New EV Battery Charger PFC Rectifier Front-End Allowing Full Power Delivery in 3-Phase and 1-Phase Operation

Abstract

:1. Introduction

- Reduced development effort since only a single product needs to be designed and tested.

- Product certification, e.g., as described in [3], which often is a time-consuming process for automotive supply equipment, needs to be conducted for only one product instead of two.

- Reduction of the number of different components, in particular magnetic components.

- Only a single production line is needed to manufacture the EV charger.

2. Modifications for 1-Phase Operation

- Dc-side unfolder (passive diode bridge-leg) for the return current.

- Dc-side relay to enable dc-side CM filtering with a CM filter capacitor for 1-phase and 3-phase operation.

- Modified EMI filter: 4-phase CM chokes; no CM chokes in the filter stages directly connected to the switching stage.

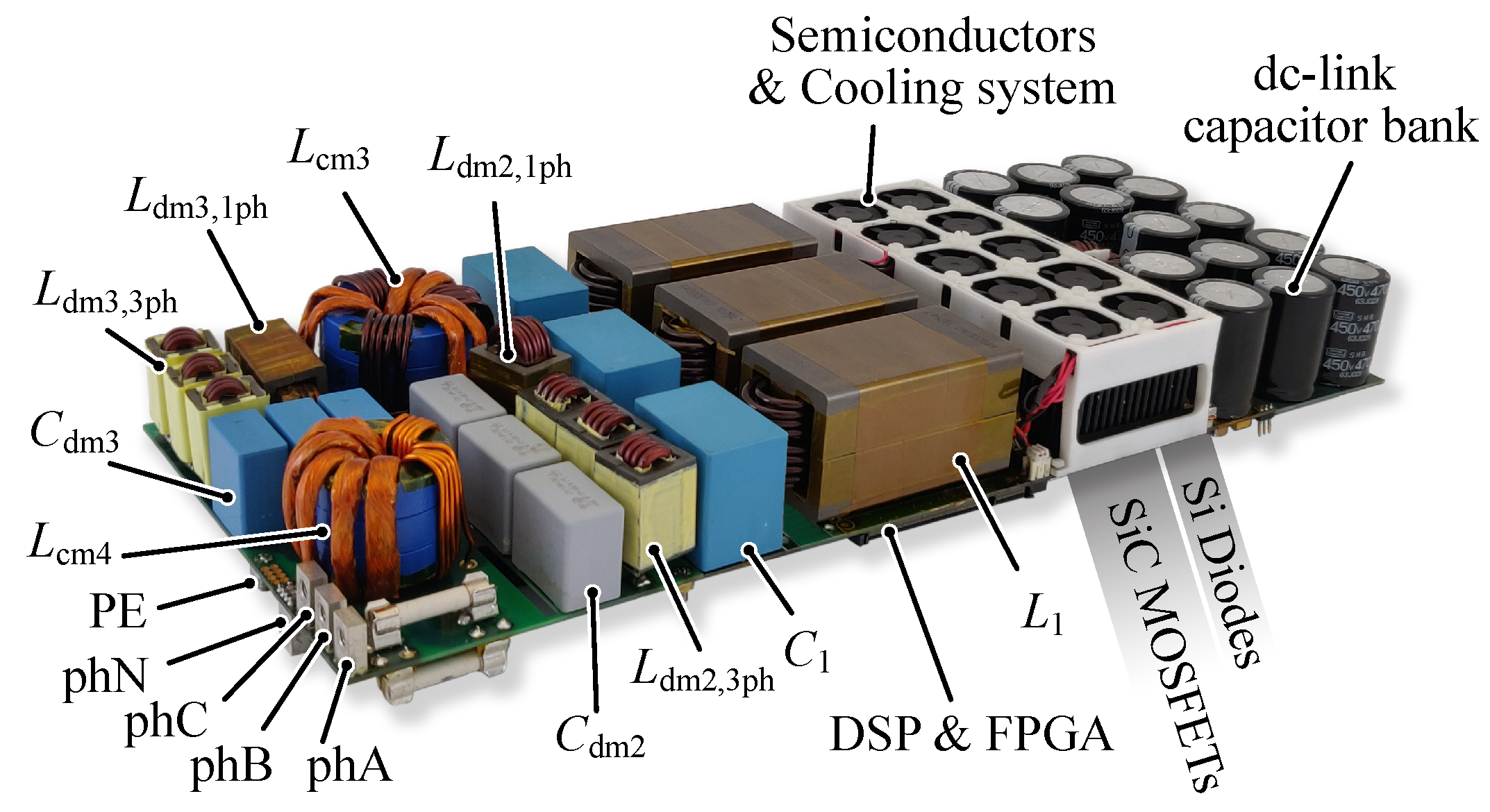

3. Design of Main Power Stage

3.1. Switching Frequency and Current Ripple

3.2. Power Components

4. Generated EMI Noise and Filtering

4.1. Conducted EMI for 3-Phase Operation

4.2. Conducted EMI of 1-Phase Operation

4.3. Basic Design Guideline for the EMI Filter

4.4. Experimental Evaluation of the EMI Filter

5. Experimental Results

- The influence of the switched currents on the switching speeds of the employed SiC MOSFETs, in particular during turn-off [49]. With increasing currents, the switching speeds increase and, with this, the EMI noise in the higher frequency ranges also increases. With regard to the setup at hand, a worst-case scenario with constant rise and fall times of 20 ns for all drain-source voltages during switching has been considered. With this, the envelope of the simulated EMI noise spectrum decays with dB/decade for .

- The inductors, which are realized with powder cores, feature inductances that decrease with increasing currents. Accordingly, the efficacy of the filter decreases for higher inductor currents [50].

- The HF current components in the commutation loops depend on the load current and the associated magnetic fields can lead to induced voltages in the EMI filter components that increase the EMI noise.

