Performance of Micronized Biowax Powders Replacing PTFE Fillers in Bio-Based Epoxy Resin Coatings

Abstract

:1. Introduction

2. Materials and Methods

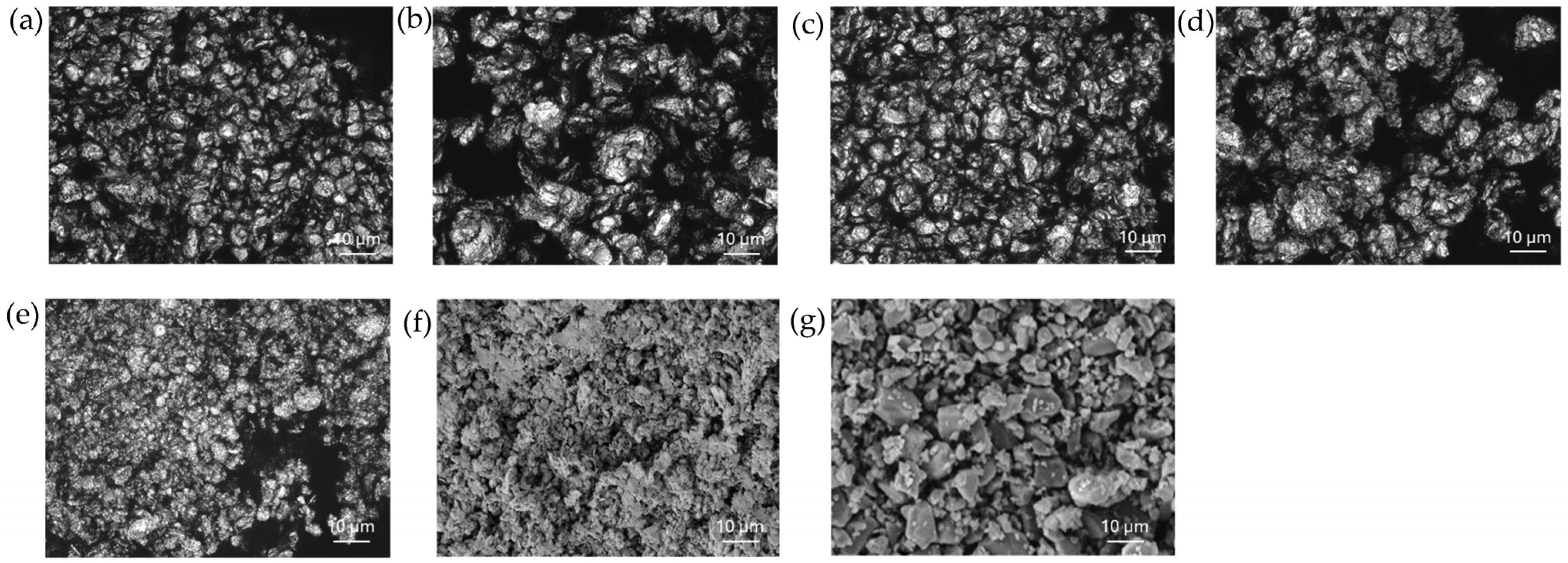

2.1. Materials

2.2. Coating Formulation and Deposition

2.3. Characterization Methods

3. Results

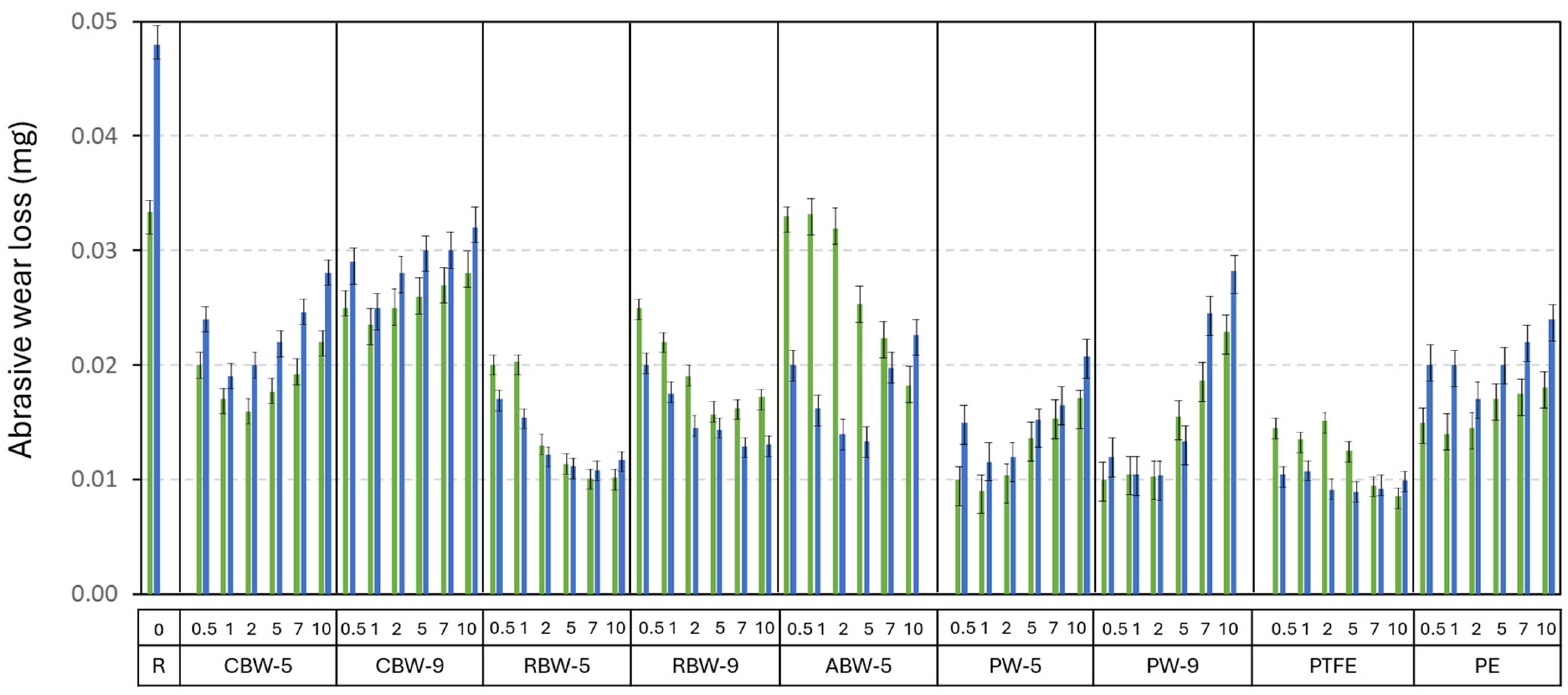

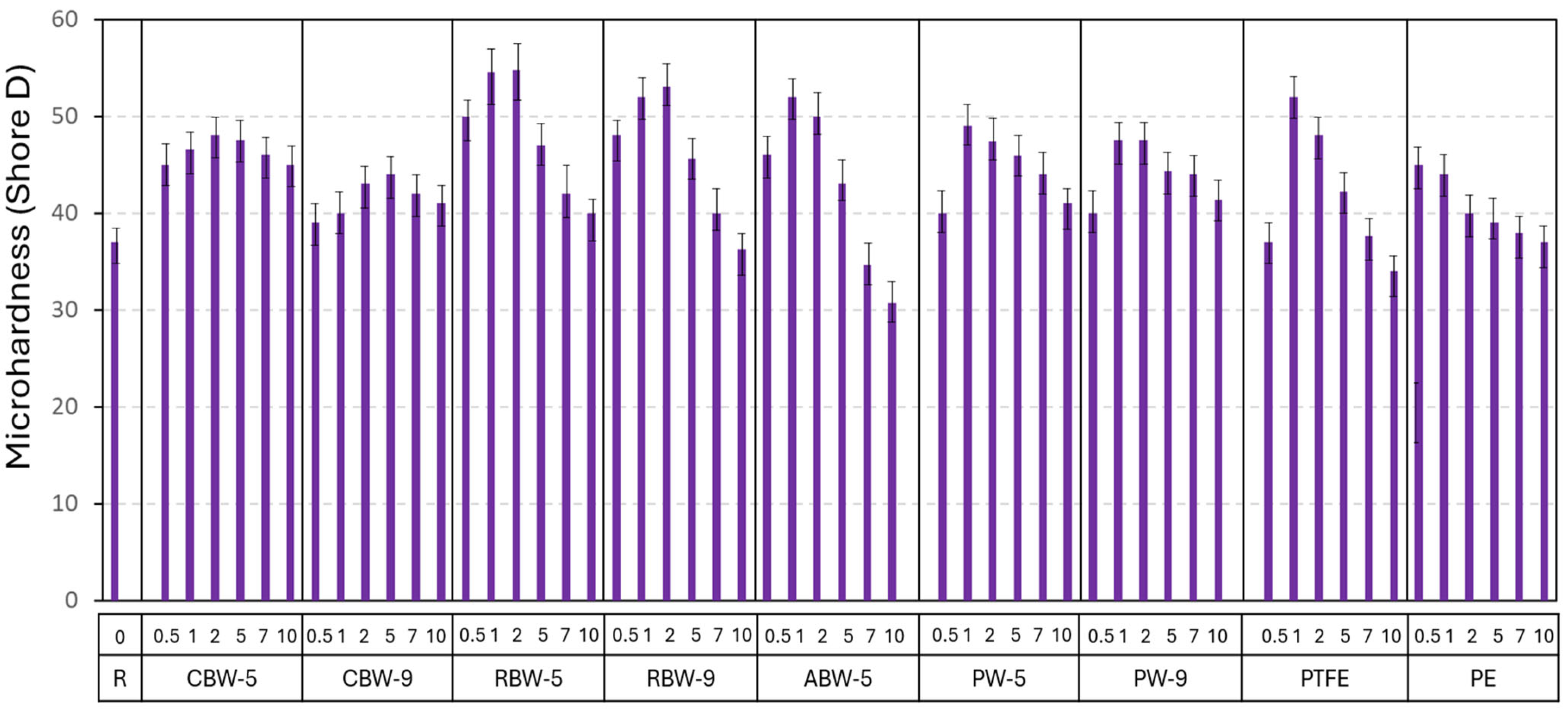

3.1. Mechanical Coating Performance

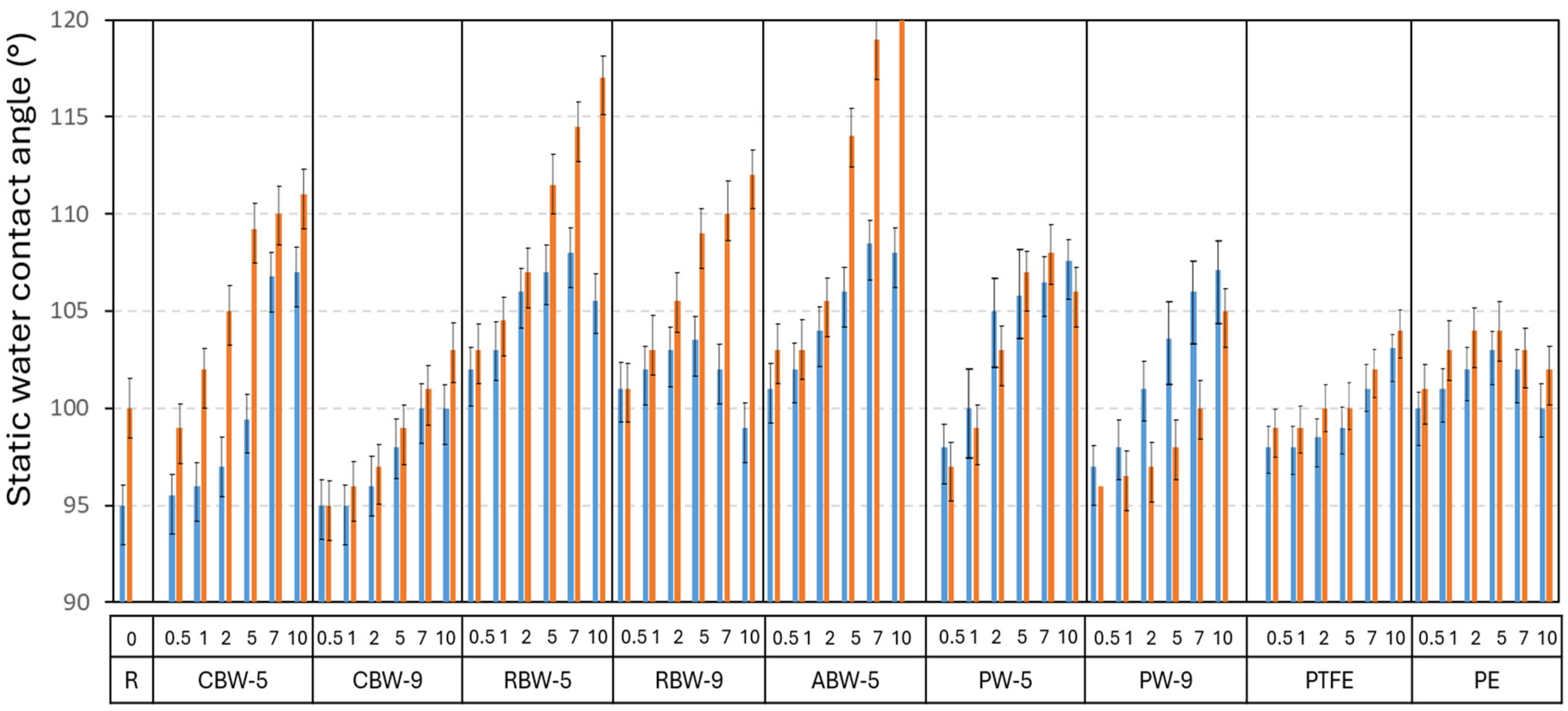

3.2. Physical Coating Performance

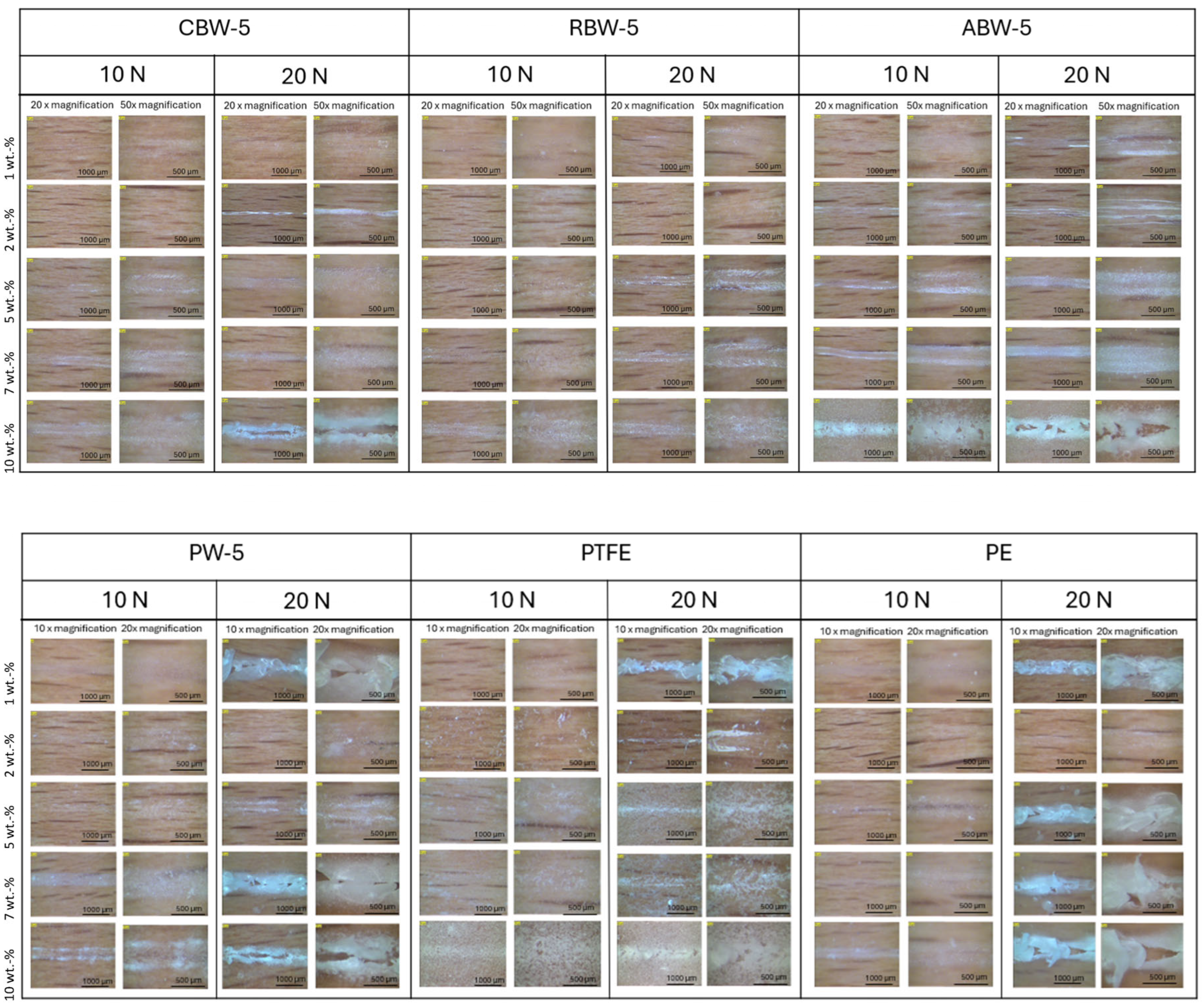

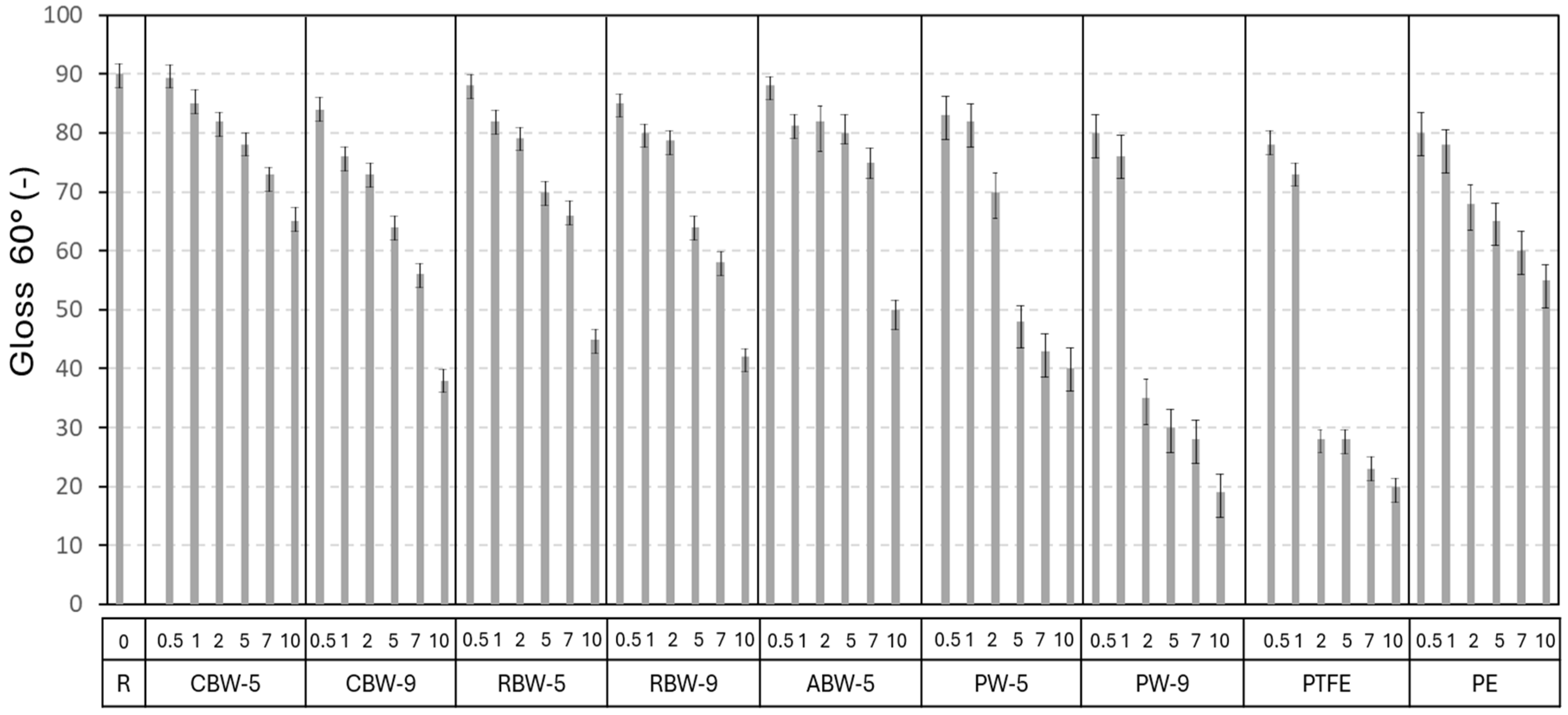

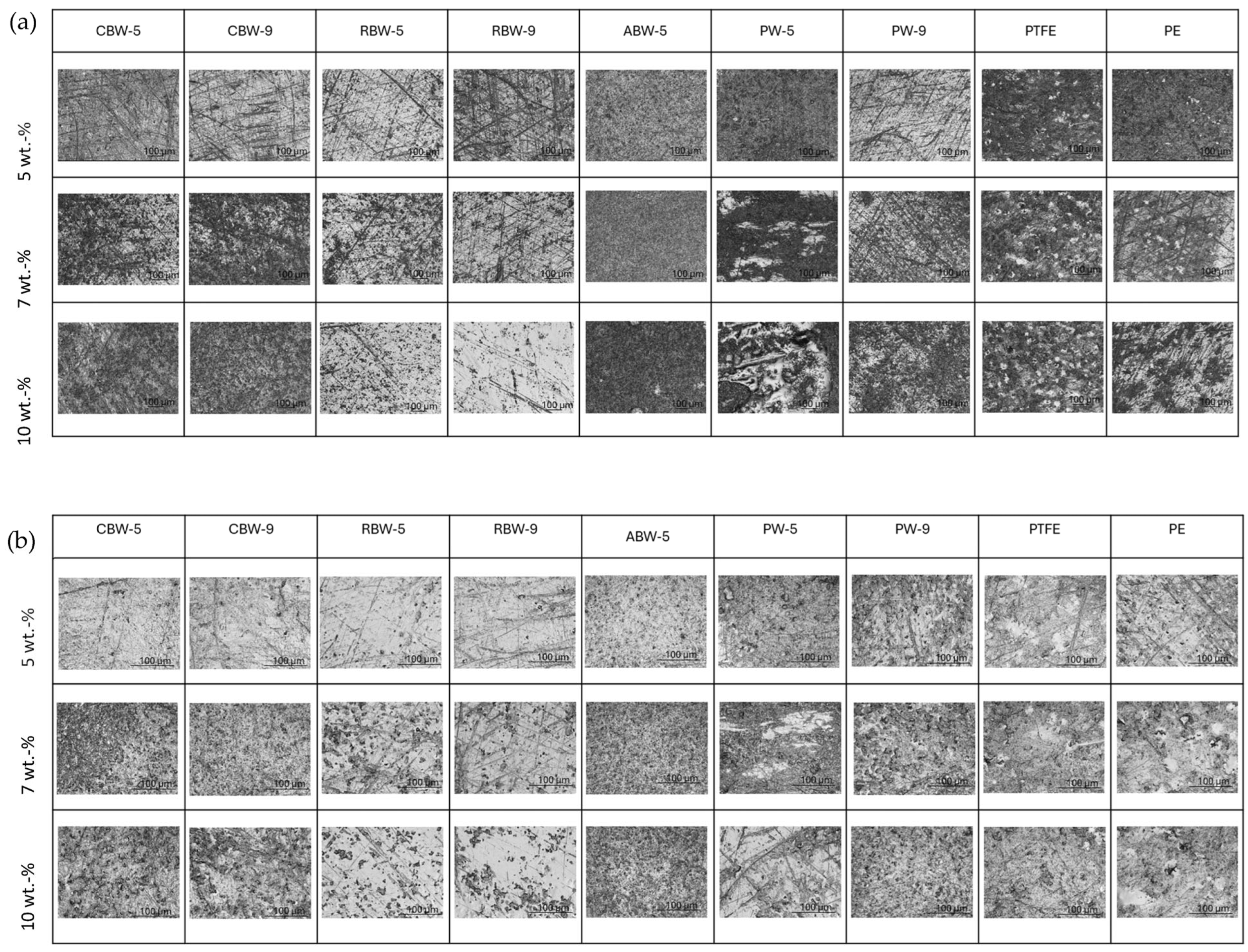

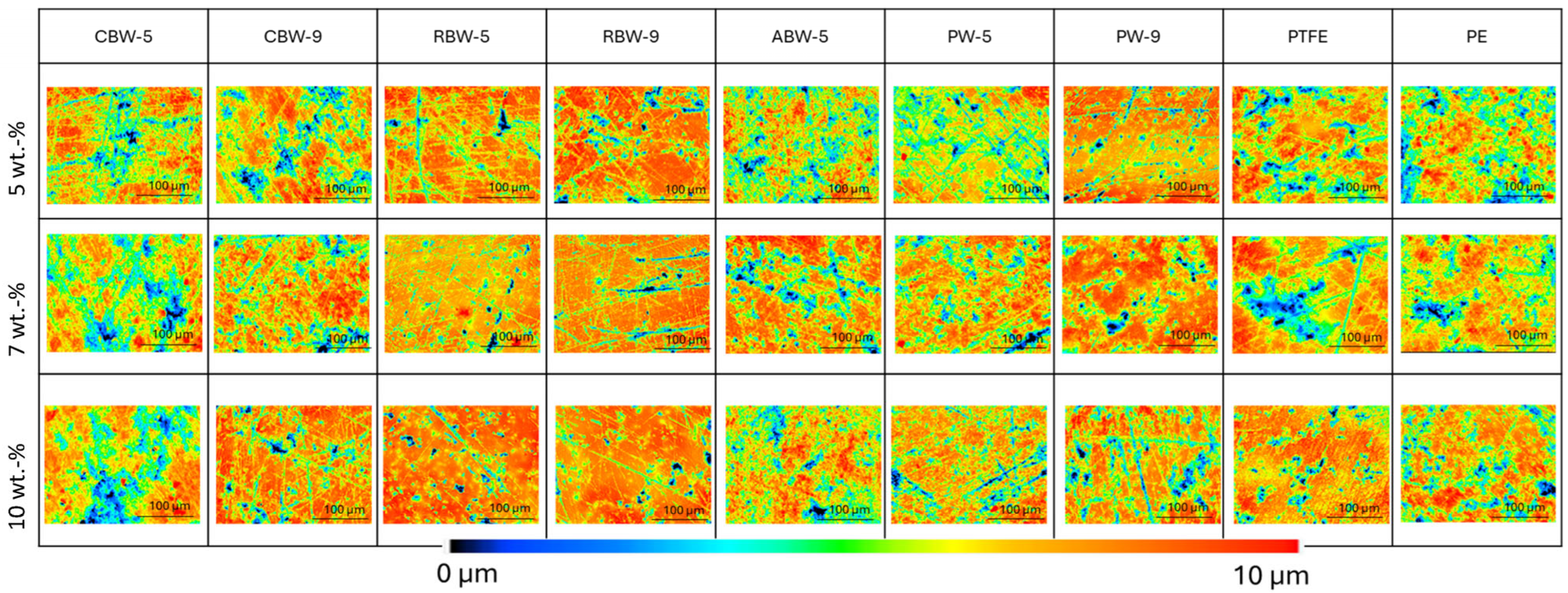

3.3. Microscopic Evaluation

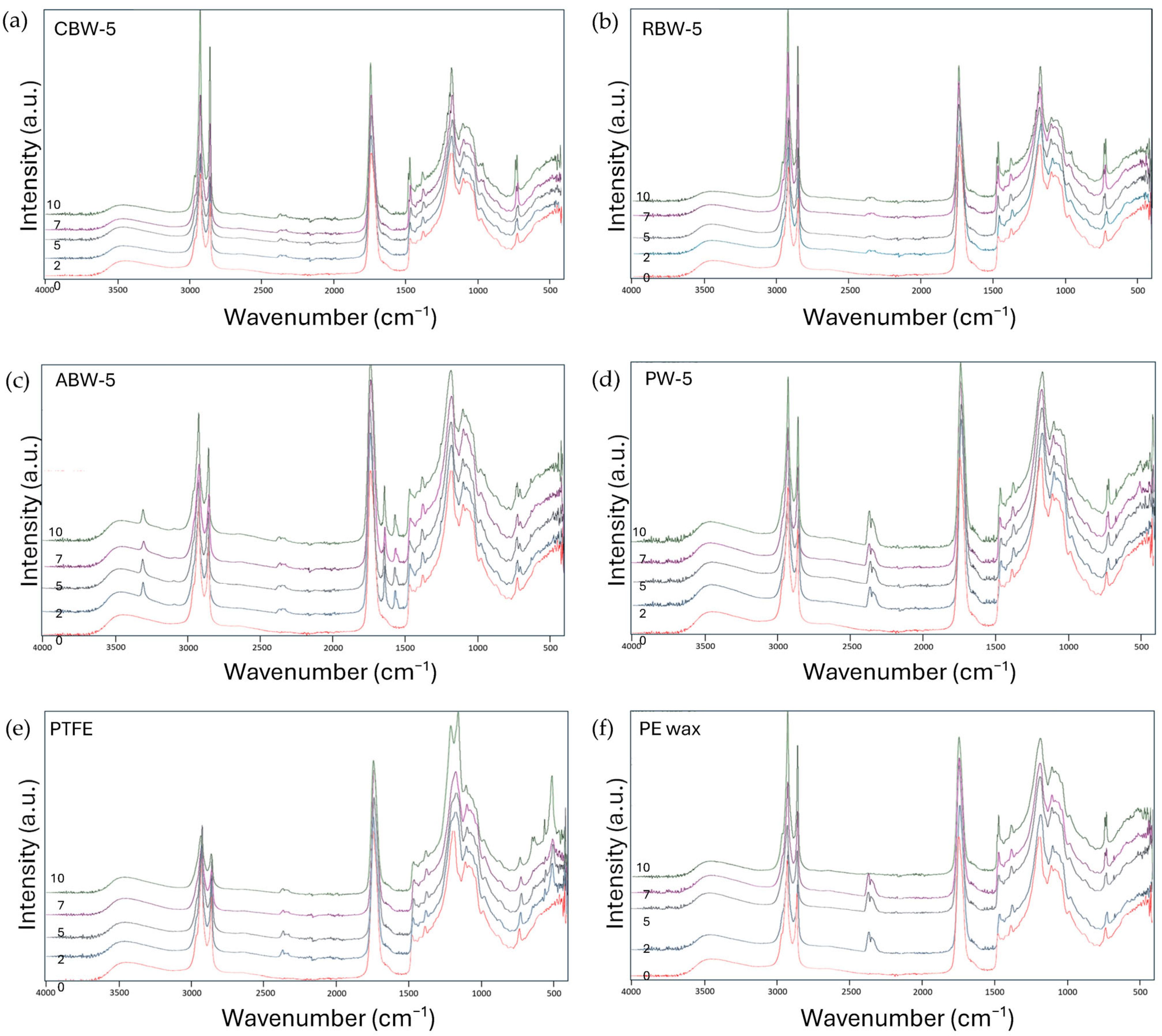

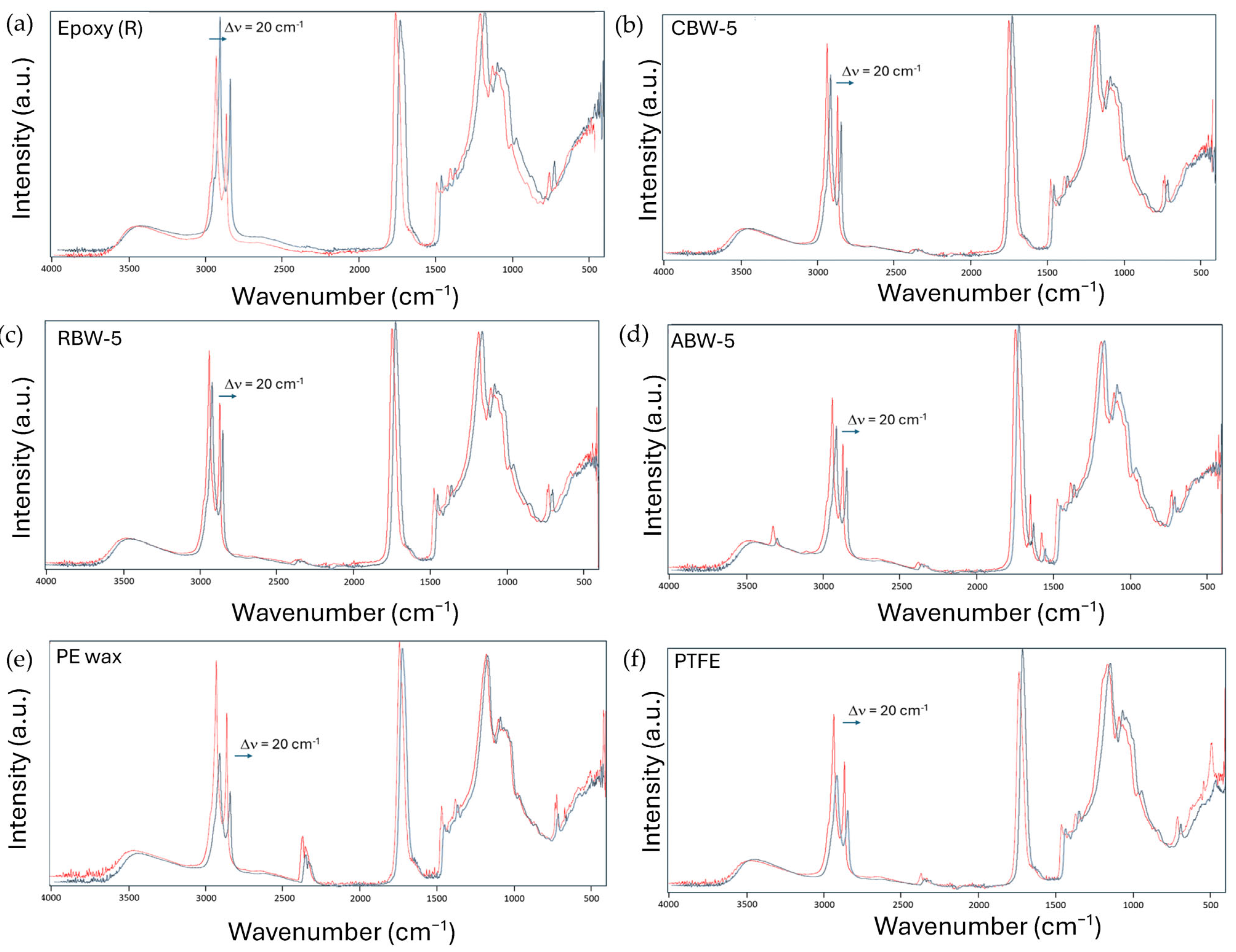

