The Performance of Sulfoaluminate Cement Mortar with Secondary Aluminum Dross

Abstract

:1. Introduction

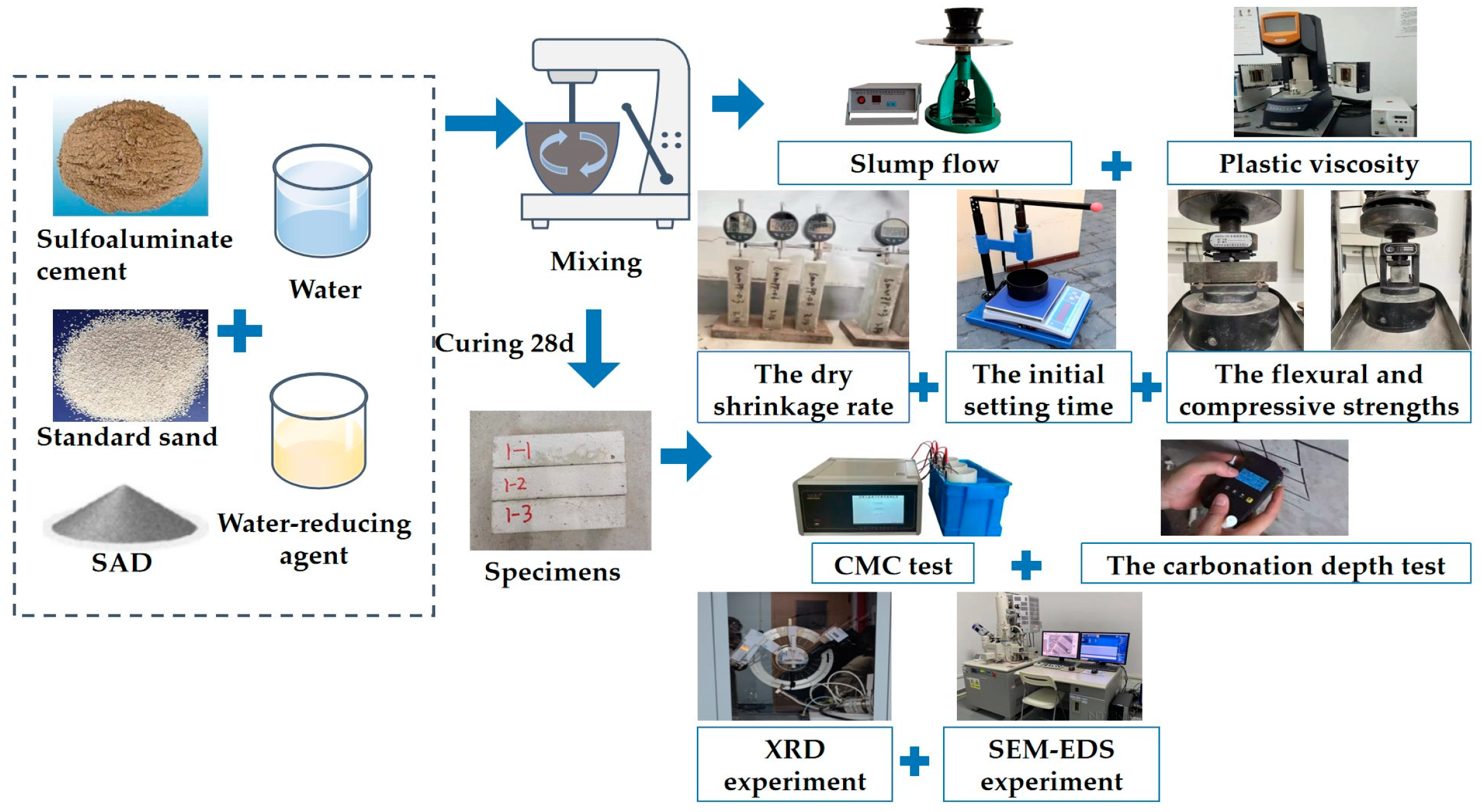

2. Experimental

2.1. Raw Materials

2.2. The Preparation of Mortar

2.3. The Measuring Process

