Strengthening Mechanism of High-Temperature Compression Properties of High Nb–TiAl Alloy by Laser-Directed Energy Deposition

Abstract

1. Introduction

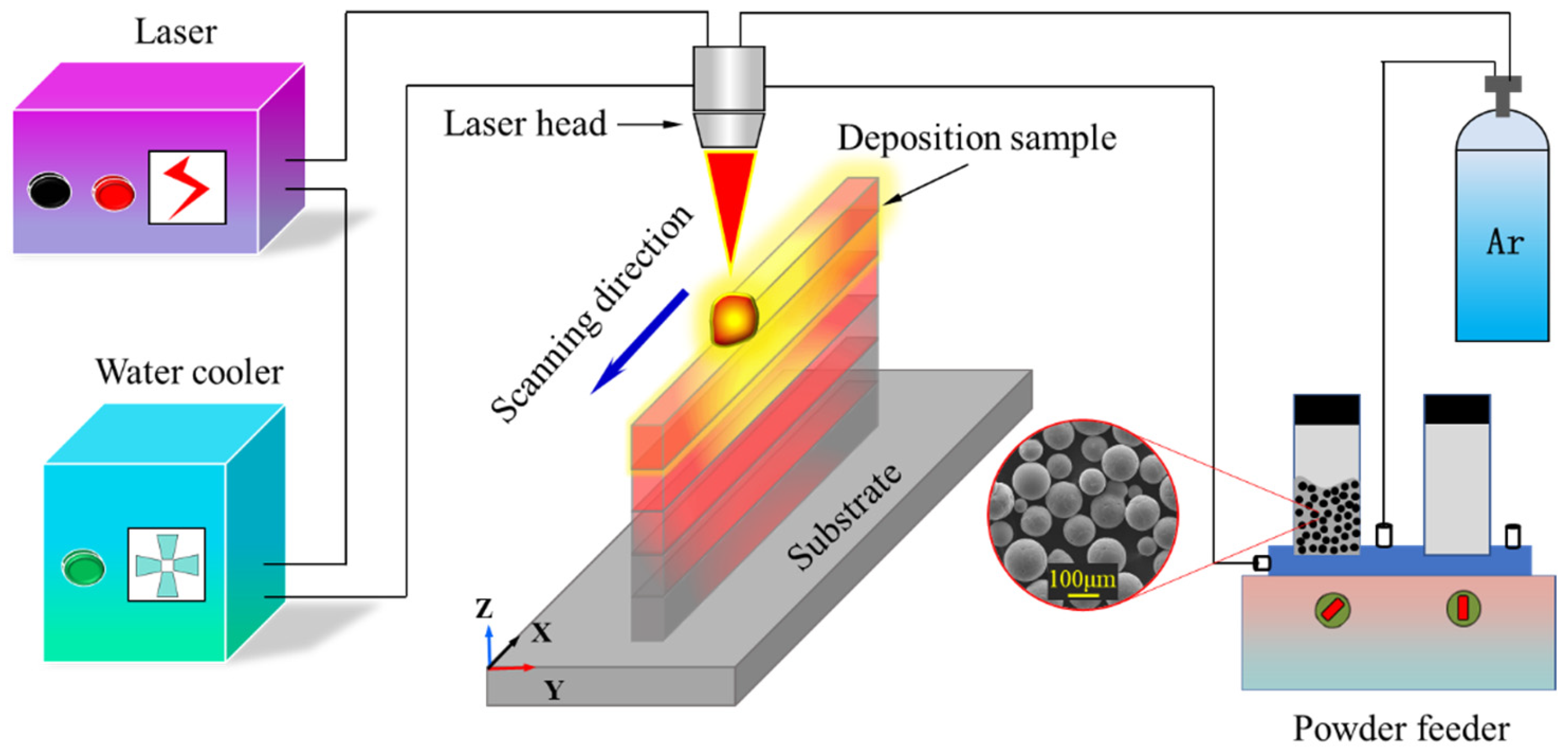

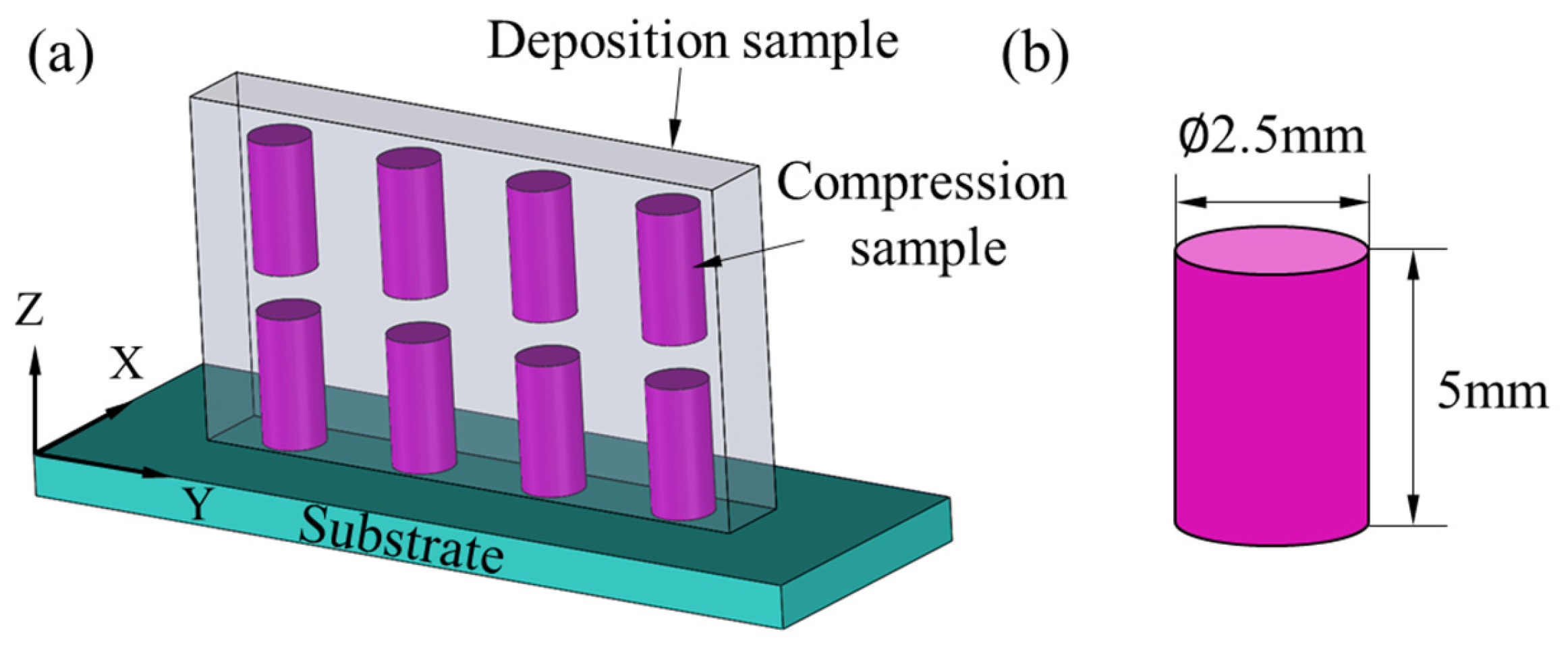

2. Experimental Condition

3. Result Discussion

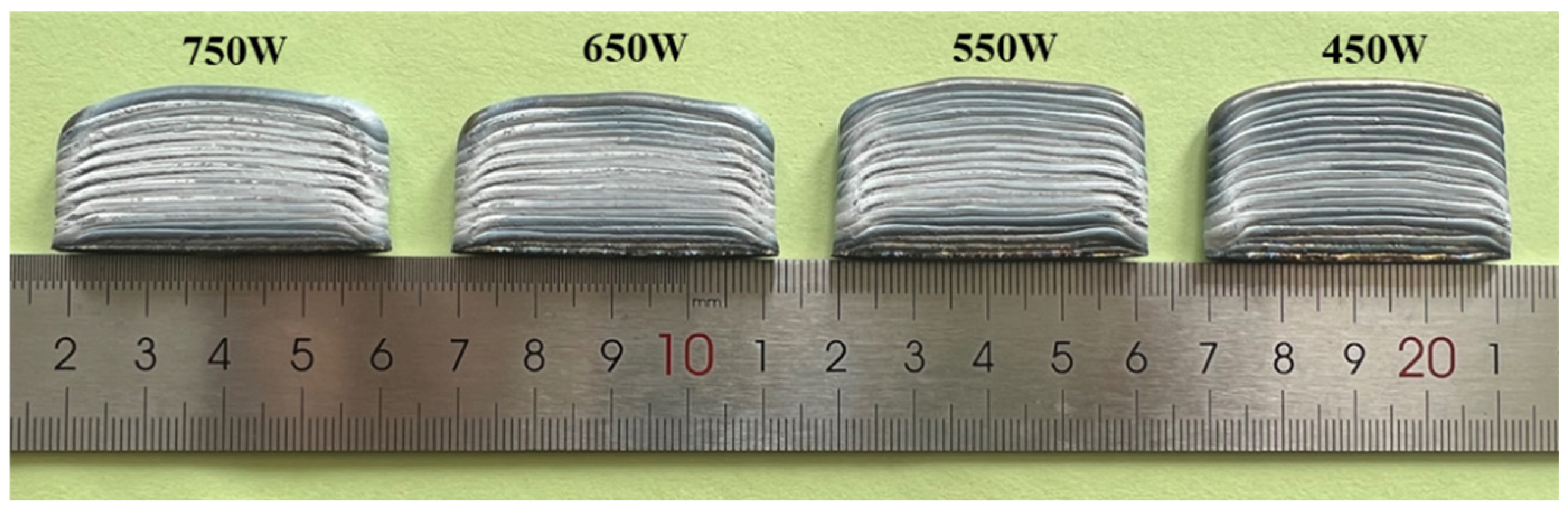

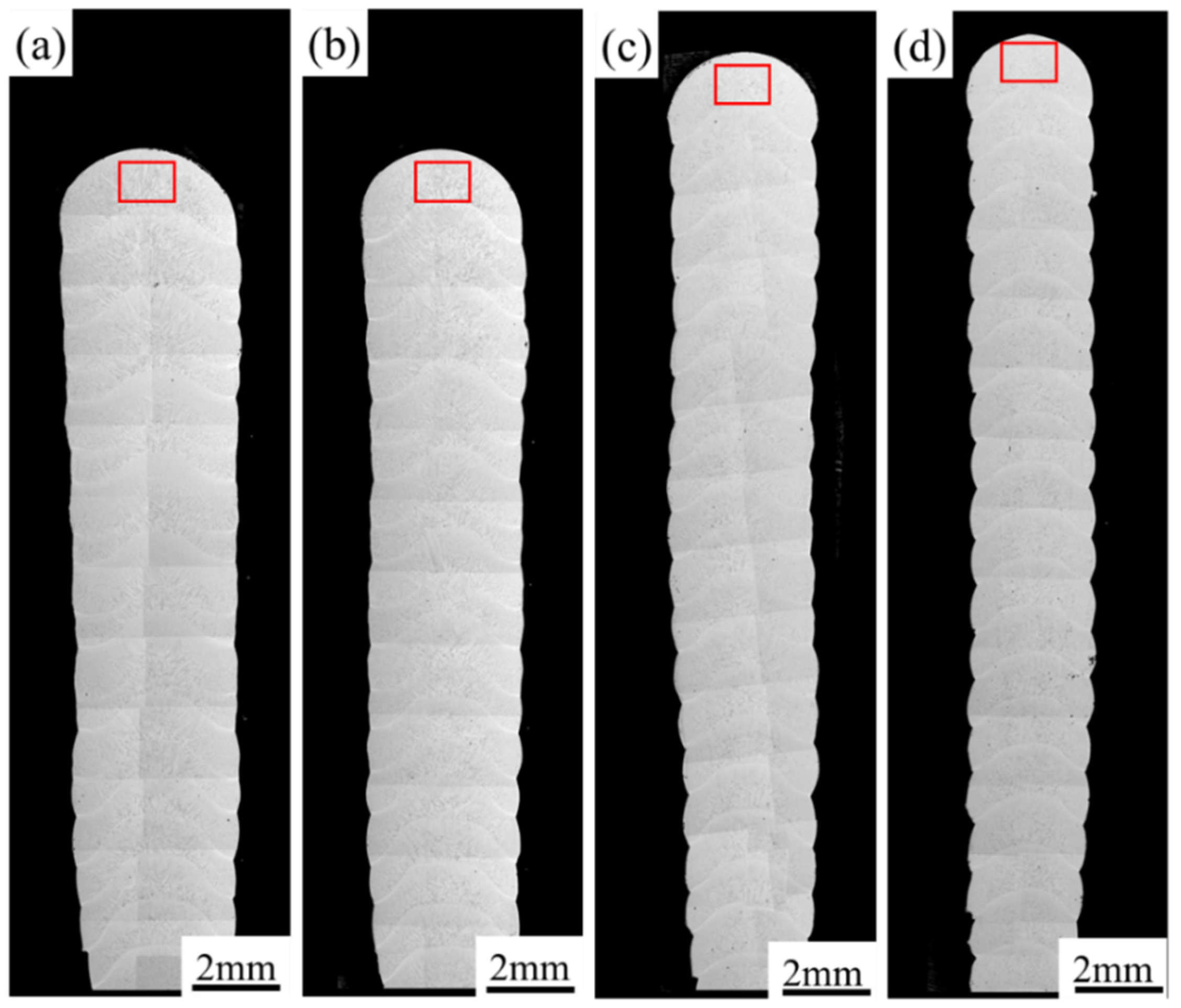

3.1. Macrostructure

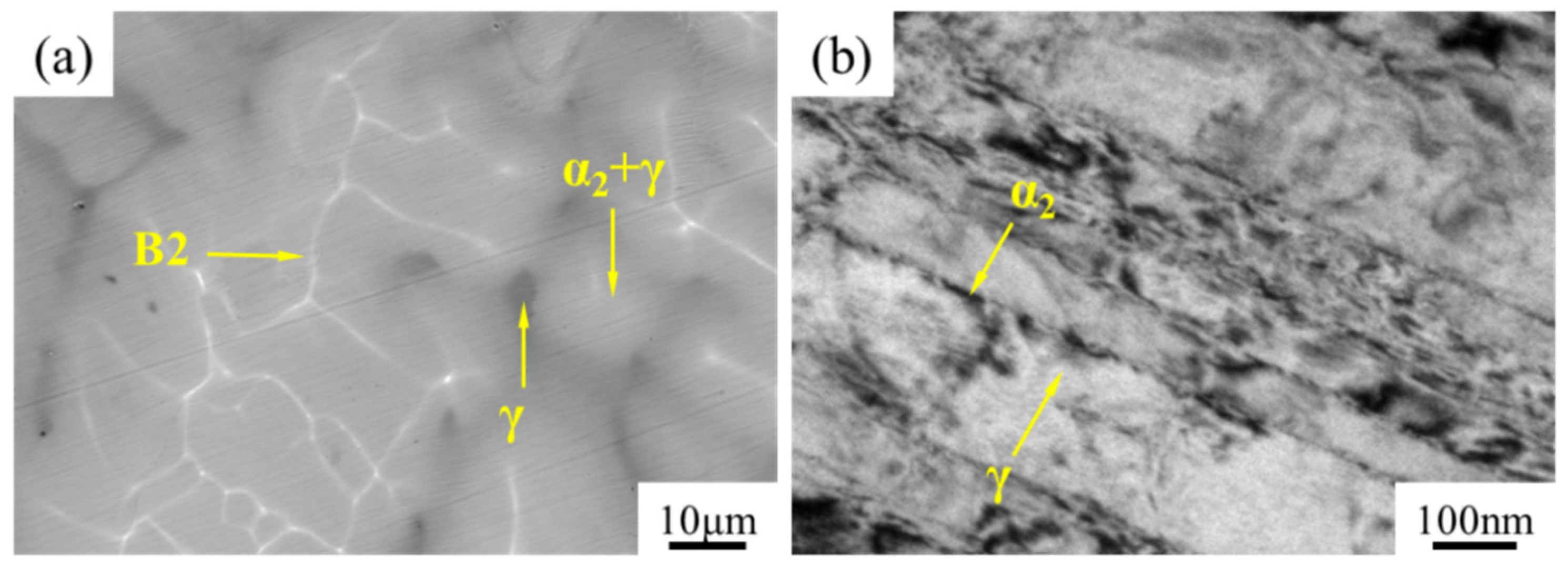

3.2. Microstructure Morphology

3.3. Texture Characterization

4. Compression Performance Analysis

4.1. RT Compressive Properties

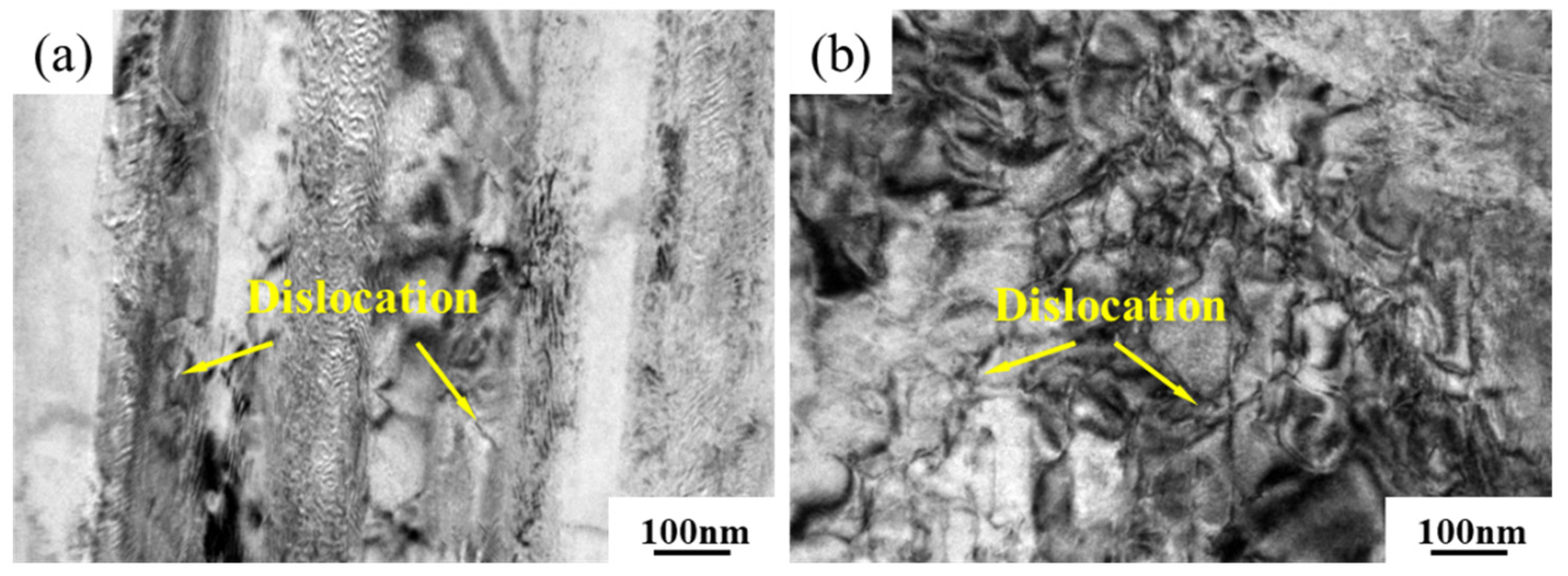

