3D-Printed Conformal Thin Film Thermocouple Arrays for Distributed High-Temperature Measurements

Abstract

:1. Introduction

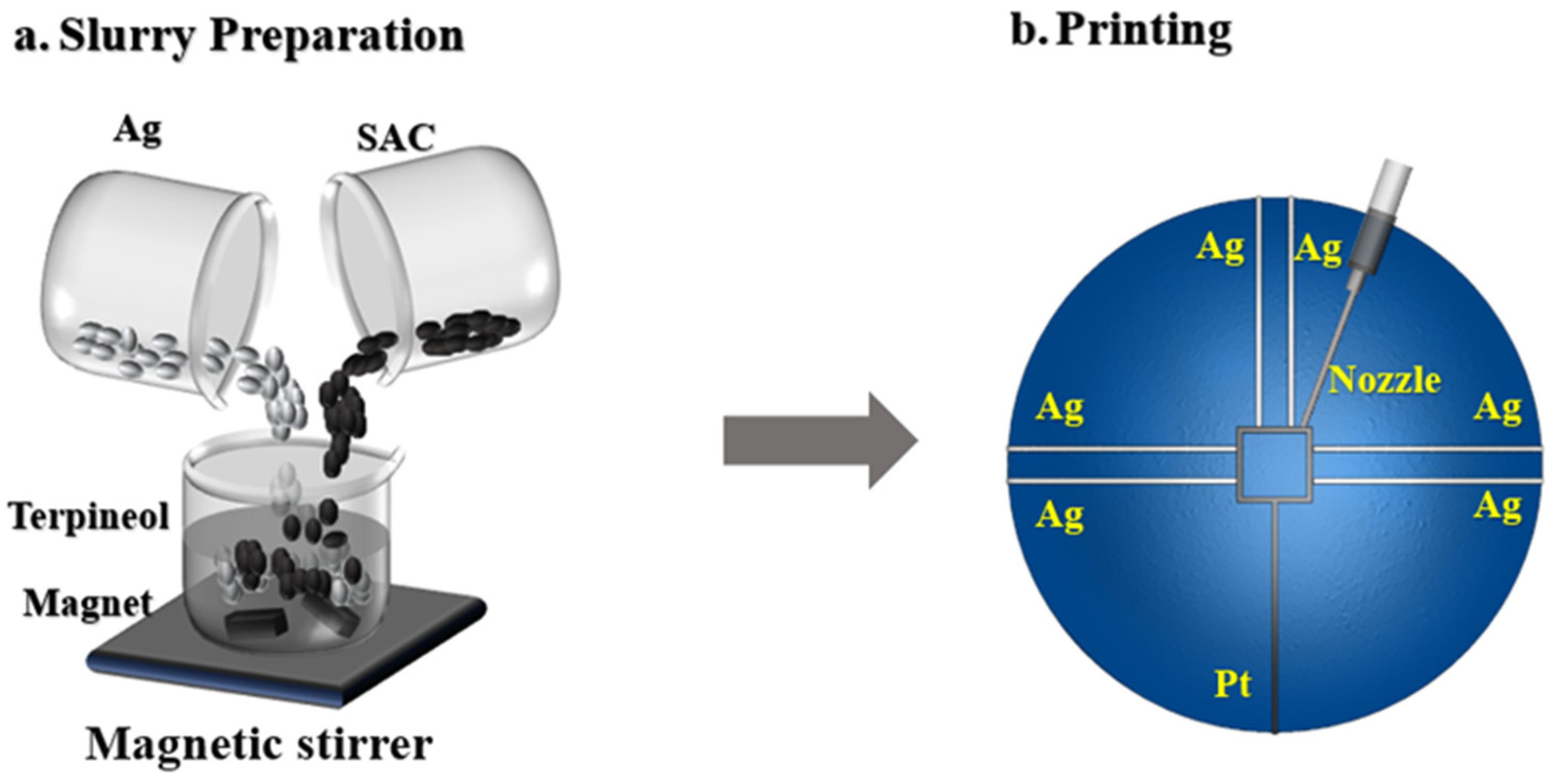

2. Materials and Methods

2.1. Material

2.2. Fabrication Methods

2.3. Characterization Methods

2.4. Test Methods

3. Results

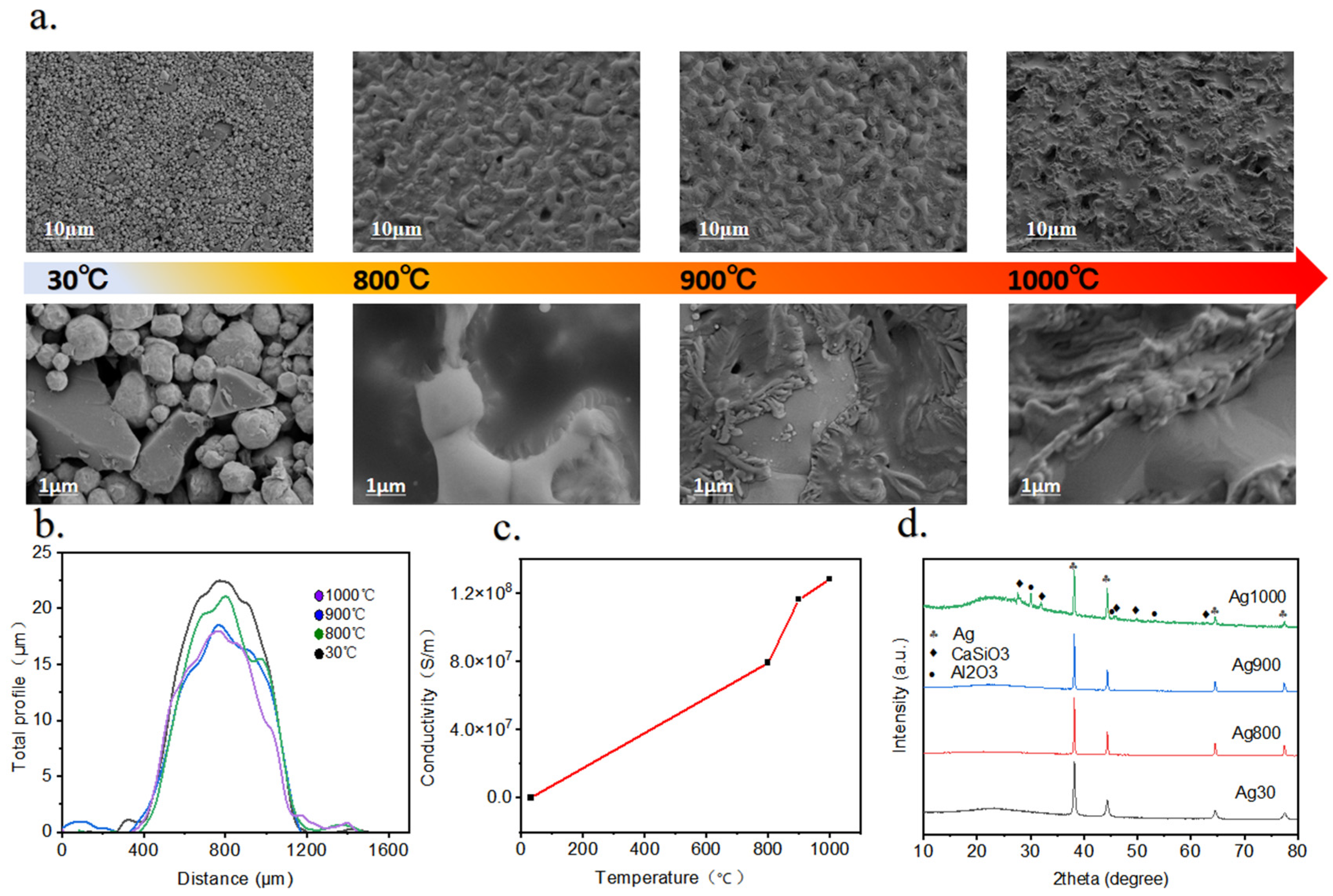

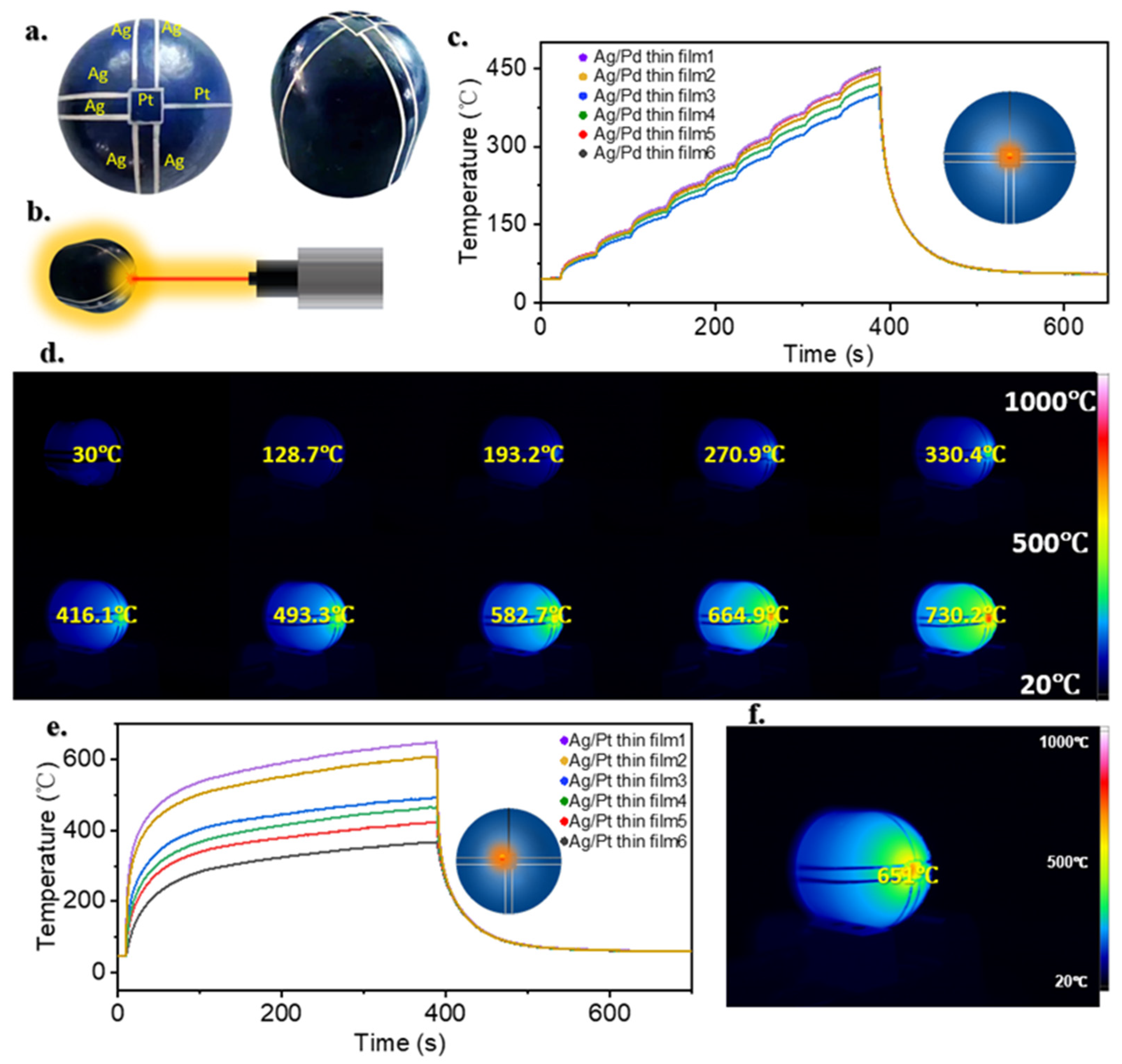

3.1. Sintering Process and Characterization

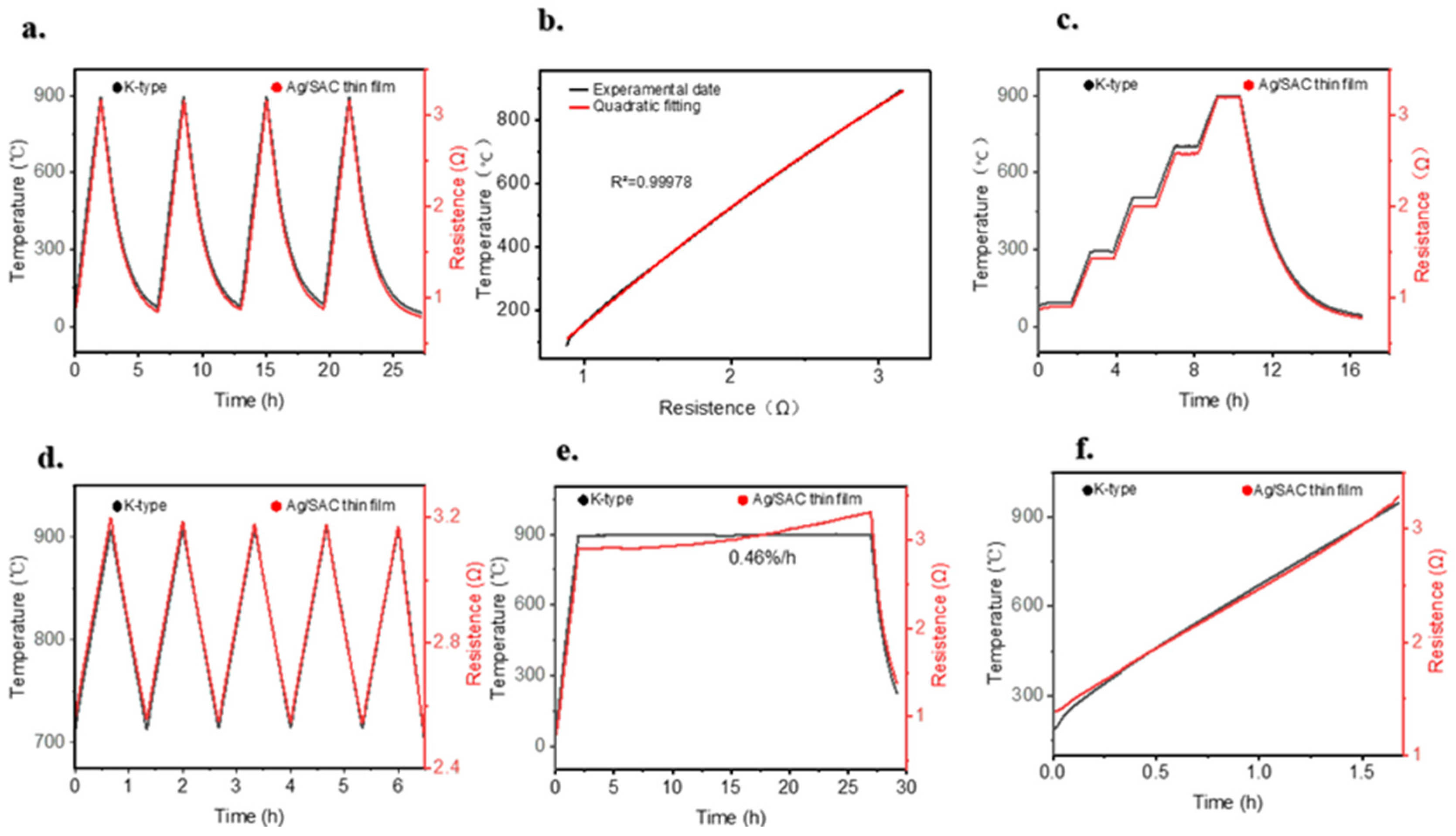

