Peak Arm Current Minimization of Modular Multilevel Converter Using Multiple Circulating Current Injection

Abstract

1. Introduction

- (1)

- CC elimination control (CCEC). The elimination of the CC is a commonly adopted control target, which aims to reduce the power loss of the MMC by reducing the RMS of its arm current [20,21]. However, power loss reduction by this mean is quite insignificant since the CC only increases the RMS of the arm current slightly [22]. In addition, the elimination of the CC will increase the peak arm current of the MMC compared with the scenario where the CC is naturally present [23].

- (2)

- CC injection control (CCIC). The presence of a moderate CC in the arm current of the MMC is acceptable and it can be utilized as a control freedom to optimize the characteristics of the MMC. Compared with the control target of the CCEC, this group can be uniformly categorized as the CCIC. Following this idea, researchers have conducted in-depth studies on the links between the CCIC technique and the performance improvement of the MMC, such as capacitor voltage ripple suppression [24,25], thermal management optimization [26,27], and operation region extension that has been presented in [19], etc. Compared with the CCEC, the CCIC trades off the conversion efficiency of the system in exchange for the MMC’s performance improvement in a particular area. Therefore, the CCIC is suitable for scenarios where there are special requirements for a particular aspect of the MMC.

- (1)

- It reveals the relationship among the SOCC, the FOCC, and the peak arm current of the MMC under various power factors.

- (2)

- The optimal magnitudes and phase angles of the SOCC and the FOCC allowing for peak arm current minimization of the MMC have been designed in detail under various operating conditions. It can further reduce the peak arm current of the MMC in comparison with the technique proposed in [19], leading to enhanced power handling capacity of the MMC.

- (3)

- It designs a decoupling control strategy to obtain accurate control of the SOCC and the FOCC.

