Effect of the Mineralogical Composition of Sandstones on the Wear of Mining Machinery Components

Abstract

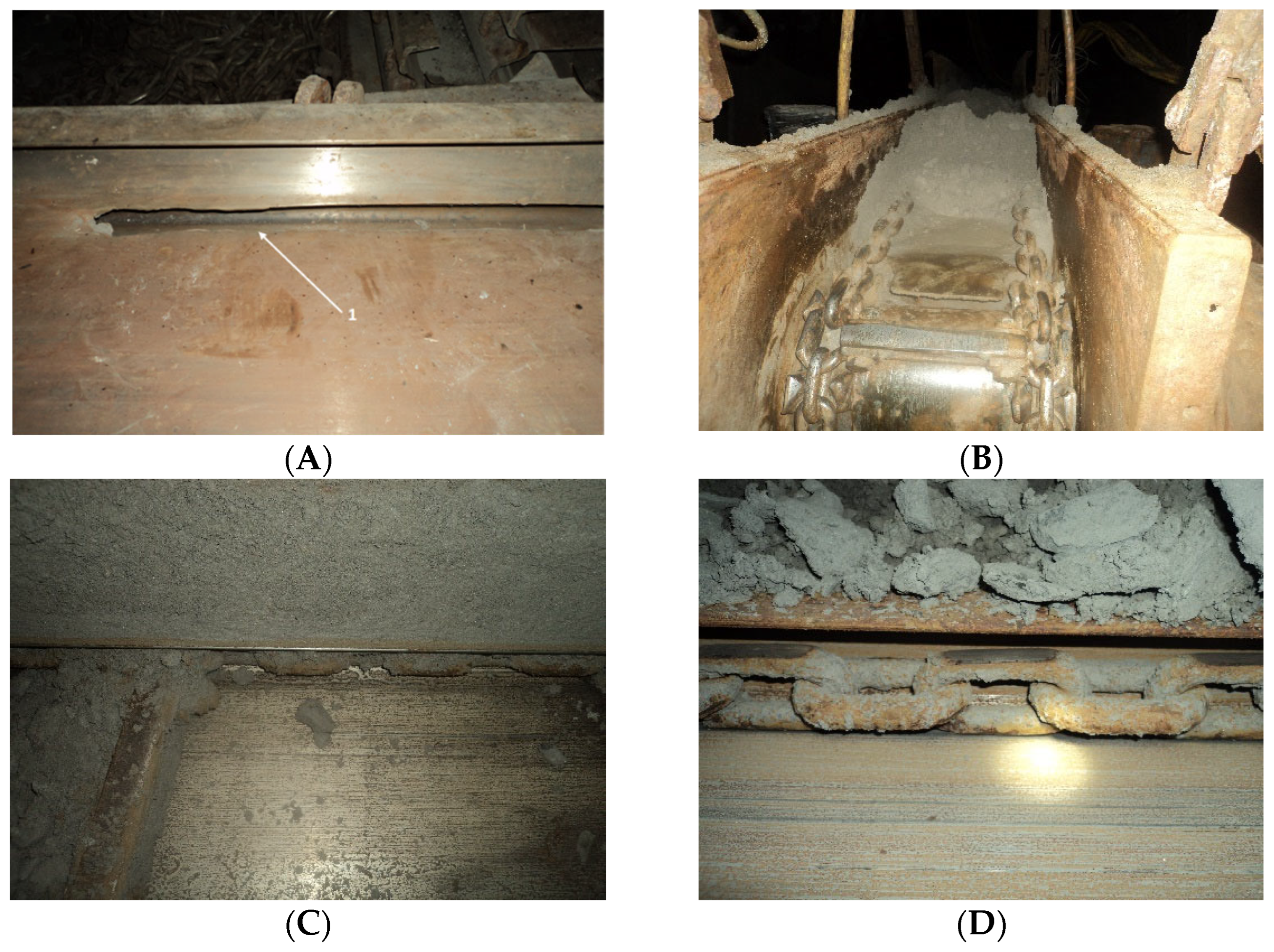

:1. Introduction

- To identify the mechanisms of surface damage of wear-resistant steels in the presence of sandstones featuring different kinds of mineral cement;

- To determine the effect of the fraction of quartz in the sandstones examined on the wear of wear-resistant steels;

- To define the interaction between the damage mechanism and the sandstone cement type.

