A Review on Micropitting Studies of Steel Gears

Abstract

:1. Introduction

2. Some Influence Factors on Gear Micropitting

2.1. Gear Materials and Macroscopic Geometries

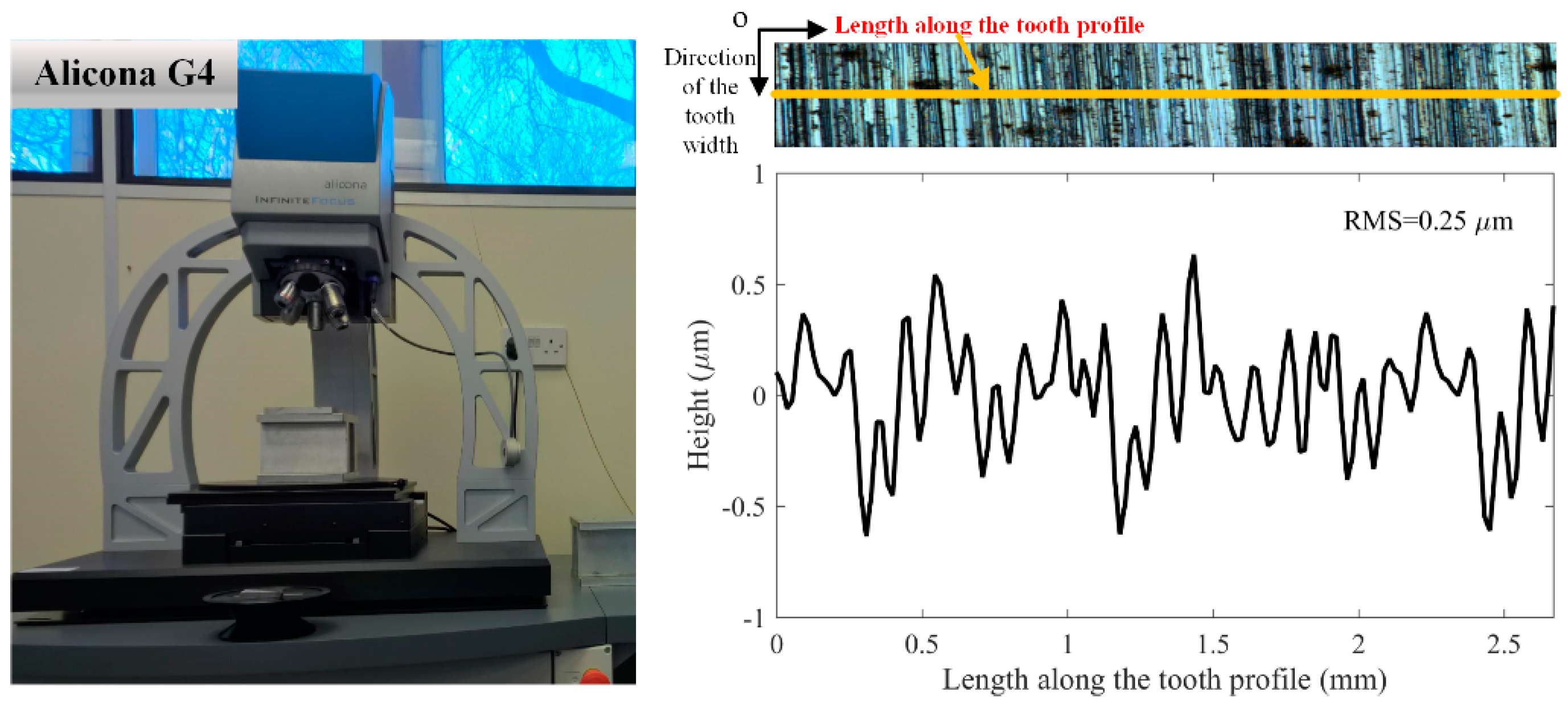

2.2. Gear Surface Microscopic Topographies and Surface Treatments

2.3. Working Conditions

2.3.1. The Normal Load Condition

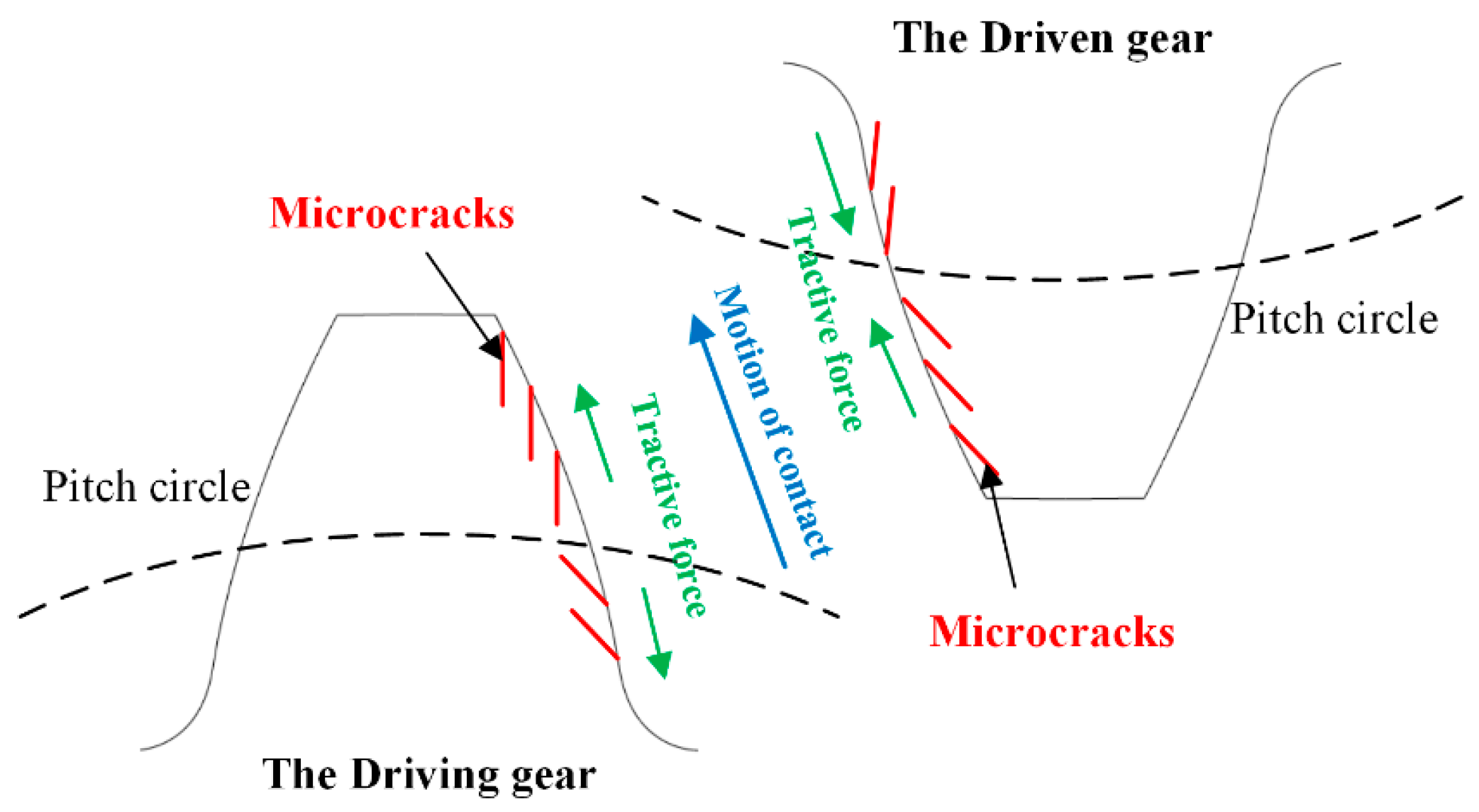

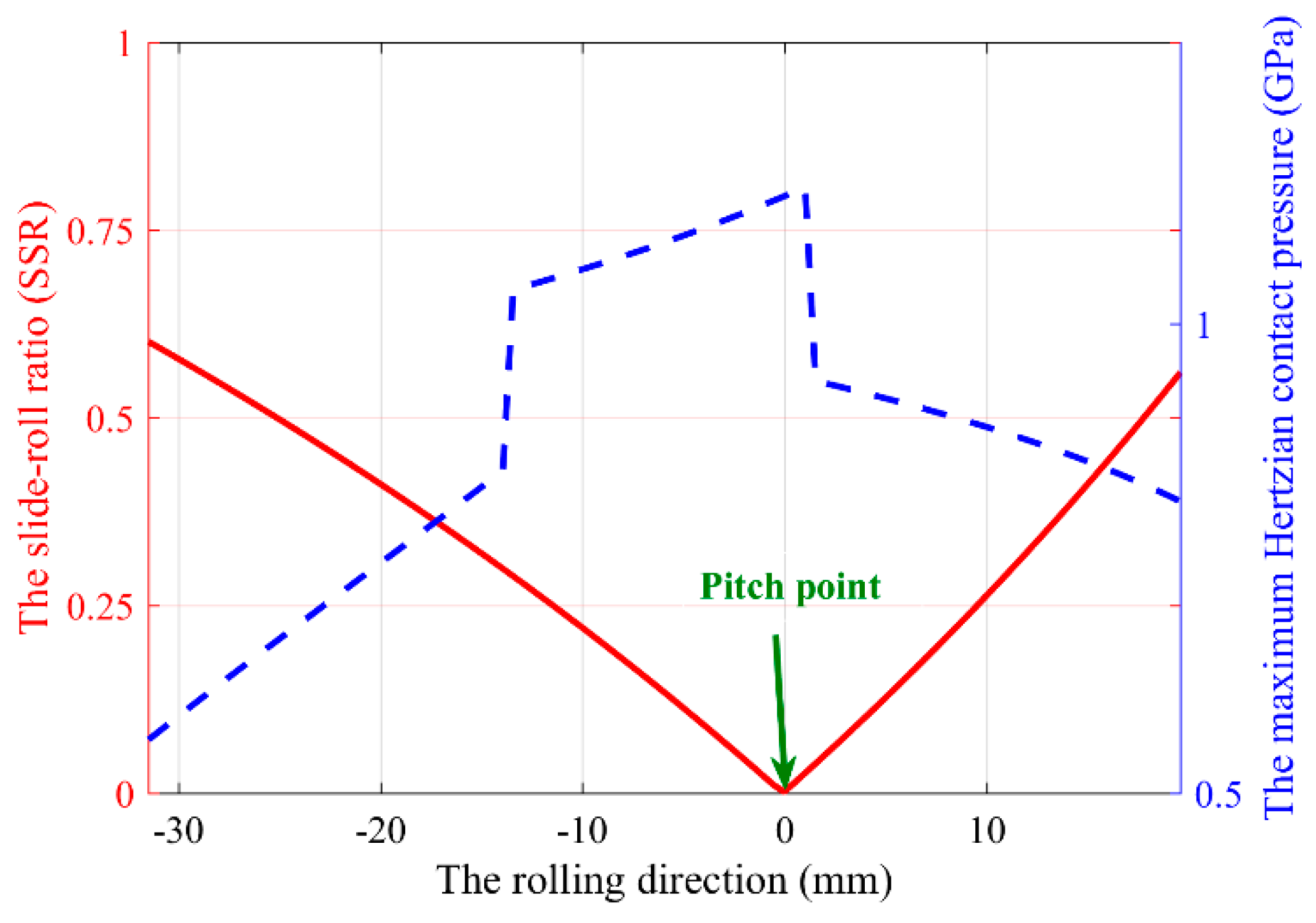

2.3.2. The Sliding/Rolling Condition

2.3.3. Lubrication Conditions

3. The Contact Fatigue Failure Competitive Mechanism Considering Wear Effect

