Microstructures and Properties of Laser-Cladded FeCoCrNiAlTi High-Entropy Alloy with Intensive Repair Potential

Abstract

1. Introduction

2. Experimental Section

3. Results and Discussion

4. Conclusions

- (1)

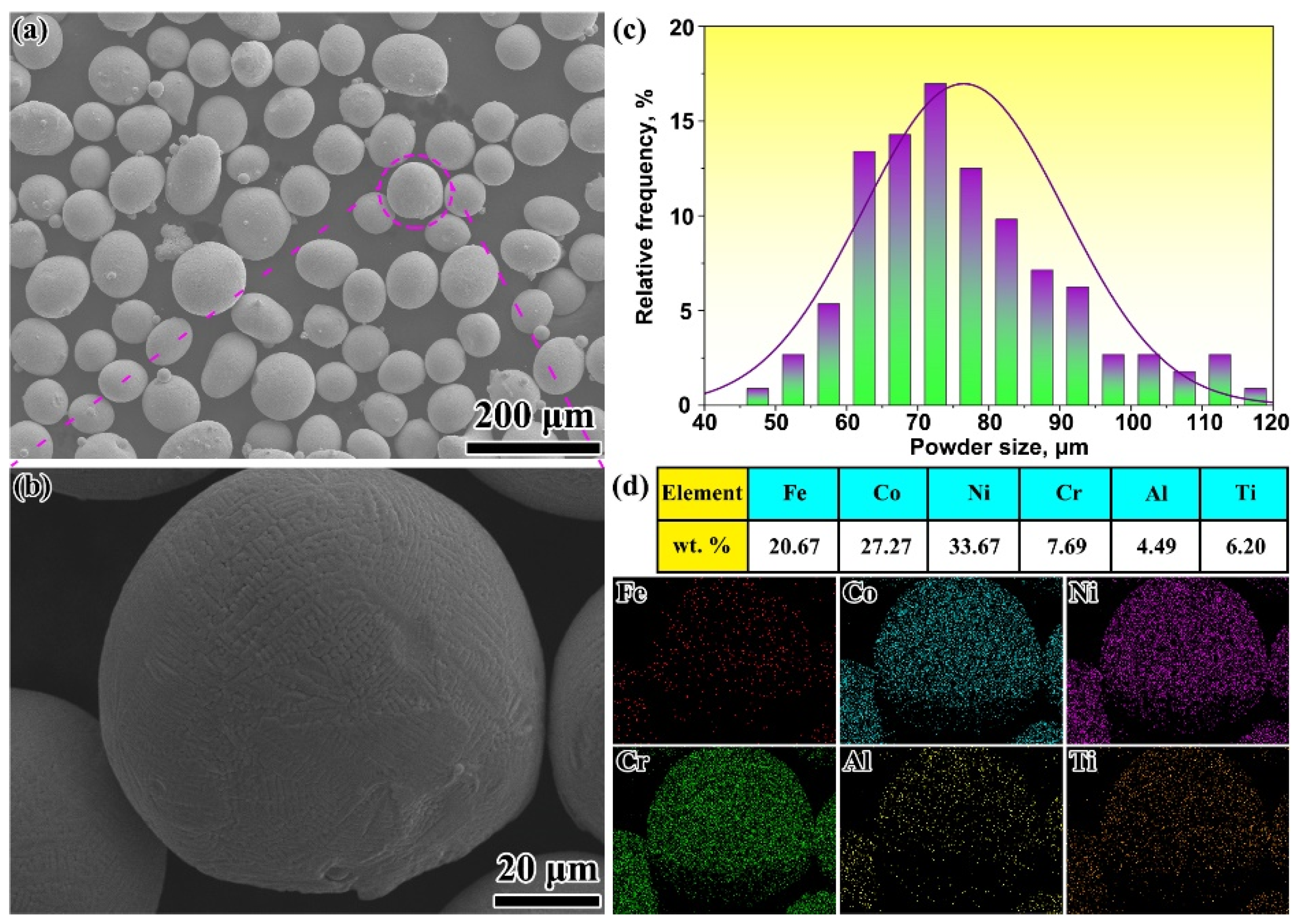

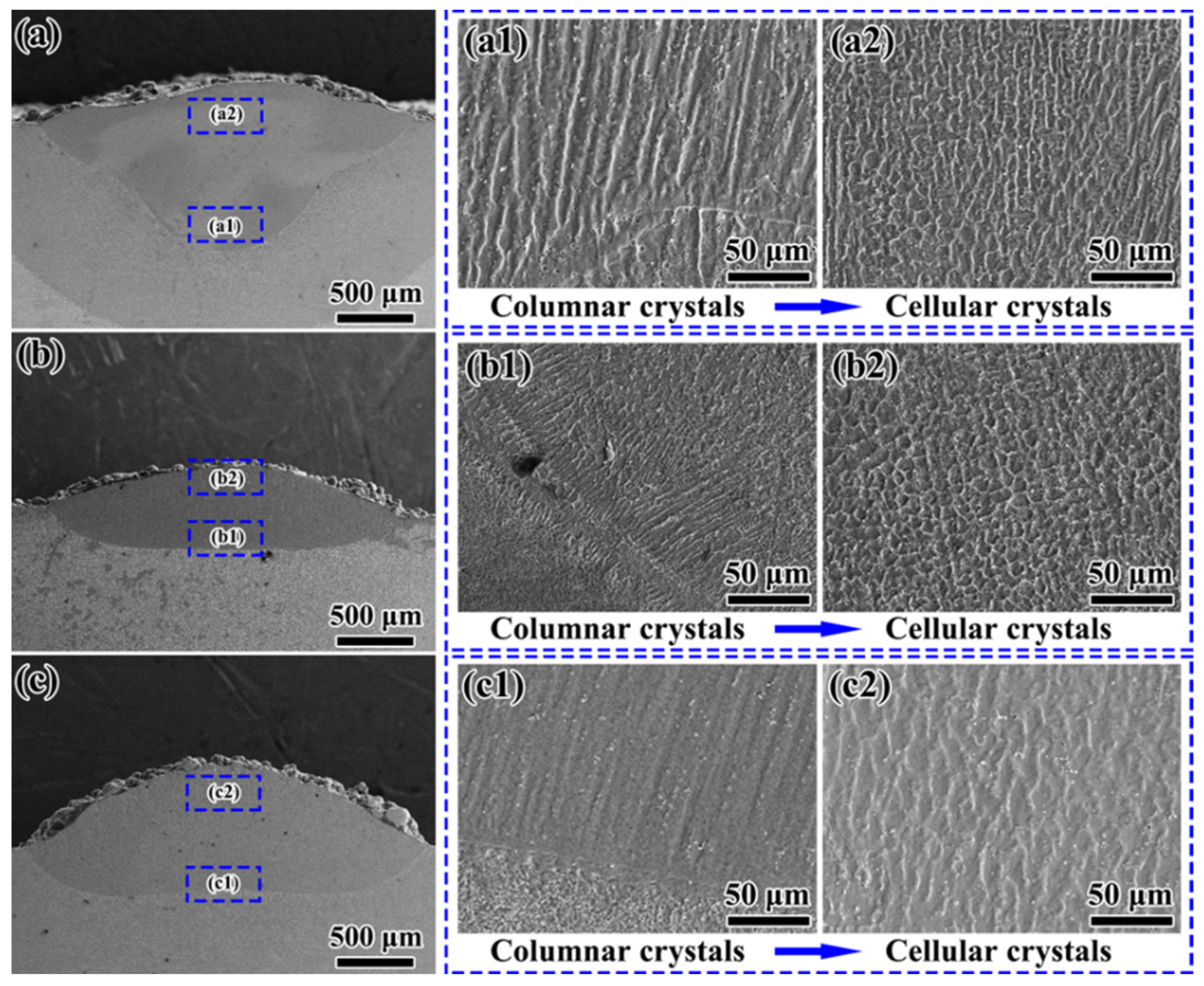

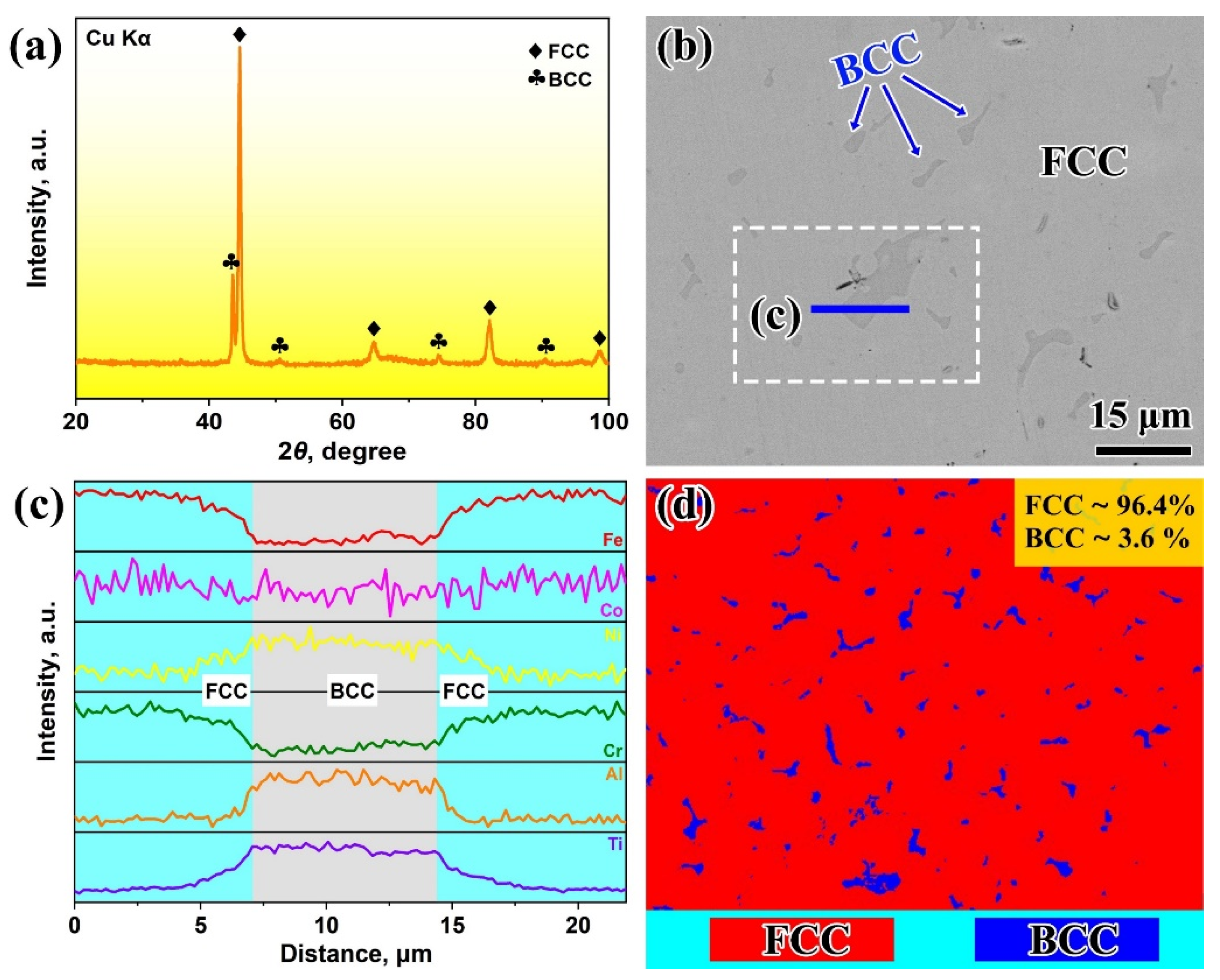

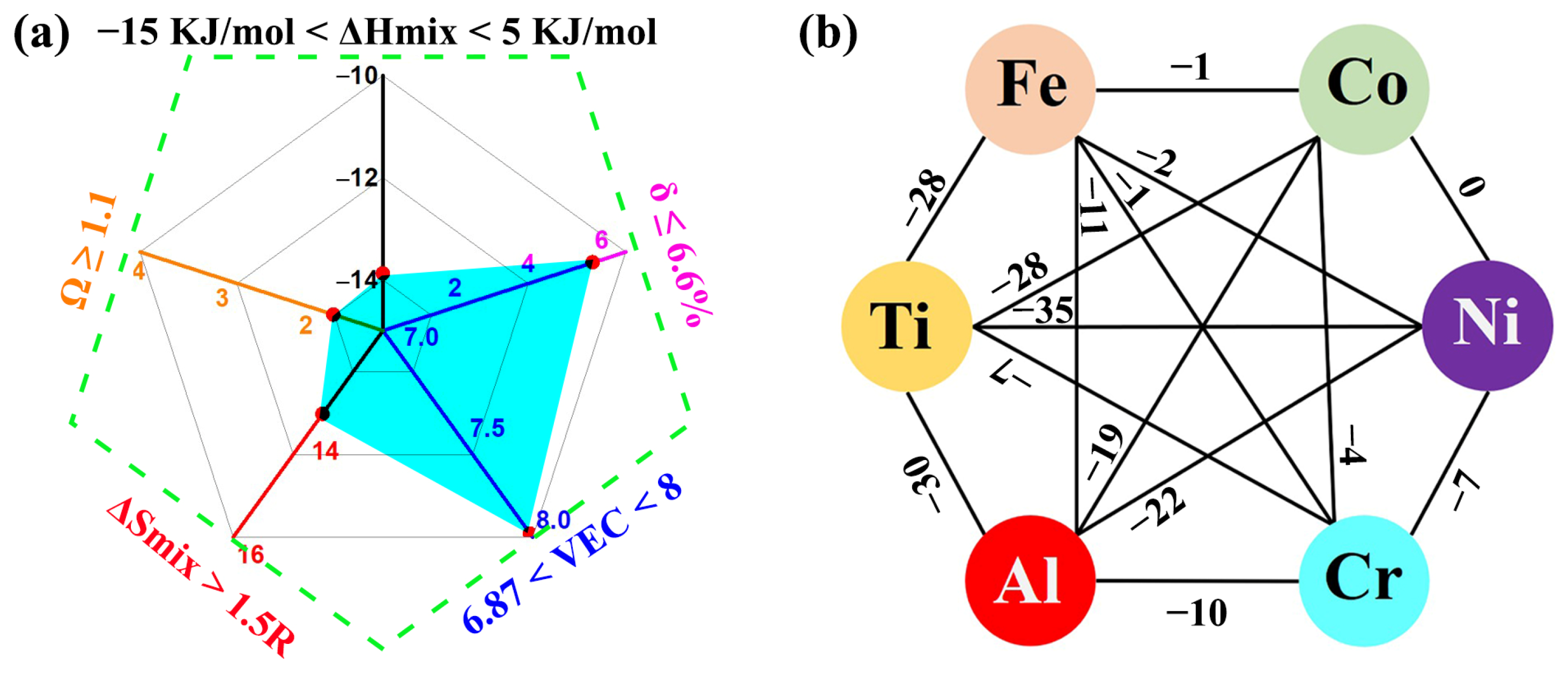

- The HEA-RL prepared by laser cladding forms a metallurgical bond with the three substrates. The cladding layer is composed of a dominant (Fe, Cr)-rich FCC phase and a small amount of (Ni, Ti, and Al)-rich BCC phases. The high ΔSmix of the HEA-RL promotes the formation of simple solid-solution phases, but the strong affinity between Ti, Al, and Ni leads to the formation of BCC phases.

