Natural Selection on Hydroxyapatite Fiber Orientations for Resisting Damage of Enamel

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Nanoindentation Tests

2.3. Nanoscratch Tests

2.4. Statistical Analysis

3. Results and Discussion

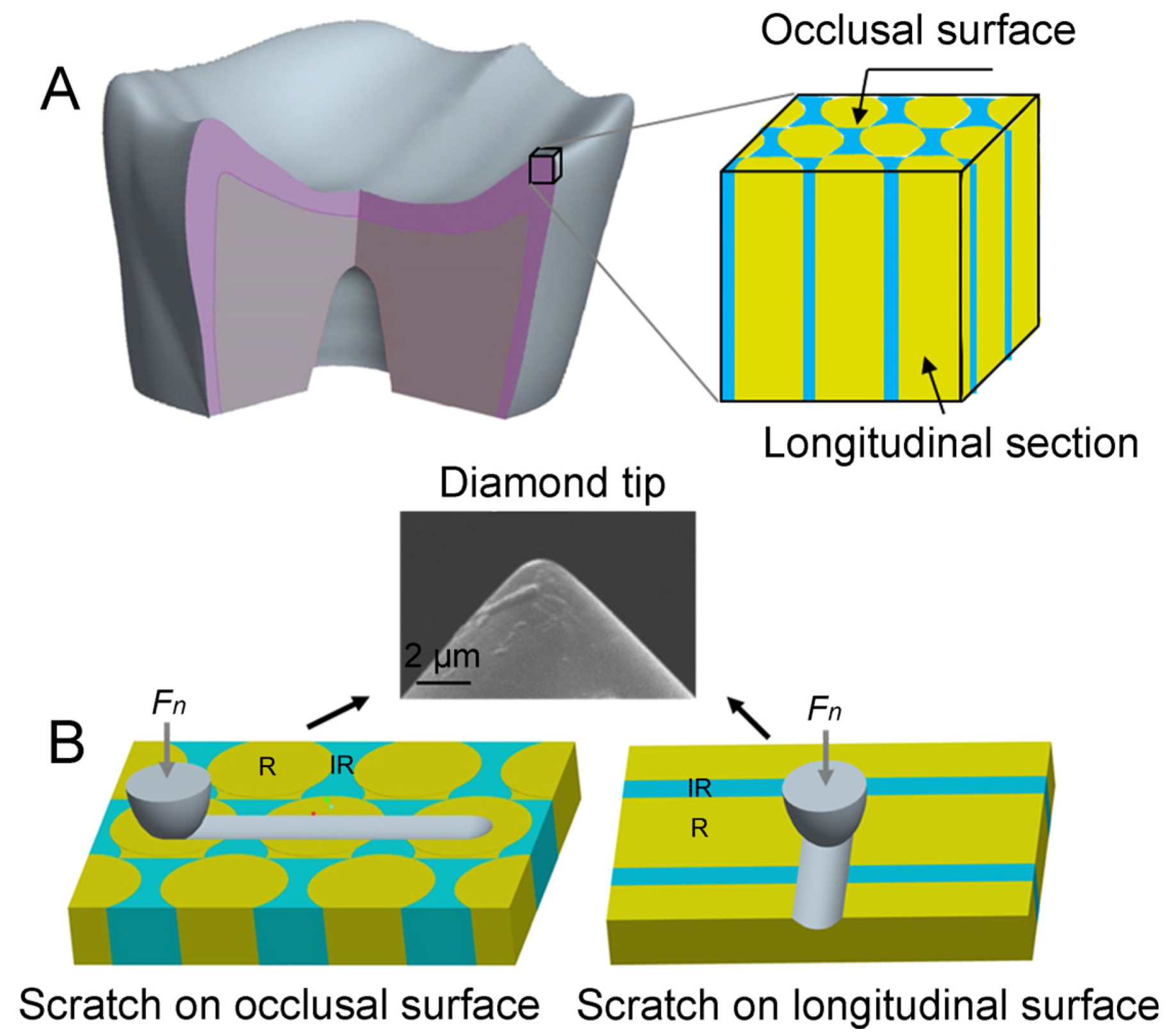

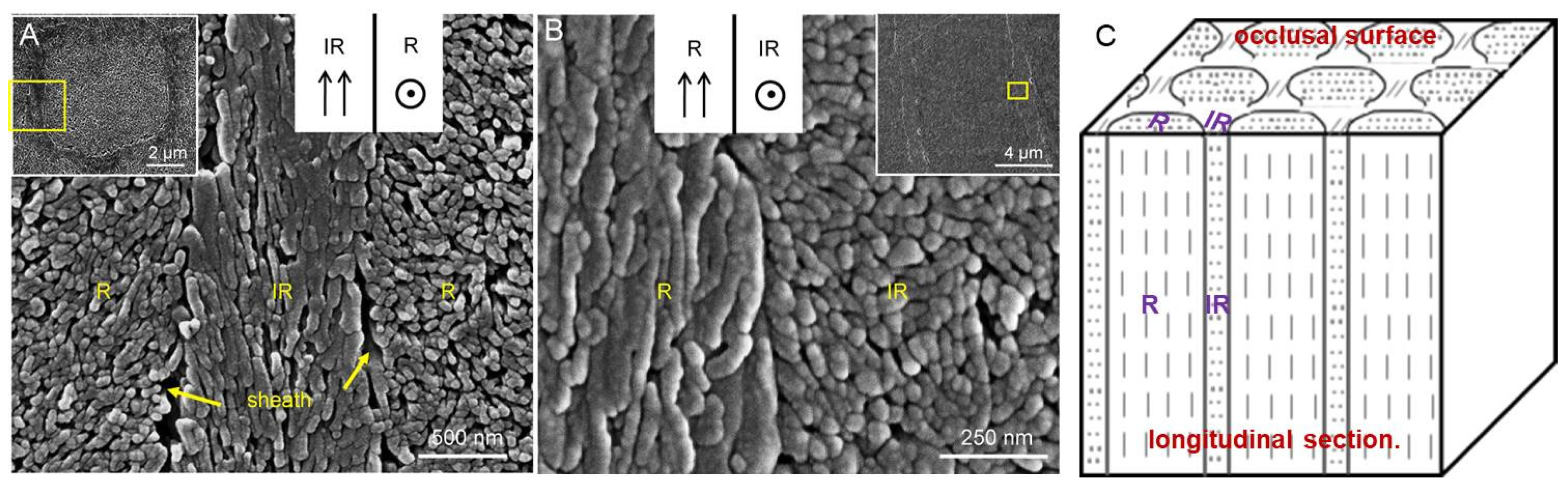

3.1. HAp Fiber Orientations in Occlusal Surface and Longitudinal Section

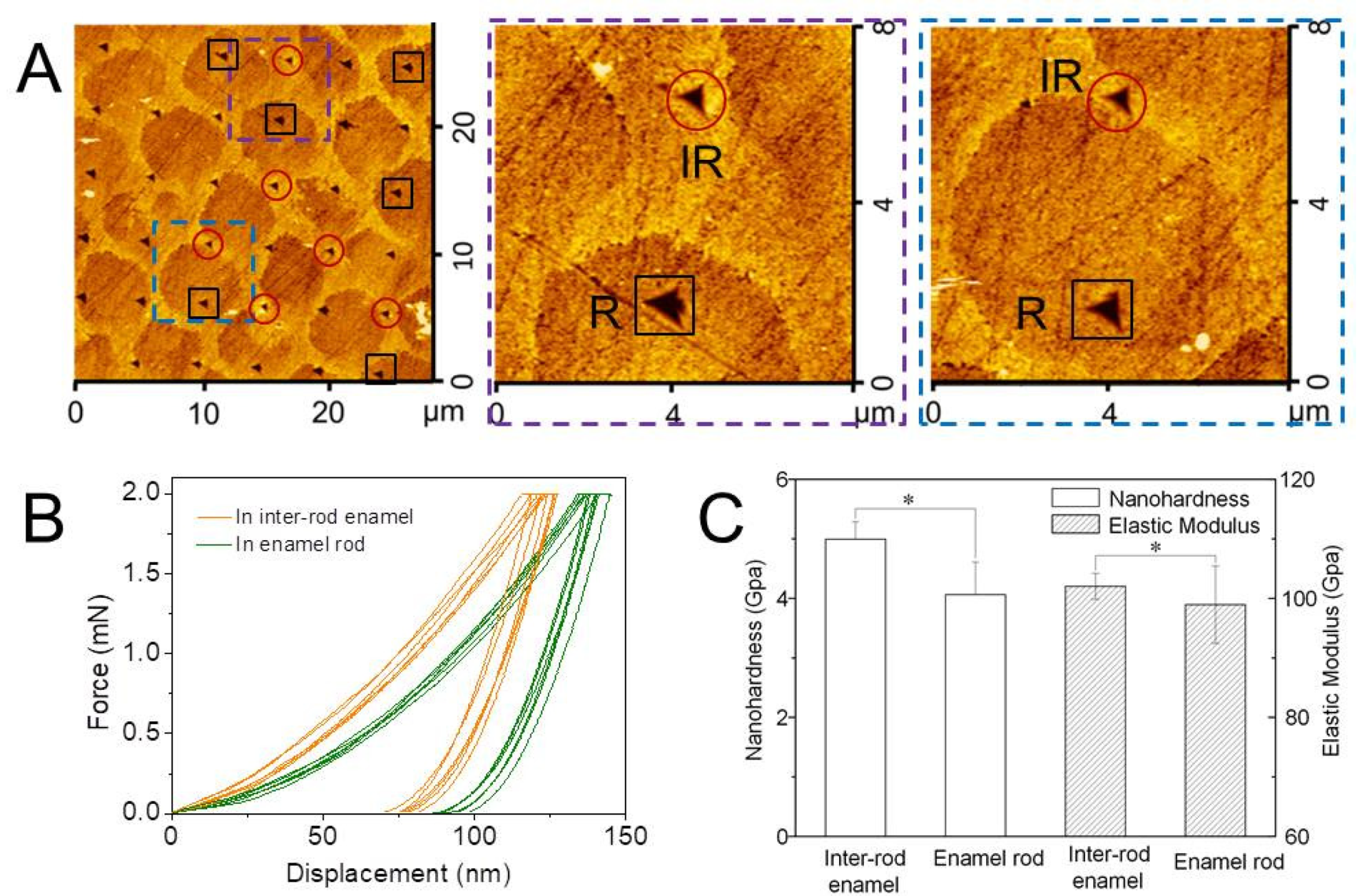

3.2. Effect of Fiber Orientation on Mechanical Properties of Enamel

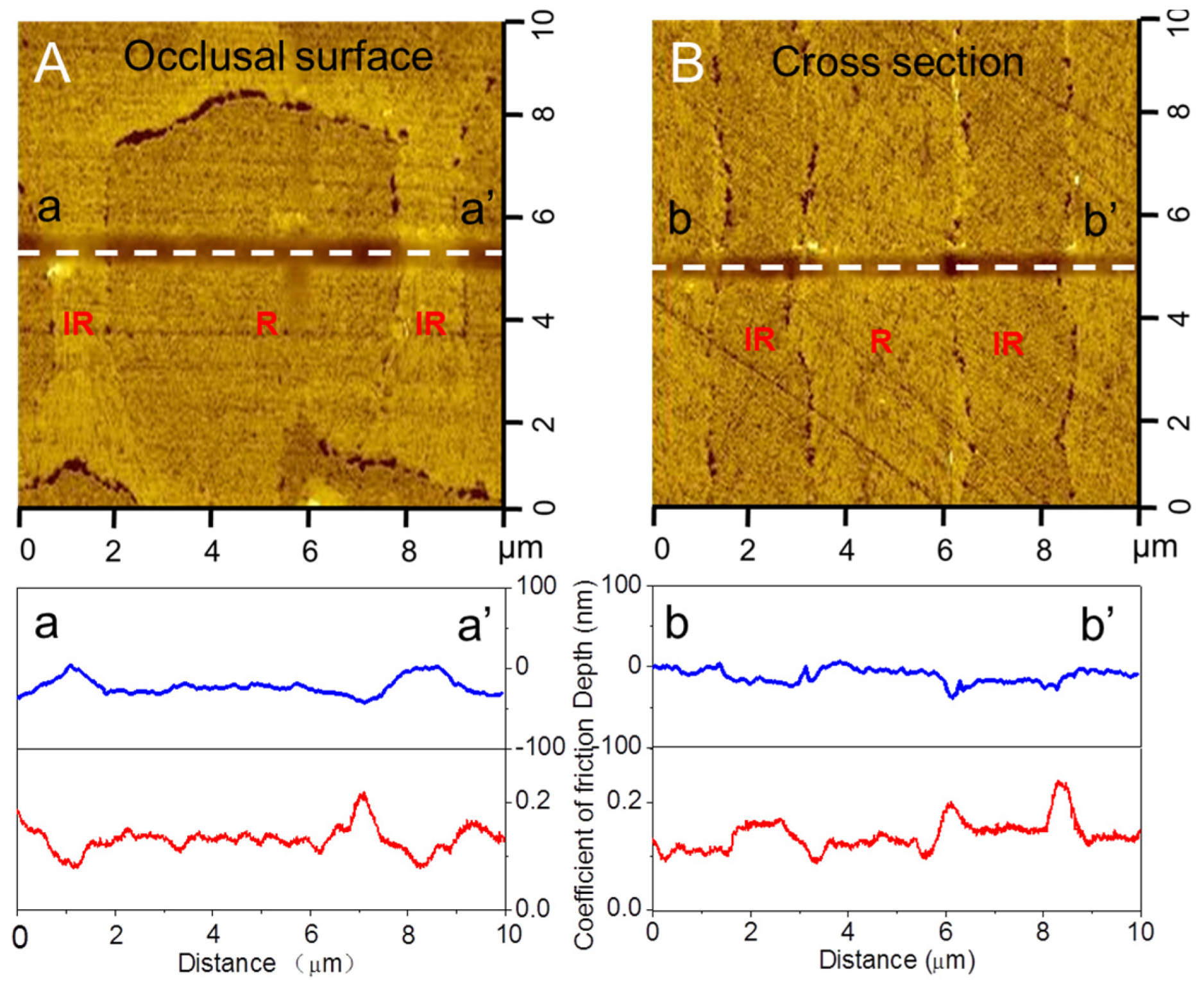

3.3. Effect of Fiber Orientation on Microfriction Behavior of Enamel

3.4. Effect of Fiber Orientation on the Wear Behavior of Enamel

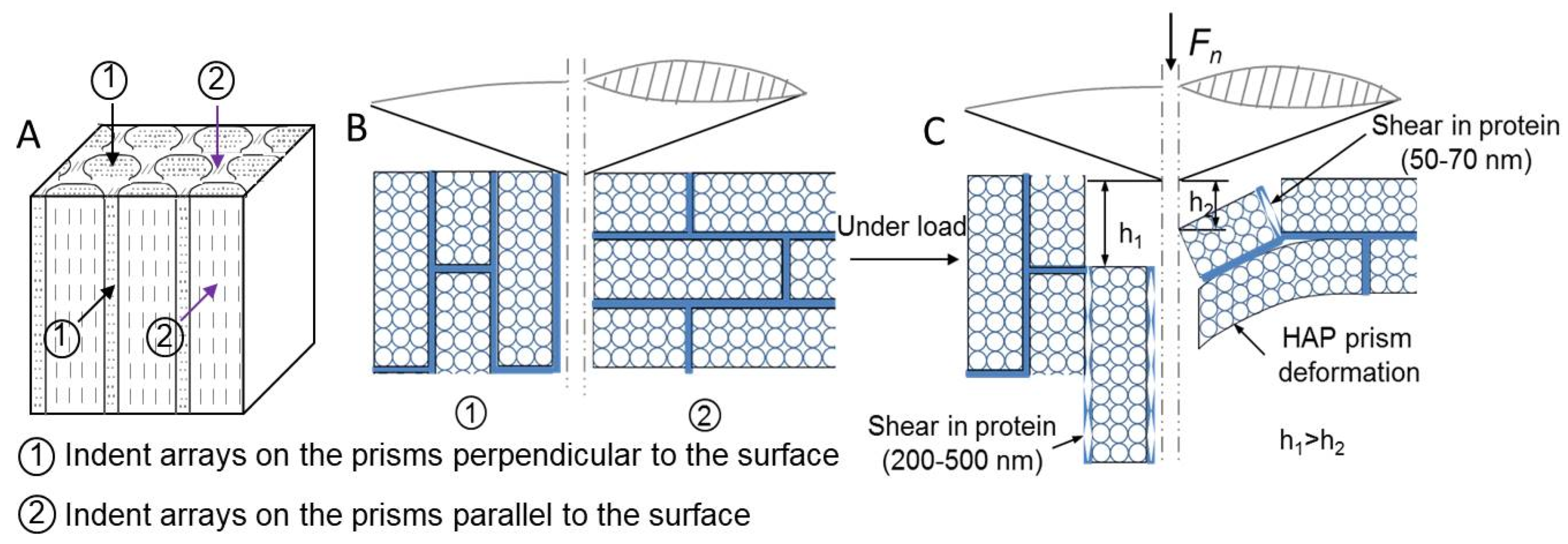