4.2. HT Compressive Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, Q.; Wang, Y.; Lv, L.; Luo, Y.; Su, L.; Liu, B. Hot deformation behavior and dynamic recrystallization mechanism of Ti-48Al-2Nb-2Cr with microstructure. J. Alloys Compd. 2023, 945, 169378. [Google Scholar] [CrossRef]

- Li, T.R.; Liu, G.H.; Xu, M.; Fu, T.L.; Tian, Y.; Misra, R.J.D.K.; Wang, Z.D. Hot Deformation Behavior and Microstructural Characteristics of Ti–46Al–8Nb Alloy. Acta Metall. Sin. 2018, 31, 933–944. [Google Scholar] [CrossRef]

- Lin, X.; Huang, H.; Yuan, X.; Zheng, B.; Wang, Y.; Zuo, X.; Zhou, G. Microstructure change characteristic and fracture mechanism of Ti-47.5Al-2.5V-1.0Cr-0.2Zr alloy during high temperature tensile deformation. J. Alloys Compd. 2023, 952, 169963. [Google Scholar] [CrossRef]

- Kim, Y.W.; Kim, S.L. Advances in Gammalloy Materials–Processes–Application Technology: Successes, Dilemmas, and Future. JOM 2018, 70, 553–560. [Google Scholar] [CrossRef]

- Zhang, S.; Tian, N.; Li, J.; Yang, G.; Yang, W.; Wang, G.; Liu, Z.; Li, Y. Microstructure evolution of a forged TiAl-Nb alloy during high-temperature tensile testing. Mater. Charact. 2023, 205, 113268. [Google Scholar] [CrossRef]

