On-Wafer Temperature Monitoring Sensor for Condition Monitoring of Repaired Electrostatic Chuck

Abstract

1. Introduction

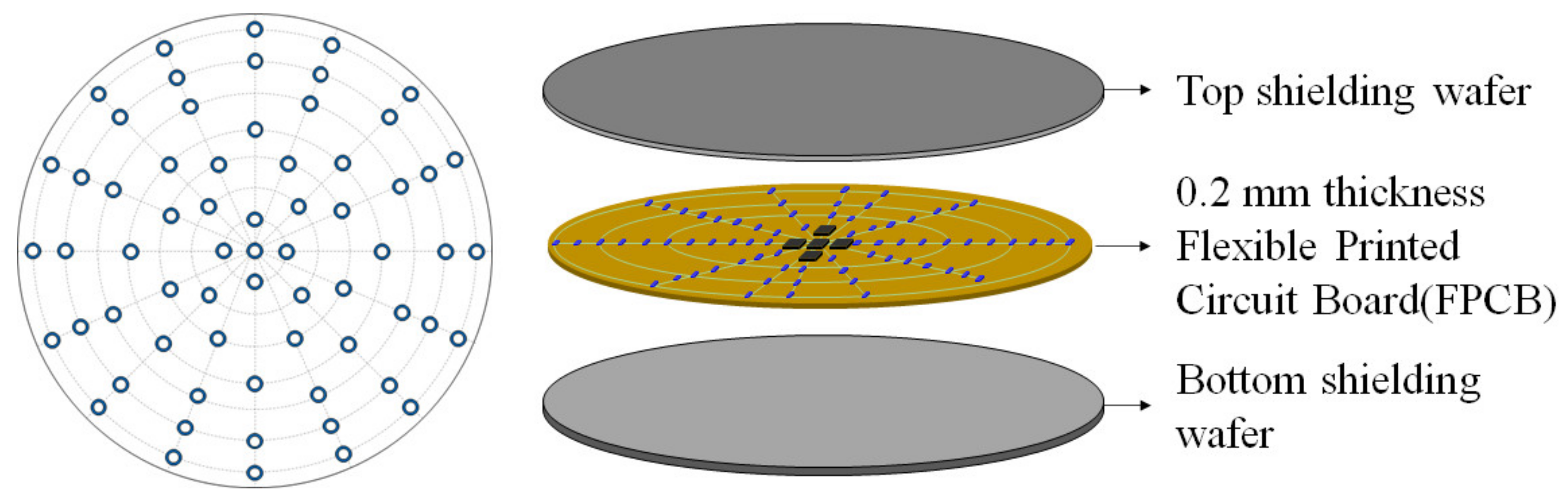

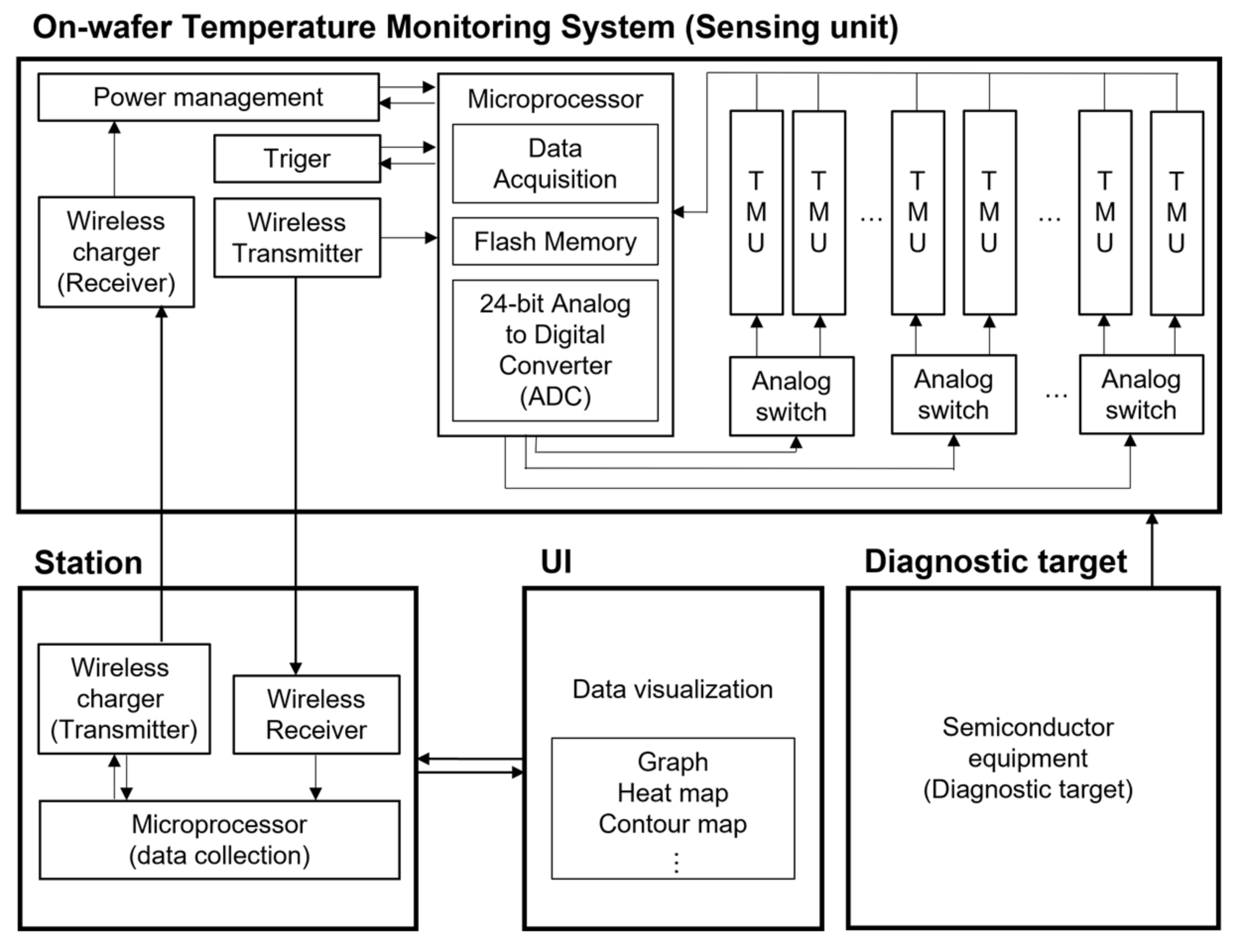

2. Hardware Design Consideration

3. System Design

3.1. Sensing Unit

3.2. Film Battery and Charging Circuit

3.3. Station and User Interface Software

4. System Verification

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yugma, C.; Blue, J.; Dauzère-Pérès, S.; Obeid, A. Integration of Scheduling and Advanced Process Control in Semiconductor Manufacturing: Review and Outlook. J. Sched. 2015, 18, 195–205. [Google Scholar] [CrossRef]

- Abe, H.; Yoneda, M.; Fujiwara, N. Developments of Plasma Etching Technology for Fabricating Semiconductor Devices. Jpn. J. Appl. Phys. 2008, 47, 1435–1455. [Google Scholar] [CrossRef]

- Baek, K.H.; Coonan, B.; Carbery, M.; Joo, J.; Woo, H.; Lee, T.S.; An, H.S.; Koo, Y.; Han, C.; Han, S.; et al. Process and Chamber Health Monitoring of Plasma Enhanced Ti Deposition Process through High Performance VI-probe. In Proceedings of the 2007 International Symposium on Semiconductor Manufacturing, Santa Clara, CA, USA, 15–17 October 2007; pp. 1–4. [Google Scholar]