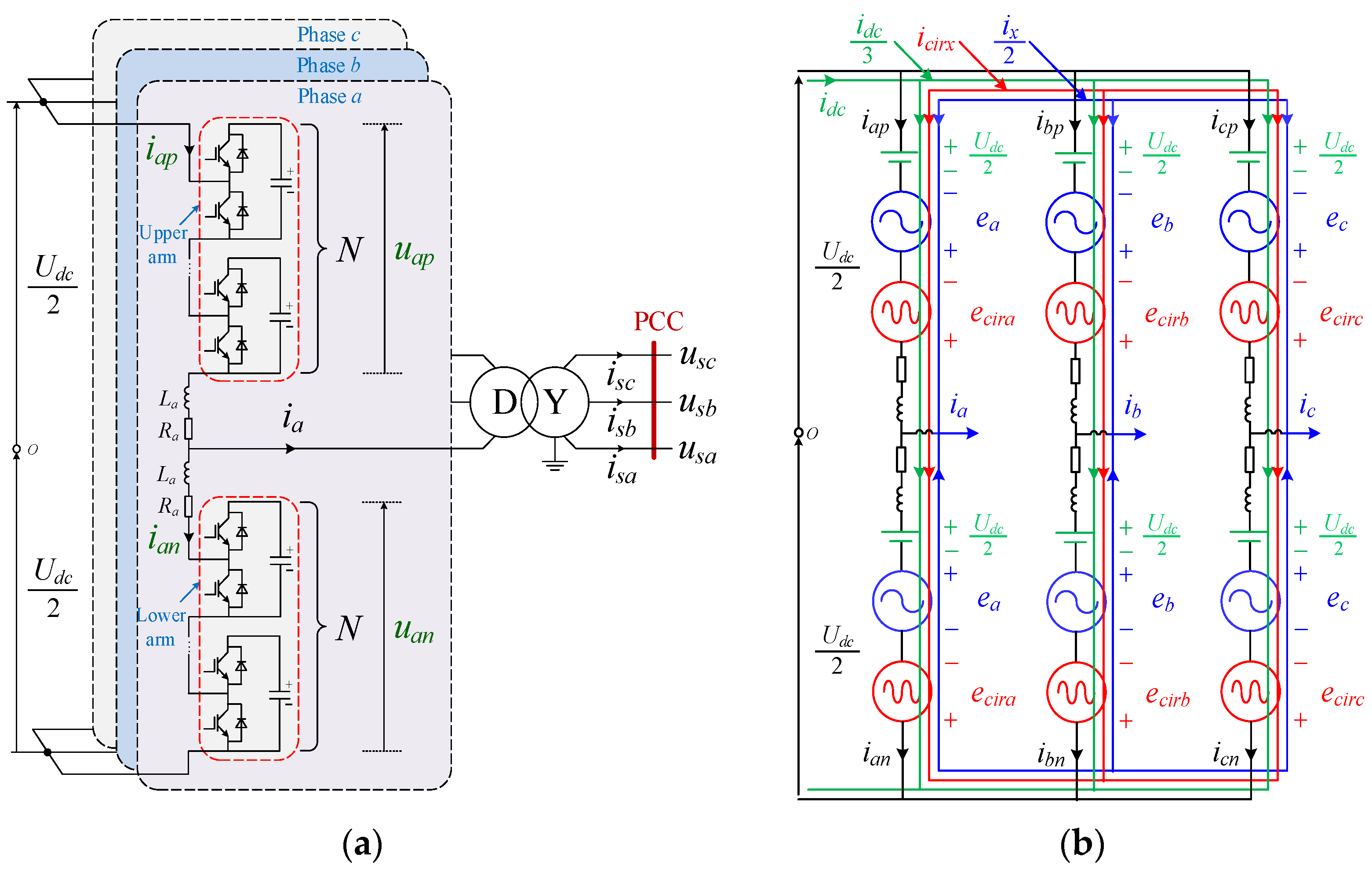

2. Operation Principle and Peak Arm Current Analysis of the MMC with the CCEC Scheme

2.1. Structure and Operation of the MMC

2.2. Analysis of the Peak Arm Current of the MMC with the CCEC Scheme

3. Proposed Control Method for Peak Arm Current Minimization

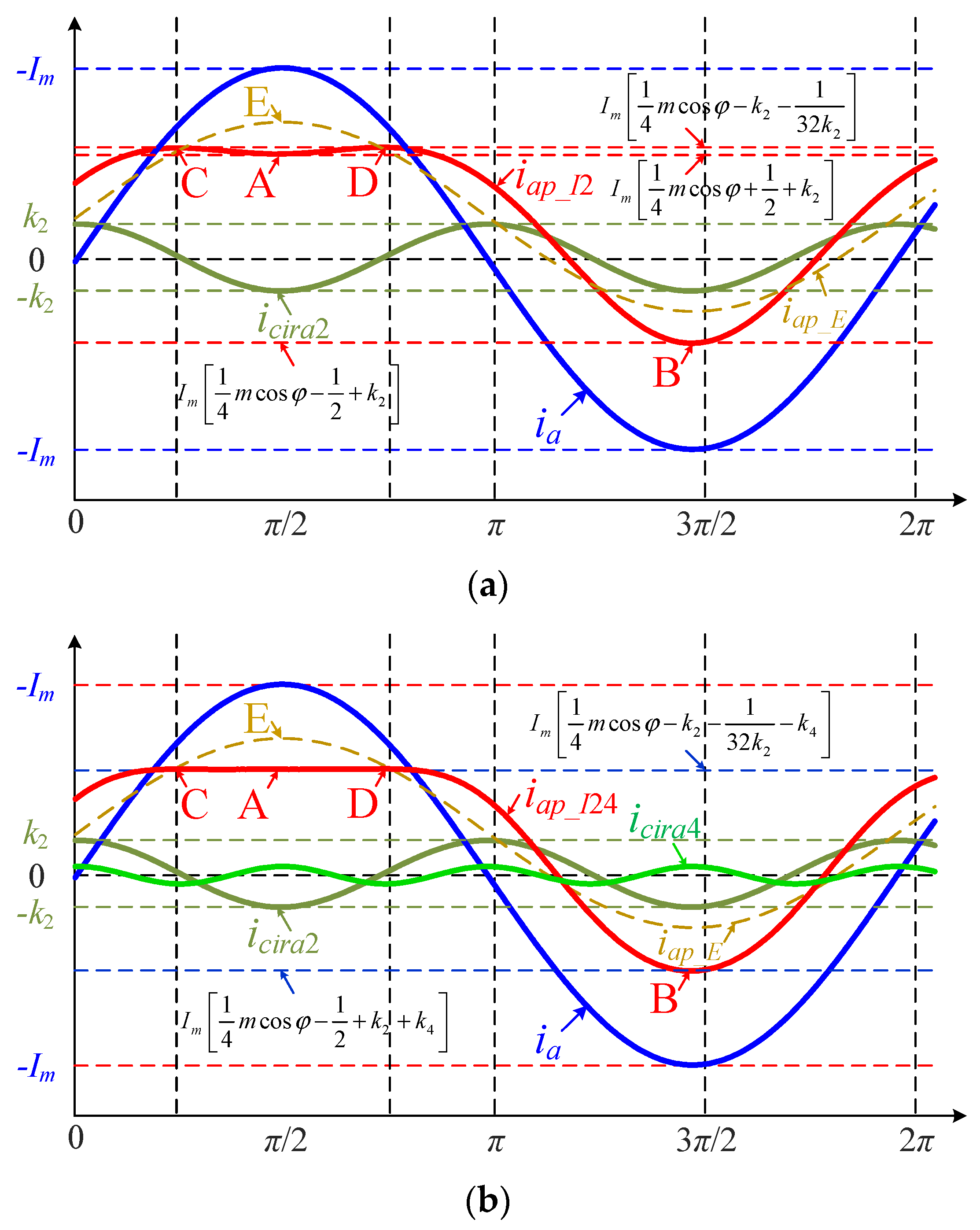

3.1. Analysis of the Peak Current of the MMC Operating in the Inverter Mode

3.1.1. Single Injection of SOCC

- Case I: iap_I2_A = iap_I2_C = iap_I2_D.

- Case II: iap_I2_A ≠ iap_I2_C = iap_I2_D.

