Fatigue Damage in Asphalt Pavement Based on Axle Load Spectrum and Seasonal Temperature

Abstract

:1. Introduction

2. Test Section and Monitoring System

3. Calculation Methods for Fatigue Damage

3.1. Method Based on the Axle Load Spectra (ALS)

3.2. Method Based on the Equivalent Standard Axle Loads (ESALs)

4. Results and Discussion

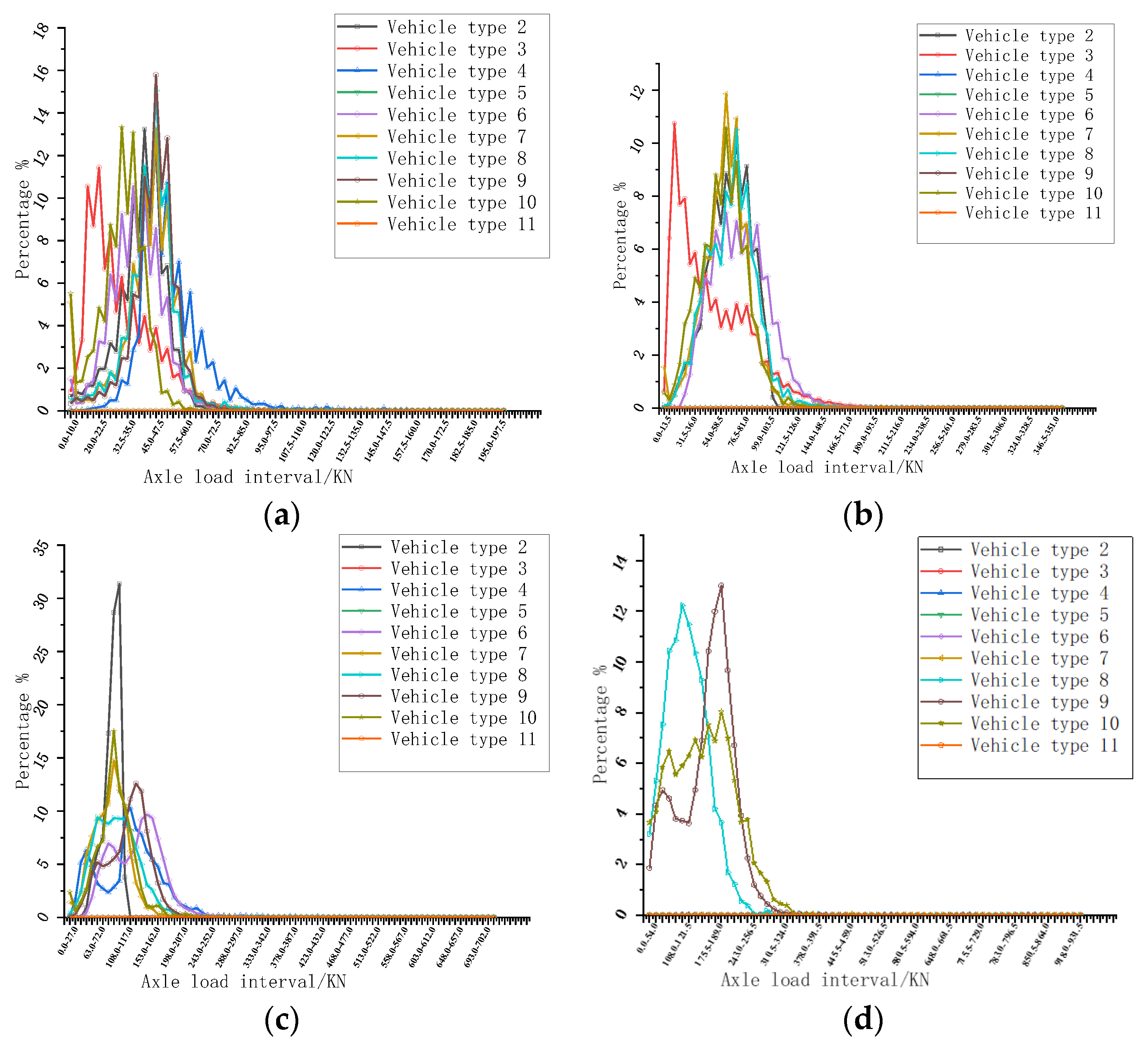

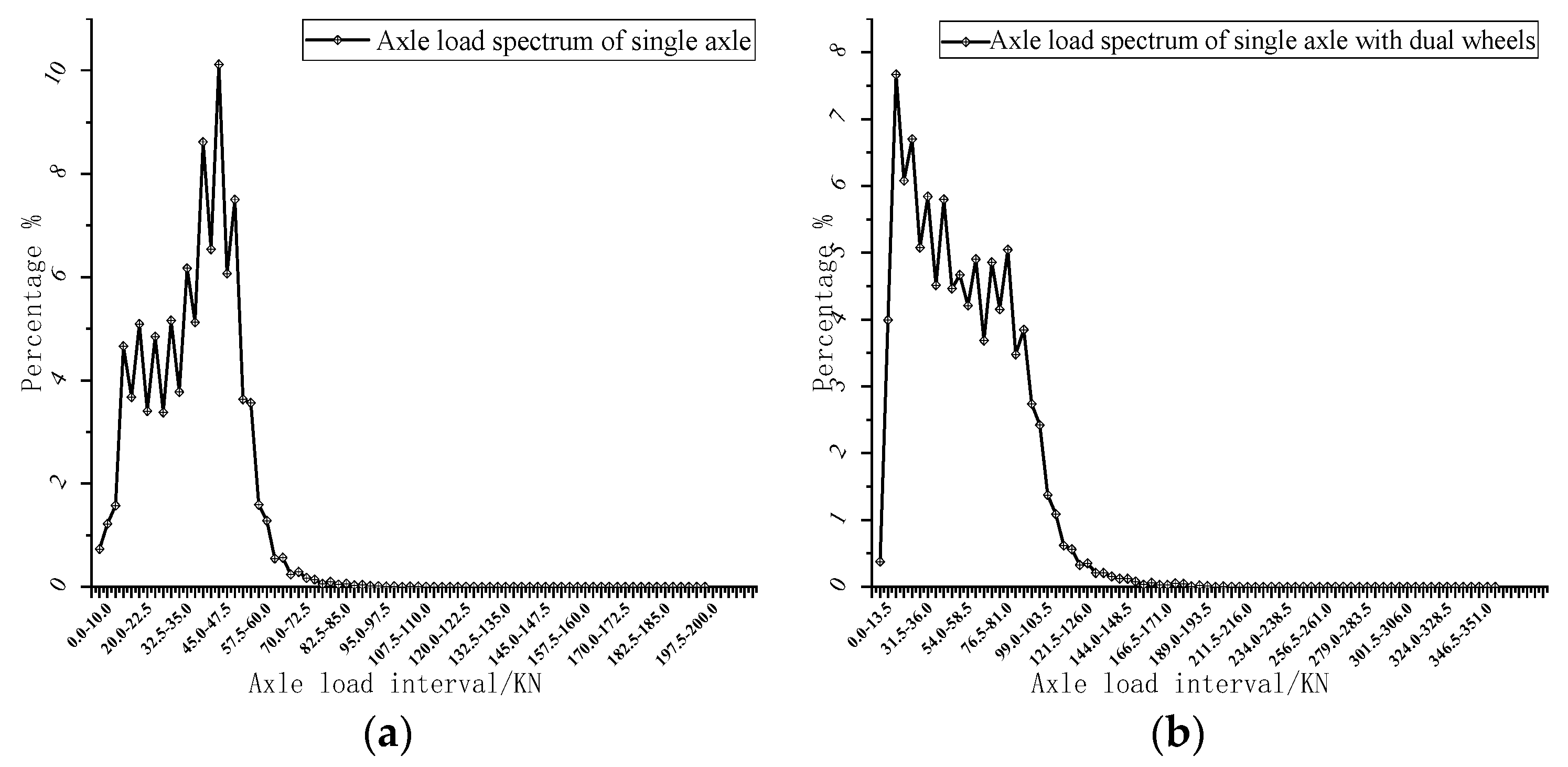

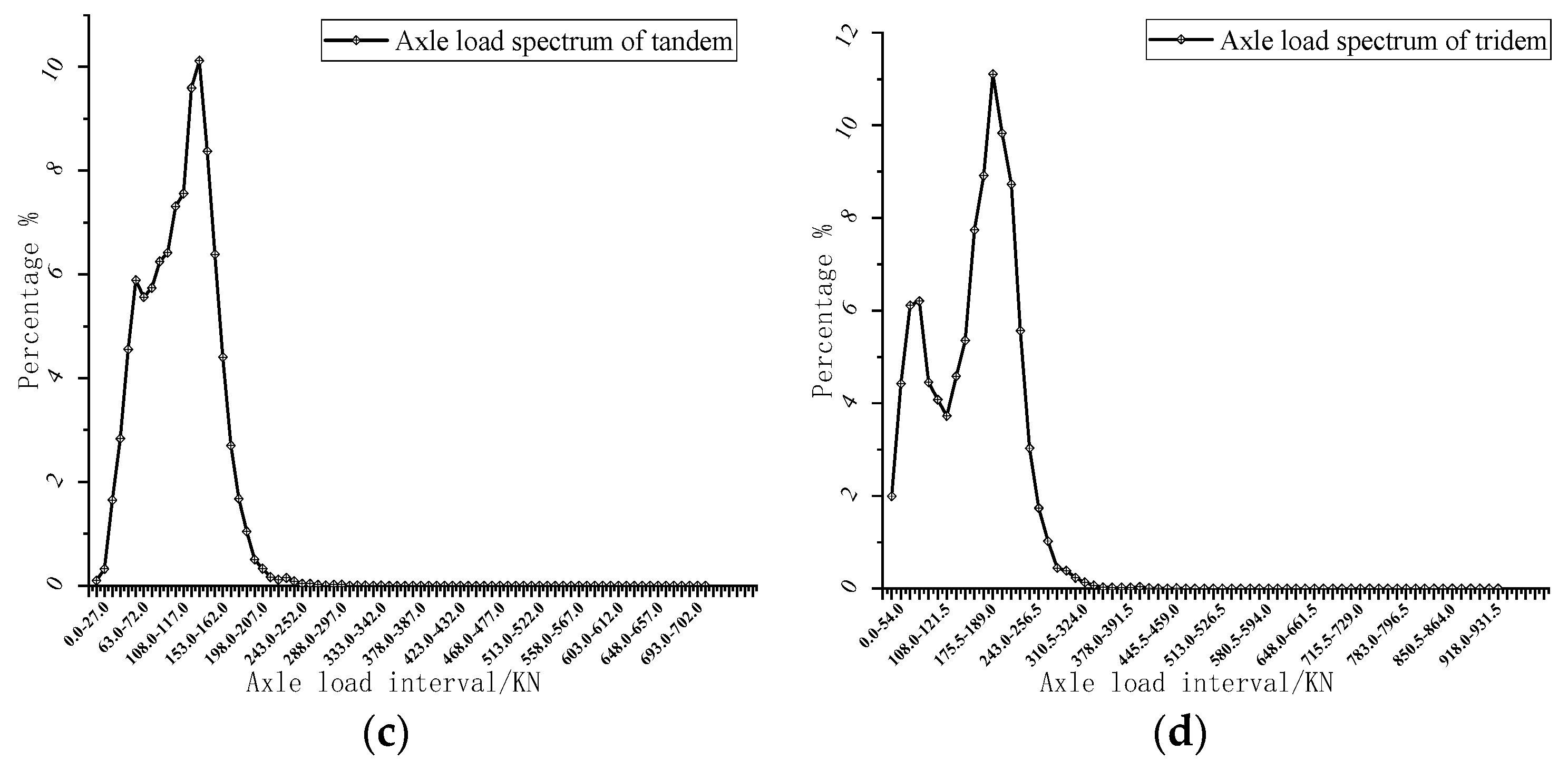

4.1. Axle Load Characterizations

4.1.1. Axle Load Spectra

