Enhanced Analysis of Ice Accretion on Rotating Blades of Horizontal-Axis Wind Turbines Using Advanced 3D Scanning Technology

Abstract

1. Introduction

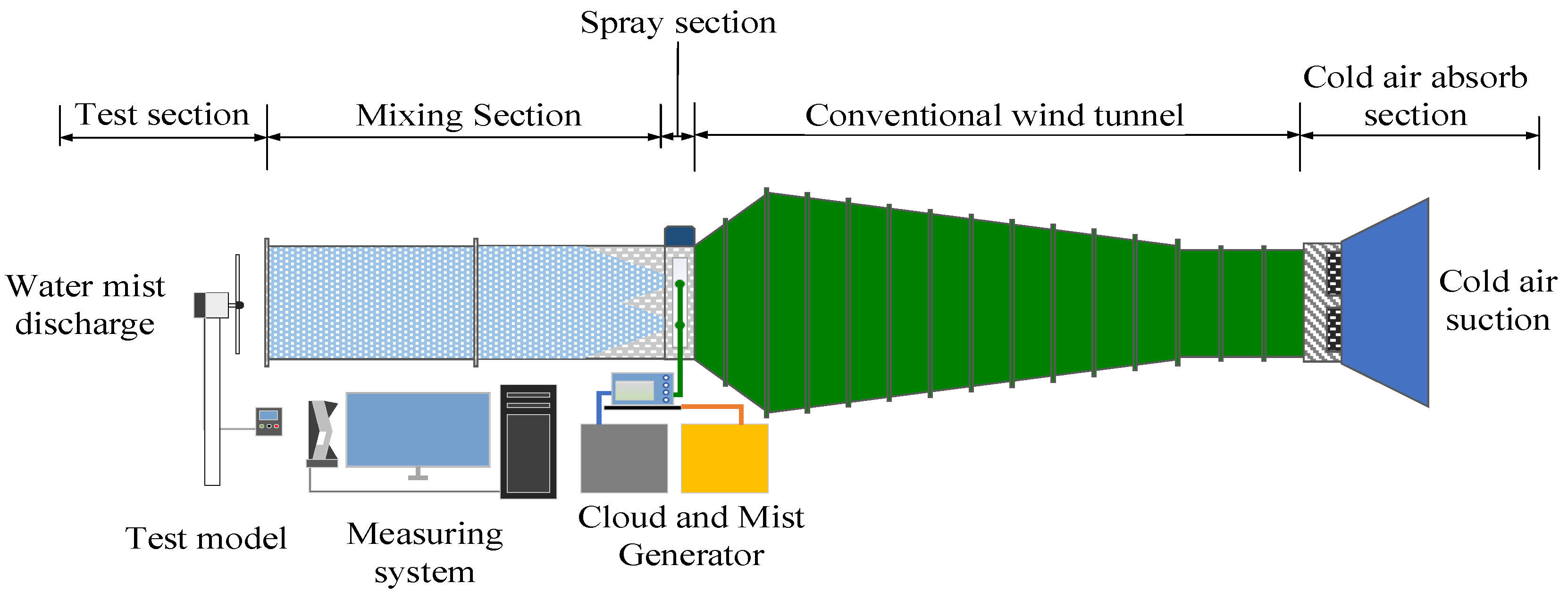

2. Experimental System

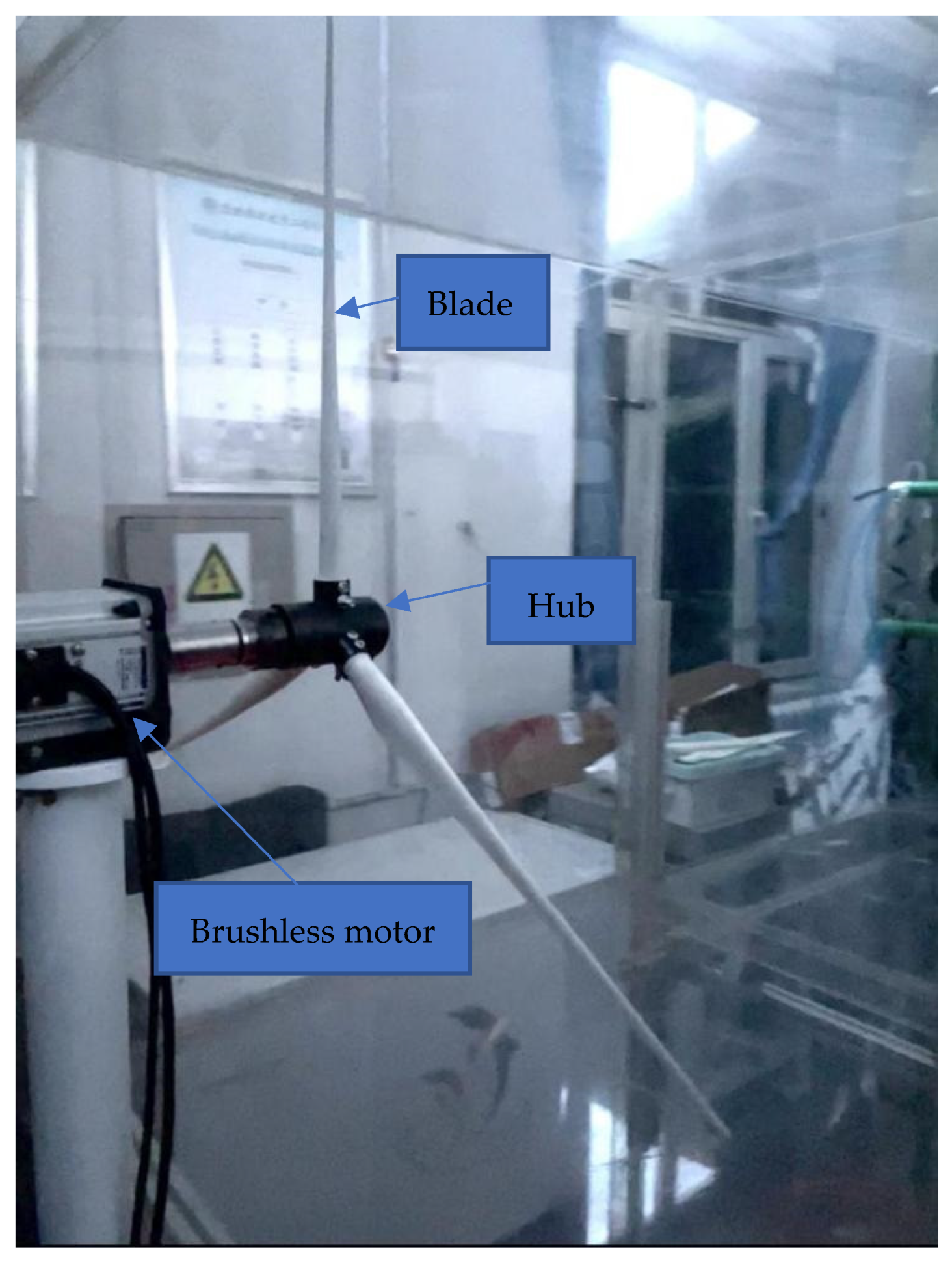

2.1. Experimental Model

2.2. Measurement Equipment

3. Experimental Methods

3.1. Ice Accretion Similarity Criteria

- (1)

- The characteristic length of the scaled model is selected as follows:

- (2)

- The pitch angle of the blades is determined based on geometric similarity as follows:

- (3)

- The test wind speed for the scaled model is selected as follows:

- (4)

- The test temperature (T) is determined using thermodynamic similarity as follows:

- (5)

- The test droplet particle diameter (d) is obtained using the modified inertia parameter [36] as follows:

- (6)

- The ice water content LWC in the scaled model test is calculated as follows [34]:

- (7)

- The test pressure (P) is determined based on dynamic pressure similarity principles as follows [34]:

- (8)

- The test time (t) is determined based on the similarity aggregation factor (Ac) [34] as follows:

- (9)

- The tip speed ratio during rotation is determined based on rotational parameter similarity as follows:

