Research on the Measurement and Estimation Method of Wheel Resistance on a Soil Runway

Abstract

1. Introduction

2. Theory and Methodology

2.1. Characterization Method of Wheel Resistance on Soil Road Surfaces

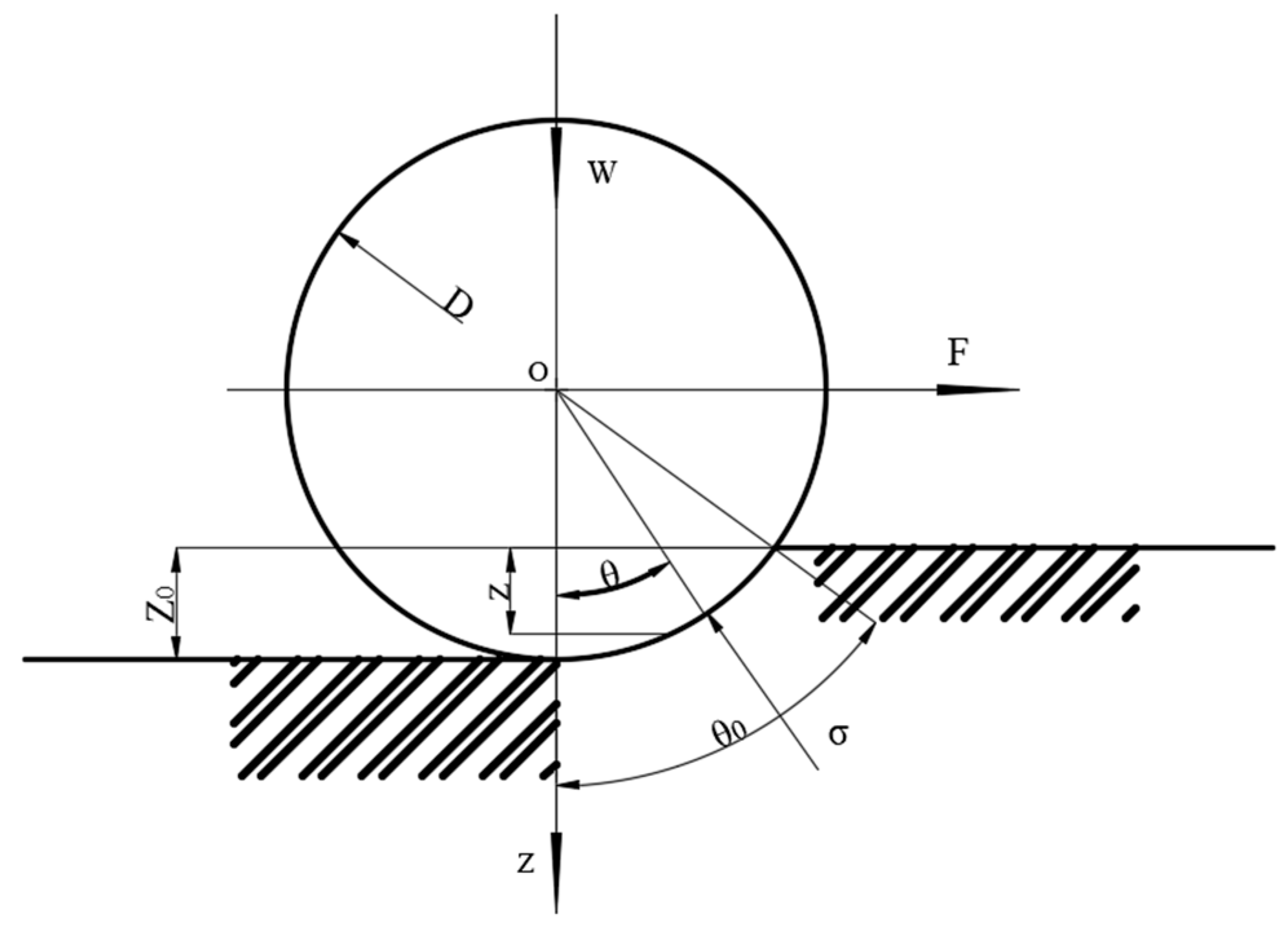

2.1.1. Driving Resistance Characterization Method Based on the Mechanical Model

2.1.2. Kinematic Model-Based Driving Resistance Characterization Method

2.2. Field Testing of Driving Resistance Based on the Mechanical Model

2.2.1. Basic Conditions of the Test Site

2.2.2. Test Method

- (1)