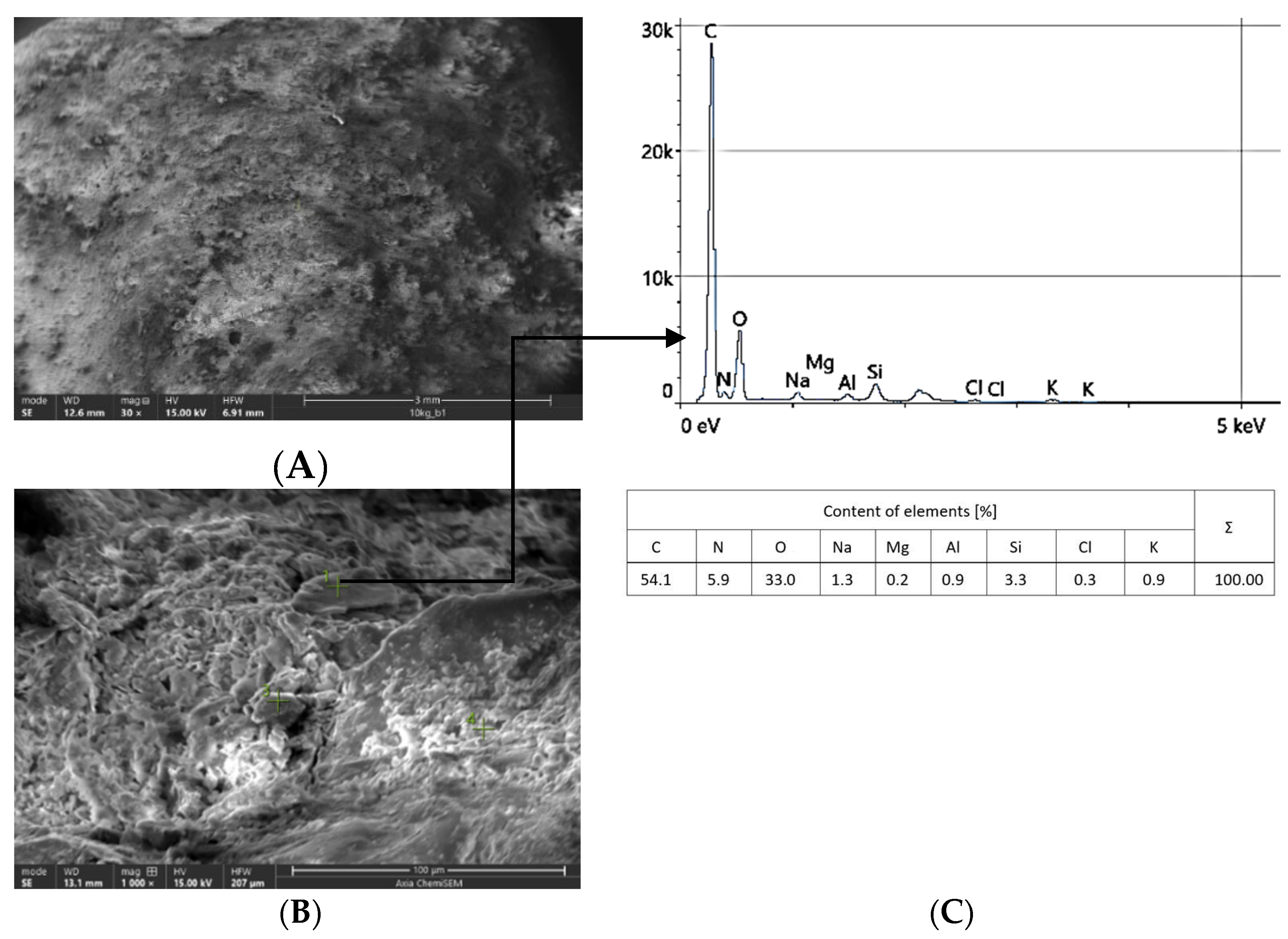

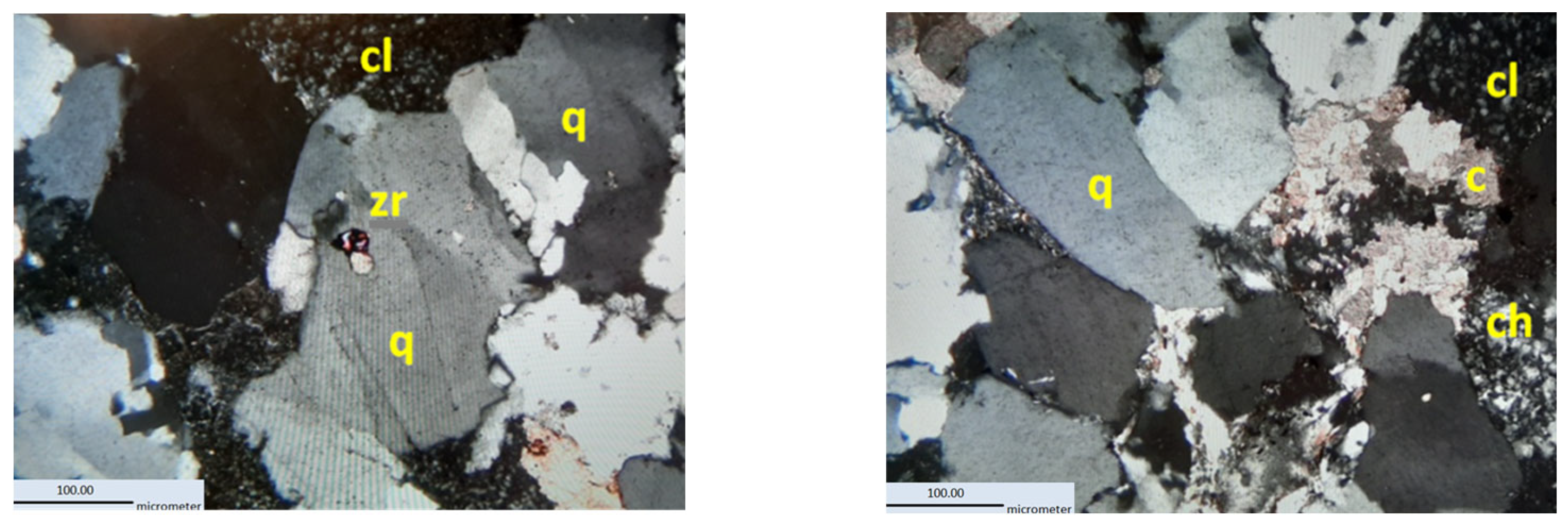

- Mineralogical and chemical identification of the analysed abrasive material based on microscopic observations of thin plates using a scanning electron microscope, as well as analysis of chemical composition by X-ray fluorescence (XRF);

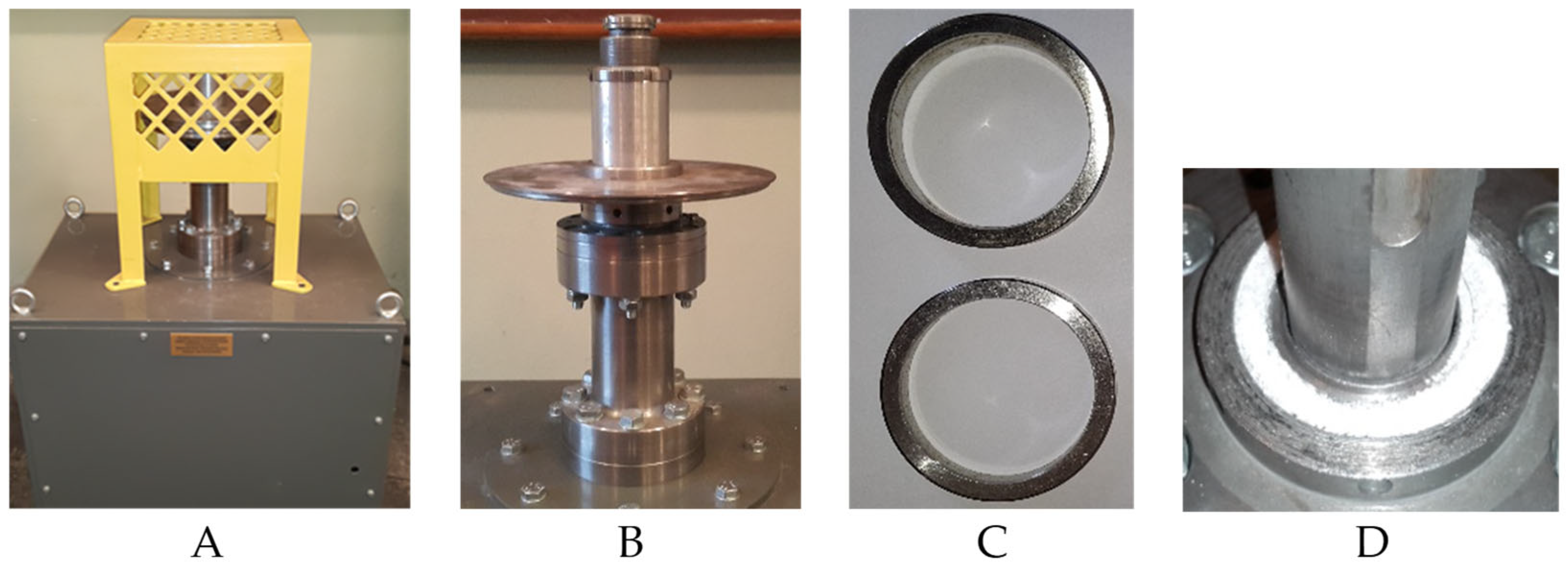

- Wear testing of wear-resistant steels in the presence of comminuted sandstone grains and quartz sand;

- Identification of the surface damage mechanisms observed in the samples based on scanning microscopy observations and EDS analysis.

- Carboniferous sandstone obtained from the Piast-Ziemowit hard coal mine in Bieruń;

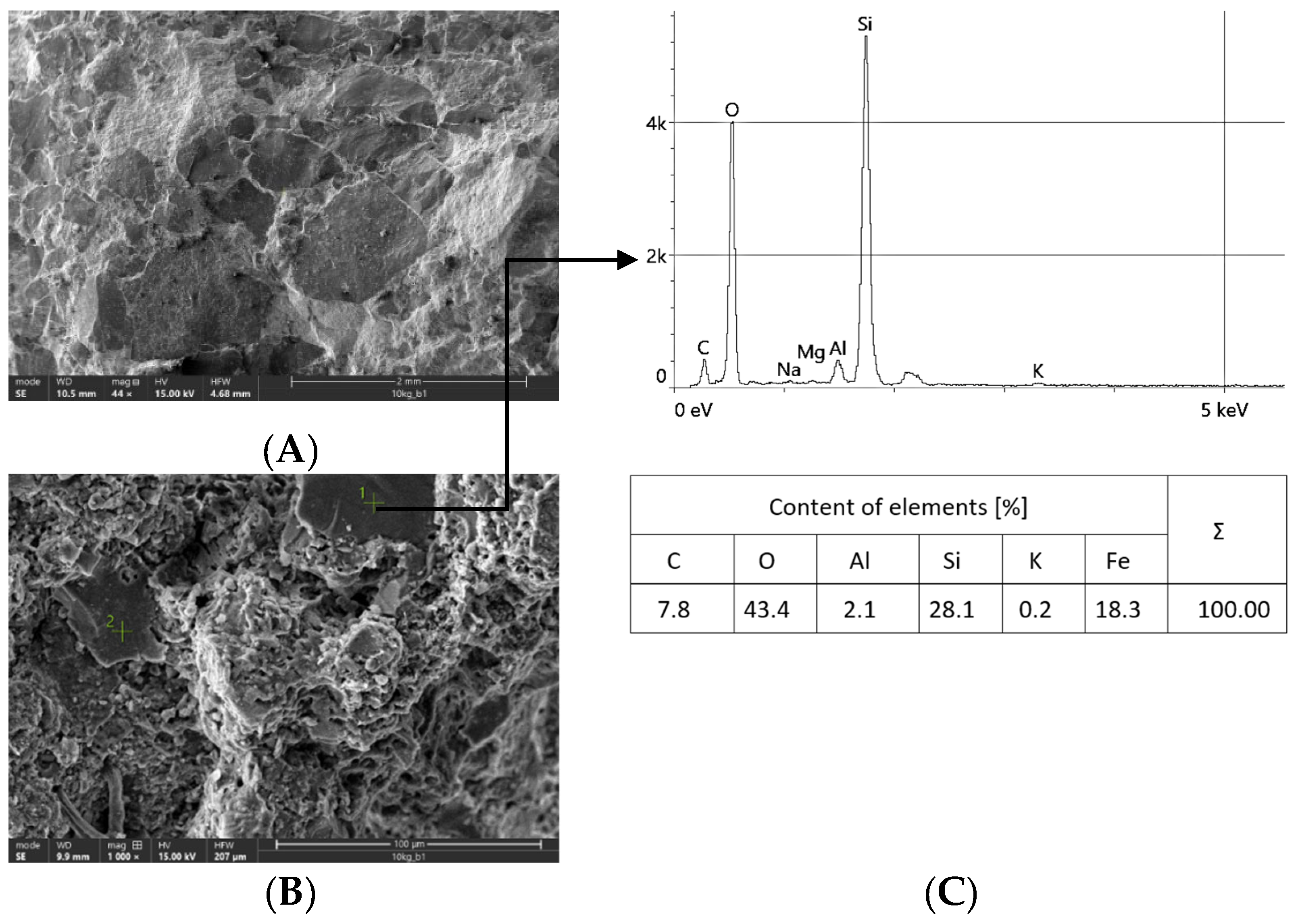

- Permian ferruginous sandstone from the Lower Silesian deposits found in the district of Kłodzko;