3.1.2. Joint Injection of SOCC and FOCC

3.1.3. Determination of Feasibility Boundary

3.2. Analysis of the Peak Current of the MMC in the Rectifier Mode

4. Evaluation of the Performance of the MMC with the MCCIC Scheme

4.1. Evaluation of the Arm Current Reduction

4.2. Evaluation of the Power Handling Capacity Improvement

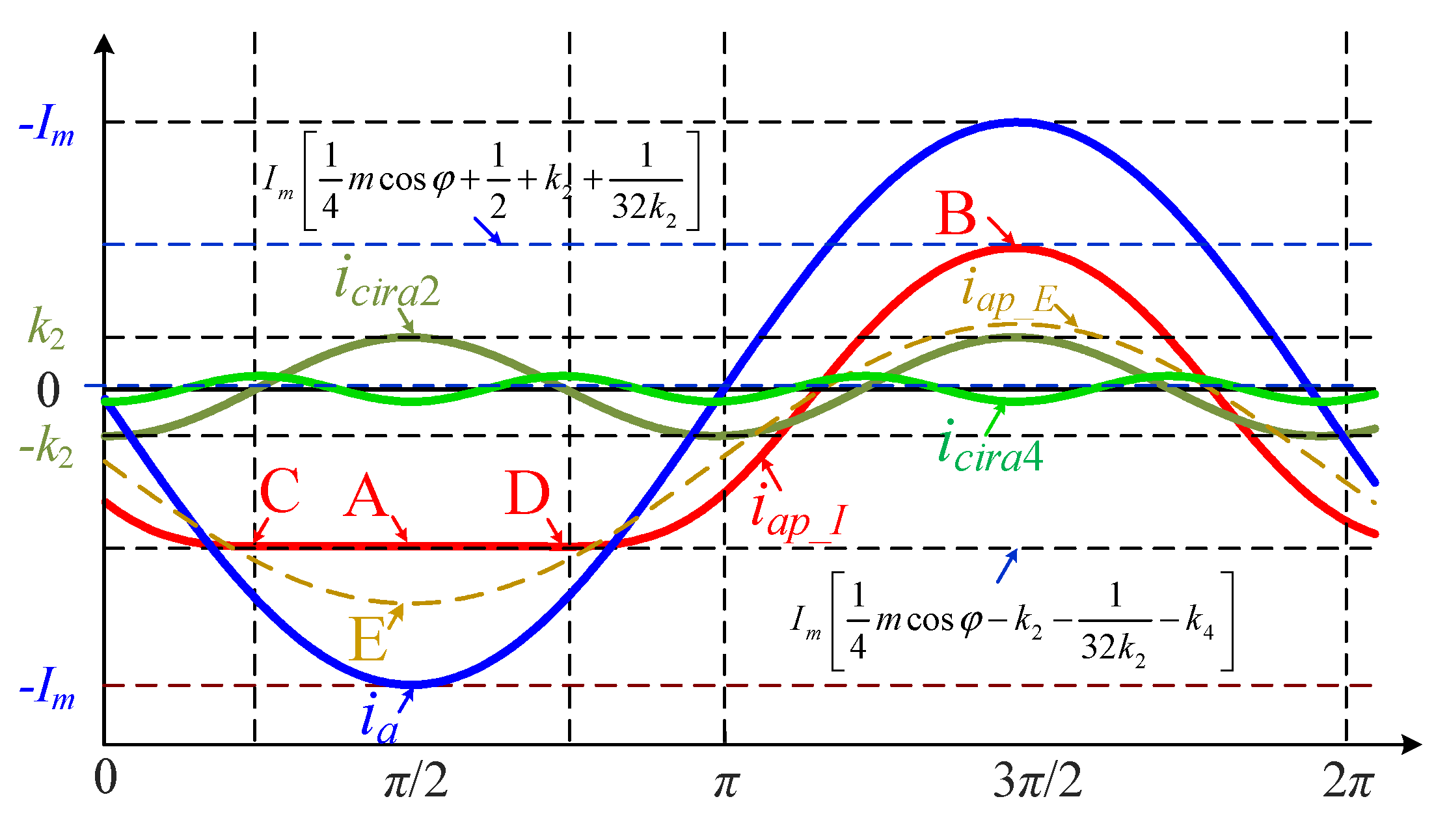

4.3. Evaluation of the System Loss Increase

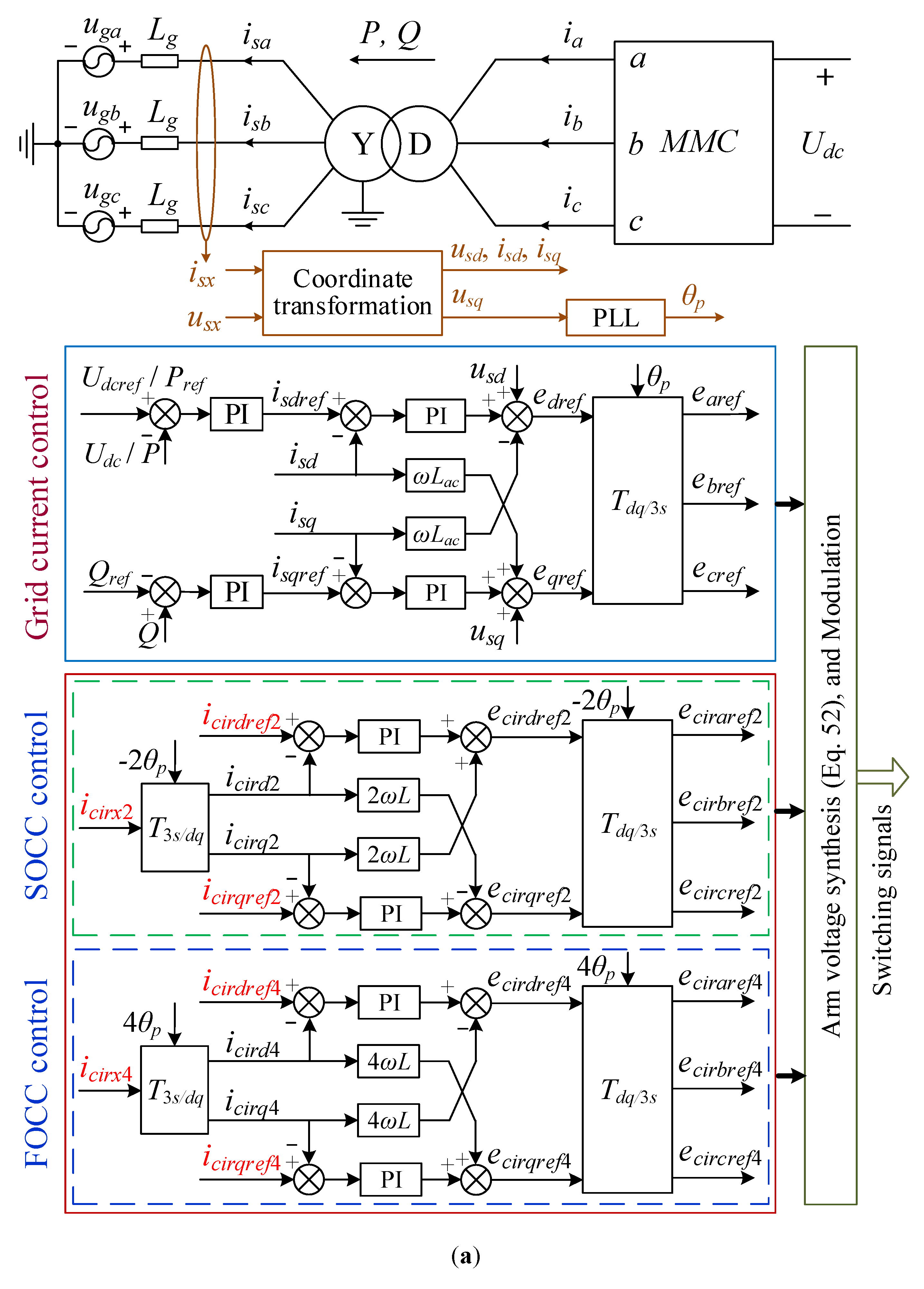

5. Controller Implementation and Decoupling Control of SOCC and FOCC

5.1. Controller Implementation

- (1)

- The PLL-based dual closed-loop control loops for active power or DC-side voltage, reactive power and the three-phase grid currents;

- (2)

- The SOCC control links and the FOCC control links;

- (3)

- The modulation synthesis link and the modulation link;

- (4)

- A series of coordinate transformation links.