3.2. Experimental Parameters

3.3. Experimental Implementation

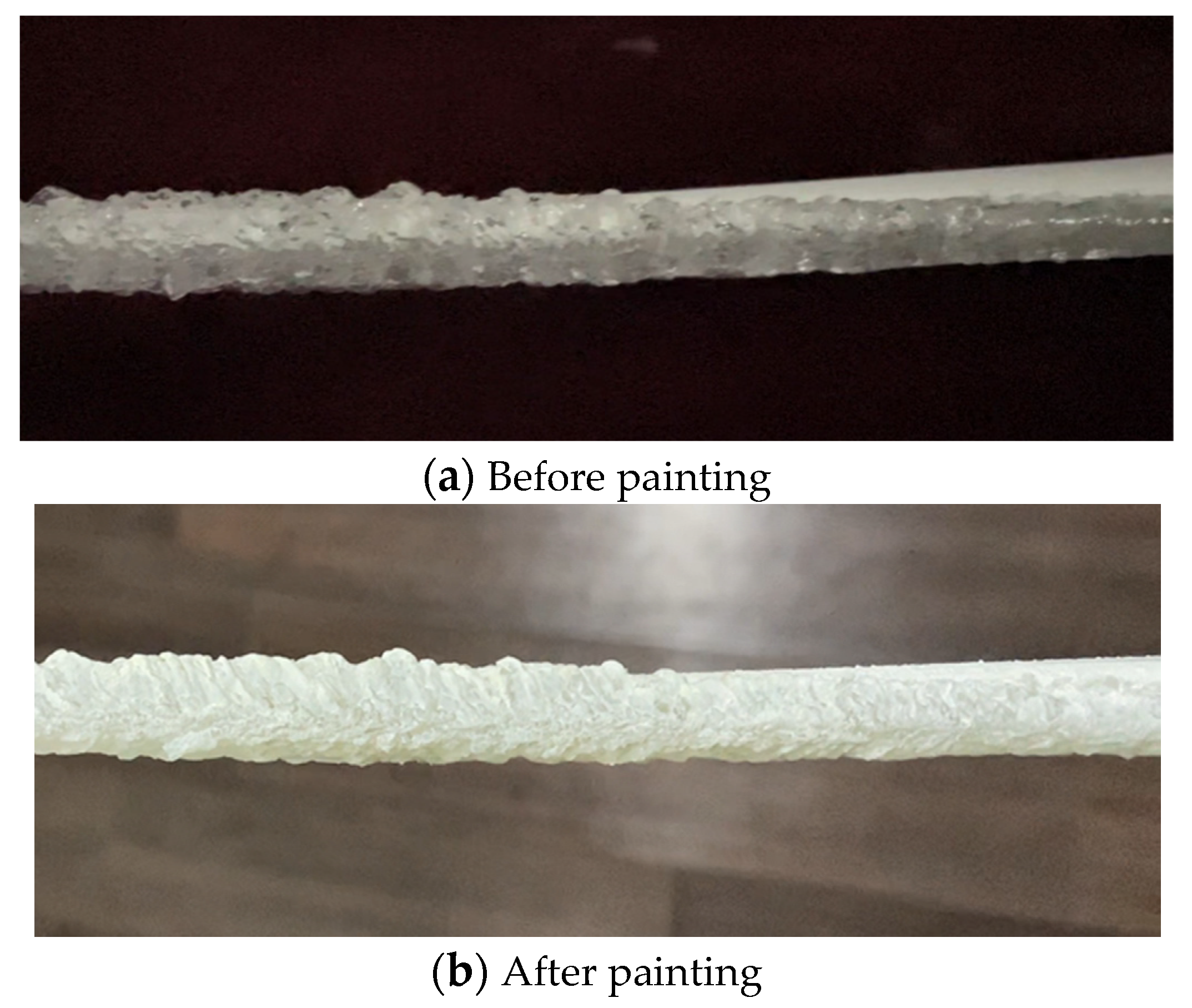

3.3.1. Preparation of Contrast Agent

3.3.2. Experimental Procedure

- Before the icing experiment begins, the model is adjusted to the experimental state, the computer is started, and the scanner is connected. The scanner exposure is adjusted using the software to ensure optimal performance under the experimental conditions of the day;

- The wind tunnel is opened, and the wind speed is adjusted to the experimental set speed, introducing outdoor cold air flow;

- Once the temperature reaches the set experimental temperature, the spray system is activated, and the motor controller is adjusted to rotate the wind turbine model according to the specified parameters. The icing time is recorded, and the icing wind tunnel experiment is started;

- After 120 s of icing time, the icing wind tunnel test system is shut down, marking the end of the icing wind tunnel experiment;

- Following the experiment, the ice-covered blades are carefully removed. A contrast agent is uniformly sprayed on the ice positions using a spray gun, and the ice-covered blades are fixed on the scanning stage;

- A handheld 3D laser scanner with a laser scanning probe is used to measure 3D ice profiles of the ice-covered blades from multiple angles. After scanning, the ice shape point cloud data are inspected to ensure comprehensive coverage of the areas to be measured, minimizing data discontinuities;

- Both the clean model surface point cloud data and the ice shape point cloud data are reconstructed to form model reconstruction surfaces and ice shape reconstruction surfaces. These are aligned and matched to obtain the model-ice shape reconstruction surfaces.

3.3.3. Processing of Scanned Data

- Noise Reduction: During the scanning process, uncertainties stemming from the scanner and the scanning environment can lead to certain points deviating from the surface being scanned, thus creating outliers. The utilization of the noise reduction command aids in repositioning these points to their statistically accurate locations, thereby guaranteeing a more seamless arrangement of points;