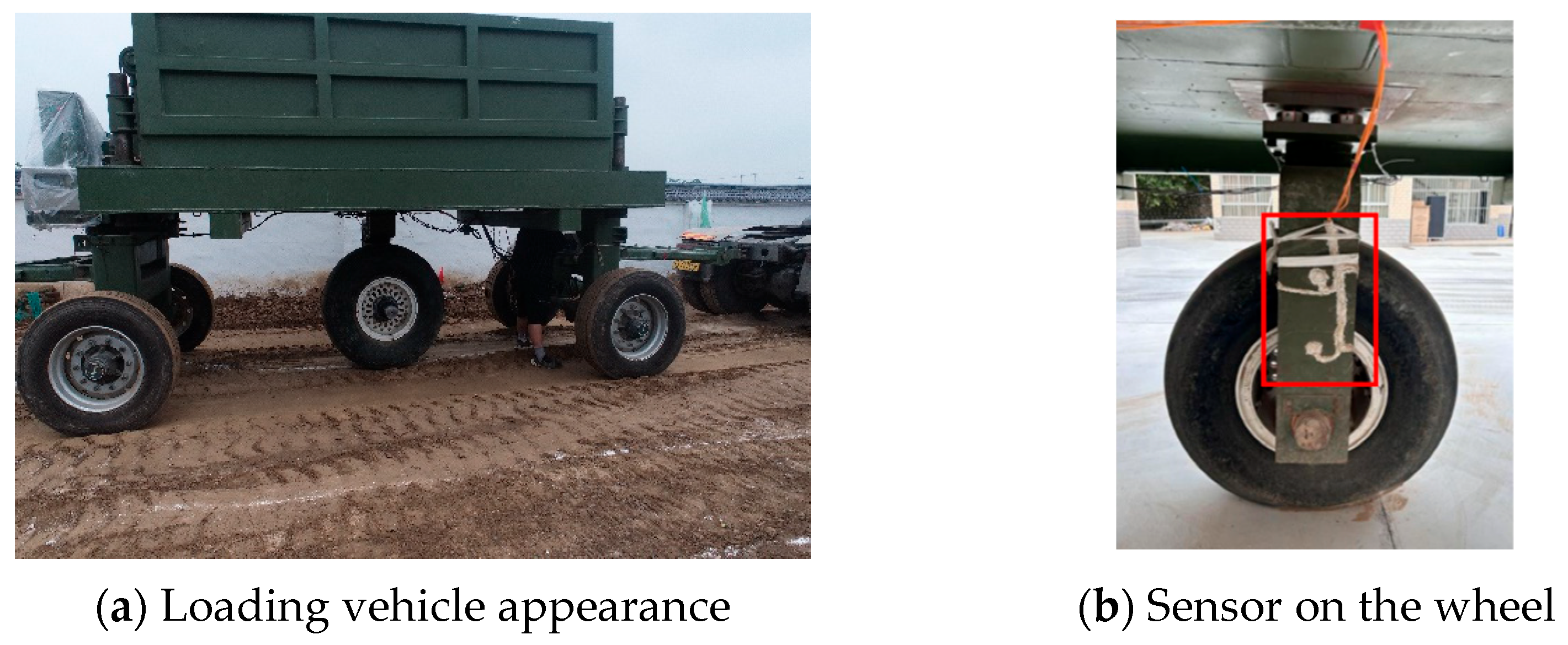

- Test equipment

- (2)

- Test process.