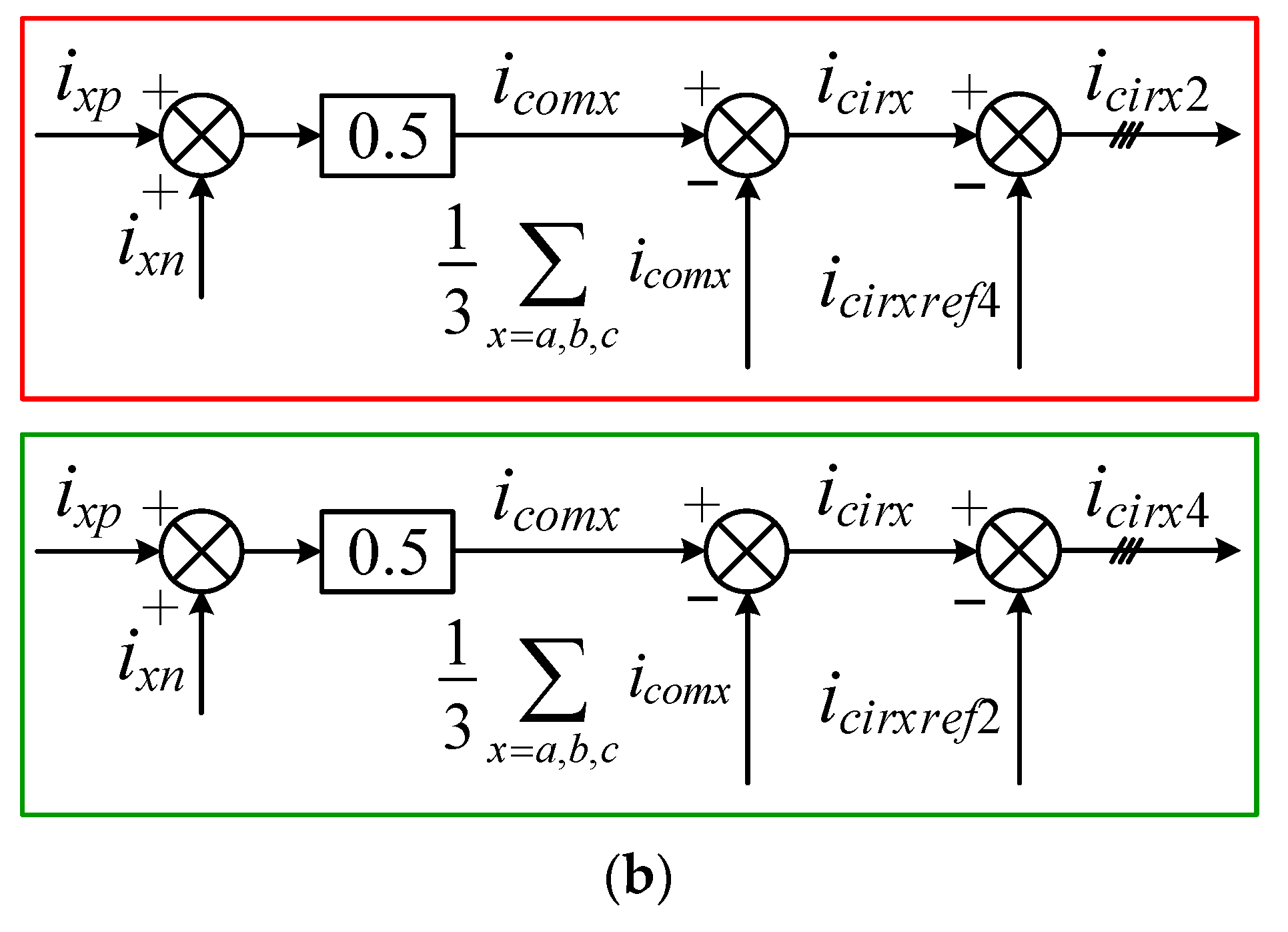

5.2. Decoupling Control of SOCC and FOCC

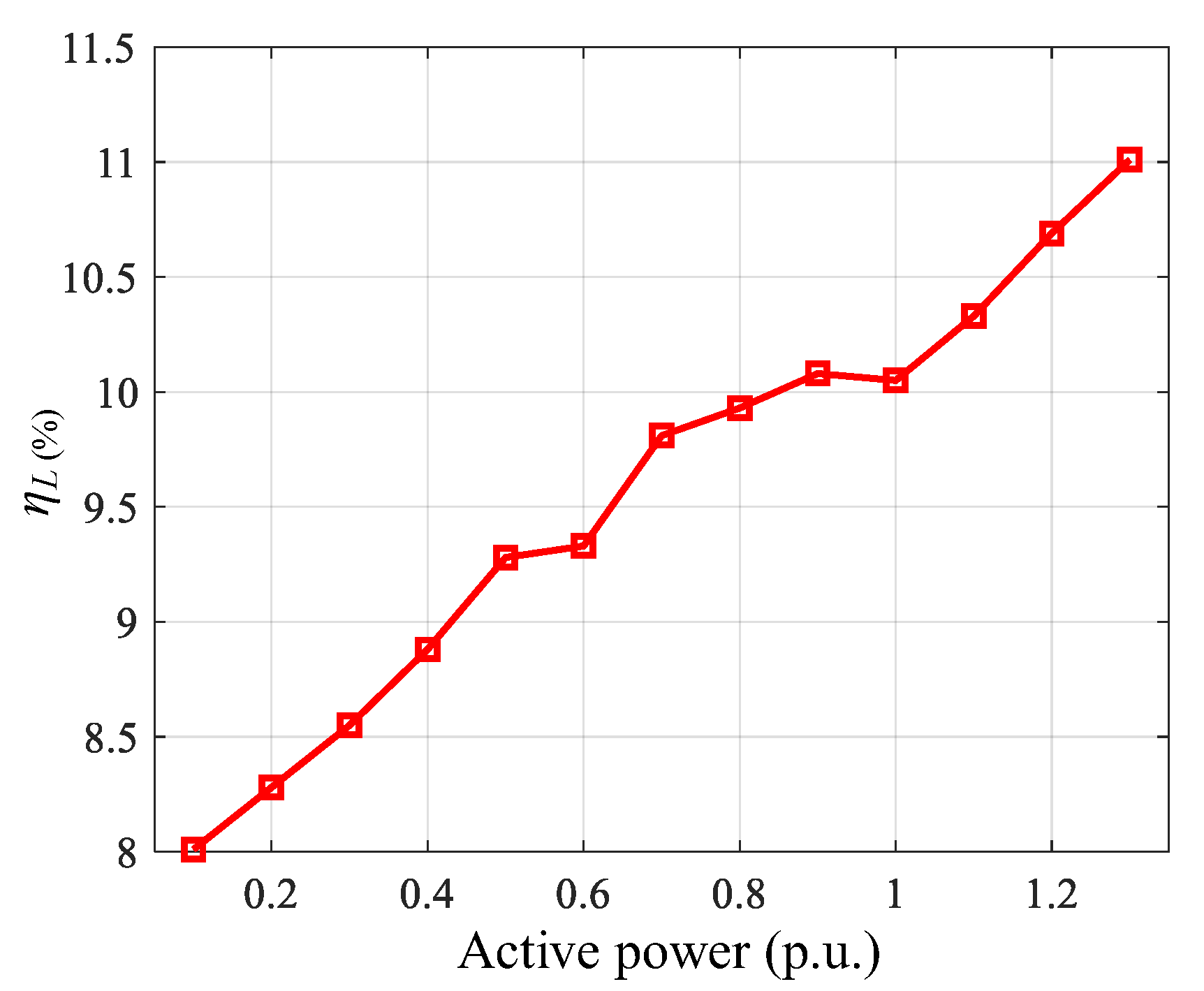

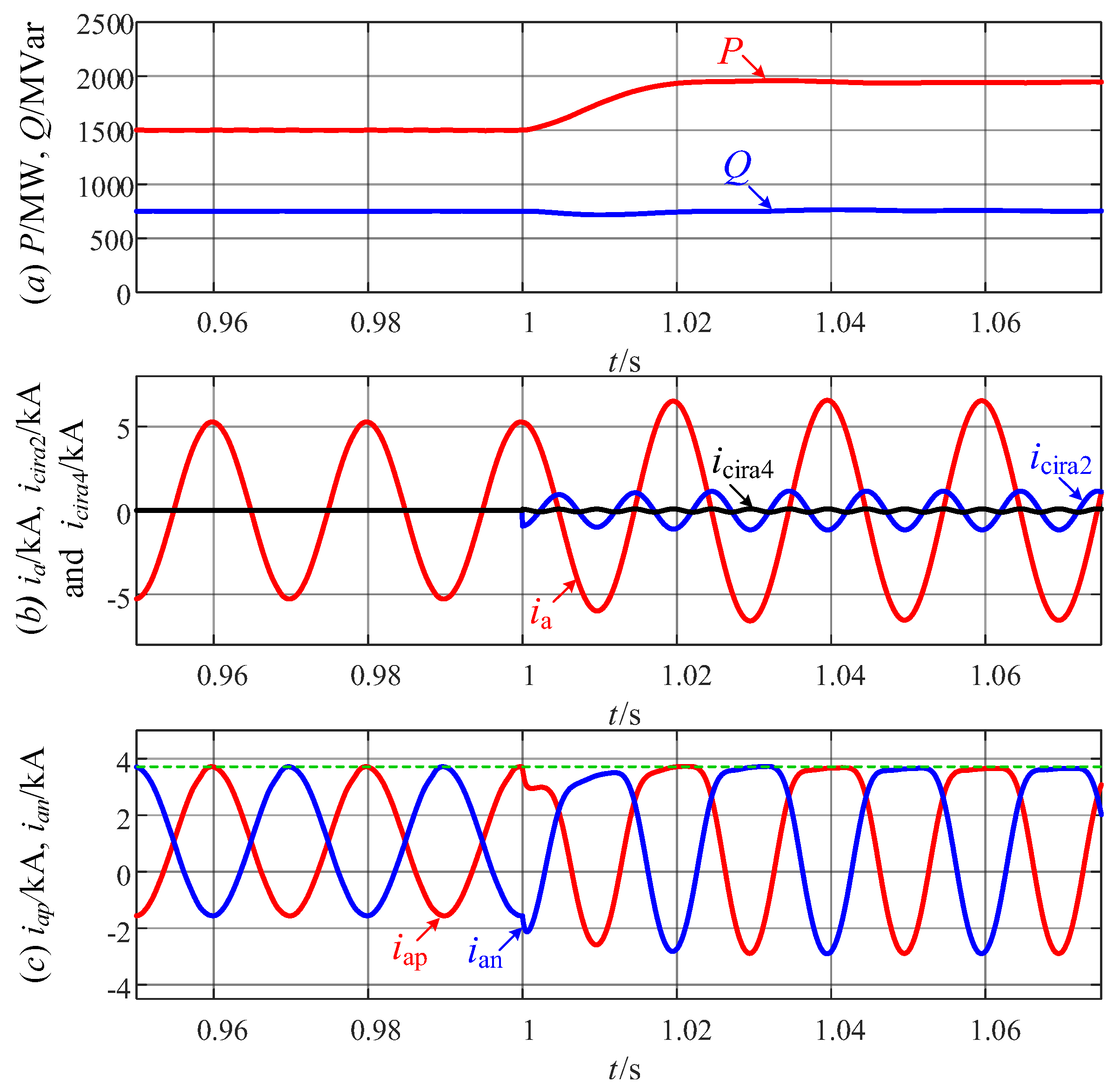

6. Simulation Verification

- (1)

- Active power P and reactive power Q;

- (2)

- Grid current ia, SOCC icira2 and FOCC icira4 of phase a;

- (3)

- Upper arm current iap and lower arm current ian of phase a.