- (2)

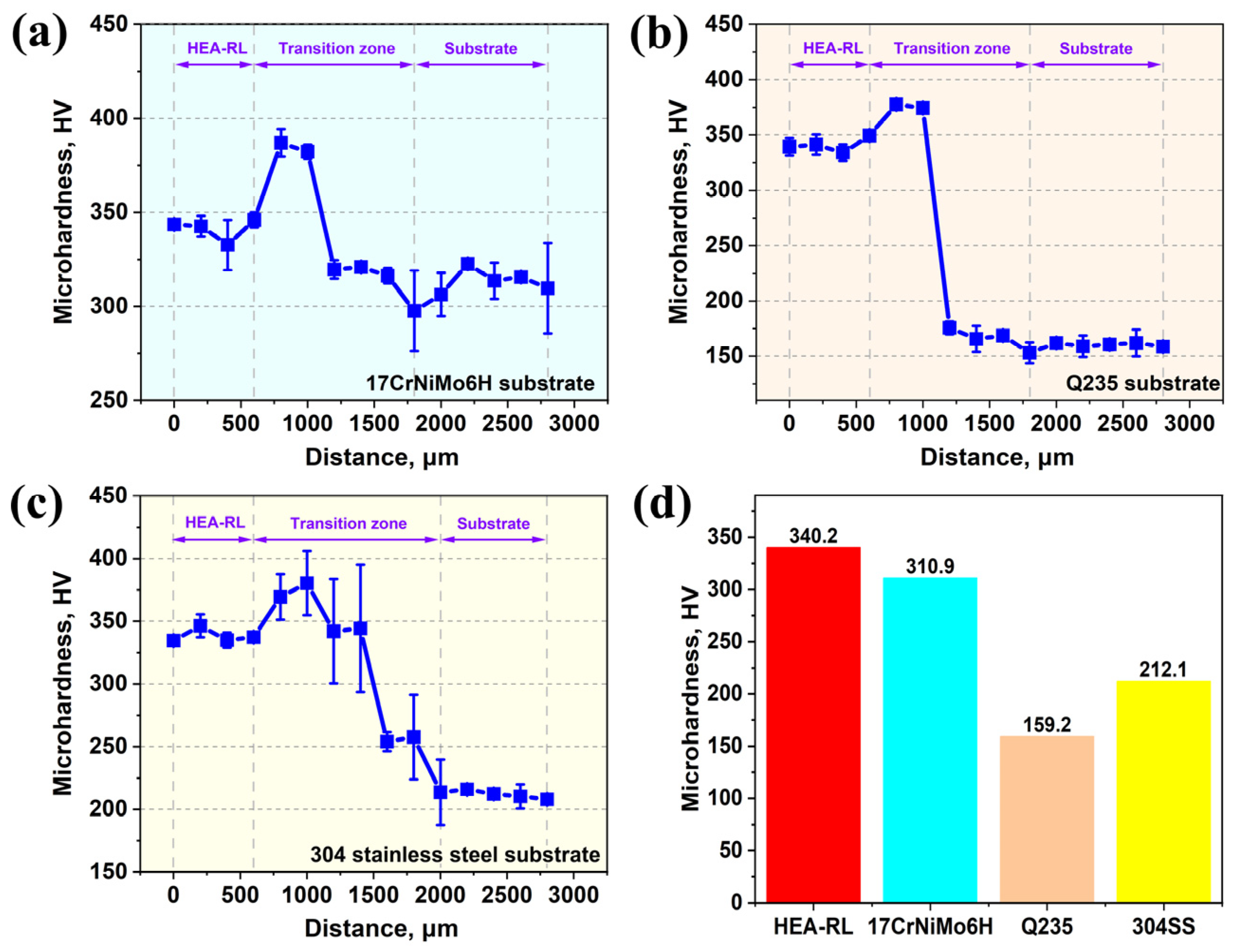

- Compared to the three substrates, the HEA-RL shows much higher hardness, about 340 HV, which is 1.1, 2.1, and 1.6 times higher than the average hardness of the 17CrNiMo6H, Q235, and 304SS substrates, respectively. Such delightful hardness is attributed to the solid-solution strengthening effect and the dispersion-strengthening effect of the BCC phase.