- Increased power leads to increased temperatures of the EMI filter components. However, this effect is disregarded, as the resulting tolerances are below 5%.

5.1. 3-Phase Operation

5.2. 1-Phase Operation

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Asymmetric Construction of the 4-Phase CM Choke: Implications on Stray Inductance

- Three inductances of phase a:

- (a)

- For phase b being shorted:

- (b)

- For phase c being shorted:

- (c)

- For phases b and c being shorted:

- Three inductances of phase b for separate and simultaneous short-circuits across phases a and c: , , and .

| Constr. | Phase | Condition | Variable | Sim. | Meas. |

|---|---|---|---|---|---|

| Figure 4a | a | shorted b | 3.87 H | 4.41 H | |

| shorted c | 5.02 H | 6.20 H | |||

| shorted b, c | 3.40 H | 4.03 H | |||

| b | shorted a | 3.98 H | 4.43 H | ||

| shorted c | 3.98 H | 4.38 H | |||

| shorted a, c | 2.70 H | 2.95 H | |||

| Figure 4b | a | shorted b | 4.71 H | 5.86 H | |

| shorted c | 4.71 H | 6.01 H | |||

| shorted b, c | 3.53 H | 4.52 H | |||

| b | shorted a | 4.71 H | 6.00 H | ||

| shorted c | 4.71 H | 5.80 H | |||

| shorted a, c | 3.53 H | 4.40 H |

Appendix B. Analysis of Power Components’ Stresses

Appendix B.1. 3-Phase Operation

Appendix B.1.1. Semiconductors

Appendix B.1.2. Boost Inductor

Appendix B.2. 1-Phase Operation

Appendix B.2.1. Semiconductors and Boost Inductor

Appendix B.2.2. Electrolytic Capacitors of the Dc-Link

Appendix B.3. 1-Phase Operation at Half Dc-Link Voltage

| 375 V | 66 W | 38 W | 72 W | 5.6 W | 0.6 W | 5.3 W | 15 W |

| 750 V | 66 W | 101 W | 72 W | 5.6 W | 2.9 W | 22.1 W | 15 W |

Appendix C. Extension to Three-Level Converters with Inherent Utilization of the Dc Midpoint

- Three-level operation for 3-phase mains connection (middle leg enabled, ).

- Two-level operation for 1-phase ac input (middle leg disabled, ).

- A relay circuit for series/parallel reconfiguration of the dc-link capacitors and the subsequent dc/dc converters is provided.

