Research on the Formation Behaviour and Tribological Service Mechanism of Ni-Based Composite Coatings Prepared by Thermal Spraying Assisted with Alternating Current Magnetic Field

Abstract

1. Introduction

2. Experimental

2.1. Coating Preparation

2.2. Coating Characterisation and Evaluation

3. Results and Discussion

3.1. Microstructure and Phase Structure Analysis of Coating

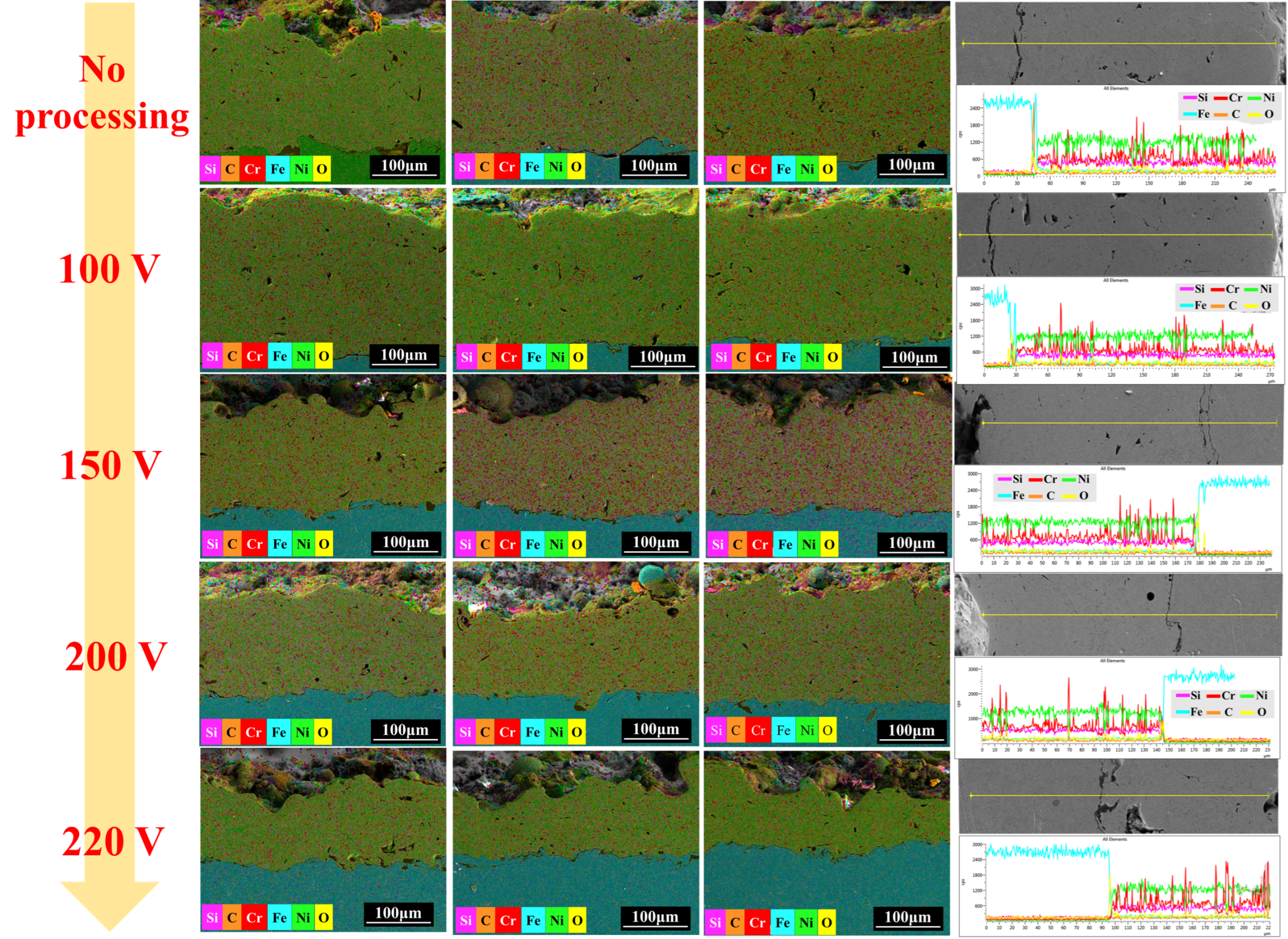

3.1.1. Analysis of Sectional Structure and Dimensional Characteristics of Coating

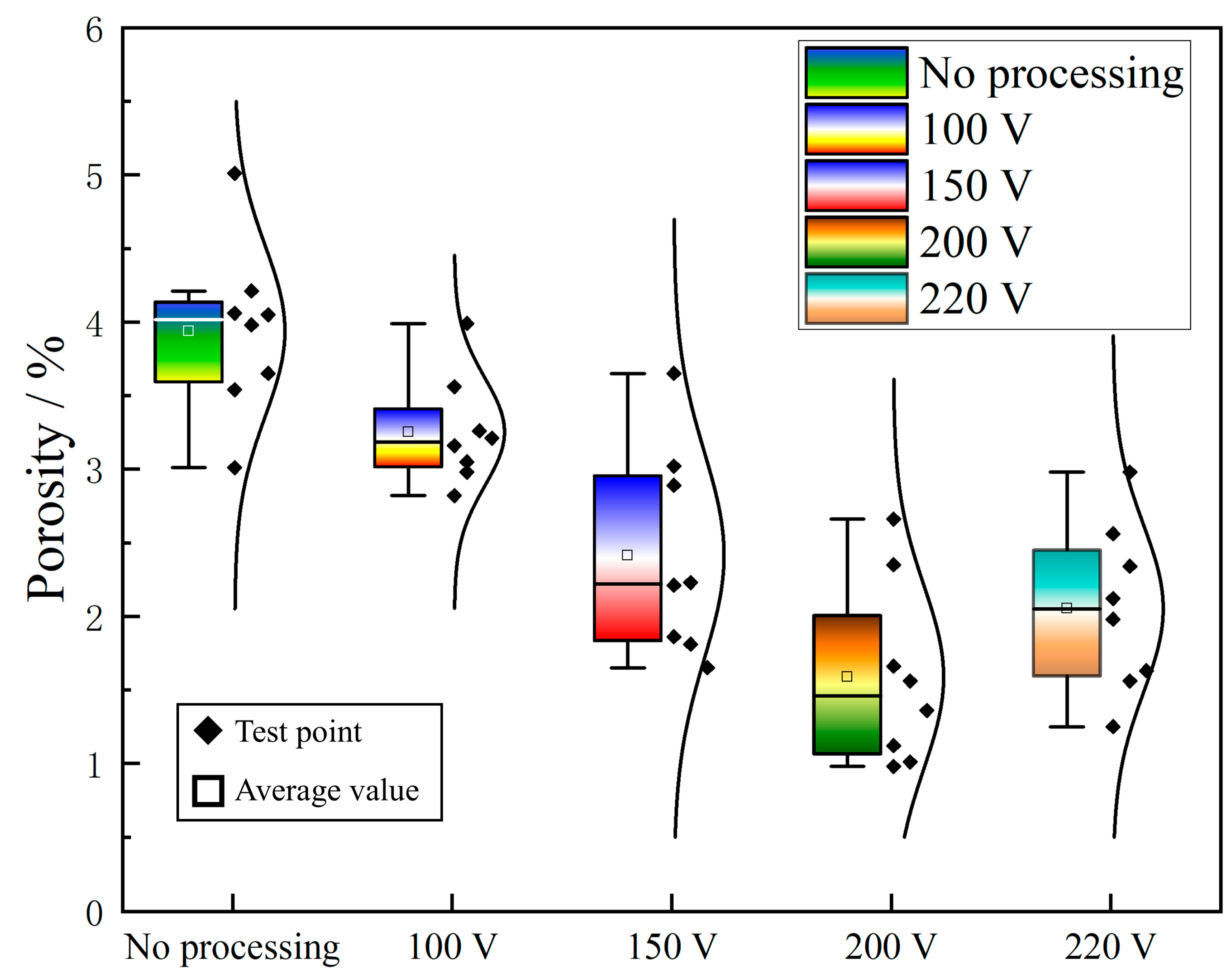

3.1.2. Analysis of Coating Porosity Results

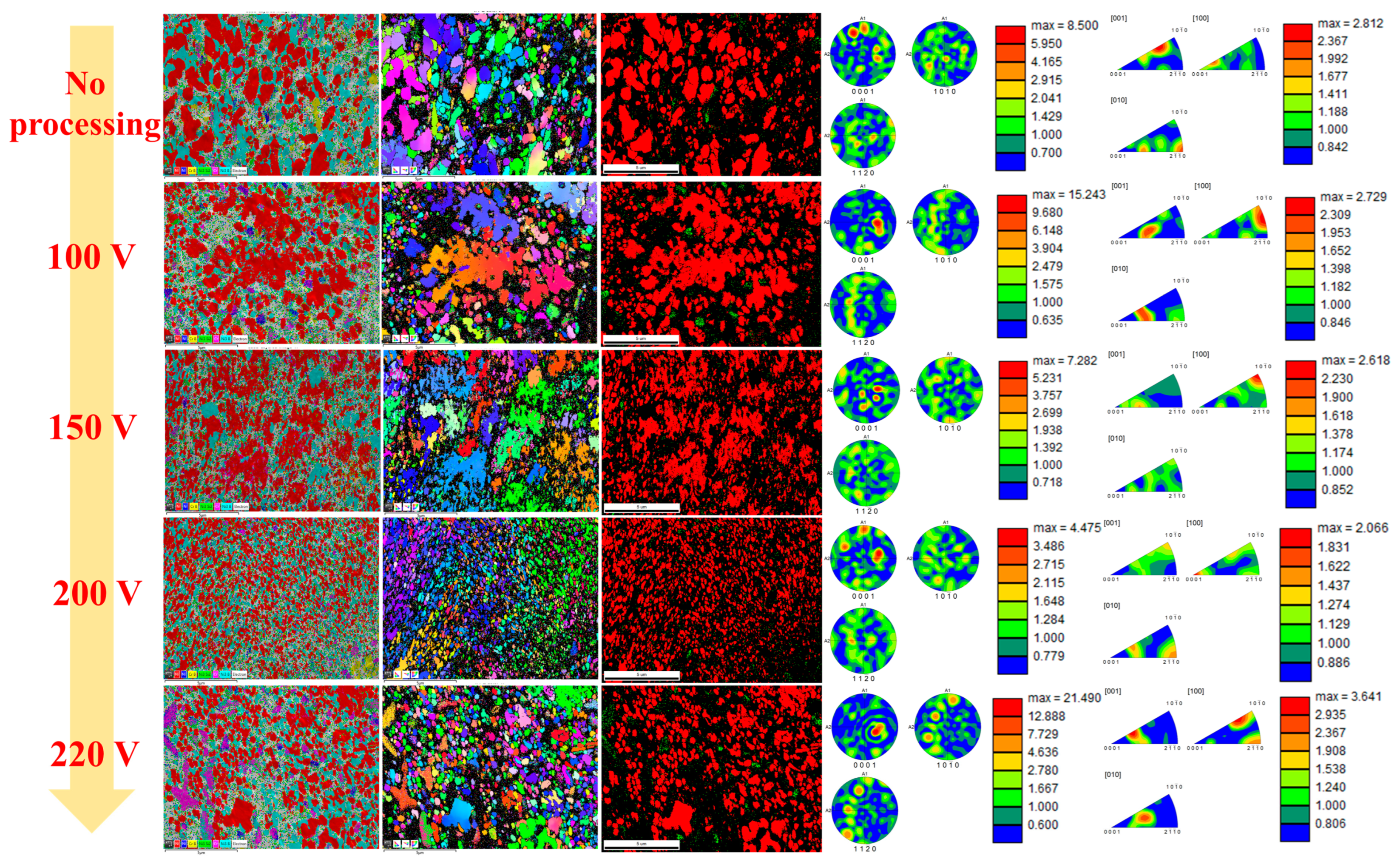

3.1.3. Analysis of Coating Crystallographic Parameters