3.5. Influence Mechanism of Hydroxyapatite Alignment on Tooth Enamel Properties

4. Conclusions

- There are two types of orientation of HAp fibers in the outer layer of tooth enamel: parallel and perpendicular to the occlusal surface.

- The arrangements of HAp fibers significantly influenced the mechanical and microtribological behavior of human tooth enamel. HAp fibers with long axes parallel to the surface had higher hardness and elastic modulus and showed better microtribological behavior.

- Teeth resist damaging fractures by combining hard and soft structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carreon, A.H.; Funkenbusch, P.D. Nanoscale properties and deformation of human enamel and dentin. J. Mech. Behav. Biomed. Mater. 2019, 97, 74–84. [Google Scholar] [CrossRef] [PubMed]

- Borrero-Lopez, O.; Constantino, P.J.; Bush, M.B.; Lawn, B.R. On the vital role of enamel prism interfaces and graded properties in human tooth survival. Biol. Lett. 2020, 16, 20200498. [Google Scholar] [CrossRef] [PubMed]

- Chai, H.; Lee, J.J.-W.; Constantino, P.J.; Lucas, P.W.; Lawn, B.R. Remarkable resilience of teeth. Proc. Natl. Acad. Sci. USA 2009, 106, 7289–7293. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, K.; Xu, W.; Gong, X.; Zhang, F. Mapping the mechanical gradient of human dentin-enamel-junction at different intratooth locations. Dent. Mater. 2018, 34, 376–388. [Google Scholar] [CrossRef]