- The middle power switches of the T-type converter are connected to the switch-node of the diode rectifier, O’, as the electrical potential of O’ is always defined (the node O is floating during 1-phase operation).

References

- Plugs, Socket-Outlets, Vehicle Connectors and Vehicle Inlets—Conductive Charging of Electric Vehicles. IEC 62196.

- SAE Surface Vehicle Recommended Practice J1772, SAE Electric Vehicle Conductive Charge Coupler. SAE J1772.

- Byczek, R. EVSE Testing and Global Certifications—What Manufacturers Need to Know. Available online: https://www.intertek.com/blog/2020-10-02-evse/ (accessed on 17 August 2021).

- PFM-Isolated & Regulated Converter with PFC for AC–DC Systems. Available online: http://www.vicorpower.com/ac-dc/converters/isolated-ac-dc-converter-pfc (accessed on 22 December 2020).

- Schmenger, J.; Endres, S.; Zeltner, S.; März, M. A 22 kW on-board charger for automotive applications based on a modular design. In Proceedings of the IEEE Conference on Energy Conversion (CENCON), Johor Bahru, Malaysia, 13–14 October 2014. [Google Scholar] [CrossRef]

- Lu, J.; Bai, K.; Taylor, A.R.; Liu, G.; Brown, A.; Johnson, P.M.; McAmmond, M. A modular-designed three-phase high-efficiency high-power-density EV battery charger using dual/triple-phase-shift control. IEEE Trans. Power Electron. 2018, 33, 8091–8100. [Google Scholar] [CrossRef]

- Yoo, K.; Kim, K.; Lee, J. Single- and three-phase PHEV onboard battery charger using small link capacitor. IEEE Trans. Ind. Electron. 2013, 60, 3136–3144. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, C.; Lei, B.; Teng, H.; Bai, H.K.; Kirtley, J.L. Power-loss analysis and efficiency maximization of a silicon-carbide MOSFET-based three-phase 10-kW bidirectional EV charger using variable-DC-bus control. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 880–892. [Google Scholar] [CrossRef]

- Zhao, H.; Shen, Y.; Ying, W.; Ghosh, S.S.; Ahmed, M.R.; Long, T. A single- and three-phase grid compatible converter for electric vehicle on-board chargers. IEEE Trans. Power Electron. 2020, 35, 7545–7562. [Google Scholar] [CrossRef]

- BRUSA Elektronik AG. NLG664-On Board Fast Charger. NLG664 Datasheet. 2018. Available online: https://www.brusa.biz/wp-content/uploads/2021/03/BRUSA_DB_EN_NLG664.pdf (accessed on 26 August 2021).

- Stengert, K. On-board 22 kW fast charger ‘NLG6’. In Proceedings of the World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–20 November 2013. [Google Scholar]

- Papamanolis, P.; Krismer, F.; Kolar, J.W. 22 kW EV battery charger allowing full power delivery in 3-phase as well as 1-phase operation. In Proceedings of the IEEE International Conference on Power Electronics (ICPE-ECCE Asia), Busan, Korea, 27–31 May 2019. [Google Scholar] [CrossRef]

- Gong, X.; Wang, G.; Bhardwaj, M. 6.6 kW three-phase interleaved totem pole PFC design with 98.9% peak efficiency for HEV/EV onboard charger. In Proceedings of the Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 17–21 March 2019. [Google Scholar] [CrossRef]

- Kolar, J.W.; Drofenik, U.; Miniböck, J.; Ertl, H. A new concept for minimizing high-frequency common-mode EMI of three-phase PWM rectifier systems keeping high utilization of the output voltage. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition sition (APEC), New Orleans, LA, USA, 6–10 February 2000. [Google Scholar] [CrossRef]

- Dong, D.; Zhang, X.; Luo, F.; Boroyevich, D.; Mattavelli, P. Common-mode EMI noise reduction for grid-interface converter in low-voltage DC distribution system. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Orlando, FL, USA, 5–9 February 2012. [Google Scholar] [CrossRef]

- Hartmann, M.; Ertl, H.; Kolar, J.W. EMI filter design for a 1 MHz, 10 kW three-phase/level PWM rectifier. IEEE Trans. Power Electron. 2011, 26, 1192–1204. [Google Scholar] [CrossRef]