3.2. Analysis of Mechanical Properties of Coating

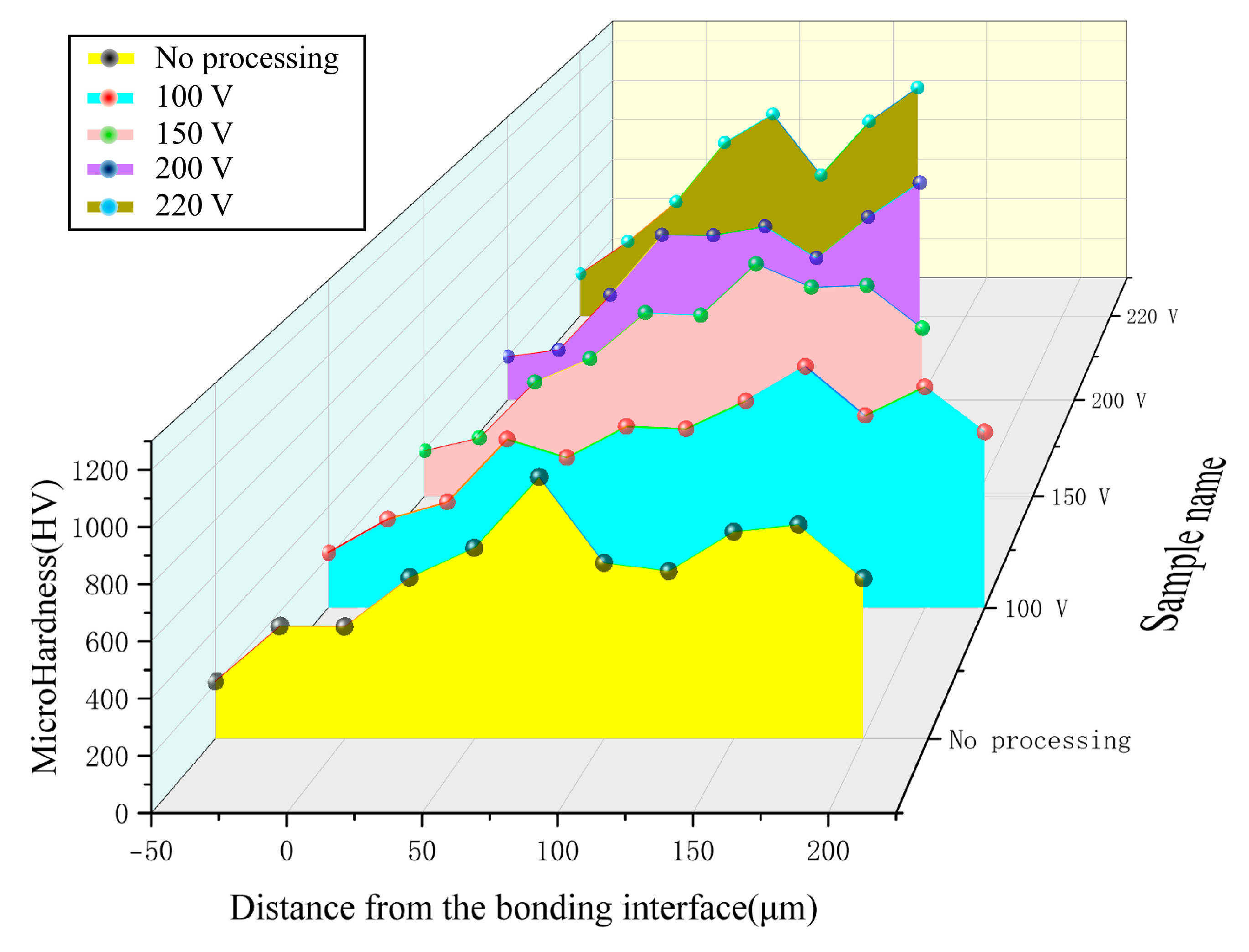

3.2.1. Analysis of Hardness Test Results of the Coating

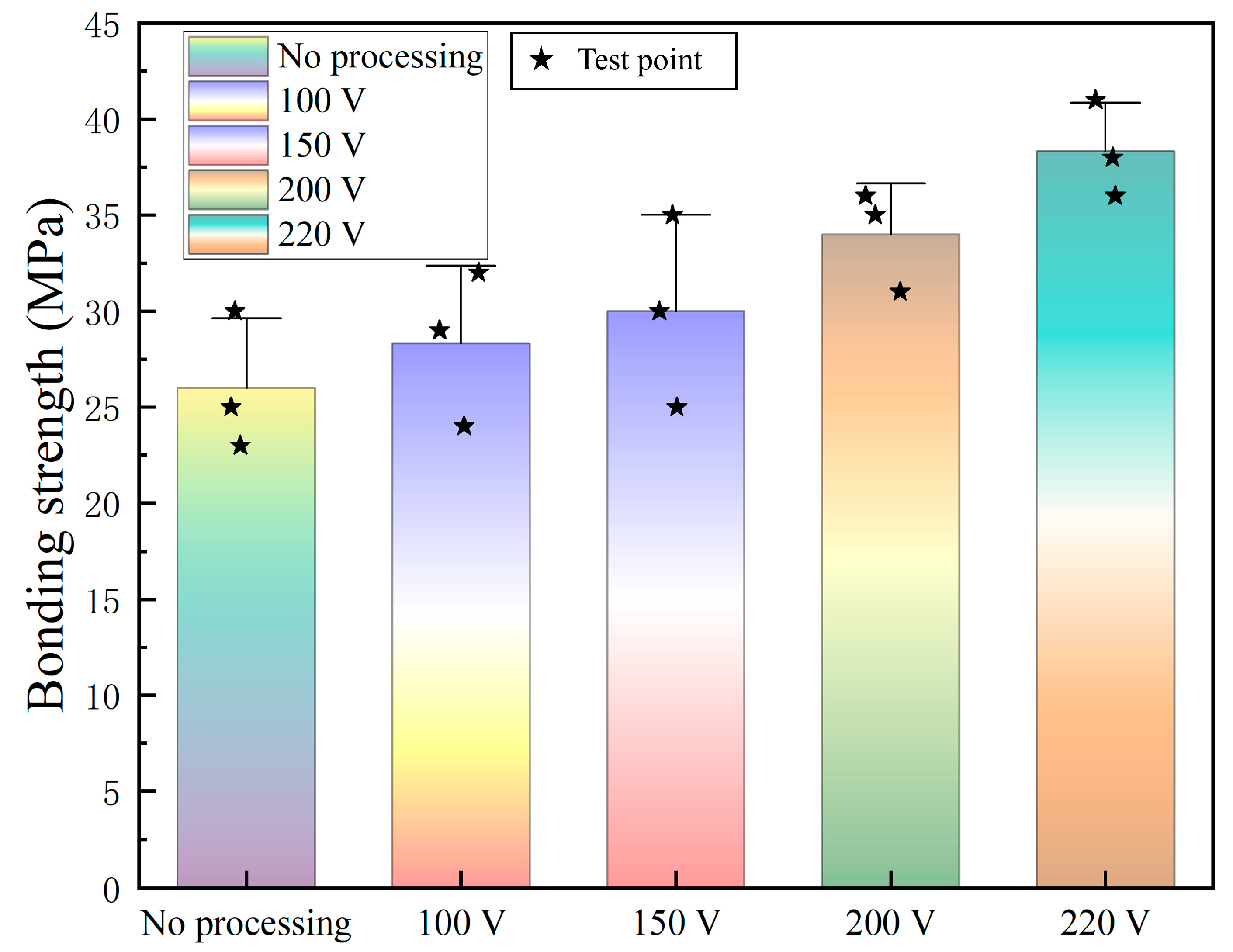

3.2.2. Analysis of Test Results of Bonding Strength of Coating

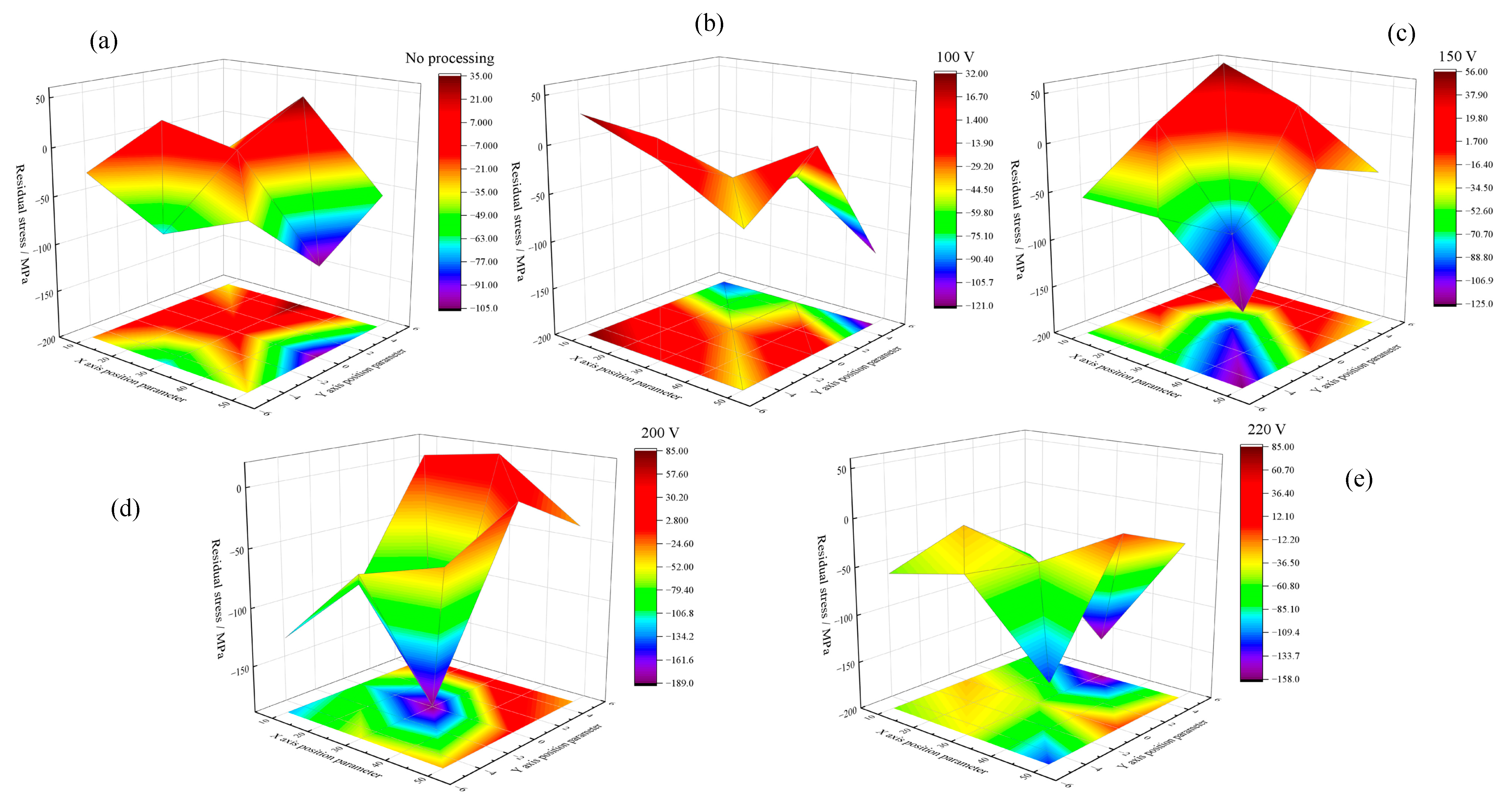

3.2.3. Analysis of Residual Stress Test Results of Coating

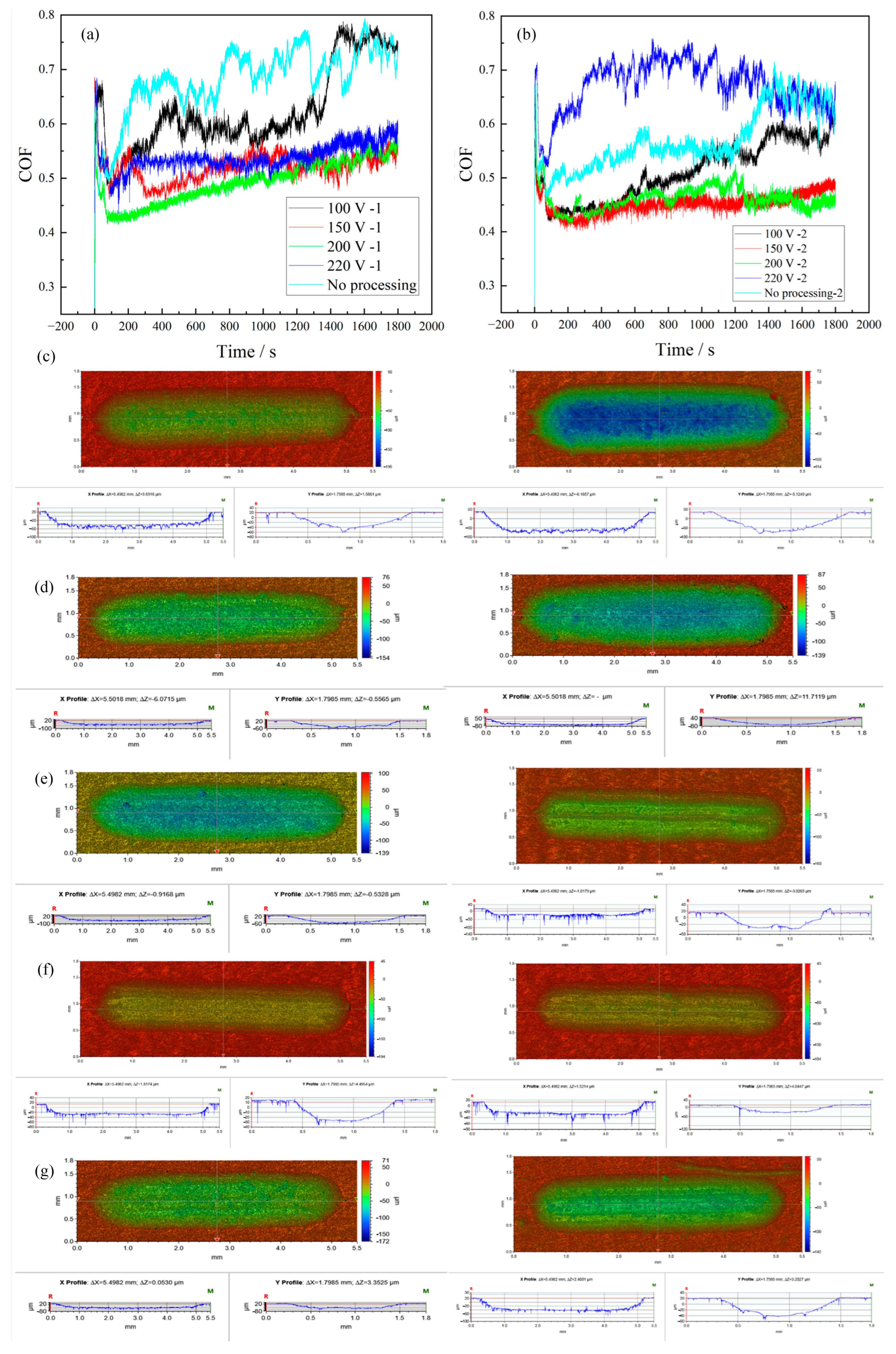