3.1. Review on the Studies Considering the Competitive Mechanism

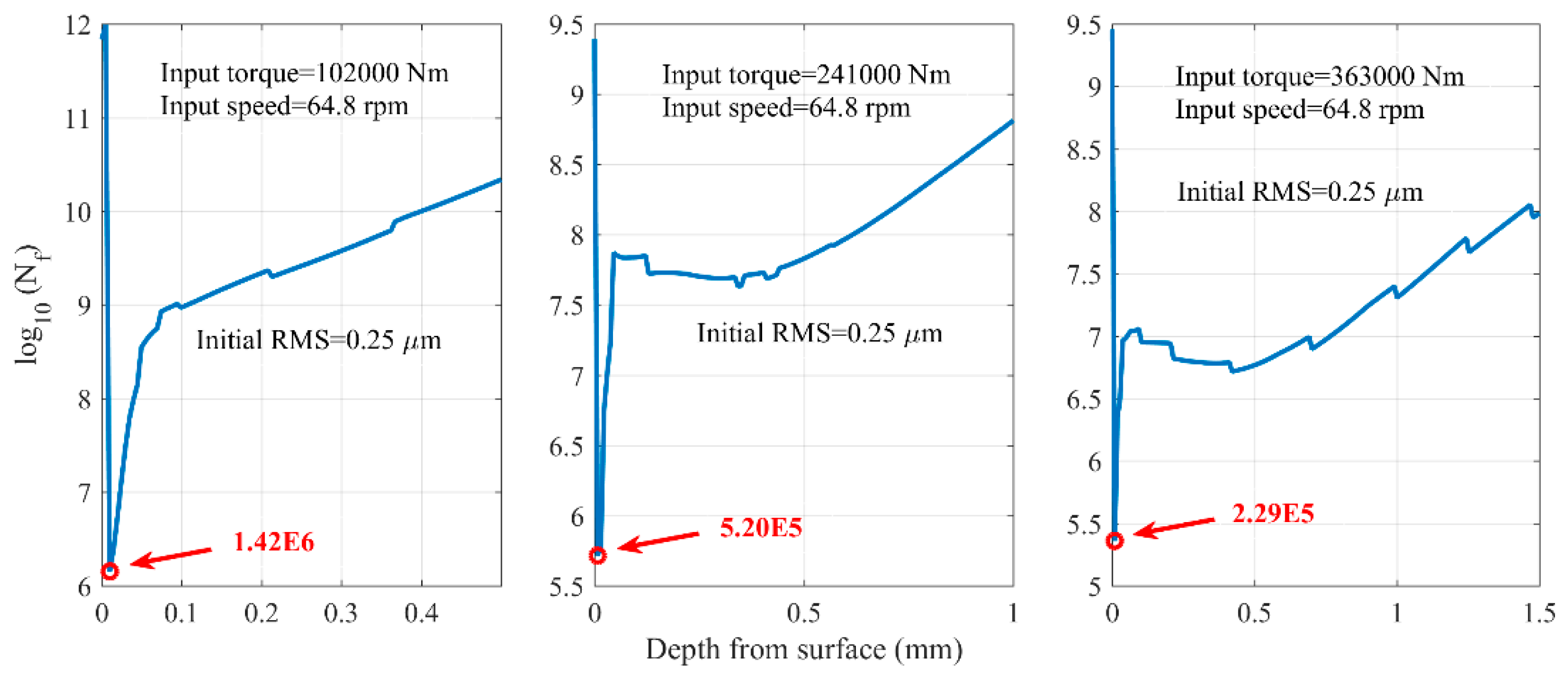

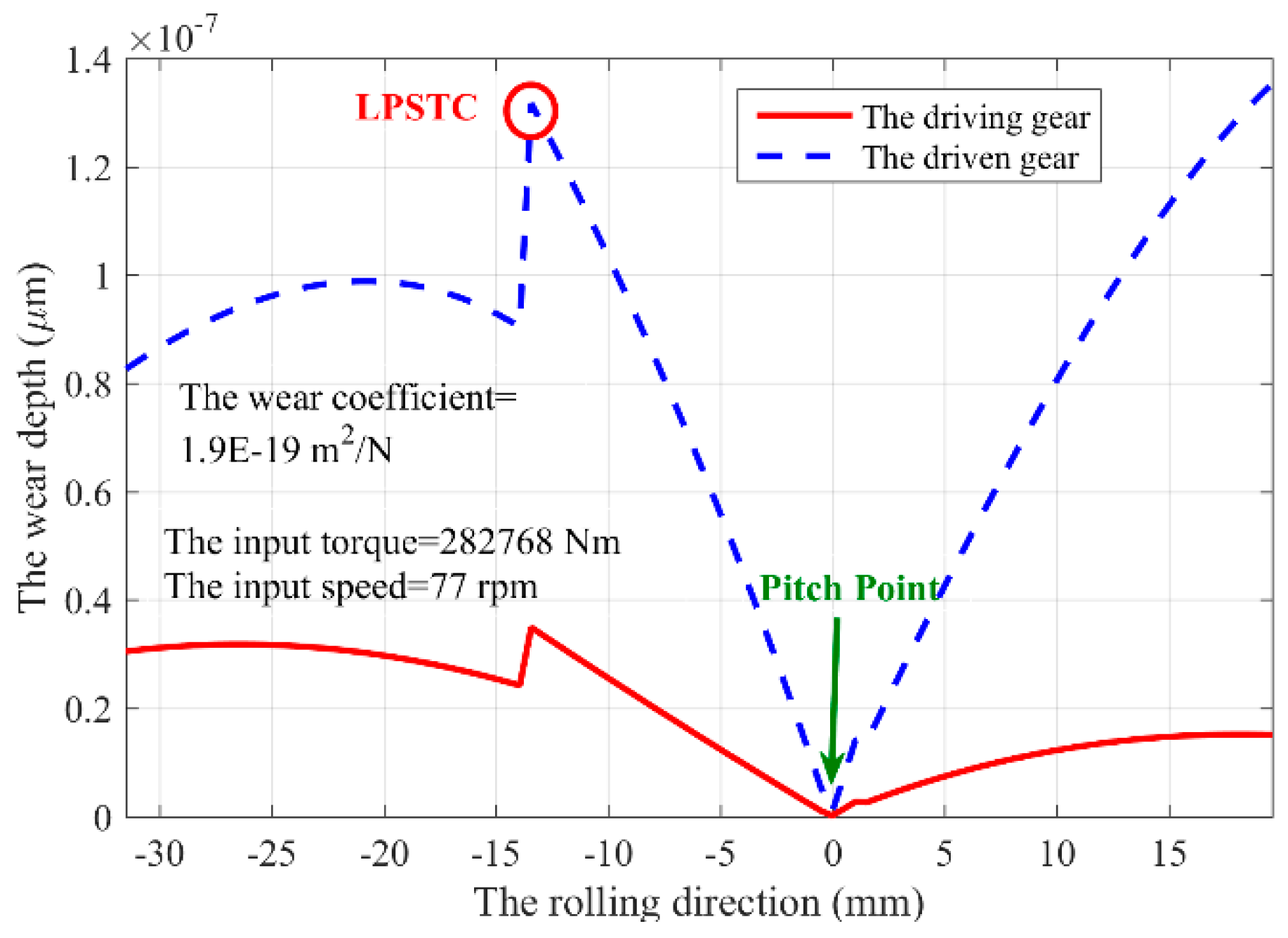

3.2. Progress on Competitive Mechanism

4. Conclusions

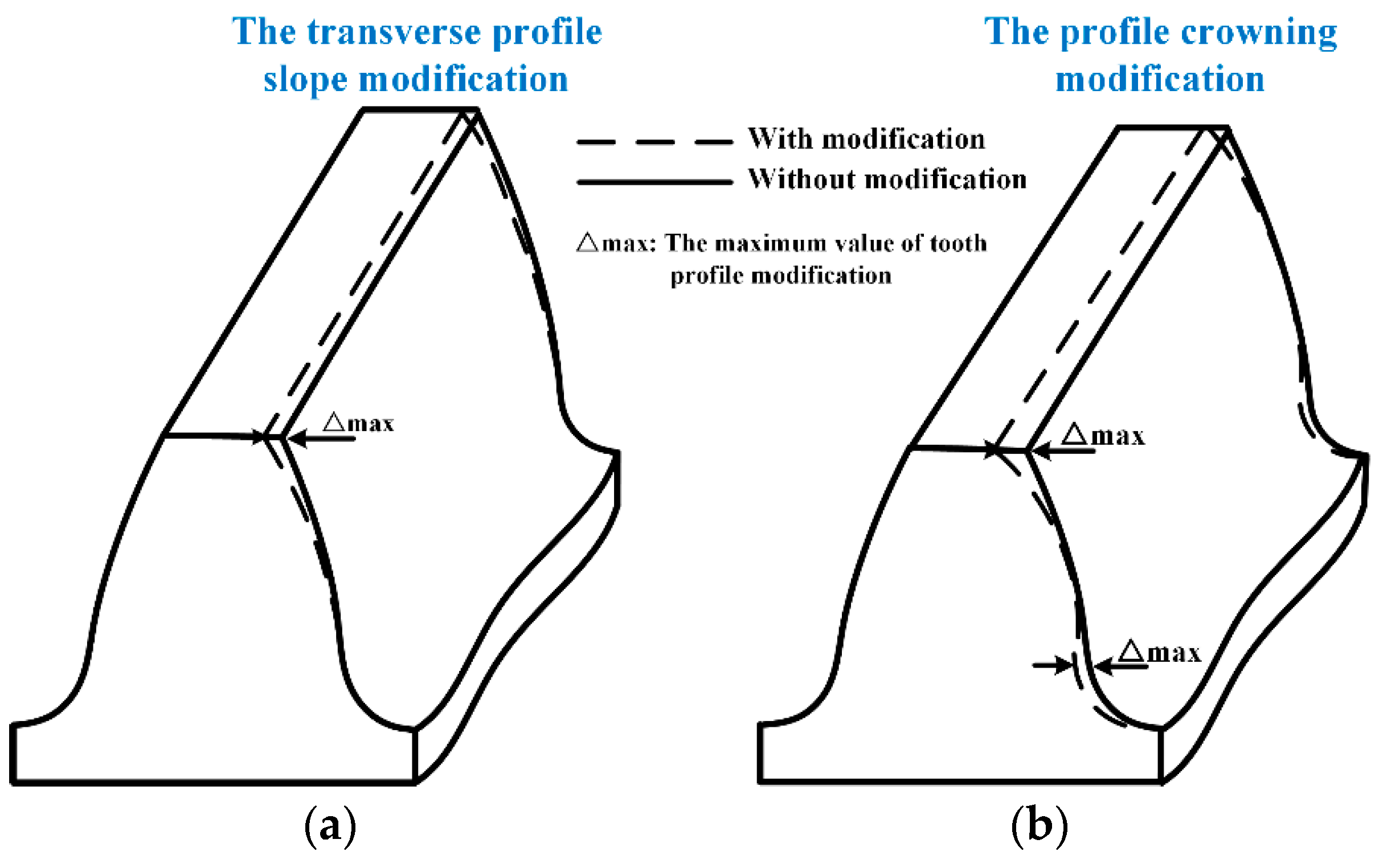

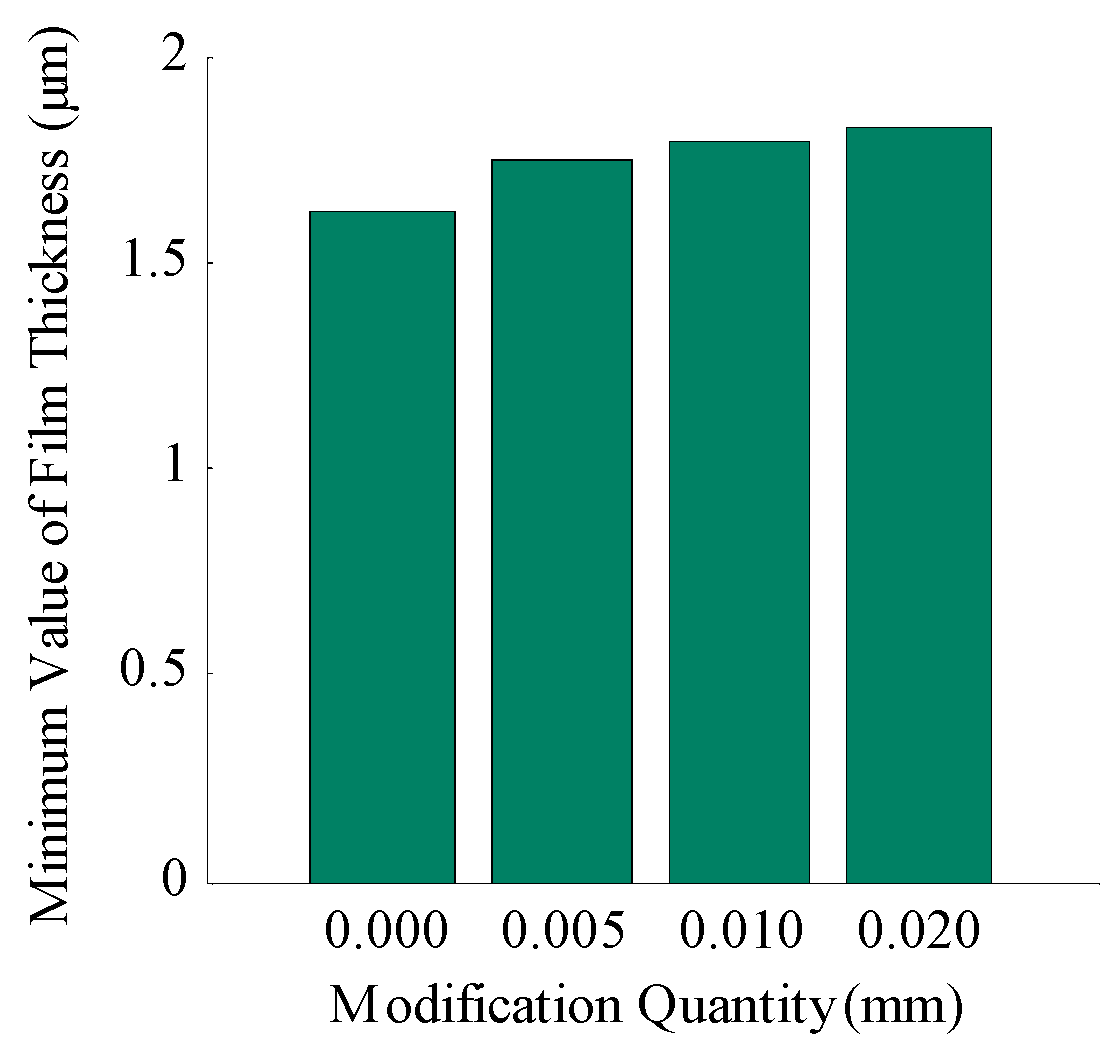

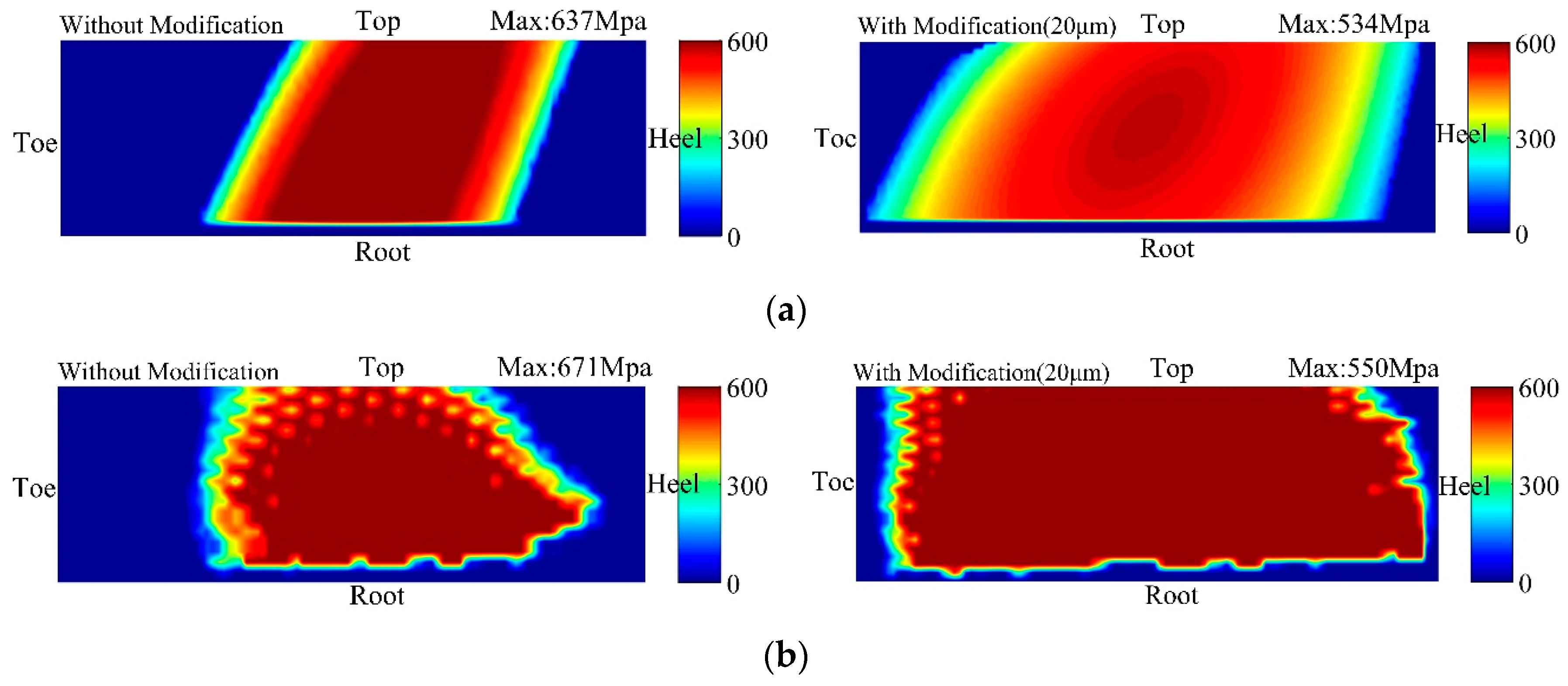

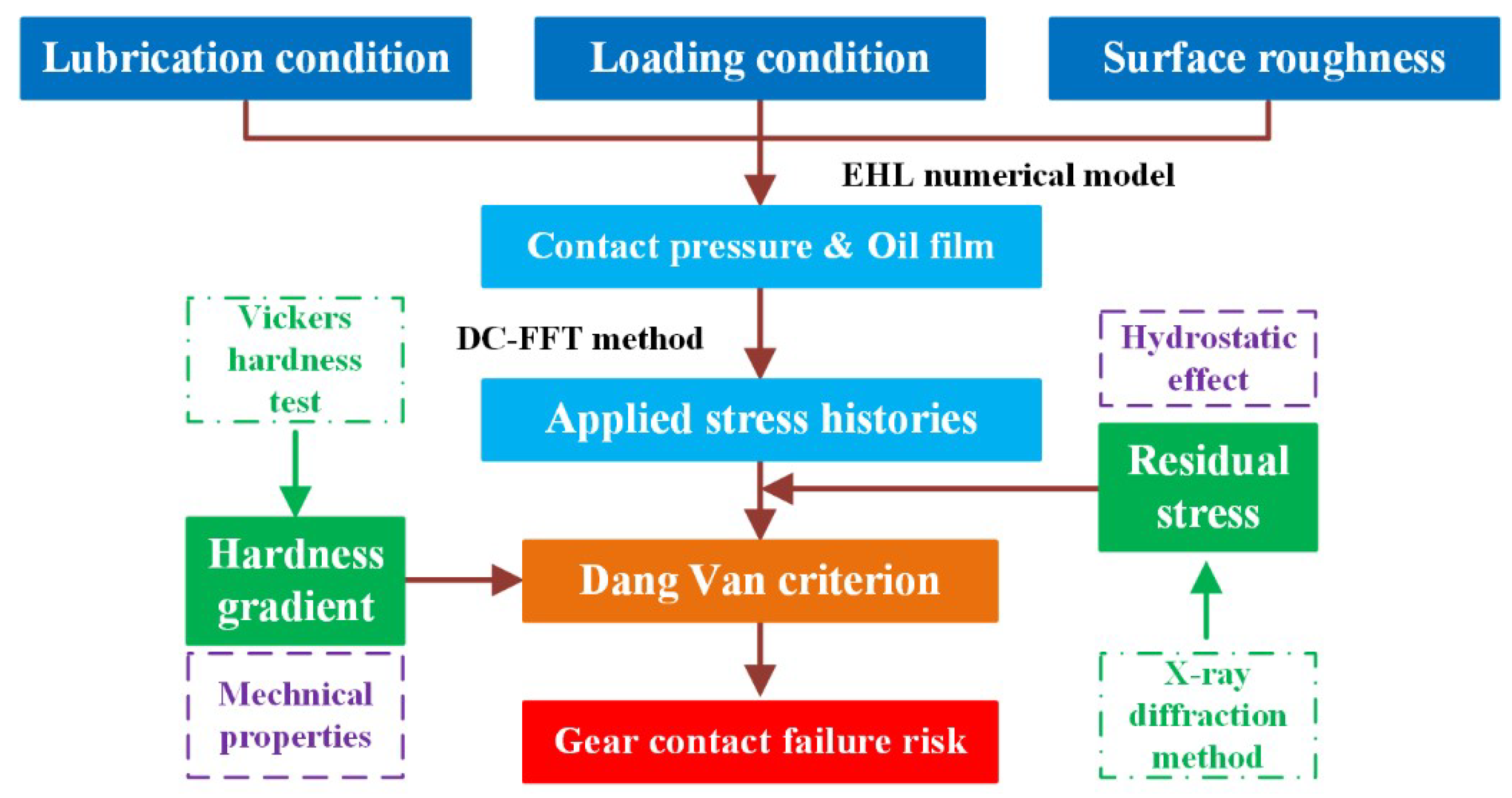

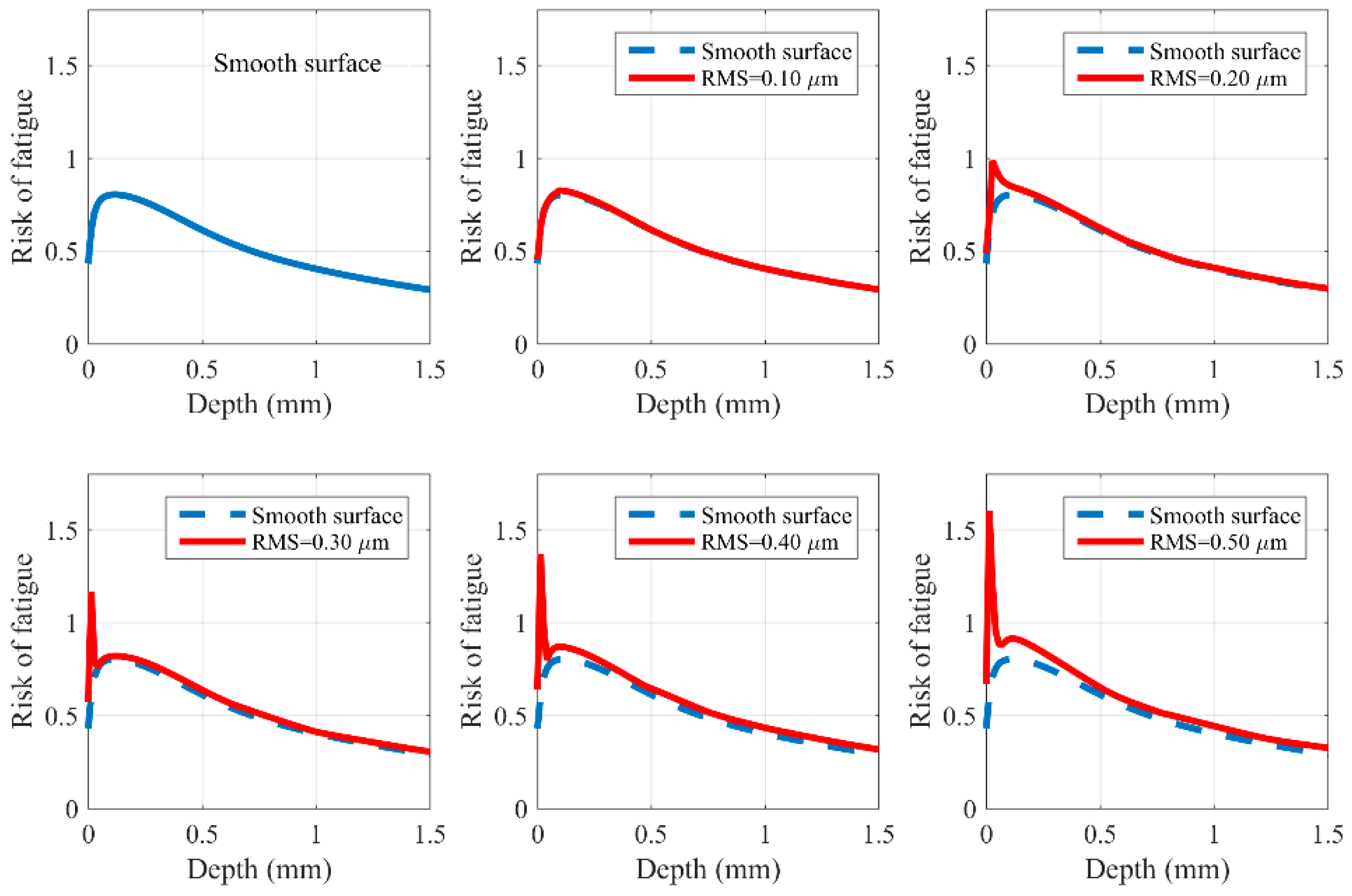

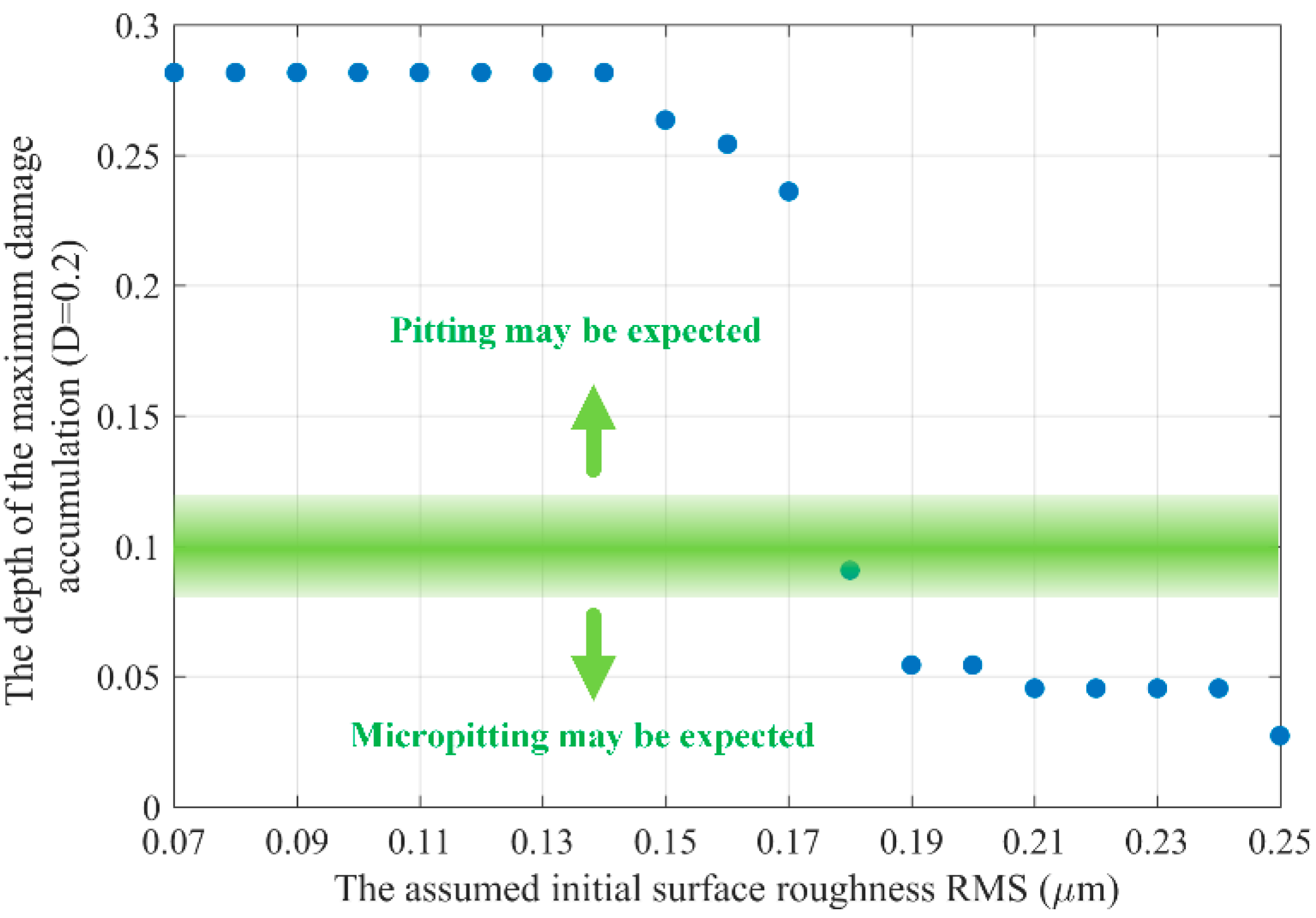

- The gear micropitting resistance can be influenced by both macroscopic and microscopic geometry factors. The appropriate