- Shi, K.; Shoyama, M.; Tomioka, S. Common mode noise reduction in totem-pole bridgeless PFC converter. In Proceedings of the IEEE International Power Electronics and Application Conference and Exposition (PEAC), Shanghai, China, 5–8 November 2014. [Google Scholar] [CrossRef]

- Zhang, B.; Lin, Q.; Imaoka, J.; Shoyama, M.; Tomioka, S.; Takegami, E. Conducted noise prediction for zero-crossing issue in totem-pole bridgeless PFC converter. In Proceedings of the IEEE International Telecommunications Energy Conference (INTELEC), Broadbeach, Australia, 22–26 October 2017. [Google Scholar] [CrossRef]

- Qu, S.; Chen, D. Mixed-mode EMI noise and its implications to filter design in offline switching power supplies. IEEE Trans. Power Electron. 2002, 17, 502–507. [Google Scholar] [CrossRef]

- Jin, M.; Weiming, M. A new technique for modeling and analysis of mixed-mode conducted EMI noise. IEEE Trans. Power Electron. 2004, 19, 1679–1687. [Google Scholar] [CrossRef]

- Kolar, J.W.; Krismer, F.; Lobsiger, Y.; Muhlethaler, J.; Nussbaumer, T.; Minibock, J. Extreme efficiency power electronics. In Proceedings of the IEEE International Conference on Integrated Power Electronics Systems (CIPS), Nuremberg, Germany, 6–8 March 2012. [Google Scholar]

- Boillat, D.O.; Krismer, F.; Kolar, J.W. Optimization and comparative evaluation of multiloop control schemes for controllable ac sources with two-stage LC output filters. IEEE Trans. Power Electron. 2016, 31, 7353–7368. [Google Scholar] [CrossRef]

- Krismer, F.; Böhler, J.; Kolar, J.W.; Pammer, G. New series-resonant solid-state DC transformer providing three self-stabilized isolated medium-voltage input ports. In Proceedings of the International Conference on Power Electronics (ICPE-ECCE Asia), Busan, Korea, 27–30 May 2019. [Google Scholar]

- Papamanolis, P.; Guillod, T.; Krismer, F.; Kolar, J.W. Minimum loss operation and optimal design of high-frequency inductors for defined core and litz wire. IEEE Open J. Power Electron. 2020, 1, 469–487. [Google Scholar] [CrossRef]

- Kanyakam, S.; Bureerat, S. Multiobjective optimization of a pin-fin heatsink using evolutionary algorithms. J. Electron. Packag. 2012, 134, 021008. [Google Scholar] [CrossRef]

- Thermal Resistance Calculator—Round Pin Heat Sink. Available online: https://myheatsinks.com/calculate/thermal-resistance-round-pin/ (accessed on 8 May 2021).

- Infineon Technologies AG. Comprehensive Solutions for Fast EV Charging Design 2019. Available online: https://infineoncommunity.com/register_for_ev_charging_whitepaper_presentation_ID1048?ic=00d1003 (accessed on 20 June 2021).

- Heldwein, M.L. EMC Filtering of Three-Phase PWM Converters. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2008. [Google Scholar]

- Xie, Y.; Chen, C.; Huang, Z.; Liu, T.; Kang, Y.; Luo, F. High frequency conducted EMI investigation on packaging and modulation for a SiC-based high frequency converter. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 1789–1804. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, S. A survey of EMI research in power electronics systems with wide-bandgap semiconductor devices. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 626–643. [Google Scholar] [CrossRef]

- Ye, H.; Yang, Z.; Dai, J.; Yan, C.; Xin, X.; Ying, J. Common mode noise modeling and analysis of dual boost PFC circuit. In Proceedings of the IEEE International Telecommunications Energy Conference (INTELEC), Chicago, IL, USA, 19–23 September 2004. [Google Scholar] [CrossRef]

- Wang, S.; Kong, P.; Lee, F.C. Common Mode Noise Reduction for Boost Converters Using General Balance Technique. IEEE Trans. Power Electron. 2007, 22, 1410–1416. [Google Scholar] [CrossRef]