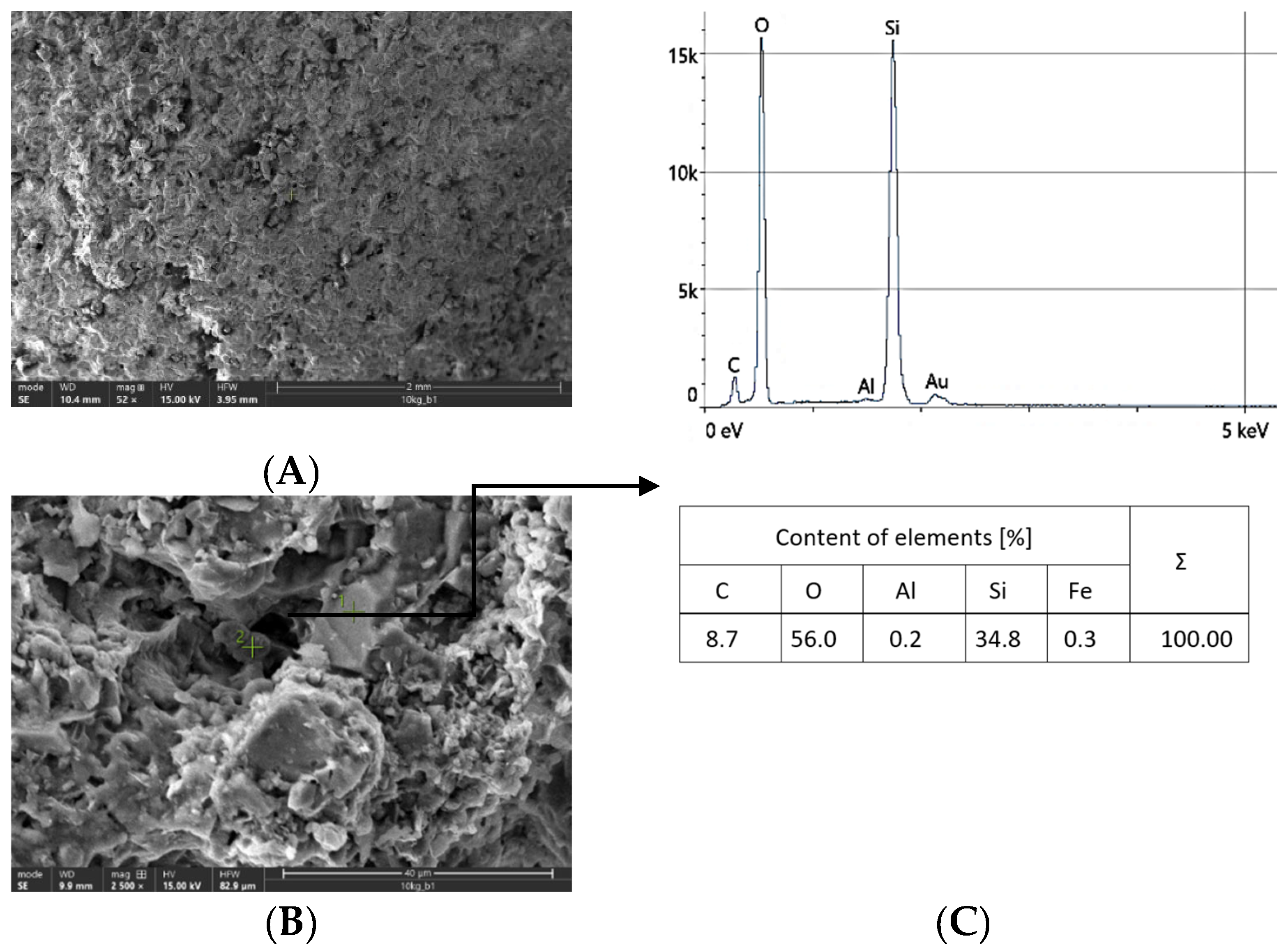

- Sandstone from the bottom Godulian strata extracted in the town of Wisła, dating back to the Upper Cretaceous.

2. Experimental Details

- Carboniferous sandstone from the mine workings of KWK Piast-Ziemowit in Bieruń;

- Ferruginous sandstone dating from the Permian originating from Lower Silesian deposits in the Kłodzko district;

- Sandstone from the lower Godula beds in Vistula, dating to the Upper Cretaceous.