- Kang, G.; An, S.; Kim, K.; Hong, S. An In Situ Monitoring Method for PECVD Process Equipment Condition. Plasma Sci. Technol. 2019, 21, 064003. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, C.; Hong, S.J. Industrial Internet of Things for Condition Monitoring and Diagnosis of Dry Vacuum Pumps in Atomic Layer Deposition Equipment. Electronics 2022, 11, 375. [Google Scholar] [CrossRef]

- Hong, S.J.; Lim, W.Y.; Cheong, T.; May, G.S. Fault Detection and Classification in Plasma Etch Equipment for Semiconductor Manufacturing e-Diagnostics. IEEE Trans. Semi. Manufac. 2011, 25, 83–93. [Google Scholar] [CrossRef]

- Yang, R.; Chen, R. Real-Time Plasma Process Condition Sensing and Abnormal Process Detection. Sensors 2010, 10, 5703–5723. [Google Scholar] [CrossRef]

- Sana, M.; Saleem, U.; Farooq, M.; Qamar, A.; Bhutta, M.M.A.; Zafar, S. Identification of Failure Modes on Electrostatic Chuck through Reliability Centered Maintenance: A Case Study: Identification of Failure Modes on ESC through RCM. Proc. Pak. Acad. Sci. A 2018, 55, 21–32. [Google Scholar]

- Lee, H.J.; Lee, S.H. Numerical Evaluation on Surface Temperature Uniformity of Multi-zone and Single-zone Ceramic Heaters with the Electrostatic Chuck. J. Mech. Sci. Technol. 2021, 35, 3763–3770. [Google Scholar] [CrossRef]