2.3. Field Test of Driving Resistance Based on the Kinematic Model

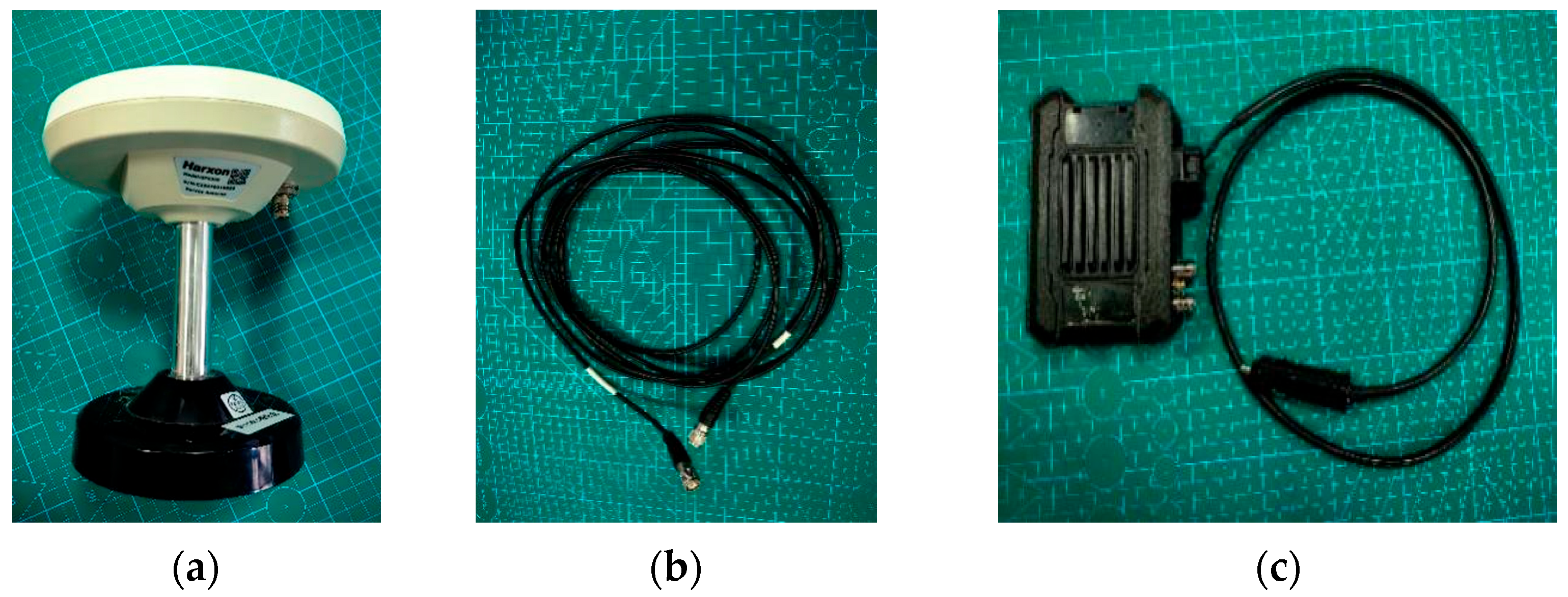

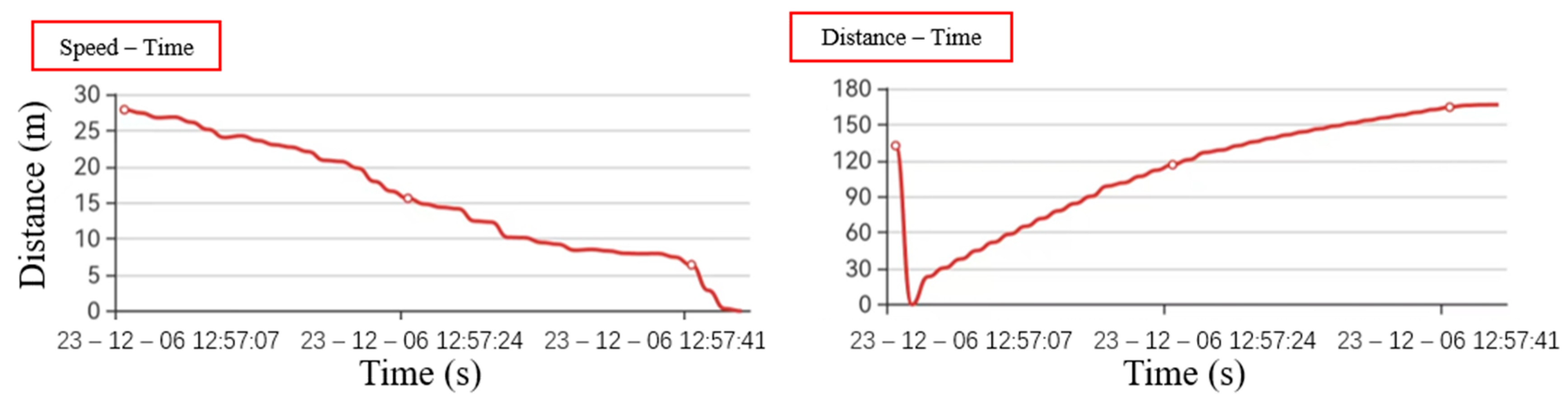

2.3.1. The Test Principle of Speed and Distance

2.3.2. Test Vehicle Selection

