Reflectance Minimization of GaAs Solar Cell with Single- and Double-Layer Anti-Reflection Coatings: A Simulation Study

Abstract

1. Introduction

2. Materials and Methods

| Parameters | n-GaAs | p-GaAs |

|---|---|---|

| Thickness | 300 nm [28] | 5 μm [39] |

| Energy bandgap (eV) | 1.45 [40] | 1.45 [40] |

| Electron affinity | 4.28 [41] | 4.28 [41] |

| Refractive index | 3.0 [41] | 3.0 [41] |

| Bulk recombination time | 100 μs [41] | 100 μs [41] |

| Doping concentration | 1 × 1016 cm−3 [42] | 1 × 1016 cm−3 [42] |

| Excitation mode | transient | transient |

| Light intensity | One sun | One sun |

| Dielectric constant | 13.8 [43] | 13.8 [43] |

| Temperature | 300 K | 300 K |

| Light intensity | 0.1 W/cm2 | 0.1 W/cm2 |

| Primary light source | AM 1.5 D spectrum | AM 1.5 D spectrum |

| Other parameters | Internal PC1D | Internal PC1D |

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Spillias, S.; Kareiva, P.; Ruckelshaus, M.; McDonald-Madden, E. Renewable energy targets may undermine their sustainability. Nat. Clim. Change 2020, 10, 974–976. [Google Scholar] [CrossRef]

- Liu, L.; He, G.; Wu, M.; Liu, G.; Zhang, H.; Chen, Y.; Shen, J.; Li, S. Climate change impacts on planned supply–demand match in global wind and solar energy systems. Nat. Energy 2023, 8, 870–880. [Google Scholar] [CrossRef]

- Thirunavukkarasu, G.S.; Seyedmahmoudian, M.; Chandran, J.; Stojcevski, A.; Subramanian, M.; Marnadu, R.; Alfaify, S.; Shkir, M. Optimization of Mono-Crystalline Silicon Solar Cell Devices Using PC1D Simulation. Energies 2021, 14, 4986. [Google Scholar] [CrossRef]

- Yang, H.-Y.; Chuquer, A.; Han, S.-H.; Gaudel, G.S.; Pham, X.-H.; Kim, H.-M.; Yun, W.-J.; Jun, B.-H.; Rho, W.-Y. Optimizing the Aspect Ratio of Nanopatterned Mesoporous TiO2 Thin-Film Layer to Improve Energy Conversion Efficiency of Perovskite Solar Cells. Int. J. Mol. Sci. 2021, 22, 12235. [Google Scholar] [CrossRef] [PubMed]

- Hussain, B.; Aslam, A.; Khan, T.M.; Creighton, M.; Zohuri, B. Electron Affinity and Bandgap Optimization of Zinc Oxide for Improved Performance of ZnO/Si Heterojunction Solar Cell Using PC1D Simulations. Electronics 2019, 8, 238. [Google Scholar] [CrossRef]

- Zulqarnain Haider, S.; Iqbal, S.; Anwar, H.; Ismail, A.; Ali, J. Theoretical study on performance of heterojunction solar cell using wide bandgap metal oxide semiconductors. J. Optoelectron. Adv. Mater. 2022, 23, 554–559. [Google Scholar]

- Kephart, J.M.; McCamy, J.W.; Ma, Z.; Ganjoo, A.; Alamgir, F.M.; Sampath, W.S. Band alignment of front contact layers for high-efficiency CdTe solar cells. Sol. Energy Mater Sol. Cells 2016, 157, 266–275. [Google Scholar] [CrossRef]

- Parajuli, D.; Kc, D.; Khattri, K.B.; Adhikari, D.R.; Gaib, R.A.; Shah, D.K. Numerical assessment of optoelectrical properties of ZnSe–CdSe solar cell-based with ZnO antireflection coating layer. Sci. Rep. 2023, 13, 12193. [Google Scholar] [CrossRef] [PubMed]

