Effect of AlTiN Coating Structure on the Cutting Performance of Cemented Carbide PCB Microdrills

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Tools

2.2. Coating Deposition

2.3. Drilling Experiments

2.4. Testing Instruments

3. Experimental Results and Analysis

3.1. Analysis of Coating Adhesion Strength in Different Deposition Samples

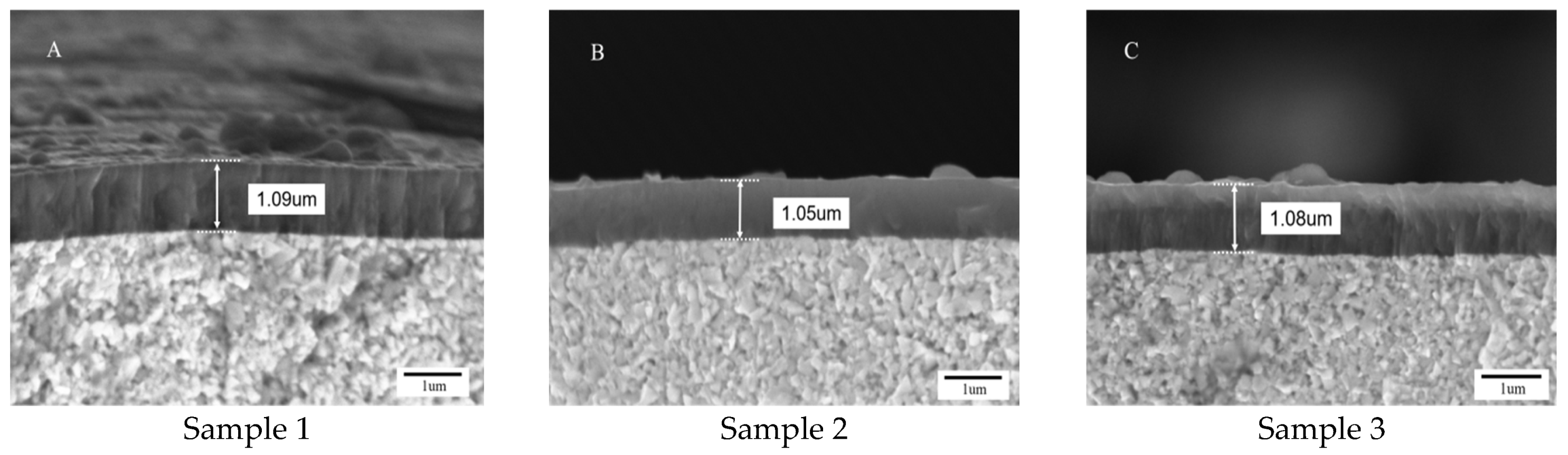