- Boillat, D.O.; Krismer, F.; Kolar, J.W. EMI filter volume minimization of a three-phase, three-level T-type PWM converter system. IEEE Trans. Power Electron. 2017, 32, 2473–2480. [Google Scholar] [CrossRef]

- Heldwein, M.L.; Nussbaumer, T.; Kolar, J.W. Differential mode EMC input filter design for three-phase ac-dc-ac sparse matrix PWM converters. In Proceedings of the IEEE Power Electronics Specialists Conference (PESC), Aachen, Germany, 20–25 June 2004. [Google Scholar]

- Silva, M.; Hensgens, N.; Oliver, J.; Alou, P.; García, Ó.; Cobos, J.A. New considerations in the input filter design of a three-phase buck-type PWM rectifier for aircraft applications. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE USA), Phoenix, AZ, USA, 17–22 September 2011. [Google Scholar]

- West, R. Common Mode Inductors for EMI Filters Require Careful Attention to core Material Selection. PCIM Mag. 1995. Available online: https://elnamagnetics.com/wp-content/uploads/library/Magnetics-Documents/Common_Mode_Inductors_for_EMI_Filters_Require_Careful_Attention_to_Core_Material_Selection.pdf (accessed on 15 May 2021).

- Wang, S.; Lee, F.C.; Chen, D.Y.; Odendaal, W.G. Effects of parasitic parameters on EMI filter performance. IEEE Trans. Power Electron. 2004, 19, 869–877. [Google Scholar] [CrossRef]

- Rossetto, L.; Buso, S.; Spiazzi, G. Conducted EMI issues in a 600-W single-phase boost PFC design. IEEE Trans. Ind. Appl. 2000, 36, 578–585. [Google Scholar] [CrossRef] [Green Version]

- Agilent 4294A—Precision Impedance Analyzer 40 Hz to 110 MHz. Available online: http://literature.cdn.keysight.com/litweb/pdf/5968-3808E.pdf (accessed on 16 October 2020).

- Wang, R.; Boroyevich, D.; Blanchette, H.F.; Mattavelli, P. High power density EMI filter design with consideration of self-parasitic. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Orlando, FL, USA, 5–9 February 2012. [Google Scholar] [CrossRef]

- Vector Network Analyzer. Available online: https://www.picotest.com/images/download/Bode-100_Product_Brochure_V7-2002.pdf (accessed on 22 December 2020).

- Wang, R.; Fortin Blanchette, H.; Mu, M.; Boroyevich, D.; Mattavelli, P. Influence of high-frequency near-field coupling between magnetic components on EMI filter design. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013. [Google Scholar] [CrossRef]

- Wang, S.; Lee, F.; Odendaal, W. Improving the performance of boost PFC EMI filters. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Miami Beach, FL, USA, 9–13 February 2003. [Google Scholar] [CrossRef]

- Bishnoi, H.; Mattavelli, P.; Burgos, R.; Boroyevich, D. EMI behavioral models of DC-fed three-phase motor drive systems. IEEE Trans. Power Electron. 2014, 29, 4633–4645. [Google Scholar] [CrossRef]

- Sun, B.; Burgos, R.; Boroyevich, D. Common-mode EMI unterminated behavioral model of wide-bandgap-based power converters operating at high switching frequency. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 2561–2570. [Google Scholar] [CrossRef]

- R & S ESPI Test Receiver. Available online: https://www.rohde-schwarz.com/us/product/espi-productstartpage_63493-8645.html?change_c=true (accessed on 22 December 2020).

- R & S ENV216 Two-Line V-Network. Available online: https://www.rohde-schwarz.com/us/product/env216-productstartpage_63493-9775.html?change_c=true (accessed on 22 December 2020).