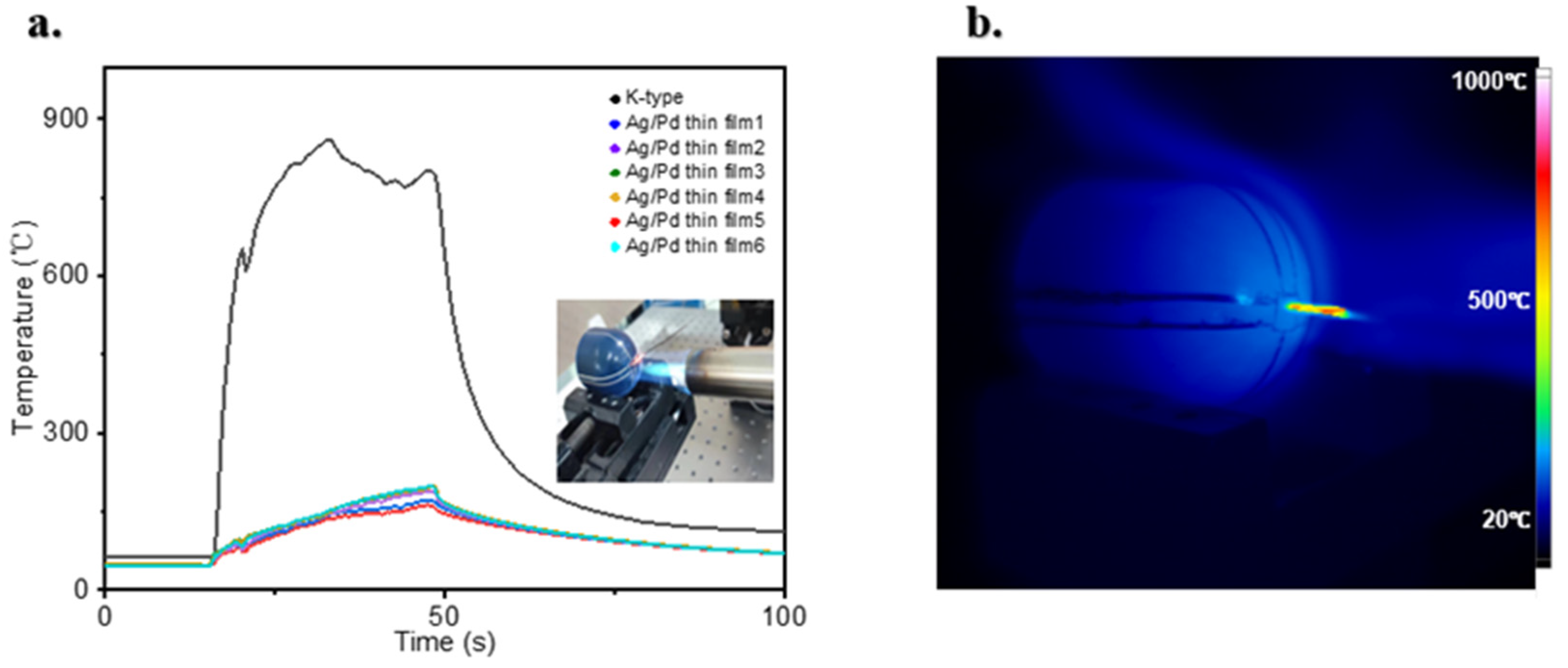

3.2. Ag/SAC Composite Slurry Film Thermal Resistance Test

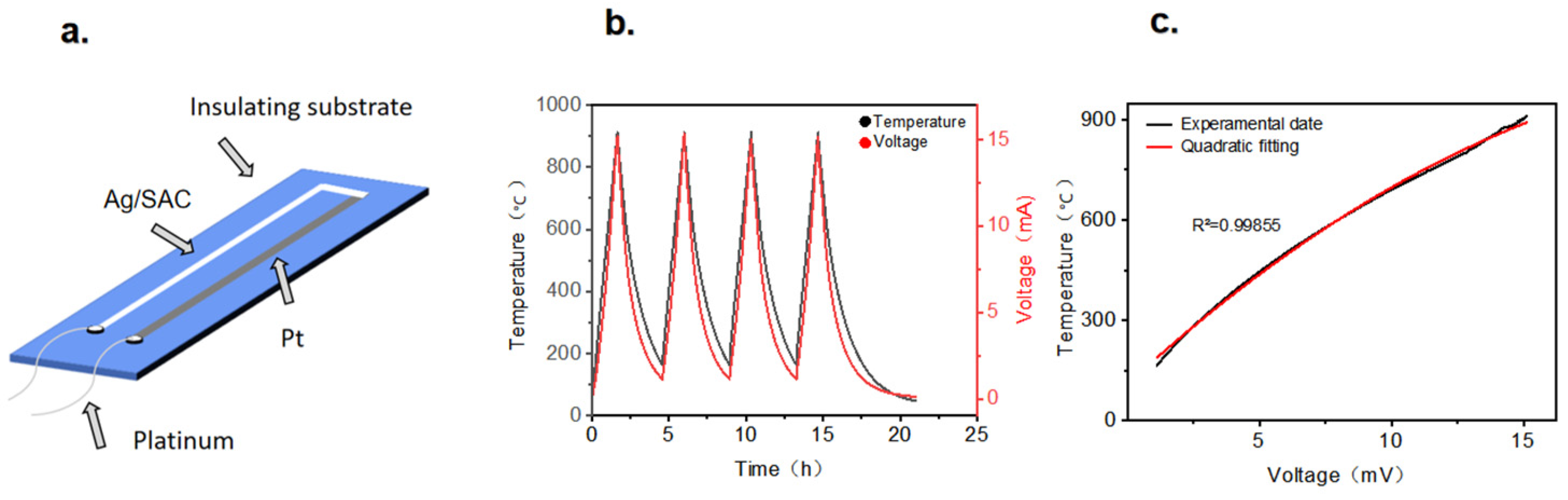

3.3. Application Verification of Ag/Pt Conformal Thin Film Thermocouple Arrays

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ketui, D.; Chi, F.; Shan, G. Single wavelength and ratio pyrometry reflection errors in temperature measurement of gas turbine blade. Measurement 2016, 86, 133–140. [Google Scholar] [CrossRef]