4.1.2. Equivalent Standard Axle Loads

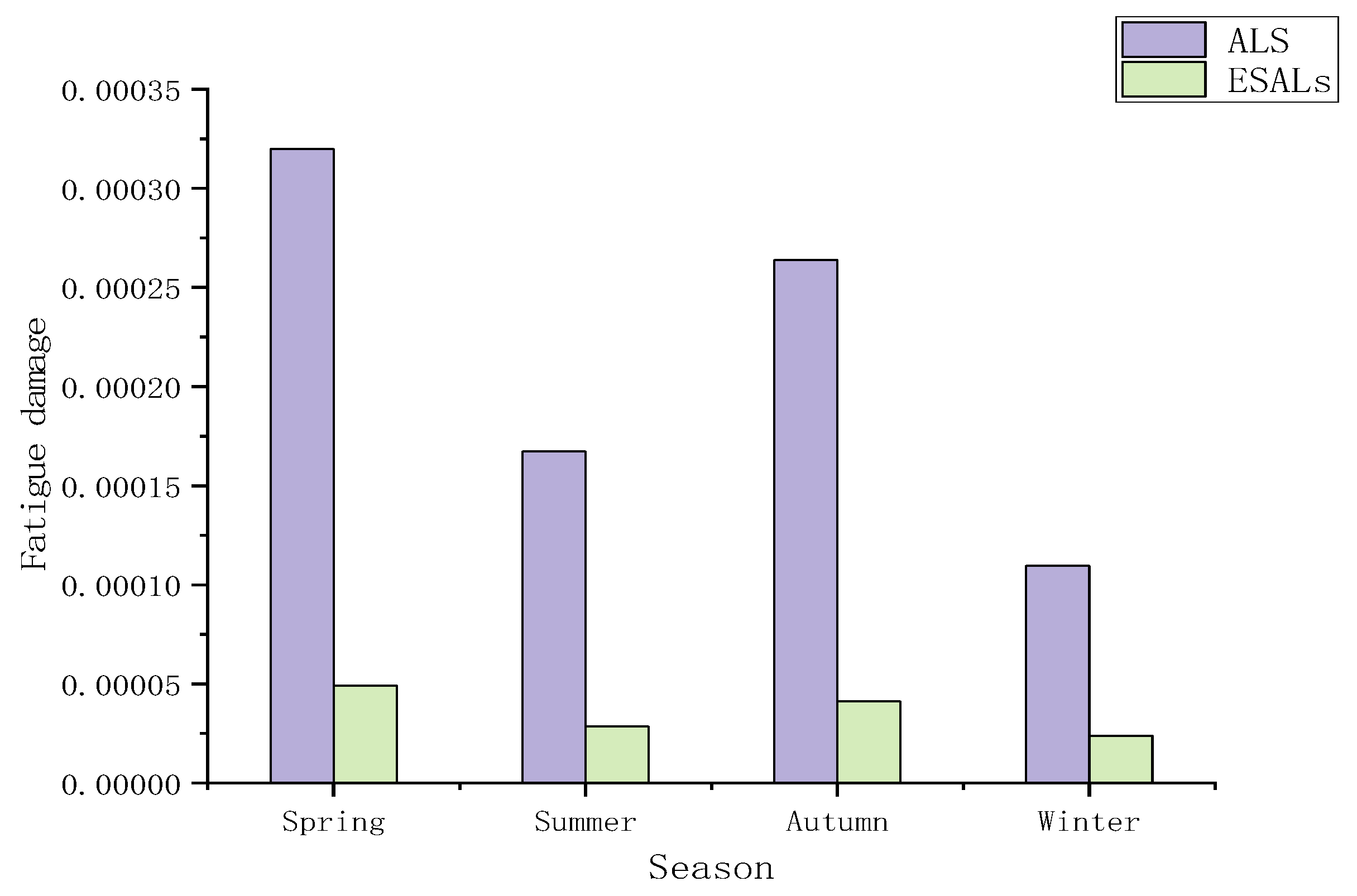

4.2. Fatigue Damage Analysis

4.2.1. Fatigue Damage for a Single Vehicle

4.2.2. Fatigue Damage for a Single Month with Consistent Temperature

4.2.3. Fatigue Damage for One Year with Seasonal Average Temperature

5. Conclusions

- (1)

- The axle load spectrum provides a more intuitive reflection of traffic load information. In 2022, the main vehicle types on this expressway were Type 3 and Type 9, and no Type 5 or Type 11 vehicles were observed. The main axle load ranges for single axle, single axle with dual wheels, tandem, and tridem are, respectively, 35–52.5 kN, 18–67.5 kN, 54–162 kN, and 54–243 kN.

- (2)

- In the fatigue damage calculations for a single vehicle, a single month, and one year, the results consistently indicate that the ESALs method underestimates pavement fatigue damage compared to the ALS method by approximately 6.05 times. The ALS method directly computed fatigue damage using the axle load spectrum and subsequently accumulated the data, without the need for conversion to equivalent standard axle load. This characteristic renders the fatigue damage data calculated from the ALS method more reliable and precise.

- (3)

- By employing the ALS method to calculate fatigue damage while simultaneously considering seasonal temperature variations, more detailed information which is consistent with actual pavement service conditions can be obtained. This will be helpful to improve pavement structure design decisions.