- (3)

- The evaluation of corrosion performance reveals that the HEA-RL holds a corrosion resistance comparable to 304SS, which is much better than that of the 17CrNiMo6H and Q235 substrates, despite the fact that the Cr content in the HEA-RL is only half of that in 304SS. The presence of relatively high concentrations of Ti and Al is believed to play a key role in empowering the corrosion resistance of HEA-RL by promoting the heterogeneous nucleation of Cr2O3. Mott–Schottky’s analysis suggests that the passive film upon HEA-RL displays an n-type semiconductor property.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ning, J.; Zhang, H.B.; Chen, S.M.; Zhang, L.J.; Na, S.J. Intensive laser repair through additive manufacturing of high-strength martensitic stainless steel powders (I)–powder preparation, laser cladding and microstructures and properties of laser-cladded metals. J. Mater. Res. Technol. 2021, 15, 5746–5761. [Google Scholar] [CrossRef]

- Zhu, S.; Zhou, C.J. Additive remanufacturing for ‘made in China 2025’. Therm. Spray Technol. 2016, 8, 1–4. [Google Scholar]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Li, W.D.; Xie, D.; Li, D.Y.; Zhang, Y.; Gao, Y.T.; Liaw, P.K. Mechanical behavior of high-entropy alloys. Prog. Mater Sci. 2021, 118, 100777. [Google Scholar] [CrossRef]

- Zheng, Q.F.; Lu, W.Y.; Han, D.; Li, T.R.; Guo, H.; Qiu, K.Q.; Yang, B.J.; Wang, J.Q. Effect of Al content on microstructure, mechanical, and corrosion properties of (Fe33Cr36Ni15Co15Ti1)100-xAlx High-Entropy Alloys. Adv. Eng. Mater. 2024, 25, 2301013. [Google Scholar] [CrossRef]

- Liu, Z.C.; Kong, D.J. Microstructure, corrosive-wear and immersion corrosion performances of laser cladded FeCoNiMo(Al,Ti) high-entropy alloy coatings. Corros. Sci. 2024, 227, 111766. [Google Scholar]

- Su, J.L.; Li, A.; Ruan, Y.; Qiu, X.M.; Liang, J.W. Repair of tungsten heavy alloy die casting molds with laser cladded CoCrFeNiWx high entropy alloy Coatings: Microstructure, wear properties and tempering stability. Eng. Fail. Anal. 2024, 161, 108291. [Google Scholar] [CrossRef]

- Qiu, X. Microstructure and mechanical properties of CoCrFeNiMo high-entropy alloy coatings. Mater. Res. Technol. 2020, 9, 5127–5133. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Z.; Dong, J.W.; Luo, Z. Enhancing performance and microstructure analysis in laser welded of R60702 zirconium alloy and 304 stainless steel with TA2/Q235 composite interlayer. Mater. Lett. 2024, 359, 135960. [Google Scholar] [CrossRef]

- Bian, X.X.; Liu, Y.R.; Zhang, J.T. Fracture analysis on involute spline of large tunnel boring machine. Eng. Fail. Anal. 2022, 142, 106728. [Google Scholar] [CrossRef]

- Wang, J.N.; Liu, K.Y.; Xue, X.Y.; Li, J.S.; Chen, B. Columnar-to-equiaxed transition mechanism and remarkable strengthening effect in additive manufactured pure titanium induced by copper addition. Mater. Charact. 2024, 209, 113750. [Google Scholar] [CrossRef]

- Zhao, W.J.; Sun, Y.G.; Che, P.C.; Ning, Z.L.; Fan, H.B.; Yang, H.Y.; Sun, J.F.; Liaw, P.K.; Ngan, A.H.; Huang, Y.J. The columnar to equiaxed transition of CoCrNi medium-entropy alloy fabricated by laser directed energy deposition. Mater. Des. 2024, 237, 112538. [Google Scholar] [CrossRef]

- Kurz, W.; Bezençon, C.; Gäumann, M. Columnar to equiaxed transition in solidification processing. Sci. Technol. Adv. Mater. 2001, 2, 185–191. [Google Scholar] [CrossRef]