- Huang, H.; Liao, M.; Yu, Q.; Liu, G.; Wang, Z. The Effects of Hot-Pack Coating Materials on the Pack Rolling Process and Microstructural Characteristics during Ti-46Al-8Nb Sheet Fabrication. Materials 2020, 13, 762. [Google Scholar] [CrossRef]

- Wu, X. Review of alloy and process development of TiAl alloys. Intermetallics 2006, 14, 1114–1122. [Google Scholar] [CrossRef]

- Paul, J.D.H.; Lorenz, U.; Oehring, M.; Appel, F. Up-scaling the size of TiAl components made via ingot metallurgy. Intermetallics 2013, 32, 318–328. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Li, W.P.; Wang, H.; Zhou, Y.H.; Zhu, Y.Y.; Wang, N. Yttrium for the Selective Laser Melting of Ti-45Al-8Nb Intermetallic: Powder Surface Structure, Laser Absorptivity, and Printability. J. Alloys Compd. 2021, 892, 161970. [Google Scholar] [CrossRef]

- Huo, J.; He, B.; Lan, L. Effects of Boron on Microstructure and Mechanical Properties of High-Nb TiAl Alloy Fabricated via Laser Melting Deposition. J. Mater. Eng. Perform. 2023, 32, 10104–10114. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Wang, Q.; Zheng, M.; Ye, Z.; Gu, J. Unusual ordered phases with long periodic stacking structures in an additively manufactured TiAl alloy. Mater. Res. Lett. 2020, 8, 454–461. [Google Scholar] [CrossRef]

- Schwerdtfeger, J.; Koerner, C. Selective electron beam melting of Ti-48Al-2Nb-2Cr: Microstructure and aluminium loss. Intermetallics 2014, 49, 29–35. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, H.; Zhang, H.; Liu, S.; Chen, R.; Guo, J.; Fu, H. Growth rates dependence of macro/microstructures and mechanical properties of Ti-47Al-2Nb-2Cr-0.2Er alloy directionally solidified by cold crucible. Mater. Des. 2017, 125, 146–157. [Google Scholar] [CrossRef]