2.3.1. The Measurement of Rheological Parameters

2.3.2. The Drying Shrinkage Rate

2.3.3. The Initial Setting Time

2.3.4. The Mechanical Strength

2.3.5. Chloride Ion Permeability Coefficient of Concrete

2.3.6. Carbonation Depth of Concrete

2.3.7. Micro-Analysis

3. Results and Discussion

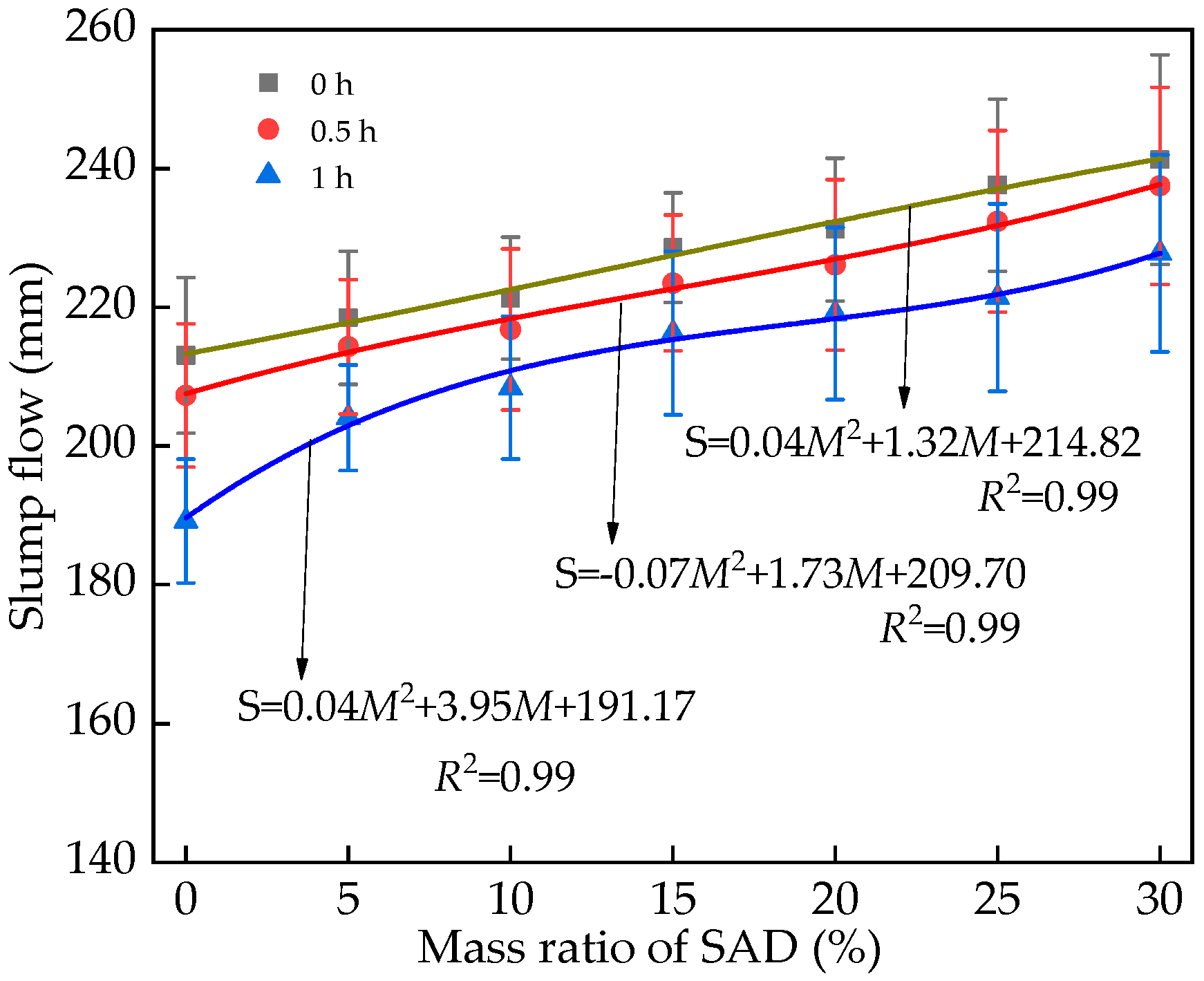

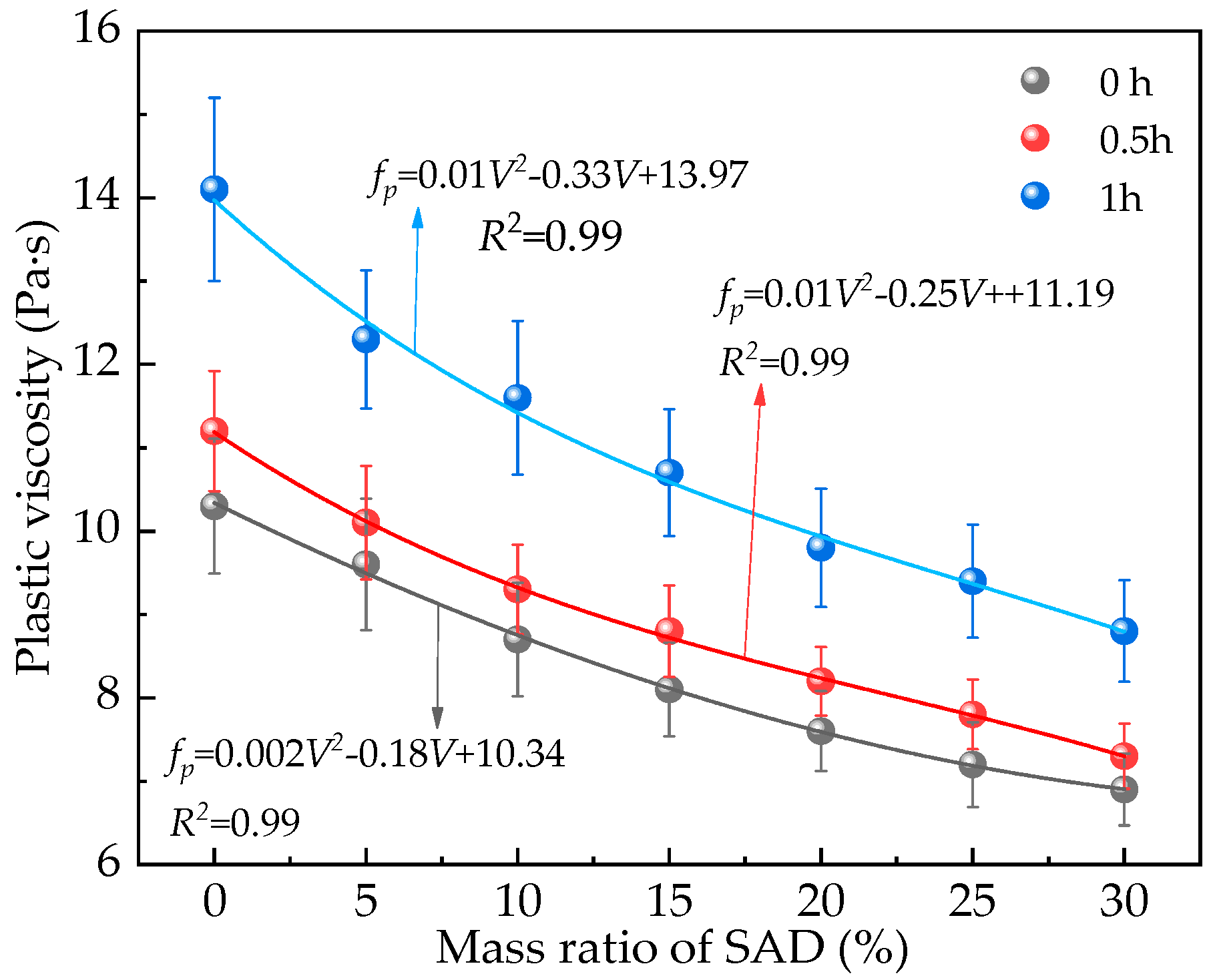

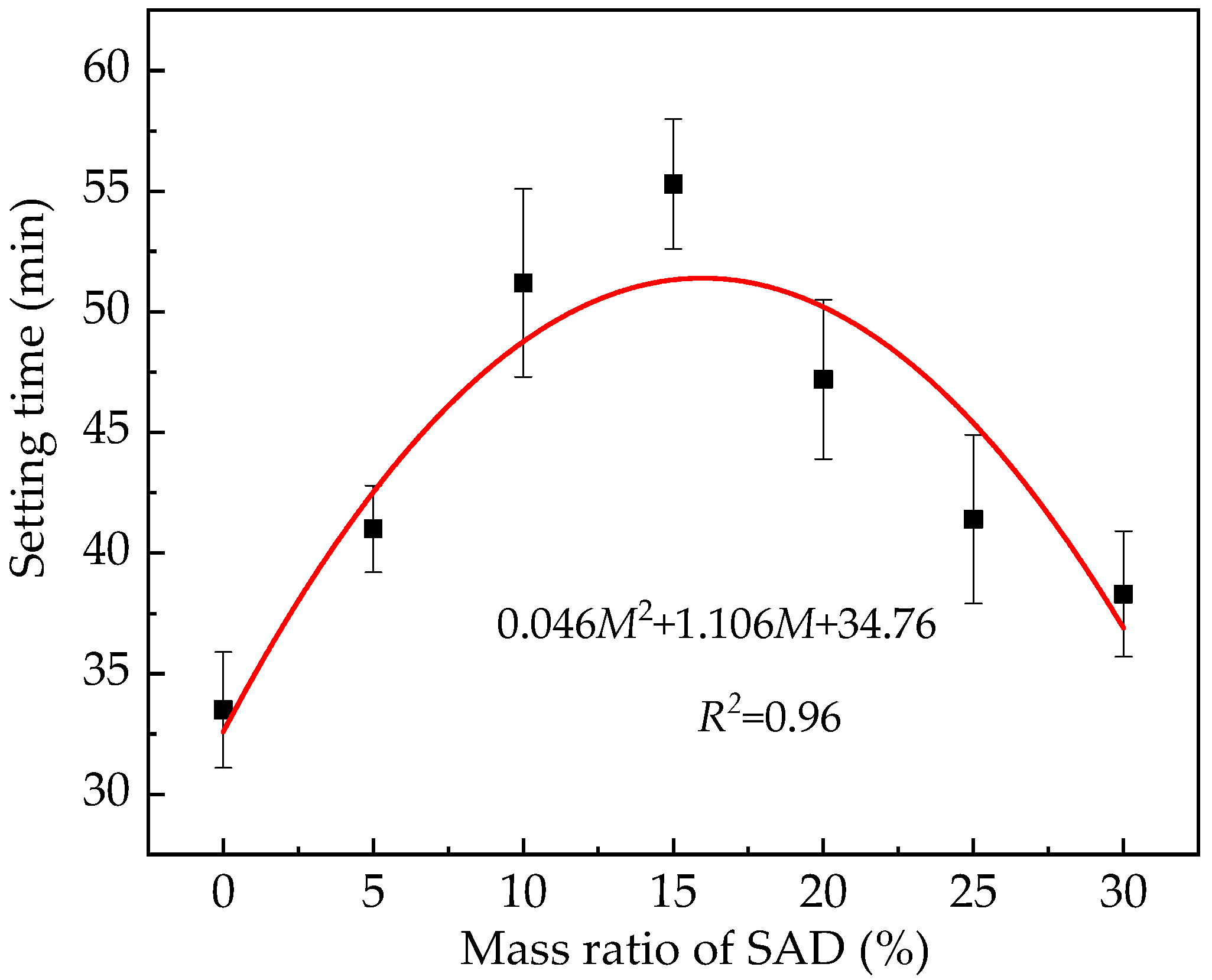

3.1. The Rheological Parameters

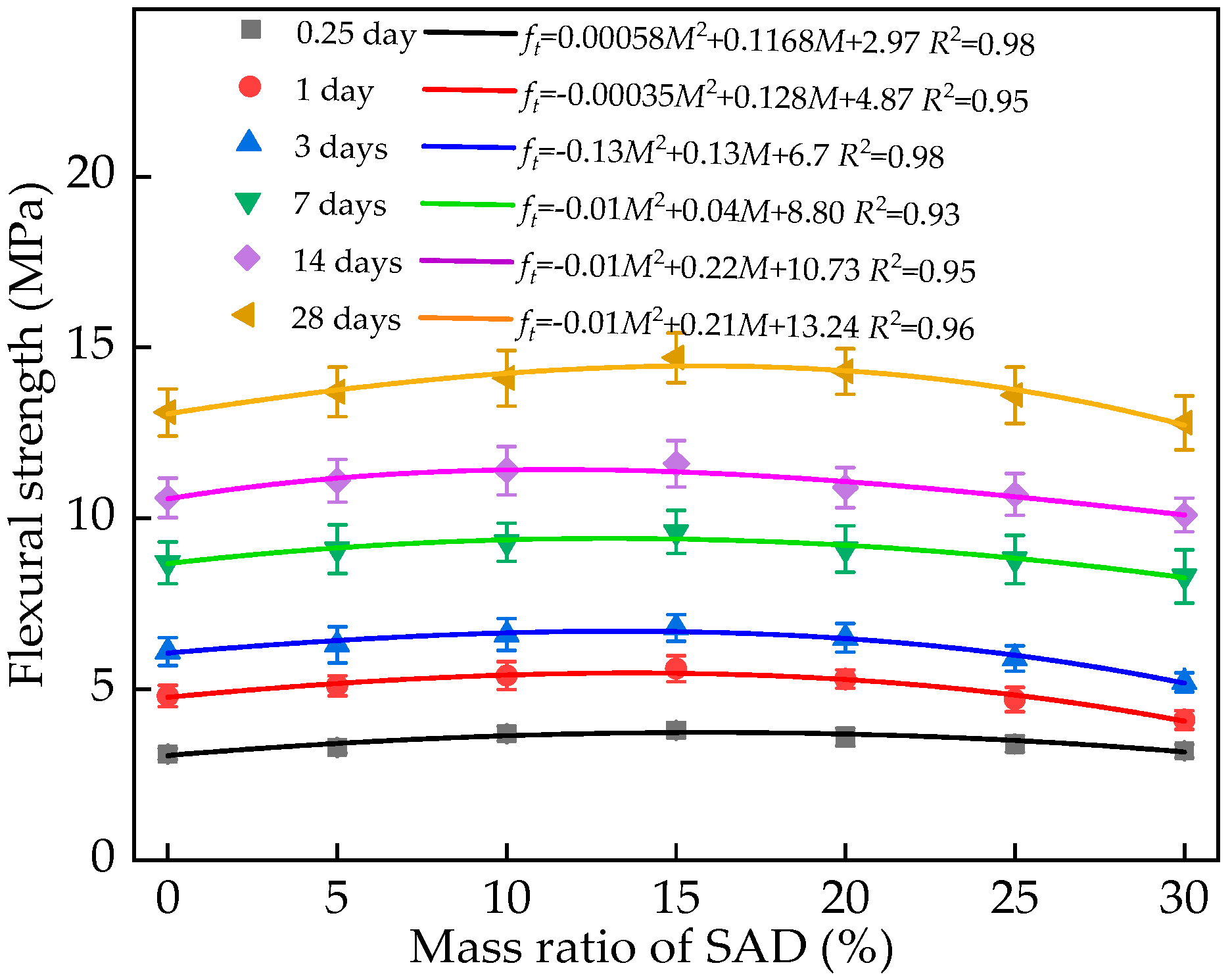

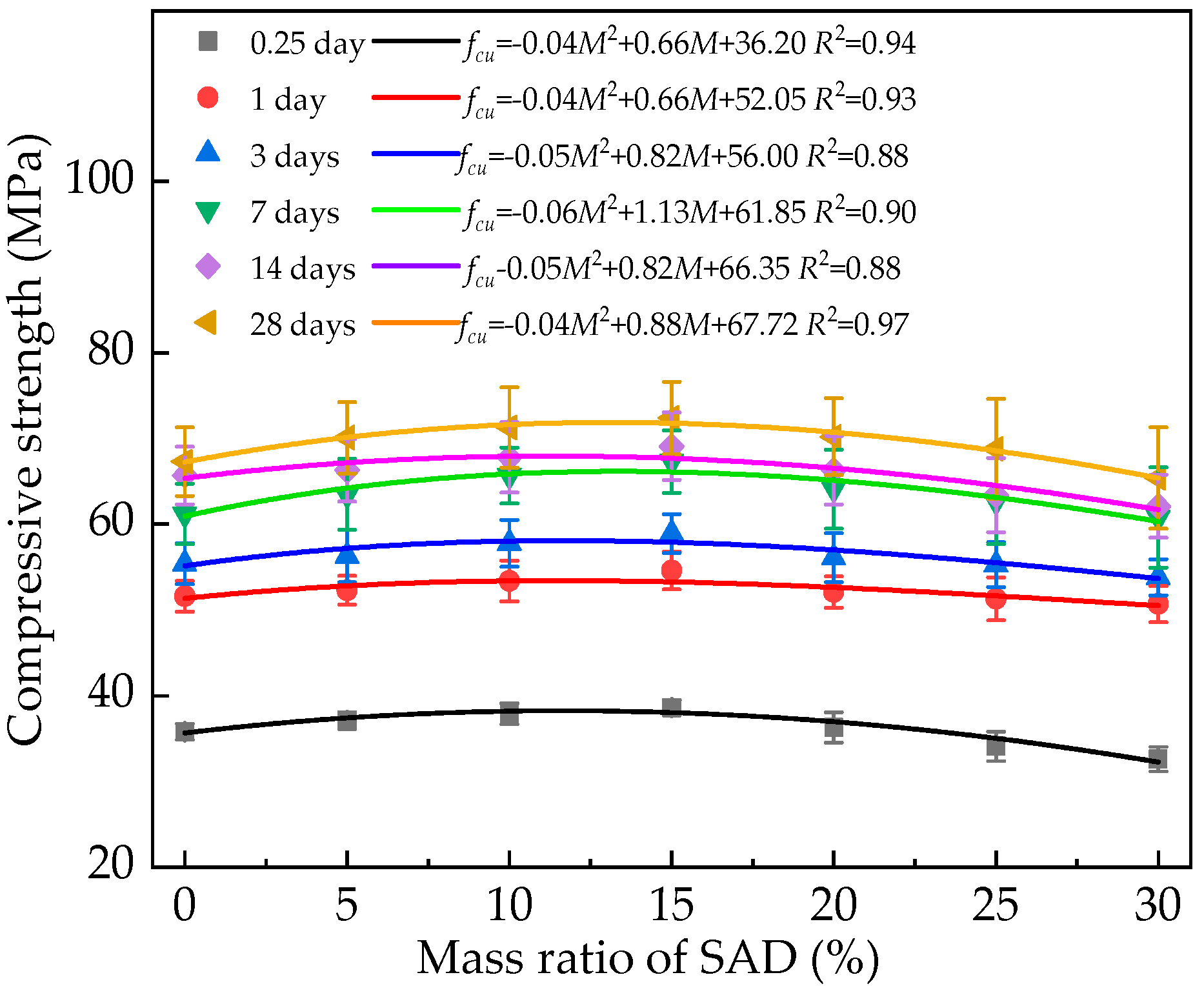

