Abstract

The microstructures and structures of modified Al2O3/IF-WS2 coatings prepared on aluminum substrates are studied. Amorphous Al2O3 oxide coatings are obtained on EN AW 5251 aluminum alloy using the electrooxidation process. The quality of the IF-WS2 nanopowder is of great importance in the process of its introduction into the nanopores of the Al2O3 oxide coating. Commercial nanopowder tends to agglomerate, and without appropriate pretreatment, it is difficult to introduce it into the nanopores of the coating. To improve the degree of fragmentation of the IF-WS2 nanopowder, an experiment was carried out to distribute the nanopowder in the presence of strong ultrasounds, and new conditions for introducing the powder into the nanopores were used. A two-level design of experiment (DOE) was used. The SEM examination made it possible to conclude that Method A contributed to a more even distribution of nanoparticles in the microstructure of Al2O3 coatings. GIXD analyses showed the presence of WO3 derived from the IF-WS2 modifier next to crystal structures derived from aluminum and WS2. Modification of coatings using Method A resulted in surfaces with lower contact angles measured with polar liquids and higher surface free energy compared to Method B.

1. Introduction

High-strength aluminum alloys are widely used in various branches of the machinery, automotive, and aerospace industries, mainly due to their exceptional weight-dependent mechanical properties. The most frequently used alloy additives in the production of aluminum alloys are Cu, Si, Mg, Mn, and Zn. These elements influence the strength and corrosion resistance properties of aluminum alloys in different ways. For example, alloys of the 3xxx–6xxx series (i.e., the addition of Mn, Si, Mg, Mg + Si, respectively) are resistant to corrosion, while alloys of the 7xxx series (i.e., the addition of Zn + Mg) are characterized by the highest strength of all aluminum alloys, with low corrosion resistance [1]. Alloys that are also worthy of special attention are alloys containing 2 ÷ 5% Mg and 0.1 ÷ 0.4% Mn (e.g., EN AW-5251), which are characterized by good corrosion resistance, high plasticity, and weldability. An additional advantage of these alloys is the low content of intermetallic phases, which increases the susceptibility to anodic oxidation. Without proper preparation, the surface of aluminum or its alloys is also exposed to adhesive wear due to friction. One well-known method that provides adequate corrosion protection and significantly improves surface properties is anodizing. This process, which depends on many parameters (e.g., voltage or temperature, electrolyte composition, the nature of the anodized substrate, and additional technological treatments before and after anodizing), is complex and multidisciplinary [2,3]. Research on the anodizing process of aluminum and its alloys has been ongoing for over 100 years and continues to be a current research trend, largely due to the potential for producing aluminum and its alloys from recycled sources, which is expected to significantly contribute to the reduction of CO2 emissions [4]. Matijosius et al. demonstrated in their studies that the phase of anodic Al2O3 depends on the method of its formation, composition, and the nature of the substrate [5]. As demonstrated by Elkilany et al., intermetallic phases in aluminum alloys influence the growth rate and morphology of anodic coatings. In the oxide coatings formed on Al 2014 and 6061 alloys, which contained coarse intermetallic phases, significant voids and surface defects were observed. In contrast, the anodic coating formed on the 7075 alloy exhibited greater uniformity and fewer defects due to the presence of fine precipitates [6]. Based on his research, Kchaou concluded that the anodizing time has a noticeable impact on the thickness of the oxide coating. Longer anodizing times resulted in a thicker and harder aluminum oxide coating, which, in his studies, led to an increased coefficient of friction [7]. Benea et al. found that extending the duration of the oxidation process to a constant potential and consequently increasing the thickness of the nanoporous aluminum oxide coatings results in more homogeneous coatings [8]. Dervishi et al. found that the porosity and thickness of the anodic coating depend on the anodizing time and the type of electrolyte. Studies on the porosity of anodic coatings produced in phosphoric acid showed that the porosity of the coatings decreases with increasing anodizing time [9]. Kwolek et al. observed that the nanoscale porosity of the coating on 5005 aluminum alloy changes with the thickness of the coating as a result of increased anodizing voltage, significantly affecting the protective properties of the coatings [10]. As demonstrated by Brudzisz et al., the incorporation of anions during the anodization of metals plays a crucial role in the formation of anodic oxides, affecting the resulting morphology. Additionally, the incorporated anions lead to the emergence of unique features, such as photoluminescence and galvanoluminescence of anodic aluminum oxide. Therefore, anion incorporation is recognized as a method of electrochemical doping of nanostructured anodic oxides, which may advance new applications [11].

In recent decades, considerable attention has been given to various modifications aimed at improving the tribological properties of anodic coatings produced on aluminum alloys. The surface oxide coatings formed in the hard-anodizing process are materials with highly developed surfaces, and their properties can be very diverse, depending mainly on the conditions in which they are produced [12]. It has been found that the porosity of anodic oxide coatings can be utilized as a lubricant reservoir to create self-lubricating systems, reducing friction and wear [13,14]. The primary challenges were often the dimensions of the lubricant powder particles, which exceeded the pore sizes of the oxide coatings. Additionally, it was observed that a reduction in the thickness of the aluminum oxide coating resulted in a decrease in the mechanical strength of the oxide surface. Interest in the aforementioned issue was also raised in studies [15], where authors emphasized that the selection of the dopant substance is not straightforward. In recent years, nanoparticles as lubricant additives have increasingly garnered attention [16,17,18,19,20,21]. The current state of knowledge clearly indicates that nanolubricants can enhance tribological performance and processing efficiency due to their nanoscale characteristics; they minimize friction, wear, and energy consumption, thereby extending the lifespan of components [22]. Tungsten disulfide (WS2), similar to molybdenum disulfide (MoS2) and graphite, belongs to the category of solid lubricants. Transition metal dichalcogenides MS2 (M = Mo, W) and their complexes are part of a large class of so-called two-dimensional or layered materials. Within the layers, atoms are bonded by strong covalent forces, whereas the individual layers are held together by Van der Waals forces [23]. Due to their layered structure and the weak Van der Waals interactions between layers, WS2, MoS2, and graphite are widely used to provide consistent lubrication through a mechanism of exfoliation. MS2 (M = Mo, W) in the form of hollow onion-like nanoparticles (known as IF—inorganic fullerene-like nanostructures) were the first inorganic fullerene-like materials, discovered in 1992 [19]. Subsequent research produced IF with a more uniform, spherical shape to enhance tribological properties [24]. These lubricating substances, often referred to as lubricants, exhibit a low coefficient of friction and excellent lubricating properties, making them highly valued in technical dry sliding friction assemblies. Due to its ability to operate across a wide temperature range and under high pressure (in vacuum up to 1316 °C), WS2 is one of the most effective solid lubricants for reducing friction in sliding components [25,26,27]. For instance, recent studies by Li et al. demonstrate the beneficial impact of graphene addition on the structure, corrosion resistance, and friction properties of coatings prepared by the MAO method on AA1060 aluminum. To prepare the graphene-doped coatings, graphene was dispersed in isopropanol with the aid of ultrasound and then added to the electrolyte in which the coatings were formed [28]. Studies on microtextured anodic coatings doped with nano-MoS2, obtained using ultrasonic impregnation, have been presented by Chen et al. [29]. The significance of methods for preparing homogeneous suspensions containing nanoparticles was demonstrated by Han et al. [30].

Given the wide range of potential applications for tungsten disulfide as a lubricating material, the authors of this work, as well as previous studies, consider it prudent to explore methods for modifying metal surfaces by applying different WS2 deposition conditions. In our recent study, we discussed the issue of nanoparticle agglomeration arising from the quality of nanopowders [31]. Therefore, it appears necessary to explore methods for breaking down agglomerates of modifiers and obtaining a homogeneous suspension to facilitate the incorporation of modifiers into nanoporous oxide coatings. This article presents the results of an experiment aimed at improving the dispersion of inorganic fullerene-like tungsten disulfide (IF-WS2) nanopowder in the presence of strong ultrasonication using novel conditions for introducing the powder into nanopores of Al2O3 coatings. In the article, an attempt was also made to correlate scanning electron microscope (SEM) and grazing angle incidence X-ray diffraction (GIXD) analysis with surface wetting angle measurements and surface tension studies, which has not been found in articles of similar subject matter. The paper employs statistical techniques in the design and analysis of Design of Experiments (DOE) to optimize processes and elucidate the relationships between input variables and measured outcomes. The SEM analysis revealed that Method A facilitated a more uniform dispersion of nanoparticles within the microstructure of the Al2O3 coatings. GIXD analysis identified the presence of WO3, originating from the IF-WS2 modifier, alongside crystalline structures from aluminum and WS2. The modification of coatings via Method A resulted in surfaces exhibiting lower contact angles with polar liquids and higher surface free energy compared to those modified using Method B.

2. Materials and Methods

2.1. Sample Preparation

The material under investigation was an Al2O3/IF-WS2 composite oxide film produced via a two-step process. The first step involved the fabrication of a graded Al2O3 coating on the surface of the European aluminum wrought with magnesium (EN AW-5251) aluminum alloy. Prior to oxidation, the samples underwent sequential etching in a 5% KOH (Avantor Performance Materials Poland S.A., Gliwice, Poland) solution for 45 min, followed by a 10% HNO3 (Avantor Performance Materials Poland S.A., Gliwice, Poland) solution for 10 min, both at room temperature. The oxide film was obtained through the electrochemical oxidation of the aluminum alloy in a ternary solution comprising sulfuric (Avantor Performance Materials Poland S.A., Gliwice, Poland), oxalic (Avantor Performance Materials Poland S.A., Gliwice, Poland), and phthalic acids (Avantor Performance Materials Poland S.A., Gliwice, Poland). The hard-anodizing process was performed at a constant electric charge density of 180 A·min/dm2, using varying current densities and times (Table 1) and a constant temperature of 303 ± 1 K. In the second step of the process, inorganic fullerene-like (IF) tungsten disulfide (WS2) nanoparticles (NPs; NanoMaterials Ltd., Yavne, Israel) were incorporated into the porous alumina coating using two distinct methods:

Table 1.

Conditions for coating formation and WS2 NPs incorporation, based on a two-level factorial design.

- The Al2O3-coated aluminum alloy samples were immersed in a container filled with ethanol containing IF-WS2 NPs at a concentration of 15 g/L. This container was then subjected to sonication using a VCX 130 sonicator (Sonics & Materials Inc., Newtown, CT, USA) operating at a frequency of 20 kHz, delivering 10 kJ of energy to the system. The sonication process lasted for 5 min. Following this, the samples were left undisturbed in the solution for approximately 24 h to allow for natural settling.

- Similar to Method A, the container was initially sonicated under the same conditions. However, in the second step, the container was additionally placed in an ultrasonic bath for 15 min. After this secondary sonication, the samples were removed from the solution.

The key difference between the methods is the additional ultrasonic bath treatment in Method B, which involves a second stage of sonication for 15 min after the initial treatment, while Method A relies solely on the initial sonication and subsequent settling period.

Table 1 presents the conditions for coating formation and nanopowder incorporation based on a two-level factorial design without replication.

2.2. Microscopic Analysis

To analyze the composition of the nanosized Al2O3 fibers containing self-arranged IF-WS2 NPs, the fabricated samples were examined using a HITACHI S-4700 (Hitachi, Tokyo, Japan) scanning electron microscope (SEM) equipped with a NORAN Vantage digital energy dispersive X-ray microanalysis (EDS) system. The surface and cross-section of the Al2O3/IF-WS2 NPs coatings were analyzed using SEM in the secondary electron (BSE) mode with a yttrium aluminum garnet (YAG) detector. The YAG single crystal was employed to minimize electron dose. The cross-section of the Al2O3/IF-WS2 NPs was acquired by fresh fracture. Prior to this analysis, the samples were coated with a thin carbon film using a sputtering apparatus to enhance image contrast and prevent blurring caused by charge accumulation.