- Wang, J.; Luo, Q.; Wang, H.; Wu, Y.; Cheng, X.; Tang, H. Microstructure characteristics and failure mechanisms of Ti-48Al-2Nb-2Cr titanium aluminide intermetallic alloy fabricated by directed energy deposition technique. Addit. Manuf. 2020, 32, 101007. [Google Scholar] [CrossRef]

- Thomas, M.; Malot, T.; Aubry, P. Laser Metal Deposition of the Intermetallic TiAl Alloy. Metall. Mater. Trans. A 2017, 48, 3143–3158. [Google Scholar] [CrossRef]

- Huang, K.; Xu, F.; Liu, X.; Liu, S.; Wang, Q.; Baker, I.; Song, M.; Wu, H. Microstructure, Mechanical, and Tribological Properties of Nb-Doped TiAl Alloys Fabricated via Laser Metal Deposition. Materials 2024, 17, 4260. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, S.; Cheng, X.; Wang, H. Investigation on solid-state phase transformation in a Ti-47Al-2Cr-2V alloy due to thermal cycling during laser additive manufacturing process. J. Alloys Compd. 2019, 799, 325–333. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Yang, G.Y.; Li, J.B.; Liu, B.; Wang, J.W.; Li, H.Z. Hot deformation behaviors of β phase containing Ti–43Al–4Nb–1.4W-based alloy. Mater. Sci. Eng. A 2013, 577, 210–217. [Google Scholar] [CrossRef]

- Di, T.; Wang, J.; Ma, G.; Song, C.; Niu, F.; Wu, D. The columnar dendrite and equiaxed dendrite transformation of high Nb-TiAl alloy by laser-directed energy deposition. J. Alloys Compd. 2024, 980, 173439. [Google Scholar] [CrossRef]

- Xu, X.; Ding, H.; Li, W.; Huang, H.; Liang, H.; Kwak, S.; Chen, R.; Guo, J.; Fu, H. The smooth and notched three-point bending fatigue behavior of directionally solidified high-Nb TiAl alloy. Mater. Charact. 2021, 181, 111444. [Google Scholar] [CrossRef]

- Liu, T.; Luo, L.S.; Zhang, D.H.; Wang, L.; Li, X.Z.; Chen, R.R.; Su, Y.Q.; Guo, J.J.; Fu, H.Z. Comparison of microstructures and mechanical properties of as-cast and directionally solidified Ti-47Al-1W-0.5Si alloy. J. Alloys Compd. 2016, 682, 663–671. [Google Scholar] [CrossRef]

- Youn, S.-J.; Kim, Y.-K.; Kim, S.-W.; Lee, K.-A. Elevated temperature compressive deformation behaviors of γ-TiAl-based Ti-48Al-2Cr-2Nb alloy additively manufactured by electron beam melting. Intermetallics 2020, 124, 106859. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.Y.; Xiao, S.L.; Kong, F.T.; Zhang, C.J. High temperature deformation behaviors of Ti-45Al-2Nb-1.5V-1Mo-Y alloy. Intermetallics 2011, 19, 1767–1774. [Google Scholar] [CrossRef]

- Liu, Z.C.; Lin, J.P.; Wang, Y.L.; Lin, Z.; Chen, G.L.; Chang, K.M. High temperature deformation behaviour of As-cast Ti-46Al-8.5Nb-0.2W alloy. Mater. Lett. 2004, 58, 948–952. [Google Scholar] [CrossRef]

- Singh, V.; Mondal, C.; Kumar, A.; Bhattacharjee, P.P.; Ghosal, P. High temperature compressive flow behavior and associated microstructural development in a β-stabilized high Nb-containing γ-TiAl based alloy. J. Alloys Compd. 2019, 788, 573–585. [Google Scholar] [CrossRef]

