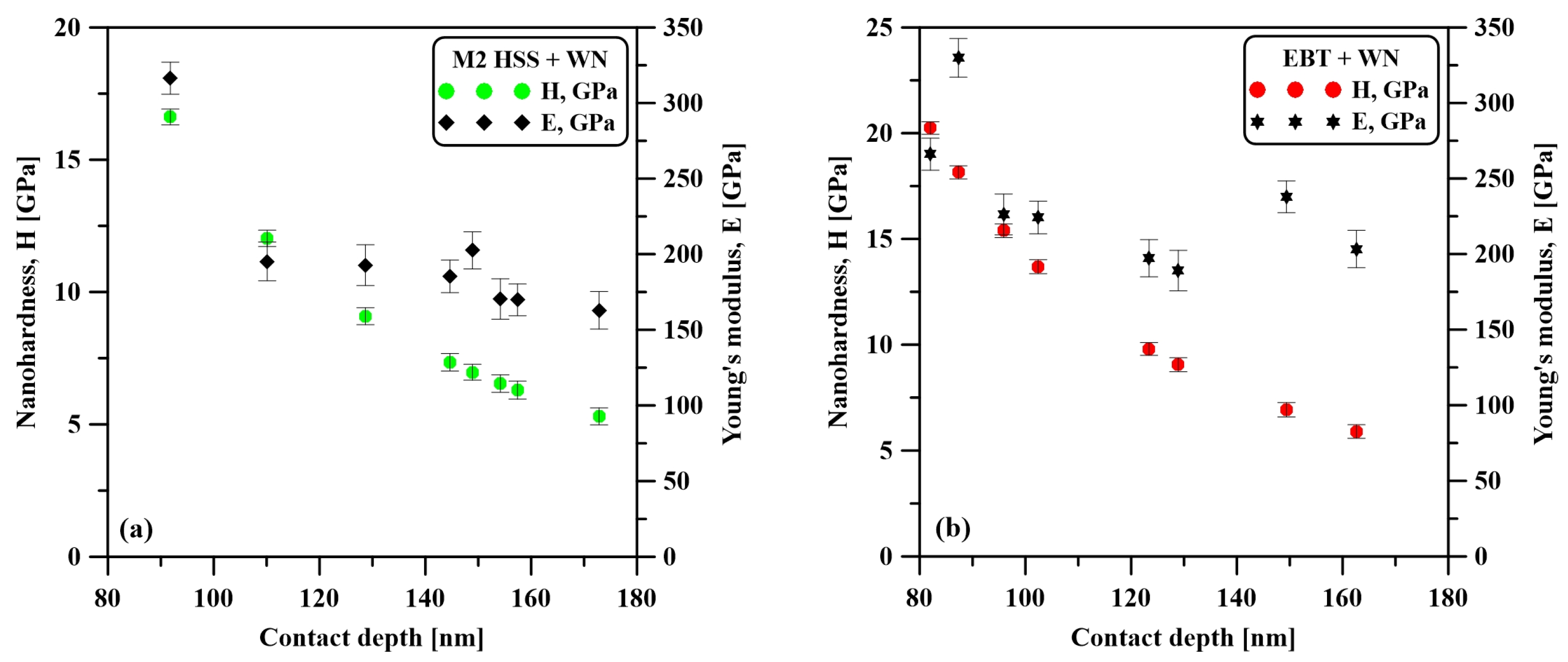

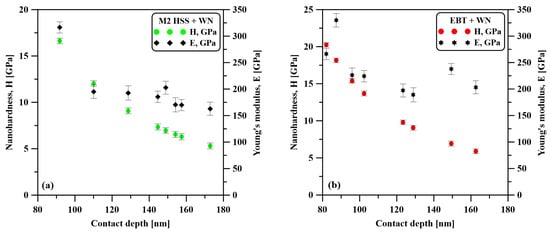

The hardness and Young’s modulus of the WN coating deposited on M2 steel substrates with and without electron-beam surface modification are summarized in Table 5. The values of the discussed mechanical characteristics for the base material are also shown for comparison. The measured hardness and Young’s modulus of the substrate material are 2.5 GPa and 190 GPa, respectively. The WN coating deposited on the untreated substrate exhibits a hardness of 8.8 GPa and Young’s modulus of 194 GPa. The measured hardness and elastic modulus of the electron-beam-modified M2 HSS specimen are 9 GPa and 206 GPa, respectively. The hardness of the film applied on the electron-beam modified M2 steel significantly exceeds that of the untreated one, where the measured values are about 12.4 GPa. The Young’s modulus of the same sample is 234 GPa. Therefore, the application of the electron-beam surface modification procedure has led to a further increase in the hardness and Young’s modulus. As already mentioned, the treatment of the surface of the steel by a scanning electron beam leads to an increase in the hardness due to the formation of a finer microstructure. This could be considered a prerequisite for the higher hardness of the duplex-treated specimen.