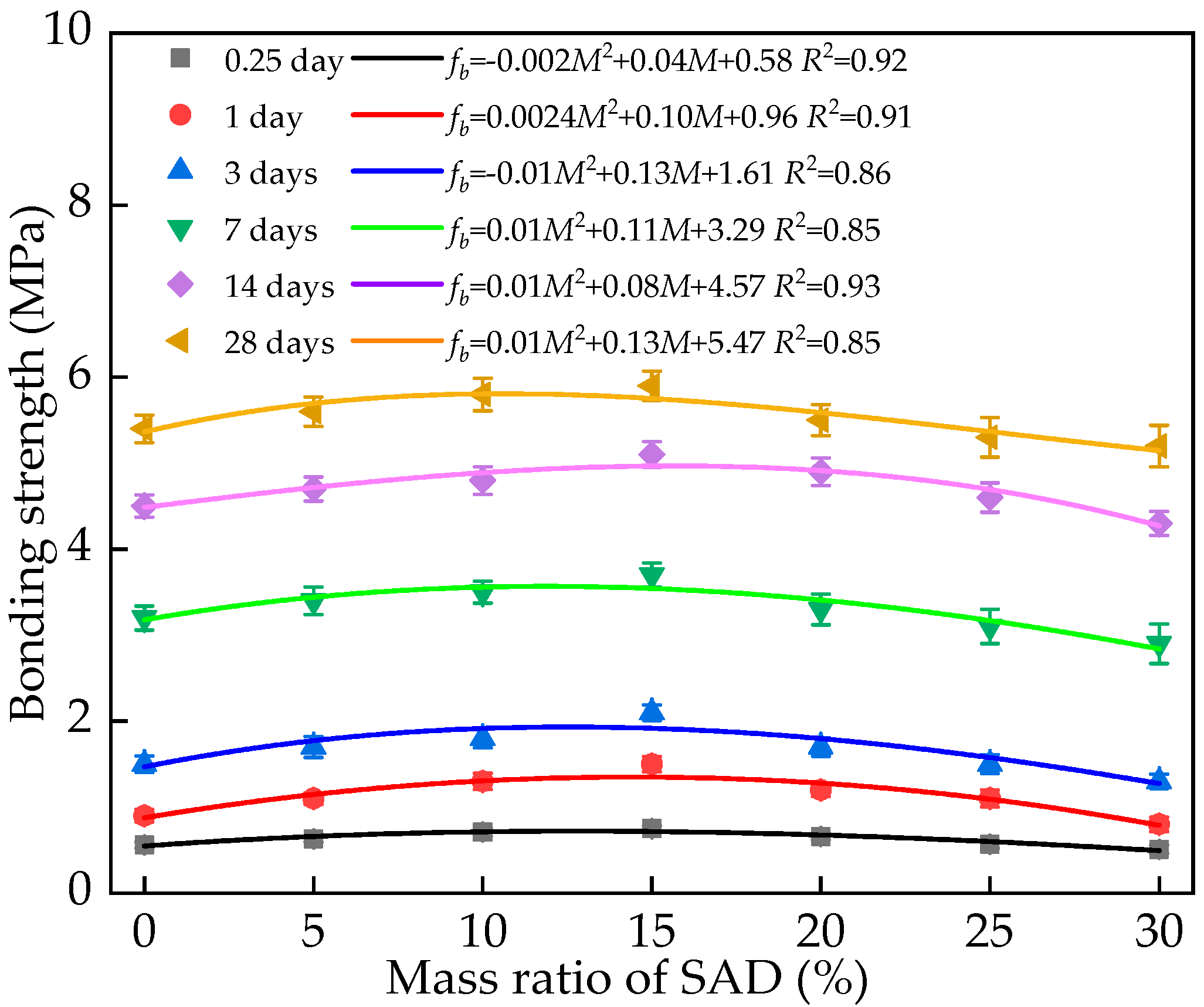

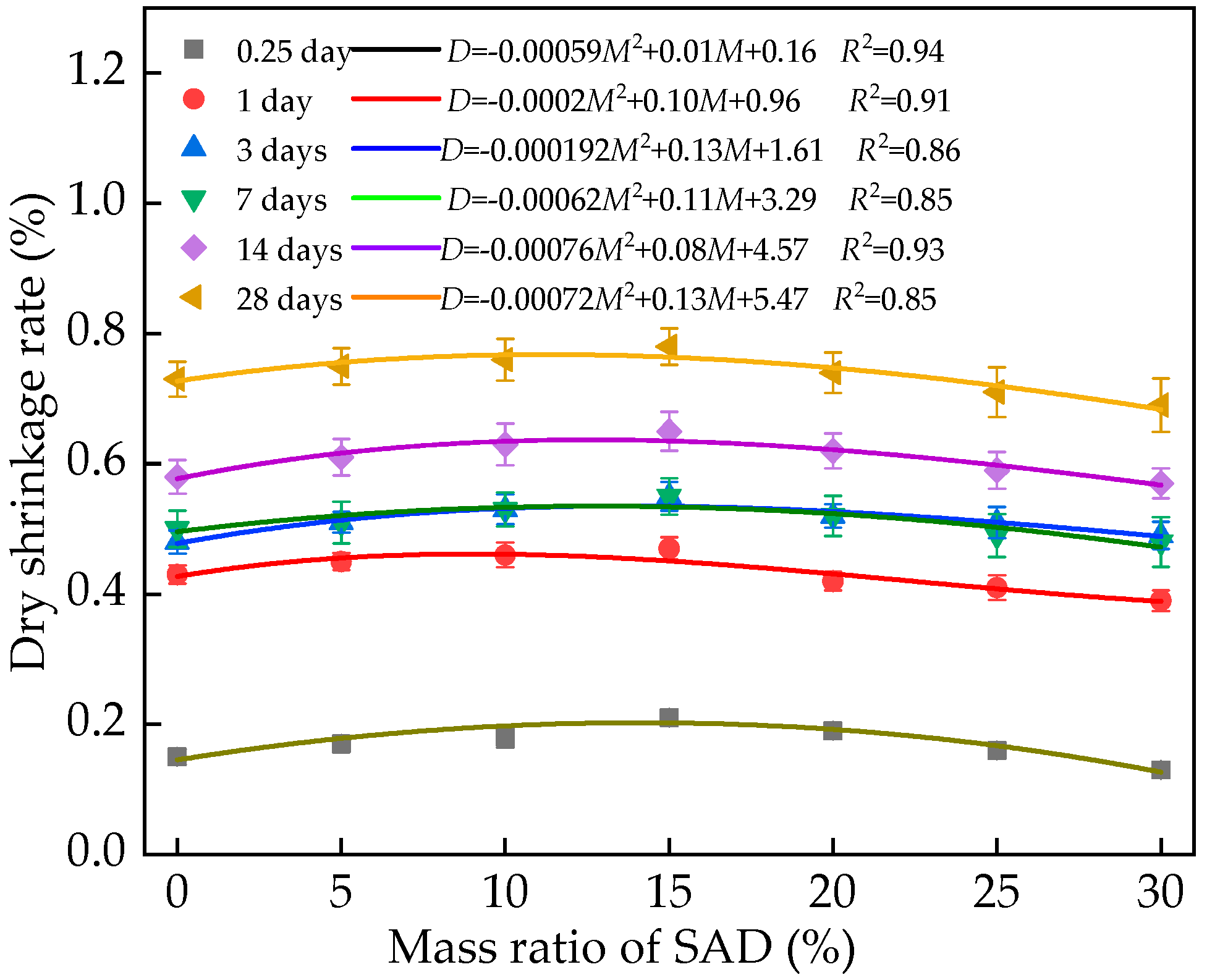

3.2. The Mechanical Strength and Drying Shrinkage Rate

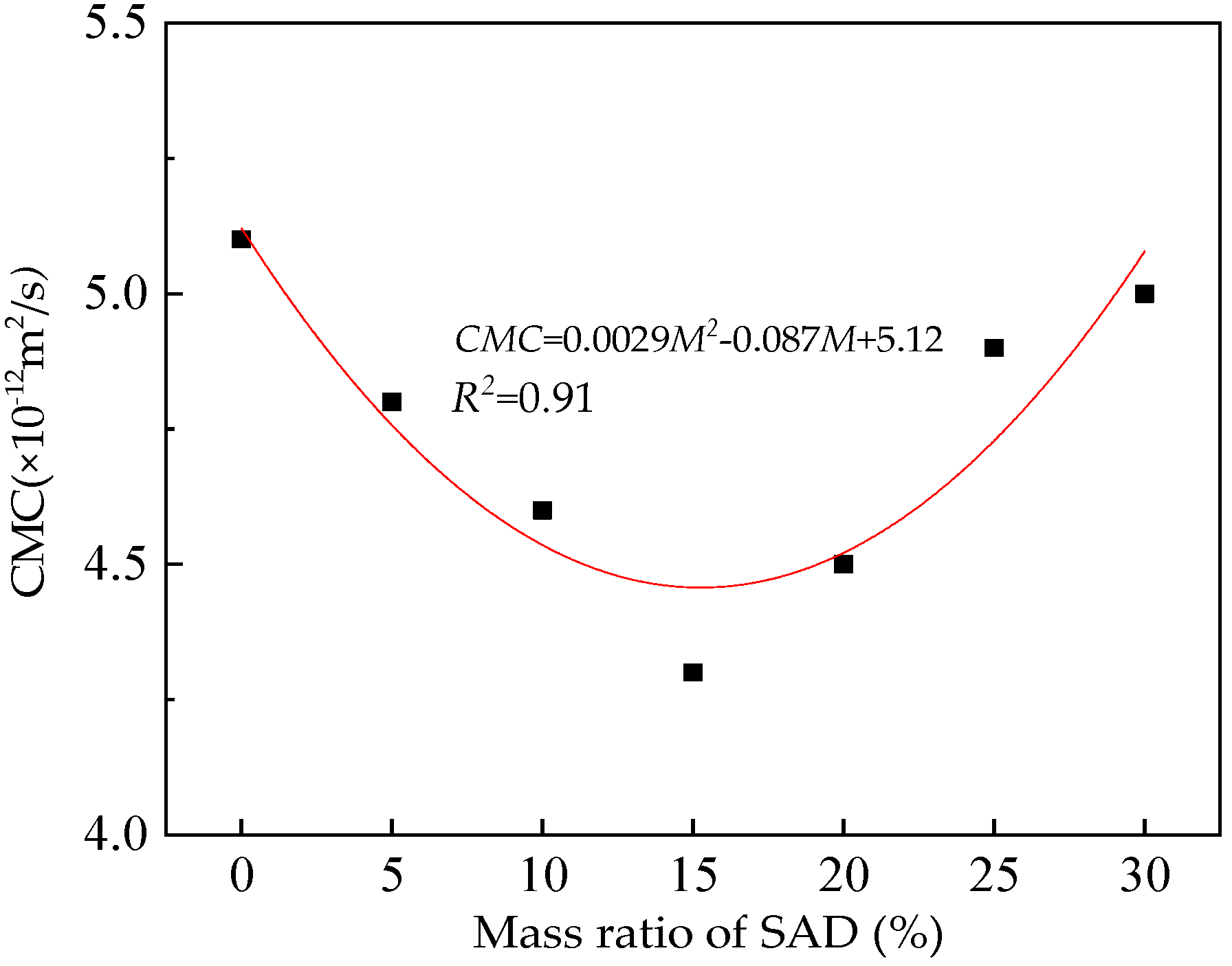

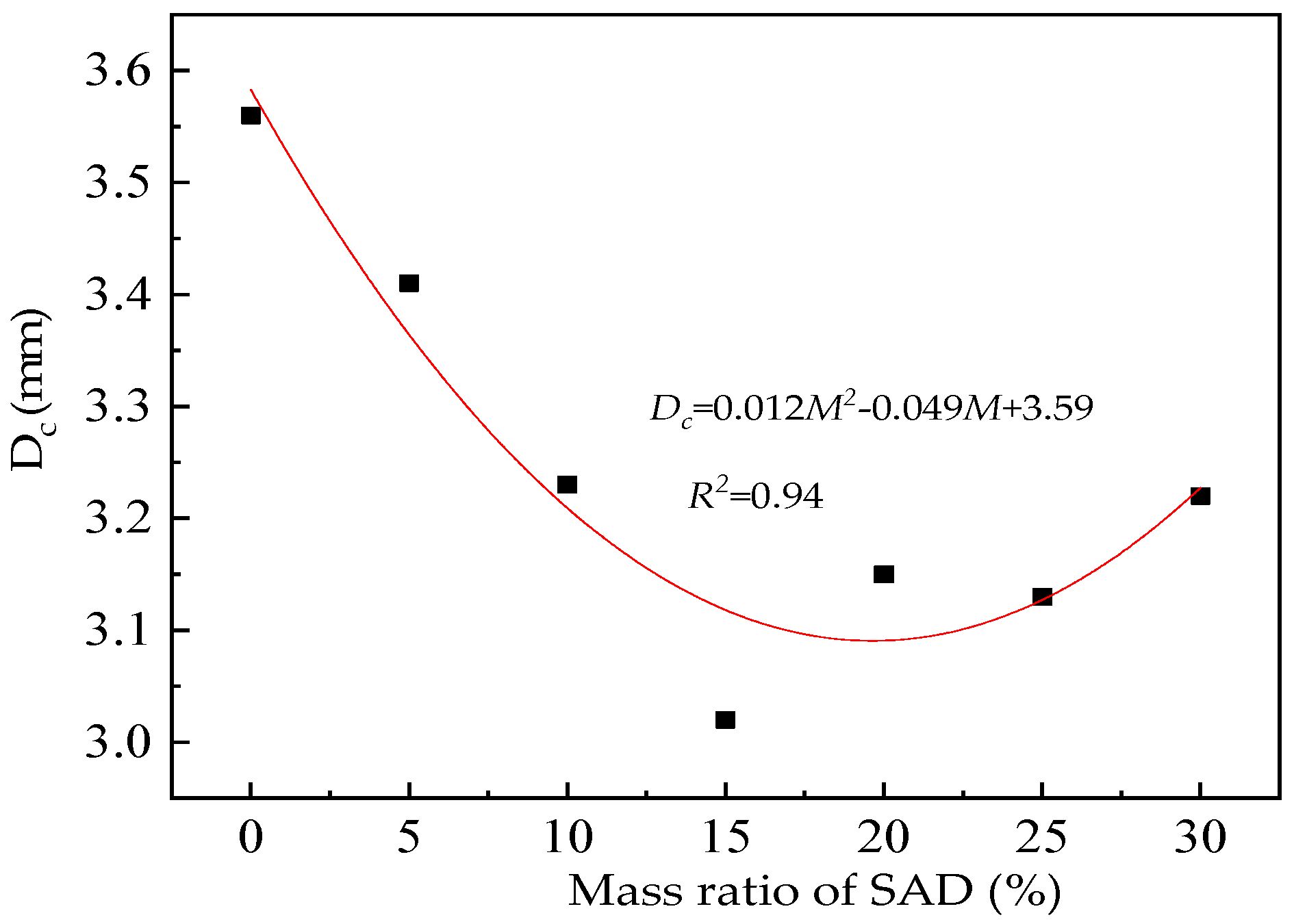

3.3. The Chloride Ion Migration Coefficient and Carbonation Depth