- Laird, I.; Yuan, X.; Scoltock, J.; Forsyth, A.J. A design optimization tool for maximizing the power density of 3-phase DC–AC converters using silicon carbide (SiC) devices. IEEE Trans. Power Electron. 2018, 33, 2913–2932. [Google Scholar] [CrossRef] [Green Version]

- Charalambous, A.; Yuan, X.; McNeill, N. High-frequency EMI attenuation at source with the auxiliary commutated pole inverter. IEEE Trans. Power Electron. 2018, 33, 5660–5676. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; See, K.Y.; Tseng, K.J. Conducted EMI prediction of the PFC converter including nonlinear behavior of boost inductor. IEEE Trans. Electromagn. Compat. 2013, 55, 1107–1114. [Google Scholar] [CrossRef]

- Ibuchi, T.; Kamikomaki, R.; Funaki, T. Experimental evaluation on time variation of conducted noise spectrum for a PFC converter. In Proceedings of the International Symposium on Electromagnetic Compatibility, Tokyo, Japan, 12–16 May 2014. [Google Scholar] [CrossRef]

- HDO6104A. Available online: https://teledynelecroy.com/oscilloscope/hdo6000a-high-definition-oscilloscopes/hdo6104a (accessed on 22 December 2020).

- Zhu, K.; O’Grady, M.; Dodge, J.; Bendel, J.; Hostetler, J. 1.5 kW single phase CCM totem-pole PFC using 650V SiC cascodes. In Proceedings of the IEEE Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Fayetteville, AR, USA, 7–9 November 2016. [Google Scholar] [CrossRef]

- Sun, J.; Strain, N.N.; Costinett, D.J.; Tolbert, L.M. Analysis of a GaN-based CRM totem-pole PFC converter considering current sensing delay. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE USA), Baltimore, MD, USA, 29 September–3 October 2019. [Google Scholar] [CrossRef]

- De Gusseme, K.; de Sype, D.; Van den Bossche, A.; Melkebeek, J. Sample correction for digitally controlled boost PFC converters operating in both CCM and DCM. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Miami Beach, FL, USA, 9–13 February 2003. [Google Scholar] [CrossRef] [Green Version]

- De Gusseme, K.; Van de Sype, D.; Van den Bossche, A.; Melkebeek, J. Digital control of boost PFC converters operating in both continuous and discontinuous conduction mode. In Proceedings of the IEEE Power Electronics Specialists Conference (PESC), Aachen, Germany, 20–25 June 2004. [Google Scholar] [CrossRef]

- Mohan, N.; Undeland, T.M.; Robbins, W.P. Power Electronics: Converters, Applications, and Design, 3rd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2002. [Google Scholar]

- Deboy, G.; Haeberlen, O.; Treu, M. Perspective of loss mechanisms for silicon and wide band-gap power devices. IEEE CPSS Trans. Power Electron. Appl. 2017, 2, 89–100. [Google Scholar] [CrossRef]

- Krismer, F.; Hatipoglu, E.; Kolar, J.W. Novel isolated bidirectional integrated dual three-phase active bridge (D3AB) PFC rectifier. In Proceedings of the IEEE International Power Electronics Conference (IPEC-ECCE Asia), Niigata, Japan, 20–24 May 2018. [Google Scholar] [CrossRef]

- McLyman, C. Transformer and Inductor Design Handbook; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Leibl, M. Three-Phase PFC Rectifier and High-Voltage Generator for X-ray Systems. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2017. [Google Scholar]

- Albach, M.; Durbaum, T.; Brockmeyer, A. Calculating core losses in transformers for arbitrary magnetizing currents—A comparison of different approaches. In Proceedings of the IEEE Power Electronics Specialists Conference (PESC), Baveno, Italy, 23–27 June 1996. [Google Scholar] [CrossRef]

- Leicht, J.; Moses, A.; Zurek, S. Hysteresis loss component under non-sinusoidal flux waveforms. J. Magn. Magn. Mater. 2008, 320, e608–e610. [Google Scholar] [CrossRef]

- Azurza, J.A.; Zulauf, G.; Papamanolis, P.; Hobi, S.; Mirić, S.; Kolar, J.W. Three levels are not enough: Scaling laws for multilevel converters in AC/DC applications. IEEE Trans. Power Electron. 2021, 36, 3967–3986. [Google Scholar] [CrossRef]