2.3.3. Test Procedure

3. Results and Discussion

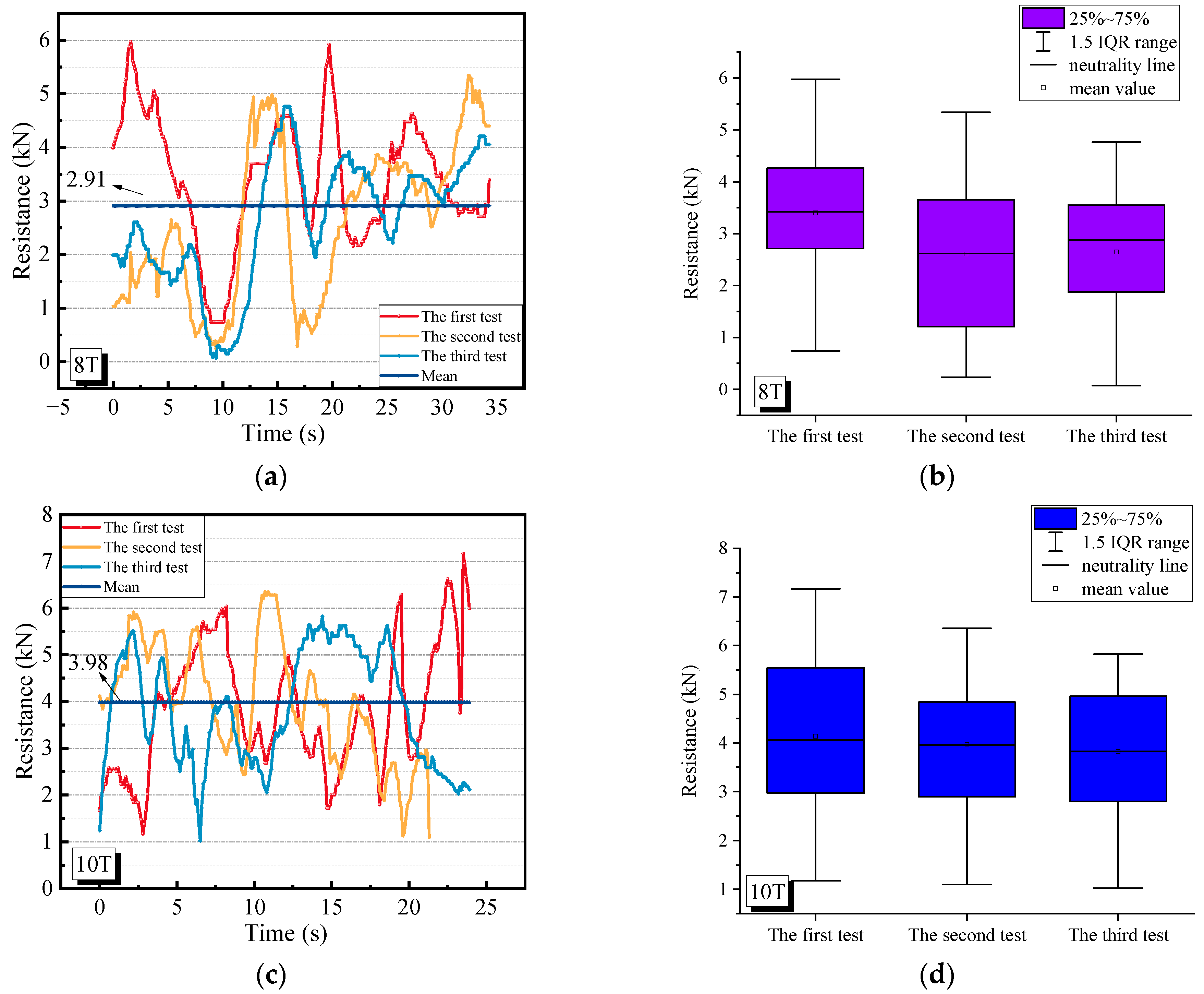

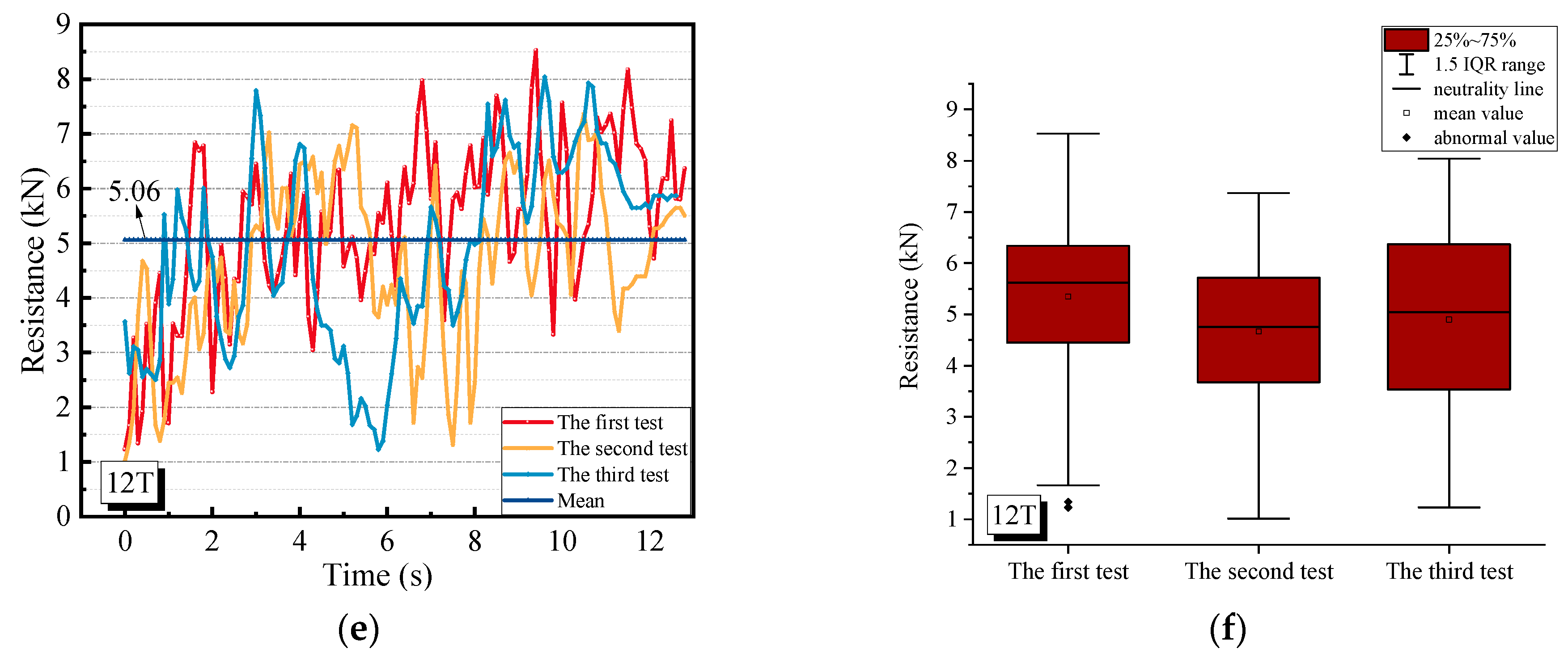

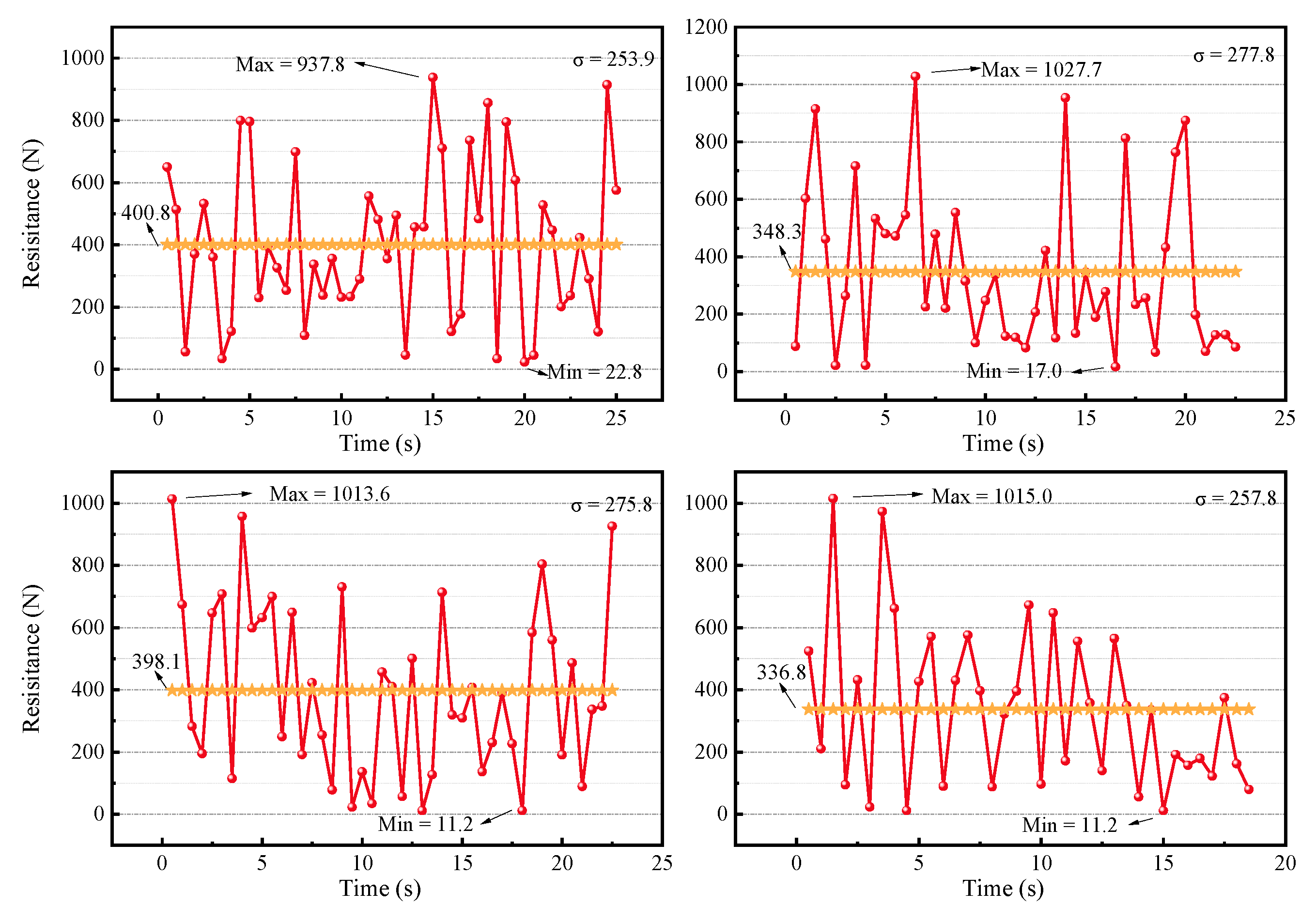

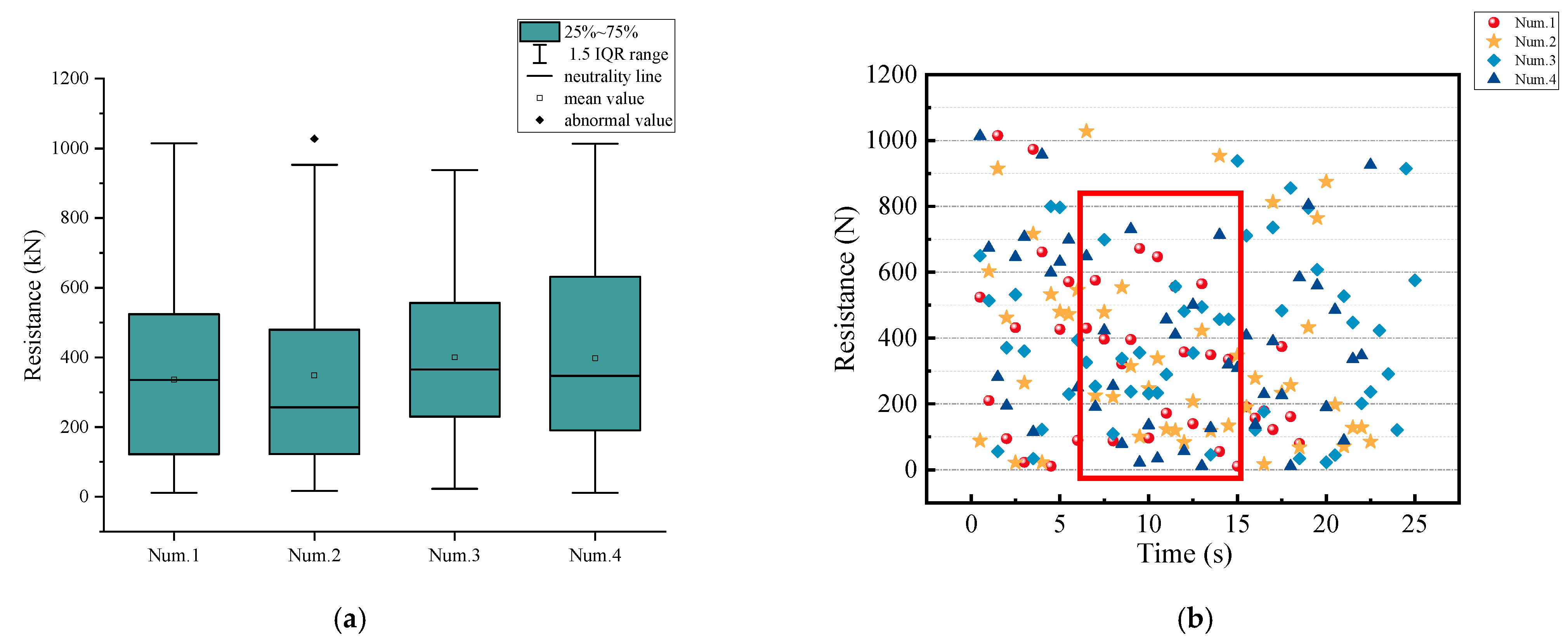

3.1. Test Result Analysis of the Mechanical Model

3.2. Test Data Analysis of the Kinematic Model

3.3. Estimation Method of Aircraft Running Resistance on the Soil Road Surface

3.3.1. Determination of the Calculation Parameters of Road Surface Driving Resistance

- 1.

