Predictive Maintenance System for Wafer Transport Robot Using K-Means Algorithm and Neural Network Model

Abstract

:1. Introduction

2. Background

3. Method

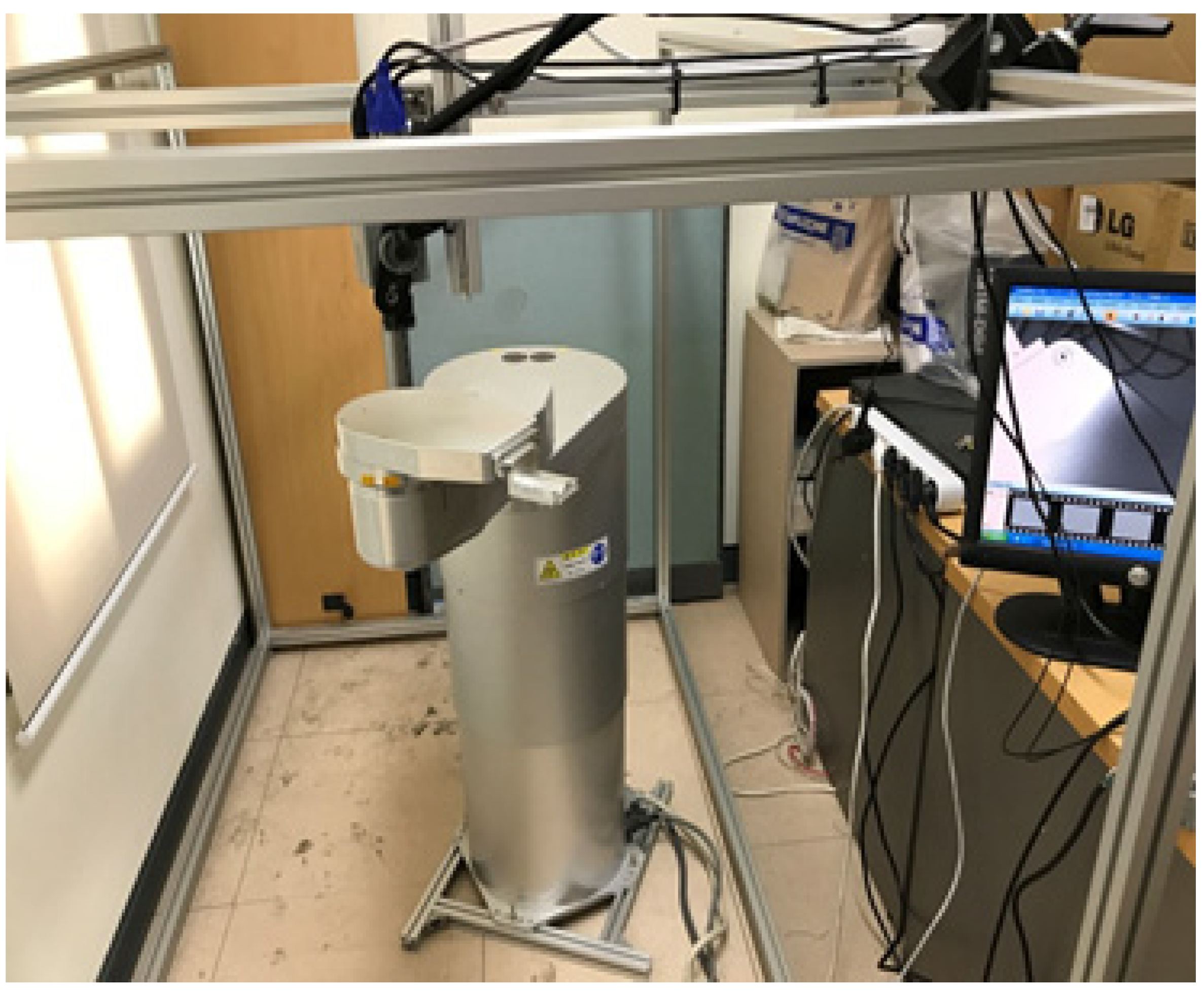

3.1. Equipment Setup

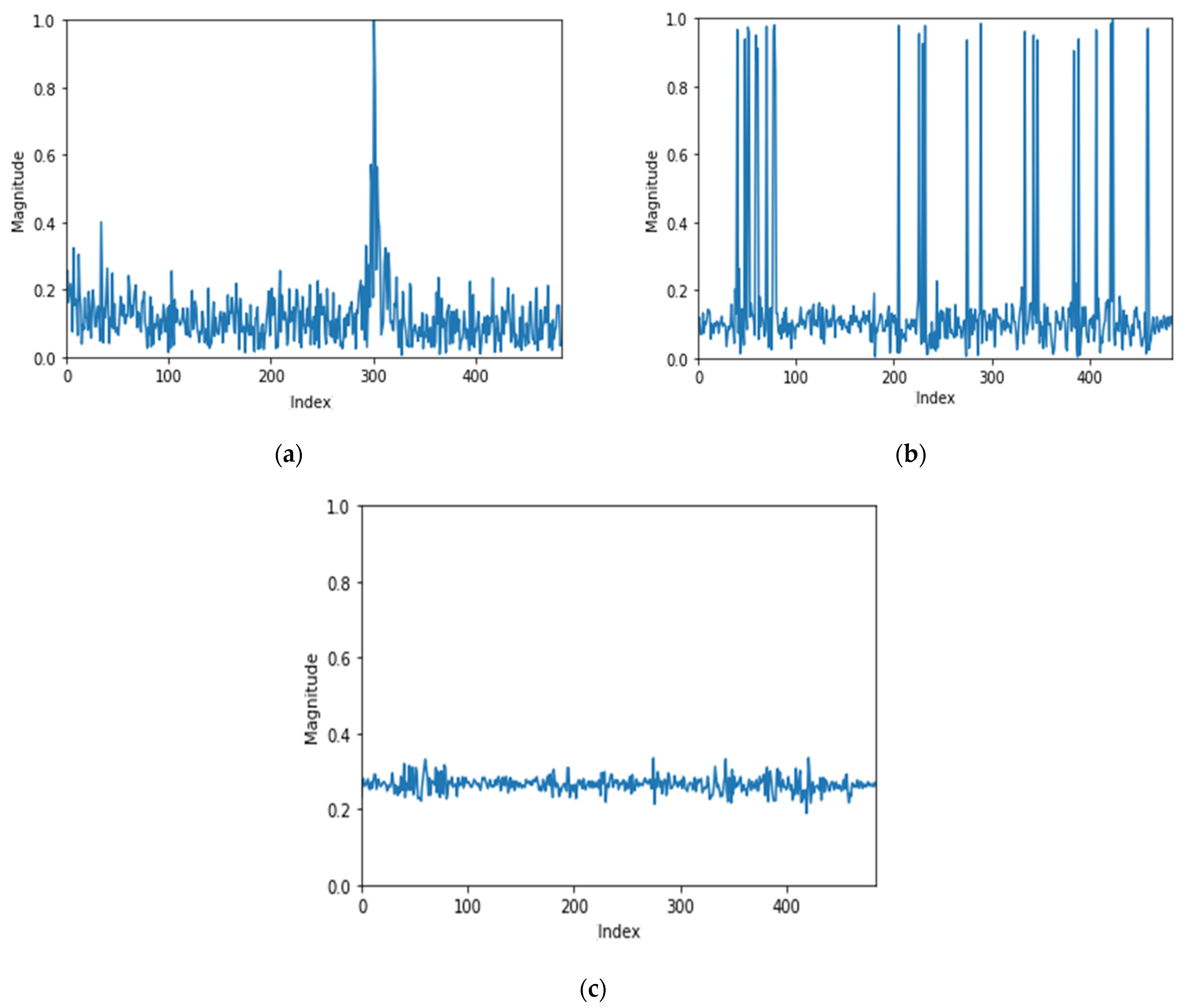

3.2. Data Acquisition Method

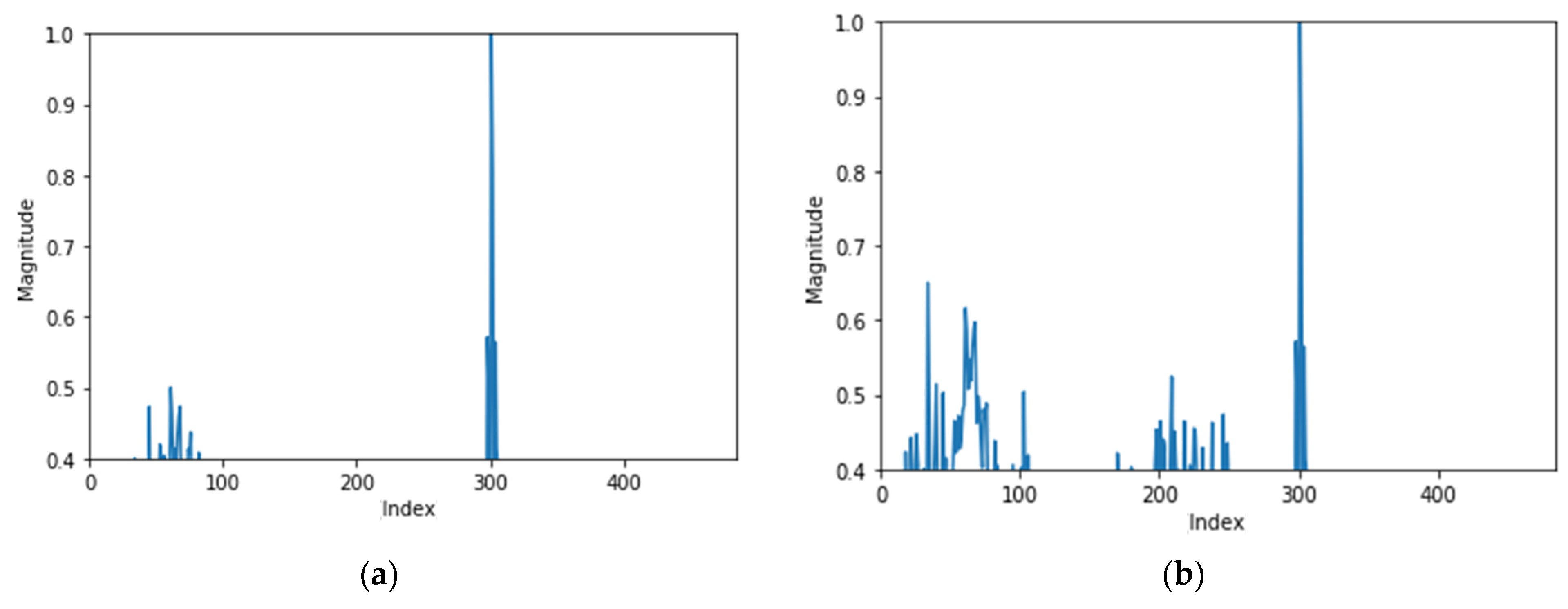

3.3. Data Preprocessing

3.4. Error Data Generation

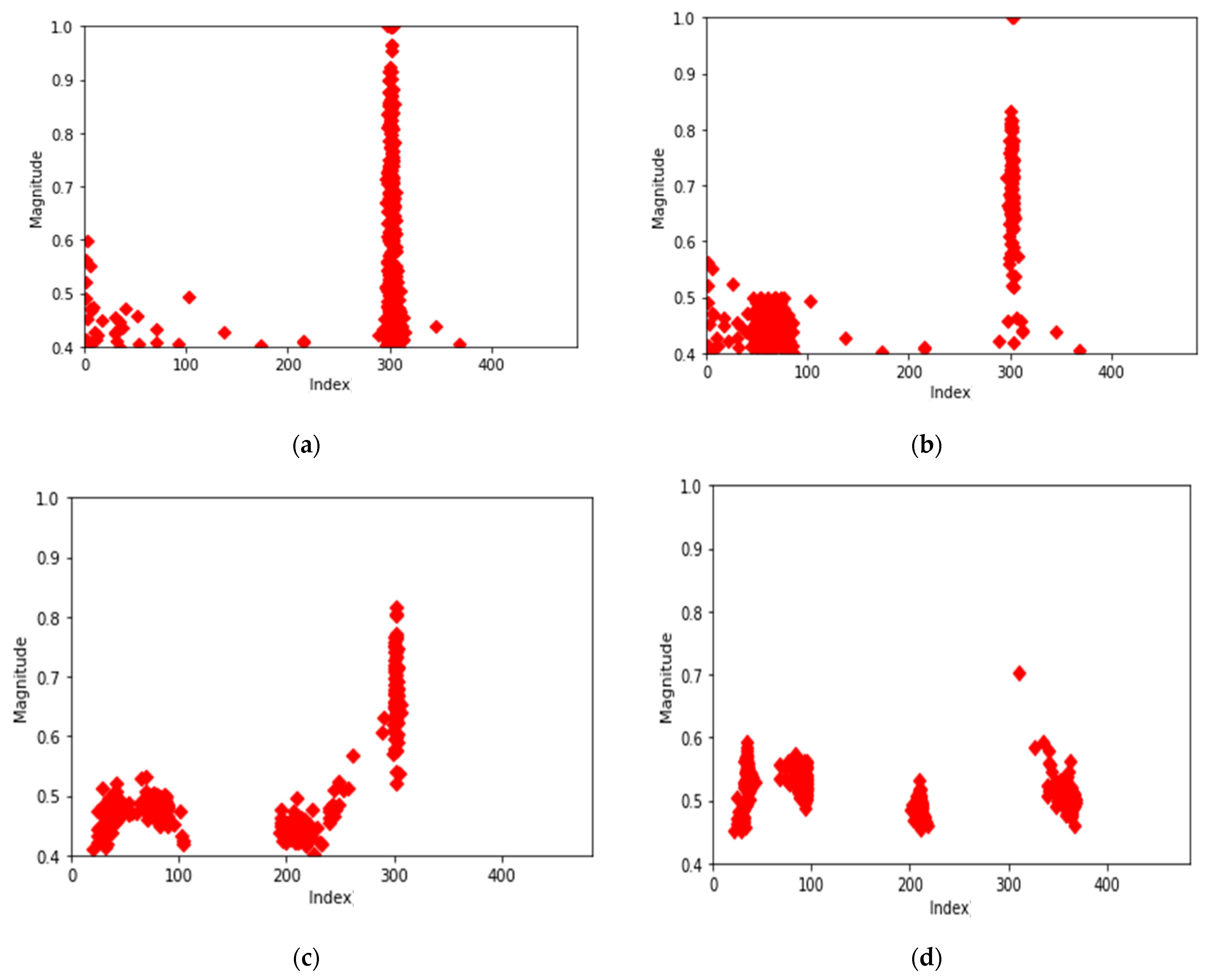

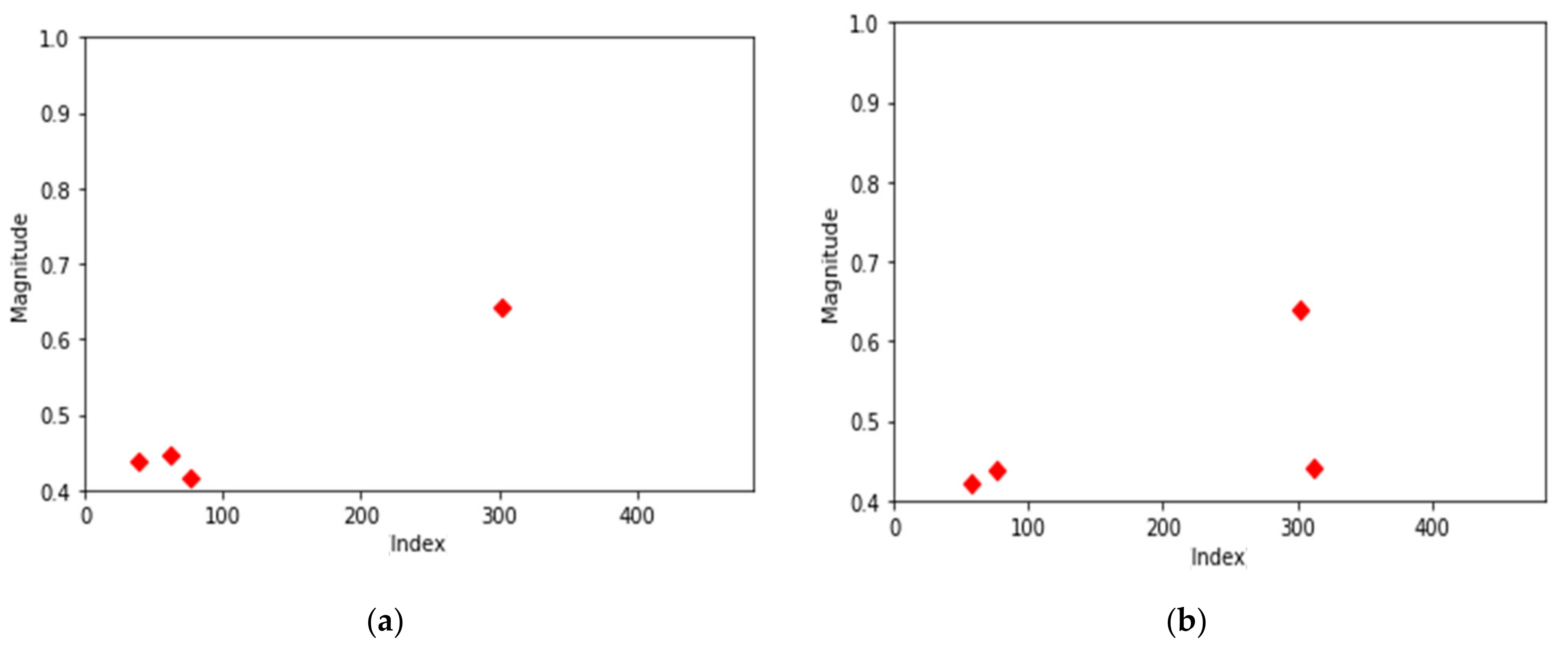

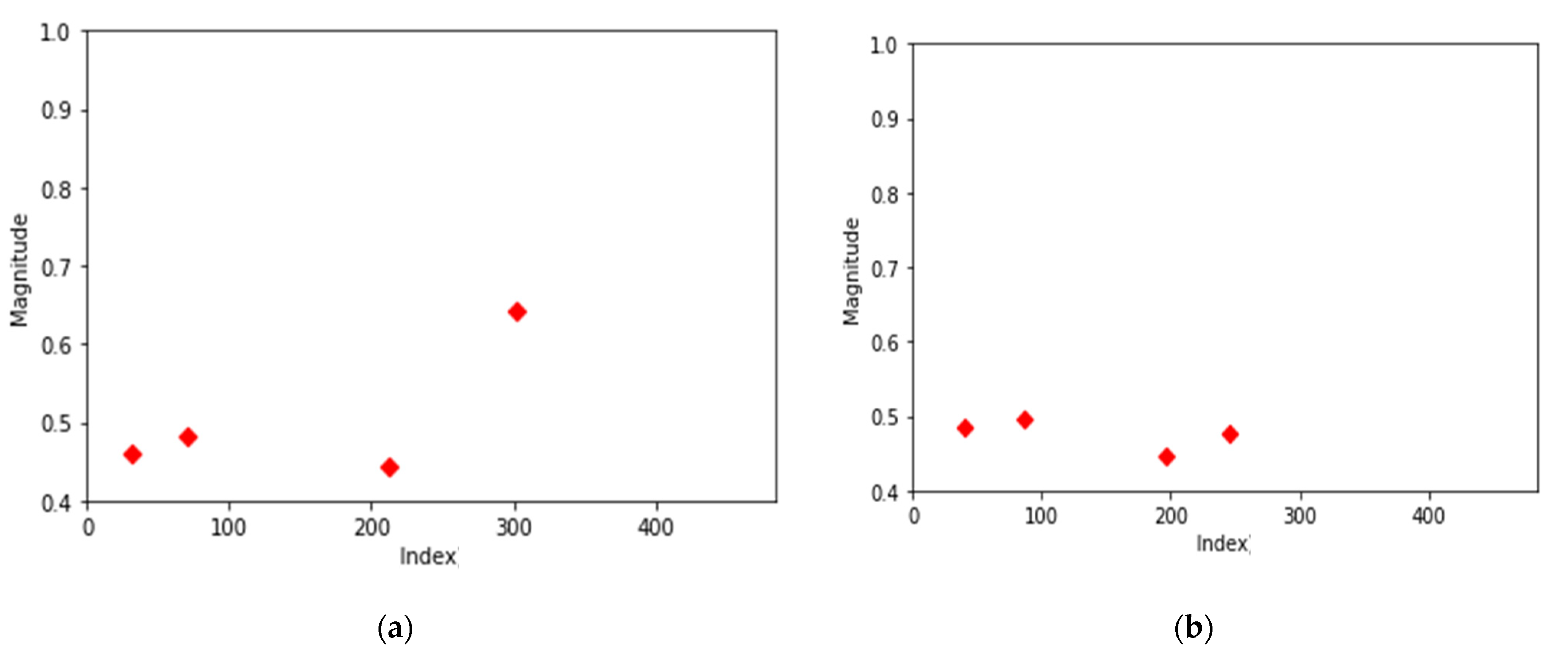