3. Results

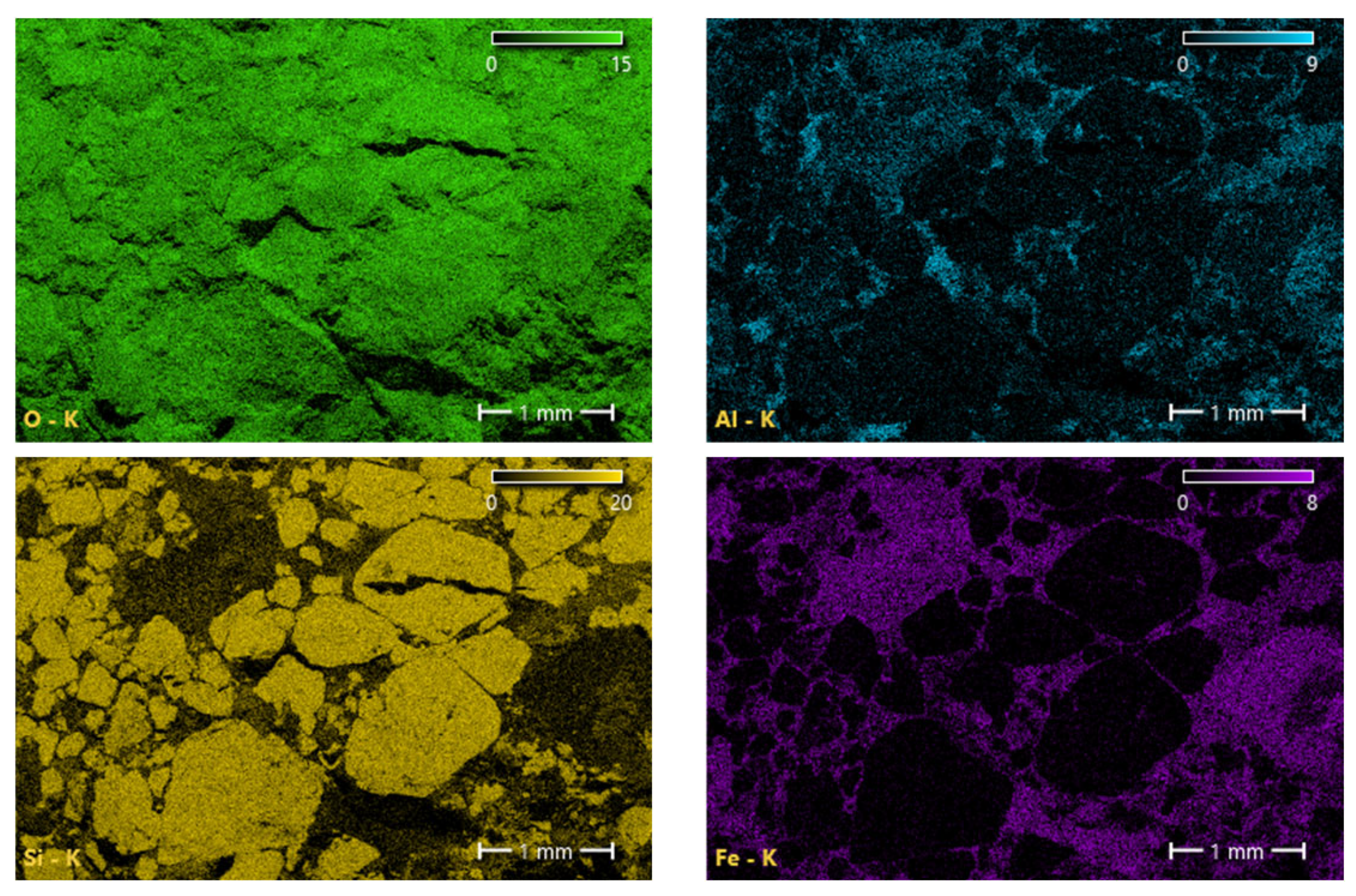

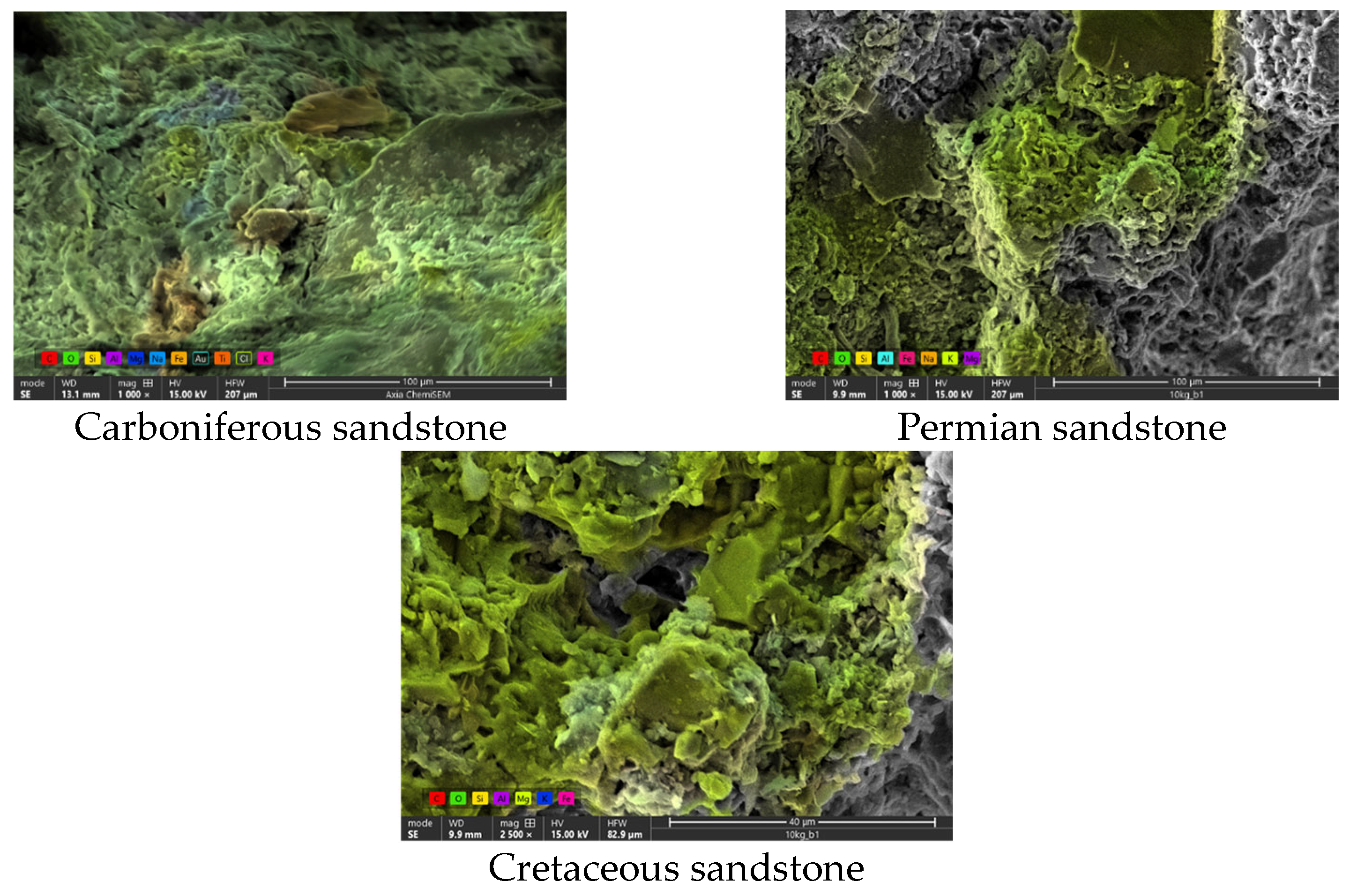

3.1. Identification Tests

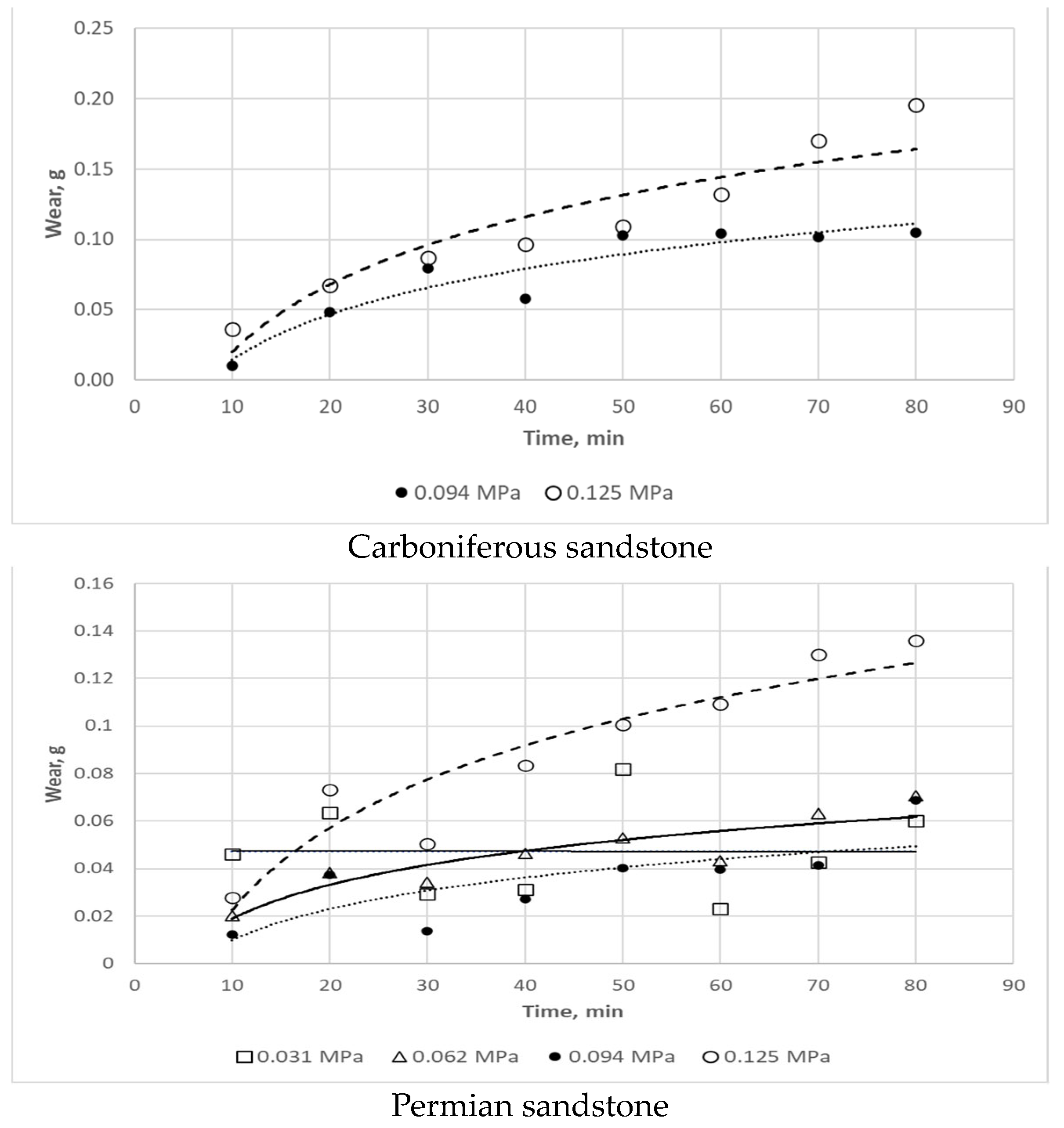

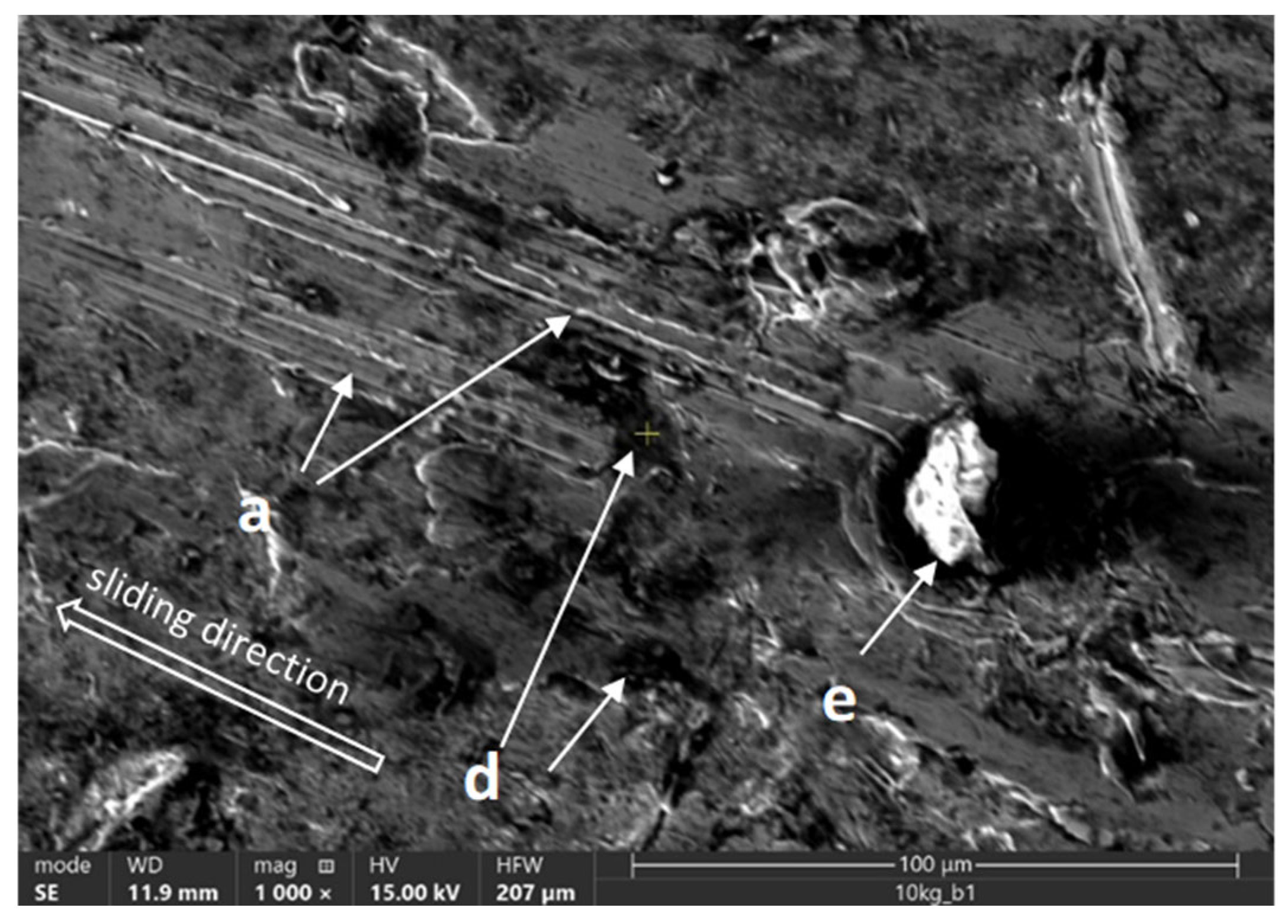

3.2. Wear Tests

- The greatest wear was observed for homogeneous hard mineral abrasives (quartz sand);

- All the wear values obtained for the wear-resistant steel in the presence of quartz sand and for all load values are very similar;

- The differences in the mass decrement caused by the presence of Permian, Carboniferous, and Cretaceous sandstone are inconsiderable and cannot be graded in terms of the intensity of their effect on the wear-resistant steel.