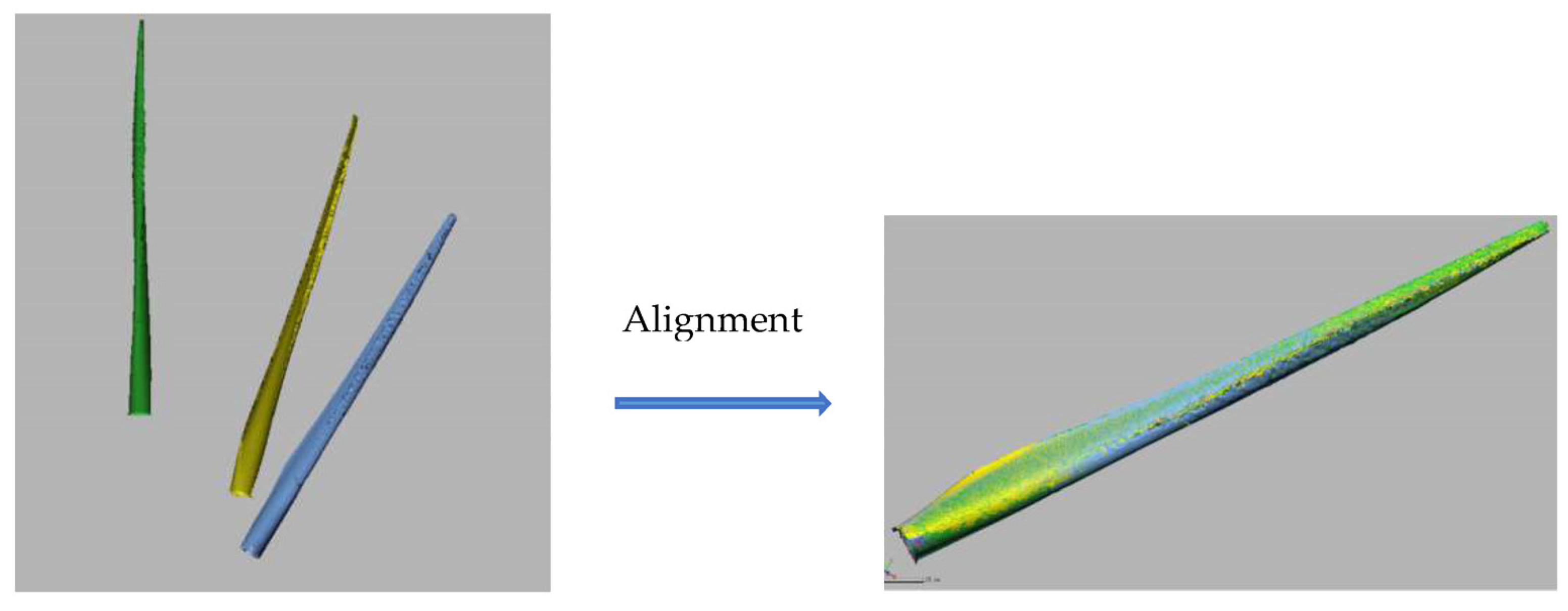

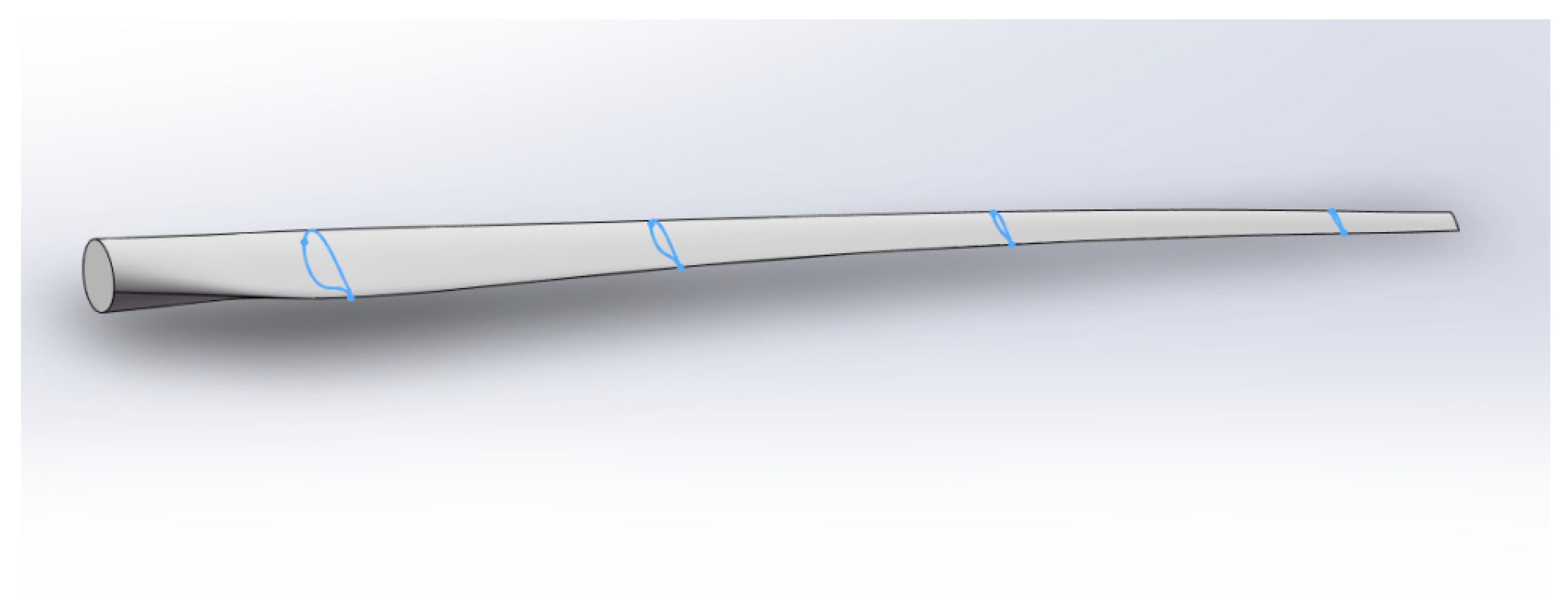

- Alignment and Merging: The process involves manually aligning multiple scanned point cloud data sets of the same ice-covered blade at various angles to create a more comprehensive point cloud data set. This procedure includes selecting two imported scanned point cloud data sets, identifying three corresponding points on the ice-covered blade that are not on the same plane based on morphological features, and aligning them using Geomagic’s algorithms. This alignment process is repeated for the remaining data sets to combine them and produce a more accurate and complete point cloud data set of the ice-covered blade (Figure 5);

- Conversion to Triangle Mesh: The merged point cloud data are converted into a triangle mesh surface. During the conversion process, offsets between the camera and laser on the scanner can result in instances where the laser projection is not recognized by the camera, especially when the ice has significant depth or is obscured by other ice features. This can create holes of varying sizes and quantities in the mesh. Smaller holes are filled directly using the “internal hole” command, while larger holes necessitate the use of commands such as “boundary hole” and “bridging” to segment large holes into smaller ones before patching;