- (4)

- Due to the limited availability of data, more pavement structure and material types and different fatigue models will be necessary to verify the differences in the fatigue damage results obtained between the two methods in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lv, W. Principles and Methods of Asphalt Mixture Design. Master’s Thesis, Tongji University Press, Shanghai, China, 2001. [Google Scholar]

- Wu, Y.; Cheng, Y.; Zeng, D.; Xu, Y. Study on fatigue life of semi-flexible pavement materials. Zhongwai Highw. 2021, 41, 313–318. [Google Scholar]

- Zhang, N.; Wu, G. Mechanical Response Analysis of Interlayer Adhesion of Asphalt Pavement Considering Temperature Influence. Highway 2020, 65, 6. [Google Scholar]

- Bao, C. Mechanical Response Analysis of Semi-Rigid Base Asphalt Pavement Under Heavy Load. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2019. [Google Scholar]

- Guo, N.; Zhao, Y.; Yu, Y. Fatigue life calculation of polyester fiber asphalt concrete pavement. J. Shenyang Jianzhu Univ. Nat. Sci. Ed. 2005, 21, 4. [Google Scholar]

- Yin, X.; Huang, H.; Zhang, J.; Can, Z. Statistical analysis of vehicle axle load on a certain highway and its impact on bridge deck. Chin. Sci. Technol. Pap. 2015, 4. [Google Scholar]

- Hveem, F.N. Pavement Deflections and Fatigue Failures. Highw. Res. Board Bull. 1955, 43–87. [Google Scholar]

- Zaghloul, S.; White, T.D. Load Equivalency Factors for Asphalt Pavements (With Discussion). J. Assoc. Asph. Paving Technol. 1994, 63, 481–510. [Google Scholar]

- Hallin, J.; Hein, D.; Popik, M. Input Requirements for The AASHTO 2002 Guide for New and Rehabilitated Pavement Structures. In Proceedings of the Transportation: From Vision to Reality Conference & Exhibition of the Transportation Association of Canada, Ottawa, ON, Canada, 15–18 September 2002. [Google Scholar]

- Ma, L.; Ge, Z.; Hu, X.; Huang, M. Analysis of fatigue damage of asphalt pavement based on predicted axle load spectrum. Sci. Technol. Eng. 2011, 11, 4506–4508. [Google Scholar]

- Prowell, B.D. Estimate of fatigue shift factors between laboratory tests and field performance. Transp. Res. Rec. 2010, 2181, 117–124. [Google Scholar] [CrossRef]

- Li, Q.; Ni, F.; Li, G. Axle load conversion method for asphalt pavement based on equivalent rutting. J. Transp. Eng. Inf. 2013, 11, 63–70. [Google Scholar]

- Bai, B. Research on Axle Load Analysis and Fatigue Life Prediction of Asphalt Pavement on Highways. Ph.D. Thesis, Changsha University of Technology, Changsha, China, 2017. [Google Scholar]

- Wang, B. Research on Fatigue Behavior of Asphalt Pavement under Vehicle Load. Ph.D. Thesis, Chang’an University, Chang’an, China, 2008. [Google Scholar]

- Chen, S.; Yu, J.; Ren, W.; Liu, Y.; Zhang, X. Research on axle load conversion of flexible base asphalt pavement based on fatigue equivalence. J. Wuhan Univ. Technol. (Transp. Sci. Eng. Ed.) 2010, 34, 762–764+768. [Google Scholar]

- Xu, J.P.; Zhao, Y.; Liang, N.X.; Qin, M. Prediction of service life of high modulus asphalt pavement based on fatigue cumulative damage. J. Chang. Univ. (Nat. Sci. Ed.) 2018, 38, 26–33. [Google Scholar] [CrossRef]

- Zhang, N. Study on Fatigue Life of Asphalt Pavement under the Combined Effects of Vehicle and Temperature. Ph.D. Thesis, Chongqing Jiaotong University, Chongqing, China, 2021. [Google Scholar] [CrossRef]

- JTG D50-2017; Specifications for Design of Highway Asphalt Pavement. China Communications Press Co., Ltd.: Beijing, China, 2017.