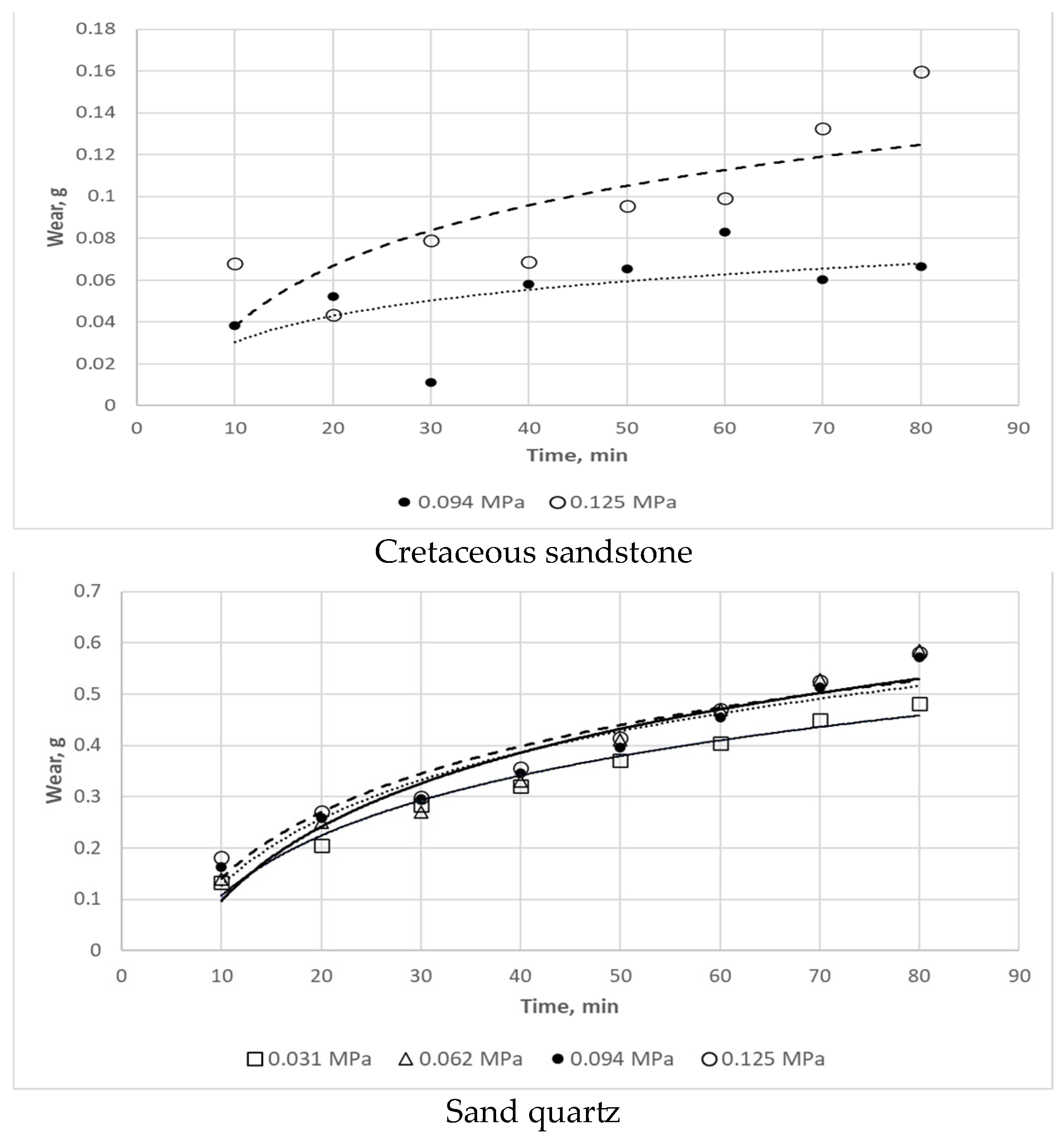

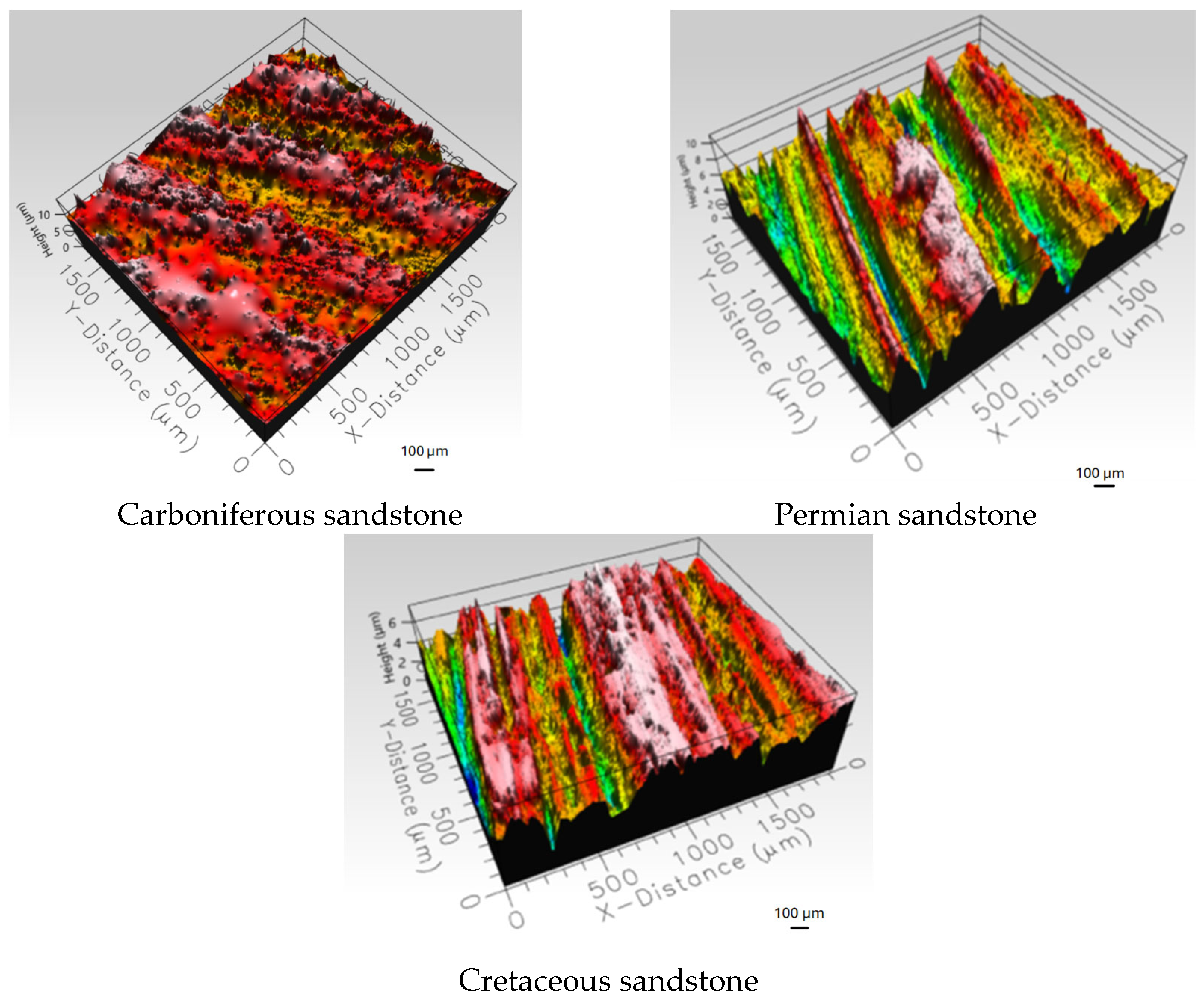

3.3. Surface Analysis after Wear Tests

4. Discussion

- Surface abrasion by hard mineral grains and wear products;

- Capacity for the formation of extensive surface cracks between abrasion areas as a consequence of aggregate accumulation in surface cracking areas.

- Facilitating the settling of mineral abrasive grains in surface damage areas and partially converting the three-body form of abrasive wear into two-body abrasive wear;

- Enabling limited capture of hard abrasive particles by discontinuous cement films;

- Limiting oxygen access to the loosened steel surface fragments via consolidated cement fractions.

5. Conclusions

- (1)

- The form of damage to mating surfaces depends on the type of abrasive material introduced between them:

- For abrasive material based on quartz sand, micro-scratching was found to be the primary steel damage mechanism, the secondary one being the smoothing effect of highly comminuted wear products.

- For the sandstone-based abrasive, signs of abrasion of the steel surface by grain fragments, as well as formation of films comprising minerals forming the sandstone cement (clayey minerals, hematite) and carbonaceous substance, were observed.

- (2)

- What could also be noticed in the sandstones was the deposition of hard grains, mainly of quartz, in the damaged surface areas, which was facilitated by the presence of soft cement-building minerals (clayey minerals, hematite) and, in the case of Carboniferous sandstone, the presence of carbonaceous matter inclusions.

- (3)

- On the surfaces worn in the presence of sandstones, discontinuous and irregular films of cement and carbonaceous inclusions were formed under load.

- (4)

- The following conclusions were drawn with reference to the volumetric wear values measured:

- The most extensive wear was observed in the presence of hard mineral abrasives (quartz sand);

- The wear values obtained for wear-resistant steels in the presence of all three sandstone varieties studies were very similar to one another. Moreover, the average consumption determined for the tested sandstones was 72% lower compared to the consumption observed for quartz sand.

- (5)

- Additionally, models of wear in the presence of sandstone-based abrasive material were provided in the paper.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kotwica, K. Zagrożenia generowane podczas mechanicznego urabiania skał zwięzłych—możliwości ich eliminacji lub ograniczenia. Napędy Sterow. 2018, 20, 74–83. [Google Scholar]

- Thuro, K. Geologisch-Felsmechanische Grundlagen der Gebirgslösung im Tunnelbau; Habilitationsschrift, TU: Munchen, Germany, 2002. [Google Scholar]

- Kotwica, K.; Klich, A. Maszyny i Urządzenia do Drążenia Wyrobisk Korytarzowych i Tunelowych; Wydawnictwo ITG KOMAG: Gliwice, Poland, 2011. [Google Scholar]

- Szewerda, K.; Tokarczyk, J.; Wieczorek, A. Impact of Increased Travel Speed of a Transportation Set on the Dynamic Parameters of a Mine Suspended Monorail. Energies 2021, 14, 1528. [Google Scholar] [CrossRef]

- Myszka, D.; Wieczorek, A.N. Effect of phenomena accompanying wear in dry corundum abrasive on the properties and microstructure of austempered ductile iron with different chemical composition. Arch. Metall. Mater. 2015, 60, 483–490. [Google Scholar] [CrossRef]

- Hawk, J.A.; Wilson, R.D. Tribology of Earthmoving, Mining, and Minerals Processing. In Modern Tribology Handbook; Bhushan, B., Ed.; CRC Press LLC: Boca Raton, FL, USA, 2001; Volume 35. [Google Scholar]

- Płaza, S.; Margielewski, L.; Celichowski, G. Wstęp do Tribologii i Tribochemia; Wydawnictwo Uniwersytetu Łódzkiego: Łódź, Poland, 2005. [Google Scholar]

- Tylczak, J.H. Abrasive wear. In ASM Handbook—Friction, Lubrication, and Wear Technology; ASM International: Almere, The Netherlands, 1992; Volume 18, pp. 184–190. [Google Scholar]

- Stachowiak, G.; Andrew, W. Batchelor. Engineering Tribology; Butterworth-heinemann: Oxford, UK, 2013. [Google Scholar]

- Zum Gahr, K.H. Microstructure and Wear of Materials; Tribology Series Elsevier: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Stachowiak, G.B.; Stachowiak, G.W. The effects of particle characteristics on three-body abrasive wear. Wear 2001, 249, 201–207. [Google Scholar] [CrossRef]

- Labaš, M.; Krepelka, F.; Ivaničová, L. Assessment of abrasiveness for research of rock cutting. Acta Montan. Slovaca 2012, 17, 65–73. [Google Scholar]

- Xia, R.; Li, B.; Wang, X.; Yang, Z.; Liu, L. Screening the Main Factors Affecting the Wear of the Scraper Conveyor Chute Using the Plackett–Burman Method. Math. Probl. Eng. 2019, 2019, 1204091. [Google Scholar] [CrossRef]

- Wieczorek, A.N. The role of operational factors in shaping of wear properties of alloyed Austempered Ductile Iron. Part II. An assessment of the cumulative effect of abrasives processes and the dynamic activity on the wear property of Ausferritic Ductile Iron. Arch. Metall. Mater. 2014, 59, 1675–1683. [Google Scholar] [CrossRef]

- Tlotleng, M.T. Coal Characteristics that Lead to Abrasion during Grinding. Master’s Thesis, University of the Witwatersrand, Johannesburg, South Africa, 2011. [Google Scholar]

- Ratia, V.; Heino, V.; Valtonen, K.; Vippola, M.; Kemppainen, A.; Siitonen, P.; Kuokkala, V.T. Effect of abrasive properties on the high-stress three-body abrasion of steels and hard metals. Finn. J. Tribol. 2014, 32, 3–18. [Google Scholar]

- Valtonen, K.; Ratia, V.; Ojala, N.; Kuokkala, V.-T. Comparison of laboratory wear test results with the in-service performance of cutting edges of loader buckets. Wear 2017, 388–389, 93–100. [Google Scholar] [CrossRef]

- Hakami, F.; Pramanik, A.; Basak, A.K. Effect of the Abrasive Particle Size. In Tribology of Elastomers; Springer Briefs in Applied Sciences and Technology; Springer: Singapore, 2022. [Google Scholar]

- Lawrowski, Z. Tribologia. Tarcie, Zużycie i Smarowanie; PWN: Warszawa, Poland, 1993. [Google Scholar]

- Mucha, K. Ścierność Skał w Aspekcie Prognozowania Zużycia Noży Kombajnowych. Ph.D. Thesis, AGH University of Science and Technology, Kraków, Poland, 2019. [Google Scholar]

- Geological Digressions. Available online: https://www.geological-digressions.com/classification-of-sandstones (accessed on 12 February 2022).

- Kozłowski, S. Surowce Skalne Polski; Wydawnictwa Geologiczne: Warszawa, Poland, 1986. [Google Scholar]

- Available online: https://mineralseducationcoalition.org/minerals-database/sandstone/ (accessed on 29 June 2023).

