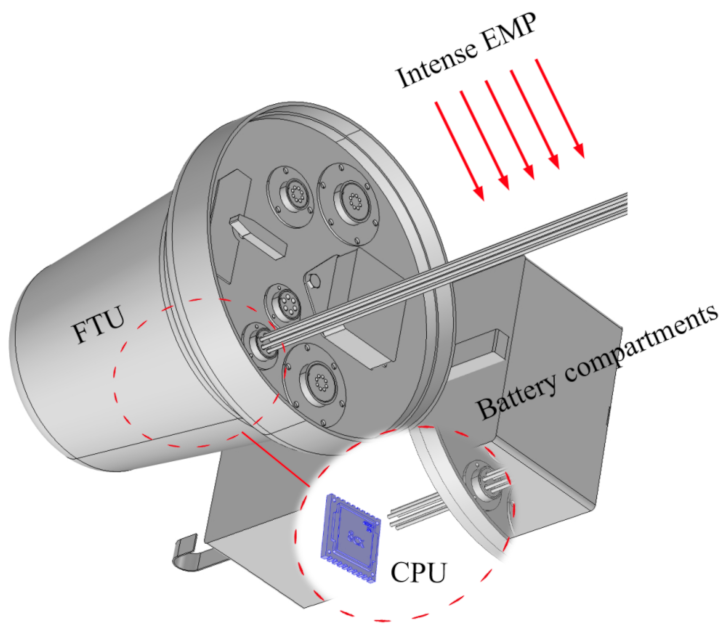

Electromagnetic-Thermal Analysis of FTU under the High-Power Electromagnetic Environment

Abstract

:1. Introduction

2. Methodology

3. Analysis of the Electromagnetic–Thermal Effect of the FTU

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FTU | Feeder Terminal Unit |

| HPEM | High-Power Electromagnetic |

| EMP | Electromagnetic Pulses |

| EMC | Electromagnetic Compatibility |

| CPU | Central Processing Unit |

| IEC | International Electrotechnical Commission |

References

- Hu, H.M.; Shi, Y.J.; Zhang, Y.H.; Fu, Y.L. Study on Power Supply of the Feeder Terminal Equipment. Appl. Mech. Mater. 2014, 672–674, 914–919. [Google Scholar] [CrossRef]

- Kizu, K.; Murakami, H.; Natsume, K.; Tsuchiya, K.; Koide, Y.; Yoshida, K.; Obana, T.; Hamaguchi, S.; Takahata, K. Manufacturing design and development of the current feeders and coil terminal boxes for JT-60SA. Fusion Eng. Des. 2015, 98–99, 1094–1097. [Google Scholar] [CrossRef]

- Han, G.Z. Harmonization of Feeder Terminal Unit Information Model Based on IEC 61850 and IEC 61968/61970. Appl. Mech. Mater. 2013, 411–414, 1787–1790. [Google Scholar] [CrossRef]

- Li, E.P. Electrical Modeling and Design for 3D Integration: 3D Integrated Circuits and Packaging. In Signal Integrity Power Integrity and EMC; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Zeng, K.; Jiao, D. Matrix-free method for transient maxwell-thermal cosimulation in arbitrary unstructured meshes. IEEE Trans. Microw. Theory Tech. 2018, 66, 5439–5448. [Google Scholar] [CrossRef]

- Xie, J.; Xie, B.; Swaminathan, M. Electrical-thermal modeling of through-silicon via (TSV) arrays in interposer. Int. J. Numer. Model. Electron. Netw. Devices Fields 2013, 26, 545–559. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, W.; Chen, A.; Zhang, Y.; Li, M. A co-simulation method based on coupled thermoelectric model for electrical and thermal behavior of the lithium-ion battery. IEEE Access 2019, 7, 180727–180737. [Google Scholar] [CrossRef]

- Xie, J.; Swaminathan, M. Fast electrical-thermal co-simulation using multigrid method for 3D integration. In Proceedings of the IEEE 62nd Electronic Components and Technology Conference, San Diego, CA, USA, 29 May–1 June 2012; pp. 651–657. [Google Scholar]

- Liu, E.X. Multi-physics modeling of through-silicon vias with equivalent-circuit approach. In Proceedings of the IEEE Conference Electrical Performance of Electronic Packaging and Systems (EPEPS), Austin, TX, USA, 25–27 October 2010; pp. 33–36. [Google Scholar]

- Dong, Y.; Tang, M.; Li, P.; Mao, J. Transient Electromagnetic-Thermal Simulation of Dispersive Media Using DGTD Method. IEEE Trans. Electromagn. Compat. 2019, 61, 1305–1313. [Google Scholar] [CrossRef]