6.1. Performance of the MMC in the Inverter Mode

6.2. Performance of the MMC in the Rectifier Mode

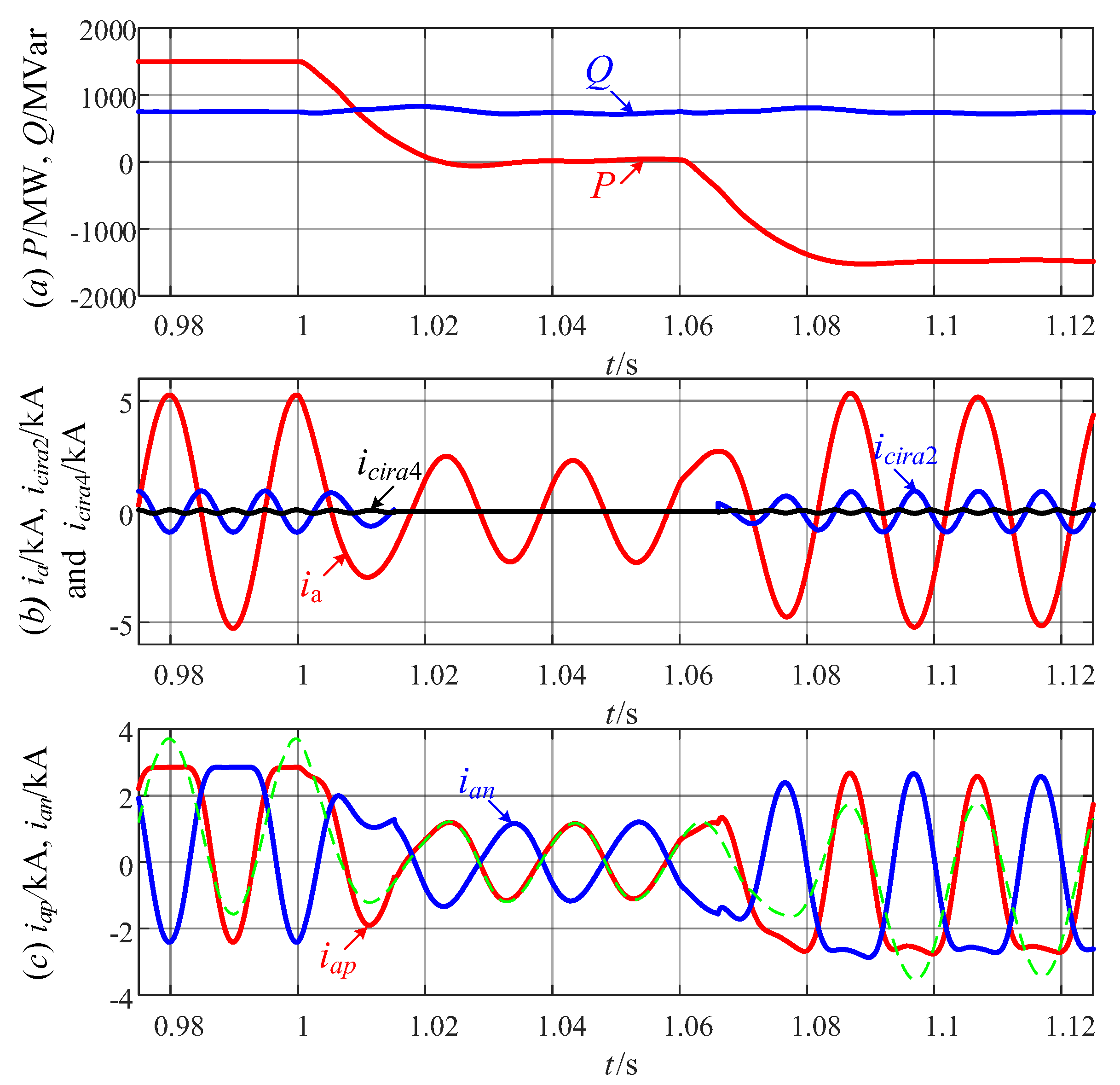

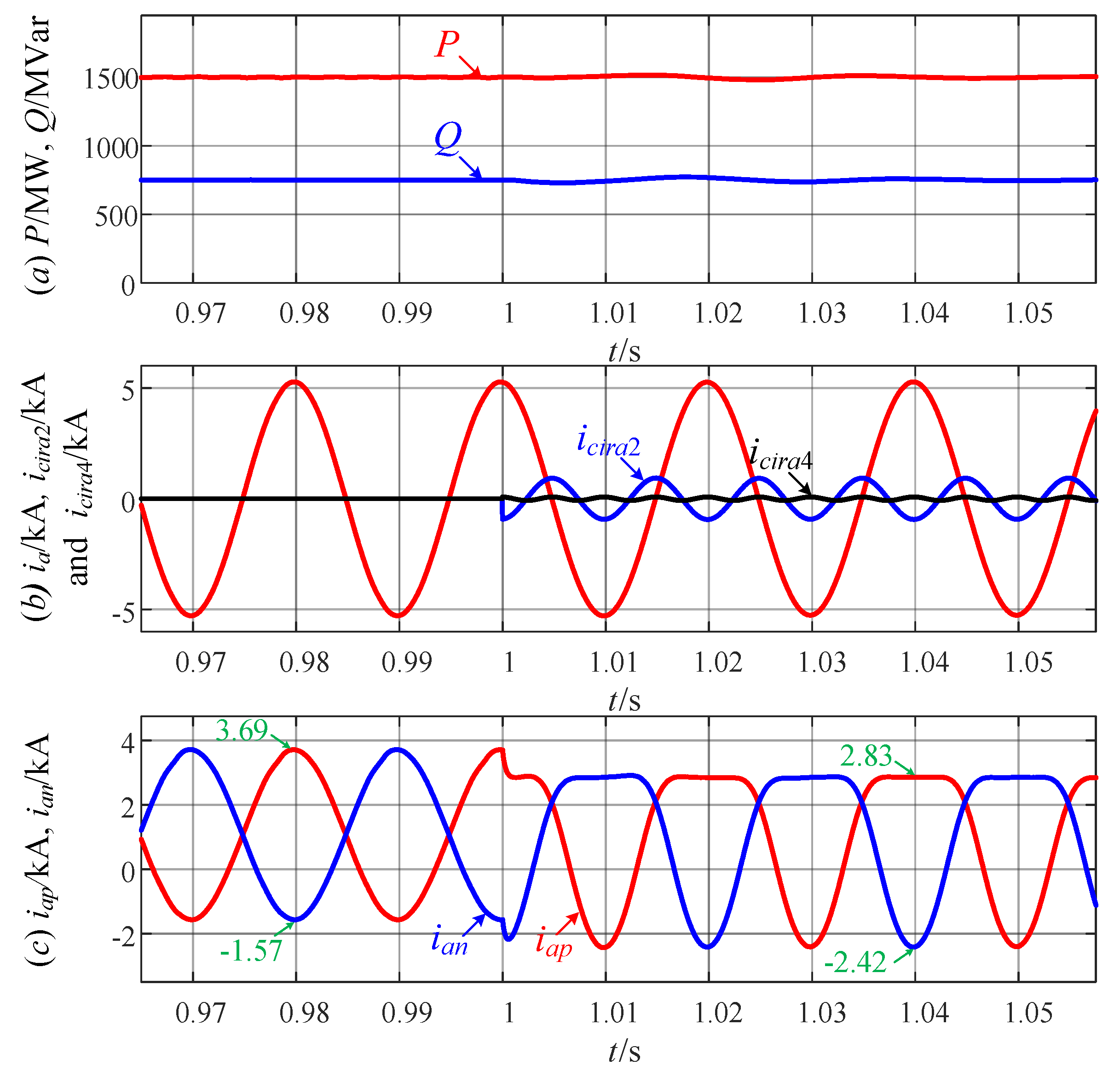

6.3. Dynamic Performance of the MMC Considering Switching Processing

- (1)

- Stage 1 [t < 1 s]: the MMC is set to operate in (P = 1500 MW, Q = 750 MVar) condition. In this stage, the maximum value of the arm current is reduced by 23.0%.

- (2)

- Stage 2 [1 s < t < 1.06 s]: the MMC is set to operate in (P = 0, Q = 750 MVar) condition. In this stage, k2 = k4 = 0 can be obtained since α is less than 0.32. Hence, the arm current waveform of the MCCIC strategy is the same as that of the CCEC strategy.