gear tooth modification method is beneficial to the anti-micropitting capacity. The increase of the surface roughness RMS makes the maximum index of failure risk significantly increase and its occurrence position comes closer to the surface (about 0.05 mm when RMS = 0.5 μm), where the micropitting is more likely to occur. However, the superfinishing may completely eliminate micropitting due to mitigating the effect of surface roughness.

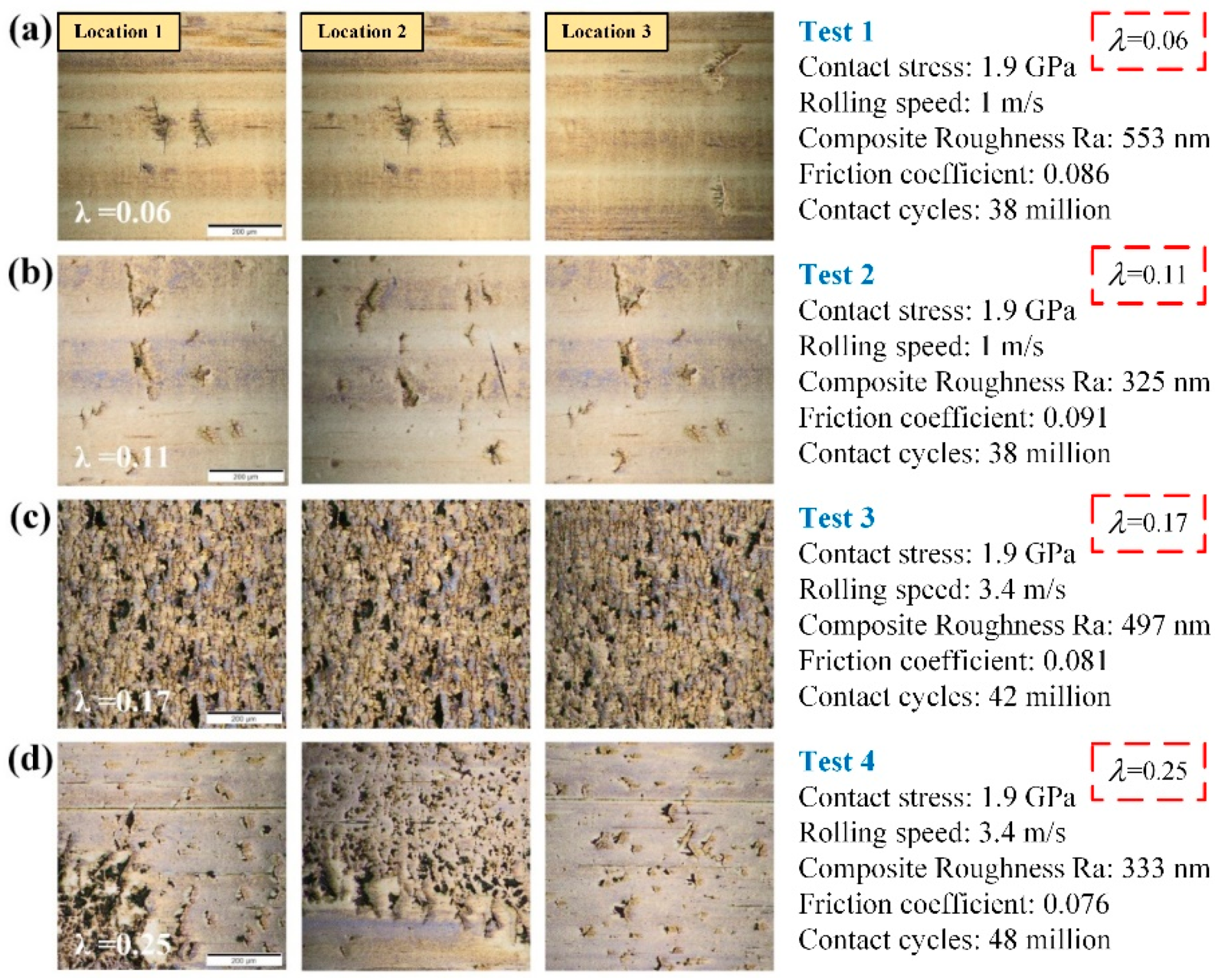

- The micropitting initiation is mostly controlled by contact pressure, whereas the propagation process can be significantly influenced by the sliding/rolling condition, and the micropitting damage may commonly be observed at higher speeds. With the increase of the specific lubricant film thickness from 0.06 to 0.17, the micropitting damage becomes more severe unless the Ra of the surface roughness is relatively low. The extreme pressure (EP) or anti-wear (AW) lubricant additives may be detrimental to the micropitting resistance because the surface roughness can be protected from wearing, leading to greater micropitting damage at the running-in stage.