2.3. Structural Analysis

Grazing angle incidence X-ray diffraction (GIXD) experiments were conducted using an X’Pert Philips PW 3040/60 diffractometer (PANalytical, Almelo, The Netherlands), operating at 30 mA and 40 kV, equipped with a vertical goniometer and Eulerian cradle. The radiation wavelength (λCuKa) employed was 1.54178 Å. GIXD patterns were recorded within the 2θ range from 20° to 70° with a step size of 0.058 for incident angles of 0.2°, 0.3° 0.5°, and 1.0°. Lower incident angles allow X-rays to penetrate only the surface coatings of the sample, while higher incident angles enable deeper penetration into the sample [32]. To ensure comparable intensities of diffraction lines, the conditions for pattern collection (step size and counting time) were appropriately adjusted.

2.4. Surface Wettability Methodology

The surface wettability of the samples was assessed by measuring the contact angle using the sitting drop method. A video-based goniometer, OCA 15EC (DataPhysics Instruments GmbH, Filderstadt, Germany), was employed for this purpose [33,34]. Measurements were conducted at a constant ambient temperature of about 298 K. Two types of liquids were utilized: a polar liquid (distilled water) and a non-polar liquid (diiodomethane). Ten drops of each liquid were deposited along the length of each sample using a micropipette equipped with an automatic feeder. Following the application of each drop, a photograph was taken and transferred to a computer. The software employed enabled automatic measurement of the contact angle on both the right and left sides of the droplet, which were subsequently averaged. The average values of the angles obtained from the ten drops were utilized to determine the average contact angle for each sample. Two methods were employed to determine surface free energy: the OWRK method (Owens, Wendt, Rabel, and Kaelble) [35], also known as the two-factor method, which is widely used for assessing the surface free energy of solids; and the Wu method [36], also referred to as the harmonic method, which offers an alternative to the OWRK method. In the OWRK method, the surface free energy of the material is divided into two components: dispersive and polar . This approach utilizes equations that incorporate the surface energies of the liquid and solid, as well as the contact angles of the liquid on the solid surface.

The OWRK equation is as follows:

where is the dispersive component of the surface free energy of a solid, is the polar component of the surface free energy of a solid, is the dispersive component of liquid surface free energy, and is the polar component of the liquid surface free energy.

To determine and , the contact angle θ must be measured for at least two liquids with known values of and .

The Wu method, similarly to the OWRK method, divides the surface free energy into two components: dispersive and polar . The difference is in how these components are calculated.

The Wu equation (i.e., the harmonic method) is as follows:

where is the dispersive component of the surface free energy of a solid, is the polar component of the surface free energy of a solid, is the dispersive component of liquid surface free energy, and

is the polar component of the liquid surface free energy.

To apply the Wu method, similar to the OWRK method, it is essential to employ at least two measuring liquids with known dispersive and polar components of surface energy. The Wu method utilizes a harmonic distribution of energy components, offering an alternative approach to analyzing the surface properties of materials.

2.5. Experimental Design

To investigate the impact of input parameters on the contact angle, an experiment based on the 2k factorial design without repetition was conducted using Statistica 13 software. The independent variables chosen for this study were current density (3 and 6 A/dm2) and method (A and B), while the dependent variable was the contact angle. A benchmark analysis of all dependent variables against a factorial design and a two-factor model with interaction was conducted. A Pareto chart was selected due to its efficiency in identifying the factors exerting the greatest influence on the process. This chart is commonly employed to assess the magnitude and significance of effects. In statistical software, the p-value is frequently utilized for interpreting the statistical significance of factors in the process. In the Pareto chart, bars that intersect the reference line (in the current article, p-value = 0.05) are considered statistically significant at the 0.05 level. In statistical analysis, normal probability plots of residuals are utilized to assess whether the residuals of a model (i.e., the differences between observed and predicted values) follow a normal distribution. This is crucial because many statistical techniques, such as linear regression, assume that residuals are normally distributed. If the residuals are normally distributed, the points on the plot should align along a straight line. Deviations from this line may indicate departures from normality [37]. Additionally, marginal mean plots with 95% confidence intervals were utilized to visually represent the statistical analysis of the results. The DOE methodology is discussed in detail in studies [38,39].

