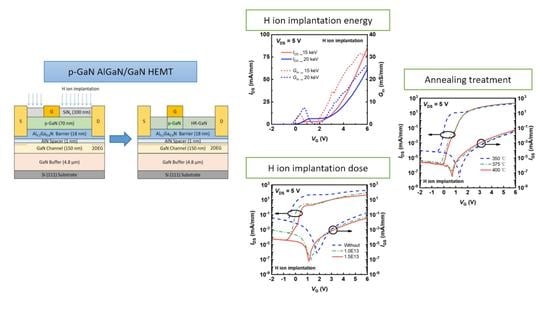

p-GaN Selective Passivation via H Ion Implantation to Obtain a p-GaN Gate Normally off AlGaN/GaN HEMT

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ambacher, O.; Foutz, B.; Smart, J.; Shealy, J.; Weimann, N.G.; Chu, K.; Murphy, M.; Sierakowski, A.J.; Schaff, W.J.; Eastman, L.F.; et al. Two dimensional electron gases induced by spontaneous and piezoelectric polarization in undoped and doped AlGaN/GaN heterostructures. J. Appl. Phys. 2000, 87, 334–344. [Google Scholar] [CrossRef]

- Xing, H.; Keller, S.; Wu, Y.-F.; McCarthy, L.; Smorchkova, I.P.; Buttari, D.; Coffie, R.; Green, D.S.; Parish, G.; Heikman, S.; et al. Gallium nitride based transistors. J. Phys. Condens. Matter. 2001, 13, 7139. [Google Scholar] [CrossRef]

- Mishra, U.K.; Parikh, P.; Wu, Y.-F. AlGaN/GaN HEMTs-an overview of device operation and applications. Proc. IEEE 2002, 90, 1022–1031. [Google Scholar] [CrossRef]

- Hudgins, J.L.; Simin, G.S.; Santi, E.; Khan, M.A. An assessment of wide bandgap semiconductors for power devices. IEEE Trans. Power Electron. 2003, 18, 907–914. [Google Scholar] [CrossRef]

- Miyoshi, M.; Egawa, T.; Ishikawa, H. Structural characterization of strained AlGaN layers in different Al content AlGaN/GaN heterostructures and its effect on two-dimensional electron transport properties. J. Vac. Sci. Technol. B 2005, 23, 1527–1531. [Google Scholar] [CrossRef]

- Effect of Source Field Plate Cracks on the Electrical Performance of AlGaN/GaN HEMT Devices. Crystals 2022, 12, 1195. [CrossRef]

- Khan, M.A.; Chen, Q.; Sun, C.; Yang, J.; Blasingame, M.; Shur, M.; Park, H. Enhancement and depletion mode GaN/AlGaN heterostructure field effect transistors. Appl. Phys. Lett. 1996, 68, 514–516. [Google Scholar] [CrossRef]

- Cai, Y.; Zhou, Y.; Chen, K.J.; Lau, K.M. High-performance enhancement-mode AlGaN/GaN HEMTs using fluoride-based plasma treatment. IEEE Electron Device Lett. 2005, 26, 435–437. [Google Scholar]

- Cai, Y.; Zhou, Y.; Lau, K.M.; Chen, K.J. Control of threshold voltage of AlGaN/GaN HEMTs by fluoride-based plasma treatment: From depletion mode to enhancement mode. IEEE Trans. Electron Devices 2006, 53, 2207–2215. [Google Scholar] [CrossRef]

- Nanjo, T.; Takeuchi, M.; Suita, M.; Oishi, T.; Abe, Y.; Tokuda, Y.; Aoyagi, Y. Remarkable breakdown voltage enhancement in AlGaN channel high electron mobility transistors. Appl. Phys. Lett. 2008, 92, 263502. [Google Scholar] [CrossRef]

- Meneghini, M.; Hilt, O.; Wuerfl, J.; Meneghesso, G. Technology and reliability of normally-off GaN HEMTs with p-type gate. Energies 2017, 10, 153. [Google Scholar] [CrossRef]

- Greco, G.; Iucolano, F.; Roccaforte, F. Review of technology for normally-off HEMTs with p-GaN gate. Mater. Sci. Semicond. Process. 2018, 78, 96–106. [Google Scholar] [CrossRef]

- Roccaforte, F.; Greco, G.; Fiorenza, P.; Iucolano, F. An overview of normally-off GaN-based high electron mobility transistors. Materials 2019, 12, 1599. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.; Li, S.; Li, T.; Wang, X.; Li, X.; Wu, Y. Channel Engineering of Normally-OFF AlGaN/GaN MOS-HEMTs by Atomic Layer Etching and HighHigh- κ Dielectric. IEEE Electron Device Lett. 2018, 39, 1377–1380. [Google Scholar] [CrossRef]