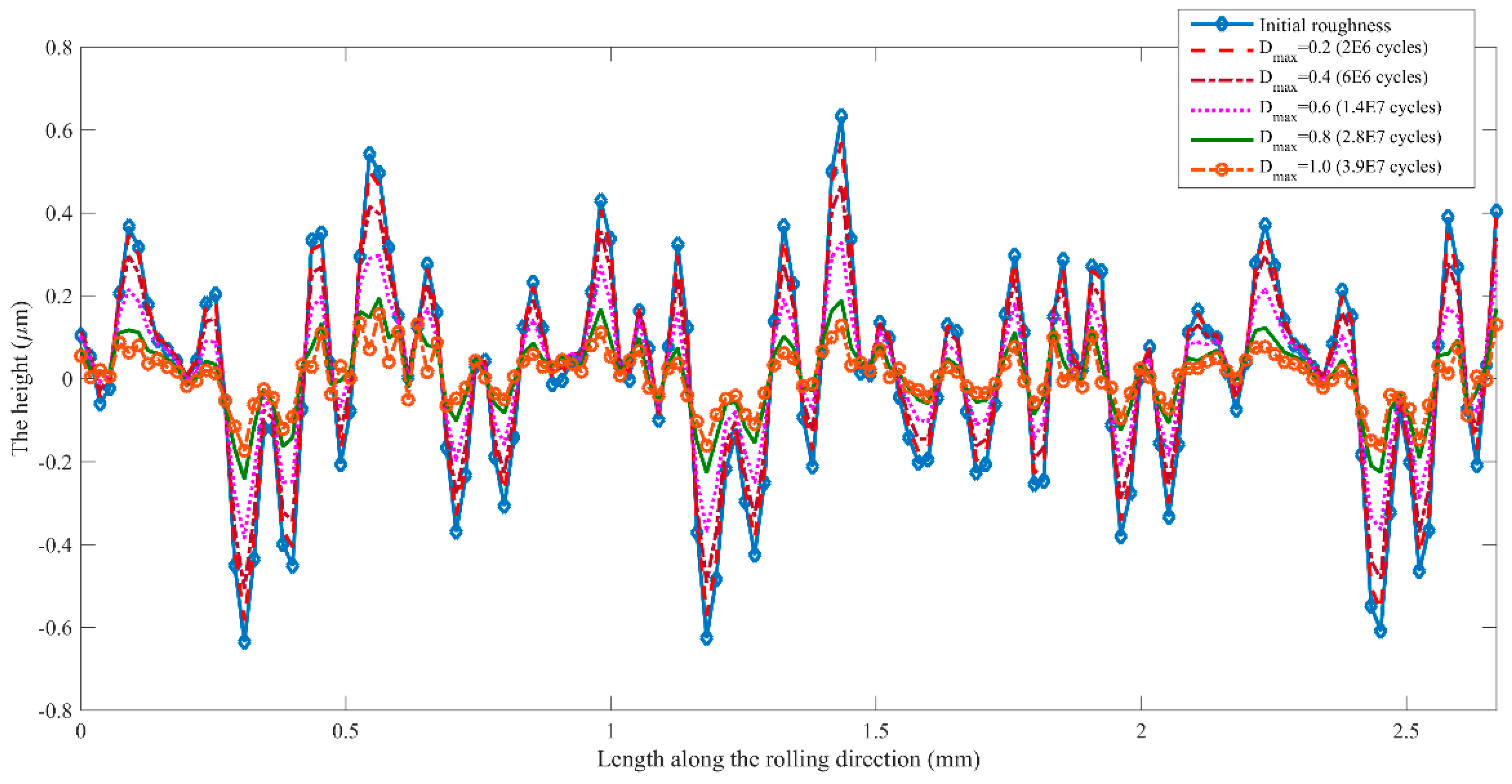

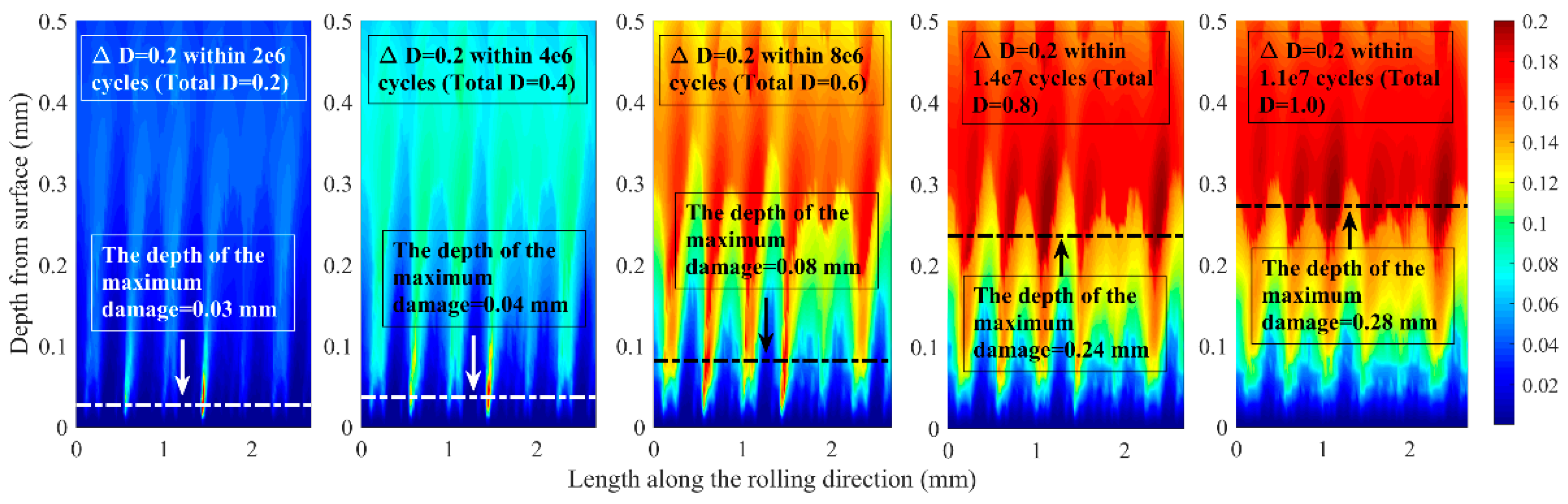

- Merging the effects of the wear process and surface fatigue failure damages of the gear tooth surface is essential for the successful gear micropitting modelling. During the wear process, the position of the maximum damage accumulation moves gradually from near-surface to subsurface, indicating that the pitting failure is becoming more dominant than micropitting. The occurrence probability of micropitting can be significantly reduced due to the existence of the wear, resulting in the competitive mechanism between micropitting and pitting during the loading cycles.

Funding

Conflicts of Interest

Nomenclutare

| AW | Anti-wear |

| The fatigue strength index and the ductility index, respectively | |

| The constants used in Morrow–Brown–Miller criterion | |

| Contact tooth width, m | |

| The tip clearance coefficient | |

| The damage accumulation | |

| Young’s modulus of the driving and the driven gears, respectively, Pa | |

| EHL | Elastohydrodynamic lubrication |

| EP | Extreme pressure |

| The lubricant film thickness with the assumption that the contact surface is smooth, μm | |

| The wear depth, m | |

| The wear coefficient, m2 N−1 | |

| LOA | Line of action |

| LPSTC | The lowest point of single tooth contact |

| The normal module of the gear pair, m | |

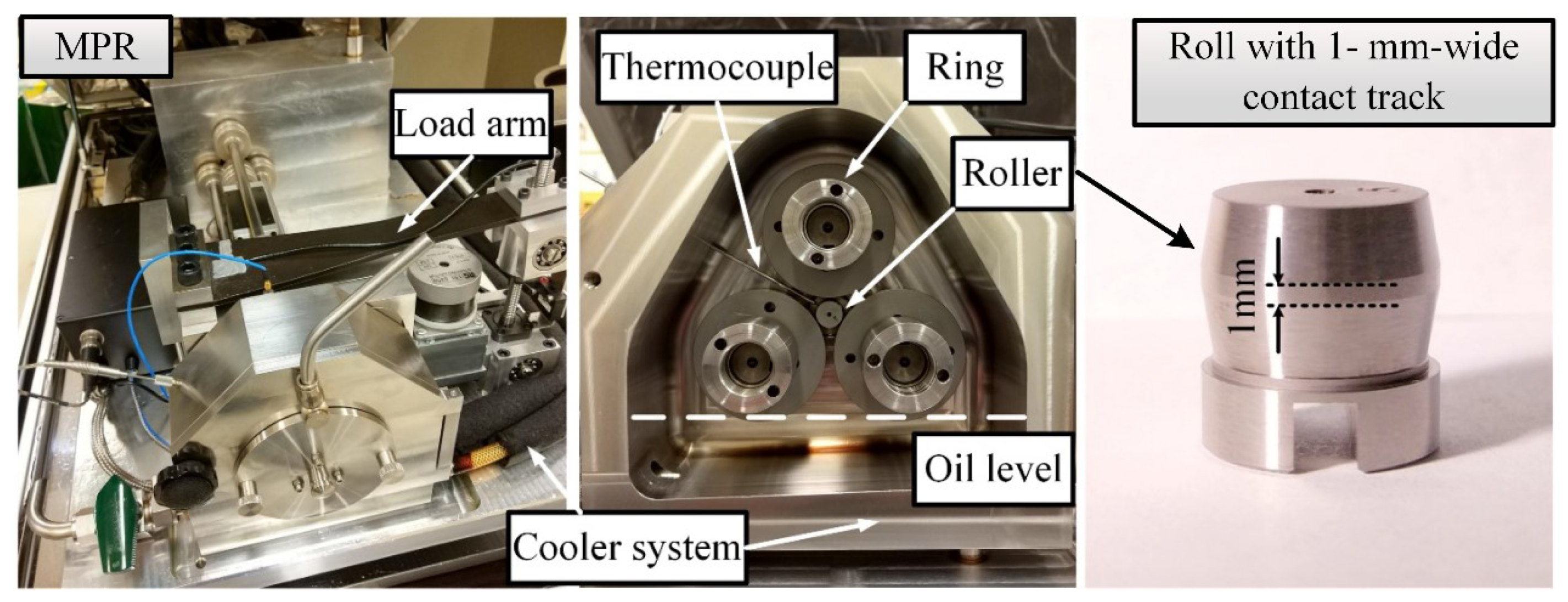

| MPR | Micropitting rig |

| MSI | Micropitting severity index |

| The reference input speed of the driving gear, rpm | |

| The number of cycles of fatigue | |

| The maximum Hertzian contact pressure, Pa | |

| The mean value of the local contact pressure, Pa | |

| RA | The retained austenite |

| RCF | Rolling contact fatigue |

| RMS | The root-mean-square, μm |

| The effective arithmetic mean roughness value, μm | |

| The RMS of contact surfaces of the driving and the driven gears, respectively, μm | |

| The combined RMS value, μm | |

| The relative sliding distance, m | |

| The safety factor representing the micropitting load capacity | |

| The minimum required safety factor | |

| SRR | The slide-roll ratio |

| The reference input torque of the driving gear, Nm | |

| The shifting coefficients of the driving and the driven gears, respectively | |

| The teeth number of the driving and the driven gears, respectively | |

| ZDDP | The Zinc Dialkyl Dithiophosphate |

| The pressure angle of the gear, ° | |

| The material parameter used in Dang Van criteria | |

| The transverse pressure angle of the gear,° | |

| The helix angle of the gear, ° | |

| The axial fatigue strength coefficient, MPa | |

| The mean of the normal stress at the critical plane, MPa | |

| The maximum amplitude of the shear strain | |

| The Dang Van equivalent stress, MPa | |

| The maximum shear stress, MPa | |

| The axial fatigue ductility coefficient | |

| The amplitude of normal tensile strain at the critical plane | |

| The Poisson’s ratio of materials | |

| The specific lubricant film thickness | |

| The minimum specific lubricant film thickness in the contact area | |

| The permissible specific lubricant film thickness |

References

- Oila, A.; Bull, J. Assessment of the factors influencing micropitting in rolling/sliding contacts. Wear 2005, 258, 1510–1524. [Google Scholar] [CrossRef]

- Brandão, J.; Martins, R.; Seabra, J.; Castro, M. An approach to the simulation of concurrent gear micropitting and mild wear. Wear 2015, 324–325, 64–73. [Google Scholar] [CrossRef]