3. Results and Discussion

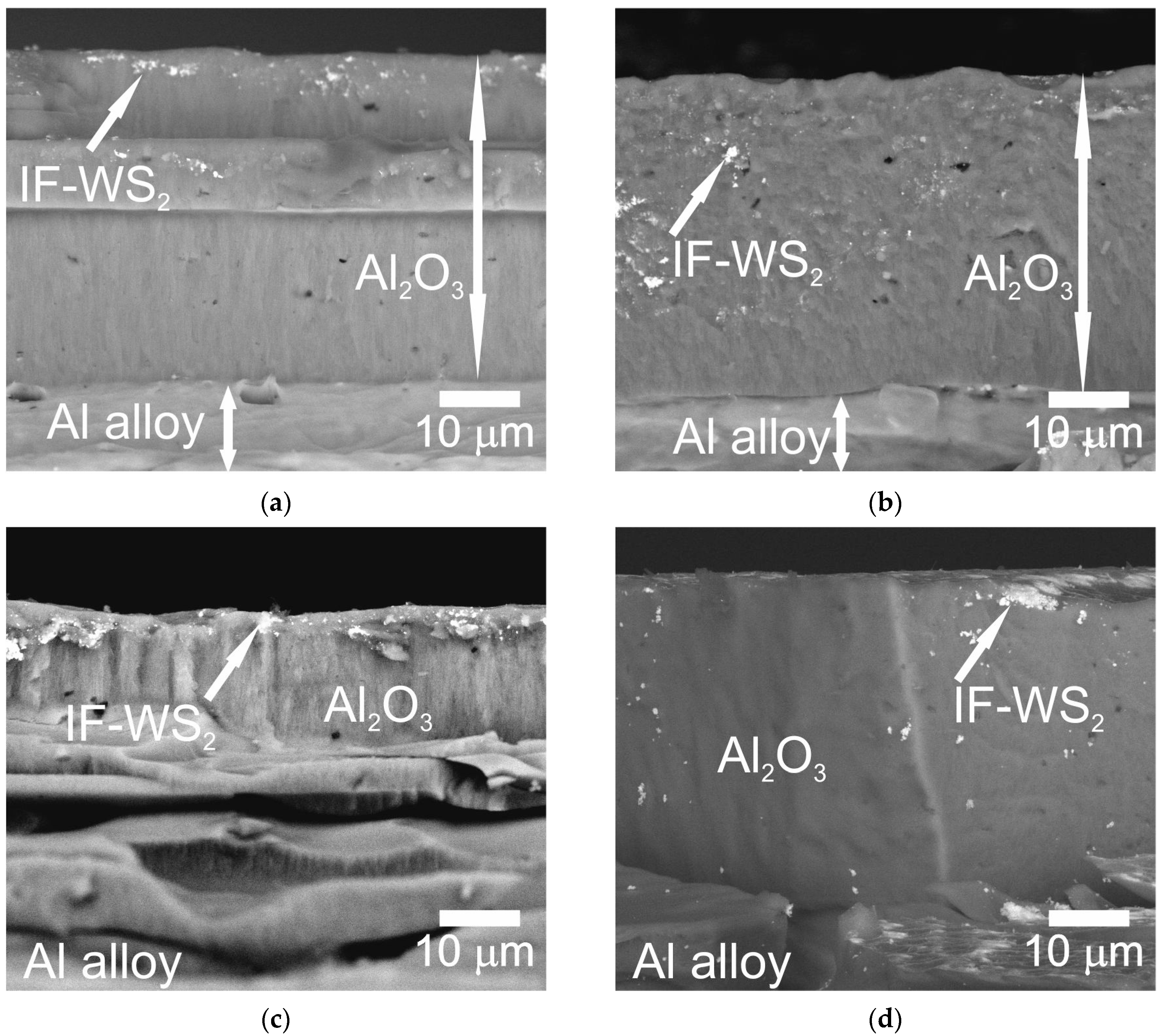

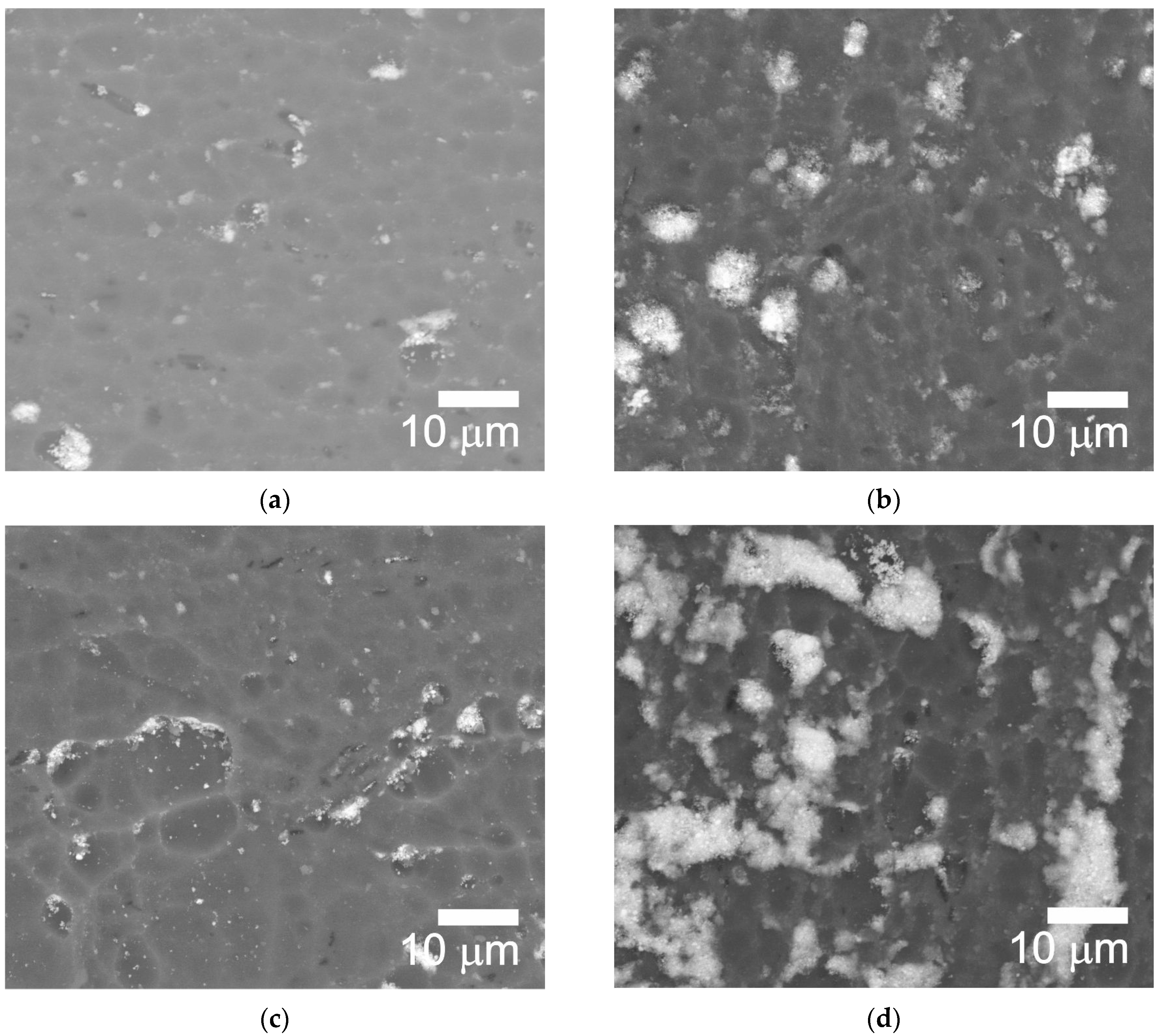

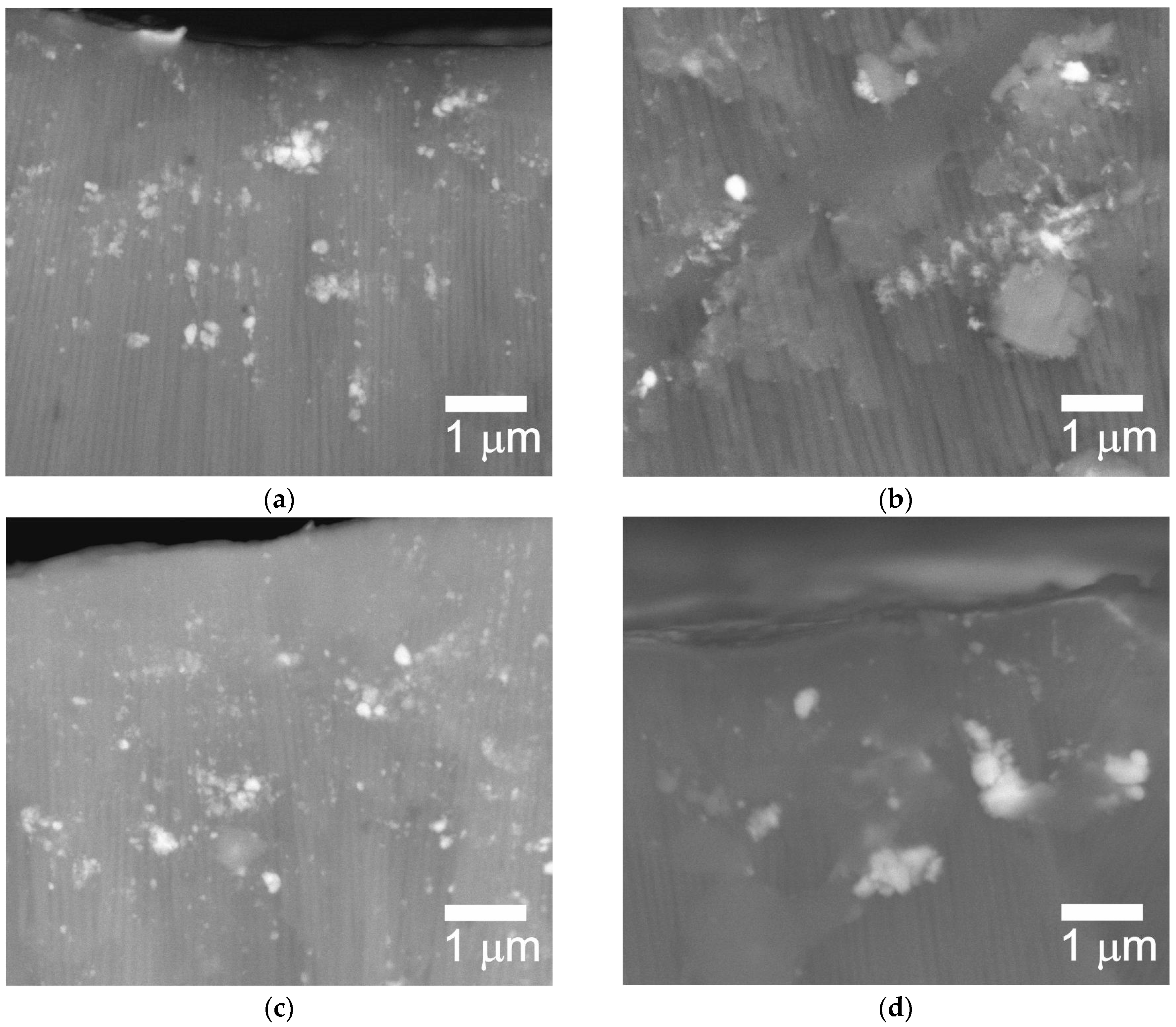

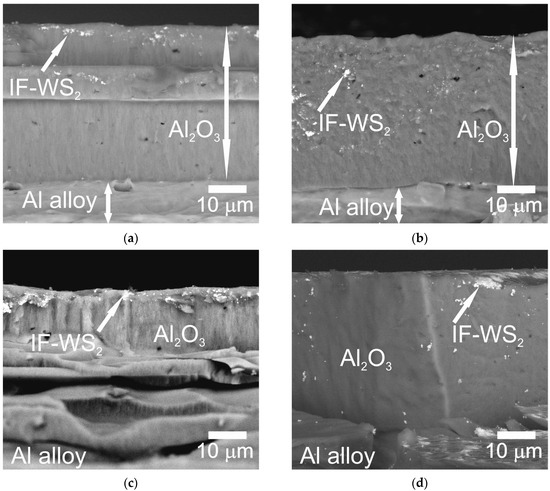

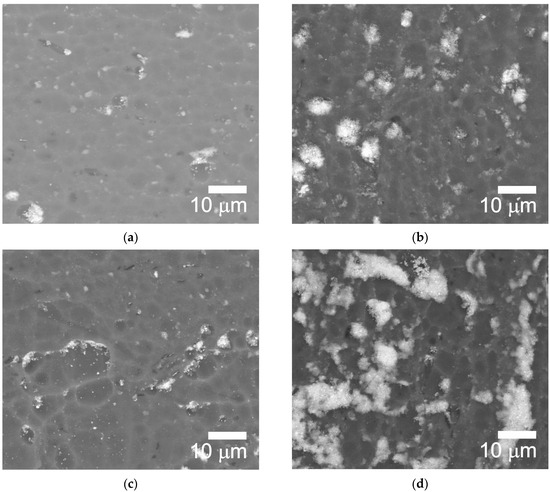

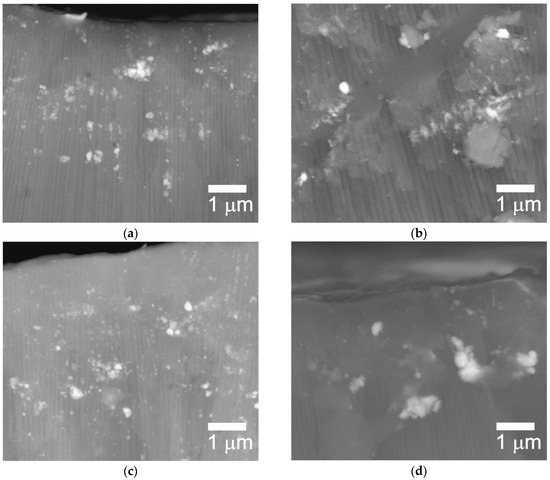

Figure 1a–d shows the SEM/YAG-BSE images (magnification ×1000) of the cross-sections of Al2O3/IF-WS2 coatings from samples 1 to 4. The images highlight the Al2O3 coating, the EN AW 5251 aluminum alloy substrate, and the embedded IF-WS2. In Figure 1c,d, the visible boundary between the coating and the substrate is not marked, as the coating appears delaminated due to the fracturing of the sample. Figure 2a–d shows the SEM/YAG-BSE images (magnification ×1000) of the surface of an Al2O3/IF-WS2 coatings from samples 1 to 4. In our view, the free settling of NPs in Method A (Figure 2a,c) results in better dispersion of the NPs across the surface, with fewer agglomerations of IF-WS2 NPs forming within the spherical indentations of the coating compared to Method B (Figure 2b,d). The free settling method also allows for more uniform incorporation of the IF-WS2 NPs into the upper coating of the coating (Figure 1a,c). In contrast, Method B (Figure 1b,d), which involves the introduction of NPs using an ultrasonic bath, likely facilitates the penetration of the NPs deeper into the coating. This effect is particularly evident for coatings obtained at a current density of 3 A/dm2 (Figure 1b).

Figure 1.

Microstructures (×1000) of the fresh cross-section of the Al2O3/IF-WS2 coatings: (a) sample 1—Method A; (b) sample 2—Method B; (c) sample 3—Method A; and (d) sample 4—Method B.

Figure 2.

Microstructures (×1000) of the surface of the Al2O3/IF-WS2 coatings: (a) sample 1—Method A; (b) sample 2—Method B; (c) sample 3—Method A; and (d) sample 4—Method B.