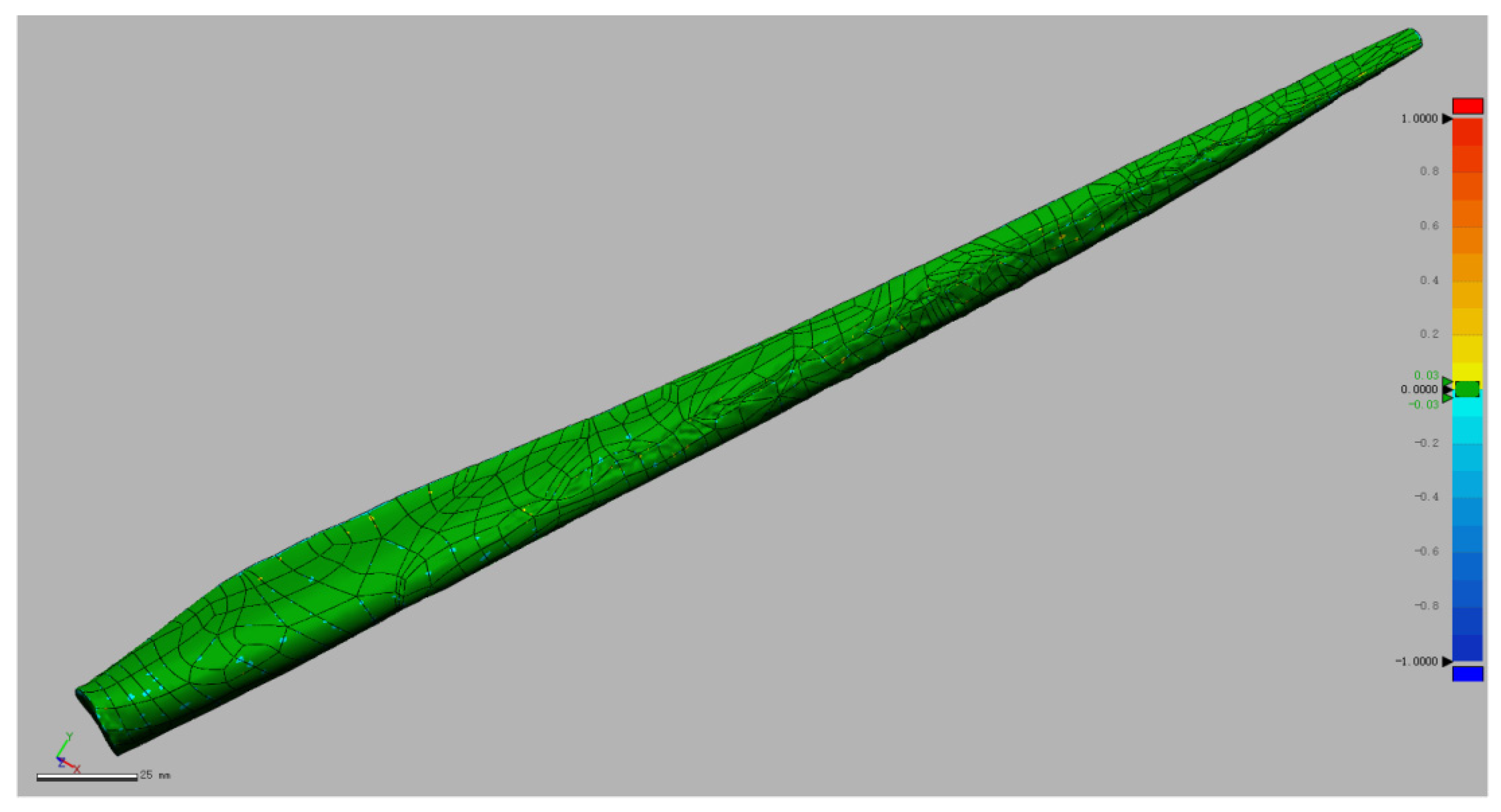

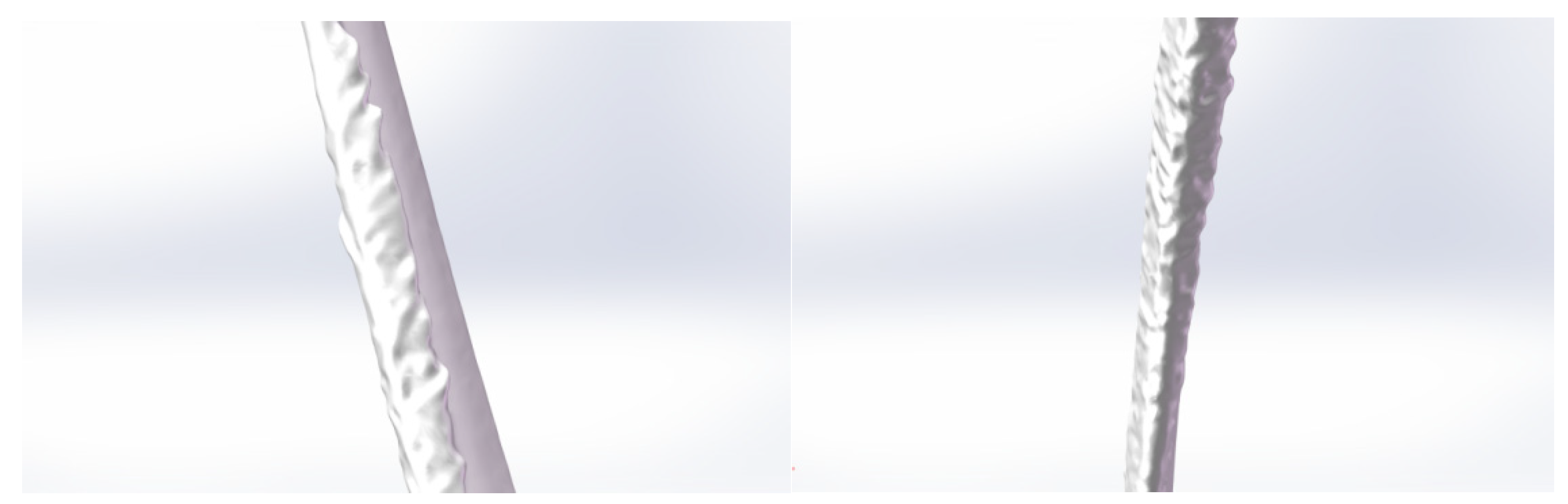

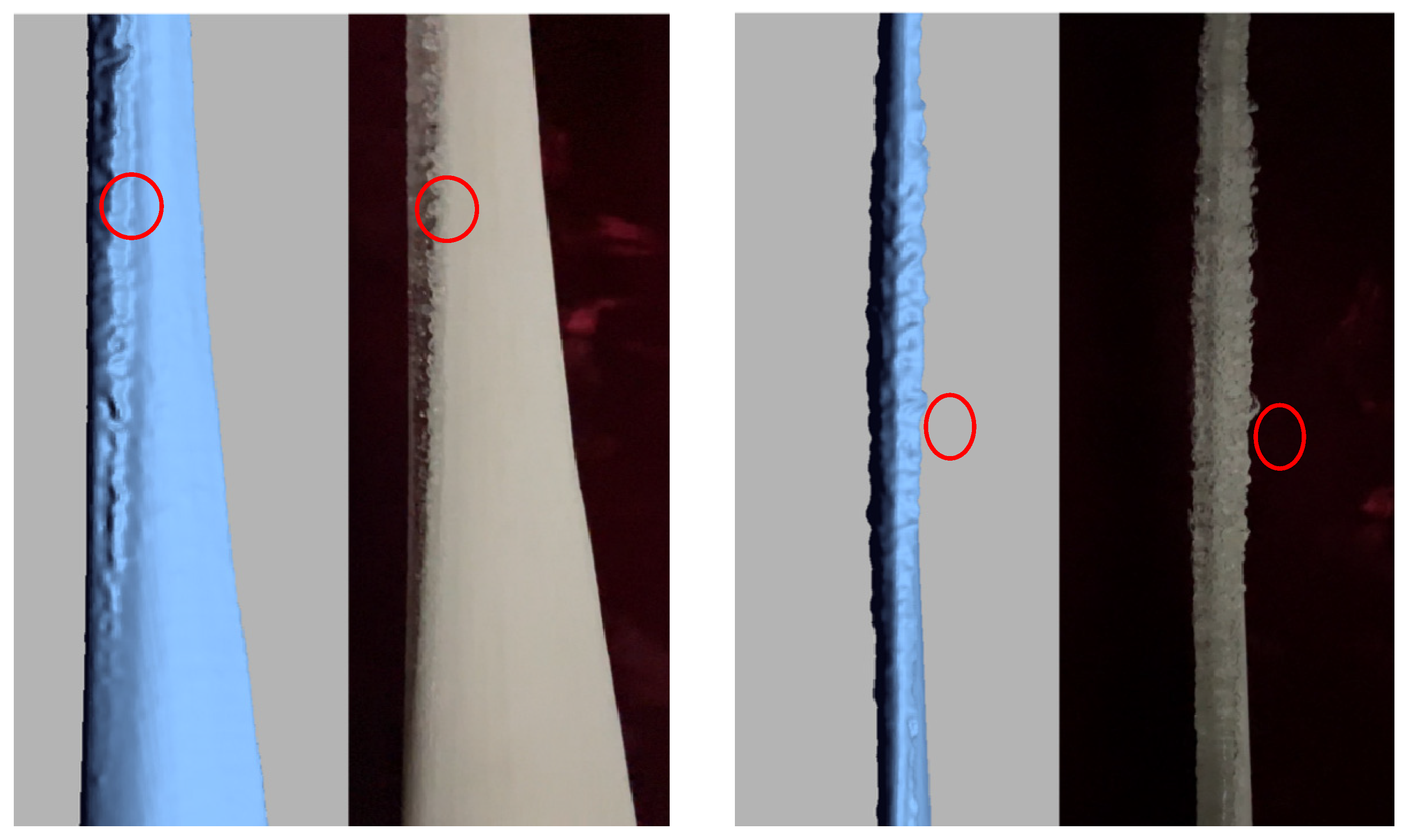

- After analyzing the point cloud data, different model reconstruction surfaces and ice shape reconstruction surfaces are produced to create solid structures. Figure 6 illustrates a color map representing volumetric deviations between the processed model and the initial scan data, indicating that the majority of locations in the processed model adhere to the specified accuracy threshold of 0.03 mm. Figure 7 depicts detailed perspectives of the ice-covered blade entity formed during post-processing.