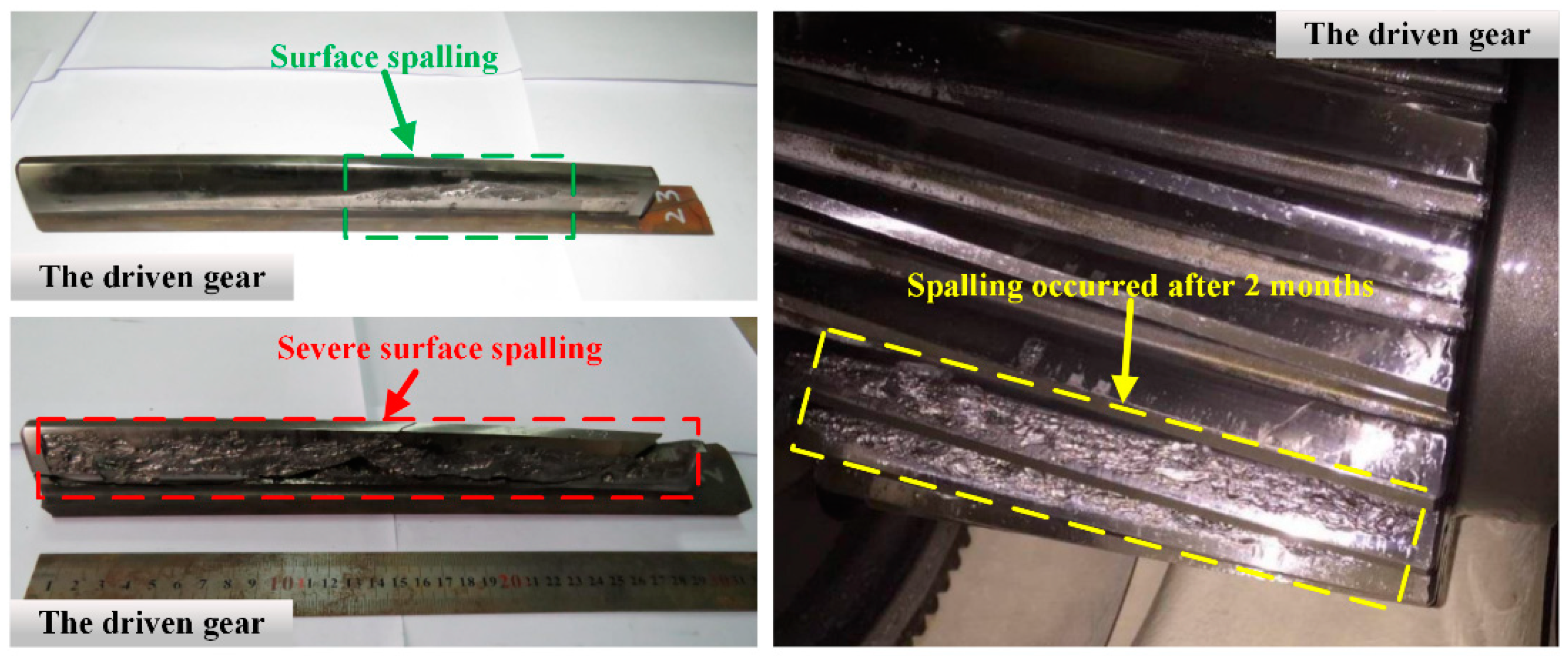

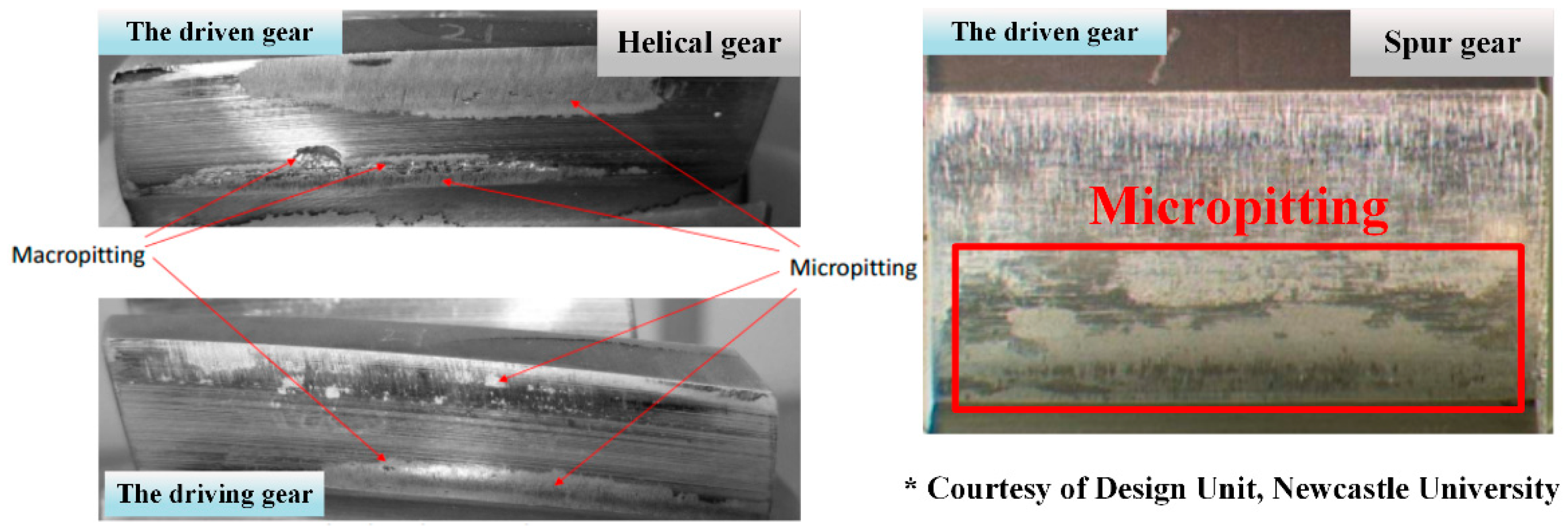

- Terrin, A.; Dengo, C.; Meneghetti, G. Experimental analysis of contact fatigue damage in case hardened gears for off-highway axles. Eng. Fail. Anal. 2017, 76, 10–26. [Google Scholar] [CrossRef]

- Höhn, B.-R.; Oster, P.; Emmert, S. Micropitting in case-carburized gears-FZG micro-pitting test. VDI Berichte 1996, 1230, 331–344. [Google Scholar]

- Sheng, S. Wind Turbine Micropitting Workshop: A Recap; National Renewable Energy Laboratory: Golden, CO, USA, 2010.

- Winkelmann, L. Surface Roughness and Micropitting; National Renewable Energy Laboratory, Wind Turbine Tribology Seminar: Golden, CO, USA, 2011.

- Martins, R.; Locatelli, C.; Seabra, J. Evolution of tooth flank roughness during gear micropitting tests. Ind. Lubr. Tribol. 2011, 63, 34–45. [Google Scholar] [CrossRef]

- Brandão, J.; Seabra, J.; Castro, J. Surface initiated tooth flank damage: Part I: Numerical model. Wear 2010, 268, 1–12. [Google Scholar] [CrossRef]

- Brandão, J.; Seabra, J.; Castro, J. Surface initiated tooth flank damage. Part II: Prediction of micropitting initiation and mass loss. Wear 2010, 268, 13–22. [Google Scholar] [CrossRef]

- Whitby, R. Micropitting: An engineering or chemistry problem? Tribol. Lubr. Technol. 2004, 60, 56. [Google Scholar]

- Winter, H.; Oster, P. Influence of the Lubricant on Pitting and Micro Pitting (Grey Staining, Frosted Areas) Resistance of Case Carburized Gears: Test Procedures; American Gear Manufacturers Association: Alexandria, VI, USA, 1987. [Google Scholar]

- Brechot, P.; Cardis, A.; Murphy, W.; Theissen, J. Micropitting resistant industrial gear oils with balanced performance. Ind. Lubr. Tribol. 2000, 52, 125–136. [Google Scholar] [CrossRef]

- Sun, Y.; Bailey, R. Effect of sliding conditions on micropitting behaviour of AISI 304 stainless steel in chloride containing solution. Corros. Sci. 2018, 139, 197–205. [Google Scholar] [CrossRef]

- Way, S. Pitting due to rolling contact. J. Appl. Mech. 1935, 2, A49–A58. [Google Scholar]

- Dawson, P. Effect of metallic contact on the pitting of lubricated rolling surfaces. J. Mech. Eng. Sci. 1962, 4, 16–21. [Google Scholar] [CrossRef]

- Berthe, D.; Flamand, L.; Foucher, D.; Godet, M. Micropitting in Hertzian contacts. J. Lubr. Technol. 1980, 102, 478–489. [Google Scholar] [CrossRef]

- Snidle, R.; Evans, H. Elastohydrodynamics of gears. Tribol. Ser. 1997, 271–280. [Google Scholar] [CrossRef]

- Olver, A. Gear lubrication-a review. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2002, 216, 255–267. [Google Scholar] [CrossRef]

- Tallian, T. On competing failure modes in rolling contact. ASLE Trans. 1967, 10, 418–439. [Google Scholar] [CrossRef]

- ISO/TR 15144-1:2010 Calculation of Micropitting Load Capacity of Cylindrical Spur and Helical Gears-Part 1: Introduction and Basic Principles; ISO: Geneva, Switzerland, 2010.

- Höhn, B.-R.; Michaelis, K. Influence of oil temperature on gear failures. Tribol. Int. 2004, 37, 103–109. [Google Scholar] [CrossRef]

- Höhn, B.-R.; Oster, P.; Radev, T.; Steinberger, G.; Tobie, T. Improvement of standardized test methods for evaluating the lubricant influence on micropitting and pitting resistance of case carburized gears. In Proceedings of the AGMA Fall Technical Meeting, Orlando, FL, USA, 22–24 October 2006. [Google Scholar]

- Houser, D.; Shon, S. An Experimental Evaluation of the Procedures of the ISO/TR 15144 Technical Report for the Prediction of Micropitting. In Proceedings of the AGMA Fall Technical Meeting, Detroit, MI, USA, 2–4 October 2016. [Google Scholar]

- Long, H.; Al-Tubi, I.; Martineze, M. Analytical and Experimental Study of Gear Surface Micropitting due to Variable Loading. Appl. Mech. Mater. 2015, 750, 96–103. [Google Scholar] [CrossRef]

- Al-Tubi, I.; Long, H.; Zhang, J.; Shaw, B. Experimental and analytical study of gear micropitting initiation and propagation under varying loading conditions. Wear 2015, 328, 8–16. [Google Scholar] [CrossRef] [Green Version]

- ISO/TR 15144-1:2014 Calculation of Micropitting Load Capacity of Cylindrical Spur and Helical Gears-Introduction and Basic Principles; ISO: Geneva, Switzerland, 2014.