- Principle of parameter determination.

- 2.

- Determination of calculation parameters based on the actual test.

3.3.2. Estimation of Road Surface Driving Resistance

3.3.3. Accuracy Analysis of the Estimation Method

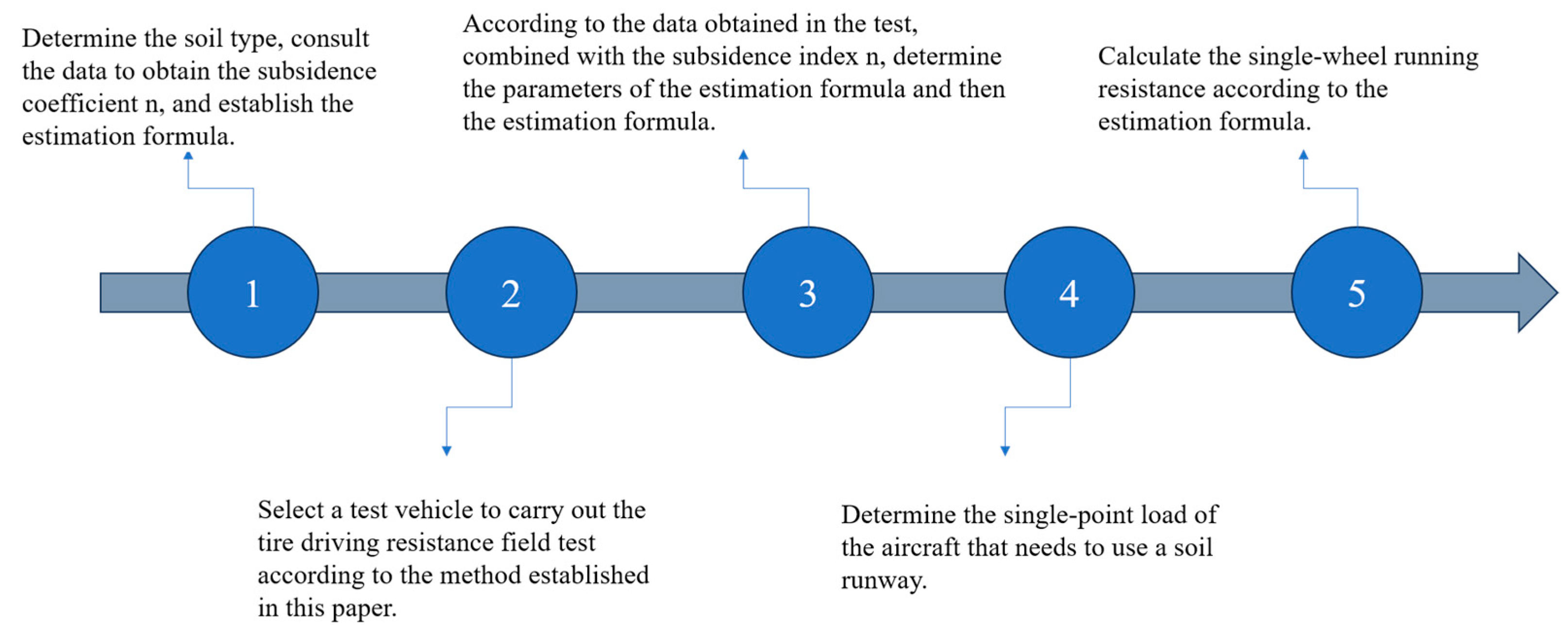

3.3.4. The Process of Estimating the Driving Resistance of Soil Pavement

4. Conclusions

- (1)

- Different methods can be used to characterize the driving resistance of the wheel on a soil road surface. Corresponding to different characterization methods, the driving resistance can be tested in two ways as follows: the stress state and the motion state.

- (2)

- The tire resistance test method based on the motion state can better test the driving resistance of the tire on the soil road. This method can also be used to evaluate the load that the vehicle can bear on temporary soil roads.

- (3)