- Hasegawa, M.; Tanaka, R.; Zhong, J.; Kobayashi, M.; Manabe, A.; Shibata, Y. Deciphering load attenuation mechanisms of the dentin-enamel junction, Insights from a viscoelastic constitutive model. Acta Biomater. 2023, 171, 193–201. [Google Scholar] [CrossRef]

- Yamada, Y.; Inoue, T.; Saito, M.; Nishimura, F.; Miyazaki, T. Anisotropic ultimate strength and microscopic fracture patterns during tensile testing in the dentin–enamel junction region. Dent. Mater. J. 2020, 39, 272–277. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, S.; Ye, J.; Guo, H.; Wang, R. Investigation of Fracture-resistance of Human Teeth at the Dentin-enamel Junction Using the J-integral Calculation of Finite Element Analysis. J. Mech. Med. Biol. 2022, 22, 2250069. [Google Scholar] [CrossRef]

- White, S.; Luo, W.; Paine, M.; Fong, H.; Sarikaya, M.; Snead, M. Biological organization of hydroxyapatite crystallites into a fibrous continuum toughens and controls anisotropy in human enamel. J. Dent. Res. 2001, 80, 321–326. [Google Scholar] [CrossRef]

- Xie, Z.-H.; Mahoney, E.; Kilpatrick, N.; Swain, M.; Hoffman, M. On the structure–property relationship of sound and hypomineralized enamel. Acta Biomater. 2007, 3, 865–872. [Google Scholar] [CrossRef]

- Cui, F.Z.; Ge, J. New observations of the hierarchical structure of human enamel, from nanoscale to microscale. J. Tissue Eng. Regen. Med. 2007, 1, 185–191. [Google Scholar] [CrossRef]