- Clarke, A.; Weeks, I.; Snidle, R.; Evans, H. Running-in and micropitting behaviour of steel surfaces under mixed lubrication conditions. Tribol. Int. 2016, 101, 59–68. [Google Scholar] [CrossRef] [Green Version]

- Jao, T.; Rollin, A.; Carter, R.; Aylott, C.; Shaw, B. Influence of Material Property on Micropitting and Pitting Behavior. In Proceedings of the World Tribology Congress III, Washington, DC, USA, 12–16 September 2005; Volume 2, pp. 103–104. [Google Scholar]

- Oila, A.; Bull, S. Phase transformations associated with micropitting in rolling/sliding contacts. J. Mater. Sci. 2005, 40, 4767–4774. [Google Scholar] [CrossRef]

- D’Errico, F. Micropitting Damage Mechanism on Hardened and Tempered, Nitrided, and Carburizing Steels. Mater. Manuf. Processes 2011, 26, 7–13. [Google Scholar] [CrossRef]

- Martins, R.; Seabra, J.; Magalhães, L. Micropitting of Austempered Ductile Iron Gears: Biodegradable Ester vs. Mineral Oil. Revista da Associação Portuguesa de Análise Experimental de Tensões 2006, 122, 922. [Google Scholar]

- Wilkinson, C.; Olver, A. The Durability of Gear and Disc Specimens-Part I: The Effect of Some Novel Materials and Surface Treatments. ASLE Trans. 1999, 42, 503–510. [Google Scholar] [CrossRef]

- Oila, A.; Shaw, B.; Aylott, C.; Bull, S. Martensite decay in micropitted gears. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2005, 219, 77–83. [Google Scholar] [CrossRef]

- Le, M.; Ville, F.; Kleber, X.; Cavoret, J.; Sainte-Catherine, M.; Briancon, L. Influence of grain boundary cementite induced by gas nitriding on the rolling contact fatigue of alloyed steels for gears. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 917–928. [Google Scholar] [CrossRef]

- Tobie, T.; Hippenstiel, F.; Mohrbacher, H. Optimizing gear performance by alloy modification of carburizing steels. Metals 2017, 7, 415. [Google Scholar] [CrossRef]

- Roy, S.; Ooi, G.; Sundararajan, S. Effect of retained austenite on micropitting behavior of carburized AISI 8620 steel under boundary lubrication. ACTA Mater. 2018, 3, 192–201. [Google Scholar] [CrossRef]

- Liu, S.; Song, C.; Zhu, C.; Ni, G. Effects of tooth modifications on mesh characteristics of crossed beveloid gear pair with small shaft angle. Mech. Mach. Theory 2018, 119, 142–160. [Google Scholar] [CrossRef]

- Kissling, U. Application of the first international calculation method for micropitting. Gear Technol. 2012, 29, 54–60. [Google Scholar]

- Predki, W.; Nazifi, K.; Lutzig, G. Micropitting of Big Gearboxes: Influence of Flank Modification and Surface Roughness. Gear Technol. 2011, 42–46. [Google Scholar]

- Li, S. An investigation on the influence of misalignment on micro-pitting of a spur gear pair. Tribol. Lett. 2015, 60, 35. [Google Scholar] [CrossRef]

- Weber, C.; Tobie, T.; Stahl, K. Investigation on the flank surface durability of gears with increased pressure angle. Forsch. Ingenieurwes 2017, 81, 207–213. [Google Scholar] [CrossRef]

- Ni, G.; Zhu, C.; Song, C.; Shi, J.; Liu, S. Effects of rack-cutter parabolic modification on loaded contact characteristics for crossed beveloid gears with misalignments. Int. J. Mech. Sci. 2018, 141, 359–371. [Google Scholar] [CrossRef]

- Liu, S.; Song, C.; Zhu, C.; Fan, Q. Concave modifications of tooth surfaces of beveloid gears with crossed axes. Proc. Inst. Mech. Eng. C J. Mech. 2018, 0954406218768842. [Google Scholar] [CrossRef]

- Clarke, A.; Evans, H.P.; Snidle, R. Understanding micropitting in gears. Proc. Inst. Mech. Eng. C J. Mech. 2016, 230, 1276–1289. [Google Scholar] [CrossRef]

- Bell, M.; Sroka, G.; Benson, R. The Effect of the Surface Roughness Profile on Micropitting. Gear Solutions, 8 March 2013; 46–53. [Google Scholar]

- Morales-Espejel, G.; Rycerz, P.; Kadiric, A. Prediction of micropitting damage in gear teeth contacts considering the concurrent effects of surface fatigue and mild wear. Wear 2018, 398, 99–115. [Google Scholar] [CrossRef]

- Evans, H.; Snidle, R.; Sharif, K.; Shaw, B.; Zhang, J. Analysis of micro-elastohydrodynamic lubrication and prediction of surface fatigue damage in micropitting tests on helical gears. J. Tribol. 2013, 135, 011501. [Google Scholar] [CrossRef]

- Sheng, L.; Ahmet, K. A physics-based model to predict micro-pitting lives of lubricated point contacts. Int. J. Fatigue 2013, 47, 205–215. [Google Scholar] [CrossRef]

- Li, S.; Kahraman, A. A micro-pitting model for spur gear contacts. Int. J. Fatigue 2014, 59, 224–233. [Google Scholar] [CrossRef]

- Li, S. A computational study on the influence of surface roughness lay directionality on micropitting of lubricated point contacts. J. Tribol. 2015, 137, 021401. [Google Scholar] [CrossRef]

- AL-Mayali, M.; Hutt, S.; Sharif, K.; Clarke, A.; Evans, H. Experimental and Numerical Study of Micropitting Initiation in Real Rough Surfaces in a Micro-elastohydrodynamic Lubrication Regime. Tribol. Lett. 2018, 66, 150. [Google Scholar] [CrossRef]

- Mallipeddi, D.; Norell, M.; Sosa, M.; Nyborg, L. The effect of manufacturing method and running-in load on the surface integrity of efficiency tested ground, honed and superfinished gears. Tribol. Int. 2019, 131, 277–287. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Q.; Liu, G. A versatile method of discrete convolution and FFT (DC-FFT) for contact analyses. Wear 2000, 243, 101–111. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Zhu, C.; Liu, M.; Song, C. Oil film stiffness and damping in an elastohydrodynamic lubrication line contact-vibration. J. Mech. Sci. Technol. 2016, 30, 3031–3039. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, C.; Liu, H.; Song, C.; Li, Z. A numerical study on the contact fatigue life of a coated gear pair under EHL. Ind. Lubr. Tribol. 2017, 70, 23–32. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, C.; Sun, Z.; Song, C. Starved lubrication of a spur gear pair. Tribol. Int. 2016, 94, 52–60. [Google Scholar] [CrossRef]

- Charkaluk, E.; Constantinescu, A.; Maïtournam, H.; Van, D. Revisiting the Dang Van criterion. Procedia Eng. 2009, 1, 143–146. [Google Scholar] [CrossRef] [Green Version]

- Osman, T.; Velex, P. A model for the simulation of the interactions between dynamic tooth loads and contact fatigue in spur gears. Tribol. Int. 2012, 46, 84–96. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Zhu, C.; He, H.; Wei, P. Evaluation of Contact Fatigue Life of a Wind Turbine Gear Pair Considering Residual Stress. J. Tribol. 2018, 140, 041102. [Google Scholar] [CrossRef]

- Wang, W.; Liu, H.; Zhu, C.; Du, X.; Tang, J. Effect of the residual stress on contact fatigue of a wind turbine carburized gear with multiaxial fatigue criteria. Int. J. Mech. Sci. 2019, 151, 263–273. [Google Scholar] [CrossRef]

- Hua, Q. Prediction of Contact Fatigue for the Rough Surface Elastohydrodynamic Lubrication Line Contact Problem under Rolling and Sliding Conditions. Ph.D. Thesis, Cardiff University, Wales, UK, 2005. [Google Scholar]

- Ciavarella, M.; Maitournam, H. On the Ekberg, Kabo and Andersson calculation of the Dang Van high cycle fatigue limit for rolling contact fatigue. Fatigue Fract. Eng. Mech. 2004, 27, 523–526. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Liu, H.; Zhu, C.; Sun, Z.; Wei, P. Study on contact fatigue of a wind turbine gear pair using the EHL model considering surface roughness. Friction, (accepted).

- Karpuschewski, B.; Knoche, H.; Hipke, M. Gear finishing by abrasive processes. CIRP Ann. Manuf. Technol. 2008, 57, 621–640. [Google Scholar] [CrossRef]

- Krantz, T.; Alanou, M.; Evans, H.; Snidle, R. Surface fatigue lives of case-carburized gears with an improved surface finish. J. Tribol. 2001, 123, 709–716. [Google Scholar] [CrossRef]

- Winkelmann, L.; El-Saeed, O.; Bell, M. The effect of superfinishing on gear micropitting. Gear Technol. 2009, 2, 60–65. [Google Scholar]

- Rabaso, P.; Gauthier, T.; Diaby, M.; Ville, F. Rolling Contact Fatigue: Experimental Study of the Influence of Sliding, Load, and Material Properties on the Resistance to Micropitting of Steel Discs. Tribol. Trans. 2013, 56, 203–214. [Google Scholar] [CrossRef]

- Shaikh, J.; Jain, N.; Venkatesh, V. Precision Finishing of Bevel Gears by Electrochemical Honing. Mater. Manuf. Processes 2013, 28, 1117–1123. [Google Scholar] [CrossRef]

- Ronkainen, H.; Elomaa, O.; Varjus, S.; Kilpi, L.; Jaatinen, T.; Koskinen, J. The influence of carbon based coatings and surface finish on the tribological performance in High-load contacts. Tribol. Int. 2016, 96, 402–409. [Google Scholar] [CrossRef]

- Pariente, I.F.; Guagliano, M. Influence of shot peening process on contact fatigue behavior of gears. Mater. Manuf. Processes 2009, 24, 1436–1441. [Google Scholar] [CrossRef]

- Moorthy, V.; Shaw, B. Effect of as-ground surface and the BALINIT® C and Nb–S coatings on contact fatigue damage in gears. Tribol. Int. 2012, 51, 61–70. [Google Scholar] [CrossRef]

- Widmark, M.; Melander, A. Effect of material, heat treatment, grinding and shot peening on contact fatigue life of carburised steels. Int. J. Fatigue 1999, 21, 309–327. [Google Scholar] [CrossRef]

- Terrin, A.; Meneghetti, G. A comparison of rolling contact fatigue behaviour of 17NiCrMo6-4 case-hardened disc specimens and gears. Fatigue Fract. Eng. Mach. 2018, 41, 2321–2337. [Google Scholar] [CrossRef]

- Pariente, I.; Guagliano, M. Contact fatigue damage analysis of shot peened gears by means of X-ray measurements. Eng. Fail. Anal. 2009, 16, 964–971. [Google Scholar] [CrossRef]

- Koenig, J.; Koller, P.; Tobie, T.; Stahl, K. Correlation of relevant case properties and the flank load carrying capacity of case-hardened gears. In Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015. [Google Scholar]

- Qin, H.; Ren, Z.; Zhao, J.; Ye, C.; Doll, G.; Dong, Y. Effects of ultrasonic nanocrystal surface modification on the wear and micropitting behavior of bearing steel in boundary lubricated steel-steel contacts. Wear 2017, 392, 29–38. [Google Scholar] [CrossRef]

- Krantz, T.; Cooper, C.; Townsend, D.; Hansen, B. Increased surface fatigue lives of spur gears by application of a coating. J. Mech. Des. 2004, 126, 1047–1054. [Google Scholar] [CrossRef]

- Vetter, J.; Barbezat, G.; Crummenauer, J.; Avissar, J. Surface treatment selections for automotive applications. Surf. Coat. Technol. 2005, 200, 1962–1968. [Google Scholar] [CrossRef]

- Martins, R.; Amaro, R.; Seabra, J. Influence of low friction coatings on the scuffing load capacity and efficiency of gears. Tribol. Int. 2008, 41, 234–243. [Google Scholar] [CrossRef]

- Bayón, R.; Zubizarreta, C.; Nevshupa, R.; Carlos Rodriguez, J.; Fernández, X.; Ruiz de Gopegui, U.; Igartua, A. Rolling-sliding, scuffing and tribocorrosion behaviour of PVD multilayer coatings for gears application. Ind. Lubr. Tribol. 2011, 63, 17–26. [Google Scholar] [CrossRef]

- Moorthy, V.; Shaw, B. Contact fatigue performance of helical gears with surface coatings. Wear 2012, 276–277, 130–140. [Google Scholar] [CrossRef]

- Moorthy, V.; Shaw, B. An observation on the initiation of micro-pitting damage in as-ground and coated gears during contact fatigue. Wear 2013, 297, 878–884. [Google Scholar] [CrossRef]

- Singh, H.; Ramirez, G.; Eryilmaz, O.; Greco, A.; Doll, G.; Erdemir, A. Fatigue resistant carbon coatings for rolling/sliding contacts. Tribol. Int. 2016, 98, 172–178. [Google Scholar] [CrossRef] [Green Version]

- Benedetti, M.; Fontanari, V.; Torresani, E.; Girardi, C.; Giordanino, L. Investigation of lubricated rolling sliding behaviour of WC/C, WC/C-CrN, DLC based coatings and plasma nitriding of steel for possible use in worm gearing. Wear 2017, 378, 106–113. [Google Scholar] [CrossRef]