- Chang, Y.-C.; Ho, Y.-L.; Huang, T.-Y.; Huang, D.-W.; Wu, C.-H. Investigation of Normally-Off p-GaN/AlGaN/GaN HEMTs Using a Self-Terminating Etching Technique with Multi-Finger Architecture Modulation for High Power Application. Micromachines 2021, 12, 432. [Google Scholar] [CrossRef] [PubMed]

- Hao, R.; Fu, K.; Yu, G.; Li, W.; Yuan, J.; Song, L.; Zhang, Z.; Sun, S.; Li, X.; Cai, Y.; et al. Normally-off p-GaN/AlGaN/GaN high electron mobility transistors using hydrogen plasma treatment. Appl. Phys. Lett. 2016, 109, 152106. [Google Scholar] [CrossRef]

- Xu, N.; Hao, R.; Chen, F.; Zhang, X.; Zhang, H.; Zhang, P.; Ding, X.; Song, L.; Yu, G.; Cheng, K. Gate leakage mechanisms in normally off p-GaN/AlGaN/GaN high electron mobility transistors. Appl. Phys. Lett. 2018, 113, 152104. [Google Scholar] [CrossRef]

- Sayadi, L.; Iannaccone, G.; Sicre, S.; Häberlen, O.; Curatola, G. Threshold voltage instability in p-GaN gate AlGaN/GaN HFETs. IEEE Trans. Electron Devices 2018, 65, 2454–2460. [Google Scholar] [CrossRef]

- Saravade, V.; Ghods, A.; Woode, A.P.; Zhou, C.; Ferguson, I. GaN-based Room Temperature Spintronics for Next Generation Low Power Consumption Electronic Devices. In Proceedings of the 2019 IEEE 16th International Conference on Smart Cities: Improving Quality of Life Using ICT & IoT and AI (HONET-ICT), Charlotte, NC, USA, 6–9 October 2019; pp. 203–204. [Google Scholar]

- Cho, K.S.; Huang, T.-Y.; Wang, H.-S.; Lin, M.-G.; Chen, T.-M.; Liang, C.-T.; Chen, Y.F.; Lo, I. Zero-field spin splitting in modulation-doped AlxGa1−xN/GaN two-dimensional electron systems. Appl. Phys. Lett. 2005, 86, 222102. [Google Scholar] [CrossRef]

- Lin, D.; Kang, W.; Wu, Q.; Song, A.; Wu, X.; Liu, G.; Wu, J.; Wu, Y.; Li, X.; Wu, Z.; et al. High-Efcient Spin Injection in GaN at Room Temperature Through A Van der Waals Tunnelling Barrier. Nanoscale Res. Lett. 2022, 17, 74. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, X.; Yuan, X.; Ju, T.; Yu, G.; Zhang, B.; Du, Z.; Zeng, Z.; Zhang, B.; Zhang, X. p-GaN Selective Passivation via H Ion Implantation to Obtain a p-GaN Gate Normally off AlGaN/GaN HEMT. Electronics 2023, 12, 1424. https://doi.org/10.3390/electronics12061424

Ding X, Yuan X, Ju T, Yu G, Zhang B, Du Z, Zeng Z, Zhang B, Zhang X. p-GaN Selective Passivation via H Ion Implantation to Obtain a p-GaN Gate Normally off AlGaN/GaN HEMT. Electronics. 2023; 12(6):1424. https://doi.org/10.3390/electronics12061424

Chicago/Turabian StyleDing, Xiaoyu, Xu Yuan, Tao Ju, Guohao Yu, Bingliang Zhang, Zhongkai Du, Zhongming Zeng, Baoshun Zhang, and Xinping Zhang. 2023. "p-GaN Selective Passivation via H Ion Implantation to Obtain a p-GaN Gate Normally off AlGaN/GaN HEMT" Electronics 12, no. 6: 1424. https://doi.org/10.3390/electronics12061424

APA StyleDing, X., Yuan, X., Ju, T., Yu, G., Zhang, B., Du, Z., Zeng, Z., Zhang, B., & Zhang, X. (2023). p-GaN Selective Passivation via H Ion Implantation to Obtain a p-GaN Gate Normally off AlGaN/GaN HEMT. Electronics, 12(6), 1424. https://doi.org/10.3390/electronics12061424