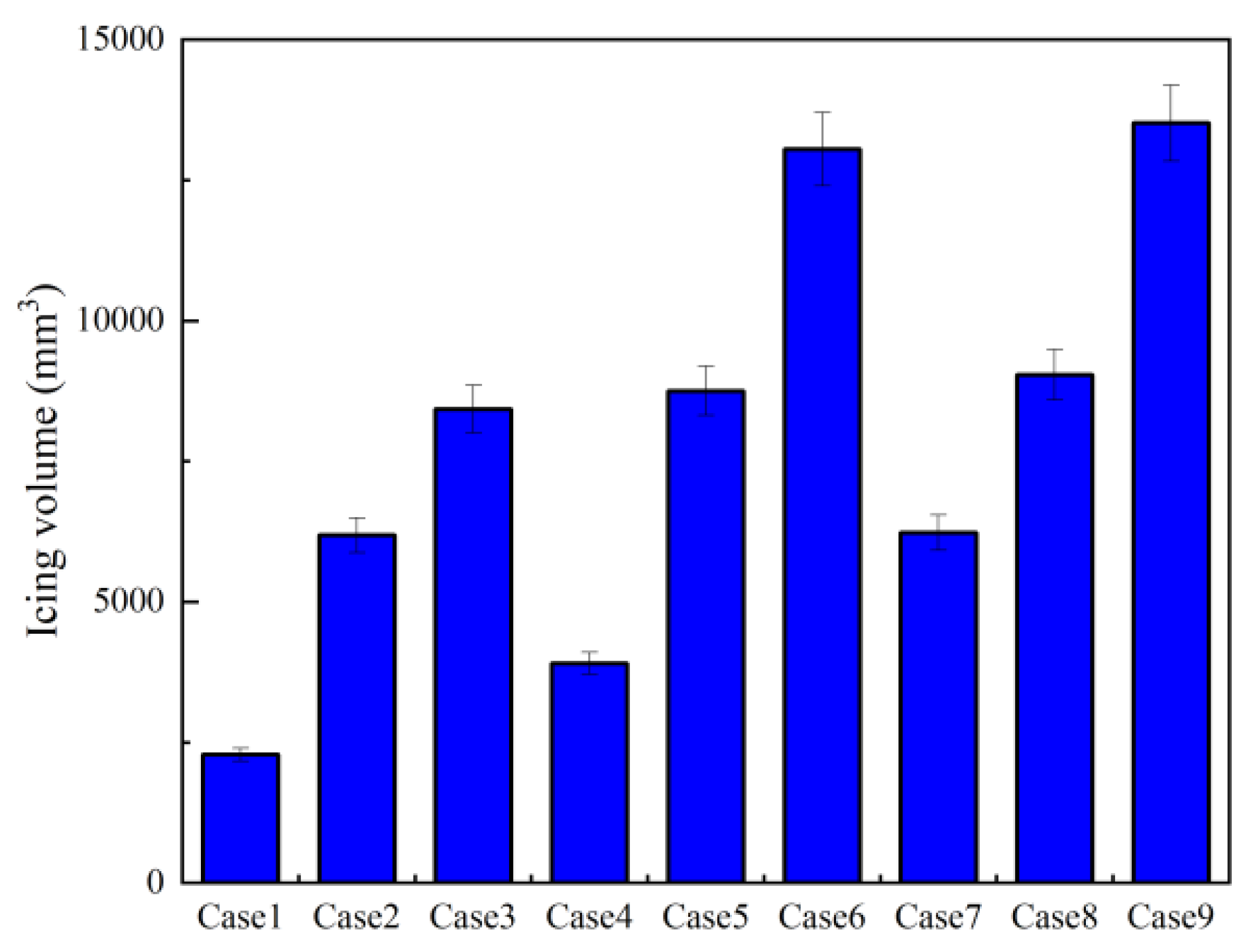

4. Experimental Results and Analysis

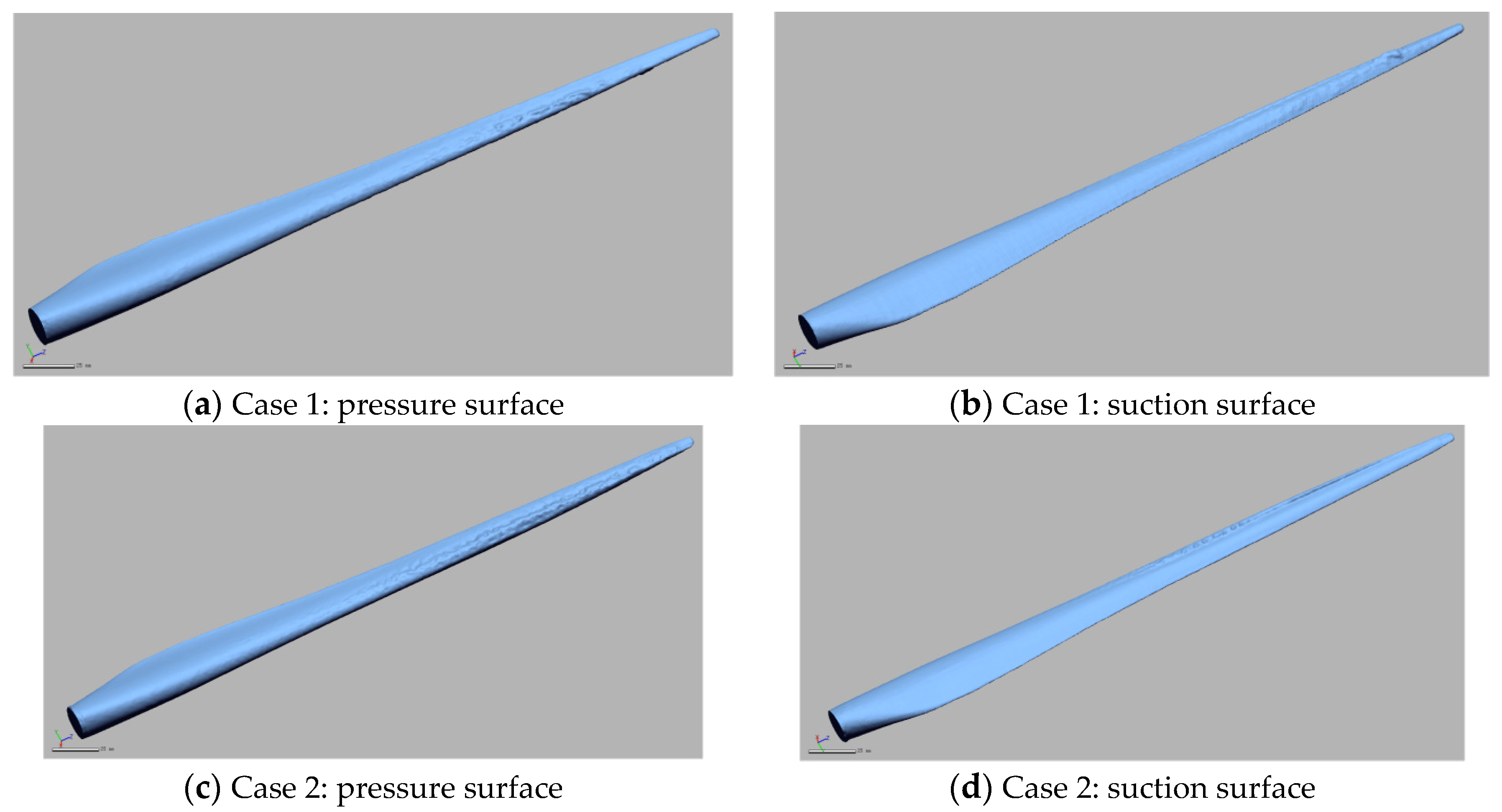

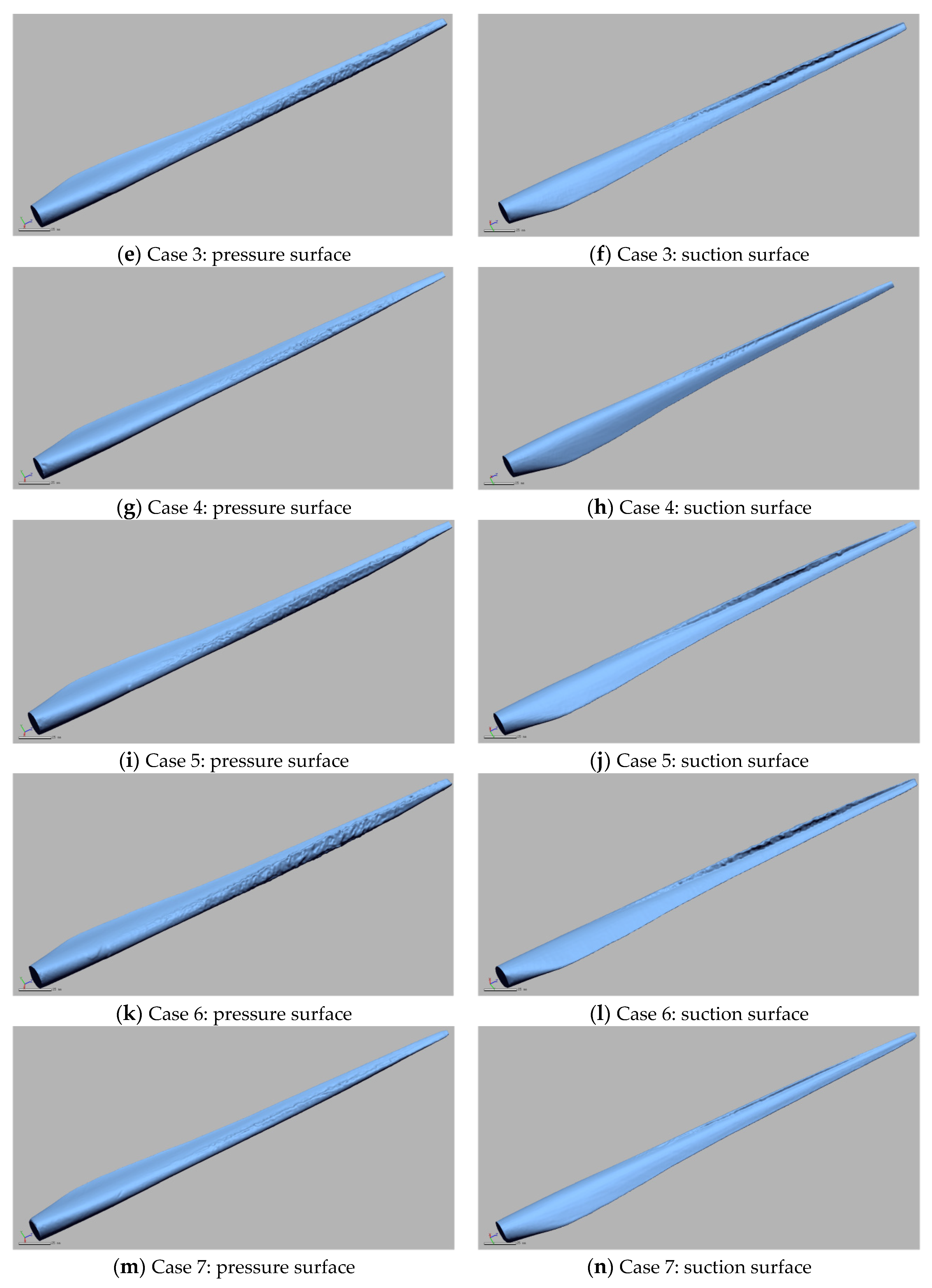

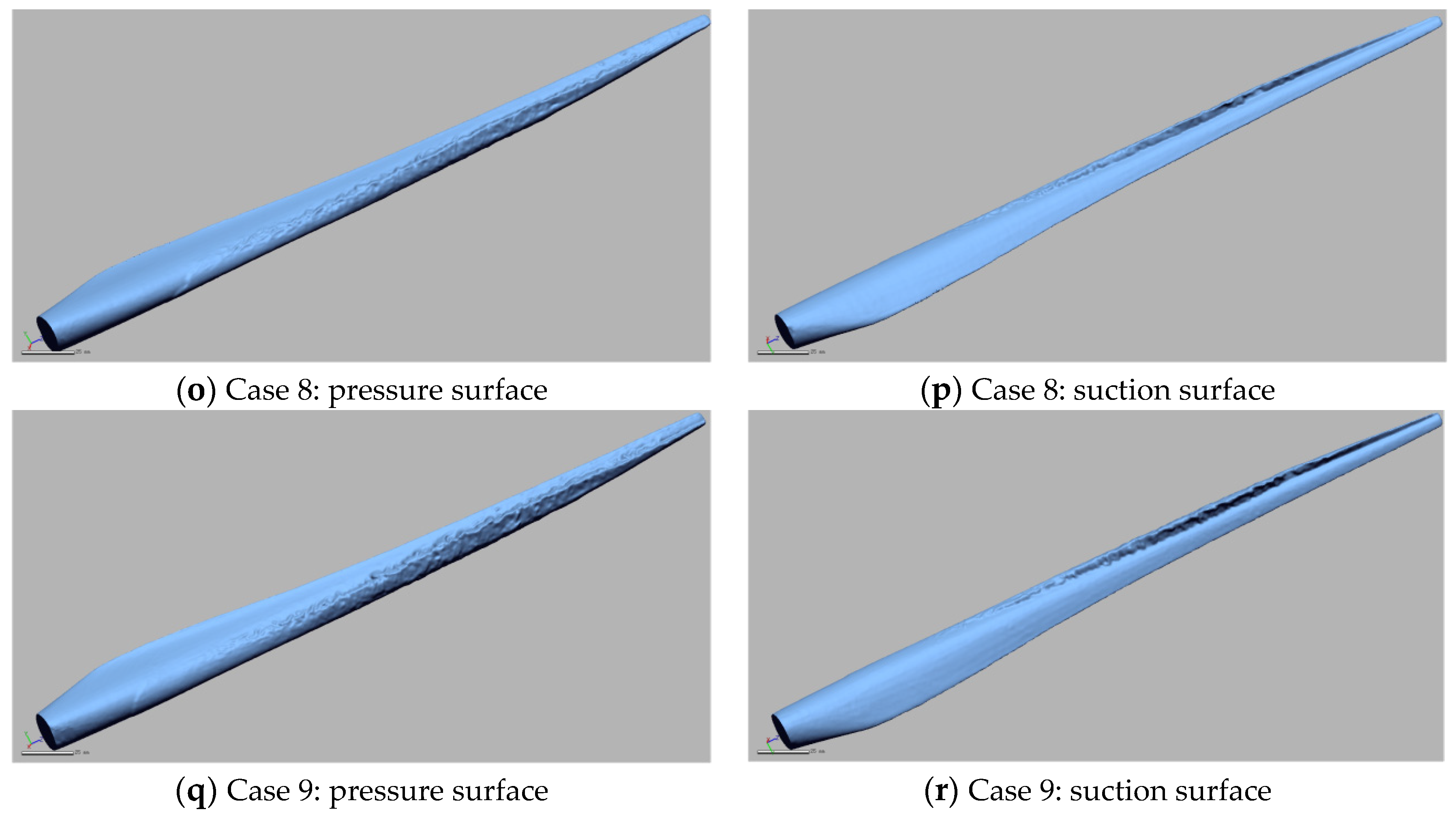

4.1. Three-Dimensional Morphology of Rotating Blade Ice Accretion

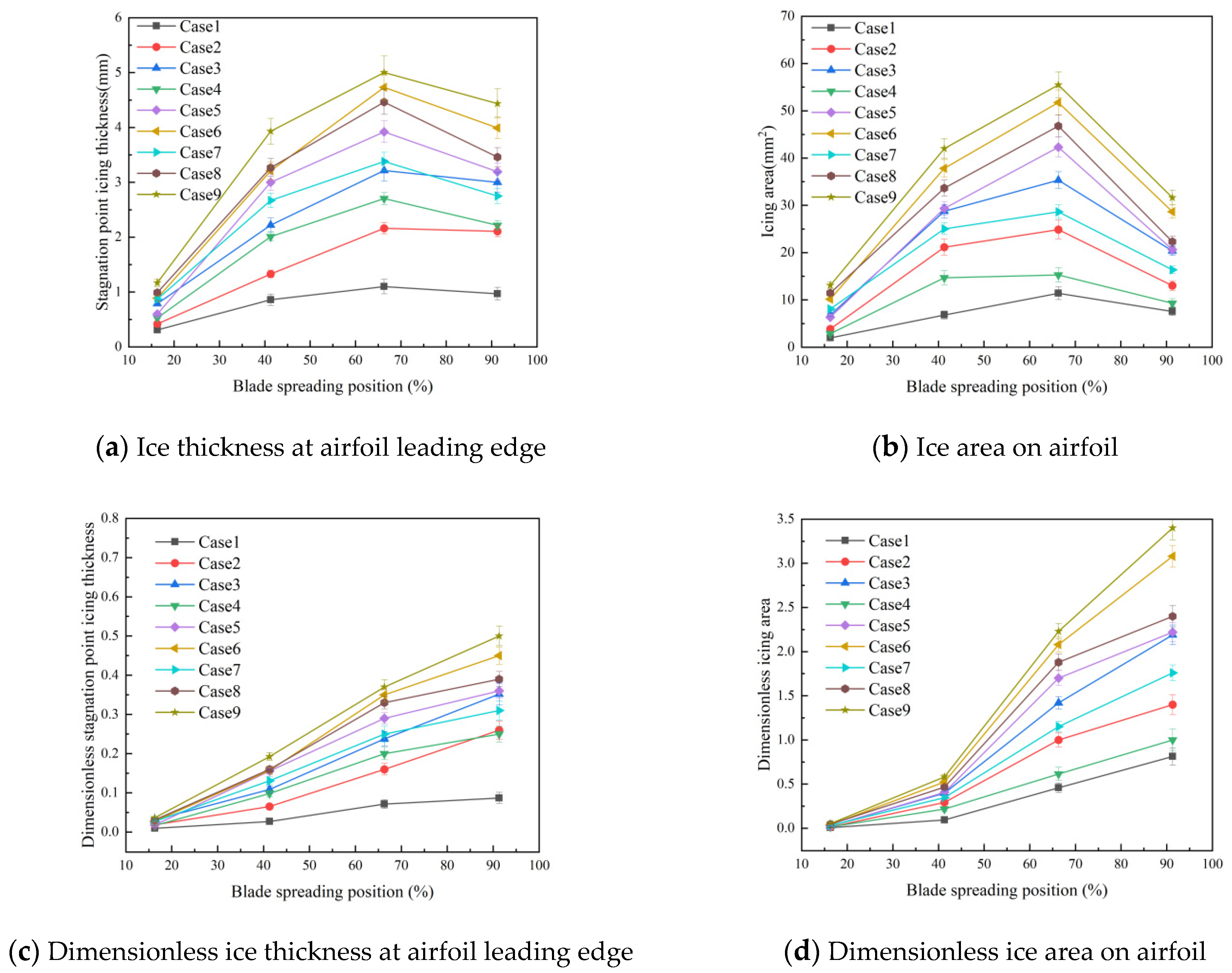

4.2. Analysis of Ice Accretion Characteristics

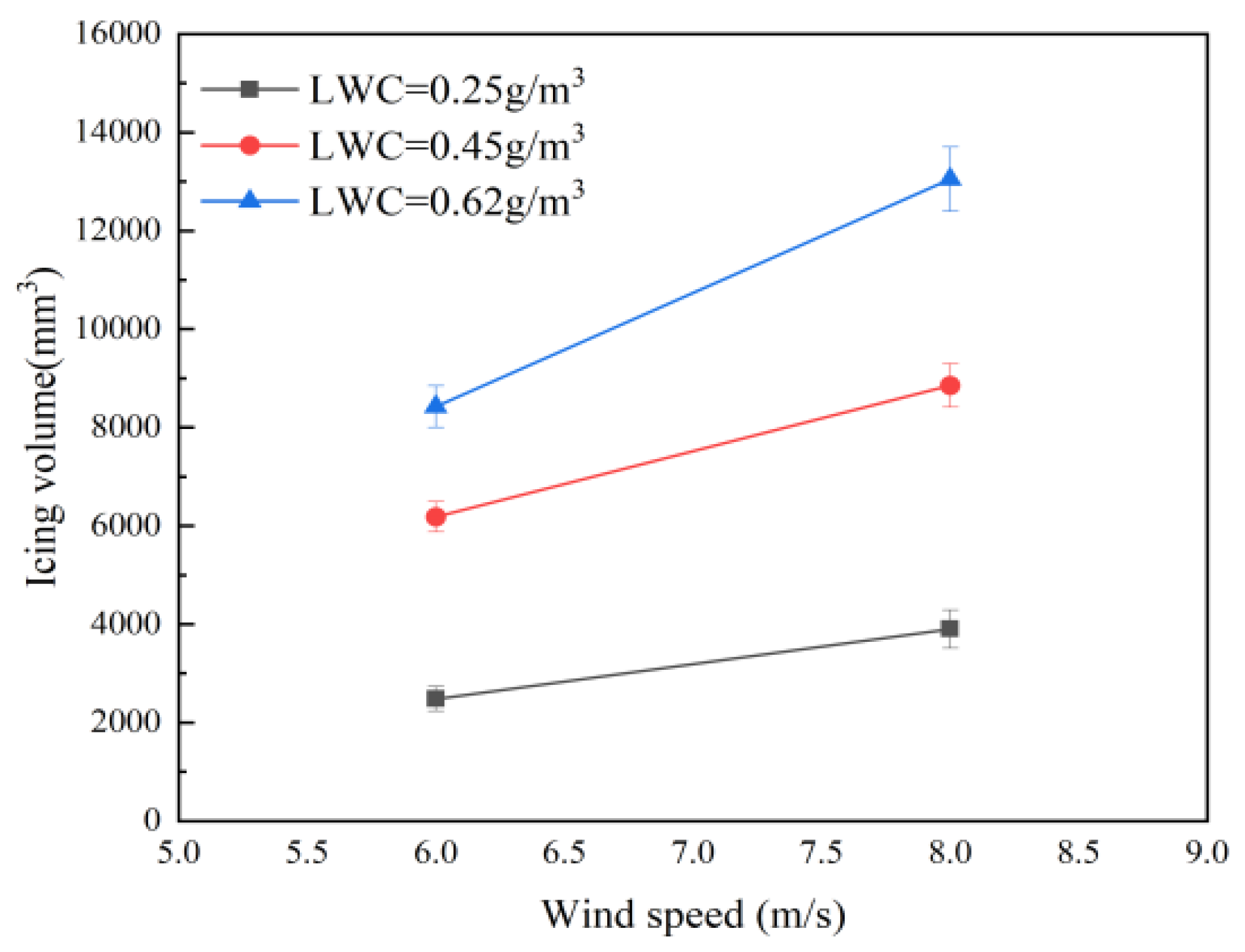

4.3. Analysis of Ice Accretion Characteristics on Blade Surfaces at Different Wind Speeds

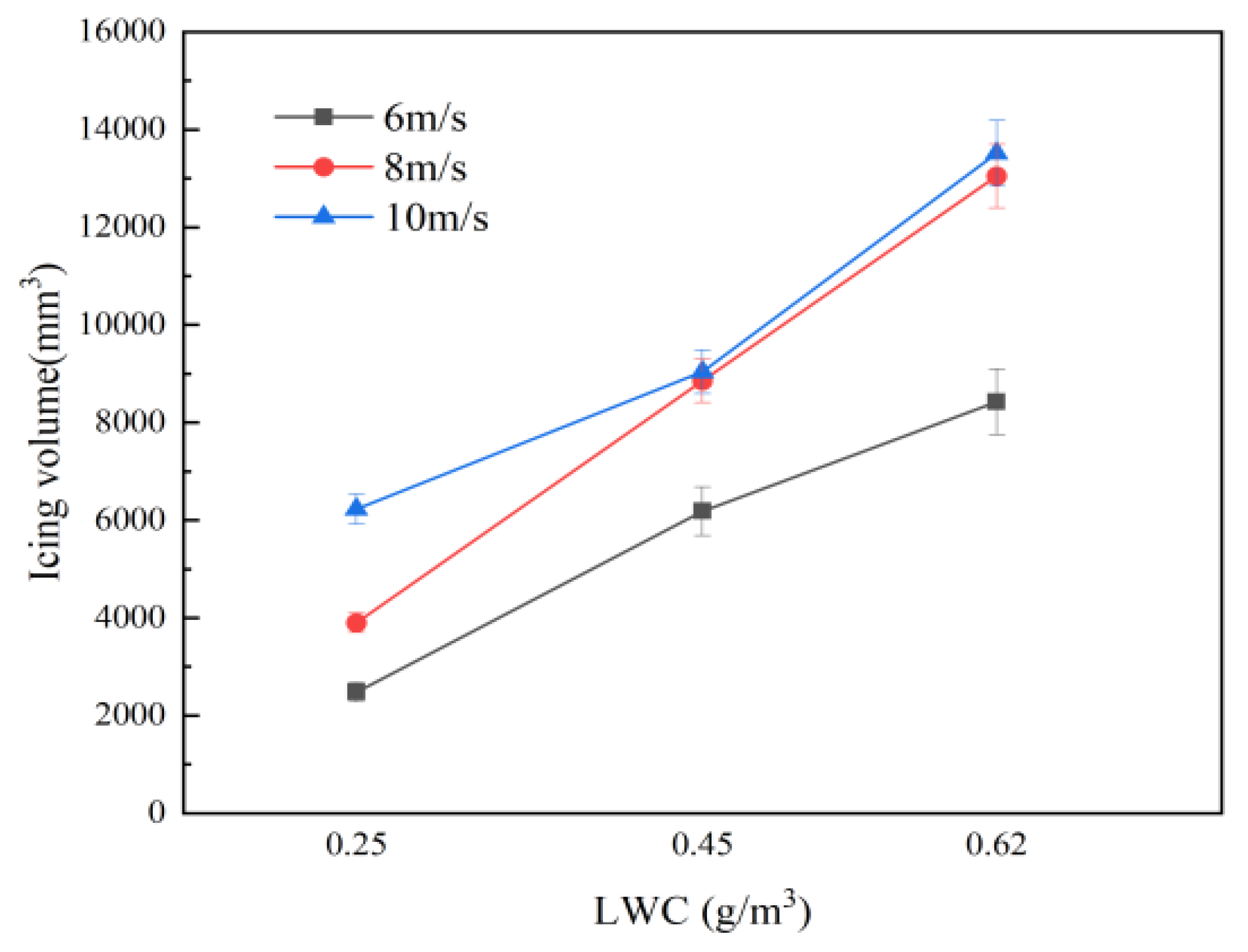

4.4. Analysis of Ice Accretion Characteristics on Blade Surfaces under Different LWCs

5. Conclusions

- (1)

- Under the specified experimental parameters, blade icing predominantly manifested in clear ice and mixed ice states. The icing area emerged within 30% to 50% of the leading edge of the blades. Progressing along the blade’s span from the base, the ice accumulation on the surface shifted from being smooth to rough, with the rough regions exhibiting inclined or irregular patterns that modified the aerodynamic properties of the blades;

- (2)

- Under the limit conditions set in this study, the maximum ice thickness on 2D wing cross-sections of the ice-covered blades reached 0.5102 m, with an ice-covered area of up to 0.5549 m2, and the icing volume reached 13.514 m3 under the test conditions. When analyzing the influence of the position of the section on the ice accretion characteristics, the 0D maximum ice thickness and ice-covered area increased consistently along the blade’s direction, indicating that the impact of ice accretion is more pronounced on wing sections nearer to the blade tip;

- (3)