- Guo, M.; Yang, C.; Gao, D.; Li, Q.; Zhang, A.; Feng, J.; Yang, H.; Tao, R.; Fan, Z.; Zeng, M. A flexible and high temperature tolerant strain sensor of La0.7Sr0.3MnO3/Mica. J. Mater. Sci. Technol. 2020, 44, 42–47. [Google Scholar] [CrossRef]

- Habib, Z.; Parthasarathy, R.; Gollahalli, S. Performance and emission characteristics of biofuel in a small-scale gas turbine engine. Appl. Energy 2010, 87, 1701–1709. [Google Scholar] [CrossRef]

- Guangsheng, Z.; Chunsheng, N.; Zhanwei, C.; Ye, Y. Research progress of aerodynamic thermal environment test and measurement technology. J. Exp. Fluid Mech. 2019, 33, 1–10. [Google Scholar]

- Duan, F.L.; Li, J.; Gao, J.; Ding, G.; Cao, X. Integrated fabrication of high-temperature microelectromechanical system sensor on aeroengine turbine blade. J. Thermophys. Heat Transf. 2018, 32, 828–830. [Google Scholar] [CrossRef]

- Zaghari, B.; Weddell, A.S.; Esmaeili, K.; Bashir, I.; Harvey, T.J.; White, N.M.; Mirring, P.; Wang, L. High-temperature self-powered sensing system for a smart bearing in an aircraft jet engine. IEEE Trans. Instrum. Meas. 2020, 69, 6165–6174. [Google Scholar] [CrossRef]

- Ghazanfari, A.; Li, W.; Leu, M.C.; Zhuang, Y.; Huang, J. Advanced ceramic components with embedded sapphire optical fiber sensors for high temperature applications. Mater. Des. 2016, 112, 197–206. [Google Scholar] [CrossRef]

- Chilles, J.S.; Croxford, A.; Bond, I.P. Design of an embedded sensor, for improved structural performance. Smart Mater. Struct. 2015, 24, 115014. [Google Scholar] [CrossRef]

- Li, X.; Sun, D.; Liu, B.; Cui, Z.; Chen, Q.; He, G.; Hai, Z. High-sensitive thin film heat flux gauge with ITO/In2O3 thermopile on nickel alloys for turbine blade applications. IEEE Sens. J. 2021, 22, 3911–3919. [Google Scholar] [CrossRef]