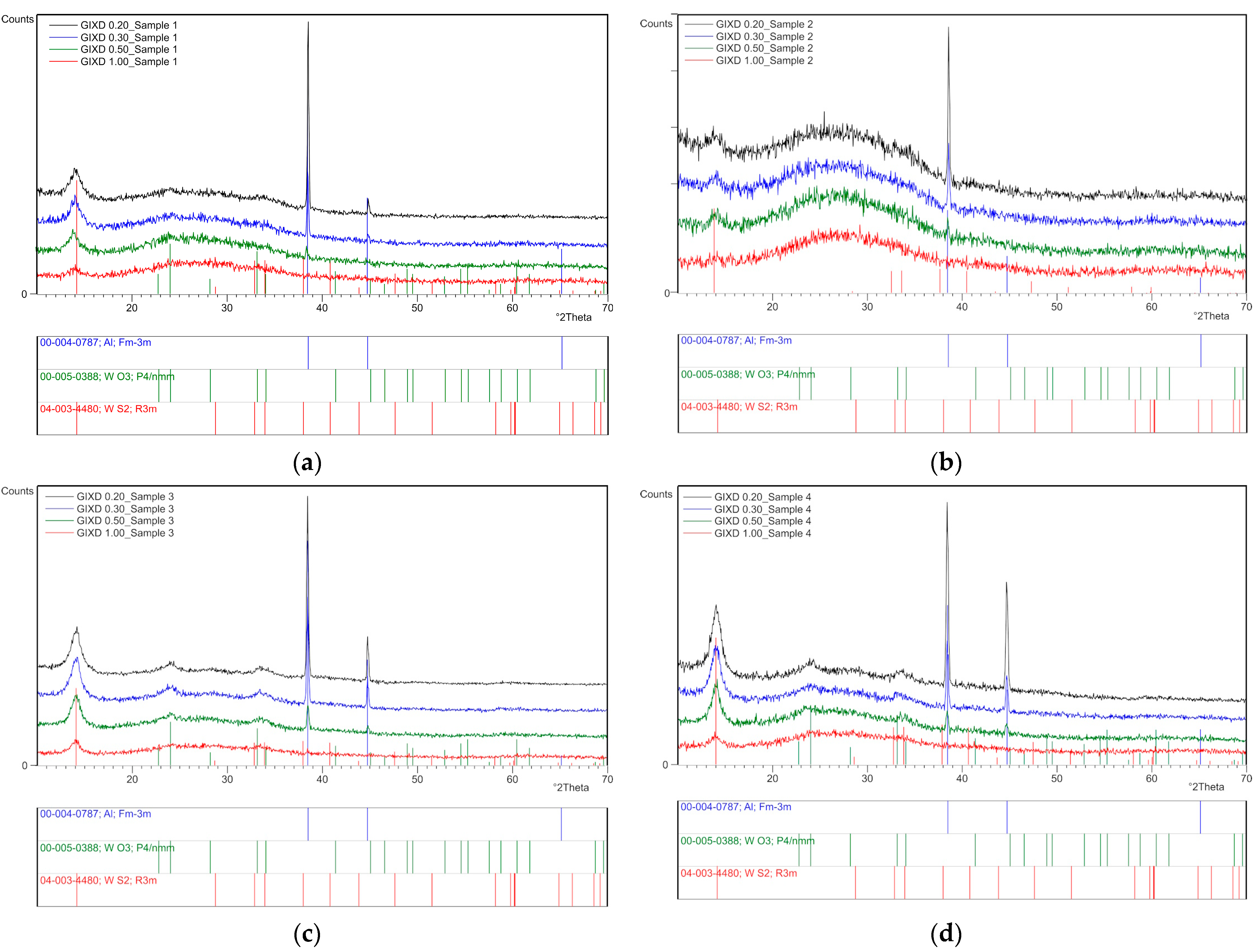

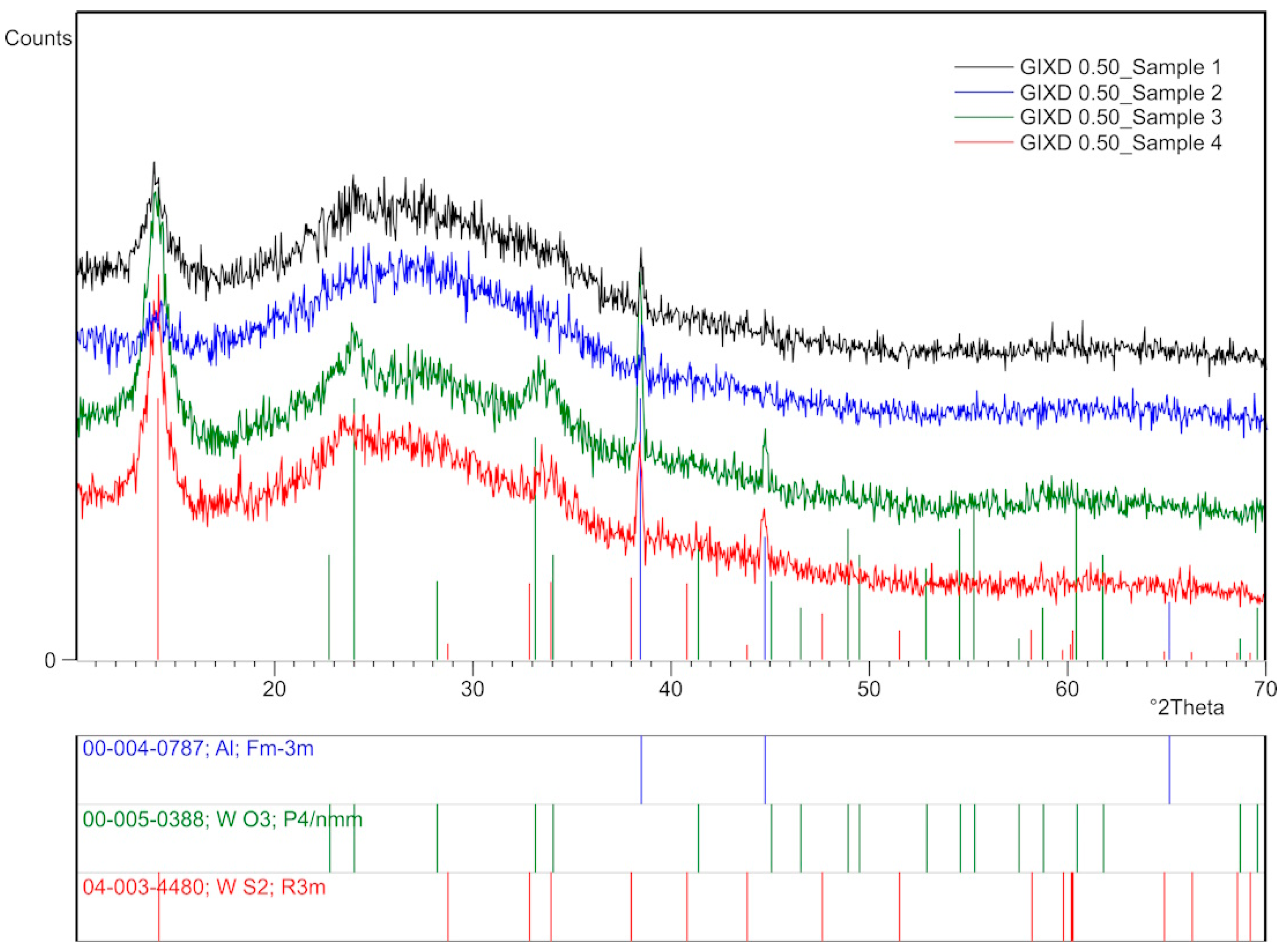

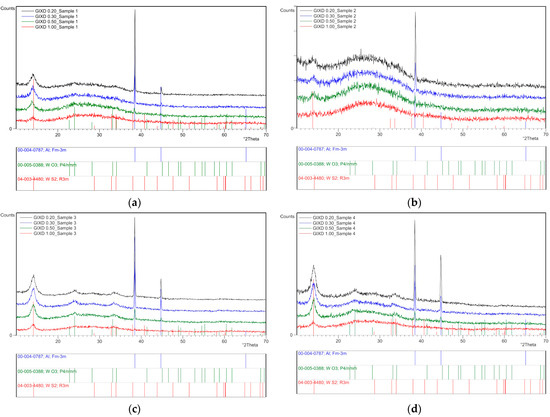

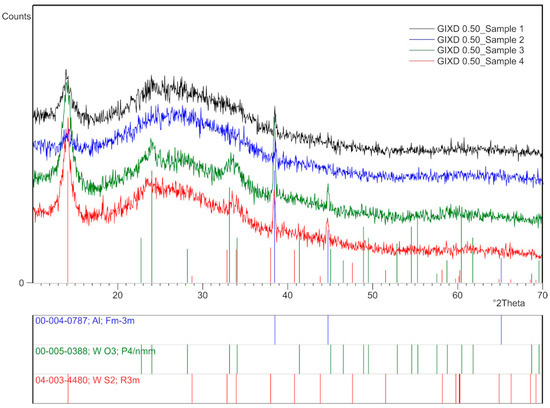

The GIXD spectra of the Al2O3/IF-WS2 composite coatings for samples 1–4 are presented in Figure 3a–d. The analysis of GIXD diffraction patterns obtained in this study indicates that the polycrystalline structure with a cubic phase consists of aluminum coatings, with the (111) and (200) planes corresponding to peaks at 38.08° 2θ and 44.03° 2θ, respectively, in agreement with JCPDS PDF 5 004-0787. The detection of the crystalline aluminum phase is most likely due to the glancing interaction of the beam with the surface of the coating, leading to its contact with the edges of the cross-sectioned sample, where substrate material may be present. Alternatively, this effect could be caused by chips from the substrate introduced during the cutting of samples for GIXD analysis. Furthermore, the presence of the rhombohedral phase of WS2 modifier (JCPDS PDF 5 04-003-4480) and the tetragonal phase of WO3 (JCPDS PDF 5 005-0388) were detected. The observed X-ray “amorphous halo” suggests that a portion of the material exists in an amorphous state, corroborated by a broad peak centered at 28° 2θ, indicative of the amorphous Al2O3 oxide coating. A detailed examination of the diffraction patterns revealed variations in the contributions of crystalline and amorphous phases as the beam angle (α) increases. At the smallest angle of α = 0.20°, corresponding to the surface coating, the crystalline phases (Al and WS2) dominate. With an increase in the beam angle to α = 1.00°, the amorphous phase becomes more pronounced. Based on diffraction analysis obtained by the GIXD method, it was found that the obtained material has a layered structure, where the upper zone is a mixture of amorphous, two crystalline phases, and the WO3 phase in two cases. In the deeper layers, for the beam angle of α = 1.00°, the zone is the amorphous phase and WS2. The reduced frequency of diffraction lines originating from WS2 is likely due to a diminished concentration of WS2 in the lower regions, approaching the detection limit of the method. It is important to emphasize that identifying the amorphous phase in the X-ray analysis encompasses materials lacking long-range order and nanocrystalline materials where the crystallites do not exceed 3–4 nm in size.

Figure 3.

GIXD data of Al2O3/IF-WS2 coatings: (a) sample 1—Method A; (b) sample 2—Method B; (c) sample 3—Method A; and (d) sample 4—Method B.

Figure 4 shows the summary of GIXD diffractograms obtained at an incidence angle of 0.50° for all samples. It can be observed that the highest reflections originating from the WO3 phase are present in samples 3 and 4. The formation of WO3 from WS2 is most likely associated with the high energy during the dispersion of WS2 in a sonicator. Other methods for synthesizing WO3 were cited in Pragati’s work [40], including Mandal’s study, in which water-dispersed WO3 was prepared from commercial WS2 powder [41].

Figure 4.

GIXD data of Al2O3/IF-WS2 coatings for all samples at the beam angle of α = 0.50°.

Figure 5a–d shows the SEM/YAG-BSE micrographs (magnification ×10,000) of the cross-sections of Al2O3/IF-WS2 coatings from samples 1 to 4. In samples obtained by both methods, the Al2O3 nanofibers with IF-WS2 nanoparticles dispersed between them are visible. A detailed examination of the fresh cross-sections of the coatings shown in Figure 5a,c reveals that the IF-WS2 nanoparticles, visible as bright spots, are uniformly distributed within the near-surface coating of the porous alumina coating produced using Method A. In contrast, the distribution of the IF nanoparticles differs significantly in the samples prepared by Method B, as depicted in Figure 5b,c. In these samples, large agglomerates are evident on the coating’s surface, with some penetrating deeply into the voids of the porous film, which is more clearly illustrated in Figure 1b,d.

Figure 5.

Microstructures (×10,000) of the fresh cross-section of the Al2O3/IF-WS2 coatings: (a) sample 1—Method A; (b) sample 2—Method B; (c) sample 3—Method A; and (d) sample 4—Method B.

