Investigation of Lithium-Ion Battery Negative Pulsed Charging Strategy Using Non-Dominated Sorting Genetic Algorithm II

Abstract

1. Introduction

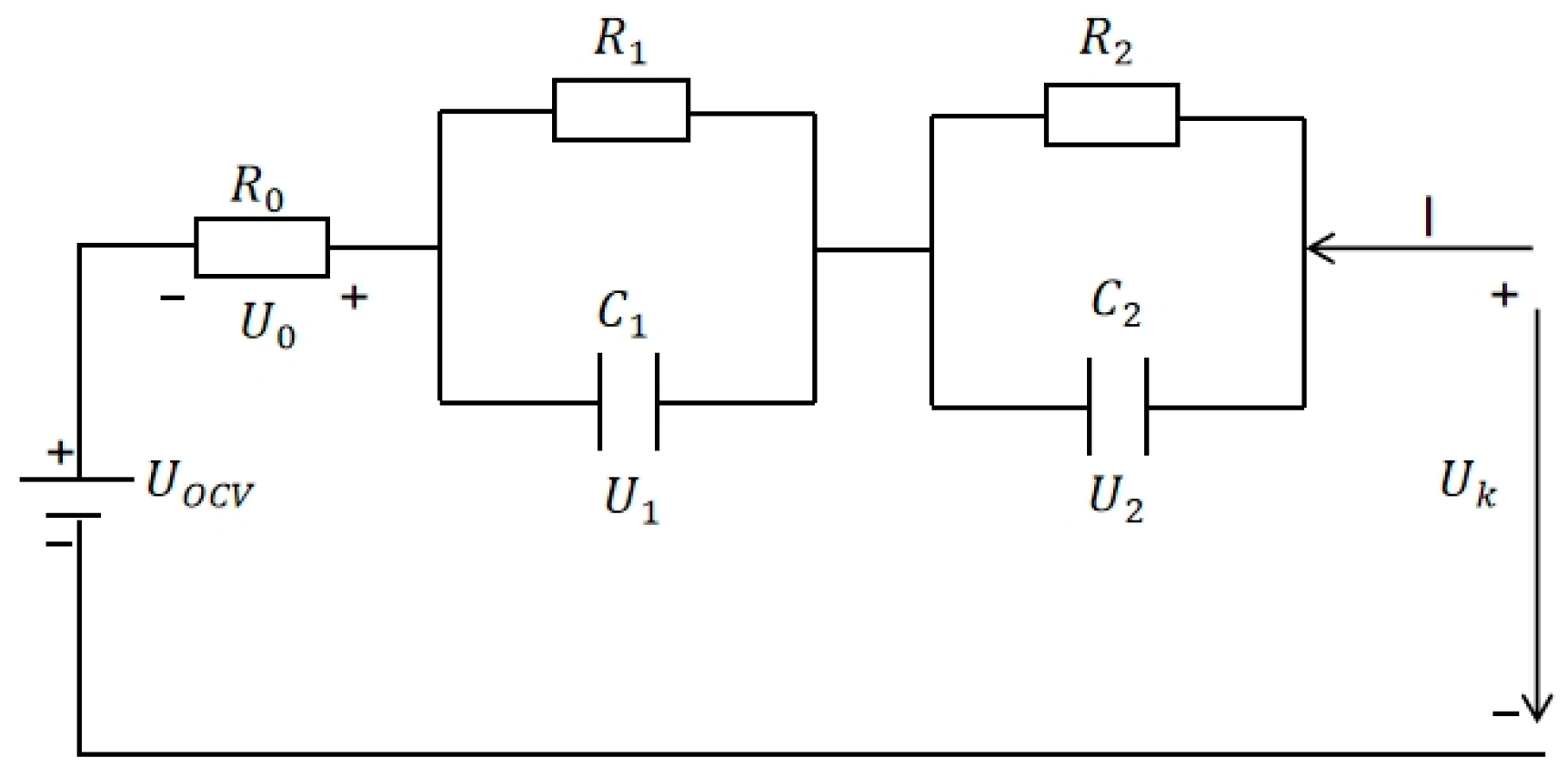

2. Electrothermal Coupling Model

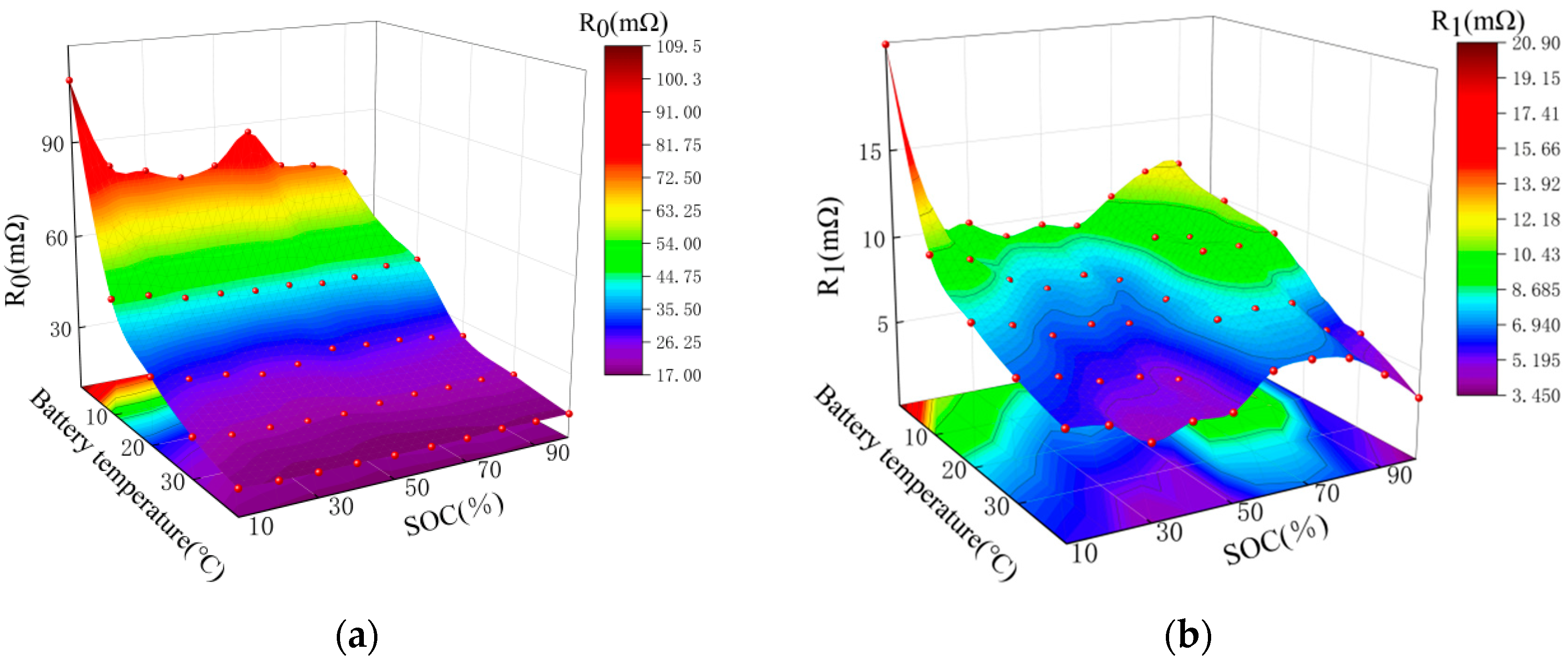

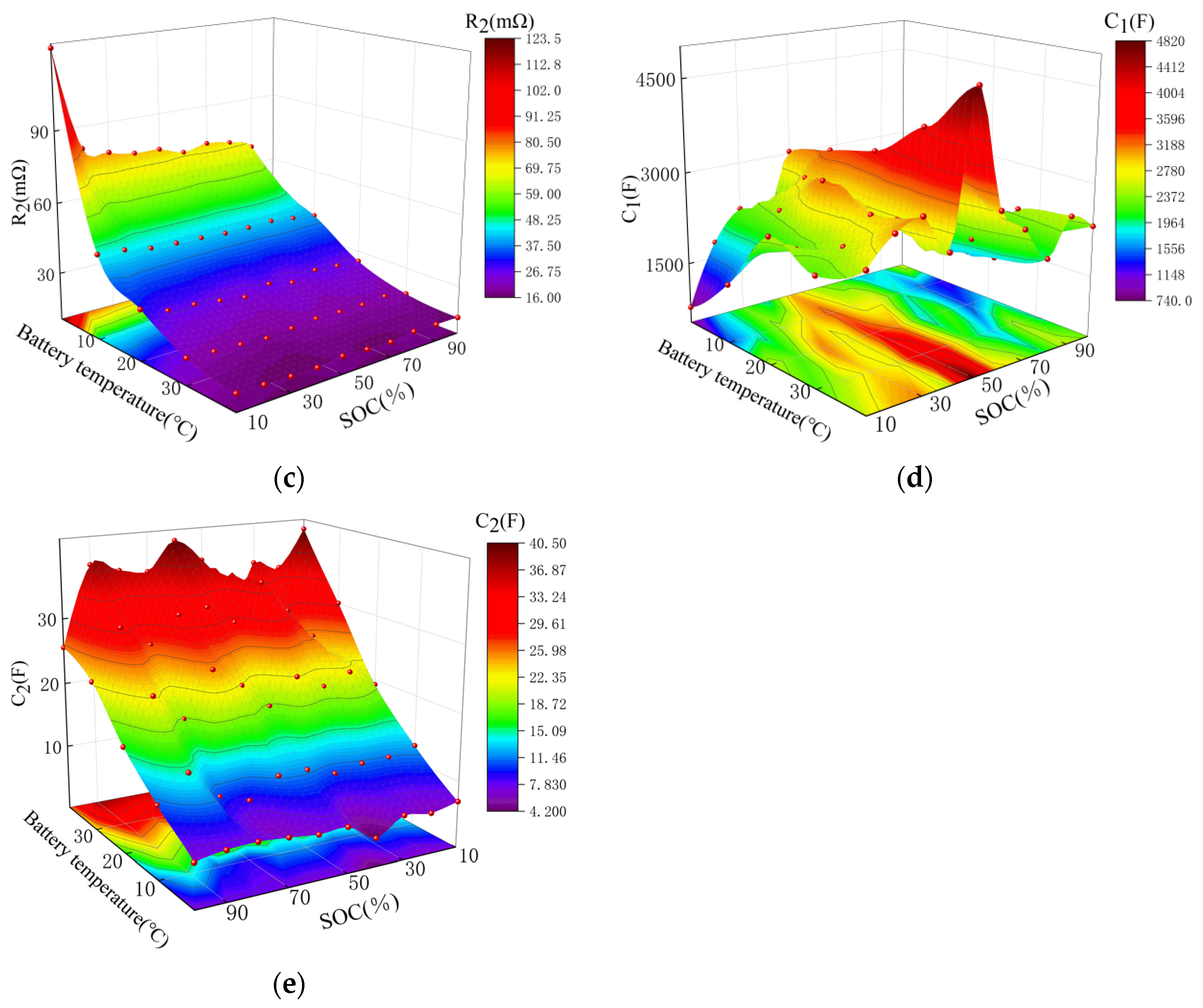

2.1. Electrical Model

2.2. Thermal Model