- Available online: https://www.britannica.com/science/sedimentary-rock/Sedimentary-rock-types (accessed on 29 June 2023).

- Garzanti, E. Petrographic classification of sand and sandstone. Earth-Sci. Rev. 2019, 19, 545–563. [Google Scholar] [CrossRef]

- Folk, R.L. Petrology of Sedimentary Rock; Hemphill’s.: Austin, TX, USA, 1968. [Google Scholar]

- Pettijohn, F.J.; Potter, P.E.; Siever, R. Sand and Sandstone; Springer: New York, NY, USA, 1972. [Google Scholar]

- Song, Z.; Konietzky, H.; Wu, Y.; Du, K.; Cai, X. Mechanical behaviour of medium-grained sandstones exposed to differential cyclic loading with distinct loading and unloading rates. J. Rock Mech. Geotech. Eng. 2022, 14, 1849–1871. [Google Scholar] [CrossRef]

- Bagde, N.; Petroš, V. Fatigue properties of intact sandstone samples subjected to dynamic uniaxial cyclical loading. Int. J. Rock Mech. Min. 2005, 42, 237–250. [Google Scholar] [CrossRef]

- Bagde, M.N.; Petroš, V. Waveform Effect on Fatigue Properties of Intact Sandstone in Uniaxial Cyclical Loading. Rock Mech. Rock Eng. 2005, 38, 169–196. [Google Scholar] [CrossRef]

- Bagde, M.N.; Petroš, V. The effect of machine behaviour and mechanical properties of intact sandstone under static and dynamic uniaxial cyclic loading. Rock Mech. Rock Eng. 2005, 38, 59–67. [Google Scholar] [CrossRef]

- Song, H.; Zhang, H.; Kang, Y.; Huang, G.; Fu, D.; Qu, C. Damage evolution study of sandstone by cyclic uniaxial test and digital image correlation. Tectonophysics 2013, 608, 1343–1348. [Google Scholar] [CrossRef]

- Xin, C.; Zilong, Z.; Lihai, T.; Haizhi, Z.; Zhengyang, S. Fracture behavior and damage mechanisms of sandstone subjected to wetting-drying cycles. Eng. Fract. Mech. 2020, 234, 107109. [Google Scholar]

- Zhao, Y.; Zhou, H.; Zhong, J. Study on the relation between damage and permeability of sandstone at depth under cyclic loading. Int. J. Coal Sci. Technol. 2019, 6, 479–492. [Google Scholar] [CrossRef]

- Vaneghi, R.G.; Ferdosi, B.; Okoth, A.D.; Kuek, B. Strength degradation of sandstone and granodiorite under uniaxial cyclic loading. J. Rock Mech. Geotech. 2018, 10, 117–126. [Google Scholar] [CrossRef]

- Yang, S.Q.; Ranjith, P.G.; Huang, Y.H.; Yin, P.F.; Jing, H.W.; Gui, Y.L.; Yu, Q.L. Experimental investigation on mechanical damage characteristics of sandstone under triaxial cyclic loading. Geophys. J. Int. 2015, 201, 662–682. [Google Scholar] [CrossRef]

- Yang, S.Q.; Jing, H.W. Evaluation on strength and deformation behavior of red sandstone under simple and complex loading paths. Eng. Geol. 2013, 164, 1–17. [Google Scholar] [CrossRef]

- Yang, S.Q.; Jing, H.W.; Wang, S.Y. Experimental investigation on the strength, deformability, failure behavior and acoustic emission locations of red sandstone under triaxial compression. Rock Mech. Rock Eng. 2012, 45, 583–606. [Google Scholar] [CrossRef]

- Zhao, G.F.; Russell, A.R.; Zhao, X.; Khalili, N. Strain rate dependency of uniaxial tensile strength in Gosford sandstone by the Distinct Lattice Spring Model with X-ray micro CT. Int. J. Solids Struct. 2014, 51, 1587–1600. [Google Scholar] [CrossRef]

- Liu, E.; He, S. Effects of cyclic dynamic loading on the mechanical properties of intact rock samples under confining pressure conditions. Eng. Geol. 2012, 125, 81–91. [Google Scholar] [CrossRef]

- Ray, S.K.; Sarkar, M.; Singh, T.N. Effect of cyclic loading and strain rate on the mechanical behaviour of sandstone. Int. J. Rock Mech. Rock Eng. 1999, 36, 543–549. [Google Scholar] [CrossRef]

- Feng, X.T.; Chen, S.; Zhou, H. Real-time computerized tomography (CT) experiments on sandstone damage evolution during triaxial compression with chemical corrosion. Int. J. Rock Mech. Rock Eng. 2004, 41, 181–192. [Google Scholar] [CrossRef]

- Figarska-Warchoł, B.; Rembi’s, M. Lamination and Its Impact on the Physical and Mechanical Properties of the Permian and Triassic Terrestrial Sandstones. Resources 2021, 10, 42. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, Y.; Song, Q.; Wang, P.; Liu, D. Dynamic Mechanical Properties and Failure Characteristics of Sandstone with Pre-Flaws Parallel to the Loading Direction. Sustainability 2023, 15, 3587. [Google Scholar] [CrossRef]

- Strzałkowski, P.; Kaźmierczak, U.; Wolny, M. Assessment of the method for abrasion resistance determination of sandstones on Böhme abrasion test apparatus. Bull. Eng. Geol. Environ. 2020, 79, 4947–4956. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, L.; Zhao, N.; Yang, J.; Li, X. Analysis of the Variation of Friction Coefficient of Sandstone Joint in Sliding. Adv. Civ. Eng. 2020, 8863960. [Google Scholar] [CrossRef]

- Mucha, K. Application of Rock Abrasiveness and Rock Abrasivity Test Methods—A Review. Sustainability 2023, 15, 11243. [Google Scholar] [CrossRef]

- Jonczy, I.; Mucha, K. Relationships between the Petrographic and Abrasive Properties of Sandstones in the Aspect of Their Cutting. Energies 2022, 15, 2692. [Google Scholar] [CrossRef]

- Tang, S.-H.; Zhang, X.-P.; Liu, Q.-S.; Xie, W.-Q.; Wang, H.-J.; Li, X.-F.; Zhang, X.-Y. New soil abrasion testing method for evaluating the influence of geological parameters of abrasive sandy ground on scraper wear in TBM tunnelling. Tunn. Undergr. Space Technol. 2022, 128, 104604. [Google Scholar] [CrossRef]

- Abu Bakar, M.; Majeed, Y.; Rostami, J. Influence of moisture content on the LCPC test results and its implications on tool wear in mechanized tunneling. Tunn. Undergr. Space Technol. 2018, 81, 165–175. [Google Scholar] [CrossRef]

- Terva, J.; Teeri, T.; Kuokkala, V.-T.; Siitonen, P.; Liimatainen, J. Abrasive wear of steel against gravel with different rock–steel combinations. Wear 2009, 267, 1821–1831. [Google Scholar] [CrossRef]

- Yarali, O.; Yasar, E.; Bacak, G.; Ranjith, P.G. A study of rock abrasivity and tool wear in Coal Measures Rocks. Int. J. Coal Geol. 2008, 74, 53–66. [Google Scholar] [CrossRef]

- Barzegari, G.; Uromeihy, A.; Zhao, J. Parametric study of soil abrasivity for predicting wear issue in TBM tunneling projects. Tunn. Undergr. Sp. Technol. Inc. Trenchless Technol. Res. 2015, 48, 43–57. [Google Scholar] [CrossRef]

- Jakobsen, P.D.; Lohne, J. Challenges of methods and approaches for estimating soil abrasivity in soft ground TBM tunnelling. Wear 2013, 308, 166–173. [Google Scholar] [CrossRef]

- Konat, Ł. Struktury i Właściwości Stali Hardox a Ich Możliwości Aplikacyjne w Warunkach Zużywania Ściernego i Obciążeń Dynamicznych. Ph.D. Thesis, Politechnika Wrocławska, Wrocław, Poland, 2007. [Google Scholar]

- Hardox—Das Verschleiβblech der vielen Möglichkeiten; SSAB: Oxelösund, Sweden, 2002.