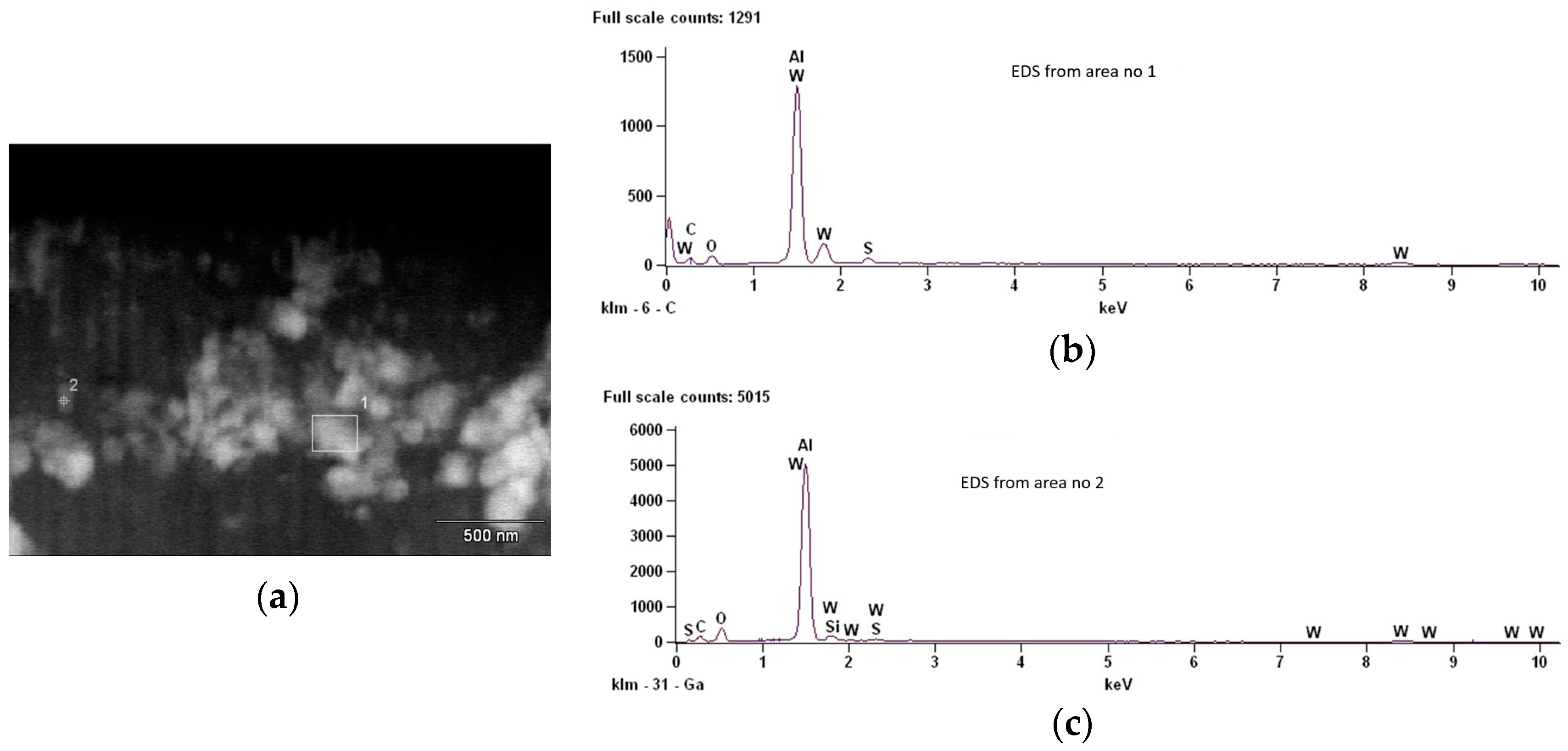

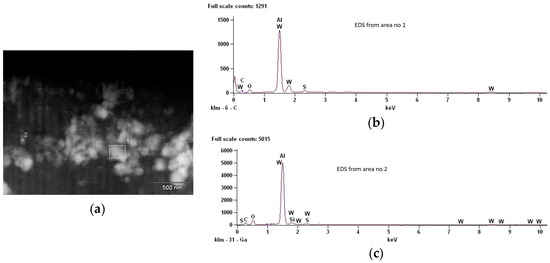

EDS analysis was performed at the points labeled 1 and 2 in Figure 6. The results are summarized in Table 2. The “Atom %” column indicates the atomic percentage (at%) of each element, while the “Compnd %” column represents the weight percentage (wt%). The chemical composition of the coating was determined by identifying and quantifying the elements present in the selected regions, with the results expressed in terms of their respective compound formulas.

Figure 6.

(a) SEM/YAG-BSE of a fresh fracture cross-section with a marked area of EDS analysis; (b) EDS from area no 1; and (c) EDS from area no 2.

Table 2.

Quantitative results for EDS from areas number 1 and 2.

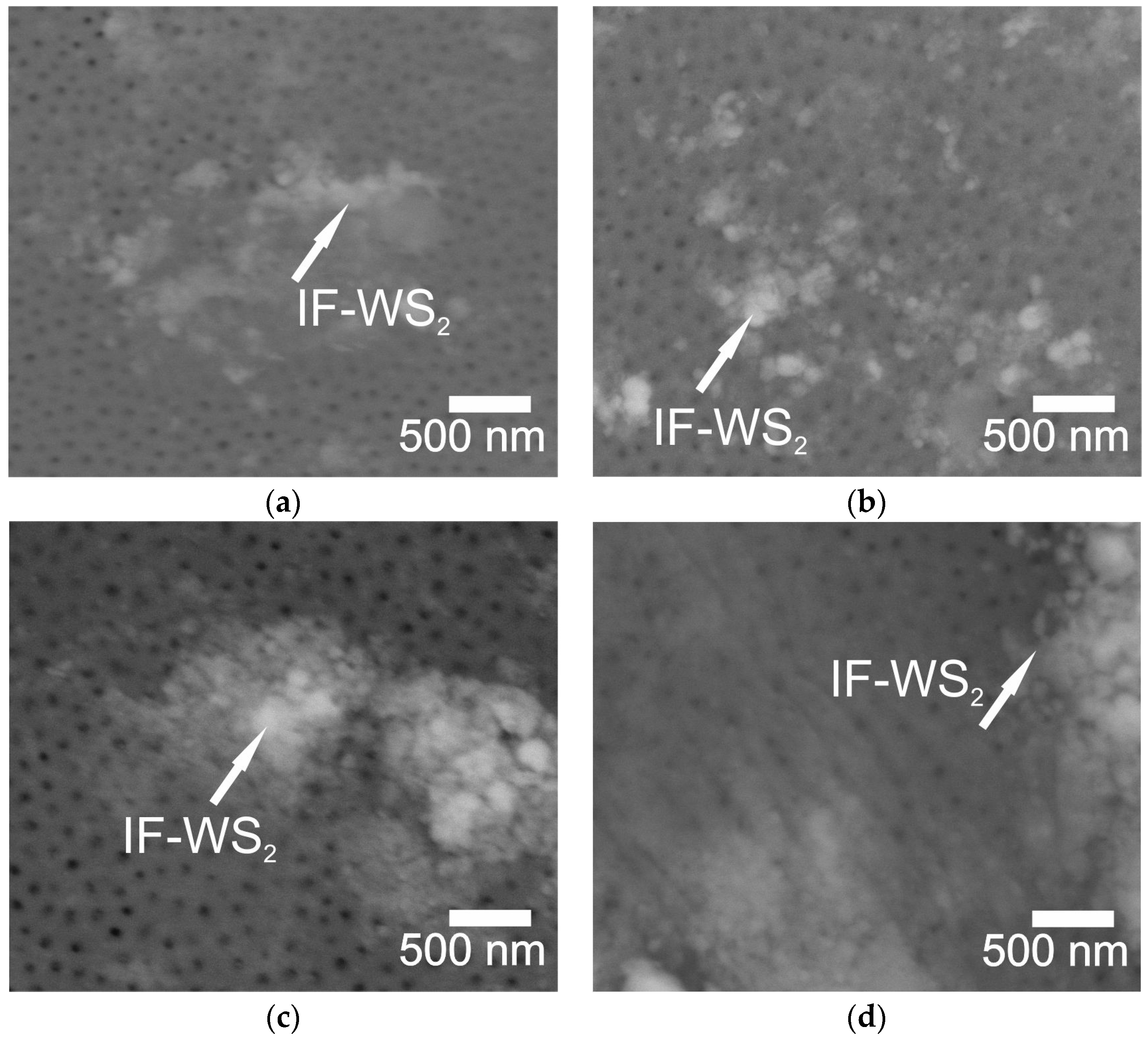

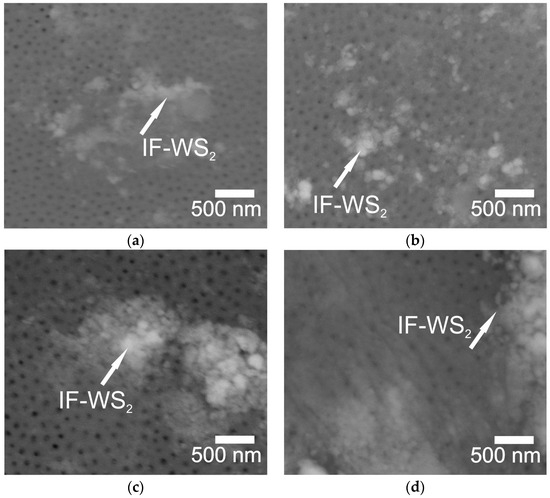

Figure 7a–d shows the SEM/YAG-BSE micrographs (magnification ×25,000) of the surface of Al2O3/IF-WS2 coatings from samples 1 to 4. When analyzing the coating surfaces at higher magnifications, the difference in the deposition of IF-WS2 nanoparticles is not as clearly visible as at lower magnifications. While observing these surfaces, one can notice fine, brightly shining spots of randomly distributed IF-WS2 nanoparticles or aggregates formed by them.

Figure 7.

Microstructures (×25,000) of the surface of the Al2O3/IF-WS2 coatings: (a) sample 1—Method A; (b) sample 2—Method B; (c) sample 3—Method A; and (d) sample 4—Method B.

Table 3 shows the results of contact angle measurements using distilled water and diiodomethane and surface free energy.

Table 3.

Contact angles of oxide coatings measured with distilled water and diiodomethane.