3.4. The Leached Cr and Zn

3.5. Micro-Analysis Results

3.5.1. The Scanning Electron Microscope

3.5.2. Scanning Electron Microscopy–Energy-Dispersive Spectroscopy

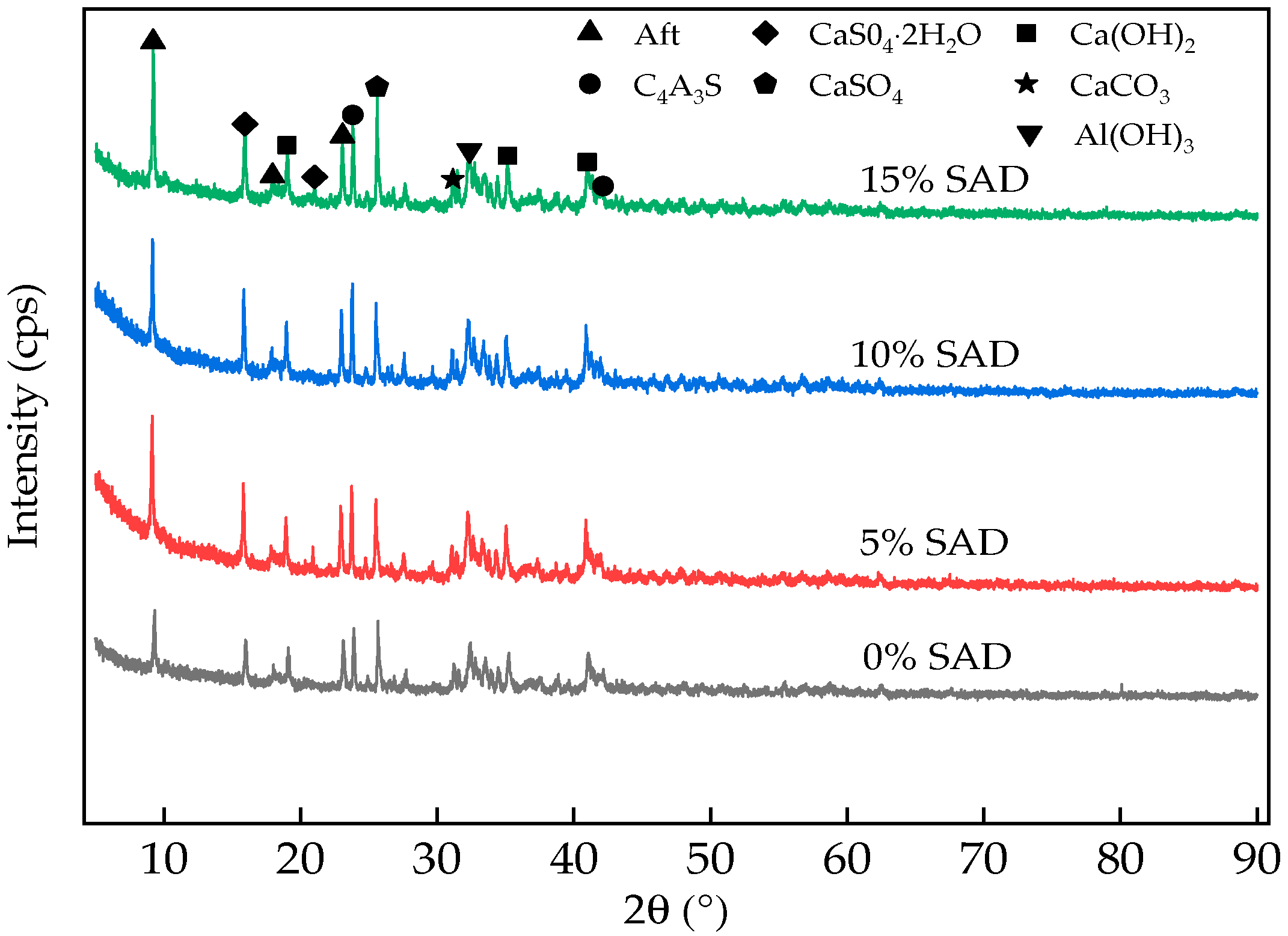

3.5.3. The X-Ray Diffraction Spectrum

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Serelis, E.; Vaitkevicius, V. Effect of waste glass powder and liquid glass on the Physico-Chemistry of Aluminum-Based Ultra-Lightweight concrete. Constr. Build. Mater. 2023, 390, 131615. [Google Scholar] [CrossRef]