- Duan, F.L.; Xie, Z.; Ji, Z.; Weng, H. Robust thin-film temperature sensors embedded on nozzle guide vane surface. AIAA J. 2020, 58, 1441–1445. [Google Scholar] [CrossRef]

- Bhatt, H.D.; Vedula, R.; Desu, S.B.; Fralick, G.C. Thin film TiC/TaC thermocouples. Thin Solid Film. 1999, 342, 214–220. [Google Scholar] [CrossRef]

- Martin, L.C.; Wrbanek, J.D.; Fralick, G.C. Thin film sensors for surface measurements [in aerospace simulation facilities]. In Proceedings of the ICIASF 2001 Record, 19th International Congress on Instrumentation in Aerospace Simulation Facilities (Cat. No. 01CH37215), Cleveland, OH, USA, 27–30 August 2001; pp. 196–203. [Google Scholar]

- Fralick, G.; Wrbanek, J.; Blaha, C. Thin film heat flux sensor of improved design. In Proceedings of the 48th International Instrumentation Symposium, San Diego, CA, USA, 5–9 May 2002. [Google Scholar]

- Tougas, I.M.; Amani, M.; Gregory, O.J. Metallic and Ceramic Thin Film Thermocouples for Gas Turbine Engines. Sensors 2013, 13, 15324–15347. [Google Scholar] [CrossRef] [PubMed]

- Gregory, O.J.; Busch, E.; Fralick, G.C.; Chen, X. Preparation and characterization of ceramic thin film thermocouples. Thin Solid Films 2010, 518, 6093–6098. [Google Scholar] [CrossRef]

- Zribi, A.; Barthès, M.; Bégot, S.; Lanzetta, F.; Rauch, J.Y.; Moutarlier, V. Design, fabrication and characterization of thin film resistances for heat flux sensing application. Sens. Actuators A Phys. 2016, 245, 26–39. [Google Scholar] [CrossRef]

- Liu, Z.; Liang, J.; Zhou, H.; Sun, H.; Lu, W.; Wang, B.; Li, Q.; Zhao, X.; Wang, D.; Xu, J. Effect of nitrogen partial pressure on the piezoresistivity of magnetron sputtered ITO thin films at high temperatures. Appl. Surf. Sci. 2023, 608, 155292. [Google Scholar] [CrossRef]

- Ji, Z.; Duan, F.L.; Xie, Z. Transient measurement of temperature distribution using thin film thermocouple array on turbine blade surface. IEEE Sens. J. 2020, 21, 207–212. [Google Scholar] [CrossRef]

- Kennedy, F.E.; Frusescu, D.; Li, J. Thin film thermocouple arrays for sliding surface temperature measurement. Wear 1997, 207, 46–54. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Domínguez-Fernández, A.; Gómez-Gejo, A. Effect of printing parameters on dimensional error and surface roughness obtained in direct ink writing (DIW) processes. Materials 2020, 13, 2157. [Google Scholar] [CrossRef] [PubMed]

- Lewis, J.A.; Smay, J.E.; Stuecker, J.; Cesarano, J. Direct ink writing of three-dimensional ceramic structures. J. Am. Ceram. Soc. 2006, 89, 3599–3609. [Google Scholar] [CrossRef]

- Saadi, M.; Maguire, A.; Pottackal, N.T.; Thakur, M.S.H.; Ikram, M.M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct ink writing: A 3D printing technology for diverse materials. Adv. Mater. 2022, 34, 2108855. [Google Scholar] [CrossRef]

- Shahzad, A.; Lazoglu, I. Direct ink writing (DIW) of structural and functional ceramics: Recent achievements and future challenges. Compos. Part B Eng. 2021, 225, 109249. [Google Scholar] [CrossRef]

- Teegen, I.-S.; Schadte, P.; Wille, S.; Adelung, R.; Siebert, L.; Kern, M. Comparison of properties and cost efficiency of zirconia processed by DIW printing, casting and CAD/CAM-milling. Dent. Mater. 2023, 39, 669–676. [Google Scholar] [CrossRef]