3.4. Spectroscopic Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dhanumalayan, E.; Joshi, G.M. Performance properties and applications of polytetrafluoroethylene (PTFE)—A review. Adv. Comp. Hybrid Mater. 2018, 1, 247–268. [Google Scholar] [CrossRef]

- Zhou, S.; Jia, X.; Li, S.; Li, Y.; Tian, R.; Song, H. Epoxy/polytetrafluoro-wax composite coatings demonstrate remarkable wear resistance, offering rapid and durable cyclic self-healing capabilities facilitated by the “sweating” behavior of polytetrafluoro-wax. Prog. Org. Coat. 2024, 188, 108227. [Google Scholar] [CrossRef]

- Holzdörfer, U.; Ali, W.; Schollmeyer, E.; Gutmann, J.S.; Mayer-Gall, T.; Textor, T. Novel approach for the preparation of a highly hydrophobic coating material exhibiting self-healing properties. Molecules 2024, 29, 3766. [Google Scholar] [CrossRef]

- Gansukh, B.; Zhang, Q.; Bariashir, C.; Vignesh, A.; Ma, Y.; Liang, T.; Sun, W.-H. Unifying molecular weights of highly linear polyethylene waxes through unsymmetrical 2,4-bis(imino)pyridylchromium chlorides. Molecules 2020, 25, 5584. [Google Scholar] [CrossRef]