For a better understanding of the hardness and Young’s modulus of the WN coating deposited on M2 high-speed steel with and without electron-beam surface modification, the distribution of the aforementioned mechanical characteristics from the top surface to the depth of the coatings was studied, and the results are presented in Figure 8. Figure 8a presents the results for the WN film deposited on the untreated substrate, while Figure 8b shows the data of the coating deposited on the electron-beam surface modified one. The values were studied at a depth range from about 90 to 170 nm. It is obvious that the hardness of the film deposited on the untreated high-speed steel is about 17 GPa and slowly decreases to about 5 GPa at a depth of 170 nm. The Young’s modulus at a depth of about 90 nm was measured to be about 320 GPa and about 160 GPa at 170 nm. The hardness of the specimen deposited on the EBT substrate exhibits a similar trend. However, the hardness on the top of the film is more than 20 GPa and decreases to about 6 GPa at 170 nm. The modulus of elasticity is about 300 GPa on top of the coating and drops to about 200 GPa at a depth of 170 nm. Therefore, it can be concluded that the duplex-treated sample has a higher hardness compared to the single-treated one (with just a coating). The same could be said about the modulus of elasticity. This, again, could be attributed to the improved mechanical properties of the substrate material after the electron-beam surface treatment procedure. It is known that the substrate material affects the nanoindentation results, and any improvement of the mechanical properties of the substrate would imminently lead to an increase in the measured values of the duplex-treated sample.

Figure 8.

Nanohardness and Young’s modulus of WN coating deposited on untreated (a) and the electron beam treated (b) M2 steel substrate.

High-speed tool steels are widely known for their excellent mechanical properties and wear resistance. Regardless of this, the advances in materials science and engineering provide various industries with high-strength materials that need to be post-processed. Also, due to a rapid increase in the utilization of natural resources nowadays, topics regarding efficiency in every industrial branch are highly discussed. Due to this, an even further improvement of the mechanical properties of HSS tools is required.

In this investigation, results of the duplex surface modification of an M2 high-speed steel are presented. The effect of electron beam treatment and subsequent deposition of a WN coating on the phase composition, microstructure, chemical composition, microhardness, and coefficient of friction of the treated specimens were studied. The obtained results show that the applied treatment, including EBT and the deposition of WN coating, influences the functional properties. The EBT of M2 HSS was realized using a deflection of a flux of accelerated electrons in the form of a line. During this work regime, the thermal cycling gradient is the highest resulting in the formation of the finest microstructure, leading to higher hardness. However, the measured coefficient of friction exhibited higher values in the case of WN film deposition on EBT substrate in comparison with that on untreated material corresponding to a higher wear rate. Mechanical characteristics such as high hardness are highly indicative of the functional properties and application of the WN coating [37]. Typically, WN coatings are characterized by their high hardness, which is problematic for their application on much “softer” materials, such as the present M2 steel substrate [38]. To improve the adhesion between the two, the coating’s hardness and the substrate’s hardness need to be equalized in some manner. Considering this, the results of the performed electron beam treatment indicate the possibility of modifying the structure of the substrate in order to increase its hardness and improve its compatibility with the coating. The procedure of hardening the substrate is also favorable for the reduction of the internal stresses formed between it and the applied thin film. The surface microhardness values of the duplex surface modification (EBT + WN) were even higher, reaching up to 12.4 GPa. The coefficient of friction has the lowest value in the case of the duplex surface modification approach, including EBT and subsequent deposition of WN coating, which could be attributed to the higher surface roughness, which is typical for electron-beam surface-modified substrate materials [33]. However, the trend of the friction coefficient from the initial moment to the 900 s. does not exhibit any fluctuations, meaning that the adhesion is significantly better in comparison with that of the film deposited on the untreated substrate. This, again, could be attributed to the EBT procedure. The authors of [8] have studied the influence of combined treatment, including WN coating and subsequent EBT of the R18 HSS on the microhardness, and their results presented that the rise in this mechanical characteristic is about 1.7 times without tungsten nitride coating and about two times with WN film. However, in the present investigation, it was shown that the surface hardness is close to 6 times higher than that of the untreated M2 HSS substrate, meaning that the EBT on the steel surface and deposited WN film leads to a significant improvement in the functional characteristics. The deposition of a hard coating on a substrate characterized by significantly lower hardness leads to the formation of undesirable defects, such as residual stresses at the substrate-coating interface, cracks, poor adhesion, and other defects [38]. These results are of major importance for a number of modern industrial branches where improved functional properties on the top of the materials, where they are mostly exposed to exploitation, are required, and therefore, the combined approach for the surface modification (including preliminary electron-beam treatment procedure followed by the deposition of a hard coating, such as WN) can be considered as very promising for the purposes where materials with significantly enhanced mechanical properties on the surface are required.