- (3)

- Stage 3 [t > 1.06 s]: the MMC is set to operate in (P = −1500 MW, Q = 750 MVar) condition. In this stage, the maximum value of the arm current is reduced by 23.2%.

6.4. Overload Performance of the MMC

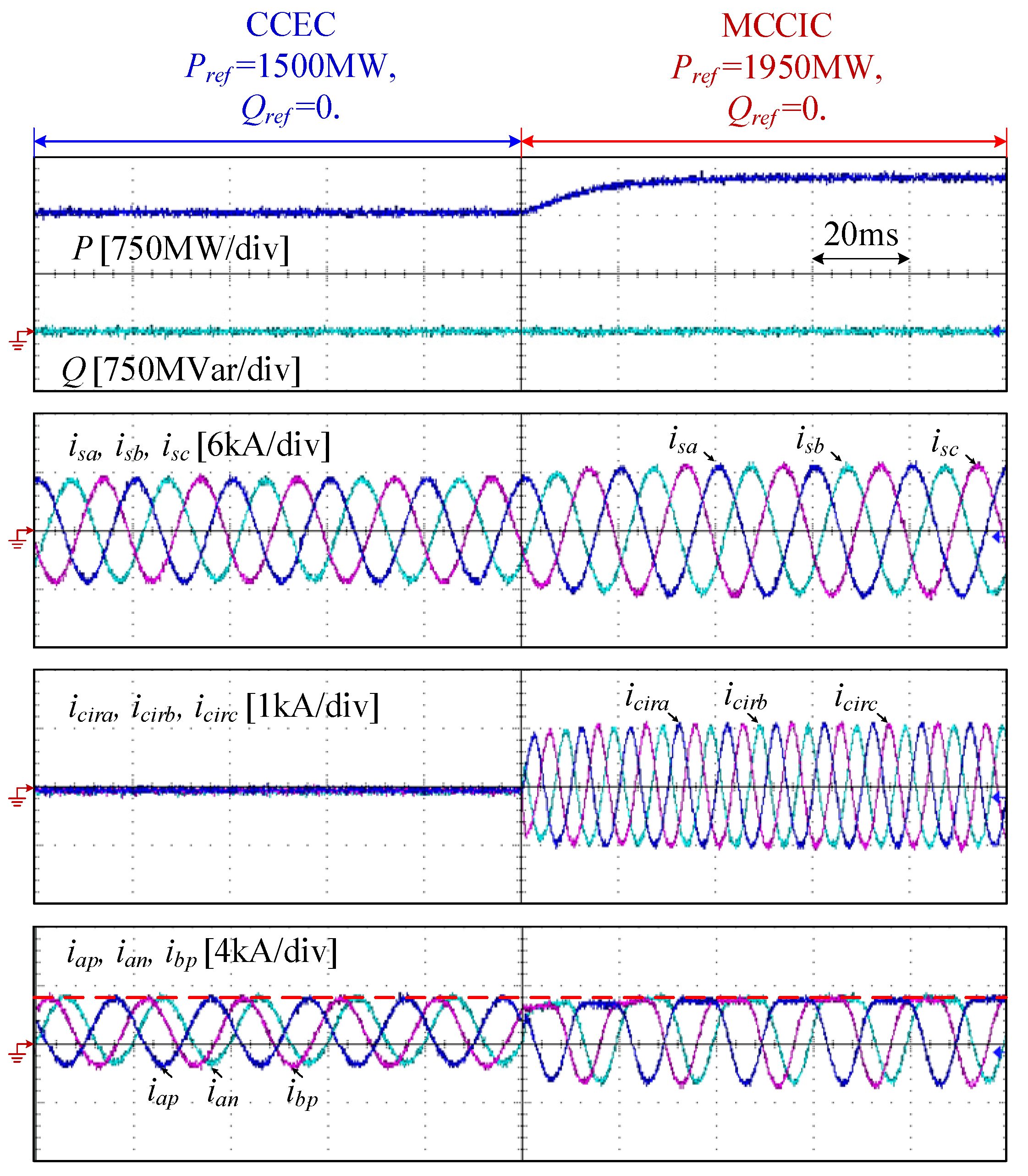

7. Experimental Verification

- (1)

- Active power P and reactive power Q;

- (2)

- Three-phase AC grid currents isa, isb and isc;

- (3)

- Three-phase CCs icira, icirb, and icirc (including aggregated SOCC and FOCC);

- (4)

- Currents flowing through the upper arm and lower arm of phase a, i.e., iap and ian, and the current flowing through the upper arm of phase B, i.e., ibp.