- Patton, C.C.; Casad, B.M. Paraffin deposition from refined wax-solvent systems. SPE J. 1970, 10, 17–24. [Google Scholar] [CrossRef]

- Guy, A. Coatings components beyond binders. In The Chemistry and Physics of Coatings; Marrion, A.R., Ed.; RSC Books: London, UK, 2004; pp. 267–316. [Google Scholar]

- Hasanagic, R.; Fathi, L.; Sefidruh, M.; Bahmani, M. Natural alternatives to chemical wood preservatives: A review of recent research. In Proceedings of the 14th International Scientific Conference on Manufacturing Engineering—RIM 2023, Sarajevo, Bosnia and Herzegovina, 21 September 2023; pp. 615–625. [Google Scholar]

- Koen, L. The Micronisation of Synthetic Waxes. Master’s Thesis, Stellenbosch University, Stellenbosch, South Africa, 2003. [Google Scholar]

- Jung, J.; Perrut, M. Particle design using supercritical fluids: Literature and patent survey. J. Supercrit. Fluid 2001, 20, 179–219. [Google Scholar] [CrossRef]

- Abedin, N.R. Micronization of Polyethylene Wax in an Extrusion Process Using Supercritical Carbon Dioxide. Master’s Thesis, University of Waterloo, Waternloo, ON, Canada, 2011. [Google Scholar]

- Rodriguez, L.; Albertini, B.; Passerini, N.; Cavallari, C.; Giovannelli, L. Hot air coating technique as a novel method to produce microparticles. Drug Dev. Ind. Pharm. 2004, 30, 913–923. [Google Scholar] [CrossRef]

- Saleem, I.Y.; Smyth, H.D.C. Micronization of a soft material: Air-jet and micro-ball milling. AAPS Pharm. Sci. Tech. 2010, 11, 1642–1649. [Google Scholar] [CrossRef]

- Bodmeier, R.; Bhagwatwar, J.W. Process and formulation variables in the preparation of wax microparticles by a melt dispersion technique. I. Oil-in-water technique for water-insoluble drugs. J. Microencaps. 1992, 9, 89–98. [Google Scholar] [CrossRef]