4. Conclusions

The results obtained in this investigation demonstrate a duplex surface modification of M2 high-speed steel, including electron beam treatment (EBT) followed by a tungsten nitride (WN) coating deposition. The influence of the EBT on the functional properties of the film was also studied. Prior to any surface treatment, the phase composition of the M2 HSS was investigated, and a consistent concentration of the following phases was determined: α’-Fe, γ-Fe, M6C, and MC. The surface treatment of the M2 samples led to a phase transformation during which the disappearance of the MC carbides was observed. The EBT led to the improvement of the mechanical characteristics of the M2 steel by increasing the hardness from 2.5 GPa to 9 GPa. A successful deposition of the WN coating was achieved, leading to a further rise in the hardness, up to 12.4 GPa. The application of the electron beam treatment procedure and deposition of WN film leads to an improvement in the tribological properties where the coefficient of friction decreases from 0.81 to 0.66. However, the same coating deposited on untreated substrate exhibits even less friction coefficient values of 0.54. It should be noted that the EBT procedure of the base material leads to a stable friction curve without fluctuations. The results obtained in the present study could have a number of new potential practical applications where better functional properties are required.

Author Contributions

Conceptualization, M.O. and S.V.; methodology, M.O., G.K., D.D., N.I., B.S. and S.V.; formal analysis, M.O., D.D. and N.I.; investigation, M.O., G.K., D.D., N.I., B.S. and S.V.; writing—original draft preparation, M.O. and S.V.; writing—review and editing, M.O. and S.V.; visualization, M.O. and G.K.; supervision, S.V.; project administration, M.O.; funding acquisition, S.V. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Bulgarian Ministry of Education and Science under the National Research Programme “Young Scientists and Postdoctoral Students-2” approved by DCM 206/07.04.2022.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

Electron beam surface treatment experiments were performed thanks to the research equipment of the “Centre of competence”—BG05M2OP001−1.002−0023−C01 “Intelligent Mechatronics, Eco- and Energy-saving Systems and Technologies” (IMEEST).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kawasegi, N.; Sugimori, H.; Marimoto, H.; Morita, N.; Hori, I. Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precis. Eng. 2009, 33, 248–254. [Google Scholar] [CrossRef]

- Sugihara, T.; Enomoto, T. Performance of cutting tools with dimple textured surfaces: A comparative study of different texture patterns. Precis. Eng. 2017, 49, 52–60. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, J.; Chen, M. Enhancing the machining performance by cutting tool surface modifications: A focused review. Mach. Sci. Technol. 2019, 23, 477–509. [Google Scholar] [CrossRef]

- Childs, T. Metal Machining: Theory and Applications, 1st ed.; Arnold: London, UK, 2000; pp. 118–136. [Google Scholar]

- Rakhadilov, B.; Kurbanbekov, S.; Skakov, M.; Wieleba, W.; Zhurerova, L. Effect of plasma beam irradiation on the microstructure and phase composition of high-speed steel R6M5. Mater. Test. 2020, 62, 11. [Google Scholar] [CrossRef]

- Panin, A.V.; Kazachenok, M.S.; Borodovitsina, O.M.; Sinyakova, E.L.; Ivanov, Y.F.; Leontieva-Smirnova, M.V. Surface modification of structural materials by low-energy high-current pulsed electron beam treatment. AIP Conf. Proc. 2014, 1623, 467–470. [Google Scholar]

- Rakhadilov, B.; Kengesbekov, A.; Zhurerova, L.; Kozhanova, R.; Sagdoldina, Z. Impact of electronic radiation on the morphology of the fine structure of the surface layer of R6M5 steel. Machines 2021, 9, 24. [Google Scholar] [CrossRef]