- Olver, A. The mechanism of rolling contact fatigue: An update. Proc. Inst. Mech. Eng. J J. Eng. Tribol. 2005, 219, 313–330. [Google Scholar] [CrossRef]

- Fajdiga, G.; Flašker, J.; Glodež, S.; Hellen, T. Numerical modelling of micro-pitting of gear teeth flanks. Fatigue Fract. Eng. Mach. 2003, 26, 1135–1143. [Google Scholar] [CrossRef]

- Webster, M.; Norbart, C. An Experimental Investigation of Micropitting Using a Roller Disk Machine. ASLE Trans. 1995, 38, 883–893. [Google Scholar] [CrossRef]

- Moallem, H.; Akbarzadeh, S.; Ariaei, A. Prediction of micropitting life in spur gears operating under mixed-lubrication regime using load-sharing concept. Proc. Inst. Mech. Eng. J J. Eng. Tribol. 2016, 230, 591–599. [Google Scholar] [CrossRef]

- Mallipeddi, D.; Norell, M.; Sosa, M.; Nyborg, L. Influence of running-in on surface characteristics of efficiency tested ground gears. Tribol. Int. 2017, 115, 45–58. [Google Scholar] [CrossRef] [Green Version]

- An, S.; Lee, S.; Son, J.; Cho, Y. New Approach for Prediction of Non-Conformal Contact Fatigue Life Considering Lubrication Performance Parameters. J. Frict. Wear 2017, 38, 419–423. [Google Scholar] [CrossRef]

- Brown, M.; Miller, K. A theory for fatigue failure under multiaxial stress-strain conditions. Proc. Inst. Mech. Eng. 1973, 187, 745–755. [Google Scholar] [CrossRef]

- Kadiric, A.; Rycerz, P. Influence of Contact Conditions on the Onset of Micropitting in Rolling-Sliding Contacts Pertinent to Gear Applications. Gear Solutions, 17 February 2017; 45–53. [Google Scholar]

- Martins, R.; Seabra, J.; Magalhães, L. Austempered ductile iron (ADI) gears: Power loss, pitting and micropitting. Wear 2008, 264, 838–849. [Google Scholar] [CrossRef]

- Morales-Espejel, G.; Gabelli, A. The Progression of Surface Rolling Contact Fatigue Damage of Rolling Bearings with Artificial Dents. Tribol. Trans. 2015, 58, 418–431. [Google Scholar] [CrossRef]

- Zhou, R.; Cheng, H.; Mura, T. Micropitting in rolling and sliding contact under mixed lubrication. J. Tribol. 1989, 111, 605–613. [Google Scholar] [CrossRef]

- Errichello, R. Morphology of micropitting. Gear Technol. 2012, 4, 74–81. [Google Scholar]

- Sanekata, J.; Koga, N.; Umezawa, O. Effects of Slip Ratio on Damage and Microcracks in Carburized SCM420 Steel under Rolling Contact Fatigue. Key Eng. Mater. 2017, 741, 94–98. [Google Scholar] [CrossRef]

- Cen, H.; Morina, A.; Neville, A. Effect of slide to roll ratio on the micropitting behaviour in rolling-sliding contacts lubricated with ZDDP-containing lubricants. Tribol. Int. 2018, 122, 210–217. [Google Scholar] [CrossRef]

- Flodin, A.; Andersson, S. A simplified model for wear prediction in helical gears. Wear 2001, 249, 285–292. [Google Scholar] [CrossRef]

- Krantz, T.; Kahraman, A. An experimental investigation of the influence of the lubricant viscosity and additives on gear wear. Tribol. Trans. 2005, 21, 138–148. [Google Scholar] [CrossRef]

- Brandão, J.; Martins, R.; Seabra, J.; Castro, M. Calculation of gear tooth flank surface wear during an FZG micropitting test. Wear 2014, 311, 31–39. [Google Scholar] [CrossRef]

- Al-Mayali, M.; Evans, H.; Sharif, K. Assessment of the effects of residual stresses on fatigue life of real rough surfaces in lubricated contact. In Proceedings of the International Conference for Students on Applied Engineering, Newcastle, UK, 20–21 October 2016; pp. 123–128. [Google Scholar]

- Janakiraman, V. An Investigation of the Impact of Contact Parameters on the Wear Coefficient. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2013. [Google Scholar]

- Liu, H.; Liu, H.; Zhu, C.; Tang, J. Study on contact fatigue failure competitive mechanism of a wind turbine gear pair considering tooth wear evolution. J. Tribol. (under review).

- Winter, H.; Oster, P. Influence of lubrication on pitting and micropitting resistance of gears. Gear Technol. 1990, 7, 16–23. [Google Scholar]

- Morales-Espejel, G.; Brizmer, V.; Piras, E. Roughness evolution in mixed lubrication condition due to mild wear. Proc. Inst. Mech. Eng. J J. Eng. Tribol. 2015, 229, 1330–1346. [Google Scholar] [CrossRef]

- Vrcek, A.; Hultqvist, T.; Baubet, Y.; Björling, M.; Marklund, P.; Larsson, R. Micro-pitting and wear assessment of engine oils operating under boundary lubrication conditions. Tribol. Int. 2019, 129, 338–346. [Google Scholar] [CrossRef]

- Lainé, E.; Olver, A.; Beveridge, T. Effect of lubricants on micropitting and wear. Tribol. Int. 2008, 41, 1049–1055. [Google Scholar] [CrossRef]

- Van-Rensselar, J. Trends in industrial gear oils. Tribol. Lubr. Technol. 2013, 69, 26–33. [Google Scholar]

- Errichello, R. Selecting and applying lubricants to avoid micropitting of gear teeth. Mach. Lubr. 2002, 2, 30–36. [Google Scholar]

- Martins, R.; Seabra, J. Micropitting performance of mineral and biodegradable ester gear oils. Ind. Lubr. Tribol. 2008, 60, 286–292. [Google Scholar] [CrossRef]

- Cardoso, R.; Martins, C.; Seabra, O.; Igartua, A.; Rodríguez, C.; Luther, R. Micropitting performance of nitrided steel gears lubricated with mineral and ester oils. Tribol. Int. 2009, 42, 77–87. [Google Scholar] [CrossRef]

- Lainé, E.; Olver, A.; Lekstrom, M.; Shollock, B.; Beveridge, T.; Hua, D. The Effect of a Friction Modifier Additive on Micropitting. Tribol. Trans. 2009, 52, 526–533. [Google Scholar] [CrossRef]

- De la Guerra Ochoa, E.; Otero, J.E.; Tanarro, E.C.; Munoz-Guijosa, J.; del Rio Lopez, B.; Cordero, C.A. Analysis of the effect of different types of additives added to a low viscosity polyalphaolefin base on micropitting. Wear 2015, 322, 238–250. [Google Scholar] [CrossRef]

- Soltanahmadi, S.; Morina, A.; van Eijk, M.C.; Nedelcu, I.; Neville, A. Investigation of the effect of a diamine-based friction modifier on micropitting and the properties of tribofilms in rolling-sliding contacts. J. Phys. D Appl. Phys. 2016, 49, 505302. [Google Scholar] [CrossRef] [Green Version]

- Engelhardt, C.; Witzig, J.; Tobie, T.; Stahl, K. Influence of water contamination in gear lubricants on wear and micro-pitting performance of case carburized gears. Ind. Lubr. Tribol. 2017, 69, 612–619. [Google Scholar] [CrossRef]

- Ward, W.; O’connor, B.; Vinci, J. Lubricants That Decrease Micropitting for Industrial Gears. U.S. Patent Application 11/866,696, 9 April 2009. [Google Scholar]

- Fu, X.; Hua, X.; Zhang, J. Industrial Gear Lubricating Oil Composition Used for Resisting Micro-Pitting. U.S. Patent 9,347,016, 24 May 2016. [Google Scholar]

- Moss, J.; Kahraman, A.; Wink, C. An Experimental Study of Influence of Lubrication Methods on Efficiency and Contact Fatigue Life of Spur Gears. J. Tribol. 2018, 140, 051103. [Google Scholar] [CrossRef]

- Seireg, A. Thermal stress effects on the surface durability of gear teeth. Proc. Inst. Mech. Eng. C J. Mech. 2001, 215, 973–979. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, C.; Gould, B.; Demas, N.; Liu, H.; Greco, A. The effect of contact severity on micropitting: simulation and experiments. Tribol. Int. (under review).

- Morales-Espejel, G.; Brizmer, V. Micropitting Modelling in Rolling–Sliding Contacts: Application to Rolling Bearings. Tribol. Trans. 2011, 54, 625–643. [Google Scholar] [CrossRef]

- Archard, F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Brizmer, V.; Pasaribu, H.; Morales-Espejel, G. Micropitting Performance of Oil Additives in Lubricated Rolling Contacts. Tribol. Trans. 2013, 56, 739–748. [Google Scholar] [CrossRef]

- Benyajati, C.; Olver, A.; Hamer, C. An experimental study of micropitting using a new miniature test-rig. Tribol. Ser. 2003, 43, 601–610. [Google Scholar]

- O’connor, B. The influence of additive chemistry on micropitting. Gear Technol. 2005, 22, 34–41. [Google Scholar]

- Yang, Q. Fatigue test and reliability design of gears. Int. J. Fatigue 1996, 18, 171–177. [Google Scholar] [CrossRef]

- Li, F.; Hu, W.; Meng, Q.; Zhan, Z.; Shen, F. A new damage-mechanics-based model for rolling contact fatigue analysis of cylindrical roller bearing. Tribol. Int. 2017, 120, 105–114. [Google Scholar] [CrossRef]

- Weibring, M.; Gondecki, L.; Tenberge, P. Simulation of fatigue failure on tooth flanks in consideration of pitting initiation and growth. Tribol. Int. 2019, 131, 299–307. [Google Scholar] [CrossRef]

- Wang, W.; Liu, H.; Zhu, C.; Wei, P.; Tang, J. Effects of microstructure on rolling contact fatigue of a wind turbine gear based on crystal plasticity modeling. Int. J. Fatigue 2019, 120, 73–86. [Google Scholar] [CrossRef]

- Rajinikanth, V.; Soni, M.K.; Mahato, B.; Rao, M.A. Study of microstructural degradation of a failed pinion gear at a cement plant. Eng. Fail. Anal. 2019, 95, 117–126. [Google Scholar] [CrossRef]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Teeth Number | Z1 =121, Z2 = 24 | Pressure Angle | α0 = 20° |

| Normal Module | m0 = 0.011 m | Helix Angle | β0 = 12° |

| Shifting Coefficients | x1 = 0.034, x2 = 0.4 | Contact Tooth Width | B = 0.295 m |

| Poisson’s Ratio of Materials | v1,2 = 0.3 | Young’s Modulus | E1,2 = 2.10 × 1011 Pa |

| Transverse Pressure Angle | αt = 20.41° | Tip Clearance Coefficient | c* = 0.4 |

| Reference Input Torque of the Gear Pair | Tref = 241000 N m | Reference Input Speed of the Gear Pair | Nref = 64.8 rpm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Liu, H.; Zhu, C.; Zhou, Y. A Review on Micropitting Studies of Steel Gears. Coatings 2019, 9, 42. https://doi.org/10.3390/coatings9010042

Liu H, Liu H, Zhu C, Zhou Y. A Review on Micropitting Studies of Steel Gears. Coatings. 2019; 9(1):42. https://doi.org/10.3390/coatings9010042

Chicago/Turabian StyleLiu, Huaiju, Heli Liu, Caichao Zhu, and Ye Zhou. 2019. "A Review on Micropitting Studies of Steel Gears" Coatings 9, no. 1: 42. https://doi.org/10.3390/coatings9010042

APA StyleLiu, H., Liu, H., Zhu, C., & Zhou, Y. (2019). A Review on Micropitting Studies of Steel Gears. Coatings, 9(1), 42. https://doi.org/10.3390/coatings9010042