3.3. Analysis of Tribological Properties of Coatings

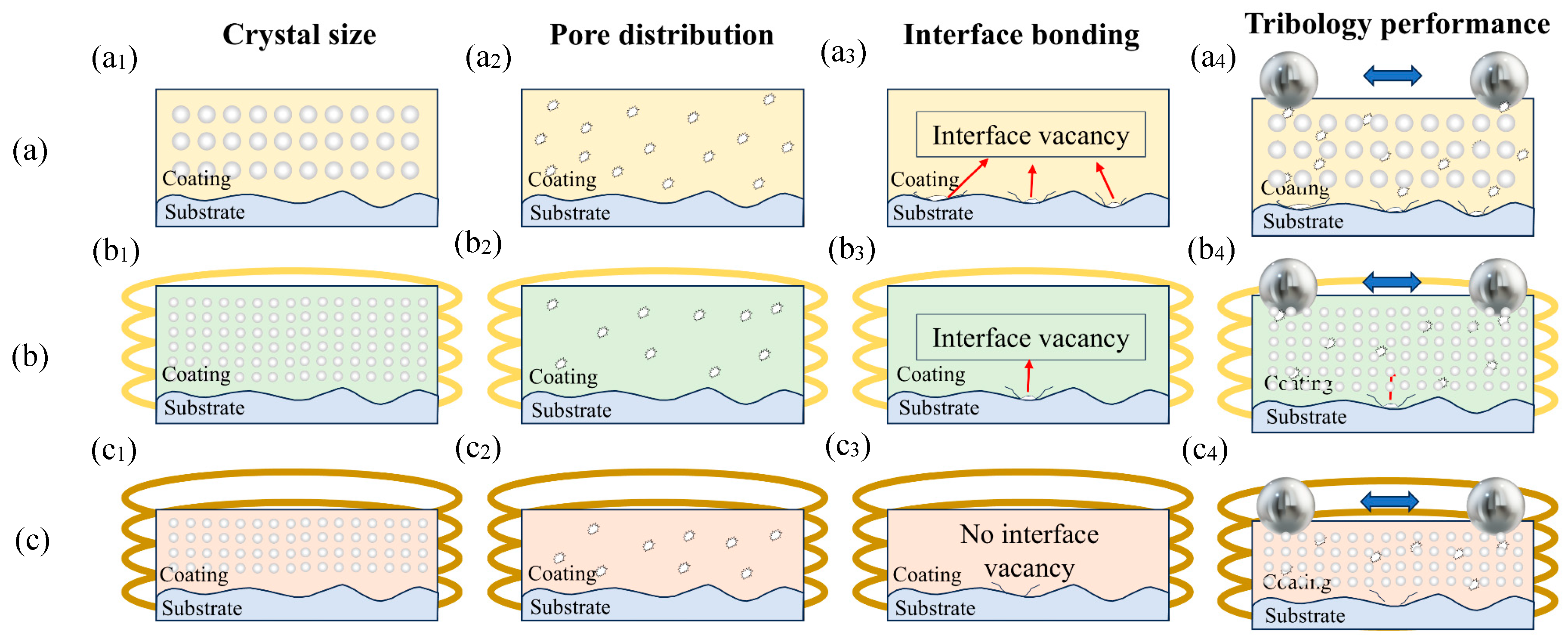

3.4. The Forming Mechanism and Tribological Behaviour of Coating Were Discussed with the Aid of High Strength Energy Field

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.; Liu, H.; Guo, W.; Zhou, L.; Cui, Q.; Deng, X.; Shu, W.; Shi, T.; Xing, Z.; Wang, H. Effect of TiO2 content on the thermal control properties of Al2O3-xTiO2 composite coatings prepared by supersonic plasma spraying technology. J. Mater. Res. Technol. 2024, 32, 3582–3593. [Google Scholar] [CrossRef]

- Kalluri, S.; Yoon, M.; Jo, M.; Liu, H.K.; Dou, S.X.; Cho, J.; Guo, Z. Feasibility of cathode surface coating technology for high-energy lithium-ion and beyond-lithium-ion batteries. Adv. Mater. 2017, 29, 1605807. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Liang, Y.; Huang, T.; Jin, Q.; Kong, D.; Song, P. Oxidation behaviour properties of carbide ceramic reinforced Ni-based composite coatings at 700 °C. Ceram. Int. 2024, 50, 37504–37517. [Google Scholar] [CrossRef]