3.2. Analysis of Coating Morphology in Different Deposition Samples

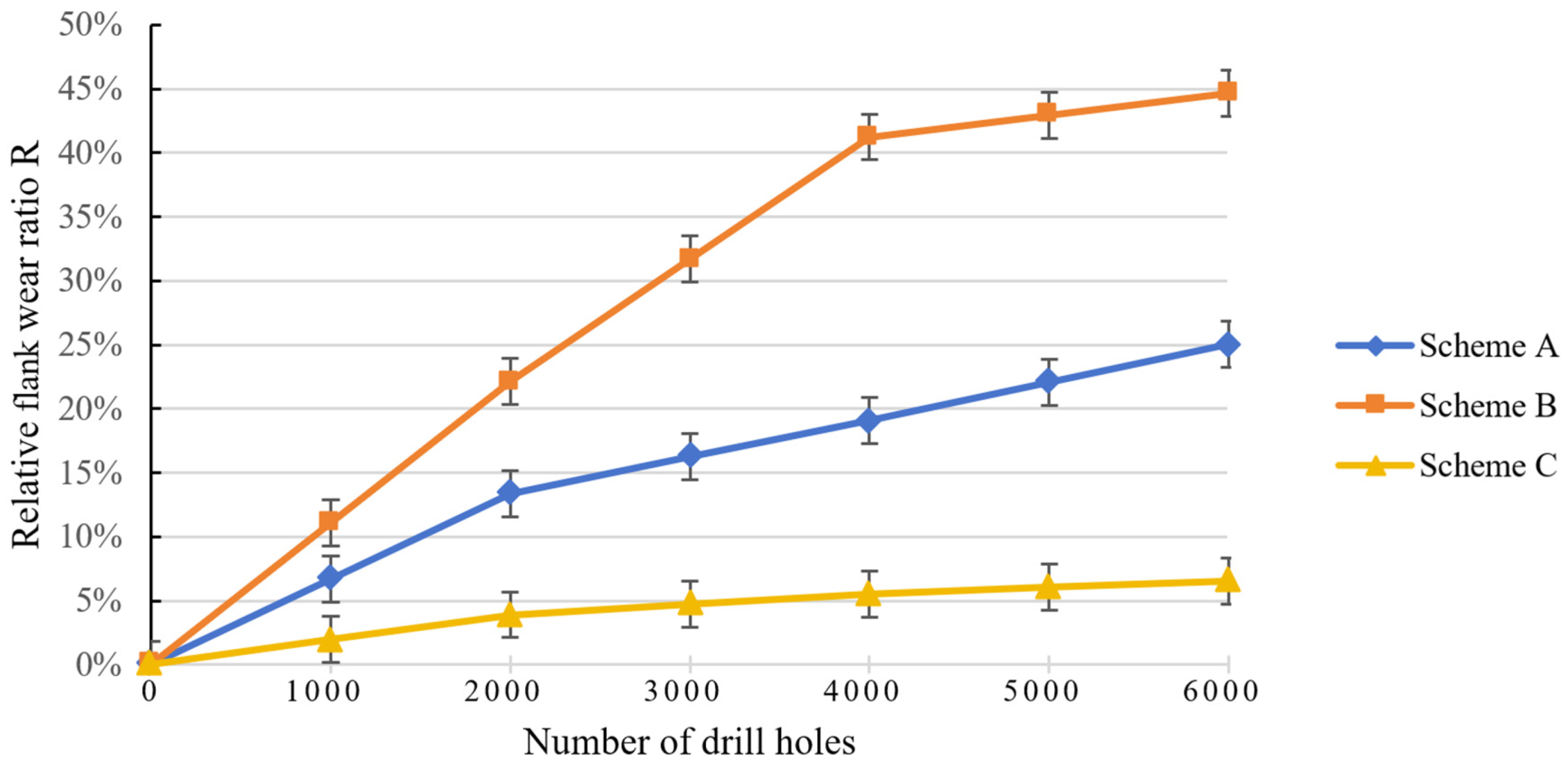

3.3. Comparative Analysis of the Tool Life in Different Deposition Samples

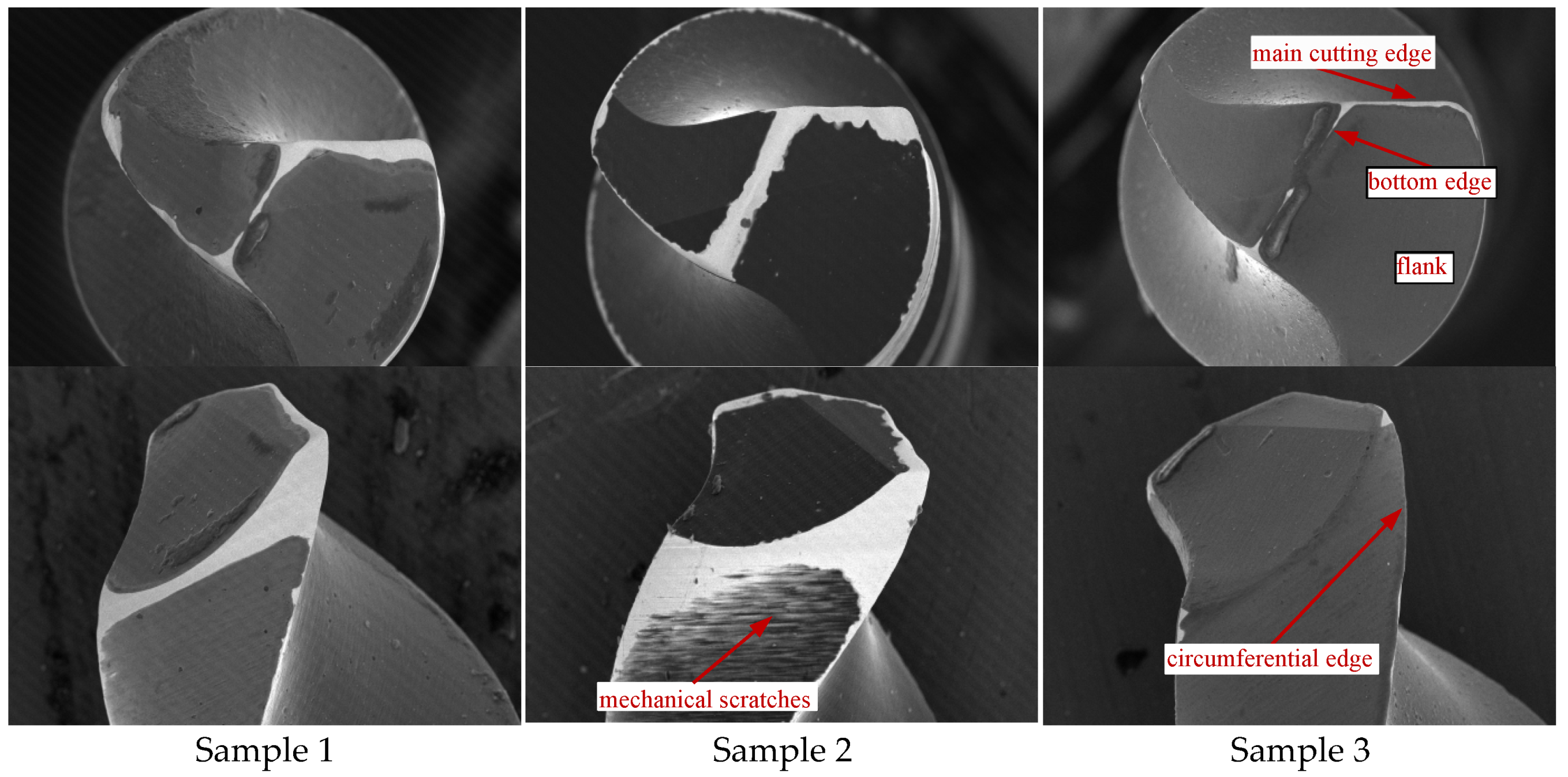

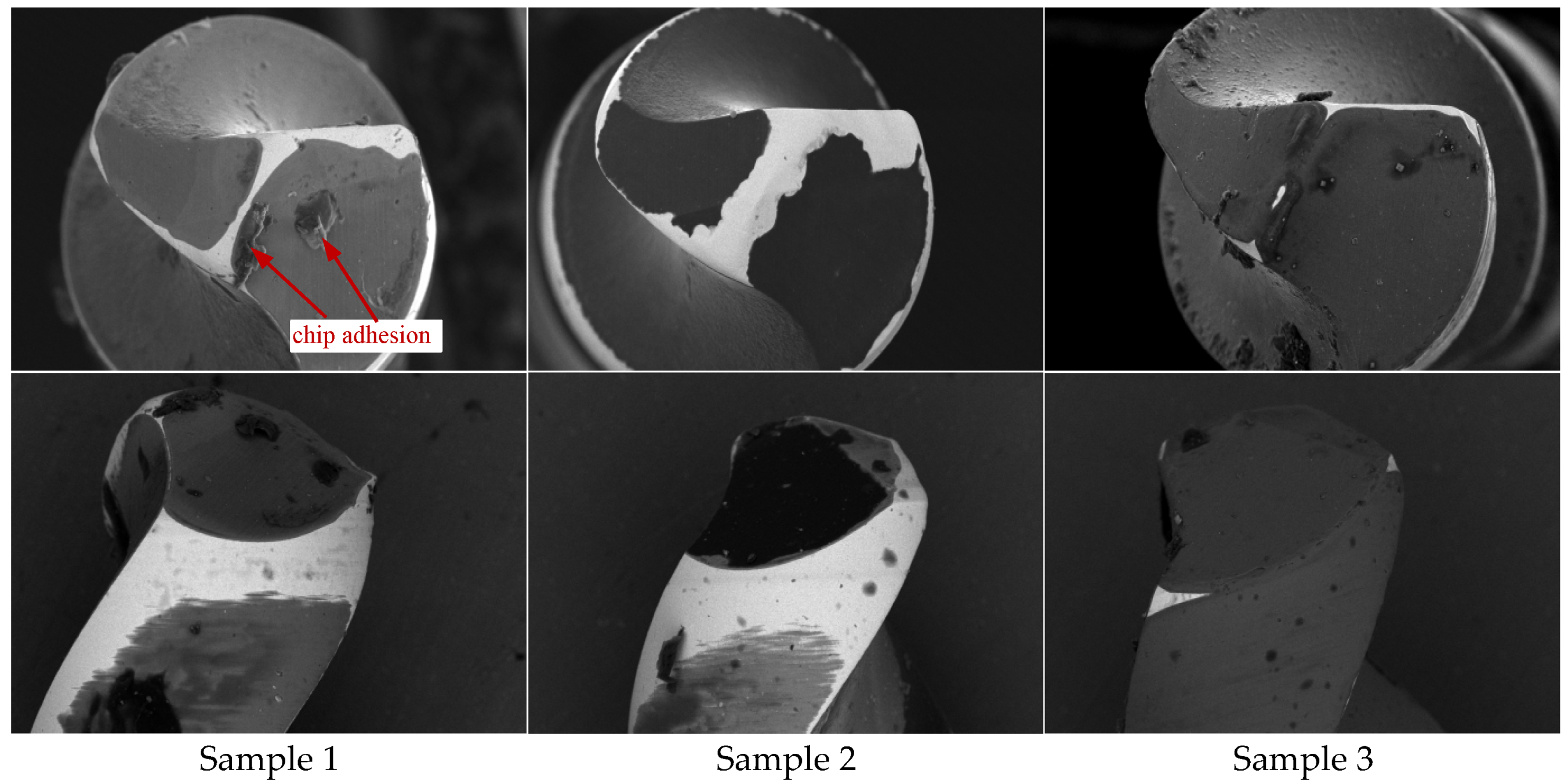

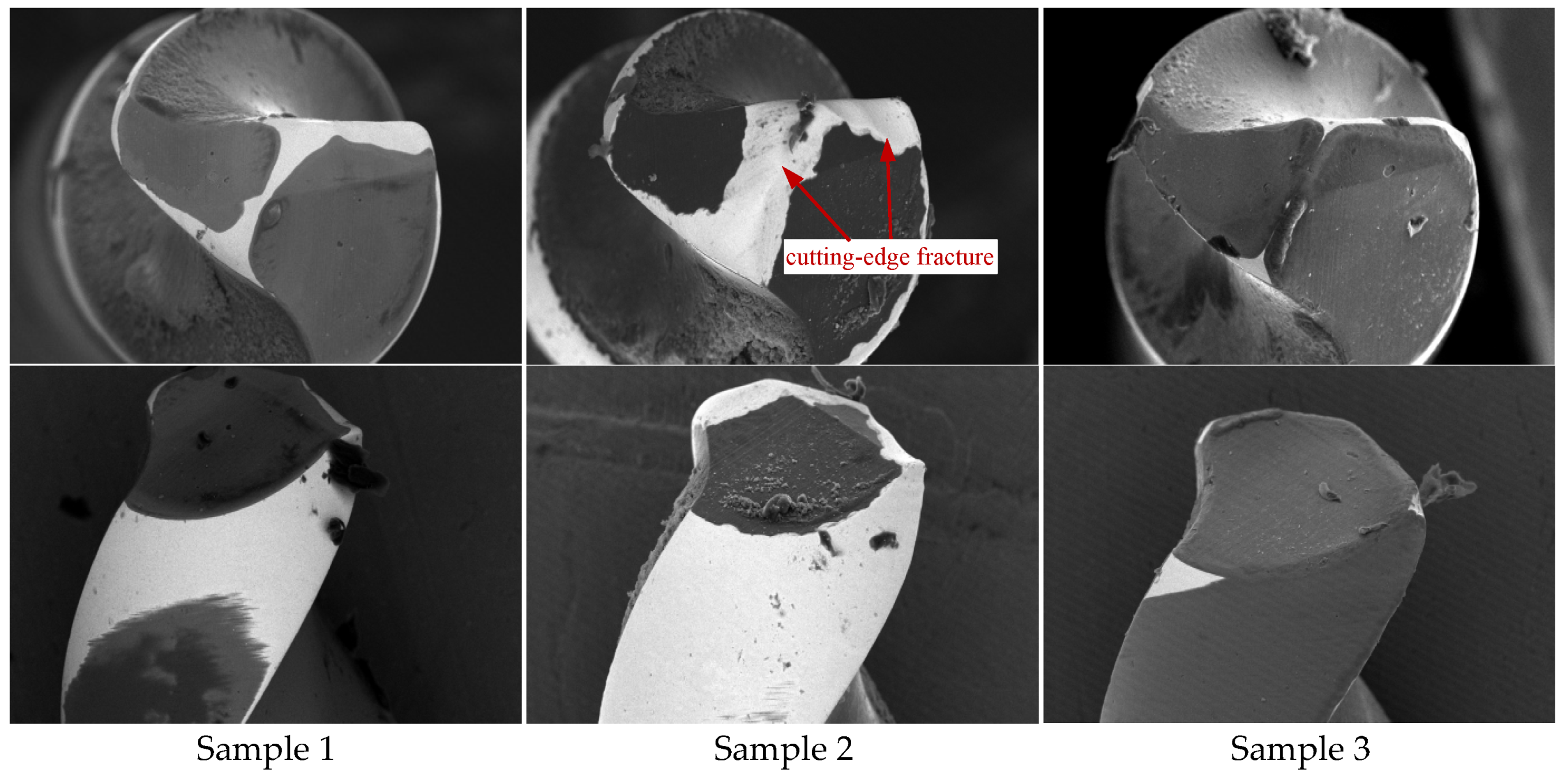

3.4. Analysis of the Wear Morphology of Microdrills in Different Deposition Samples

4. Conclusions

- Using arc ion plating technology, conventional AlTiN columnar crystal coatings and AlTiN nanocrystalline coatings were, respectively, deposited on cemented carbide specimens and PCB microdrill substrates. Meanwhile, a novel multilayer composite coating structure with alternating AlTiN columnar and nanocrystalline layers was also designed and deposited. Indentation tests and morphological analysis indicate that the coating adhesion strength of both the columnar crystal coating and the columnar/nanocrystalline composite coating surpassed that of nanocrystalline coatings, while the nanocrystalline coating exhibited the smoother surface.

- The surface layer of the novel AlTiN columnar/nanocrystalline composite coating has a nanocrystalline structure that enhances its surface quality, while the underlying layer has a columnar crystal structure that improves its adhesion strength with the substrate. This multilayer composite structure effectively mitigates grain boundary sliding and inhibits crack propagation, thereby enhancing the toughness and adhesion strength of the coating and also reducing the friction between the microdrill and the chip.