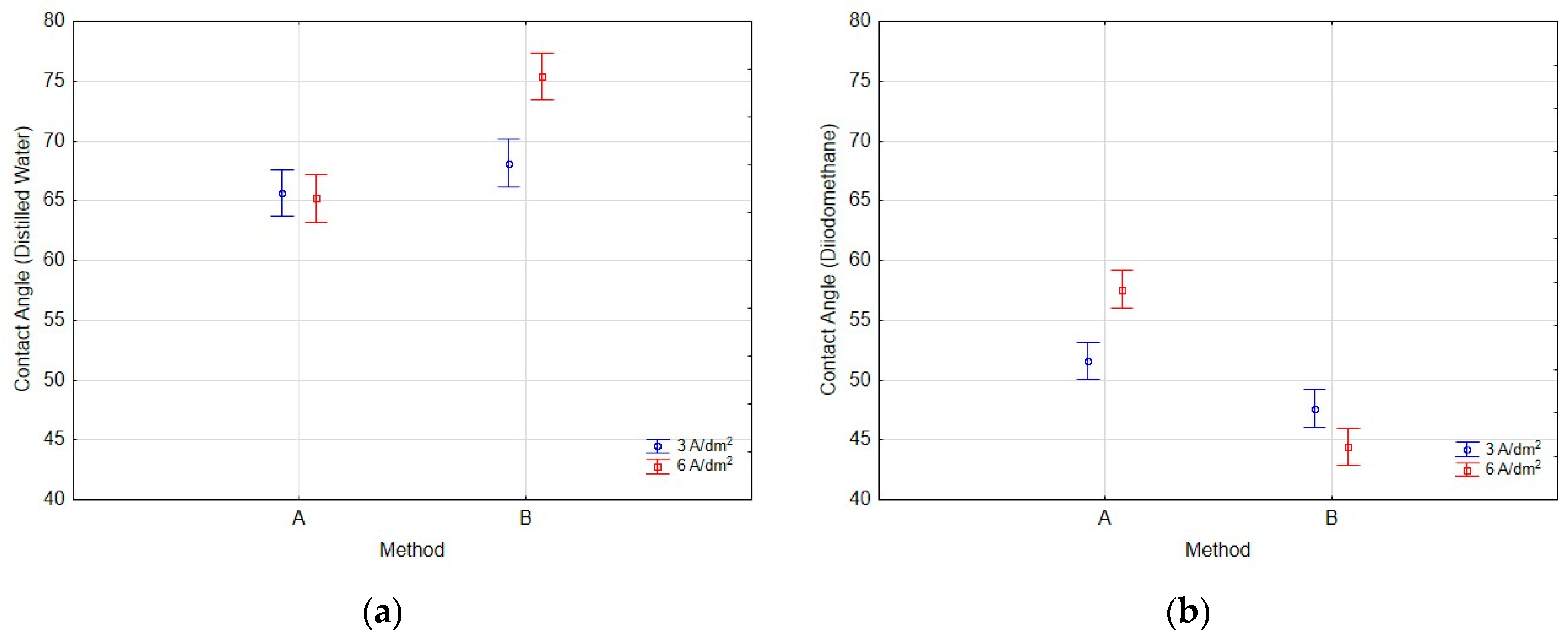

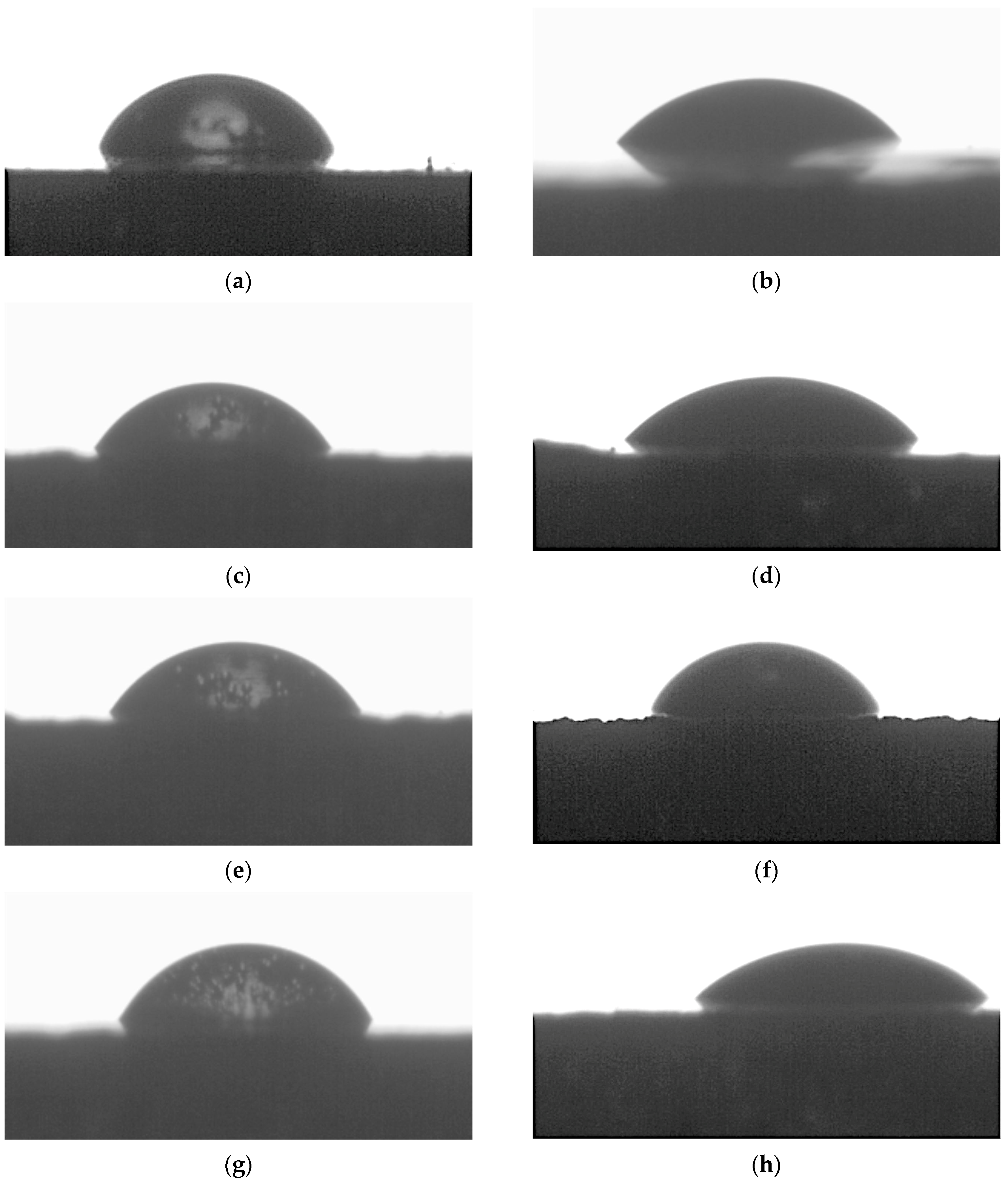

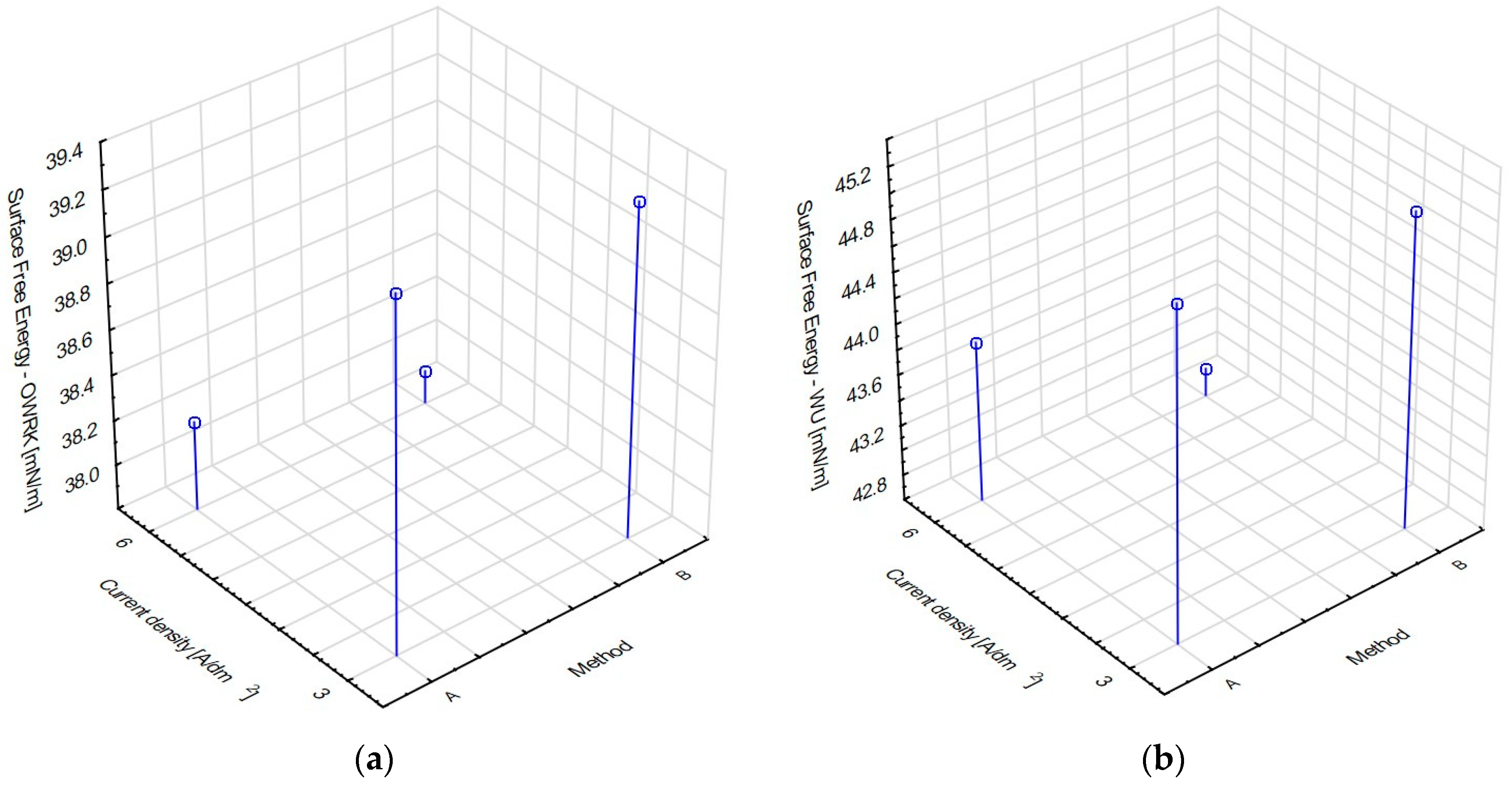

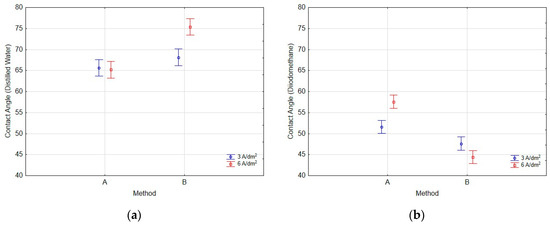

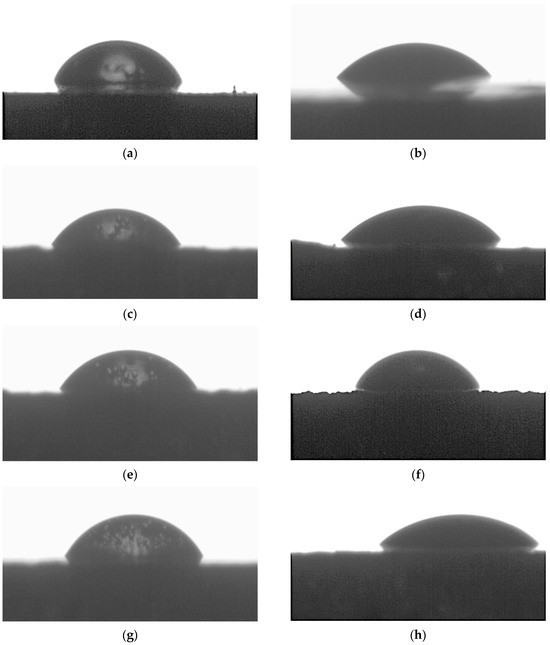

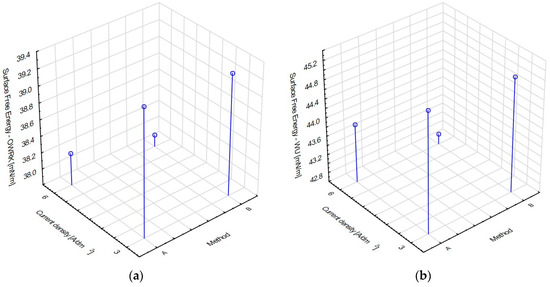

Coatings produced at both 3 A/dm2 and 6 A/dm2 using Method A for applying IF-WS2 NPs exhibit more uniform and lower contact angle measurements (Figure 8a) when using distilled water as the polar liquid (Figure 9a,e) compared to Method B (Figure 9c,g), indicating an increase in surface hydrophilicity for surfaces obtained by Method A. The surface free energy (Figure 10) is higher for samples anodized for 60 min at a current density of 3 A/dm2, indicating that a longer anodization time combined with a lower current density promotes the formation of surfaces with higher surface energy. This could be advantageous for enhancing adhesive properties and protective coatings. Modification of the coatings using Method A results in surfaces with lower contact angles measured with a polar liquid and higher surface free energy compared to Method B, suggesting that Method A is more effective in increasing the hydrophilicity and surface energy of the coatings. This effect may be due to the uniform distribution of IF-WS2 NPs within the near-surface oxide coating. In the case of Method B, the formation of agglomerates on the oxide coating surface significantly altered the surface wettability, particularly noticeable for sample 4. Such a method may be applicable for oxide coatings intended to minimize surface wettability.

Figure 8.

Charts of marginal means and confidence intervals (95%) for the contact angle measured using (a) distilled water and (b) diiodomethane.

Figure 9.

Images of droplets of the media used during contact angle measurements: (a) sample 1—distilled water; (b) sample 1—diiodomethane; (c) sample 2—distilled water; (d) sample 2—diiodomethane; (e) sample 3—distilled water; (f) sample 3—diiodomethane; (g) sample 4—distilled water; and (h) sample 4—diiodomethane.

Figure 10.

Surface free energy plot as a function of the method of introducing IF-WS2 NPs into the coating and current density during coating deposition: (a) OWRK, and (b) WU.