- Xu, C.; Quinn, B.; Lebel, L.L.; Therriault, D.; L’Espérance, G. Multi-material direct ink writing (DIW) for complex 3D metallic structures with removable supports. ACS Appl. Mater. Interfaces 2019, 11, 8499–8506. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.; Xie, B.; Xu, Z.; Wu, H. A systematic printability study of direct ink writing towards high-resolution rapid manufacturing. Int. J. Extrem. Manuf. 2023, 5, 035002. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, P.; Liu, K.; Xu, P.; Wei, H.; Hai, Z.; Wu, D.; Zhao, Y.; Jin, X.; Wang, X. Polymer-derived ceramic thin-film thermocouples for high temperature measurements. Ceram. Int. 2023, 49, 31248–31254. [Google Scholar] [CrossRef]

- Cui, Y.; Yang, D.; Jia, Y.; Zeng, Q.; Sun, B. Dynamic calibration of the cutting temperature sensor of NiCr/NiSi thin-film thermocouple. Target 2011, 88, 95.15. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, H.; Zhang, W.; Liu, X.; Jiang, S. Film thickness influences on the thermoelectric properties of NiCr/NiSi thin film thermocouples. Mod. Phys. Lett. B 2013, 27, 1350103. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, C.; Jiu, J.; Nagao, S.; Suganuma, K. High-temperature reliability of low-temperature and pressureless micron Ag sintered joints for die attachment in high-power device. J. Mater. Sci. Mater. Electron. 2018, 29, 8854–8862. [Google Scholar] [CrossRef]

- He, Y.; Li, L.; Su, Z.; Xu, L.; Guo, M.; Duan, B.; Wang, W.; Cheng, B.; Sun, D.; Hai, Z. Electrohydrodynamic Printed Ultra-Micro AgNPs Thin Film Temperature Sensors Array for High-Resolution Sensing. Micromachines 2023, 14, 1621. [Google Scholar] [CrossRef]

- Gong, X.; Cheng, B.; Zhang, C.; Wang, B.; He, Y.; Guo, M.; Su, Z.; Duan, B.; Hai, Z. Electrohydrodynamic-Printed AgNPs/PR Thin-Film Temperature Sensors With Micro Dimensions and Higher Temperature Measurement Capabilities. IEEE Sens. J. 2024, 24, 17441–17451. [Google Scholar] [CrossRef]

- Hai, Z.; Guo, M.; Xu, L.; Su, Z.; Wang, Y.; He, Y.; Zhao, Y.; Sun, D. Printable silicate and RuO2 composite with wide-range linear PTC for high-temperature sensors. Ceram. Int. 2024, 50 Pt B, 30776–30784. [Google Scholar] [CrossRef]

- Mei, X.; Chen, Q.; Wang, S.; Wei, W.; Sun, D. The microscale Weissenberg effect for high-viscosity solution pumping at the picoliter level. Nanoscale 2018, 10, 7127–7137. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Xu, L.; Zhou, X.; Zhao, F.; Wang, Y.; Wang, S.; Lv, W.; Sun, D.; Chen, Q. 3D-Printed Conformal Thin Film Thermocouple Arrays for Distributed High-Temperature Measurements. Coatings 2024, 14, 967. https://doi.org/10.3390/coatings14080967

Liu J, Xu L, Zhou X, Zhao F, Wang Y, Wang S, Lv W, Sun D, Chen Q. 3D-Printed Conformal Thin Film Thermocouple Arrays for Distributed High-Temperature Measurements. Coatings. 2024; 14(8):967. https://doi.org/10.3390/coatings14080967

Chicago/Turabian StyleLiu, Jun, Lida Xu, Xiong Zhou, Fuxin Zhao, Yusen Wang, Siqi Wang, Wenlong Lv, Daoheng Sun, and Qinnan Chen. 2024. "3D-Printed Conformal Thin Film Thermocouple Arrays for Distributed High-Temperature Measurements" Coatings 14, no. 8: 967. https://doi.org/10.3390/coatings14080967