- Kuehnle, A. Process for the Production of Micronized Waxes. U.S. Patent 4,846,887, 19 September 1985. [Google Scholar]

- Hassan, A.; Hassan, A.; Borsinger, A.A. High Shear Process for Producing Micronized Waxes. U.S. Patent 8,669,401, 24 April 2013. [Google Scholar]

- Arezoo, A. The effect of micronized wax on the basis of a PTFE-modified PE for improving scratch resistance properties in marine coating systems. In Proceedings of 9th Meeting of Young Chemical Engineers, Zagreb, Croatia, 16–17 February 2012. [Google Scholar]

- Leotsakos, G.; Gravatt, W.M.; Smith, C.P.; Kocur, M.A. Wax Dispersion Formulations, Method of Producing Same, and Uses. U.S. Patent 9,404,007, 31 December 2013. [Google Scholar]

- Yücetürk, M.; Seydibeyoglu, M.O. Bio-based polyethylene masterbatch preparation and investigation of the effect of process conditions on pigment dispersion. Coloration Technol. 2024, in press. [Google Scholar] [CrossRef]

- Calovi, M.; Zanardi, A.; Rossi, S. Recent advances in bio-based wood protective systems: A comprehensive review. Appl. Sci. 2024, 14, 736. [Google Scholar] [CrossRef]

- Lozhechnikova, A.; Bellanger, H.; Michen, B.; Burgert, I.; Österberg, M. Surfactant-free carnauba wax dispersion and its use for layer-by-layer assembled protective surface coatings on wood. Appl. Surf. Sci. 2017, 396, 1273–1281. [Google Scholar] [CrossRef]

- Woch, J.; Małachowska, E.; Korasiak, K.; Lipkiewicz, A.; Dubowik, M.; Chrobak, J.; Iłowska, J.; Przybysz, P. Barrier dispersion-based coatings containing natural and paraffin waxes. Molecules 2022, 27, 930. [Google Scholar] [CrossRef] [PubMed]

- Czarnecki, R. Novel Natural additives for surface coatings. Coatings Tech. 2022, 7, 30–37. [Google Scholar]