- Cai, Z.; Ren, J.; Shen, G.; Jin, C.; Gu, X.; Cheng, W.; Wang, H. The Influence of Assembly Unit of Fibers on the Mechanical and Long-Term Properties of Reactive Powder Concrete. Coatings 2023, 13, 412. [Google Scholar] [CrossRef]

- Wei, Y.; Gao, X.; Zhang, Q. Evaluating performance of concrete pavement joint repair using different materials to reduce reflective cracking in asphalt concrete overlay. Road Mater Pavement Des. 2014, 15, 966–976. [Google Scholar]

- Li, Y.; Li, X.; Tan, Y. Effect of aging on fatigue performance of cement emulsified asphalt repair material. Constr. Build. Mater. 2021, 292, 123417. [Google Scholar] [CrossRef]

- Qiao, F.; Chau, C.; Li, Z. Property evaluation of magnesium phosphate cement mortar as patch repair material. Constr. Build. Mater. 2010, 24, 695–700. [Google Scholar] [CrossRef]

- Wang, Y.; Ye, J.; Liu, Y.; Qiang, X.; Feng, L. Influence of freeze–thaw cycles on properties of asphalt-modified epoxy repair materials. Constr. Build. Mater. 2013, 41, 580–585. [Google Scholar] [CrossRef]

- Li, Y.; Sun, H.; He, X.; Tan, Y. Freeze-thaw damage and creep behavior of cement asphalt composite binder. Constr. Build. Mater. 2020, 245, 118407. [Google Scholar] [CrossRef]

- Jin, B.; Chen, L.; Chen, B. Factors assessment of a repair material for brick masonry loaded cracks using magnesium phosphate cement. Constr. Build. Mater. 2020, 252, 119098. [Google Scholar] [CrossRef]

- Liu, S.; Yang, K.; Yu, L.; Xu, L.; Yuan, Q.; Wu, K.; Yang, Z. Integrated assessment of magnesium phosphate cement repaired concrete from the perspective of mechanical, geometric and electrochemical compatibility. Cem. Concr. Compos. 2025, 157, 105958. [Google Scholar] [CrossRef]

- Jin, H.; Yu, H.; Fu, Z.; Shan, L.; Zhang, S.; Zhao, Y. Early performance modification of a waste-derived super-sulfated cement from arsenic-containing bio-oxidation waste via calcium aluminate and calcium sulfoaluminate cement. Constr. Build. Mater. 2024, 441, 137529. [Google Scholar]

- Meng, Y.; Gao, D.; Yang, L.; Fang, J. A green ultra-high performance calcium sulfoaluminate cement concrete containing recycled fine aggregate: Mechanical properties, microstructure and environmental impact. Constr. Build. Mater. 2025, 470, 140641. [Google Scholar] [CrossRef]

- Gao, D.; Che, Q.; Meng, Y.; Yang, L.; Xie, X. Properties evolution of calcium sulfoaluminate cement blended with ground granulated blast furnace slag suffered from sulfate attack. J. Mater. Res. Technol. 2022, 17, 1642–1651. [Google Scholar] [CrossRef]

- Meng, Y.; Gao, D.; Yang, L.; Fang, J.; Li, Y.; Zhang, T. Effect of ultra-fine supplementary cementitious materials on the properties of calcium sulfoaluminate cement-based ultra-high performance concrete. Case Stud. Constr. Mater. 2024, 21, e03547. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Al-Tarawneh, M.; Ghaffar, S.H.; Chougan, M.; Jweihan, Y.S.; Rahman, M.M. Resistance of hydrophobic concrete with different moisture contents to advanced freeze–thaw cycles. Struct. Concr. 2021, 22, E1050–E1061. [Google Scholar] [CrossRef]

- Tan, B.; Okoronkwo, M.; Kumar, A.; Ma, H. Durability of calcium sulfoaluminate cement concrete. J. Zhejiang Univ. Sci. A 2020, 21, 118–128. [Google Scholar] [CrossRef]

- Leone, M.; Blasi, G.; Colonna, D. Long-term flexural response of reinforced calcium sulfoaluminate/cement concrete beams. Eng. Struct. 2023, 292, 116585. [Google Scholar] [CrossRef]

- Shang, C.; Wu, C.; Liu, Y.; Wang, J.; Fu, Q.; Lu, L.; Sheng, Z.; Xing, F. Impact of sulfoaluminate cement modification on corrosion resistance of reactive powder concrete subjected to ammonium sulfate-rich sewer environment. Constr. Build. Mater. 2024, 411, 134652. [Google Scholar] [CrossRef]

- Park, S.; Lee, N.; Park, K. Early-age hydration behavior of calcium sulfoaluminate (CSA) cement/ordinary Portland cement-blended ultra-high performance concrete. J. Build. Eng. 2024, 87, 109058. [Google Scholar] [CrossRef]

- Kumar, S.; Sharma, U. Mechanical performance of cement concrete with use of combined fibers of basalt and bamboo. Phys. Chem. Earth Parts A/B/C 2025, 137, 103799. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, C.; Li, Q.; Song, G.; Hu, Y. The synergistic effect of recycled steel fibers and rubber aggregates from waste tires on the basic properties, drying shrinkage, and pore structures of cement concrete. Constr. Build. Mater. 2025, 470, 140574. [Google Scholar] [CrossRef]

- Katebi, A.; Asadollahfardi, G.; Salehi, A.; Ahmadi, G.; Soleymani-tushmanlo, A. Investigation of the properties of self-compacting concrete using treated rubber powder, polypropylene fibers, and wash water. Case Stud. Constr. Mater. 2025, 22, e04443. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Du, G.; Li, Y. Synergistic effects of polypropylene fiber and basalt fiber on the mechanical properties of concrete incorporating fly ash ceramsite after freeze-thaw cycles. J. Build. Eng. 2024, 91, 109593. [Google Scholar] [CrossRef]

- Socrates, P.; Juan, M. Influence of the secondary aluminum chip on the physical and mechanical properties of concrete. Innov. Infrastruct. Solut. 2023, 8, 45. [Google Scholar]

- Lou, B.; Shen, H.; Liu, B.; Liu, J.; Zhang, S.G. Recycling secondary aluminum dross to make building materials: A review. Constr. Build. Mater. 2023, 409, 133989. [Google Scholar] [CrossRef]

- Rotana, H.; Claudia, P.O. On utilization and mechanisms of waste aluminium in mitigating alkali-silica reaction (ASR) in concrete. J. Clean. Prod. 2019, 212, 864–879. [Google Scholar]

- Zhang, S.; Wang, K.; Li, H.; Zhang, X.; Jiang, Y. Novel SCMs produced by the calcination of secondary aluminium dross with dolomite and their potential usage in cemented paste backfill. Constr. Build. Mater. 2023, 365, 130119. [Google Scholar] [CrossRef]

- Meor Yusoff, M.; Muslimin, M.; Paulus, W. Effect of fractional precipitation on quality of nanostructured alumina produced from black aluminium dross waste. Adv. Mater. Res. 2011, 173, 24–28. [Google Scholar] [CrossRef]

- Shen, H.; Liu, B.; Ekberg, C.; Zhang, S. Harmless disposal and resource utilization for secondary aluminum dross: A review. Sci. Total Environ. 2021, 760, 143968. [Google Scholar] [CrossRef]

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2016.