- Zhou, L.; Ma, G.; Wang, H.-D.; Wang, W.; Mou, H.; Zhu, X.; Zhao, H.; Li, Y.; Tan, N. High-aspeed laser cladded Ni-based cermet coating with high ceramic phase content derived from core-shell structured powder. Surf. Coat. Technol. 2024, 489, 131110. [Google Scholar] [CrossRef]

- Miyamoto, N. Automotive Coatings and Applications. In Thermal Spray Technology; ASM International: Almere, The Netherlands, 2013; pp. 298–305. [Google Scholar]

- Michalak, M.; Latka, L.; Sokolowski, P.; Toma, F.-L.; Myalska, H.; Denoirjean, A.; Ageorges, H. Microstructural, mechanical and tribological properties of finely grained Al2O3 coatings obtained by SPS and S-HVOF methods. Surf. Coat. Technol. 2020, 404, 126463. [Google Scholar] [CrossRef]

- Nowakowska, M.; Łatka, L.; Sokołowski, P.; Szala, M.; Toma, F.-L.; Walczak, M. Investigation into microstructure mechanical properties effects on sliding wear cavitation erosion of Al2O3–TiO2 coatings sprayed by, A.P.S.; SPS; S-HVOF. Wear 2022, 508, 204462. [Google Scholar] [CrossRef]

- Kovářík, O.; Haušild, P.; Siegl, J.; Chráska, T.; Matějíček, J.; Pala, Z.; Boulos, M. The influence of substrate temperature on properties of APS and VPS W coatings. Surf. Coat. Technol. 2015, 268, 7–14. [Google Scholar] [CrossRef]

- Alidokht, S.A.; Wu, L.; Bessette, S.; Chromik, R.R. Microstructure and tribology of cold spray additively manufactured multimodal Ni-WC metal matrix composites. Wear 2024, 538, 205218. [Google Scholar] [CrossRef]

- XZhang, C.; Xu, B.S.; Tu, S.T.; Xuan, F.Z.; Wang, H.D.; Wu, Y.X. Effect of spraying power on the microstructure and mechanical properties of supersonic plasma-sprayed Ni-based alloy coatings. Appl. Surf. Sci. 2008, 254, 6318–6326. [Google Scholar] [CrossRef]

- Han, D.; Pan, Y.; Niu, Y.; Chen, Y.; Qi, Z.; Pan, X.; Zheng, X.; Chen, G. Isothermal oxidation resistance microstructure evolution of VPS-TiAlCrY coating on TiAl single crystals at 1100–1200 °C. Corros. Sci. 2022, 208, 110664. [Google Scholar] [CrossRef]

- Song, J.; He, D.; Guo, W.; Huang, Y.; Li, Z.; Wang, H.; Xing, Z. Effect of magnetic field type on the flight state of supersonic plasma spray particles and coating properties. J. Therm. Spray Technol. 2023, 32, 1637–1651. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, Y.; Zhou, J.; Zhang, L.; Xing, Z.; Wang, H.; Shan, D. Effect of Fe content on the tribological properties of Ni60 coatings applied by pulsed magnetic field assisted supersonic plasma spraying. Mater. Charact. 2022, 185, 111771. [Google Scholar] [CrossRef]

- Zhou, J.; Guo, W.; He, D.; Huang, Y.; Cai, Z.; Zhou, L.; Xing, Z.; Wang, H. Study on preparation and wear resistance of NiCrBSi-WC/Co composite coatings by pulsed magnetic field assisted supersonic plasma spraying. Surf. Coat. Technol. 2022, 448, 128897. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, Y.; He, D.; Guo, W.; Li, G.; Dong, T. Effect of Steady Magnetic Field on Microstructure and Effect and Properties of NiCrBSi Coating by Supersonic Plasma Properties Plasma Spraying. Rare Met. Mater. Eng. 2023, 52, 103–110. [Google Scholar]

- Wang, J.; Fautrelle, Y.; Nguyen-Thi, H.; Reinhart, G.; Liao, H.; Li, X.; Zhong, Y. Thermoelectric magnetohydrodynamic flows and their induced change of solid–liquid interface shape in static magnetic field-assisted directional solidification. Metall. Mater. Trans. A 2016, 47, 1169–1179. [Google Scholar] [CrossRef]

- Long, Z.; Wang, J.; Fautrelle, Y.; Li, X. Repeated nucleation behaviors of pure bismuth under a high magnetic field. J. Alloys Compd. 2020, 831, 154746. [Google Scholar] [CrossRef]

- Bu, F.; Xue, X.; Wang, J.; Kou, H.; Li, C.; Zhang, P.; Beaugnon, E.; Li, J. Effect of strong static magnetic field on the microstructure and transformation temperature of Co–Ni–Al ferromagnetic shape memory alloy. J. Mater. Sci. Mater. Electron. 2018, 29, 19491–19498. [Google Scholar] [CrossRef]

- Wu, M.; Liu, T.; Dong, M.; Sun, J.; Dong, S.; Wang, Q. Directional solidification of Al–8wt.% Fe alloy under high magnetic field gradient. J. Appl. Phys. 2017, 121, 064901. [Google Scholar] [CrossRef]

- Hou, M.; Li, K.; Li, X.; Zhang, X.; Rui, S.; Wu, Y.; Cai, Z. Effects of pulsed magnetic fields of different intensities on dislocation density, residual stress, and hardness of Cr4Mo4V steel. Crystals 2020, 10, 115. [Google Scholar] [CrossRef]