- Xiang, S.; Luan, H.; Wu, J.; Yao, K.F.; Li, J.F.; Liu, X.; Tian, Y.Z.; Mao, W.L.; Bai, H.; Le, G.M. Microstructures and mechanical properties of CrMnFeCoNi high entropy alloys fabricated using laser metal deposition technique. J. Alloy Compd. 2019, 773, 387–392. [Google Scholar] [CrossRef]

- He, R.; Wu, M.P.; Cui, C.; Jie, D.D.; Gong, Y.L.; Miao, X.J. Microstructure evolution, mechanical properties of FeCrNiMnAl high entropy alloy coatings fabricated by laser cladding. Surf. Coat. Tech. 2022, 447, 128851. [Google Scholar]

- Zhang, W.; Chabok, A.; Kooi, B.J.; Pei, Y.T. Additive manufactured high entropy alloys: A review of the microstructure and properties. Mater. Des. 2022, 220, 110875. [Google Scholar] [CrossRef]

- Zhou, Y.K.; Kang, J.J.; Zhang, J.; Fu, Z.Q.; Zhu, L.N.; She, D.S.; Yue, W. Microstructure and sliding wear behavior of HVOF sprayed Al(1−x)CoCrFeNiTix high-entropy alloy coatings. Mater. Lett. 2022, 314, 131929. [Google Scholar] [CrossRef]

- Oñate, A.; Sanhueza, J.P.; Ramirez, J.; Medina, C.; Melendrez, M.F.; Rojas, D. Design of Fe36.29Cr28.9Ni26.15Cu4.17Ti1.67V2.48C0.46 HEA using a new criterion based on VEC: Microstructural study and multiscale mechanical response. Mater. Today Commun. 2023, 35, 105681. [Google Scholar] [CrossRef]

- Zheng, W.; Lü, S.; Wu, S.; Chen, X.; Guo, W. Development of MoNbVTax refractory high entropy alloy with high strength at elevated temperature. Mater. Sci. Eng. A 2022, 850, 143554. [Google Scholar] [CrossRef]

- Guan, Y.J.; Cui, X.F.; Chen, D.; Su, W.N.; Zhao, Y.; Li, J.; Feng, L.T.; Li, X.Y.; Jin, G. Realizing excellent tribological properties of BCC/FCC gradient high -entropy alloy coating via an in-situ interface reaction. Mater. Today Commun. 2023, 35, 106098. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its ap-plication to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Aidhy, D.S. Chemical randomness, lattice distortion and the wide distributions in the atomic level properties in high entropy alloys. Comp. Mater. Sci. 2024, 237, 112912. [Google Scholar] [CrossRef]

- Hao, X.H.; Liu, H.X.; Zhang, X.W.; Chen, L.; Wang, Y.Y.; Yang, C.; Liu, Y.X. Friction-wear behaviors and microstructure of AlTiVCrNb lightweight refractory high-entropy alloy coating prepared by laser cladding on Ti-6Al-4V substrate. J. Mater. Res. Technol. 2024, 29, 1–11. [Google Scholar] [CrossRef]

- Chen, B.; Li, X.M.; Tian, L.Y.; Jia, H.Y.; Li, H.; Li, Y.J. The CrFeNbTiMox refractory high-entropy alloy coatings prepared on the 40Cr by laser cladding. J. Alloy Compd. 2023, 966, 171630. [Google Scholar] [CrossRef]

- Feng, M.Y.; Lin, T.X.; Lian, G.F.; Chen, C.R.; Huang, X.J. Effects of Nb content on the microstructure and properties of CoCrFeMnNiNbx high-entropy alloy coatings by laser cladding. Mater. Res. Technol. 2024, 28, 3835–3848. [Google Scholar] [CrossRef]

- Sun, M.; Yang, Z.N.; Song, S.C.; Zhang, J.X.; Lu, B.H. Effect of Cr content on microstructure, mechanical, and corrosion properties of CoCrxFeMnNi high-entropy alloys fabricated by selective laser melting. Mater. Charact. 2024, 212, 113949. [Google Scholar] [CrossRef]

- Zhang, C.L.; Huang, L.F.; Li, S.X.; Li, K.; Lu, S.Y.; Li, J.F. Improved corrosion resistance of laser melting deposited CoCrFeNi series high-entropy alloys by Al addition. Corro. Sci. 2023, 225, 111599. [Google Scholar] [CrossRef]