- Sanimu, S.N.; Yang, H.-Y.; Kandel, J.; Moon, Y.-C.; Sharma Gaudel, G.; Yu, S.-J.; Kim, Y.J.; Kim, S.; Jun, B.-H.; Rho, W.-Y. Machine Learning-Assisted Fabrication of PCBM-Perovskite Solar Cells with Nanopatterned TiO2 Layer. Energy Environ. Mater. 2024, 7, e12676. [Google Scholar] [CrossRef]

- Hu, D.; Zhang, J.; Yuan, S.; Chen, H.; Wang, C.; Yu, X.; Cheng, X. Effects of metal impurities at the edges of cast Si ingot on crystal quality and solar cell performance. Sol. Energy 2022, 246, 224–233. [Google Scholar] [CrossRef]

- Acevedo-Luna, A.; Bernal-Correa, R.; Montes-Monsalve, J.; Morales-Acevedo, A. Design of thin film solar cells based on a unified simple analytical model. J. Appl. Res. Technol. 2017, 15, 599–608. [Google Scholar] [CrossRef]

- Bauer, G. Absolutwerte der optischen Absorptionskonstanten von Alkalihalogenidkristallen im Gebiet ihrer ultravioletten Eigenfrequenzen. Ann. Der Phys. 1934, 411, 434–464. [Google Scholar] [CrossRef]

- Cretì, A.; Prete, P.; Lovergine, N.; Lomascolo, M. Enhanced Optical Absorption of GaAs Near-Band-Edge Transitions in GaAs/AlGaAs Core–Shell Nanowires: Implications for Nanowire Solar Cells. ACS Appl. Nano Mater. 2022, 5, 18149–18158. [Google Scholar] [CrossRef]

- Prashant, D.V.; Agnihotri, S.K.; Bhattarai, S.; Pandey, R.; Madan, J.; Hossain, M.K.; Samajdar, D.P. Systematic Investigation of the Optoelectronic Properties of GaAs Nanowire and Nanocone Solar Cells: Effect of Geometrical Nonuniformities, Angle of Incidence, and Structural and Electronic Parameters. ACS Appl. Electron. Mater. 2023, 5, 4885–4898. [Google Scholar] [CrossRef]

- Gu, Z.; Prete, P.; Lovergine, N.; Nabet, B. On optical properties of GaAs and GaAs/AlGaAs core-shell periodic nanowire arrays. J. Appl. Phys. 2011, 109, 064314. [Google Scholar] [CrossRef]

- Campbell, P.; Green, M.A. Light trapping properties of pyramidally textured surfaces. J. Appl. Phys. 1987, 62, 243–249. [Google Scholar] [CrossRef]

- Parajuli, D.; Gaudel, G.S.; Kc, D.; Khattri, K.B.; Rho, W.-Y. Simulation study of TiO2 single layer anti-reflection coating for GaAs solar cell. AIP Adv. 2023, 13, 085002. [Google Scholar] [CrossRef]

- Fraunhofer, J.; Lommel, E.v. Joseph von Fraunhofer’s Gesammelte Schriften; Lommel, E., Ed.; Verlag der K. Akademie: Munich, Germany, 1888. [Google Scholar]

- Chattopadhyay, S.; Huang, Y.F.; Jen, Y.J.; Ganguly, A.; Chen, K.H.; Chen, L.C. Anti-reflecting and photonic nanostructures. Mater. Sci. Eng. R Rep. 2010, 69, 1–35. [Google Scholar] [CrossRef]

- Beye, M.; Faye, M.; Ndiaye, A.; Ndiaye, F.; Maiga, A.S. Optimization of SiNx single and double layer ARC for silicon thin film solar cells on glass. Res. J. Appl. Sci. Eng. Technol. 2013, 6, 412–416. [Google Scholar] [CrossRef]

- Kaddouri, A.M.; Kouzou, A.; Hafaifa, A.; Khadir, A. Optimization of anti-reflective coatings using a graded index based on silicon oxynitride. J. Comput. Electron. 2019, 18, 971–981. [Google Scholar] [CrossRef]