- The quantitative analysis of experimental data revealed that wind speed and the LWC in the air are the predominant factors affecting ice accretion on blade surfaces. When tip speed ratios were held constant, higher wind speeds were found to correlate with elevated surface ice volumes, potentially increasing by 43.2%~57.2% with the escalation of wind speeds. Likewise, higher LWC levels were associated with a greater surface ice volume, potentially increasing by 36.3%~149.2% with higher LWC concentrations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fortin, G.; Perron, J. Wind Turbine Icing and De-Icing. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2009. [Google Scholar]

- Tan, C.; Papadakis, M.; Miller, D.; Bencic, T.; Tate, P.; Laun, M. Experimental Study of Large Droplet Splashing and Breakup. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2007; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2007. [Google Scholar]

- Miller, D.; Potapczuk, M.; Langhals, T. Preliminary Investigation of Ice Shape Sensitivity to Parameter Variations. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2005. [Google Scholar]

- Anderson, D.N.; Tsao, J.-C. Ice Shape Scaling for Aircraft in SLD Conditions; NASA/CR-2008-215302; NASA: Washington, DC, USA, 2008. [Google Scholar]

- Broeren, A.P.; Addy, H.E.; Bragg, M.B.; Busch, G.T.; Montreuil, E. Aerodynamic Simulation of Ice Accretion on Airfoils; NASA: Washington, DC, USA, 2011. [Google Scholar]

- Diebold, J.M.; Broeren, A.P.; Bragg, M. Aerodynamic Classification of Swept-Wing Ice Accretion. In Proceedings of the 5th AIAA Atmospheric and Space Environments Conference, San Diego, CA, USA, 24–27 June 2013; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2013. [Google Scholar]