- (1)

- Stage 1 [t < 0.04 s]: the CCEC strategy is used and the MMC is set to operate in (P = 1500 MW, Q = 0) condition. In this stage, the maximum value of the arm current is 3.40 kA.

- (2)

- Stage 2 [0.04 s < t < 0.14 s]: the MCCIC strategy is enabled and the MMC keeps operating in (P = 1500 MW, Q = 0) condition. In this stage, the maximum value of the arm current is 3.62 kA, achieving a reduction of 22.7%.

- (3)

- Stage 3 [t > 0.14 s]: the MCCIC strategy keeps enabled and the MMC is set to operate in (P = 1500 MW, Q = 750 MVar) condition. In this stage, the maximum value of the arm current is 2.81 kA. Obviously, the arm current waveform of the MMC has been sliced off.

8. Conclusions

- (1)

- By injecting both the appropriate SOCC and FOCC, the maximum value of the arm current can be reduced by about 23%, which allows up to a 30% overload ability of the MMC operating with high power factors beyond its active power limit set by the peak arm current.

- (2)

- The CC decoupling control technology developed to take advantage of the high bandwidth of the current loop allows precise control of the SOCC and the FOCC to be achieved.

- (3)

- Compared to the CCEC scheme, the losses of the MMC operating with high active power levels are increased by about 11% when using the proposed scheme. However, this increased loss can be neglected due to the short-term overload operation setting.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lesnicar, A.; Marquardt, R. An Innovative Modular Multilevel Converter Topology Suitable for a Wide Power Range. In Proceedings of the IEEE Bologna Power Tech Conference Proceedings, Bologna, Italy, 23–26 June 2003; Volume 3, p. 6. [Google Scholar]

- Marquardt, R. Modular Multilevel Converters: State of the Art and Future Progress. IEEE Power Electron. Mag. 2018, 5, 24–31. [Google Scholar] [CrossRef]

- Deng, F.; Chen, Y.; Dou, J.; Liu, C.; Chen, Z.; Blaabjerg, F. Isolation Forest Based Submodule Open-Circuit Fault Localization Method for Modular Multilevel Converters. IEEE Trans. Ind. Electron. 2023, 70, 3090–3102. [Google Scholar] [CrossRef]

- Liu, C.; Deng, F.; Zhang, J.; Cai, X.; Chen, Z.; Blaabjerg, F. Power Loss Reduction Control for Modular Multilevel Converters Based on Resistor Controllable Submodule. IEEE Trans. Power Electron. 2022, 37, 9767–9776. [Google Scholar] [CrossRef]

- Perez, M.A.; Ceballos, S.; Konstantinou, G.; Pou, J.; Aguilera, R.P. Modular Multilevel Converters: Recent Achievements and Challenges. IEEE Open J. Ind. Electron. Soc. 2021, 2, 224–239. [Google Scholar] [CrossRef]

- Jin, Y.; Xiao, Q.; Jia, H.; Ji, Y.; Dragicevic, T.; Teodorescu, R.; Blaabjerg, F. A Novel Detection and Localization Approach of Open-Circuit Switch Fault for the Grid-Connected Modular Multilevel Converter. IEEE Trans. Ind. Electron. 2023, 70, 112–124. [Google Scholar] [CrossRef]

- Jiang, Y.; Shu, H.; Liao, M. Fault-Tolerant Control Strategy for Sub-Modules Open-Circuit Fault of Modular Multilevel Converter. Electronics 2023, 12, 1080. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Ma, N.; Zeng, R.; Wang, Z. Waveform-Similarity-Based Protection Scheme for AC Transmission Lines of MMC-HVDC System with Offshore Wind Farms. Energies 2022, 15, 9107. [Google Scholar] [CrossRef]

- Castro, L.; Acha, E. On the Provision of Frequency Regulation in Low Inertia AC Grids Using HVDC Systems. IEEE Trans. Smart Grid 2016, 7, 2680–2690. [Google Scholar] [CrossRef]

- Vilmann, B.; Hjerrild, J.; Randewijk, P.J.; Khalil, A. Frequency and Voltage Compliance Capability of Grid-Forming Wind Turbines in Offshore Wind Farms in Weak Grids with a Power Imbalance. In Proceedings of the 2022 57th International Universities Power Engineering Conference (UPEC), Istanbul, Turkey, 30 August–2 September 2022; p. 8. [Google Scholar]

- Poulose, A.; Kim, S. Transient Stability Analysis and Enhancement Techniques of Renewable-Rich Power Grids. Energies 2023, 16, 2495. [Google Scholar] [CrossRef]

- Ippolito, M.G.; Musca, R.; Zizzo, G. Analysis and Simulations of the Primary Frequency Control during a System Split in Continental Europe Power System. Energies 2021, 14, 1456. [Google Scholar] [CrossRef]

- Yang, R.; Shi, G.; Cai, X.; Zhang, C.; Li, G.; Liang, J. Autonomous Synchronizing and Frequency Response Control of Multi-terminal DC Systems with Wind Farm Integration. IEEE Trans. Sustain. Energy 2020, 11, 2504–2514. [Google Scholar] [CrossRef]

- Chen, Y.; Li, W.; Lannuzzo, F.; Luo, H.; He, X.; Blaabjerg, F. Investigation and Classification of Short-Circuit Failure Modes Based on Three-Dimensional Safe Operating Area for High-Power IGBT Modules. IEEE Trans. Power Electron. 2018, 33, 1075–1086. [Google Scholar] [CrossRef]

- Ilves, K.; Antonopoulos, A.; Norrga, S.; Nee, H.-P. Steady-State Analysis of Interaction Between Harmonic Components of Arm and Line Quantities of Modular Multilevel Converters. IEEE Trans. Power Electron. 2012, 27, 57–68. [Google Scholar] [CrossRef]

- Wang, S.; Adam, G.P.; Massoud, A.M.; Holliday, D.; Williams, B.W. Analysis and Assessment of Modular Multilevel Converter Internal Control Schemes. IEEE Trans. Emerg. Sel. Topics Power Electron. 2020, 8, 697–719. [Google Scholar] [CrossRef]

- Bergna, G.; Suul, J.A.; Berne, E.; Vannier, J.D.; Molinas, M. Optimal Shaping of the MMC Circulating Currents for Preventing AC-Side Power Oscillations from Propagating into HVdc Grids. IEEE Trans. Emerg. Sel. Topics Power Electron. 2019, 7, 1015–1030. [Google Scholar] [CrossRef]

- Reddy, G.A.; Shukla, A. Arm-Current-Sensorless Circulating Current Control of MMC. IEEE Trans. Ind. Appl. 2022, 58, 444–456. [Google Scholar] [CrossRef]