- Gupta, S.; Ivvala, J.; Grewal, H.S. Development of natural wax based durable superhydrophobic coatings. Ind. Crops Prod. 2021, 171, 113871. [Google Scholar] [CrossRef]

- Junio, E.J.M.; Stephen, J.R.; Muthuvel, M.; Roy, A.; Rodrigue, P.; Filho, M.J.; Teixeira, R.A.; Barbosa, A.P.; Benjamin, S.R. Chemistry, biological activities, and uses of carnauba wax. In Gums, Resins and Latexes of Plant Origin; Murthy, H.N., Ed.; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Krendlinger, E.J.; Wolfmeuer, U.H. Amide waxes. In Natural and Synthetic Waxes: Origin, Production, Technology and Applications; Krendlinger, E.J., Wolfmeier, U.H., Eds.; Wiley: Weinheim, Germany, 2023; pp. 573–599. [Google Scholar]

- Briscoe, B.; Mustafaev, V.; Tabor, D. Lubrication of polythene by oleamide and stearamide. Wear 1972, 19, 399–414. [Google Scholar] [CrossRef]

- Zhang, D.; Song, K. Effects of photoinitiators on curing performance of wood wax oil coating on wood. Coatings 2024, 14, 2. [Google Scholar] [CrossRef]

- Campanella, A.; Baltanas, M.A. Degradation of the oxirane ring of epoxidized vegetable oils in a liquid–liquid–solid heterogeneous reaction system. Chem. Eng. Proc. Process Intens. 2007, 46, 210–221. [Google Scholar] [CrossRef]

- Campanella, A.; Baltanas, M.A. Degradation of the oxirane ring of epoxidized vegetable oils with solvated acetic acid using cation-exchange resins. Eur. J. Lipid. Sci. Technol. 2004, 106, 524–530. [Google Scholar] [CrossRef]

- Necolau, M.I.; Damian, C.M.; Olaret, E.; Iovu, H.; Balanuca, B. Comparative thermo-mechanical properties of sustainable epoxy polymer networks derived from linseed oil. Polymers 2022, 14, 4212. [Google Scholar] [CrossRef]

- Ozsoy, I.; Ozsoy, N.; Unal, H.; Mimaroglu, A. Evaluation of the influences of wax content on the tribological and mechanical performance of polytetrafluoroethylene-blended polyamide. Proc. Inst. Mech. Eng. J. Eng. Tribol. 2013, 227, 1399–1405. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, S. Synergistic contribution of bio-based additives in wood paint: The combined effect of pigment deriving from spirulina and multifunctional filler based on carnauba wax. Prog. Org. Coat. 2023, 182, 107713. [Google Scholar] [CrossRef]

- Kittipongpatana, O.S.; Trisopon, K.; Wattanaarsakit, P.; Kittipongpatana, N. Utilization and evaluation of rice bran and rice bran wax as a tablet lubricant. Pharmaceutics 2024, 16, 428. [Google Scholar] [CrossRef] [PubMed]

- Fei, T.; Ren, K.; Wang, T. Investigation of tribological properties of vegetable oil based hard wax alternatives in comparison with carnauba wax. Eur. J. Lipid Sci. Technol. 2020, 122, 1900437. [Google Scholar] [CrossRef]

- Carmona, E.R.; Tobon, A.E.; Aperador, W. Study of the tribological properties of paraffin and polyethylene wax as antiwear additives in refined sesame oil. Sci. Tech. 2019, 24, 590. [Google Scholar]

- Wu, L.; Guo, X.; Zhang, J. Abrasive resistant coatings—A review. Lubricants 2014, 2, 66–89. [Google Scholar] [CrossRef]

- Iqbal, T.; Briscoe, B.J.; Luckham, P.F. Scratch deformations of poly(etheretherketone). Wear 2011, 271, 1181–1193. [Google Scholar] [CrossRef]

- Kurkcu, P.; Andena, L.; Pavan, A. An experimental investigation of the scratch behaviour of polymers: 2. influence of hard or soft fillers. Wear 2014, 317, 277–290. [Google Scholar] [CrossRef]

- Samyn, P.; Bosmans, J.; Cosemans, P. Benchmark study of epoxy coatings with selection of bio-based phenalkamine versus fossil-based amine crosslinkers. Molecules 2023, 28, 4259. [Google Scholar] [CrossRef]

- Lange, J.; Luisier, A.; Hult, A. Influence of crosslink density, glass transition temperature and addition of pigment and wax on the scratch resistance of an epoxy coating. J. Coat. Technol. 1997, 69, 77–82. [Google Scholar] [CrossRef]

- Janesch, J.; Arminger, B.; Gindl-Altmutter, W.; Hansmann, C. Superhydrophobic coatings on wood made of plant oil and natural wax. Prog. Org. Coat. 2020, 148, 105891. [Google Scholar] [CrossRef]

- Eck, M.; Stoltze, C.; Mecking, S. Waxes from long-chain aliphatic difunctional monomers. ACS Sus. Chem. Eng. 2023, 11, 16716–16721. [Google Scholar] [CrossRef] [PubMed]

- Fletcher, T.E. A simple model to describe relationships between gloss behaviour, matting agent concentration and the rheology of matted paints and coatings. Prog. Org. Coat. 2002, 44, 25–36. [Google Scholar] [CrossRef]

- Uribe-Padilla, J.; Graells, M.; Salgado-Valle, J.; Serrano, J.L. A viscosity-mediated model for relating gloss and film thickness of coatings. Prog. Org. Coat. 2019, 136, 105195. [Google Scholar] [CrossRef]

- Endlein, E.; Peleikis, K.H. Natural Waxes—Properties, Compositions and Applications. SOFW J. 2011, 137, 16–26. [Google Scholar]

- Gunde, M.K.; Kunaver, M.; Cekada, M. Surface analysis of matt powder coatings. Dye. Pigment. 2007, 74, 202–207. [Google Scholar] [CrossRef]

- Yong, Q.; Xu, D.; Liu, Q.; Xiao, Y.; Wei, D. Advances in polymer-based matte coatings: A review. Polym. Adv. Technol. 2021, 33, 5–19. [Google Scholar] [CrossRef]

- Sun, Z.; Fan, H.; Chen, Y.; Huang, J. Synthesis of self-matting waterborne polyurethane coatings with excellent transmittance. Polym. Internat. 2017, 67, 78–84. [Google Scholar] [CrossRef]

- Yong, Q.; Chang, J.; Liu, Q.; Jiang, F.; Wei, D.; Li, H. Matt Polyurethane Coating: Correlation of Surface Roughness on Measurement Length and Gloss. Polymers 2020, 12, 326. [Google Scholar] [CrossRef]

- Yahyaei, H.; Ebrahimi, M.; Tahami, H.V.; Mafi, E.R.; Akbarinezhad, E. Toughening mechanisms of rubber modified thin film epoxy resins: Part 2—Study of abrasion, thermal and corrosion resistance. Prog. Org. Coat. 2017, 113, 136–142. [Google Scholar] [CrossRef]

