Controlling the Crawling Speed of the Snake Robot along a Cable Based on the Hopf Oscillator

Abstract

:1. Introduction

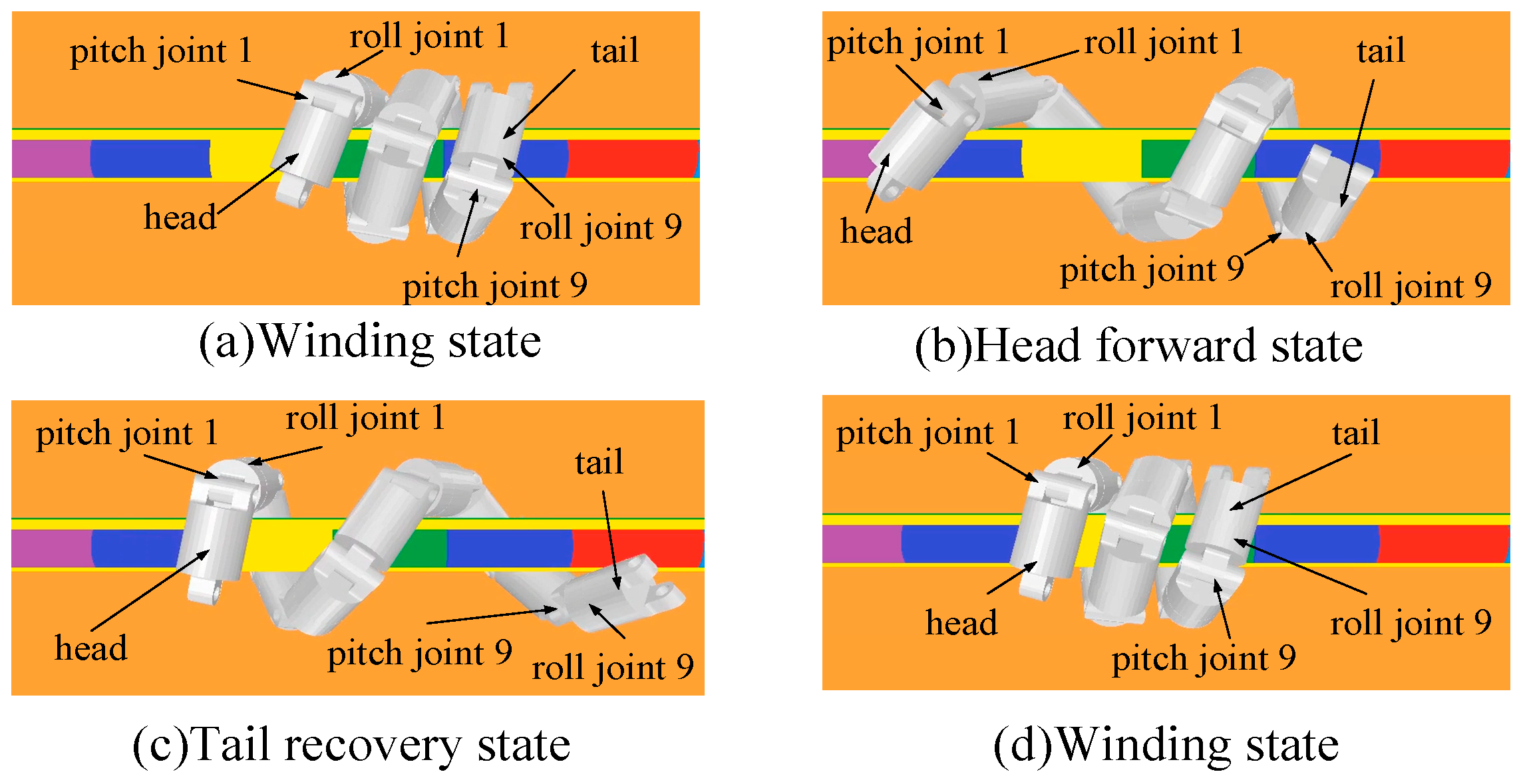

2. Introduction to Snake Robot Gait

2.1. Conformation and Gait Analysis of the Snake Robot

2.2. Confirmation of the Joint Angle of the Snake Robot

3. Mathematical Model of Double-Chain Hopf Oscillator

3.1. Mathematical Model of Hopf Oscillator

3.2. Structure of the Double-Chain Hopf Controller

4. Simulation

4.1. Spiral-Winding Gait

4.2. Optimization of the Crawling Speed of the Snake Robot

5. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liljebäck, P.; Pettersen, K.Y.; Stavdahl, Ø.; Gravdahl, J.T. A review on modelling, implementation, and control of snake robots. Robot. Auton. Syst. 2012, 60, 29–40. [Google Scholar] [CrossRef] [Green Version]

- Stamper, S.A.; Sefati, S.; Cowan, N.J. Snake robot uncovers secrets to sidewinders’ maneuverability. Proc. Natl. Acad. Sci. USA 2015, 112, 5870–5871. [Google Scholar] [CrossRef] [PubMed]

- Girma, A.; Bahadori, N.; Sarkar, M.; Tadewos, T.G.; Behnia, M.R.; Mahmoud, M.N.; Karimoddini, A.; Homaifar, A. IoT-Enabled Autonomous System Collaboration for Disaster-Area Management. IEEE/CAA J. Autom. Sin. 2020, 7, 1249–1262. [Google Scholar] [CrossRef]