- Prashant, D.V.; Agnihotri, S.K.; Biswas, A.; Samajdar, D.P. Design perspectives of a thin film GaAs solar cell integrated with Carrier Selective contacts and anti-reflection coatings: Optical and device analysis. J. Phys. Chem. Solids 2025, 196, 112396. [Google Scholar] [CrossRef]

- Zhang, W.; Tu, J.; Long, W.; Lai, W.; Sheng, Y.; Guo, T. Preparation of SiO2 anti-reflection coatings by sol-gel method. Energy Procedia 2017, 130, 72–76. [Google Scholar] [CrossRef]

- Armstrong, S.; Datta, P.K.; Miles, R.W. Properties of zinc sulfur selenide deposited using a close-spaced sublimation method. Thin Solid Film. 2002, 403–404, 126–129. [Google Scholar] [CrossRef]

- Kesmez, Ö.; Erdem Çamurlu, H.; Burunkaya, E.; Arpaç, E. Preparation of antireflective SiO2 nanometric films. Ceram. Int. 2010, 36, 391–394. [Google Scholar] [CrossRef]

- Cingolani, R.; Lomascolo, M.; Lovergine, N.; Dabbicco, M.; Ferrara, M.; Suemune, I. Excitonic properties of ZnSe/ZnSeS superlattices. Appl. Phys. Lett. 1994, 64, 2439–2441. [Google Scholar] [CrossRef]

- Raj, V.; Haggren, T.; Tournet, J.; Tan, H.H.; Jagadish, C. Electron-Selective Contact for GaAs Solar Cells. ACS Appl. Energy Mater. 2021, 4, 1356–1364. [Google Scholar] [CrossRef]

- Thosar, A.J.; Thosar, M.; Khanna, R. Optimization of anti-reflection coating for improving the performance of GaAs solar cell. Indian J. Sci. Technol. 2014, 7, 637–641. [Google Scholar] [CrossRef]

- Mercy, P.A.M.; Joseph Wilson, K.S. Tuning the optical properties of GaAs solar cell through triple-layer antireflection coatings. Mater. Today Proc. 2022, 64, 1778–1782. [Google Scholar] [CrossRef]

- Bahrami, A.; Mohammadnejad, S.; Abkenar, N.J.; Soleimaninezhad, S. Optimized Single and Double Layer Antireflection Coatings for GaAs Solar Cells. Int. J. Renew. Energy Res. 2013, 3, 79–83. [Google Scholar]

- Liu, S.; Zhang, Y.-H. MgF2/ZnS double-layer anti-reflection coating design for ultra-thin GaAs single-junction solar cells. In Proceedings of the Renewable Energy and the Environment, Tucson, AZ, USA, 7 November 2013; p. RM4D.5. [Google Scholar]

- Alexieva, Z.I.; Nenova, Z.S.; Bakardjieva, V.S.; Milanova, M.M.; Hr, M.D. Antireflection coatings for GaAs solar cell applications. J. Phys. Conf. Ser. 2010, 223, 012045. [Google Scholar] [CrossRef]

- Nayak, P.P.; Dutta, J.P.; Mishra, G.P. Performance Evaluation of InGaP/GaAs Solar Cell with Double Layer ARC. In Proceedings of the Intelligent Computing, Communication and Devices; Springer: New Delhi, India, 2015; pp. 553–559. [Google Scholar] [CrossRef]

- Basore, P.A.; Clugston, D.A. PC1D version 4 for Windows: From analysis to design. In Proceedings of the Conference Record of the Twenty Fifth IEEE Photovoltaic Specialists Conference, Washington, DC, USA, 13–17 May 1996; pp. 377–381. [Google Scholar] [CrossRef]

- Subramanian, M.; Nagarajan, B.; Ravichandran, A.; Subhash Betageri, V.; Thirunavukkarasu, G.S.; Jamei, E.; Seyedmahmoudian, M.; Stojcevski, A.; Mekhilef, S.; Minnam Reddy, V.R. Optimization of Effective Doping Concentration of Emitter for Ideal c-Si Solar Cell Device with PC1D Simulation. Crystals 2022, 12, 244. [Google Scholar] [CrossRef]