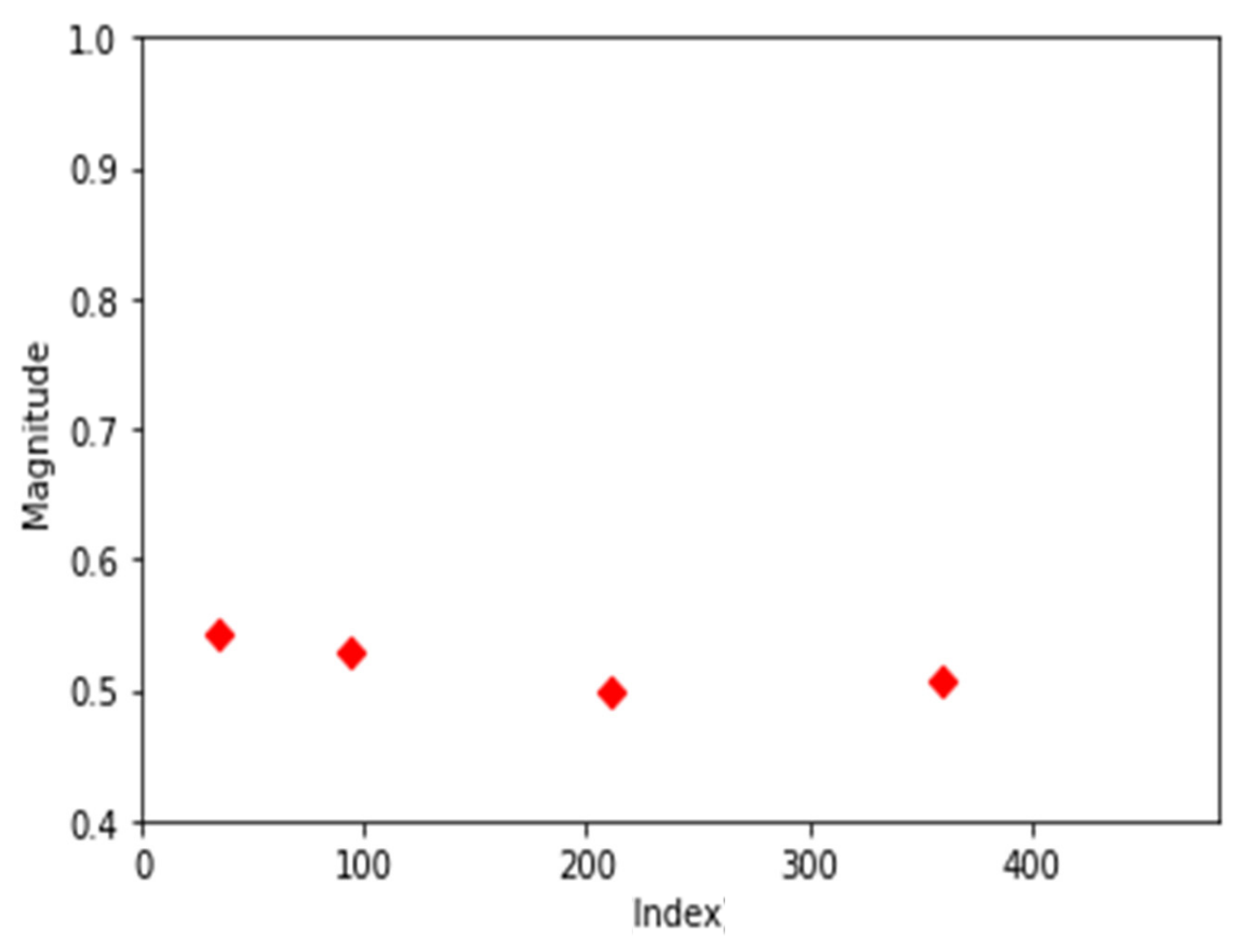

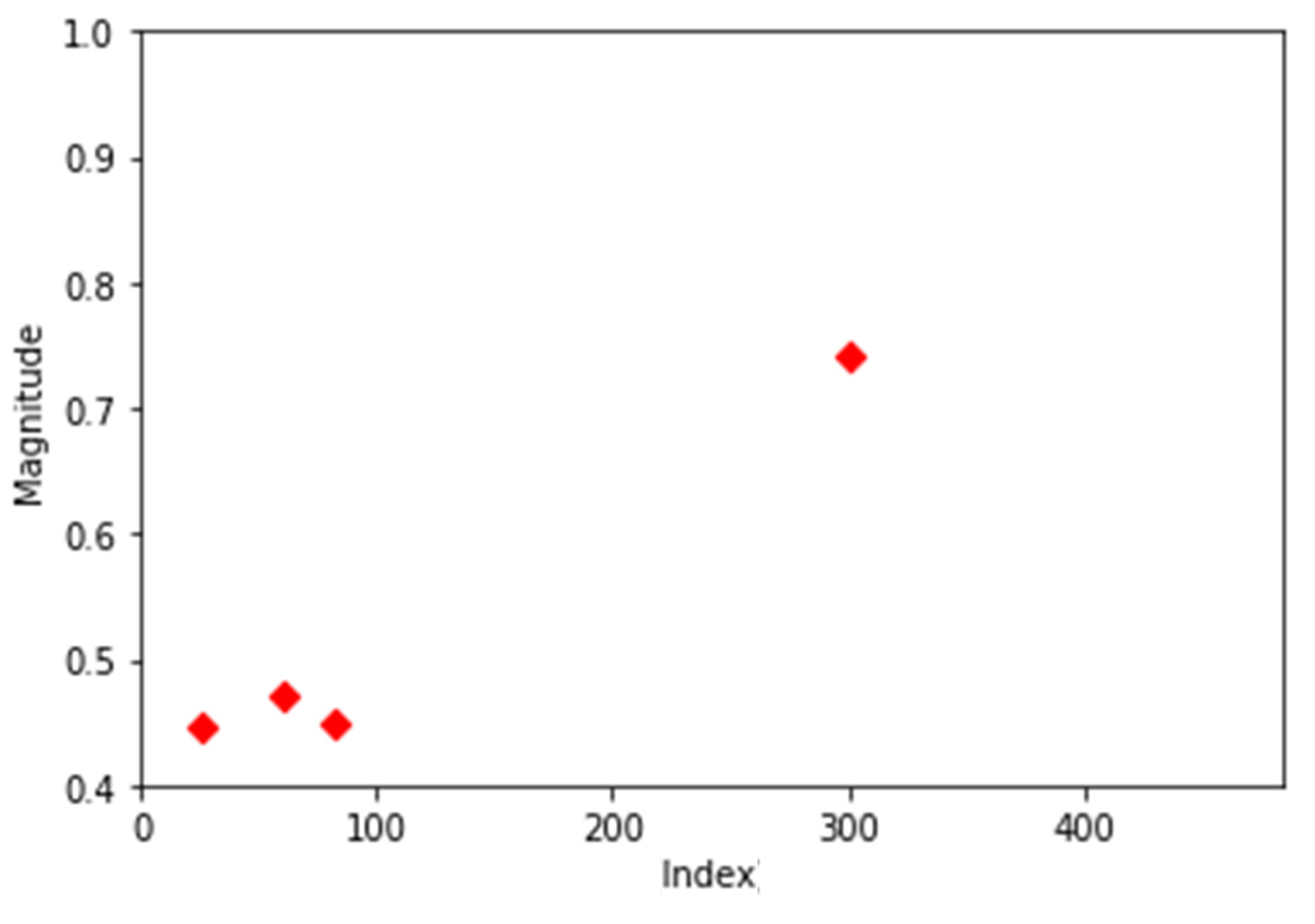

3.5. Clustering

3.6. Modeling

4. Results and Discussion

5. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Amruthnath, N.; Gupta, T. A Research Study on Unsupervised Machine Learning Algorithms for Early Fault Detection in Predictive Maintenance. In Proceedings of the 2018 5th International Conference on Industrial Engineering and Applications, Singapore, 26–28 April 2018; pp. 355–361. [Google Scholar]