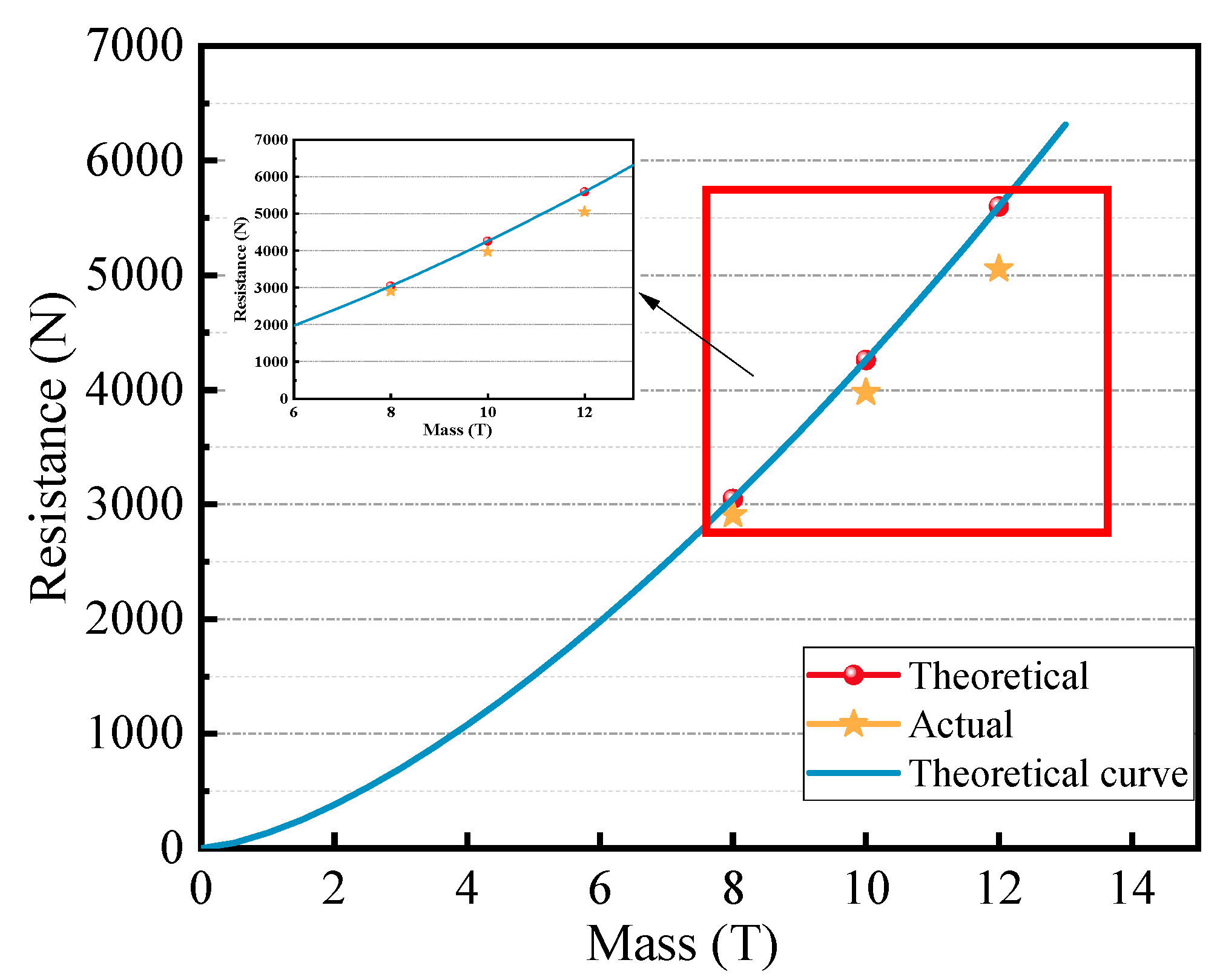

- The resistance of the aircraft simulated load-loading vehicle is 2910 N, 3978 N, and 5055 N, respectively, when the single wheel load of 8T, 10T, and 12T is run on the soil pavement. The results obtained by the estimation method established in this paper are 3048 N, 4260 N, and 5600 N, and the deviations are 4.53%, 6.62%, and 9.73%, respectively. These small deviations indicate that our proposed resistance estimation method is feasible for practical application in estimating aircraft tire running resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mataei, B.; Zakeri, H.; Zahedi, M.; Nejad, F.M. Pavement Friction and Skid Resistance Measurement Methods: A Literature Review. Open J. Civ. Eng. 2016, 6, 537–565. [Google Scholar] [CrossRef]

- Tan, Y.Q.; Xiao, S.Q.; Xiong, X.T. Testing Technology of Dynamic Road Friction. J. Traffic Transp. Eng. 2021, 21, 32–47. [Google Scholar] [CrossRef]

- Gui, Z.; Liu, H.; Zhang, Z. Research Progress of pavement texture Characterization and anti-skid performance detection technolog. Highw. Traffic Sci. Technol. Appl. Technol. Ed. 2012, 4, 62–65. [Google Scholar]

- Eubanks, J.J.; Haight, W.R.R.; Malmsbury, R.N.; Casteel, D.A. A Comparison of Devices Used to Measure Vehicle Braking Deceleration; SAE Technical Paper; SAE: Detroit, MI, USA, 1993. [Google Scholar] [CrossRef]

- Kordani, A.A.; Rahmani, O.; Nasiri, A.S.A.; Boroomandrad, S.M. Effect of Adverse Weather Conditions on Vehicle Braking Distance of Highways. Civ. Eng. J. 2018, 4, 46–57. [Google Scholar] [CrossRef]

- Lee, Y.P.K.; Fwa, T.F.; Choo, Y.S. Effect of Pavement Surface Texture on British Pendulum Test. J. East. Asia Soc. Transp. Stud. 2005, 6, 1247–1257. [Google Scholar]

- Zhang, P.; Cui, L.L.; He, L.; Xia, Q.S. Testing Technology of Dynamic Road Friction Coefficient. Appl. Mech. Mater. 2013, 312, 249–253. [Google Scholar] [CrossRef]

- Rizenbergs, R.L.; Burchett, J.L.; Napier, C.T. Skid-Test Trailer: Description, Evaluation and Adaptation; Commonwealth of Kentucky Department of Highways: Frankfort, KY, USA, 1972. [Google Scholar]