- Gu, X.H.; Li, X.R.; Zhang, Q.H.; Wu, L.K.; Cao, F.H. Passive film and surface characterization of Alx(CoCrFeNi)100-x (x = 0, 5, 10, 15, 20) high entropy alloys. Intermetallics 2023, 162, 107994. [Google Scholar] [CrossRef]

- Wang, G.Y.; Xu, J.; Chen, Y.H.; Zhao, Y.J.; Xie, Z.H.; Munroe, P.R. Assessment of the tribocorrosion performance of a (TiZrNbTaMo)C refractory high entropy alloy carbide coating in a marine environment. J. Alloys Compd. 2023, 965, 171342. [Google Scholar] [CrossRef]

- Koka, Y.; Tana, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti-6Al-4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Wang, C.; Gao, P.F.; Liu, T.; Li, L.F.; Wang, E.Z.; Wang, Q. Microstructure and wear performance of Ni-10 wt.%Al coatings plasma sprayed on Ni-based superalloys with a sound field. Surf. Coat. Tech. 2019, 370, 157–162. [Google Scholar] [CrossRef]

- Safaie, H.; Coleman, M.; Johnston, R.; Das, A.; Russell, J.; Pleydell-Pearce, C. Circular polarized light microscopy to investigate the crystal orientation of aluminium. Mater. Charact. 2022, 185, 111749. [Google Scholar] [CrossRef]

- Nadoum, A.; Robinson, F.; Birosca, S.J. On the correlation between magnetic domain and crystallographic grain orientation in grain oriented electrical steels. Magn. Magn. Mater. 2020, 494, 165772. [Google Scholar] [CrossRef]

- Zhu, J.L.; An, Z.Q.; Zhang, A.X.; Du, Y.K.; Zhou, X.; Geng, Y.Z.; Chen, G.F. Anisotropic porous designed polymer coatings for high-performance passive all-day radiative cooling. iScience 2022, 25, 104126. [Google Scholar] [CrossRef]

- Valagiannopoulos, C.A. Study of an electrically anisotropic cylinder excited magnetically by a straight strip line Electromagn. Prog. Electromagn Res. 2007, 73, 297–325. [Google Scholar] [CrossRef][Green Version]

| Type of Substrates | C | Si | Mn | P | S | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Q235 | 0.15 | 0.35 | 1.20 | 0.045 | 0.050 | - | - | - | Bal. |

| 304SS | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0–20.0 | 8.0–11.0 | - | Bal. |

| 17CrNiMo6H | 0.20 | 0.40 | 0.60 | 0.035 | 0.035 | 1.50 | 1.70 | 0.35 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.; Liu, B.; Wang, D.; Han, G.; Han, D.; Yang, B. Microstructures and Properties of Laser-Cladded FeCoCrNiAlTi High-Entropy Alloy with Intensive Repair Potential. Coatings 2024, 14, 1068. https://doi.org/10.3390/coatings14081068

Yu H, Liu B, Wang D, Han G, Han D, Yang B. Microstructures and Properties of Laser-Cladded FeCoCrNiAlTi High-Entropy Alloy with Intensive Repair Potential. Coatings. 2024; 14(8):1068. https://doi.org/10.3390/coatings14081068

Chicago/Turabian StyleYu, Hao, Bo Liu, Debin Wang, Guofeng Han, Dong Han, and Baijun Yang. 2024. "Microstructures and Properties of Laser-Cladded FeCoCrNiAlTi High-Entropy Alloy with Intensive Repair Potential" Coatings 14, no. 8: 1068. https://doi.org/10.3390/coatings14081068

APA StyleYu, H., Liu, B., Wang, D., Han, G., Han, D., & Yang, B. (2024). Microstructures and Properties of Laser-Cladded FeCoCrNiAlTi High-Entropy Alloy with Intensive Repair Potential. Coatings, 14(8), 1068. https://doi.org/10.3390/coatings14081068