- Chen, P.Y.; Zhang, H.H.; Sha, W.E.I.; Ding, D.Z. Transient Electromagnetic-thermal Co-Simulation Based on DGTD Method. In Proceedings of the 2019 International Applied Computational Electromagnetics Society Symposium, Nanjing, China, 8–11 August 2019; pp. 1–2. [Google Scholar]

- Zhang, H.-X.; Huang, L.; Wang, W.-J.; Zhao, Z.-J.; Zhou, L.; Chen, W.; Zhou, H.; Zhan, Q.; Kolundzija, B.; Yin, W.-Y. Massively Parallel Electromagnetic–Thermal Cosimulation of Large Antenna Arrays. IEEE Antennas Wirel. Propag. Lett. 2020, 19, 1551–1555. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, J.; Li, J.; Xu, W. A Study on the Electromagnetic-Thermal Coupling Effect of Cross-Slot Frequency Selective Surface. Materials 2022, 15, 640. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Wang, X.; Si, L.; Gong, J. Numerical simulation of 3D electromagnetic-thermal phenomena in an induction heated slab. J. Iron Steel Res. Int. 2020, 27, 420–432. [Google Scholar] [CrossRef]

- Tan, E.L.; Heh, D.Y. Stability analyses of nonuniform time-step LOD-FDTD methods for electromagnetic and thermal simulations. IEEE J. Multiscalemultiphys. Comput. Techn. 2017, 2, 183–193. [Google Scholar] [CrossRef]

- Lu, T.; Jin, J.-M. Electrical-thermal co-simulation for analysis of high-power RF/Microwave components. IEEE Trans. Electromagn. Compat. 2017, 59, 93–102. [Google Scholar] [CrossRef]

- Xue, Y.; Mi, J.; Wen, P.; Ren, Q.; Zhou, Y. Efficient Transient Thermal Analysis Based on Spectral Element Time Domain Method with Curvilinear Hexahedrons. Int. J. Numer. Model. El. 2021, 34, e2814. [Google Scholar] [CrossRef]

- Xie, J.; Swaminathan, M. Electrical-thermal cosimulation with non-conformal domain decomposition method for multiscale 3-D integrated systems. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 588–601. [Google Scholar] [CrossRef]

- Lu, T.; Jin, J.-M. Electrical-thermal co-simulation for DC IR-drop analysis of large-scale power delivery. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 323–331. [Google Scholar] [CrossRef]

- Lu, T.; Jin, J.-M. Thermal-aware high-frequency characterization of large-scale through-silicon-via structures. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 1015–1025. [Google Scholar] [CrossRef]

- Xue, Y.; Ren, Q.; Chen, J.; Zhou, Y. Transient Electromagnetic-Thermal Cosimulation for Micrometer-Level Components. IEEE Trans. Microw. Theory Techn. 2021, 69, 4341–4351. [Google Scholar] [CrossRef]

- Giri, D.V.; Hoad, R.; Sabath, F. High-Power Electromagnetic Effects on Electronic Systems; Artech: Tuen Mun, Hong Kong, China, 2020. [Google Scholar]

- Giri, D.V.; Tesche, F.M.; Baum, C.E. An overview of high-power electromagnetic (HPEM) radiating and conducting systems. URSI Radio Sci. Bull. 2006, 2006, 6–12. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, D.; Chen, Y.; Wang, Y.; Zhao, Y.; Fu, Z.; Du, J.; Wang, L.; Cheng, R.; Zhen, Y.; Zhang, H.; et al. Electromagnetic-Thermal Analysis of FTU under the High-Power Electromagnetic Environment. Electronics 2022, 11, 2528. https://doi.org/10.3390/electronics11162528

Zhao D, Chen Y, Wang Y, Zhao Y, Fu Z, Du J, Wang L, Cheng R, Zhen Y, Zhang H, et al. Electromagnetic-Thermal Analysis of FTU under the High-Power Electromagnetic Environment. Electronics. 2022; 11(16):2528. https://doi.org/10.3390/electronics11162528

Chicago/Turabian StyleZhao, Dongyan, Yanning Chen, Yubo Wang, Yang Zhao, Zhen Fu, Jian Du, Licheng Wang, Ruiqi Cheng, Yan Zhen, Haifeng Zhang, and et al. 2022. "Electromagnetic-Thermal Analysis of FTU under the High-Power Electromagnetic Environment" Electronics 11, no. 16: 2528. https://doi.org/10.3390/electronics11162528

APA StyleZhao, D., Chen, Y., Wang, Y., Zhao, Y., Fu, Z., Du, J., Wang, L., Cheng, R., Zhen, Y., Zhang, H., Zhou, Y., & Ren, Q. (2022). Electromagnetic-Thermal Analysis of FTU under the High-Power Electromagnetic Environment. Electronics, 11(16), 2528. https://doi.org/10.3390/electronics11162528