- Valkov, S.; Ormanova, M.; Ivanov, N.; Dechev, D.; Bezdushnyi, R.; Petrov, P. Duplex surface modification of tool steel—Deposition of a WN film and subsequent electron-beam modification. J. Phys. Conf. Ser. 2022, 2240, 012043. [Google Scholar] [CrossRef]

- Bobzin, K.; Brogelmann, T.; Kruppe, N.; Carlet, M. Nanocomposite (Ti, Al, Cr, Si)N HPPMS coatings for high performance cutting tools. Surf. Coat. Technol. 2019, 378, 124857. [Google Scholar] [CrossRef]

- Bouzakis, E. Fatigue endurance assessment of DLC coatings on high-speed steels at ambient and elevated temperatures by repetitive impact tests. Coatings 2020, 10, 547. [Google Scholar] [CrossRef]

- Xian, G.; Xiong, J.; Fan, H.; Jiang, F.; Guo, Z.; Zhao, H.; Xian, L.; Jing, Z.; Liao, J.; Liu, Y. Investigations on microstructure, mechanical and tribological properties of TiN coatings deposited on three different tool materials. Int. J. Refr. Metals Hard Mater. 2022, 102, 105700. [Google Scholar] [CrossRef]

- Xie, X.; Chen, C.; Luo, J.; Xu, J. The microstructure and tribological properties of M50 steel surface after titanium ion implantation. Appl. Surf. Sci. 2021, 564, 150349. [Google Scholar] [CrossRef]

- Xie, X.; Chen, C.; Luo, J.; Xu, J. Effect of Nitrogen Ion Implantation Energy on the Mechanical and Chemical Properties of AISI M50 Steel. Int. J. Chem. Eng. 2021, 2021, 4630661. [Google Scholar] [CrossRef]

- Yan, C.; Zheng, Q.; He, W.; Zhu, J. Enhanced surface hardness and tribocorrosion performance of 60NiTi by boron ion implantation and post-annealing. Trib. Int. 2021, 155, 106816. [Google Scholar] [CrossRef]

- Chen, M.; Jian, X.; Sun, F.; Hu, B.; Liu, X. Development of diamond-coated drills and their cutting performance. J. Mater. Proc. Technol. 2002, 129, 81–85. [Google Scholar] [CrossRef]

- Rousseau, A.; Partridge, J.; Mayes, E.; Toton, J.; Kracica, M.; McCulloch, D.; Doyle, E. Microstructural and tribological characterisation of a nitriding/TiAlN PVD coating duplex treatment applied to M2 high speed steel tools. Surf. Coat. Technol. 2015, 272, 403–408. [Google Scholar] [CrossRef]

- Weigel, K.; Lu, J.; Bewilogua, K.; Keunecke, M.; Petersen, J.; Grumbt, G.; Zenker, R.; Hultman, L. Electron irradiation induced modifications of Ti(1−x)AlxN coatings and related buffer layers on steel substrates. Vacuum 2021, 185, 110028. [Google Scholar] [CrossRef]

- Li, J.; Yao, J.; Zhao, G.; Li, H.; Li, Y.; Liu, J. The Influence of different focusing currents on the microstructure evolution and wear properties of a scanning electron beam modified inconel 625 nickel base alloy surface. Crystals 2023, 13, 325. [Google Scholar] [CrossRef]

- Henriques, B.; Fabris, D.; Voisiat, B.; Lasagni, A.F. Multi-scale structuring of CoCrMo and AZ91D magnesium alloys using direct laser interference patterning. Metals 2023, 13, 1248. [Google Scholar] [CrossRef]

- Ormanova, M.; Petrov, P.; Kovacheva, D. Electron beam surface treatment of tool steels. Vacuum 2017, 135, 7–12. [Google Scholar] [CrossRef]

- Valkov, S.; Ormanova, M.; Petrov, P. Electron-beam surface treatment of metals and alloys: Techniques and Trends. Metals 2020, 10, 1219. [Google Scholar] [CrossRef]

- Hu, J.J.; Zhang, G.B.; Xu, H.B.; Chen, Y.F. Microstructure characteristics and properties of 40Cr steel treated by high current pulsed electron beam. Mater. Technol. 2012, 27, 301–303. [Google Scholar] [CrossRef]

- Valkov, S.; Parshorov, S.; Andreeva, A.; Rabadzhiyska, S.; Nikolova, M.; Bezdushnyi, R.; Petrov, P. Influence of beam power on the surface architecture and corrosion behavior of electron-beam treated Co-Cr-Mo alloys. Nucl. Inst. Meth. Phys. Res. B 2021, 494–495, 46–52. [Google Scholar] [CrossRef]