- Chen, J.; Wang, C. Topology and voltage-balance control of a single-phase double T-type seven-level inverter. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 1075–1087. [Google Scholar] [CrossRef]

| Parameter | Description | 3-Phase | 1-Phase |

|---|---|---|---|

| Nominal power | 22 kW | 19.2 kW | |

| Grid input voltage (rms) | 230 V | 240 V | |

| Grid input current (rms) | 32 A | 80 A | |

| Phase current (rms) | 32 A | 26.67 A | |

| Grid frequency | 50 Hz | 60 Hz | |

| Output voltage | 750 V | 750 V | |

| Switching frequency | 48 kHz | ||

| Parameter | Description | 3-Phase | 1-Phase |

|---|---|---|---|

| rms value of | 32 A | 27 A | |

| average value of | 29 A | 24 A | |

| peak value of | 50 A | 57 A | |

| rms value of the HF components of | 5.1 A | 6.0 A | |

| rms value of the LF current in the dc-link cap. | 18 A |

| Parameter | Value |

|---|---|

| Power MOSFETs (per switch) | two parallel C2M0040120D devices (Wolfspeed/Cree) |

| Power diodes (per diode) | three parallel VS-80APF10 devices (Vishay) |

| Boost inductors | summarized in Table 4 |

| Dc-link capacitors | 14 ESMR451VSN471MR40S devices ( parallel) (450 V, 470 , at 60 C, rated at |

| Parameter | Value |

|---|---|

| Magnetic core | KoolMu () E 40/20 |

| Number of turns (N) | 15 |

| Initial inductance () | 170 H |

| Inductance at peak current () | 80 H |

| Core volume () | |

| Core cross section () | |

| Area of the core window () | |

| Height of the core window () | 29.8 mm |

| Average turn length () | 214.3 mm |

| Copper fill factor () | 55% |

| Conductor diameter () | 3.0 mm |

| Steinmetz par. (, , ) |

| Parameter | Description | 3-Phase | 1-Phase |

|---|---|---|---|

| MOSFET cond. losses | 94.7 W | 66.3 W | |

| MOSFET switch. losses | 119.6 W | 101.3 W | |

| Diode cond. losses | - | 71.7 W | |

| Boost induct. LF copper losses | 8.0 W | 5.6 W | |

| Boost induct. HF copper losses | 2.1 W | 2.9 W | |

| Boost induct. core losses | 16.5 W | 22.1 W | |

| dc-link cap. losses | - | 15 W |

| Source | Operation | CISPR Freq. (kHz) | Max Noise (dBV) | Filter Att. (dB) | Class B Limit (dBV) |

|---|---|---|---|---|---|

| 3-phase | 192 | 162 | 116 | 63.9 | |

| 3-phase | 192 | 118 | 71 | ||

| 1-phase | 288 | 162.3 | 150 | 60.3 | |

| 1-phase | 288 | 126 | 73 |

| Parameter | Description | Value |

|---|---|---|

| Inductance of 1st filter stage | ||

| Capacitance of 1st filter stage | ||

| DM filter ind., 2nd filter stage | ||

| DM filter cap., 2nd filter stage | ||

| DM filter ind., 3rd filter stage | ||

| DM filter cap., 3rd filter stage | ||

| CM filter ind., 3rd filter stage | () | |

| CM filter cap., 3rd filter stage | ||

| CM filter ind., 4th filter stage | () | |

| CM filter cap., dc-side | ||

| Capacitor of split dc-link |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papamanolis, P.; Bortis, D.; Krismer, F.; Menzi, D.; Kolar, J.W. New EV Battery Charger PFC Rectifier Front-End Allowing Full Power Delivery in 3-Phase and 1-Phase Operation. Electronics 2021, 10, 2069. https://doi.org/10.3390/electronics10172069

Papamanolis P, Bortis D, Krismer F, Menzi D, Kolar JW. New EV Battery Charger PFC Rectifier Front-End Allowing Full Power Delivery in 3-Phase and 1-Phase Operation. Electronics. 2021; 10(17):2069. https://doi.org/10.3390/electronics10172069

Chicago/Turabian StylePapamanolis, Panteleimon, Dominik Bortis, Florian Krismer, David Menzi, and Johann Walter Kolar. 2021. "New EV Battery Charger PFC Rectifier Front-End Allowing Full Power Delivery in 3-Phase and 1-Phase Operation" Electronics 10, no. 17: 2069. https://doi.org/10.3390/electronics10172069