- Blanchet, T.A.; Kennedy, F.E. Sliding wear mechanism of polytetrafluoroethylene (PTFE) and PTFE composites. Wear 1992, 153, 229–243. [Google Scholar] [CrossRef]

- Supanchaiyamat, N.; Shuttleworth, P.S.; Hunt, A.J.; Clark, J.H.; Matharu, A.S. Thermosetting resin based on epoxidised linseed oil and bio-derived crosslinker. Green Chem. 2012, 14, 1759–1765. [Google Scholar] [CrossRef]

- Vigueras, E.; Tellez, G.L.; Hernandez-Lopez, S. Characterization of linseed oil epoxidized at different percentages. Superf. Y Vacío 2009, 22, 5–10. [Google Scholar]

- Pan, Y.; Pan, Y.; Cheng, Q.; Liu, Y.; Essien, C.; Via, B.; Wang, X.; Sun, R.; Taylor, S. Characterization of Epoxy Composites Reinforced with Wax Encapsulated Microcrystalline Cellulose. Polymers 2016, 8, 415. [Google Scholar] [CrossRef]

- Bayer, I.S.; Fragouli, D.; Martorana, P.J.; Martiradonna, L.; Cingolani, R.; Athanassiou, A. Solvent resistant superhydrophobic films from self-emulsifying carnauba wax–alcohol emulsions. Soft Matter 2011, 7, 7939–7943. [Google Scholar] [CrossRef]

- Bang, J.; Kim, J.; Kim, Y.; Oh, J.K.; Yeo, H.; Kwk, H.W. Preparation and characterization of hydrophobic coatings from carnauba wax/lignin blends. J. Korean Wood Sci. Technol. 2022, 10, 149–158. [Google Scholar] [CrossRef]

- Bergamonti, L.; Cirlini, M.; Graiff, C.; Lottici, P.P.; Palla, G.; Casoli, A. Characterization of Waxes in the Roman Wall Paintings of the Herculaneum Site (Italy). Appl. Sci. 2022, 12, 11264. [Google Scholar] [CrossRef]

- Brychka, S.; Brychka, A.; Hedin, N.; Mondeshki, M. Sustainable Composite Materials Based on Carnauba Wax and Montmorillonite Nanoclay for Energy Storage. Materials 2024, 17, 1978. [Google Scholar] [CrossRef]

- Regert, M.; Colinart, S.; Degrand, L.; Decavallas, O. Chemical alteration and use of beeswax through time: Accelerated ageingtests and analysis of archaeological samples from various environmental contexts. Archaeometry 2001, 43, 549–569. [Google Scholar] [CrossRef]

- Dobrosielska, M.; Dobrucka, R.; Kozera, P.; Brzakalski, D.; Gabriel, E.; Glowacka, J.; Jalbrzykowki, M.; Przekop, R.E. Beeswax as a natural alternative to synthetic waxes for fabrication of PLA/diatomaceous earth composites. Sci. Rep. 2023, 13, 1161. [Google Scholar] [CrossRef]

- Missau, J.; de Rocha, J.G.; Dotto, G.L.; Bertuol, D.A.; Ceron, L.P.; Tanabe, E.H. Purification of crude wax using a filter mediummodified with a nanofiber coating. Chem. Eng. Res. Des. 2018, 136, 734–743. [Google Scholar] [CrossRef]

- Piwowarczyk, J.; Jędrzejewski, R.; Moszyński, D.; Kwiatkowski, K.; Niemczyk, A.; Baranowska, J. XPS and FTIR Studies of Polytetrafluoroethylene Thin Films Obtained by Physical Methods. Polymers 2019, 11, 1629. [Google Scholar] [CrossRef]

- Leotsakos, G.S. Wax-based slip and mar additives. In Handbook of Coating Additives; Florio, J.J., Miller, D.J., Eds.; Marcel Dekker Inc.: New York, NY, USA, 2004; pp. 235–260. [Google Scholar]

- Richaud, E.; Guinault, A.; Baiz, S.; Nizeyimana, F. Epoxidized linseed oils based networks: Case of thermal degradation. Polym. Degrad. Stab. 2019, 166, 121–134. [Google Scholar] [CrossRef]

- Grahk, T.M.; Berger, R.; Bexell, U. Investigation of the drying process of linseed oil using FTIR and ToF-SIMS. J. Phys. Conf. Series 2008, 100, 012019. [Google Scholar] [CrossRef]

- Li, H.T.; Sun, J.; Sui, H.L.; Chai, C.G.; Li, B.H.; Yu, J.X.; He, H.T.; Yin, Y. Influencing mechanisms of a wax layer on the micro-friction behavior of the β-HMX crystal surface. Energ. Mater. Front. 2022, 3, 248–256. [Google Scholar] [CrossRef]

| Micropowder Acronym | Wax Type | Powder Size Range (µm) | Melting Temperature Range (°C) | ||

|---|---|---|---|---|---|

| d10 | d50 | d90 | |||

| CBW-5 | Carnauba biowax | 4.0 | 5.3 | 6.0 | 82–86 |

| CBW-9 | Carnauba biowax | 8.0 | 9.5 | 11.0 | 82–86 |

| RBW-5 | Rice bran biowax | 4.8 | 5.4 | 6.0 | 78–82 |

| RBW-9 | Rice bran biowax | 8.0 | 9.5 | 11.0 | 78–82 |

| ABW-5 | Stearamide biowax | 3.5 | 4.8 | 5.5 | 142 |

| PW-5 | PE wax/PTFE | 2.3 | 5.3 | 6.4 | 58–60 |

| PW-9 | PE wax/PTFE | 6.5 | 9.2 | 12.0 | 58–60 |

| PTFE | PTFE | 5.0 | 7.0 | 9.0 | (>300) |

| PE | PE wax | 5.4 | 7.0 | 9.8 | 110 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samyn, P.; Vanheusden, C.; Cosemans, P. Performance of Micronized Biowax Powders Replacing PTFE Fillers in Bio-Based Epoxy Resin Coatings. Coatings 2025, 15, 511. https://doi.org/10.3390/coatings15050511

Samyn P, Vanheusden C, Cosemans P. Performance of Micronized Biowax Powders Replacing PTFE Fillers in Bio-Based Epoxy Resin Coatings. Coatings. 2025; 15(5):511. https://doi.org/10.3390/coatings15050511

Chicago/Turabian StyleSamyn, Pieter, Chris Vanheusden, and Patrick Cosemans. 2025. "Performance of Micronized Biowax Powders Replacing PTFE Fillers in Bio-Based Epoxy Resin Coatings" Coatings 15, no. 5: 511. https://doi.org/10.3390/coatings15050511

APA StyleSamyn, P., Vanheusden, C., & Cosemans, P. (2025). Performance of Micronized Biowax Powders Replacing PTFE Fillers in Bio-Based Epoxy Resin Coatings. Coatings, 15(5), 511. https://doi.org/10.3390/coatings15050511