- Cuy, J.L.; Mann, A.B.; Livi, K.J.; Teaford, M.F.; Weihs, T.P. Nanoindentation mapping of the mechanical properties of human molar tooth enamel. Arch. Oral Biol. 2002, 47, 281–291. [Google Scholar] [CrossRef]

- He, L.H.; Swain, M.V. Enamel—A functionally graded natural coating. J. Dent. 2009, 37, 596–603. [Google Scholar] [CrossRef]

- Beniash, E.; Metzler, R.A.; Lam, R.S.; Gilbert, P. Transient amorphous calcium phosphate in forming enamel. J. Struct. Biol. 2009, 166, 133–143. [Google Scholar] [CrossRef] [PubMed]

- Habelitz, S.; Marshall, S.J.; Marshall Jr, G.W.; Balooch, M. Mechanical properties of human dental enamel on the nanometre scale. Arch. Oral Biol. 2001, 46, 173–183. [Google Scholar] [CrossRef] [PubMed]

- He, L.H.; Swain, M.V. Contact induced deformation of enamel. Appl. Phys. Lett. 2007, 90, 171916. [Google Scholar] [CrossRef]

- Jia, Y.F.; Xuan, F.Z. Anisotropic fatigue behavior of human enamel characterized by multi-cycling nanoindentation. J. Mech. Behav. Biomed. Mater. 2012, 16, 163–168. [Google Scholar] [CrossRef] [PubMed]

- Jeng, Y.R.; Lin, T.T.; Hsu, H.M.; Chang, H.J.; Shieh, D.B. Human enamel rod presents anisotropic nanotribological properties. J. Mech. Behav. Biomed. Mater. 2011, 4, 515–522. [Google Scholar] [CrossRef]

- Ang, S.F.; Schulz, A.; Fernandes, R.P.; Schneider, G.A. Sub-10-micrometer toughening and crack tip toughness of dental enamel. J. Mech. Behav. Biomed. Mater. 2011, 4, 423–432. [Google Scholar] [CrossRef]

- Xie, Z.; Swain, M.; Munroe, P.; Hoffman, M. On the critical parameters that regulate the deformation behaviour of tooth enamel. Biomaterials 2008, 29, 2697–2703. [Google Scholar] [CrossRef]

- Rathsam, C.; Farahani, R.M.; Hains, P.G.; Valova, V.A.; Charadram, N.; Zoellner, H.; Swain, M.; Hunter, N. Characterization of inter-crystallite peptides in human enamel rods reveals contribution by the Y allele of amelogenin. J. Struct. Biol. 2018, 204, 26–37. [Google Scholar] [CrossRef]

- An, B.; Wang, R.; Zhang, D. Role of crystal arrangement on the mechanical performance of enamel. Acta Biomater. 2012, 8, 3784–3793. [Google Scholar] [CrossRef] [PubMed]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Waters, N.E. Some mechanical and physical properties of teeth. Symp. Soc. Exp. Biol. 1980, 34, 99–135. [Google Scholar] [PubMed]

- Moradian-Oldak, J. Protein-mediated enamel mineralization. Front. Biosci. A J. Virtual Libr. 2012, 17, 1996. [Google Scholar] [CrossRef]

- Yilmaz, E.D.; Koldehoff, J.; Schneider, G.A. On the systematic documentation of the structural characteristics of bovine enamel, A critic to the protein sheath concept. Dent. Mater. 2018, 34, 1518–1530. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Li, Y.; Wang, X.; Zhang, L.; Tiantang Fu, B. The enamel microstructures of bovine mandibular incisors. Anat.Rec. Adv. Integr. Anat. Evol. Biol. 2012, 295, 1698–1706. [Google Scholar] [CrossRef]

- Ge, J.C.F.Z.; Cui, F.Z.; Wang, X.M.; Feng, H.L. Property variations in the prism and the organic sheath within enamel by nanoindentation. Biomaterials 2005, 26, 3333–3339. [Google Scholar]

- Mann, S. The biomimetics of enamel: A paradigm for organized biomaterials synthesis. In Ciba Foundation Symposium 205-Dental Enamel: Dental Enamel: Ciba Foundation Symposium 205; John Wiley & Sons, Ltd.: Chichester, UK, 2007; pp. 261–274. [Google Scholar]