Contact angle measurements using a non-polar liquid (diiodomethane) showed significantly lower values, primarily due to the liquid’s properties, namely its much lower surface tension compared to water and substantially lower polarity. In summary, coatings produced at both 3 A/dm2 and 6 A/dm2 using Method A for applying IF-WS2 NPs exhibit higher contact angles (Figure 8b) when diiodomethane is used as the test liquid (Figure 9b,f) compared to Method B (Figure 9d,g). Therefore, coatings obtained by Method A demonstrate lower surface wettability.

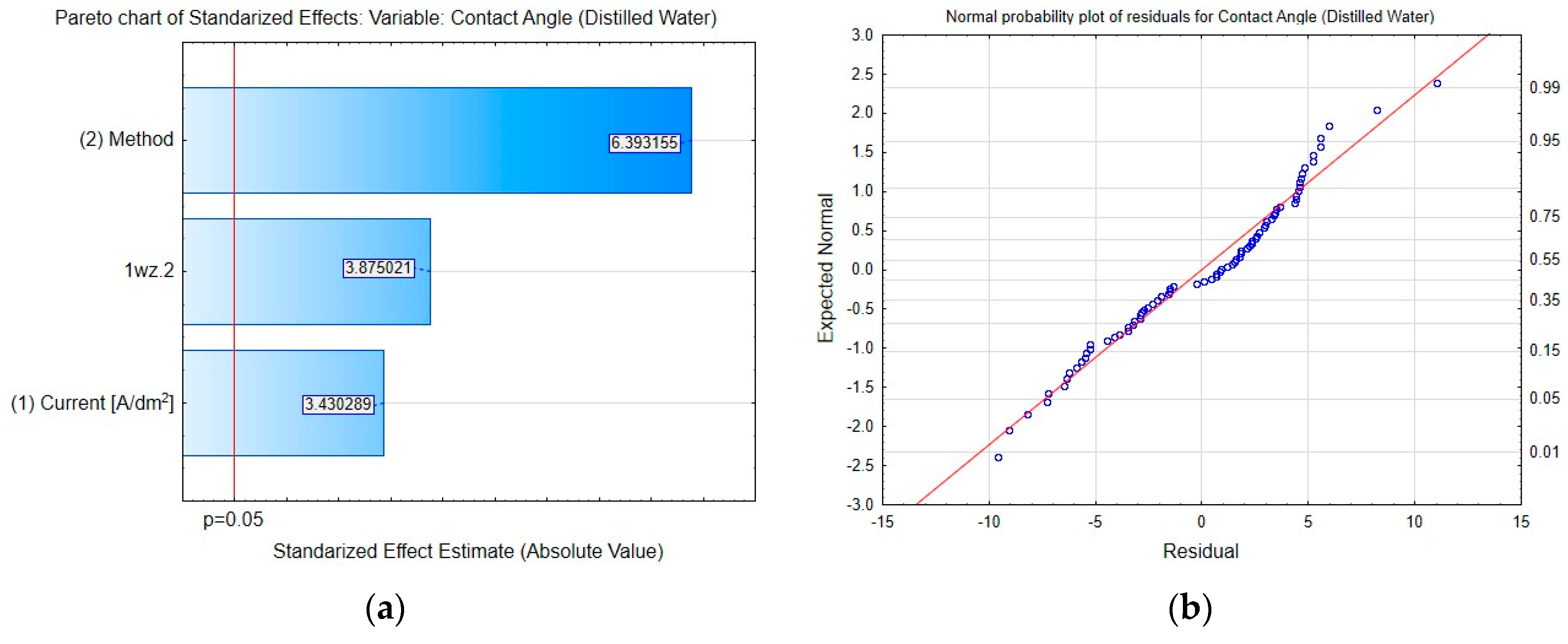

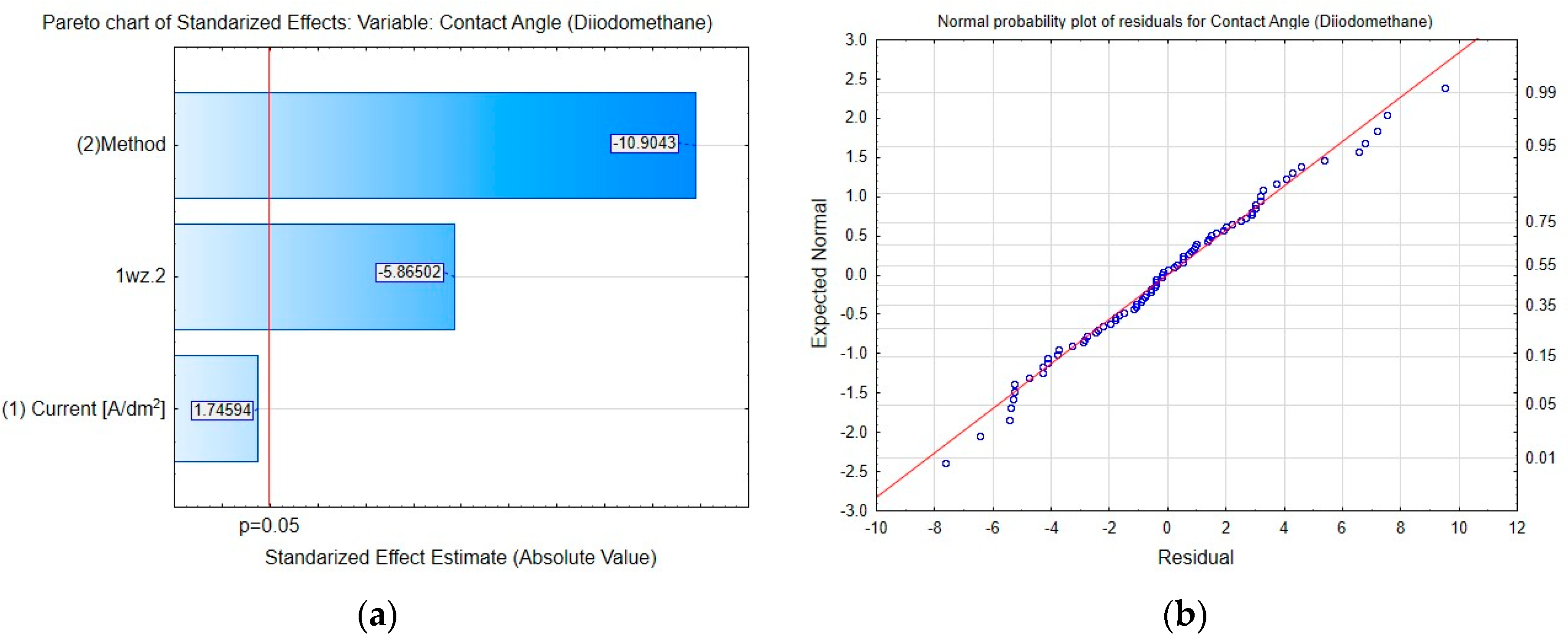

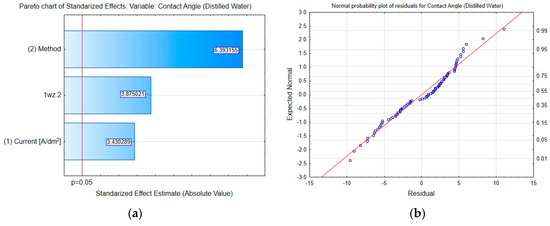

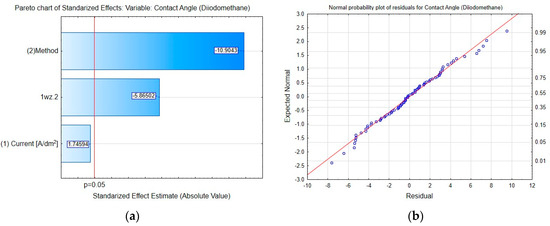

To determine the relationship between the method for obtaining coatings and contact angle measurements, Pareto charts were made for contact angles determined for distilled water (Figure 11a) and diiodomethane (Figure 12a). Pareto chart analysis (Figure 11a) revealed a linear dependence in the influence of the method of introducing IF-WS2 NPs into the Al2O3 coating, the current density used to obtain Al2O3, the interaction between the method, and current density on the contact angle values of distilled water. In the case of diiodomethane, a significant impact on the contact angle value was observed for the method of introducing IF-WS2 NPs into the coating and the interaction between the method and current density (Figure 12a). Figure 11b and Figure 12b present the normal probability plots of residuals for distilled water and diiodomethane, respectively. Based on the obtained plots, it is assumed that the residuals of the statistical model follow a normal distribution, indicating that the linear model used for statistical analysis is reliable.

Figure 11.

Two-factor model with interaction for contact angle (distilled water): (a) the Pareto chart of standardized effect, and (b) the normal probability plot of residuals.

Figure 12.

Two-factor model with interaction for contact angle (diiodomethane): (a) the Pareto chart of standardized effect, and (b) the normal probability plot of residuals.

The research results showed that both Method A and Method B can introduce IF-WS2 NPs into the microstructure and nanostructure of Al2O3 coatings. At this stage, the authors do not undertake to assess which modification method is better. The choice depends on the application of the coatings. If the goal is to reduce the friction coefficient, Method B, with larger agglomerates on the coating surface, may prove to be better. Alternatively, Method A, which hypothetically should supply NPs from the depth of the nanostructure, might be superior. This assessment will be made after tribological studies aimed at achieving the lowest possible friction coefficient and wear of the interacting element, depending on the modification method used.

4. Conclusions

To investigate the potential for better dispersion and application of IF-WS2 NPs onto Al2O3 coatings, two preparation methods utilizing an ultrasonic sonicator were employed. To assess the extent of achieving the intended effect, SEM and GIXD analyses were conducted, which were correlated with surface wetting angle and surface energy studies. The main conclusions drawn from the study are as follows:

- Method A involved two stages: NP fragmentation in the sonicator and allowing samples for slow NPs deposition. Method A contributed to a more homogeneous distribution of NPs within the microstructure of Al2O3 coatings.

- GIXD analyses revealed the presence of a polycrystalline aluminum structure, rhombohedral phase of WS2, and tetragonal phase of WO3 originating from the IF-WS2 modifier.

- The formation of WO3 from WS2 is likely associated with high energy during WS2 dispersion in the sonicator.

- EDS analysis confirmed the presence of IF-WS2 in the microstructure of Al2O3.

- Contact angle measurements using a non-polar liquid (diiodomethane) showed significantly lower values, which were primarily due to the liquid’s properties, namely its much lower surface tension compared to water and substantially lower polarity.

- Modification of coatings using Method A resulted in surfaces with lower contact angles measured with polar liquids and higher surface free energy compared to Method B, suggesting that Method A is more effective in enhancing the hydrophilicity and surface energy of coatings. This effect may stem from the even distribution of IF-WS2 nanoparticles in the near-surface oxide coating. In the case of Method B, the formation of agglomerates on the oxide coating surface significantly altered surface wettability.

- Surface free energy was higher for samples anodized for 60 min at a current density of 3 A/dm2, indicating that longer anodizing times combined with lower current density favor the creation of surfaces with higher surface energy.

- Statistical analysis demonstrated a linear relationship between the method of introducing IF-WS2 nanoparticles into Al2O3 coatings and the interaction between the method and current density on the values of contact angles measured with distilled water and diiodomethane. Additionally, it showed a linear relationship between the current density applied to obtain Al2O3 and the contact angle values measured with distilled water.

Further research is assumed to involve the preparation of samples of appropriate sizes for tribological studies and conducting these studies, as well as examining the geometric structure of the obtained surfaces before and after wear.