- Xie, S. Research on Refinement of Asphalt Pavement Axle Load Conversion Coefficient Based on Tested Axle Load Spectra. Master’s. Thesis, Xiangtan University, Xiangtan, China, 2018. [Google Scholar]

- Gao, X.; Fan, J.; Shen, Q.; Chen, F.; Zhu, Y. Optimization of asphalt pavement axle load parameters and structural life prediction based on measured axle load spectra. Highway 2022, 67, 1–8. [Google Scholar]

- Zhao, Y.; Zhang, Z.; Zhu, Y. Road axle load spectrum analysis using old vehicle types under new regulations. J. Chongqing Jiaotong Univ. (Nat. Sci. Ed.) 2021, 40, 106–113. [Google Scholar]

- Lin, J.; Fan, J.; Ma, T.; Zhu, Y. Optimization of Traffic Load Parameters on Freeways in Fujian Province Based on Axle Load Spectra. Highway 2022, 67, 1–8. [Google Scholar]

- Qiang, L.I.; Xiao, D.X.; Wang, K.C.P.; Hall, K.D.; Qiu, Y. Mechanistic-empirical pavement design guide (MEPDG): A bird’s-eye view. J. Mod. Transp. 2011, 19, 114–133. [Google Scholar] [CrossRef]

- Ma, S.; Sun, T. Analysis of typical heavy-duty traffic axle load spectrum parameters and design axle load on highways. Highway 2014, 59, 6. [Google Scholar]

- Bodin, D.; Chupin, O.; Denneman, E. Effect of Temperature and Traffic Speed on the Asphalt Moduli for Fatigue Cracking and Pavement Structural Design Considerations. In Proceedings of the RILEM International Conference on Mechanisms of Cracking and Debonding in Pavements, Nantes, France, 7–9 June 2016. [Google Scholar]

- Haider, S.W.; Musunuru, G. Differences in Predicted Flexible Pavement Performance Using the AASHTOWare Pavement-ME—ESALs versus Axle Load Spectra. In Proceedings of the International Airfield and Highway Pavements Conference 2019, Chicago, IL, USA, 21–24 July 2019. [Google Scholar]

- Dinegdae, Y.H.; Birgisson, B. Effect of Heavy Traffic Loading on Predicted Pavement Fatigue Life. In Proceedings of the RILEM International Conference on Mechanisms of Cracking and Debonding in Pavements, Nantes, France, 7–9 June 2016. [Google Scholar]

- Hu, S.; Zhou, F.; Scullion, T. Load Spectra–Incorporated Fatigue Cracking Model Implementation and Case Study. Transp. Res. Rec. J. Transp. Res. Board 2017, 2640, 1–10. [Google Scholar] [CrossRef]

- Wei, L.; Kayser, S.; Wellner, F. Impact of Surface Temperature on Fatigue Damage in Asphalt Pavement. J. Highw. Transp. Res. Dev. 2013, 7, 1–6. [Google Scholar] [CrossRef]

| Structure Layer | Thickness (mm) | Spring Temperature (°C) | Modulus (Mpa) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Spring | Summer | Autumn | Winter | Spring | Summer | Autumn | Winter | ||

| SMA-13 | 40 | 25 | 39.5 | 25 | 3.5 | 6803 | 3497 | 6803 | 25,178 |

| AC-20 | 60 | 24 | 38.5 | 25 | 3.5 | 7273 | 4312 | 7033 | 26,413 |

| AC-25 | 80 | 22 | 35.5 | 25 | 3 | 8051 | 5221 | 7311 | 29,234 |

| LSPM-30 | 160 | 20 | 32.5 | 24.5 | 3.5 | 9366 | 4689 | 8052 | 17,779 |

| Cement-stabilized gravel | 180 | 20 | 33 | 24.5 | 3.5 | 20,188 | 20,188 | 20,188 | 20,188 |

| Graded crushed stone | 120 | 20 | 34 | 24 | 3.5 | 397 | 397 | 397 | 397 |

| Cement-stabilized soil | 200 | - | - | - | - | 219 | 219 | 219 | 219 |

| Subgrade | - | - | - | - | - | 67 | 67 | 67 | 67 |

| Temperature | Axle Load Characterization | Calculation Period | |

|---|---|---|---|

| Calculation plan 1 | 20 °C | True axle weight | Single vehicle |

| Calculation plan 2 | 20 °C | Equivalent axle load | Single vehicle |

| Calculation plan 3 | 20 °C | Axle load spectra | Single vehicle |

| Calculation plan 4 | 20 °C | Equivalent axle load | Single month |

| Calculation plan 5 | 20 °C | Axle load spectra | Single month |

| Calculation plan 6 | 20 °C | Equivalent axle load | One year |

| Calculation plan 7 | Seasonal average temperature | Axle load spectra | One year |