- Sathya, P.; Supriya, P. Design and analysis of AlGaAs/GaAs/Si multi junction solar cell using PC1D. In Proceedings of the 2017 International conference on Microelectronic Devices, Circuits and Systems (ICMDCS), Vellore, India, 10–12 August 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Park, C.; Ahn, S.; Kim, B.; Song, K.; Choi, J.; Balaji, N.; Ju, M.; Lee, H.; Yi, J. An Analysis and Optimization of Selective Emitter with Etched-Back Structure of Crystalline Silicon Solar Cells Using TCAD Simulation. J. Comput. Theor. Nanosci. 2013, 10, 1772–1778. [Google Scholar] [CrossRef]

- Fell, A.; McIntosh, K.R.; Altermatt, P.P.; Janssen, G.J.; Stangl, R.; Ho-Baillie, A.; Steinkemper, H.; Greulich, J.; Müller, M.; Min, B. Input parameters for the simulation of silicon solar cells in 2014. IEEE J. Photovolt. 2015, 5, 1250–1263. [Google Scholar] [CrossRef]

- Devendra, K.C.; Shah, D.K.; Shrivastava, A. Computational study on the performance of zinc selenide as window layer for efficient GaAs solar cell. Mater. Today Proc. 2022, 49, 2580–2583. [Google Scholar] [CrossRef]

- Cheng, S.-Y. An InGaP/AlGaAs/GaAs heterojunction bipolar transistor with zero conduction-band discontinuity. Superlattices Microstruct. 2003, 33, 1–7. [Google Scholar] [CrossRef]

- Shah, D.K.; Kc, D.; Parajuli, D.; Akhtar, M.S.; Kim, C.Y.; Yang, O.B. A computational study of carrier lifetime, doping concentration, and thickness of window layer for GaAs solar cell based on Al2O3 antireflection layer. Sol. Energy 2022, 234, 330–337. [Google Scholar] [CrossRef]

- Abderrezek, M.; Djahli, F.; Fathi, M.; Ayad, M. Numerical modeling of GaAs solar cell performances. Elektron. Ir Elektrotechnika 2013, 19, 41–44. [Google Scholar] [CrossRef]

- Chhabra, B.; Jacobs, S.; Honsberg, C.B. Suns-Voc and Minority Carrier Lifetime Measurements of III-V Tandem Solar Cells. In Proceedings of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conference, Waikoloa, HI, USA, 7–12 May 2006; pp. 791–794. [Google Scholar] [CrossRef]

- Li, Z.; Yang, J.; Dezfuli, P.A.N. Study on the Influence of Light Intensity on the Performance of Solar Cell. Int. J. Photoenergy 2021, 2021, 6648739. [Google Scholar] [CrossRef]

- Asahi, S.; Teranishi, H.; Kusaki, K.; Kaizu, T.; Kita, T. Two-step photon up-conversion solar cells. Nat. Commun. 2017, 8, 14962. [Google Scholar] [CrossRef]

- Honsberg, C.B.; Bowden, S.G. Photovoltaics Education Website. Available online: https://www.pveducation.org (accessed on 27 January 2025).

- Beepat, K.G.; Sharma, D.P.; Mahajan, A.; Pathak, D.; Kumar, V. Simulation of multijunction solar cell interfaces for enhancement of the power conversion efficiency. Discov. Appl. Sci. 2024, 6, 283. [Google Scholar] [CrossRef]

- Gao, L.; Lemarchand, F.; Lequime, M. Refractive index determination of SiO2 layer in the UV/Vis/NIR range: Spectrophotometric reverse engineering on single and bi-layer designs. J. Eur. Opt. Soc. Rapid Public 2013, 8, 13010. [Google Scholar] [CrossRef]