- Baizhuma, Z.; Kim, T.; Son, C. Numerical Method to Predict Ice Accretion Shapes and Performance Penalties for Rotating Vertical Axis Wind Turbines under Icing Conditions. J. Wind. Eng. Ind. Aerodyn. 2021, 216, 104708. [Google Scholar] [CrossRef]

- Qi, H.; Chang, S.; Yang, Y.; Chang, P. Numerical Investigations on Aero-Engine Icing Characteristics at Mixed Phase Conditions. Appl. Therm. Eng. 2024, 238, 122044. [Google Scholar] [CrossRef]

- Kozelkov, A.; Galanov, N.; Semenov, I.; Zhuchkov, R.; Strelets, D. Computational Investigation of the Water Droplet Effects on Shapes of Ice on Airfoils. Aerospace 2023, 10, 906. [Google Scholar] [CrossRef]

- Son, C.; Kelly, M.; Kim, T. Boundary-Layer Transition Model for Icing Simulations of Rotating Wind Turbine Blades. Renew. Energy 2021, 167, 172–183. [Google Scholar] [CrossRef]

- Son, C.; Kim, T. Development of an Icing Simulation Code for Rotating Wind Turbines. J. Wind. Eng. Ind. Aerodyn. 2020, 203, 104239. [Google Scholar] [CrossRef]

- Kind, R.J.; Potapczuk, M.G.; Feo, A.; Golia, C.; Shah, A.D. Experimental and Computational Simulation of In-Flight Icing Phenomena. Prog. Aerosp. Sci. 1998, 34, 257–345. [Google Scholar] [CrossRef]

- Enache, A.; Bernay, B.; Glabeke, G.; Planquart, P.; van Beeck, J. Ice Shedding Phenomenon: An Experimental and Numerical Investigation. In Proceedings of the AIAA AVIATION 2020 FORUM, Virtual, 15–19 June 2020; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2020. [Google Scholar]

- Baumert, A.; Bansmer, S.; Trontin, P.; Villedieu, P. Experimental and Numerical Investigations on Aircraft Icing at Mixed Phase Conditions. Int. J. Heat Mass Transf. 2018, 123, 957–978. [Google Scholar] [CrossRef]