| Vehicle Type | Type 2 | Type 3 | Type 4 | Type 5 | Type 6 | Type 7 | Type 8 | Type 9 | Type 10 | Type 11 |

|---|---|---|---|---|---|---|---|---|---|---|

| Percentage (%) | 5.37 | 42.64 | 1.08 | 0 | 10.38 | 1.59 | 1.74 | 36.19 | 1.02 | 0 |

| Single Type 9 Vehicle | May | One Year | ||||

|---|---|---|---|---|---|---|

| Vehicle Type | Conversion Factor | Equivalent Standard Axle Load | Conversion Factor | Equivalent Standard Axle Load | Conversion Factor | Equivalent Standard Axle Load |

| Type 2 | 0 | 0 | 0.4250598 | 377 | 0.4615916 | 7856 |

| Type 3 | 0 | 0 | 0.413126 | 4419 | 0.671119 | 89,735 |

| Type 4 | 0 | 0 | 0.608845 | 114 | 1.634905 | 5419 |

| Type 5 | 0 | 0 | 0 | 0 | 0 | 0 |

| Type 6 | 0 | 0 | 1.352112 | 5517 | 1.428105 | 45,554 |

| Type7 | 0 | 0 | 0.718297 | 277 | 0.726937 | 3720 |

| Type8 | 0 | 0 | 0.80403 | 786 | 0.687984 | 3935 |

| Type 9 | 1 | 1.00 | 0.982791 | 15,768 | 0.919555 | 102,725 |

| Type 10 | 0 | 0 | 1.183736 | 662 | 0.965951 | 3120 |

| Type 11 | - | 1 | - | 0 | 0 | 0 |

| Total | 1 | 27,920 | 262,064 | |||

| Measured Axle Load | ASL | ESALs | |||||

|---|---|---|---|---|---|---|---|

| Axis Type | Type 1 | Type 5 | Type 7 | Type 1 | Type 5 | Type 7 | Equivalent Standard Axle Load |

| Axle load (kN) | 50 | 120 | 180 | 48.75 | 121.5 | 182.25 | 100 |

| ) | 10.76 | 20.59 | 28.25 | 10.45 | 21.09 | 28.92 | 18.79 |

| Fatigue life | 3.91 × 109 | 2.98 × 108 | 8.48 × 107 | 4.40 × 109 | 2.71 × 108 | 7.73 × 107 | 4.28 × 108 |

| Fatigue damage | 2.55 × 10−10 | 3.36 × 10−9 | 1.18 × 10−8 | 2.27 × 10−10 | 3.70 × 10−9 | 1.29 × 10−8 | 2.34 × 10−9 |

| Accumulated fatigue damage | 1.54 × 10−8 | 1.69 × 10−8 | 2.34 × 10−9 | ||||

| Fatigue Damage | ALS Method | ESALs Method | |||

|---|---|---|---|---|---|

| Axis Type | Single Axle | Single Axle Dual Wheels | Tandem | Tridem | Equivalent Axis |

| Fatigue damage with four axle types | 1.50 × 10−6 | 2.72 × 10−7 | 2.46 × 10−5 | 6.19 × 10−5 | 1.50 × 10−5 |

| Accumulated fatigue damage | 9.07 × 10−5 | 1.50 × 10−5 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Han, W.; Jiang, W.; Cui, T.; Wang, S.; Yang, F.; Wei, J. Fatigue Damage in Asphalt Pavement Based on Axle Load Spectrum and Seasonal Temperature. Coatings 2024, 14, 882. https://doi.org/10.3390/coatings14070882

Zhang W, Han W, Jiang W, Cui T, Wang S, Yang F, Wei J. Fatigue Damage in Asphalt Pavement Based on Axle Load Spectrum and Seasonal Temperature. Coatings. 2024; 14(7):882. https://doi.org/10.3390/coatings14070882

Chicago/Turabian StyleZhang, Wenwu, Wenyang Han, Wenqing Jiang, Ting Cui, Shanshan Wang, Fei Yang, and Jincheng Wei. 2024. "Fatigue Damage in Asphalt Pavement Based on Axle Load Spectrum and Seasonal Temperature" Coatings 14, no. 7: 882. https://doi.org/10.3390/coatings14070882