- Peiris, F.C.; Lee, S.; Bindley, U.; Furdyna, J.K. Refractive index measurements of ZnSe-based ternary epitaxial layers grown by molecular-beam epitaxy on GaAs (100). J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1999, 17, 1214–1217. [Google Scholar] [CrossRef]

- Said, A.A.; Sheik-Bahae, M.; Hagan, D.J.; Wei, T.H.; Wang, J.; Young, J.; Van Stryland, E.W. Determination of bound-electronic and free-carrier nonlinearities in ZnSe, GaAs, CdTe, and ZnTe. J. Opt. Soc. Am. B 1992, 9, 405–414. [Google Scholar] [CrossRef]

- Bouhafs, D.; Moussi, A.; Chikouche, A.; Ruiz, J.M. Design and simulation of antireflection coating systems for optoelectronic devices: Application to silicon solar cells. Sol. Energy Mater Sol. Cells 1998, 52, 79–93. [Google Scholar] [CrossRef]

- Shah, D.K.; Kc, D.; Akhtar, M.S.; Kim, C.Y.; Yang, O.B. Vertically Arranged Zinc Oxide Nanorods as Antireflection Layer for Crystalline Silicon Solar Cell: A Simulation Study of Photovoltaic Properties. Appl. Sci. 2020, 10, 6062. [Google Scholar] [CrossRef]

- Bougoffa, A.; Trabelsi, A.; Zouari, A.; Dhahri, E. Analysis of external quantum efficiency and conversion efficiency of thin crystalline silicon solar cells with textured front surface. J. Comput. Electron. 2016, 15, 1085–1094. [Google Scholar] [CrossRef]

- Shah, D.K.; Kc, D.; Kim, T.-G.; Akhtar, M.S.; Kim, C.Y.; Yang, O.B. Influence of minority charge carrier lifetime and concentration on crystalline silicon solar cells based on double antireflection coating: A simulation study. Opt. Mater. 2021, 121, 111500. [Google Scholar] [CrossRef]

- Bandić, Z.Z.; Bridger, P.M.; Piquette, E.C.; McGill, T.C. Electron diffusion length and lifetime in p-type GaN. Appl. Phys. Lett. 1998, 73, 3276–3278. [Google Scholar] [CrossRef]