- Hu, Y.; Xu, C.; Li, S.; Li, P.; Liu, L. Experimental Study on Icing and Anti-Icing of a Rotating Conical Spinner. Appl. Therm. Eng. 2023, 219, 119373. [Google Scholar] [CrossRef]

- Wong, S.-C.; Papadakis, M.; Yeong, H.-W.; Wong, S. Comparison of Experimental and Computational Ice Shapes for a Swept Wing Model; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Broeren, A.P.; Potapczuk, M.; Riley, J.; Villedieu, P.; Moens, F.; Bragg, M. Swept-Wing Ice Accretion Characterization and Aerodynamics. In Proceedings of the 5th AIAA Atmospheric and Space Environments Conference, San Diego, CA, USA, 24–27 June 2013; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2013. [Google Scholar]

- Papadakis, M.; Yeong, H.W.; Wong, S.C.; Vargas, M.; Potapczuk, M. Experimental Investigation of Ice Accretion Effects on a Swept Wing; NASA: Washington, DC, USA, 2005. [Google Scholar]

- Han, Y.; Palacios, J. Analytical and experimental determination of airfoil performance degradation due to ice accretion. In Proceedings of the 4th AIAA Atmospheric and Space Environments Conference, New Orleans, LA, USA, 25–28 June 2012; p. 2794. [Google Scholar]

- Xu, H.; Gossett, N.; Chen, B. Knowledge and Heuristic-Based Modeling of Laser-Scanned Trees. ACM Trans. Graph. 2007, 26, 19-es. [Google Scholar] [CrossRef]

- Al-Najjar, A.; Amini, M.; Rajan, S.; Green, J.R. Identifying Areas of High-Risk Vegetation Encroachment on Electrical Powerlines Using Mobile and Airborne Laser Scanned Point Clouds. IEEE Sens. J. 2024, 24, 22129–22143. [Google Scholar] [CrossRef]

- Narayanan, V.; Singh, R.; Marla, D. A 3D Computational Model of Nanosecond Pulsed Laser Texturing of Metals for Designing Engineered Surfaces. J. Manuf. Sci. Eng. 2024, 146, 051006. [Google Scholar] [CrossRef]

- Sjerve, C.; Eng, P.; Benz, A.; Kuan, L. Using Laser Scanning Creatively in a Plant Environment. Insp. J.|Asset Integr. Intell. 2024, 30. [Google Scholar]

- Bornhoft, B.; Jain, S.S.; Goc, K.; Bose, S.T.; Moin, P. Large-Eddy Simulations of the NACA23012 Airfoil with Laser-Scanned Ice Shapes. Aerosp. Sci. Technol. 2024, 146, 108957. [Google Scholar] [CrossRef]

- Lee, S.; Broeren, A.; Addy, H.; Sills, R.; Pifer, E. Development of 3D Ice Accretion Measurement Method. In Proceedings of the 4th AIAA Atmospheric and Space Environments Conference, New Orleans, LA, USA, 25–28 June 2012; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2012. [Google Scholar]

- Lee, S.; Broeren, A.P.; Kreeger, R.E.; Potapczuk, M.G.; Utt, L. Implementation and Validation of 3-D Ice Accretion Measurement Methodology. In Proceedings of the 6th AIAA Atmospheric and Space Environments Conference, Atlanta, GA, USA, 16–20 June 2014; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2014. [Google Scholar]

- Kreeger, R.E.; Tsao, J.-C. Ice Shapes on a Tail Rotor. In Proceedings of the 6th AIAA Atmospheric and Space Environments Conference, Atlanta, GA, USA, 16–20 June 2014; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2014. [Google Scholar]

- Li, Y.; Wang, S.; Zheng, Y.; Liu, Q.; Feng, F. Design of a Wind Turbine Icing Wind Tunnel Test System Utilizing Natural Low Temperatures. Exp. Fluid Mech. 2016, 30, 54–58. (In Chinese) [Google Scholar]

- Li, Y.; Wang, S.; Zheng, Y.; Liu, Q.; Feng, F. Design of a Rotating Blade Icing Wind Tunnel Test System Utilizing Natural Low Temperatures. Exp. Fluid Mech. 2018, 32, 40–47. (In Chinese) [Google Scholar]

- Li, Y.; Wang, S.; Yi, X.; Zhou, Z.; Guo, L. Icing Characteristics of a Rotating Cylinder in an Icing Wind Tunnel Test. Acta Aeronaut. Et Astronaut. Sin. 2017, 38, 111–121. (In Chinese) [Google Scholar]

- Guo, W.; Shen, H.; Li, Y.; Feng, F.; Tagawa, K. Wind Tunnel Tests of the Rime Icing Characteristics of a Straight-Bladed Vertical Axis Wind Turbine. Renew. Energy 2021, 179, 116–132. [Google Scholar] [CrossRef]

- Bragg, M.; Gregorek, G.; Shaw, R. An Analytical Approach to Airfoil Icing. In Proceedings of the 19th Aerospace Sciences Meeting, St. Louis, MO, USA, 12–15 January 1981; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2012. [Google Scholar]

- Anderson, D. Rime-, Mixed-, and Glaze-Ice Evaluations of Three Scaling Laws. In Proceedings of the 32nd Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 1994; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 1994. [Google Scholar]

- Yi, X.; Zhu, G.L. Study on Icing Test Scaling Law. In New Trends in Fluid Mechanics Research; Zhuang, F.G., Li, J.C., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 249–252. [Google Scholar]

- Shi, L.; Feng, F.; Guo, W.; Li, Y. Research and Development of a Small-Scale Icing Wind Tunnel Test System for Blade Airfoil Icing Characteristics. Int. J. Rotating Mach. Hindawi 2021, 2021, e5598859. [Google Scholar]

- Langmuir, I.; Blodgett, K. A Mathematical Investigation of Water Droplet Trajectories; Army Air Forces Headquarters, Air Technical Service Command: San Antonio, TX, USA, 1946. [Google Scholar]

- Drage, M.A.; Hauge, G. Atmospheric Icing in a Coastal Mountainous Terrain: Measurements and Numerical Simulations, A Case Study. Cold Reg. Sci. Technol. 2008, 53, 150–161. [Google Scholar] [CrossRef]

- Li, Y.; Sun, C.; Jiang, Y.; Yi, X.; Xu, Z.; Guo, W. Temperature Effect on Icing Distribution near Blade Tip of Large-Scale Horizontal-Axis Wind Turbine by Numerical Simulation. Adv. Mech. Eng. 2018, 10, 1687814018812247. [Google Scholar] [CrossRef]

| Wind Speed/(m/s) | LWC/(g/m3) | MVD/μm | Atmospheric Temperature/°C | Air Density/(kg/m3) | Air Viscosity /(m2/s) |

|---|---|---|---|---|---|

| ≤7.9 | 0.05~0.25 | 30 | −15~0 | 1.293 | 1.7162 × 10−5 |

| U (m/s) | θ (°) | n (r/min) | λ | LWC (g/m3) | MVD (μm) | T (°C) | t (s) | |

|---|---|---|---|---|---|---|---|---|

| 1 | 6 | 0 | 1250 | 9.0 | 0.25 | 30 | −8 | 120 |

| 2 | 0.45 | |||||||

| 3 | 0.62 | |||||||

| 4 | 8 | 1670 | 9.0 | 0.25 | ||||

| 5 | 0.45 | |||||||

| 6 | 0.62 | |||||||

| 7 | 10 | 1740 | 7.5 | 0.25 | ||||

| 8 | 0.45 | |||||||

| 9 | 0.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, Z.; Dong, Y.; Wang, Q.; Li, H.; Han, Y.; Feng, F. Enhanced Analysis of Ice Accretion on Rotating Blades of Horizontal-Axis Wind Turbines Using Advanced 3D Scanning Technology. Coatings 2024, 14, 970. https://doi.org/10.3390/coatings14080970

Lei Z, Dong Y, Wang Q, Li H, Han Y, Feng F. Enhanced Analysis of Ice Accretion on Rotating Blades of Horizontal-Axis Wind Turbines Using Advanced 3D Scanning Technology. Coatings. 2024; 14(8):970. https://doi.org/10.3390/coatings14080970

Chicago/Turabian StyleLei, Zhen, Yuxiao Dong, Qinghui Wang, Hailin Li, Yexue Han, and Fang Feng. 2024. "Enhanced Analysis of Ice Accretion on Rotating Blades of Horizontal-Axis Wind Turbines Using Advanced 3D Scanning Technology" Coatings 14, no. 8: 970. https://doi.org/10.3390/coatings14080970

APA StyleLei, Z., Dong, Y., Wang, Q., Li, H., Han, Y., & Feng, F. (2024). Enhanced Analysis of Ice Accretion on Rotating Blades of Horizontal-Axis Wind Turbines Using Advanced 3D Scanning Technology. Coatings, 14(8), 970. https://doi.org/10.3390/coatings14080970