- Liu, X.; Song, L.; Stark, A.; Lorenz, U.; He, Z.; Lin, J.; Pyczak, F.; Zhang, T. Deformation and phase transformation behaviors of a high Nb-containing TiAl alloy compressed at intermediate temperatures. J. Mater. Sci. Technol. 2022, 102, 89–96. [Google Scholar] [CrossRef]

- Zhang, S.; Tian, N.; Li, D.; Li, J.; Jin, F.; Wang, G.; Tian, S. Microstructure evolution and fracture mechanism of a TiAl-Nb alloy during high-temperature tensile testing. Mater. Sci. Eng. A 2022, 831, 142094. [Google Scholar] [CrossRef]

- Chen, X.; Tang, B.; Chen, W.; Yang, Y.; Zheng, G.; Fan, Z.; Li, J. Effect of inter-pass annealing on the deformation microstructure of Ti-48Al-2Cr-2Nb alloy. J. Alloys Compd. 2023, 934, 167751. [Google Scholar] [CrossRef]

- Li, M.; Li, J.; Zhou, T.; Xiao, S.; Chen, Y.; Xu, L.; Hu, L.; Shi, L. The investigation of microstructure evolution, deformation behavior and processing performance of the high niobium containing TiAl alloys. Intermetallics 2021, 138, 107336. [Google Scholar] [CrossRef]

- Tang, B.; Qi, X.S.; Kou, H.C.; Li, J.S.; Milenkovic, S. Recrystallization Behavior at Diffusion Bonding Interface of High Nb Containing TiAl Alloy. Adv. Eng. Mater. 2016, 18, 453–677. [Google Scholar] [CrossRef]

| Material | Ti | Al | Nb | V | Fe | C | O | N | H |

|---|---|---|---|---|---|---|---|---|---|

| Ti–45Al–8Nb | Bal | 28–29.5 | 17–17.8 | 0 | ≤0.05 | ≤0.025 | ≤0.12 | ≤0.02 | ≤0.003 |

| Ti–6Al–4V | Bal | 5.5–6.8 | 0 | 3.5–4.5 | 0.3 | 0.1 | 0.2 | 0.05 | 0.015 |

| p (W) | 750 | 650 | 550 | 450 |

|---|---|---|---|---|

| Scan rate (mm/min) | 120 | |||

| Powder feed rate (g/min) | 1.7 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di, T.; Song, C.; Ma, G.; Wang, J.; Wang, Z.; Wu, Y.; Niu, F.; Wu, D. Strengthening Mechanism of High-Temperature Compression Properties of High Nb–TiAl Alloy by Laser-Directed Energy Deposition. Coatings 2025, 15, 495. https://doi.org/10.3390/coatings15040495

Di T, Song C, Ma G, Wang J, Wang Z, Wu Y, Niu F, Wu D. Strengthening Mechanism of High-Temperature Compression Properties of High Nb–TiAl Alloy by Laser-Directed Energy Deposition. Coatings. 2025; 15(4):495. https://doi.org/10.3390/coatings15040495

Chicago/Turabian StyleDi, Tengda, Chenchen Song, Guangyi Ma, Jun Wang, Zhuoxi Wang, Yan Wu, Fangyong Niu, and Dongjiang Wu. 2025. "Strengthening Mechanism of High-Temperature Compression Properties of High Nb–TiAl Alloy by Laser-Directed Energy Deposition" Coatings 15, no. 4: 495. https://doi.org/10.3390/coatings15040495

APA StyleDi, T., Song, C., Ma, G., Wang, J., Wang, Z., Wu, Y., Niu, F., & Wu, D. (2025). Strengthening Mechanism of High-Temperature Compression Properties of High Nb–TiAl Alloy by Laser-Directed Energy Deposition. Coatings, 15(4), 495. https://doi.org/10.3390/coatings15040495