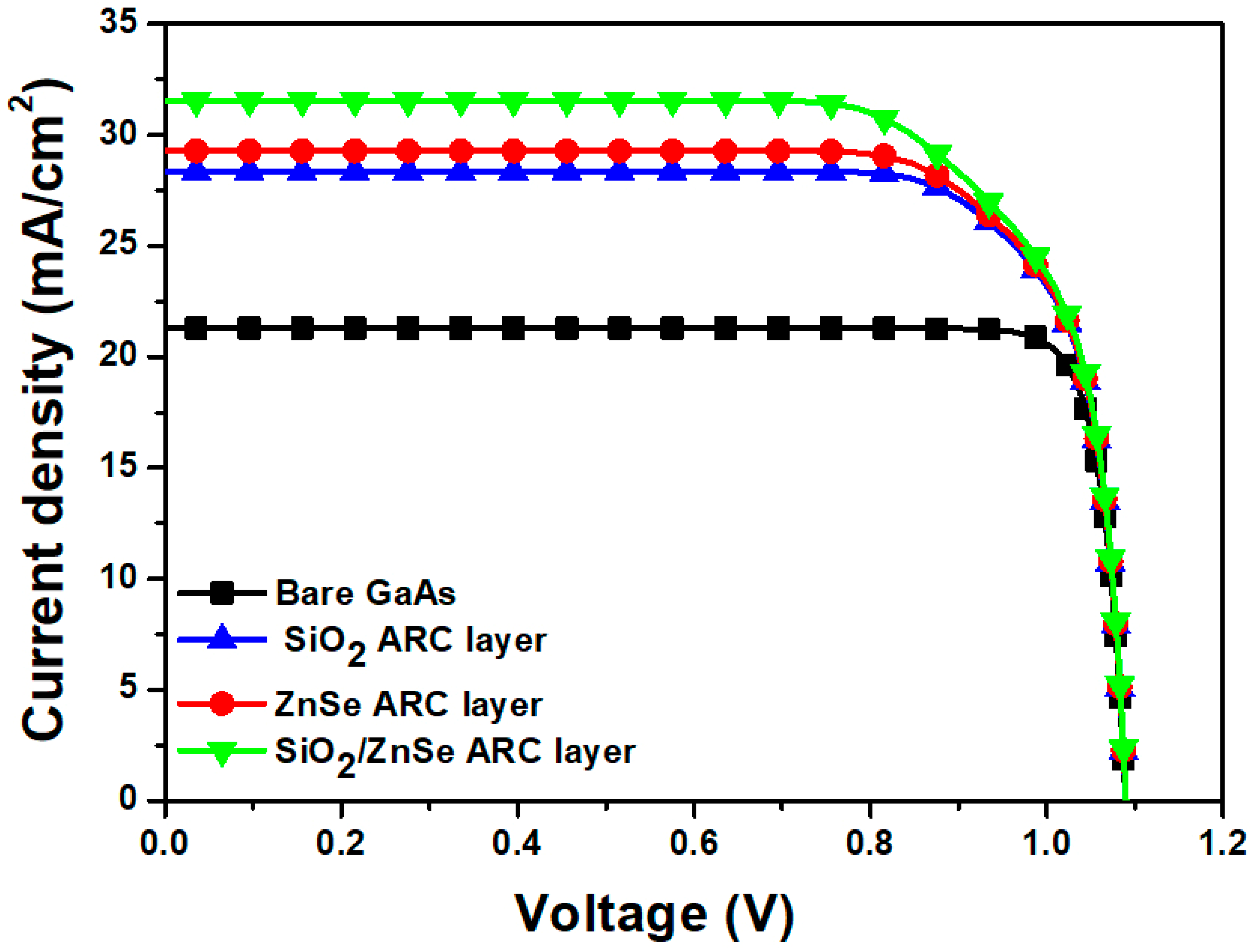

| ARC Layers | Current Density (mA/cm2) | Voc (V) | FF | Efficiency (%) |

|---|---|---|---|---|

| No ARC | 21.284 | 1.089 | 0.890 | 20.628 |

| SiO2 | 28.378 | 1.097 | 0.890 | 27.706 |

| ZnSe | 29.285 | 1.097 | 0.891 | 28.623 |

| SiO2/ZnSe2 | 31.561 | 1.099 | 0.891 | 30.904 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharma Gaudel, G.; Yu, S.-J.; Parajuli, D.; KC, D.; Khattri, K.B.; Kim, Y.J.; Rho, W.-Y. Reflectance Minimization of GaAs Solar Cell with Single- and Double-Layer Anti-Reflection Coatings: A Simulation Study. Coatings 2025, 15, 204. https://doi.org/10.3390/coatings15020204

Sharma Gaudel G, Yu S-J, Parajuli D, KC D, Khattri KB, Kim YJ, Rho W-Y. Reflectance Minimization of GaAs Solar Cell with Single- and Double-Layer Anti-Reflection Coatings: A Simulation Study. Coatings. 2025; 15(2):204. https://doi.org/10.3390/coatings15020204

Chicago/Turabian StyleSharma Gaudel, Gangasagar, Seung-Ju Yu, D. Parajuli, Devendra KC, Khim B. Khattri, Young Jun Kim, and Won-Yeop Rho. 2025. "Reflectance Minimization of GaAs Solar Cell with Single- and Double-Layer Anti-Reflection Coatings: A Simulation Study" Coatings 15, no. 2: 204. https://doi.org/10.3390/coatings15020204

APA StyleSharma Gaudel, G., Yu, S.-J., Parajuli, D., KC, D., Khattri, K. B., Kim, Y. J., & Rho, W.-Y. (2025). Reflectance Minimization of GaAs Solar Cell with Single- and Double-Layer Anti-Reflection Coatings: A Simulation Study. Coatings, 15(2), 204. https://doi.org/10.3390/coatings15020204