- William, T. 5 Use Cases for Predictive Maintenance and Big Data. Available online: https://blogs.oracle.com/bigdata/post/5-use-cases-for-predictive-maintenance-and-big-data (accessed on 13 August 2020).

- Borgi, T.; Hidri, A.; Neef, B.; Naceur, M.S. Data Analytics for Predictive Maintenance of Industrial Robots. In Proceedings of the 2017 International Conference on Advanced Systems and Electric Technologies (IC_ASET), Hammamet, Tunisia, 14–17 January 2017; pp. 412–417. [Google Scholar]

- Carvalho, T.P.; Soares, F.A.A.M.N.; Vita, R.; Francisco, R.D.P.; Basto, J.P.; Alcala, S.G.S. A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Amruthnath, N.; Gupta, T. Fault Class Prediction in Unsupervised Learning using Model-Based Clustering Approach. In Proceedings of the 2018 International Conference on Information and Computer Technologies, DeKalb, IL, USA, 23–25 March 2018; pp. 5–12. [Google Scholar]

- Adam, C. Oil Analysis Saves You Money, but How Much? Available online: https://web.archive.org/web/20171003234014/http://learnoilanalysis.com/oil-analysis-saves-you-money-but-how-much (accessed on 13 August 2020).

- Fan, S.K.S.; Hsu, C.Y.; Tsai, D.M.; He, F.; Cheng, C.C. Data-Driven Approach for Fault Detection and Diagnostic in Semiconductor Manufacturing. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1925–1936. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J. Big data analytics for forecasting cycle time in semiconductor wafer fabrication system. Int. J. Prod. Res. 2016, 54, 7231–7244. [Google Scholar] [CrossRef]

- Moyne, J.; Iskandar, J. Big data analytics for smart manufacturing: Case studies in semiconductor manufacturing. Processes 2017, 5, 39. [Google Scholar] [CrossRef] [Green Version]

- Moyne, J.; Armacost, M. Big Data Analytics Applied to Semiconductor Manufacturing. In Proceedings of the Big Data Analytics 2017-Topical Conference at the 2017 AIChE Spring Meeting and 13th Global Congress on Process Safety, San Antonio, TX, USA, 26–30 March 2017; pp. 142–143. [Google Scholar]

- Iskandar, J.; Moyne, J.; Subrahmanyam, K.; Hawkins, P.; Armacost, M. Predictive Maintenance in Semiconductor Manufacturing. In Proceedings of the 26th Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC), Saratoga Springs, NY, USA, 3–6 May 2015; pp. 384–389. [Google Scholar] [CrossRef]

- Yoon, H.S.; Han, S.S. Clustering Parameter Optimization of Predictive Maintenance Algorithm for Semiconductor Equipment Using One-way Factorial Design. In Proceedings of the International Conference on Control, Automation and Systems, Beijing, China, 19–22 April 2019; Volume 2019, pp. 1219–1221. [Google Scholar]