- Lewin, L.; Plummer, J.; Ward, R. Electrostatic Chuck. U.S. Patent 4,502,094, 26 February 1985. [Google Scholar]

- Hartsough, L. Electrostatic Wafer Holding. Solid State Technol. 1993, 36, 87–90. [Google Scholar]

- Wright, D.; Chen, L.; Federlim, P.; Forbes, K. Manufacturing Issues of Electrostatic Chucks. J. Vac. Sci. Technol. B 1995, 13, 1910–1916. [Google Scholar] [CrossRef]

- Asano, K.; Hatakeyama, F.; Yatsuzuka, K. Fundamental Study of an Electrostatic Chuck for Silicon Wafer Handling. IEEE Trans. Ind. Appl. 2002, 38, 840–845. [Google Scholar] [CrossRef]

- Yuchun, S.; Jia, C.; Yijia, L.; Yuemin, H.; Limhong, J. Design Space of Electrostatic Chuck in Etching Chamber. J. Semiconduct. 2015, 36, 084004. [Google Scholar]

- Brcka, J.; Jones, B.; Leusink, G.; Long, J.; Oliver, B.; Tweed, C. Method for Characterizing the Performance of an Electrostatic Chuck. U.S. Patent 6,853,953 B2, 8 February 2005. [Google Scholar]

- Yoshioka, K.; Takahashi, S.; Sasaki, Y. Method and Apparatus for Repairing an Electrostatic Chuck Device, and the Electrostatic Chuck Device. U.S. Patent 8,252,132 B2, 28 August 2012. [Google Scholar]

- Raj, C.; Hirahara, R. Methods and Apparatus for Electrostatic Chuck Repair and Refurbishment. U.S. Patent 9,349,630 B2, 24 May 2016. [Google Scholar]

- Raj, C.; Hirahara, R. Methods and Apparatus for Electrostatic Chuck Repair and Refurbishment. U.S. Patent 10,049,908 B2, 14 August 2018. [Google Scholar]

- Boyd, W. New Repair Method for Electrostatic Chuck. U.S. Patent 0166311 A1, 14 June 2018. [Google Scholar]

- Parkhe, V.; Narendrnath, K. Electrostatic Chuck Optimized for Refurbishment. U.S. Patent 10,056,284 B2, 21 August 2018. [Google Scholar]

- Kim, O.; Kim, O. Electrostatic Chuck and Method for Manufacturing Electrostatic Chuck. U.S. Patent 10,347,520 B2, 9 July 2019. [Google Scholar]

- Parkhe, V. Sensor System for Multi-Zone Electrostatic Chuck. U.S. Patent 10,582,570 B2, 3 March 2020. [Google Scholar]

- Hart, A.; Boyd, J.; Palma, L.; Dent, A. Electrostatic chucks and methods for refurbishing same. U.S. Patent 8,597,448, 3 December 2013. [Google Scholar]

- Shih, H. Method of refurbishing bipolar electrostatic chuck. U.S. Patent 8,291,565, 23 October 2012. [Google Scholar]

- Huslla, I.; Enke, K.; Grunwald, H.; Lorenz, G.; Stoll, H. In Situ Silicon-Wafer Temperature Measurements during RF Argon-Ion Plasma Etching via Fluoroptic Thermometry. J. Phys. D Appl. Phys. 1987, 20, 889–896. [Google Scholar] [CrossRef]

- Cardoso, A.; Srivastava, A. Improvements in Wafer Temperature Measurements. J. Vac. Sci. Technol. B 2001, 19, 397–402. [Google Scholar] [CrossRef][Green Version]

- Adams, B.; Schietinger, C. In-Situ Optical Wafer Temperature Measurement. AIP Conf. Proc. 2003, 684, 1081–1086. [Google Scholar]

- Tan, W.; Tang, J.; Loh, A.; Tay, A. In Situ Measurement of Wafer Temperature Using Two Sensors with Different Dynamical Properties. Meas. Sci. Technol. 2006, 17, 2957–2963. [Google Scholar] [CrossRef]

- Kumar, V.; Verma, J.; Maan, A.S.; Akhtar, J. Epitaxial 4H–SiC based Schottky diode temperature sensors in ultra-low current range. Vacuum 2020, 182, 109590. [Google Scholar] [CrossRef]

- Kumar, V.; Maan, A.; Akhtar, J. Barrier Height Inhomogeneities Induced Anomaly in Thermal Sensitivity of Ni/4H-SiC Schottky Diode Temperature Sensor. J. Vac. Sci. Technol. B 2014, 32, 041203. [Google Scholar] [CrossRef]