- de Solminihac, H.; Chamorro, A.; Echaveguren, T. Procedure to Process, Harmonize and Analyze Grip Tester Measurements. In Proceedings of the 7th International Conference on Managing Pavement Assets, TRB Committee AFD10, Calgary, AB, Canada, 23–28 June 2008. [Google Scholar]

- Rufford, P.G.; Gaughan, R.L. A Study of the Effect of Speed on the Skid Resistance of Fine and Coarse Textured Surfacings Using the Mu Meter. In Proceedings of the 7th Australian Road Research Board (ARRB) Conference, Adelaide, Australia, 21–25 May 1974. [Google Scholar]

- Tingle, J.S.; Norwood, G.J.; Cotter, B. Use of Continuous Friction Measurement Equipment to Predict Runway Condition Rating on Unpaved Runways. Transp. Res. Rec. 2017, 2626, 58–65. [Google Scholar] [CrossRef]

- Ward, A.B.; Falls, A.J.; Rutland, C.A. Development of Deceleration-Based Friction Prediction Models and Methods on Semiprepared Runway Surfaces. Transp. Res. Rec. J. Transp. Res. Board 2023, 1, 1–16. [Google Scholar] [CrossRef]

- Ward, A.B.; Tingle Jeb, S.; Rutland, C.A. Development of Deceleration-Based Runway Friction Measurement Methods; US Army Engineer Research and Development Center, Geotechnical and Structures Laboratory: Tampa, FL, USA, 2019. [Google Scholar]

- Thompson, R.J.; Visser, A.T. Mine Haul Road Maintenance Management Systems. J. South Afr. Inst. Min. Metall. 2003, 103, 303–312. [Google Scholar]

- McAllister, M. Reduction in the Rolling Resistance of Tyres for Trailed Agricultural Machinery. J. Agric. Eng. Res. 1983, 28, 127–137. [Google Scholar] [CrossRef]

- Rebati, J.; Loghavi, M. Investigation and Evaluation of Rolling Resistance Prediction Models for Pneumatic Tires of Agricultural Vehicles (Research Note). Iran Agric. Res. 2006, 24, 77–88. [Google Scholar]

- Elwaleed, A.K.; Yahya, A.; Zohadie, M.; Ahmad, D.; Kheiralla, A.F. Effect of Inflation Pressure on Motion Resistance Ratio of a High-Lug Agricultural Tyre. J. Terramechanics 2006, 43, 69–84. [Google Scholar] [CrossRef]

- Botta, G.F.; Tolon-Becerra, A.; Tourn, M.; Lastra-Bravo, X.; Rivero, D. Agricultural Traffic: Motion Resistance and Soil Compaction in Relation to Tractor Design and Different Soil Conditions. Soil Tillage Res. 2012, 120, 92–98. [Google Scholar] [CrossRef]

- Bekker, M.G. Land Locomotion on the Surface of Planets. ARS J. 1962, 32, 1651–1659. [Google Scholar] [CrossRef]

- Wong, J.Y. Theory of Ground Vehicles; John Wiley & Sons: Hoboken, NJ, USA, 2022; ISBN 1119719704. [Google Scholar]

- Zhang, J.; Xu, W.; Quan, Z.Q.; Wang, J.; Li, J.Y.; Zuo, S.H.; Chen, T.Y.; Wang, Y.L. Design and application of aircraft load simulation loading vehicle. Exp. Technol. Manag. 2023, 40, 141–148+162. [Google Scholar] [CrossRef]

- Wang, Z.H.; Cai, L.C.; Shao, B. Design Method of Military Airfield Runway Length. J. Transp. Eng. Inf. 2007, 5, 67–70+76. [Google Scholar]

| 8T | 10T | 12T | |||||||

|---|---|---|---|---|---|---|---|---|---|

| σ | 1.16 | 1.65 | 1.18 | 1.42 | 1.23 | 1.21 | 1.51 | 1.52 | 1.71 |

| μ | 3.39 | 2.69 | 2.65 | 4.14 | 3.97 | 3.82 | 5.35 | 4.67 | 4.89 |

| y = 134.7x1.5 | |||

|---|---|---|---|

| Mass | Theoretical Value | Actual Value | Degree of Deviation |

| 8T | 3048 | 2910 | 4.53% |

| 10T | 4260 | 3978 | 6.62% |

| 12T | 5600 | 5055 | 9.73% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Chong, X.; Wang, G.; Liu, C.; Zhang, J. Research on the Measurement and Estimation Method of Wheel Resistance on a Soil Runway. Coatings 2024, 14, 1062. https://doi.org/10.3390/coatings14081062

Wang Z, Chong X, Wang G, Liu C, Zhang J. Research on the Measurement and Estimation Method of Wheel Resistance on a Soil Runway. Coatings. 2024; 14(8):1062. https://doi.org/10.3390/coatings14081062

Chicago/Turabian StyleWang, Zihan, Xiaolei Chong, Guanhu Wang, Chaojia Liu, and Jichao Zhang. 2024. "Research on the Measurement and Estimation Method of Wheel Resistance on a Soil Runway" Coatings 14, no. 8: 1062. https://doi.org/10.3390/coatings14081062

APA StyleWang, Z., Chong, X., Wang, G., Liu, C., & Zhang, J. (2024). Research on the Measurement and Estimation Method of Wheel Resistance on a Soil Runway. Coatings, 14(8), 1062. https://doi.org/10.3390/coatings14081062