- Staines, M.; Robinson, W.H.; Hood, J.A.A. Spherical indentation of tooth enamel. J. Mater. Sci. 1981, 16, 2551–2556. [Google Scholar] [CrossRef]

- Sha, M.C.; Li, Z.; Bradt, R.C. Single-crystal elastic constants of fluorapatite, Ca5F (PO4)3. J. Appl. Phys. 1994, 75, 7784–7787. [Google Scholar] [CrossRef]

- Lacruz, R.S.; Habelitz, S.; Wright, J.T.; Paine, M.L. Dental enamel formation and implications for oral health and disease. Physiol. Rev. 2017, 97, 939–993. [Google Scholar] [CrossRef]

- Yahyazadehfar, M.; Arola, D. The role of organic proteins on the crack growth resistance of human enamel. Acta Biomater. 2015, 19, 33–45. [Google Scholar] [CrossRef]

- He, L.H.; Fujisawa, N.; Swain, M.V. Elastic modulus and stress–strain response of human enamel by nano-indentation. Biomaterials 2006, 27, 4388–4398. [Google Scholar] [CrossRef]

- He, L.H.; Swain, M.V. Enamel—A “metallic-like” deformable biocomposite. J. Dent. 2007, 35, 431–437. [Google Scholar] [CrossRef]

- He, L.H.; Swain, M.V. Nanoindentation creep behavior of human enamel. J. Biomed. Mater. Res. 2009, 91, 352–359. [Google Scholar] [CrossRef] [PubMed]

- Makrodimitris, K.; Masica, D.L.; Kim, E.T.; Gray, J.J. Structure prediction of protein–solid surface interactions reveals a molecular recognition motif of statherin for hydroxyapatite. J. Am. Chem. Soc. 2007, 129, 13713–13722. [Google Scholar] [CrossRef]

- Katz, J.L. Hard tissue as a composite material—I. Bounds on the elastic behavior. J. Biomech. 1971, 4, 455–473. [Google Scholar] [CrossRef] [PubMed]

- Spears, I.R. A three-dimensional finite element model of prismatic enamel: A re-appraisal of the data on the Young’s modulus of enamel. J. Dent. Res. 1997, 76, 1690–1697. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Liu, S.; Wei, Y.; Yue, Y.; Gao, M.; Li, Y.; Zeng, X.; Deng, X.; Kotov, N.A.; Guo, L.; et al. Multiscale engineered artificial tooth enamel. Science 2022, 375, 551–556. [Google Scholar] [CrossRef]

- Meng, Y.F.; Zhu, Y.B.; Zhou, L.C.; Meng, X.S.; Yang, Y.L.; Zhao, R.; Xia, J.; Yang, B.; Lu, Y.J.; Wu, H.A.; et al. Artificial Nacre with High Toughness Amplification Factor: Residual Stress-Engineering Sparks Enhanced Extrinsic Toughening Mechanisms. Adv. Mater. 2022, 34, 2108267. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, J.; Xin, H.; Li, X.; Kong, Y.; Zhu, S.; Zhou, Y.; Fan, Y.; Xia, J. Natural Selection on Hydroxyapatite Fiber Orientations for Resisting Damage of Enamel. Coatings 2024, 14, 1122. https://doi.org/10.3390/coatings14091122

Shen J, Xin H, Li X, Kong Y, Zhu S, Zhou Y, Fan Y, Xia J. Natural Selection on Hydroxyapatite Fiber Orientations for Resisting Damage of Enamel. Coatings. 2024; 14(9):1122. https://doi.org/10.3390/coatings14091122

Chicago/Turabian StyleShen, Junfu, Haiyan Xin, Xiaopan Li, Yiyun Kong, Siqi Zhu, Yuankai Zhou, Yujie Fan, and Jing Xia. 2024. "Natural Selection on Hydroxyapatite Fiber Orientations for Resisting Damage of Enamel" Coatings 14, no. 9: 1122. https://doi.org/10.3390/coatings14091122

APA StyleShen, J., Xin, H., Li, X., Kong, Y., Zhu, S., Zhou, Y., Fan, Y., & Xia, J. (2024). Natural Selection on Hydroxyapatite Fiber Orientations for Resisting Damage of Enamel. Coatings, 14(9), 1122. https://doi.org/10.3390/coatings14091122