- Norrga, S.; Angquist, L.; Ilves, K. Operating Region Extension for Multilevel Converters in HVDC Applications by Optimisation Methods. In Proceedings of the 10th IET International Conference on AC and DC Power Transmission, Birmingham, UK, 4–5 December 2012; p. 6. [Google Scholar]

- Tu, Q.; Xu, Z.; Lie, X. Reduced Switching-Frequency Modulation and Circulating Current Suppression for Modular Multilevel Converters. IEEE Trans. Power Del. 2011, 26, 2009–2017. [Google Scholar]

- Li, Z.; Wang, P.; Chu, Z.; Zhu, H.; Luo, Y.; Li, Y. An Inner Current Suppressing Method for Modular Multilevel Converters. IEEE Trans. Power Electron. 2013, 28, 4873–4879. [Google Scholar] [CrossRef]

- Li, X.; Song, Q.; Liu, W.; Xu, S.; Zhu, Z.; Li, X. Performance Analysis and Optimization of Circulating Current Control for Modular Multilevel Converter. IEEE Trans. Ind. Electron. 2016, 73, 716–727. [Google Scholar] [CrossRef]

- Kim, H.; Kim, S.; Chung, Y.-H.; Yoo, D.-W.; Kim, C.-K.; Hur, K. Operating Region of Modular Multilevel Converter for HVDC with Controlled Second-Order Harmonic Circulating Current: Elaborating P-Q Capability. IEEE Trans. Power Del. 2016, 31, 493–502. [Google Scholar] [CrossRef]

- Pou, J.; Ceballos, S.; Konstantinou, G.; Agelidis, V.G.; Picas, R.; Zaragoza, J. Circulating Current Injection Methods Based on Instantaneous Information for the Modular Multilevel Converter. IEEE Trans. Ind. Electron. 2015, 62, 777–788. [Google Scholar] [CrossRef]

- Alharbi, M.; Isik, S.; Bhattacharya, S. Control of Circulating Current to Minimize the Rating of the Energy Storage Device in Modular Multilevel Converters. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition, Baltimore, MD, USA, 28 November 2019; pp. 6041–6045. [Google Scholar]

- Deng, F.; Zhao, J.; Liu, C.; Wang, Z.; Cai, X.; Blaabjerg, F. Temperature-Balancing Control for Modular Multilevel Converters Under Unbalanced Grid Voltages. IEEE Trans. Power Electron. 2022, 37, 4614–4625. [Google Scholar] [CrossRef]

- Yang, L.; Li, Y.; Li, Z.; Wang, P.; Xu, S.; Gou, R. Loss Optimization of MMC by Second-Order Harmonic Circulating Current Injection. IEEE Trans. Power Electron. 2018, 33, 5739–5753. [Google Scholar] [CrossRef]

- Moranchel, M.; Bueno, E.; Sanz, I.; Rodríguez, F.J. New Approaches to Circulating Current Controllers for Modular Multilevel Converters. Energies 2017, 10, 86. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, J.; Zhao, Z.; Liu, K.; Wang, P.; Yang, B. Decoupled Current Controller Based on Reduced Order Generalized Integrator for Three-Phase Grid-Connected VSCs in Distributed System. Energies 2019, 12, 2426. [Google Scholar] [CrossRef]

- Deng, F.; Lü, Y.; Liu, C.; Heng, Q.; Yu, Q.; Zhao, J. Overview on Submodule Topologies, Modeling, Modulation, Control Schemes, Fault Diagnosis, and Tolerant Control Strategies of Modular Multilevel Converters. Chin. J. Elect. Eng. 2020, 6, 1–21. [Google Scholar] [CrossRef]

- Shi, X.; Yang, R.; Cai, X.; Fang, Z.; Dong, P.; Rao, F. Improved Comprehensive Energy-Based Control for MMC-HVDC System. Int. J. Elect. Power Energy Syst. 2023, 145, 108593. [Google Scholar] [CrossRef]

- Zhang, M.; Huang, L.; Yao, W.; Lu, Z. Circulating Harmonic Current Elimination of a CPS-PWM-Based Modular Multilevel Converter with a Plug-In Repetitive Controller. IEEE Trans. Power Electron. 2013, 29, 2083–2097. [Google Scholar] [CrossRef]

- Yang, L.; Li, Y.; Li, Z.; Wang, P.; Xu, S.; Gou, R. A Simplified Analytical Calculation Model of Average Power Loss for Modular Multilevel Converter. IEEE Trans. Ind. Electron. 2019, 66, 2313–2322. [Google Scholar] [CrossRef]

- Available online: https://search.abb.com/library/Download.aspx?DocumentID=5SYA%201450&LanguageCode=en&DocumentPartId=&Action=Launch (accessed on 10 March 2023).

| Parameters | Simples | Values | Units |

|---|---|---|---|

| Rated apparent power | SN | 1680 | MVA |

| Rated active power | PN | 1500 | MW |

| Rated reactive power | QN | 750 | MVar |

| Rated DC bus voltage | UdcN | 500 | kV |

| Grid voltage (L-L) | UmN | 230 | kV |

| Rated frequency | f | 50 | Hz |

| Transformer ratio | kT | 230/260 | / |

| Transformer leakage inductance | LT | 0.15 | pu |

| Number of submodules per arm | N | 250 | / |

| Submodule capacitance | C | 20 | mF |

| Arm inductance | La | 30 | mH |

| Grid inductance | Lg | 40 | mH |

| Inverter Mode | Rectifier Mode | |||

|---|---|---|---|---|

| CCEC | MCCIC | CCEC | MCCIC | |

| IE (kA) | 3.63 | / | −3.4 | / |

| 3.69 | / | −3.3 | / | |

| IA (kA) | / | 2.78 | / | −2.57 |

| / | 2.83 | / | −2.54 | |

| IB (kA) | / | −2.48 | / | 2.15 |

| / | −2.42 | / | 2.17 | |

| IC(D) (kA) | / | 2.78 | / | −2.56 |

| / | 2.83 | / | −2.54 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Shi, X.; Chen, M.; Lyu, J.; Li, X.; Zhang, Z.; Cai, X. Peak Arm Current Minimization of Modular Multilevel Converter Using Multiple Circulating Current Injection. Electronics 2023, 12, 1695. https://doi.org/10.3390/electronics12071695

Wang Y, Shi X, Chen M, Lyu J, Li X, Zhang Z, Cai X. Peak Arm Current Minimization of Modular Multilevel Converter Using Multiple Circulating Current Injection. Electronics. 2023; 12(7):1695. https://doi.org/10.3390/electronics12071695

Chicago/Turabian StyleWang, Yifan, Xianqiang Shi, Meifu Chen, Jing Lyu, Xiaotong Li, Zhixiang Zhang, and Xu Cai. 2023. "Peak Arm Current Minimization of Modular Multilevel Converter Using Multiple Circulating Current Injection" Electronics 12, no. 7: 1695. https://doi.org/10.3390/electronics12071695

APA StyleWang, Y., Shi, X., Chen, M., Lyu, J., Li, X., Zhang, Z., & Cai, X. (2023). Peak Arm Current Minimization of Modular Multilevel Converter Using Multiple Circulating Current Injection. Electronics, 12(7), 1695. https://doi.org/10.3390/electronics12071695