- PCB drilling experiments show that the tool life of the microdrill with the novel AlTiN columnar/nanocrystalline composite coating is approximately 1.69 times larger than that of the nanocrystalline-coated microdrills, and 1.25 times larger than that of the columnar crystal coated microdrills, under the same cutting conditions. The main factors that affect tool wear failures are abrasive wear and coating flaking.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, C.; Lin, H.D.; Wu, J.Q. Research on high-speed drilling technology of PCB with super much holes. Print. Circuit Inf. 2022, 30, 19–23. [Google Scholar] [CrossRef]

- Lu, B.Y.; Ma, F.; Ma, D.Y. Microstructure and mechanical properties of thick Cr/CrN multilayer coatings by multi-arc ion plating. Rare Met. Mater. Eng. 2022, 51, 1558–1564. Available online: http://www.rmme.ac.cn/rmmeen/article/abstract/20210205?st=alljournals (accessed on 23 April 2025).

- Duan, J.N.; Li, W.Z.; Zhao, C.L.; Zhao, Y.; Dong, M.P.; Yuan, Z.W.; Li, J.L. Structure and Tribological Property of TiAlCN and TiAlN Coatings Prepared by Multi-arc Ion Plating. Surf. Technol. 2022, 51, 139–148. [Google Scholar] [CrossRef]

- Ran, L.J.; Zheng, S.T.; Fan, H.Y.; Xian, G.; Xiong, J.; Guo, Z.X.; Zhao, H.B.; Jing, Z.B. Properties of AlCrN coatings on cemented carbide prepared by arc ion plating assisted by gas ion source. Rare Met. Cem. Carbides 2021, 49, 94–98. [Google Scholar] [CrossRef]

- Azim, S.; Gangopadhyay, S.; Mahapatra, S.S.; Mittal, R.K.; Singh, R.K. Role of PVD coating on wear and surface integrity during environment-friendly micro-drilling of Ni-based superalloy. J. Clean. Prod. 2020, 272, 122741. [Google Scholar] [CrossRef]

- Alisir, S.H.; Evrensel, D. Investigation into Coating Structure and Wear Environment Effects on Tribological Properties of Piston Ring Coated with Monolayer TiAlN and Multilayer TiN/TiAlN. J. Mater. Eng. Perform. 2022, 31, 1654–1666. [Google Scholar] [CrossRef]

- Hu, J.; Sun, Y.S.; Chen, C.; Fu, L.Y.; Qu, J.G. Effect of TiAlN-based coating thickness on the stiffness and holes position accuracy of micro drills. Cem. Carbide 2021, 38, 424–433. [Google Scholar] [CrossRef]

- Skordaris, G.; Bouzakis, K.D.; Kotsanis, T.; Charalampous, P.; Bouzakis, E.; Breidenstein, B.; Bergmann, B.; Denkena, B. Effect of PVD film’s residual stresses on their mechanical properties, brittleness, adhesion and cutting performance of coated tools. CIRP J. Manuf. Sci. Technol. 2017, 18, 145–151. [Google Scholar] [CrossRef]

- Zhang, S.; Fan, Q.X.; Hao, X.H.; Wu, Z.H.; Ma, D.Z.; Cao, F.T.; Wang, T.G. Effect of deposition bias on the mechanics and high-temperature oxidation resistance of AlCrTiN nanocomposite coatings. Chin. Surf. Eng. 2023, 36, 104–113. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, J.C.; Xu, Y.X.; Zhang, B.R.; Zhao, Z.Y.; Feng, L.M.; Zheng, J.; Wang, Q.M. Preparation and Cutting Performance of AlTiN Coatings by Arc Ion Plating and High Power Pulsed Magnetron Sputtering. Surf. Technol. 2022, 51, 57–65. [Google Scholar] [CrossRef]

- Xiao, B.J. Fabrication and Properties of AlCrN/AlTiSiN Nano-Layered Coatings on Cutting Tools. Ph.D. Thesis, Guangdong University of Technology, Guangzhou, China, 2019. (In Chinese). [Google Scholar] [CrossRef]

- Wang, Z.; Han, B.; Xiang, Y.; Tian, C.; Zou, C.; Fu, D. Effects of working pressure on microstructure and properties of TiBN/TiAlSiN nano-multilayer coatings. China Surf. Eng. 2020, 33, 77–85. Available online: https://qikan.cmes.org/zgbmgc/EN/10.11933/j.issn.1007-9289.20200911001 (accessed on 23 April 2025).