- Pan, S.; Gürleyük, Ç.; Pimenta, M.; Makinwa, K. 10.3 A 0.12 mm 2 Wien-Bridge Temperature Sensor with 0.1 °C (3σ) Inaccuracy from −40 °C to 180 °C. In Proceedings of the 2019 IEEE ISSCC, San Francisco, CA, USA, 17–21 February 2019. [Google Scholar]

- Tseng, S.; Chen, M. Yield Enhancement in Stripper Process and Related Process using SensArray HighTemp Wafer. In Proceedings of the SEMI Advanced Semiconductor Manufacturing Conference, New York, NY, USA, 16–19 May 2016. [Google Scholar]

- Kim, D.; Kim, J.; Chu, D.; Hong, D. Measuring the Wafer Temperature in HVM Process Tools Using a New Approach with Automated Wireless HighTemp-400 and EtchTemp-SE Wafer Systems. In Proceedings of the 29th SEMI Advanced Semiconductor Manufacturing Conference, New York, NY, USA, 30 April–3 May 2018. [Google Scholar]

- Fang, F.; Vaid, A.; Vinslava, A.; Casselberry, R.; Mishra, S.; Dixit, D.; Timoney, P.; Chu, D.; Porter, C.; Song, D.; et al. Correlation Study of Actual Temperature Profile and In-line Metrology Measurements for Within-Wafer Uniformity Improvement and Wafer Edge Yield Enhancement. In Proceedings of the Metrology, Inspection, and Process Control for Microlithography XXXII, Los Angeles, CA, USA, 21 March 2018. [Google Scholar]

- Lee, J.; Siegal, D.; Lapira, E. Development of a Predictive and Preventive Maintenance Demonstration System for a Semiconductor Etching Tool. ESC Trans. 2013, 52, 913–927. [Google Scholar] [CrossRef]

- Im, D.; Min, W.; Hong, S. Planar Heating Chuck to Improve Temperature Uniformity of Plasma Processing Equipment. Jpn. J. Appl. Phys. 2020, 59, SJJD01. [Google Scholar] [CrossRef]

- Park, Y.; Du, H.; Im, D.; Hong, S. Hardware Design for Cryogenic Etching Equipment. Heat Transf. Res. 2021, 52, 8. [Google Scholar] [CrossRef]

- Matula, R. Electrical Resistivity of Copper, Gold, Palladium, and Silver. J. Phys. Chem. Ref. Data 1979, 8, 1147–1298. [Google Scholar] [CrossRef]

- Newby, J.; Bieli, G.; Wollenweber, M.; Melzer, R.; Nogatz, T.; Sobe, J. Correlation Study of Spatial ESC Temperature Profile and Optical CD/CD SEM Measurements to Investigate Silicon Recess and Gate CD after Etch. In Proceedings of the 25th Annual SEMI ASMC2014, New York, NY, USA, 19–21 May 2014. [Google Scholar]

- Park, J.; Lee, J.; Choi, H.; Jang, W.; Kim, T.S.; Suh, D.; Suh, S. Electromagnetic Interference Shielding Effectiveness of Sputtered NiFe/Cu Multi-layer Thin Film at High Frequencies. Thin Solid Films 2019, 677, 130–136. [Google Scholar] [CrossRef]

- Aiello, O.; Fiori, F. On the Susceptibility of Embedded Thermal Shutdown Circuit to Radio Frequency Interference. IEEE Trans. Electromag. Compat. 2011, 54, 405–412. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-H.; Koo, Y.; Song, W.; Hong, S.J. On-Wafer Temperature Monitoring Sensor for Condition Monitoring of Repaired Electrostatic Chuck. Electronics 2022, 11, 880. https://doi.org/10.3390/electronics11060880

Kim J-H, Koo Y, Song W, Hong SJ. On-Wafer Temperature Monitoring Sensor for Condition Monitoring of Repaired Electrostatic Chuck. Electronics. 2022; 11(6):880. https://doi.org/10.3390/electronics11060880

Chicago/Turabian StyleKim, Jae-Hwan, Yoonsung Koo, Wansoo Song, and Sang Jeen Hong. 2022. "On-Wafer Temperature Monitoring Sensor for Condition Monitoring of Repaired Electrostatic Chuck" Electronics 11, no. 6: 880. https://doi.org/10.3390/electronics11060880

APA StyleKim, J.-H., Koo, Y., Song, W., & Hong, S. J. (2022). On-Wafer Temperature Monitoring Sensor for Condition Monitoring of Repaired Electrostatic Chuck. Electronics, 11(6), 880. https://doi.org/10.3390/electronics11060880