Author Contributions

Conceptualization, J.K., M.N. and M.B.; methodology, J.K. and K.C.; software, J.K.; formal analysis, J.K. and M.N.; investigation, J.K., G.D., M.S. and M.N.; writing—original draft preparation, J.K. and M.N.; writing—review and editing, J.K., G.D., K.C., M.N. and M.B.; visualization, J.K.; supervision, M.B. and W.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors gratefully acknowledge Anna Łatkiewicz, from the Jagiellonian University, for conducting research using the scanning electron microscope.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kwolek, P. Corrosion Behaviour of 7075 Aluminium Alloy in Acidic Solution. RSC Adv. 2020, 10, 26078–26089. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Viademonte, M.P.; Abrahami, S.T.; Hack, T.; Burchardt, M.; Terryn, H. A Review on Anodizing of Aerospace Aluminum Alloys for Corrosion Protection. Coatings 2020, 10, 1106. [Google Scholar] [CrossRef]

- Runge, J.M. The Metallurgy of Anodizing Aluminum: Connecting Science to Practice; Springer: Cham, Switzerland, 2018; ISBN 9783319721774. [Google Scholar]

- European Aluminium. VISION 2050|A Vision for Strategic, Low Carbon and Competitive Aluminium; European Aluminium: Brussels, Belgium, 2022. [Google Scholar]

- Matijošius, T.; Padgurskas, J.; Bikulčius, G. Possibility of Phase Transformation of Al2O3 by a Laser: A Review. Crystals 2024, 14, 415. [Google Scholar] [CrossRef]

- Elkilany, H.A.; Shoeib, M.A.; Abdel-Salam, O.E. Influence of Hard Anodizing on the Mechanical and Corrosion Properties of Different Aluminum Alloys. Metallogr. Microstruct. Anal. 2019, 8, 861–870. [Google Scholar] [CrossRef]

- Kchaou, M. Friction Behavior of Anodic Oxide Layer Coating on 2017A T4 Aluminum Alloy under Severe Friction Solicitation: The Effect of Anodizing Parameters. Eng. Technol. Appl. Sci. Res. 2024, 14, 12574–12580. [Google Scholar] [CrossRef]

- Benea, L.; Simionescu-Bogatu, N.; Chiriac, R. Electrochemically Obtained Al2O3 Nanoporous Layers with Increased Anticorrosive Properties of Aluminum Alloy. J. Mater. Res. Technol. 2022, 17, 2636–2647. [Google Scholar] [CrossRef]

- Dervishi, E.; McBride, M.; Edwards, R.; Gutierrez, M.; Li, N.; Buntyn, R.; Hooks, D.E. Mechanical and Tribological Properties of Anodic Al Coatings as a Function of Anodizing Conditions. Surf. Coat. Technol. 2022, 444, 128652. [Google Scholar] [CrossRef]

- Kwolek, P.; Obłój, A.; Kościelniak, B.; Buszta, R.; Tokarski, T.; Krupa, K.; Gradzik, A.; Nowak, W.J.; Wojnicki, M.; Motyka, M. Wear Resistance of Hard Anodic Coatings Fabricated on 5005 and 6061 Aluminum Alloys. Arch. Civ. Mech. Eng. 2024, 24, 51. [Google Scholar] [CrossRef]

- Brudzisz, A.M.; Giziński, D.; Stępniowski, W.J. Incorporation of Ions into Nanostructured Anodic Oxides—Mechanism and Functionalities. Molecules 2021, 26, 6378. [Google Scholar] [CrossRef]

- Kmita, T.; Bara, M. Surface Oxide Layers with an Increased Carbon Content for Applications in Oil-Less Tribological Systems. Chem. Process Eng.-Inz. Chem. Proces. 2012, 33, 479–486. [Google Scholar] [CrossRef]

- Takaya, M.; Hashimoto, K.; Toda, Y.; Maejima, M. Novel Tribological Properties of Anodic Oxide Coating of Aluminum Impregnated with Iodine Compound. Surf. Coat. Technol. 2003, 169–170, 160–162. [Google Scholar] [CrossRef]

- Maejima, M.; Saruwatari, K.; Takaya, M. Friction Behaviour of Anodic Oxide Film on Aluminum Impregnated with Molybdenum Sulfide Compounds. Surf. Coat. Technol. 2000, 132, 105–110. [Google Scholar] [CrossRef]

- Posmyk, A. Kształtowanie Właściwości Tribologicznych Warstw Wierzchnich Na Bazie Aluminium; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2002. [Google Scholar]

- Li, B.; Wang, X.; Liu, W.; Xue, Q. Tribochemistry and Antiwear Mechanism of Organic-Inorganic Nanoparticles as Lubricant Additives. Tribol. Lett. 2006, 22, 79–84. [Google Scholar] [CrossRef]

- Wu, N.; Hu, N.; Wu, J.; Zhou, G. Tribology Properties of Synthesized Multiscale Lamellar WS2 and Their Synergistic Effect with Anti-Wear Agent ZDDP. Appl. Sci. 2020, 10, 115. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Mufti, R.A.; Zahid, R. Tribological Performance of Nanoparticles as Lubricating Oil Additives. J. Nanoparticle Res. 2016, 18, 223. [Google Scholar] [CrossRef]

- Rapoport, L.; Bilik, Y.; Feldman, Y.; Homyonfer, M.; Cohen, S.R.; Tenne, R. Hollow Nanoparticles of WS2 as Potential Solid-State Lubricants. Nature 1997, 387, 791–793. [Google Scholar] [CrossRef]

- Rapoport, L.; Leshchinsky, V.; Lapsker, I.; Volovik, Y.; Nepomnyashchy, O.; Lvovsky, M.; Popovitz-Biro, R.; Feldman, Y.; Tenne, R. Tribological Properties of WS2 Nanoparticles under Mixed Lubrication. Wear 2003, 255, 785–793. [Google Scholar] [CrossRef]

- Song, J.; Hu, L.; Qin, B.; Fan, H.; Zhang, Y. Fabrication and Tribological Behavior of Al2O3/MoS2–BaSO4 Laminated Composites Doped with in Situ Formed BaMoO4. Tribol. Int. 2018, 118, 329–336. [Google Scholar] [CrossRef]

- Erdi Korkmaz, M.; Kumar Gupta, M. Nano Lubricants in Machining and Tribology Applications: A State of the Art Review on Challenges and Future Trend. J. Mol. Liq. 2024, 407, 125261. [Google Scholar] [CrossRef]

- Zak, A.; Feldman, Y.; Lyakhovitskaya, V.; Leitus, G.; Popovitz-Biro, R.; Wachtel, E.; Cohen, H.; Reich, S.; Tenne, R. Alkali Metal Intercalated Fullerene-like MS2 (M = W, Mo) Nanoparticles and Their Properties. J. Am. Chem. Soc. 2002, 124, 4747–4758. [Google Scholar] [CrossRef]

- Feldman, Y.; Zak, A.; Popovitz-Biro, R.; Tenne, R. New Reactor for Production of Tungsten Disulfide Hollow Onion-like (Inorganic Fullerene-like) Nanoparticles. Solid State Sci. 2000, 2, 663–672. [Google Scholar] [CrossRef]

- Sawyer, W.G.; Blanchet, T.A. Lubrication of Mo, W, and Their Alloys with H2S Gas Admixtures to Room Temperature Air. Wear 1999, 225–229, 581–586. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Zabinski, J.S. Nanocomposite and Nanostructured Tribological Materials for Space Applications. Compos. Sci. Technol. 2005, 65, 741–748. [Google Scholar] [CrossRef]

- Sorrentino, A. Tribology of Self-Lubricating Polymer Nanocomposites. In Self-Lubricating Composites; Springer: Berlin/Heidelberg, Germany, 2018; pp. 105–131. [Google Scholar] [CrossRef]

- Li, D.-l.; Jing, X.; Chen, H.; Sun, K.; Chen, W.; Huang, H.-g.; Ren, W.-j. Effects of Graphene Content in Alkaline Silicate Electrolyte on AA1060 Pure Aluminum Micro-Arc Oxidation Coating. Int. J. Appl. Ceram. Technol. 2024, 21, 1789–1801. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Shen, Q. Enhancing Tribological Performance by Anodizing Micro-Textured Surfaces with Nano-MoS2 Coatings Prepared on Aluminum-Silicon Alloys. Tribol. Int. 2018, 122, 84–95. [Google Scholar] [CrossRef]

- Han, X.; Thrush, S.J.; Zhang, Z.; Barber, G.C.; Qu, H. Tribological Characterization of ZnO Nanofluids as Fastener Lubricants. Wear 2021, 468–469, 203592. [Google Scholar] [CrossRef]

- Korzekwa, J.; Gądek-Moszczak, A.; Zubko, M. Influence of the Size of Nanoparticles on the Microstructure of Oxide Coatings. Mater. Sci. 2018, 53, 709–716. [Google Scholar] [CrossRef]

- Gorycza, T.; Dercz, G.; Prusik, K.; Pająk, L.; Łągiewska, E. Crystallite Size Determination of MgO Nanopowder from X-Ray Diffraction Patterns Registered in GIXD Technique. Solid State Phenom. 2010, 163, 177–182. [Google Scholar] [CrossRef]

- Kyrylenko, S.; Warchoł, F.; Oleshko, O.; Husak, Y.; Kazek-Kęsik, A.; Korniienko, V.; Deineka, V.; Sowa, M.; Maciej, A.; Michalska, J.; et al. Effects of the Sources of Calcium and Phosphorus on the Structural and Functional Properties of Ceramic Coatings on Titanium Dental Implants Produced by Plasma Electrolytic Oxidation. Mater. Sci. Eng. C 2021, 119, 111607. [Google Scholar] [CrossRef]

- Kazek-Kȩsik, A.; Kalemba-Rec, I.; Simka, W. Anodization of a Medical-Grade Ti-6Al-7Nb Alloy in a Ca(H2PO2)2-Hydroxyapatite Suspension. Materials 2019, 12, 3002. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the Surface Free Energy of Polymers. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Wu, S. Calculation of Interfacial Tension in Polymer Systems. J. Polym. Sci. Polym. Symp. 1971, 34, 19–30. [Google Scholar] [CrossRef]

- Pietraszek, J.; Dwornicka, R.; Krawczyk, M.; Kołomycki, M. The Non-Parametric Approach to the Quantification of the Uncertainty in the Design of Experiments Modelling. In Proceedings of the UNCECOMP 2017—2nd International Conference on Uncertainty Quantification in Computational Sciences and Engineering, Rhodes Island, Greece, 15–17 June 2017; pp. 598–604. [Google Scholar] [CrossRef]

- Pietraszek, J.; Radek, N.; Goroshko, A.V.; Jana, A.; Ii, P. Challenges for the DOE Methodology Related to the Introduction of Industry 4.0. Prod. Eng. Arch. 2020, 26, 190–194. [Google Scholar] [CrossRef]

- Dudek, A.; Lisiecka, B.; Radek, N.; Orman, Ł.J.; Pietraszek, J. Laser Surface Alloying of Sintered Stainless Steel. Materials 2022, 15, 6061. [Google Scholar] [CrossRef] [PubMed]

- Shinde, P.A.; Jun, S.C. Review on Recent Progress in the Development of Tungsten Oxide Based Electrodes for Electrochemical Energy Storage. ChemSusChem 2020, 13, 11–38. [Google Scholar] [CrossRef]

- Mandal, D.; Routh, P.; Nandi, A.K. A New Facile Synthesis of Tungsten Oxide from Tungsten Disulfide: Structure Dependent Supercapacitor and Negative Differential Resistance Properties. Small 2018, 14, 1702881. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).