- JGJ/T70-2009; Standard for Test Method of Performance on Building Mortar. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2009.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). State Administration for Market Regulation and National Standardization Management Committee: Beijing, China, 2021.

- GB/T50082-2024; Standard for Test Methods of Long-Term Performance and Durability of Concrete. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2024.

- David, O.; Opeyemi, J.; Adekunle, M.; Babatunde, F. Influence of secondary aluminum dross (SAD) on compressive strength and water absorption capacity properties of sandcrete block. Cogent. Eng. 2019, 6, 1608687. [Google Scholar]

- Panditharadhya, B.; Sampath, V.; Shankar, A. Mechanical properties of pavement quality concrete with secondary aluminium dross as partial replacement for ordinary portland cement. Mater. Sci. Eng. 2018, 431, 032011. [Google Scholar] [CrossRef]

- Satish, R.; Neeraja, D. Mechanical and durability aspects of concrete incorporating secondary aluminium slag. Resour.-Effic. Technol. 2016, 2, 225–232. [Google Scholar]

- Ewais, E.; Khalil, N.; Amin, M. Utilization of aluminum sludge and aluminum slag (dross) for the manufacture of calcium aluminate cement. Ceram. Int. 2009, 35, 3381–3388. [Google Scholar] [CrossRef]

- Elseknidy, M.H.; Salmiaton, A.; Nor Shafizah, I.; Saad, A.H. A Study on Mechanical Properties of Concrete Incorporating Aluminum Dross, Fly Ash, and Quarry Dust. Sustainability 2020, 12, 9230. [Google Scholar] [CrossRef]

- Haneef, S.; Harish, P. An Experimental Investigation on Use of Secondary Aluminium Dross in Cement Concrete. Eng. Technol. 2016, 2, 204–207. [Google Scholar]

- Mailar, G.; Sreedhara, B.M.; Manu, D.S.; Hiremath, P.; Jayakesh, K. Investigation of concrete produced using recycled aluminium dross for hot weather concreting conditions. Res. Efficient Technol. 2016, 2, 68–80. [Google Scholar] [CrossRef]

- Mahinroosta, M.; Allahverdi, A. Enhanced alumina recovery from secondary aluminum dross for high purity nanostructured γ-alumina powder production: Kinetic study. J. Environ. Manag. 2018, 212, 278–291. [Google Scholar] [CrossRef]

- Boulahbal, A.; Santamaría, L.; Azizi, A.; Boutahala, M.; Korili, S.; Gil, A. Synthesis of Cu-Al layered double hydroxides from aluminum saline slags. Miner. Eng. 2023, 204, 108413. [Google Scholar] [CrossRef]

- Zawrah, M.; Ghanaym, E.; Sadek, H.; El Defrawy, S.; Ali, O. Synthesis, characterization and sinterability of pure and Ni-doped nano layered double hydroxides from aluminum dross. Ceram. Int. 2019, 45, 17598–17610. [Google Scholar] [CrossRef]

- Nduka, D.; Ede, A. Mechanical and Water Absorption Properties of Normal Strength Concrete (NSC) Containing Secondary Aluminum Dross (SAD). Int. J. Eng. Res. Afr. 2020, 47, 1–13. [Google Scholar] [CrossRef]

- Li, P.; Guo, M.; Zhang, M.; Teng, L.D. Leaching Process Investigation of Secondary Aluminum Dross: The Effect of CO2 on Leaching Process of Salt Cake from Aluminum Remelting Process. Metall. Mater. Trans. B 2012, 43, 1220–1230. [Google Scholar] [CrossRef]

- Kępniak, M.; Łukowski, P. Analysis of Cement Mortar with Recycled Sand. Sustainability 2024, 16, 1773. [Google Scholar] [CrossRef]

- Dean, M. A Practical Guide to Multi-Criteria Analysis; University College London: London, UK, 2022. [Google Scholar]

- Dean, M. Chapter Six-Multi-criteria analysis. Adv. Transp. Policy Plan. 2020, 6, 165–224. [Google Scholar]

- Huang, G.; Wang, H.; Shi, F. Coupling Effect of Salt Freeze-Thaw Cycles and Carbonation on the Mechanical Performance of Quick Hardening Sulphoaluminate Cement-Based Reactive Powder Concrete with Basalt Fibers. Coatings 2021, 11, 1142. [Google Scholar] [CrossRef]

| Types | Particle Size/μm | ||||||

|---|---|---|---|---|---|---|---|

| 0.3 | 0.6 | 1 | 4 | 8 | 64 | 360 | |

| Quartz sand | 0 | 0 | 0 | 0 | 0.059 | 20.89 | 100 |

| SAC | 0 | 0.34 | 1.91 | 16.24 | 29.85 | 94.86 | 100 |

| SAD | 0.07 | 0.25 | 0.57 | 1.16 | 3.93 | 25.91 | 87.25 |

| Types | SiO2 | Al2O3 | FexOy | MgO | CaO | SO3 |

|---|---|---|---|---|---|---|

| Quartz sand | 99.3 | - | 0.7 | - | - | - |

| SAC | 13.94 | 15.06 | 3.2 | - | 49.9 | 13.85 |

| SAD | 4.7 | 79.2 | 3.8 | 5.9 | 1.4 | - |

| Water | SAC | SAD | Quartz Sand | Water-Reducer | Li2SO4 | Tartaric Acid |

|---|---|---|---|---|---|---|

| 236.33 | 716.26 | 0 | 945.63 | 15.76 | 1.07 | 0.25 |

| 236.33 | 626.72 | 89.54 | 945.63 | 15.76 | 0.94 | 0.22 |

| 236.33 | 537.18 | 179.08 | 945.63 | 15.76 | 0.81 | 0.19 |

| 236.33 | 447.73 | 268.53 | 945.63 | 15.76 | 0.67 | 0.16 |

| 236.33 | 358.18 | 358.08 | 945.63 | 15.76 | 0.54 | 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhang, L.; Zhang, A. The Performance of Sulfoaluminate Cement Mortar with Secondary Aluminum Dross. Coatings 2025, 15, 459. https://doi.org/10.3390/coatings15040459

Wang Q, Zhang L, Zhang A. The Performance of Sulfoaluminate Cement Mortar with Secondary Aluminum Dross. Coatings. 2025; 15(4):459. https://doi.org/10.3390/coatings15040459

Chicago/Turabian StyleWang, Qian, Linchun Zhang, and Ailian Zhang. 2025. "The Performance of Sulfoaluminate Cement Mortar with Secondary Aluminum Dross" Coatings 15, no. 4: 459. https://doi.org/10.3390/coatings15040459

APA StyleWang, Q., Zhang, L., & Zhang, A. (2025). The Performance of Sulfoaluminate Cement Mortar with Secondary Aluminum Dross. Coatings, 15(4), 459. https://doi.org/10.3390/coatings15040459