- Tillmann, W.; Grisales, D.; Stangier, D.; Thomann, C.A.; Debus, J.; Nienhaus, A.; Apel, D. Residual stresses and tribomechanical behaviour of TiAlN and TiAlCN monolayer and multilayer coatings by DCMS and HiPIMS. Surf. Coat. Technol. 2021, 406, 126664. [Google Scholar] [CrossRef]

- Ma, H.; Miao, Q.; Zhang, G.; Liang, W.; Wang, Y.; Sun, Z.; Lin, H. The influence of multilayer structure on mechanical behavior of TiN/TiAlSiN multilayer coating. Ceram. Int. 2021, 47, 12583–12591. [Google Scholar] [CrossRef]

- Lei, Z.; Zhu, X.; Li, Y.; Song, Z.; Liu, H.; Fu, Y.Q. Characterization and Tribological Behavior of TiAlN/TiAlCN Multilayer Coatings. J. Tribol.-Trans. Asme 2018, 140, 051301. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, Y.X.; Chen, L.; Mayrhofer, P.H. Improved Ti-Al-N coatings through Ta alloying and multilayer architecture. Surf. Coat. Technol. 2017, 328, 428–435. [Google Scholar] [CrossRef]

| Tool Specification | Tool Parameters | ||||

|---|---|---|---|---|---|

| Drill Diameter × Flute Length × Overall Length (mm) | Spiral Angle β (°) | Apex Angle 2φ (°) | Core Diameter DC (mm) | First Relief Angle α1 (°) | Secondary Relief Angle α2 (°) |

| 0.3 × 6.2 × 38.1 | 45° (right) | 140° | 0.156 | 12 | 30 |

| Sample | Deposition Time/Min | Working Pressure/Pa | Bias Voltage/V (Negative Value) | N2 Flow Rate/Sccm | Target Current/A | ||||

|---|---|---|---|---|---|---|---|---|---|

| AlTi | AlTi | AlTi | AlTi | ||||||

| 1 | 60 | 4 | 40 | 250 | 150 | 150 | 150 | 150 | |

| 2 | 60 | 150 | |||||||

| 3 | 5 | Alternate cycles 7 times | 40 | ||||||

| 2 | 150 | ||||||||

| 11 (surface layer) | 150 | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Lin, H.; Chen, Y.; He, Y.; Shen, Z. Effect of AlTiN Coating Structure on the Cutting Performance of Cemented Carbide PCB Microdrills. Coatings 2025, 15, 520. https://doi.org/10.3390/coatings15050520

Yang X, Lin H, Chen Y, He Y, Shen Z. Effect of AlTiN Coating Structure on the Cutting Performance of Cemented Carbide PCB Microdrills. Coatings. 2025; 15(5):520. https://doi.org/10.3390/coatings15050520

Chicago/Turabian StyleYang, Xiaofan, Haiyang Lin, Yicong Chen, Yajue He, and Zhihuang Shen. 2025. "Effect of AlTiN Coating Structure on the Cutting Performance of Cemented Carbide PCB Microdrills" Coatings 15, no. 5: 520. https://doi.org/10.3390/coatings15050520

APA StyleYang, X., Lin, H., Chen, Y., He, Y., & Shen, Z. (2025). Effect of AlTiN Coating Structure on the Cutting Performance of Cemented Carbide PCB Microdrills. Coatings, 15(5), 520. https://doi.org/10.3390/coatings15050520