- Qian, C.; Li, K.; Rui, S.-S.; Hou, M.; Zhang, X.; Wu, Y.; Cai, Z. Magnetic induced re-dissolution and microstructure modifications on mechanical properties of Cr4Mo4V steel subjected to pulsed magnetic treatment. J. Alloys Compd. 2021, 881, 160471. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhou, H.; Chen, Z.; Wang, Z.; He, F.; Xu, C. Study on Microstructure and Properties of Ni60A/WC Composite Coating by Alternating-Magnetic-Field-Assisted Laser Cladding. Micromachines 2022, 13, 653. [Google Scholar] [CrossRef] [PubMed]

- Duan, W.; Bao, J.; Liu, W.; Zhang, Z.; Cui, J. Simulation on DC casting of magnesium alloy under out-of-phase pulsed magnetic field with different coil connection strategies. Int. J. Heat Mass Transf. 2020, 162, 120353. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y. Experimental study on enhanced heat transfer and flow performance of magnetic nanofluids under alternating magnetic field. Int. J. Therm. Sci. 2021, 164, 106897. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, Y.; Guo, W.; He, D.; Wang, H.; Shan, D.; Xing, Z. Development of pulsed magnetic field assisted supersonic plasma spraying. Rev. Sci. Instrum. 2022, 93, 123901. [Google Scholar] [CrossRef]

- Munagala VN, V.; Bessette, S.; Gauvin, R.; Chromik, R.R. Sliding wear of cold sprayed Ti6Al4V coatings: Effect of porosity and normal load. Wear 2020, 450, 203268. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N. Study of cracking mechanisms in multi-layered composite nano-structured coatings. Wear 2017, 378, 43–57. [Google Scholar] [CrossRef]

- Jiang, C.-P.; Xing, Y.-Z.; Zhang, F.-Y.; Hao, J.-M.; Song, X.-D. Wear resistance and bond strength of plasma sprayed Fe/Mo amorphous coatings. J. Iron Steel Res. Int. 2014, 21, 969–974. [Google Scholar] [CrossRef]

- Lu, M.; Wang, H.; Song, X.; Sun, F. Effect of doping level on residual stress, coating-substrate adhesion and wear resistance of boron-doped diamond coated tools. J. Manuf. Process. 2023, 88, 145–156. [Google Scholar] [CrossRef]

| AC Magnetic Field Parameters | Spraying Parameters | ||

|---|---|---|---|

| voltage | 100 V/150 V/200 V/220 V | spraying voltage | 120 V |

| spraying current | 430 A | ||

| peak field strength | 426/694/920/1015 Gs | H2 Flow | 18 L/min |

| Ar Flow | 120 L/min | ||

| form of action | Continuous input | Spraying times | 10 |

| spraying distance | 125 mm | ||

| Group 1 | Group 2 | Group 3 | |

|---|---|---|---|

| No processing | 190 μm | 215 | 197 |

| 100 V | 229 | 202 | 220 |

| 150 V | 180 | 181 | 182 |

| 200 V | 166 | 121 | 164 |

| 220 V | 130 | 119 | 117 |

| Average COF-1 | Average COF-2 | The Wear Volume-1 (×10−3 mm−3) | The Wear Volume-2 (×10−3 mm−3) | |

|---|---|---|---|---|

| No processing | 0.6859 | 0.5785 | 0.1386 | 0.1344 |

| 1 Tesla | 0.6240 | 0.5113 | 0.1312 | 0.1239 |

| 3 Tesla | 0.5205 | 0.4518 | 0.1256 | 0.1202 |

| 5 Tesla | 0.4931 | 0.4670 | 0.1212 | 0.1195 |

| 7 Tesla | 0.5385 | 0.6768 | 0.1267 | 0.1335 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, Q.; Xiong, J.; Dong, Y.; Zhu, X.; Wang, Z.; Bao, F.; Li, J.; Jin, Y. Research on the Formation Behaviour and Tribological Service Mechanism of Ni-Based Composite Coatings Prepared by Thermal Spraying Assisted with Alternating Current Magnetic Field. Coatings 2025, 15, 496. https://doi.org/10.3390/coatings15050496

Yun Q, Xiong J, Dong Y, Zhu X, Wang Z, Bao F, Li J, Jin Y. Research on the Formation Behaviour and Tribological Service Mechanism of Ni-Based Composite Coatings Prepared by Thermal Spraying Assisted with Alternating Current Magnetic Field. Coatings. 2025; 15(5):496. https://doi.org/10.3390/coatings15050496

Chicago/Turabian StyleYun, Qingwen, Jun Xiong, Ying Dong, Xi Zhu, Zhiyuan Wang, Fengyuan Bao, Jinyu Li, and Yunan Jin. 2025. "Research on the Formation Behaviour and Tribological Service Mechanism of Ni-Based Composite Coatings Prepared by Thermal Spraying Assisted with Alternating Current Magnetic Field" Coatings 15, no. 5: 496. https://doi.org/10.3390/coatings15050496

APA StyleYun, Q., Xiong, J., Dong, Y., Zhu, X., Wang, Z., Bao, F., Li, J., & Jin, Y. (2025). Research on the Formation Behaviour and Tribological Service Mechanism of Ni-Based Composite Coatings Prepared by Thermal Spraying Assisted with Alternating Current Magnetic Field. Coatings, 15(5), 496. https://doi.org/10.3390/coatings15050496