- Kim, H.G.; Yoon, H.S.; Yoo, J.H.; Yoon, H.I.L.; Han, S.S. Development of Predictive Maintenance Technology for Wafer Transfer Robot using Clustering Algorithm. In Proceedings of the ICEIC 2019-International Conference on Electronics, Information, and Communication, Auckland, New Zealand, 22–25 January 2019; pp. 1–4. [Google Scholar]

- Song, K.T.; Ou, S.Q.; Yang, C.A.; Sun, Y.X.; Kang, L.R.; Wang, Z.Y.; Wang, Y.S.; Lu, P.C.; Ko, C.L.; Chen, Y.H. Scheduling and control of a wafer transfer robot for foundry equipment innovation competition. Proc. IFAC-Pap. 2019, 52, 624–632. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, H.; Mooring, B.W. Accuracy analysis of dynamic-wafer-handling robotic system in semiconductor manufacturing. IEEE Trans. Ind. Electron. 2014, 61, 1402–1410. [Google Scholar] [CrossRef]

- Analog Device Small, Low Power, 3-Axis Accelerometer (ADXL335). Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/ADXL335.pdf (accessed on 12 August 2020).

- Manjiyani, Z.A.A.; Jacob, R.T.; Kumar, K.R.; Varghese, B. Development of MEMS Based 3-Axis Accelerometer for Hand Movement Monitoring. Int. J. Scinetific Res. Publ. 2014, 4, 2–5. [Google Scholar]

- Varanis, M.; Silva, A.L.; Mereles, A.G. On mechanical vibration analysis of a multi degree of freedom system based on arduino and MEMS accelerometers. Rev. Bras. Ensino Fis. 2018, 40, e1304. [Google Scholar] [CrossRef] [Green Version]

- Fluke. Understanding the Effects of Vibration Testing. Available online: https://www.e4ds.com/webinar_tech_dn.asp?idx=58 (accessed on 2 October 2020).

- Kanungo, T.; Mount, D.M.; Netanyahu, N.S.; Piatko, C.D.; Silverman, R.; Wu, A.Y. An efficient k-means clustering algorithms: Analysis and implementation. IEEE Trans. Pattern Anal. Mach. Intell. 2002, 24, 881–892. [Google Scholar] [CrossRef]

- Xu, D.; Tian, Y. A Comprehensive Survey of Clustering Algorithms. Ann. Data. Sci. 2015, 2, 165–193. [Google Scholar] [CrossRef] [Green Version]

- Bindra, K.; Mishra, A. A Detailed Study of Clustering Algorithms. In Proceedings of the 2017 6th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions), (ICRITO), Noida, India, 20–22 September 2017; pp. 371–376. [Google Scholar]

- Available online: https://github.com/YJH-jm/WaferRobotFaultDetection.git (accessed on 16 March 2022).

| Run | Accuracy (%) |

|---|---|

| 1 | 97.00 |

| 2 | 97.25 |

| 3 | 97.00 |

| 4 | 97.50 |

| 5 | 97.50 |

| Average | 97.25 |

| Predicted | Normal | 1st Error | 2nd Error | 3rd Error | |

|---|---|---|---|---|---|

| Actual | |||||

| Normal | 96 | 2 | 1 | 1 | |

| 1st Error | 1 | 96 | 1 | 2 | |

| 2nd Error | 0 | 1 | 99 | 0 | |

| 3rd Error | 0 | 0 | 1 | 99 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, J.-H.; Park, Y.-K.; Han, S.-S. Predictive Maintenance System for Wafer Transport Robot Using K-Means Algorithm and Neural Network Model. Electronics 2022, 11, 1324. https://doi.org/10.3390/electronics11091324

Yoo J-H, Park Y-K, Han S-S. Predictive Maintenance System for Wafer Transport Robot Using K-Means Algorithm and Neural Network Model. Electronics. 2022; 11(9):1324. https://doi.org/10.3390/electronics11091324

Chicago/Turabian StyleYoo, Ji-Hyun, Young-Kook Park, and Seung-Soo Han. 2022. "Predictive Maintenance System for Wafer Transport Robot Using K-Means Algorithm and Neural Network Model" Electronics 11, no. 9: 1324. https://doi.org/10.3390/electronics11091324

APA StyleYoo, J.-H., Park, Y.-K., & Han, S.-S. (2022). Predictive Maintenance System for Wafer Transport Robot Using K-Means Algorithm and Neural Network Model. Electronics, 11(9), 1324. https://doi.org/10.3390/electronics11091324