- Geng, Y.; Chen, X.; Konovalov, S.; Panchenko, I.; Ivanov, Y.; Deev, V.; Prusov, E. Ultrafast microstructure modification by pulsed electron beam to enhance surface performance. Surf. Coat. Technol. 2022, 434, 128226. [Google Scholar] [CrossRef]

- Kelly, P.; Arnell, D. Magnetron sputtering: A review of recent developments and applications. Vacuum 2000, 56, 159–172. [Google Scholar] [CrossRef]

- Sokovic, M.; Panjan, P.; Kirn, R. Possibilities of improvement of dies casting tools with duplex treatment. J. Mater. Process. Technol. 2004, 157–158, 613–616. [Google Scholar] [CrossRef]

- Dimitrov, D.; Aprakova, M.; Valkanov, S.; Petrov, P. Electron beam hardening of ion nitrided layers. Vacuum 1998, 49, 239–246. [Google Scholar] [CrossRef]

- Grumbt, G.; Zenker, R.; Spies, H.-J.; Franke, R.; Haase, I. Improvement of the wear behaviour of highly-loaded components and tools by multi-combined surface treatment. Mater. Eng. Mater. Inžinierstvo 2014, 21, 1–10. [Google Scholar]

- Polcar, T.; Parreira, N.; Cavaleiro, A. Tribological characterization of tungsten nitride coatings deposited by reactive magnetron sputtering. Wear 2007, 262, 655–665. [Google Scholar] [CrossRef]

- Deng, Y.; Yin, S.; Hong, Y.; Wang, Y.; Zou, G.; Kuang, T.; Zhou, K. Microstructures and properties of novel nanocomposite WNx coatings deposited by reactive magnetron sputtering. Appl. Surf. Sci. 2020, 512, 145508. [Google Scholar] [CrossRef]

- Pan, F.; Wang, W.; Tang, A.; Wu, L.; Liu, T.; Cheng, R. Phase transformation refinement of coarse primary carbides in M2 high speed steel. Prog. Nat. Sci. Mater. Int. 2011, 21, 180–186. [Google Scholar] [CrossRef]

- Fu, Y.; Hu, J.; Shen, X.; Wang, Y.; Zhao, W. Surface hardening of 30CrMnSiA steel using continuous electron beam. Nucl. Inst. Meth. Phys. Res. 2017, 410, 207–214. [Google Scholar] [CrossRef]

- Petrov, P.; Dechev, D.; Ivanov, N.; Hikov, T.; Valkov, S.; Nikolova, M.; Yankov, E.; Parshorov, S.; Bezdushnyi, R.; Andreeva, A. Study of the influence of electron beam treatment of Ti5Al4V substrate on the mechanical properties and surface topography of multilayer TiN/TiO2 coatings. Vacuum 2018, 154, 264–271. [Google Scholar] [CrossRef]

- Zisman, A.A.; Nikolaev, D.I.; Lychagina, T.A.; Yashina, E.A. On the size effect for neutron diffraction by two-phase structures and applicability of composite standards in analysis of residual austenite in steels. Technol. Phys. 2018, 63, 1696–1702. [Google Scholar] [CrossRef]

- Panin, V.E.; Panin, A.V.; Perevalova, O.B.; Shugurov, A.R. Mesoscopic structural states at the nanoscale in surface layers of titanium and its alloy Ti-6Al-4V in ultrasonic and electron beam treatment. Phys. Mesomech. 2019, 22, 345–354. [Google Scholar] [CrossRef]

- Danisman, S.; Adabas, D.; Teber, M. The Effect of Coatings on the Wear Behavior of Ti6Al4V Alloy Used in Biomedical Applications. IOP Conf. Ser. Mater. Sci. Eng. 2018, 295, 012044. [Google Scholar] [CrossRef]

- Wen, M.; Meng, Q.N.; Yu, W.X.; Zheng, W.T.; Mao, S.X.; Hua, M.J. Growth, stress and hardness of reactively sputtered tungsten nitride thin films. Surf. Coat. Technol. 2010, 205, 1953–1961. [Google Scholar] [CrossRef]

- Zhang, X.; Tian, X.; Zhao, Z.; Gao, J.; Zhou, Y.; Gao, P.; Guo, Y.; Lv, Z. Evaluation of the adhesion and failure mechanism of the hard CrN coatings on different substrates. Surf. Coat. Technol. 2019, 364, 135–143. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).