- Dudziński, W.; Konat, Ł.; Pękalska, L.; Pękalski, G. Struktury i właściwości stali Hardox 400 i 500. Inżynieria Mater. 2006, 151, 139–142. [Google Scholar]

- Shi, Z.; Zhu, Z. Case study: Wear analysis of the middle plate of a heavy-load scraper conveyor chute under a range of operating conditions. Wear 2017, 380–381, 36–41. [Google Scholar] [CrossRef]

- Wang, S.; Ge, Q.; Wang, J. The impact wear-resistance enhancement mechanism of medium manganese steel and its applications in mining machines. Wear 2017, 376–377, 1097–1104. [Google Scholar]

- Heino, V. The Effect of Rock Properties on the High Stress Abrasive Wear Behavior of Steels, Hardmetals and White Cast Irons. Ph.D. Thesis, Tampere University of Technology, Tampere, Finland, 2018. [Google Scholar]

- Haiko, O.; Somani, M.; Porter, D.; Kantanen, P.; Kömi, J.; Ojala, N.; Heino, V. Comparison of impact-abrasive wear characteristics and performance of direct quenched (DQ) and direct quenched and partitioned (DQ&P) steels. Wear 2017, 400–401, 21–30. [Google Scholar]

- Ojala, N.; Valtonen, K.; Heino, V.; Kallio, M.; Aaltonen, J.; Siitonen, P.; Kuokkala, V.-T. Effects of composition and microstructure on the abrasive wear performance of quenched wear resistant steels. Wear 2014, 317, 225–232. [Google Scholar] [CrossRef]

- Thakare, M.R.; Wharton, J.A.; Wood, R.J.K.; Menger, C. Effect of abrasive particle size and the influence of microstructure on the wear mechanisms in wear-resistant materials. Wear 2012, 276–277, 16–28. [Google Scholar] [CrossRef]

- Michalczewski, R.; Kalbarczyk, M.; Mańkowska-Snopczyńska, A.; Osuch-Słomka, E.; Piekoszewski, W.; Snarski-Adamski, A.; Szczerek, M.; Tuszyński, W.; Wulczyński, J.; Wieczorek, A. The Effect of a Gear Oil on Abrasion, Scuffing, and Pitting of the DLC-Coated 18CrNiMo7-6 Steel. Coatings 2019, 9, 2. [Google Scholar] [CrossRef]

- Jonczy, I.; Wieczorek, A.N.; Podwórny, J.; Gerle, A.; Staszuk, M.; Szweblik, J. Characteristics of hard coal and its mixtures with water subjected to friction. Gospod. Surowcami Miner. Miner. Resour. Manag. 2020, 36, 185–201. [Google Scholar]

- Wieczorek, A.N. Operation-oriented studies on wear properties of surface-hardened alloy cast steels used in mining in the conditions of the combined action of dynamic forces and an abrasive material. Arch. Metall. Mater. 2017, 62, 2381–2389. [Google Scholar] [CrossRef]

- Wieczorek, A.N.; Jonczy, I.; Bala, P.; Stankiewicz, K.; Staszuk, M. Testing the Wear Mechanisms of the Components of Machines Used in Fossil Energy Resource Extraction. Energies 2021, 14, 2125. [Google Scholar] [CrossRef]

- Wieczorek, A.N.; Jonczy, I.; Filipowicz, K.; Kuczaj, M.; Pawlikowski, A.; Łukowiec, D.; Staszuk, M.; Gerle, A. Study of the Impact of Coals and Claystones on Wear-Resistant Steels. Materials 2023, 16, 2136. [Google Scholar] [CrossRef] [PubMed]

- Paszeczko, M.; Holubets, V.; Dziedzic, K.; Barszcz, M.; Montusiewicz, J. Triboprocesy, Materiały, Technologie, Optymalizacja; Wydawnictwo Politechniki Lubelskiej: Lublin, Poland, 2020. [Google Scholar]

- Wieczorek, A.N.; Polis, W. Operation-oriented method for testing the abrasive wear of mining chain wheels in the conditions of the combined action of destructive factors. Manag. Syst. Prod. Eng. 2015, 19, 175–178. [Google Scholar]

- Norman, T.E. Wear in ore processing machinery. In Wear Control Handbook; Peterson, M.B., Winer, W.O., Eds.; ASME: New York, NY, USA, 1980; pp. 1009–1051. [Google Scholar]

- Scott, D. Wear. In Industrial Tribology—The Practical Aspects of Friction, Lubrication and Wear; Elsevier: Amsterdam, The Netherlands, 1983; pp. 12–30. [Google Scholar]

- Szczerek, M.; Wiśniewski, M. Tribologia i Tribotechnika; Polskie Towarzystwo Tribologiczne, Instytut Technologii Eksploatacji, Stowarzyszenie Inżynierów i Techników mechaników Polskich: Radom, Poland, 2000; pp. 15–19. [Google Scholar]

- Kahrizsangi, H.S.; Sofia, D.; Barletta, D.; Poletto, M. Dust generation in vibrated cohesive powders. Chem. Eng. Trans. 2015, 43, 769–774. [Google Scholar]

| Mechanical Properties | Tensile Strength TS, MPa | Elongation A, % | Minimum Temperature for Which the Steel Impact Strength V is 30 J, °C | Hardness, HB |

|---|---|---|---|---|

| RAEX400 | 1250 | 10 | −40 | 383–403 |

| C | Mn | Si | S | P | Ni | Cr | Mo | B | Nb |

|---|---|---|---|---|---|---|---|---|---|

| 0.288 | 1.14 | 0.436 | 0.0124 | 0.0042 | 0.0782 | 0.457 | 0.122 | 0.0063 | <0.004 |

| Parameter | Value | |||

|---|---|---|---|---|

| Contact surface area S, mm2 | 785.3 | |||

| Compressing stress σ, MPa for | ||||

| Quartz sand | 0.031 | 0.062 | 0.094 | 0.125 |

| Carboniferous sandstone | 0.094 | 0.125 | ||

| Permian sandstone | 0.031 | 0.062 | 0.094 | 0.125 |

| Cretaceous sandstone | 0.094 | 0.125 | ||

| Tests duration, min | 8 × 10 | |||

| Sliding distance, m | 1390 | |||

| Rotational speed of the moving sample, RPM | 149.1 | |||

| Average linear speed of the moving sample, m/s | 0.29 | |||

| Number of test repetitions for each variant | 3 | |||

| Outside diameter of the sample | Ø (54,954–55,000) mm | |||

| Inside diameter of the sample | Ø (45,000–45,025) mm | |||

| Sample width (B) | for upper lid B = 10 mm, for lower lid B = 6 mm | |||

| Component, % | Carboniferous Sandstone | Permian Sandstone | Cretaceous Sandstone |

|---|---|---|---|

| SiO2 | 88.53 ± 2.21 | 80.27 ± 2.01 | 83.14 ± 2.08 |

| Al2O3 | 3.83 ± 0.19 | 5.09 ± 0.25 | 8.06 ± 0.40 |

| Fe2O3 | 0.35 ± 0.17 | 11.81 ± 0.59 | 2.88 ± 0.14 |

| TiO2 | 0.17 ± 0.09 | 0.23 ± 0.12 | 0.37 ± 0.19 |

| MnO | 0.02 ± 0.01 | 0.01 ± 0.01 | 0.04 ± 0.02 |

| CaO | 0.62 ± 0.31 | 0.03 ± 0.02 | 0.25 ± 0.12 |

| MgO | 0.49 ± 0.25 | 0.09 ± 0.05 | 0.66 ± 0.33 |

| Na2O | 0.53 ± 0.26 | 0.01 ± 0.01 | 1.63 ± 0.16 |

| K2O | 0.67 ± 0.33 | 0.43 ± 0.22 | 1.41 ± 0.14 |

| P2O5 | 0.01 ± 0.01 | 0.09 ± 0.04 | 0.07 ± 0.03 |

| loss on ignition * | 4.73 ± 0.47 | 2.42 ± 0.24 | 1.86 ± 0.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wieczorek, A.N.; Jonczy, I.; Filipowicz, K.; Kuczaj, M.; Pawlikowski, A.; Mucha, K.; Gerle, A. Effect of the Mineralogical Composition of Sandstones on the Wear of Mining Machinery Components. Coatings 2024, 14, 859. https://doi.org/10.3390/coatings14070859

Wieczorek AN, Jonczy I, Filipowicz K, Kuczaj M, Pawlikowski A, Mucha K, Gerle A. Effect of the Mineralogical Composition of Sandstones on the Wear of Mining Machinery Components. Coatings. 2024; 14(7):859. https://doi.org/10.3390/coatings14070859

Chicago/Turabian StyleWieczorek, Andrzej N., Iwona Jonczy, Krzysztof Filipowicz, Mariusz Kuczaj, Arkadiusz Pawlikowski, Kamil Mucha, and Anna Gerle. 2024. "Effect of the Mineralogical Composition of Sandstones on the Wear of Mining Machinery Components" Coatings 14, no. 7: 859. https://doi.org/10.3390/coatings14070859

APA StyleWieczorek, A. N., Jonczy, I., Filipowicz, K., Kuczaj, M., Pawlikowski, A., Mucha, K., & Gerle, A. (2024). Effect of the Mineralogical Composition of Sandstones on the Wear of Mining Machinery Components. Coatings, 14(7), 859. https://doi.org/10.3390/coatings14070859