- Yang, L.; Li, B.; Li, W.; Brand, H.; Jiang, B.; Xiao, J. Concrete defects inspection and 3D mapping using CityFlyer quadrotor robot. IEEE/CAA J. Autom. Sin. 2020, 7, 991–1002. [Google Scholar] [CrossRef]

- Cao, Z.; Zhang, D.; Zhou, M. Direction Control and Adaptive Path Following of 3-D Snake-Like Robot Motion. IEEE Trans. Cybern. 2021, 52, 10980–10987. [Google Scholar] [CrossRef] [PubMed]

- Ariizumi, R.; Matsuno, F. Dynamic Analysis of Three Snake Robot Gaits. IEEE Trans. Robot. 2017, 33, 1075–1087. [Google Scholar] [CrossRef]

- Grillner, S. Biological Pattern Generation: The Cellular and Computational Logic of Networks in Motion. Neuron 2006, 52, 751–766. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, J.; Tan, M.; Chen, J.; Zhang, J. A Survey on CPG-Inspired Control Models and System Implementation. IEEE Trans. Neural Netw. Learn. Syst. 2014, 25, 441–456. [Google Scholar] [CrossRef] [PubMed]

- Nor, N.M.; Ma, S. Smooth transition for CPG-based body shape control of a snake-like robot. Bioinspir. Biomim. 2014, 9, 016003. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Gao, Q.; Zhao, H. CPG-Inspired Locomotion Control for a Snake Robot Basing on Nonlinear Oscillators. J. Intell. Robot. Syst. 2017, 85, 209–227. [Google Scholar] [CrossRef]

- Fujiki, S.; Aoi, S.; Yamashita, T.; Funato, T.; Tomita, N.; Senda, K.; Tsuchiya, K. Adaptive splitbelt treadmill walking of a biped robot using nonlinear oscillators with phase resetting. Auton. Robots 2013, 35, 15–26. [Google Scholar] [CrossRef] [Green Version]

- Kimura, H.; Fukuoka, Y.; Cohen, A.H. Adaptive Dynamic Walking of a Quadruped Robot on Natural Ground Based on Biological Concepts. Int. J. Robot. Res. 2007, 26, 475–490. [Google Scholar] [CrossRef]

- Ijspeert, A.J.; Crespi, A.; Ryczko, D.; Cabelguen, J.M. From Swimming to Walking with a Salamander Robot Driven by a Spinal Cord Model. Science 2007, 315, 1416–1420. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, X.; Ma, S. Adaptive creeping locomotion of a CPG-controlled snake-like robot to environment change. Auton. Robot. 2010, 28, 283–294. [Google Scholar]

- Cao, Z.; Zhang, D.; Hu, B.; Liu, J. Adaptive Path Following and Locomotion Optimization of Snake-Like Robot Controlled by the Central Pattern Generator. Complexity 2019, 2019, 8030374. [Google Scholar] [CrossRef] [Green Version]

- Manzoor, S.; Choi, Y. A unified neural oscillator model for various rhythmic locomotions of snake-like robot. Neurocomputing 2016, 173, 1112–1123. [Google Scholar] [CrossRef]

- Miao, H.; Tian, Y.C. Dynamic robot path planning using an enhanced simulated annealing approach. Appl. Math. Comput. 2013, 222, 420–437. [Google Scholar] [CrossRef] [Green Version]

- Kwok, D.P.; Sheng, F. Genetic algorithm and simulated annealing for optimal robot arm PID control. In Proceedings of the First IEEE Conference on Evolutionary Computation. IEEE World Congress on Computational Intelligence, Orlando, FL, USA, 27–29 June 1994; pp. 707–713. [Google Scholar]

| Parameter | Value |

|---|---|

| Number of snake robot units | 10 |

| Length of each unit | 105 mm |

| Radius of each unit | 31.5 mm |

| Pitch joint mass | 1 kg |

| Roll joint mass | 0.5 kg |

| Parameter | Value |

|---|---|

| Opposite-side phase difference | 0 |

| Same-side phase difference and | |

| Overall coupling gain | 1 |

| Amplitude | 1 |

| Attraction rate | 100 |

| Frequency of the oscillator | |

| Duration of oscillator pause | 4 s |

| Parameter | Value |

|---|---|

| Winding arc | |

| Winding arc | |

| Decay parameter | 0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Wang, F.; Liu, J.; Fang, Z.; Tian, C.; Zhang, D. Controlling the Crawling Speed of the Snake Robot along a Cable Based on the Hopf Oscillator. Electronics 2023, 12, 3094. https://doi.org/10.3390/electronics12143094

Yang Z, Wang F, Liu J, Fang Z, Tian C, Zhang D. Controlling the Crawling Speed of the Snake Robot along a Cable Based on the Hopf Oscillator. Electronics. 2023; 12(14):3094. https://doi.org/10.3390/electronics12143094

Chicago/Turabian StyleYang, Zhiyong, Fan Wang, Jianguo Liu, Zhen Fang, Chen Tian, and Daode Zhang. 2023. "Controlling the Crawling Speed of the Snake Robot along a Cable Based on the Hopf Oscillator" Electronics 12, no. 14: 3094. https://doi.org/10.3390/electronics12143094