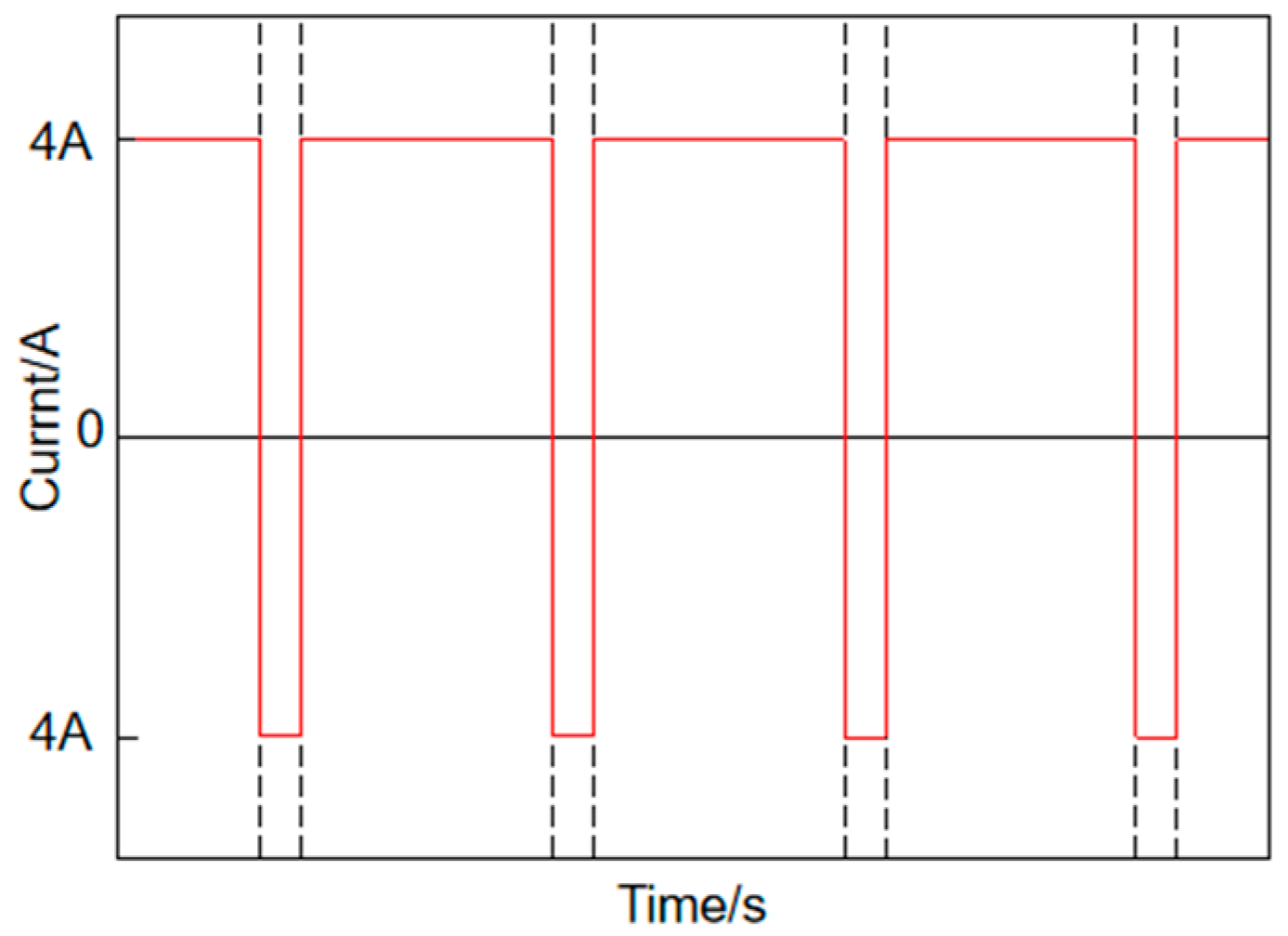

3. Negative Pulsed-Current Charging Strategy Based on NSGA-II

3.1. Optimization Targets

3.2. Constraint

3.3. Optimization Algorithm

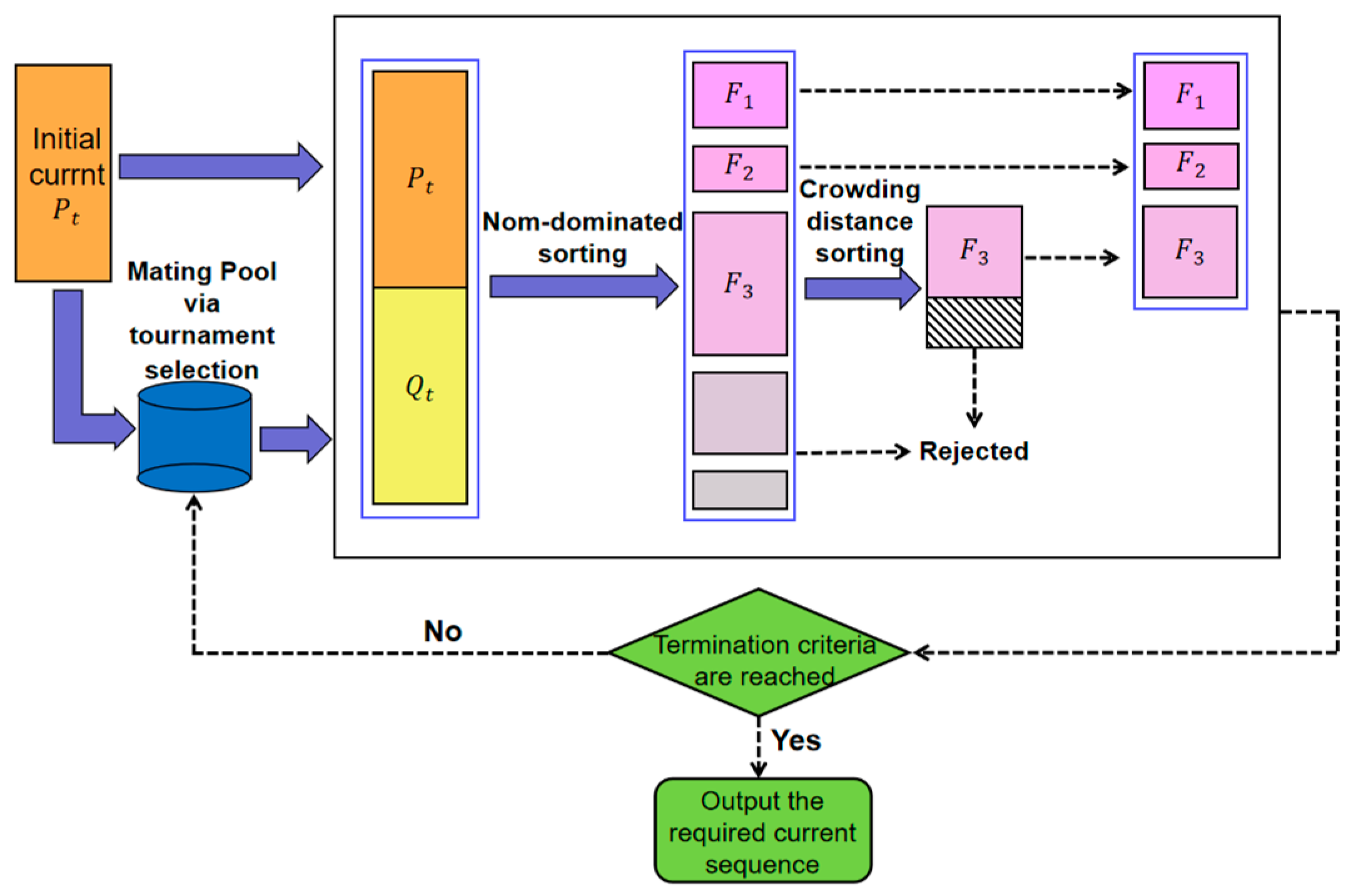

- The electrothermal coupling model and the objective function formula were imported to generate the initial current sequence in accordance with the negative pulsed-current charging characteristics. In this process, the population size and the number of iterations were set to 100. Based on the constraint conditions, M random charge and discharge current sequences were generated. = [], = [];

- 2.

- The charging and discharging current sequences were optimized by implementing selection and cross-mutation operators. The objective functions considered charging time, charging efficiency, and battery temperature rise. The resulting current sequence was compared using non-dominated sorting and crowding distance sorting to obtain the globally optimal charging and discharging current sequence [23,24];

- 3.

- The optimal current sequence and the result of the objective function were constantly updated to verify whether the output charging current sequence satisfied the iterative requirements. If it satisfied the iterative requirements, the final result was derived from the output Pareto front; otherwise, the iteration continued. This section is primarily based on the genetic algorithm toolbox and programming in MATLAB 2022b software.

4. Optimization Results and Discussion

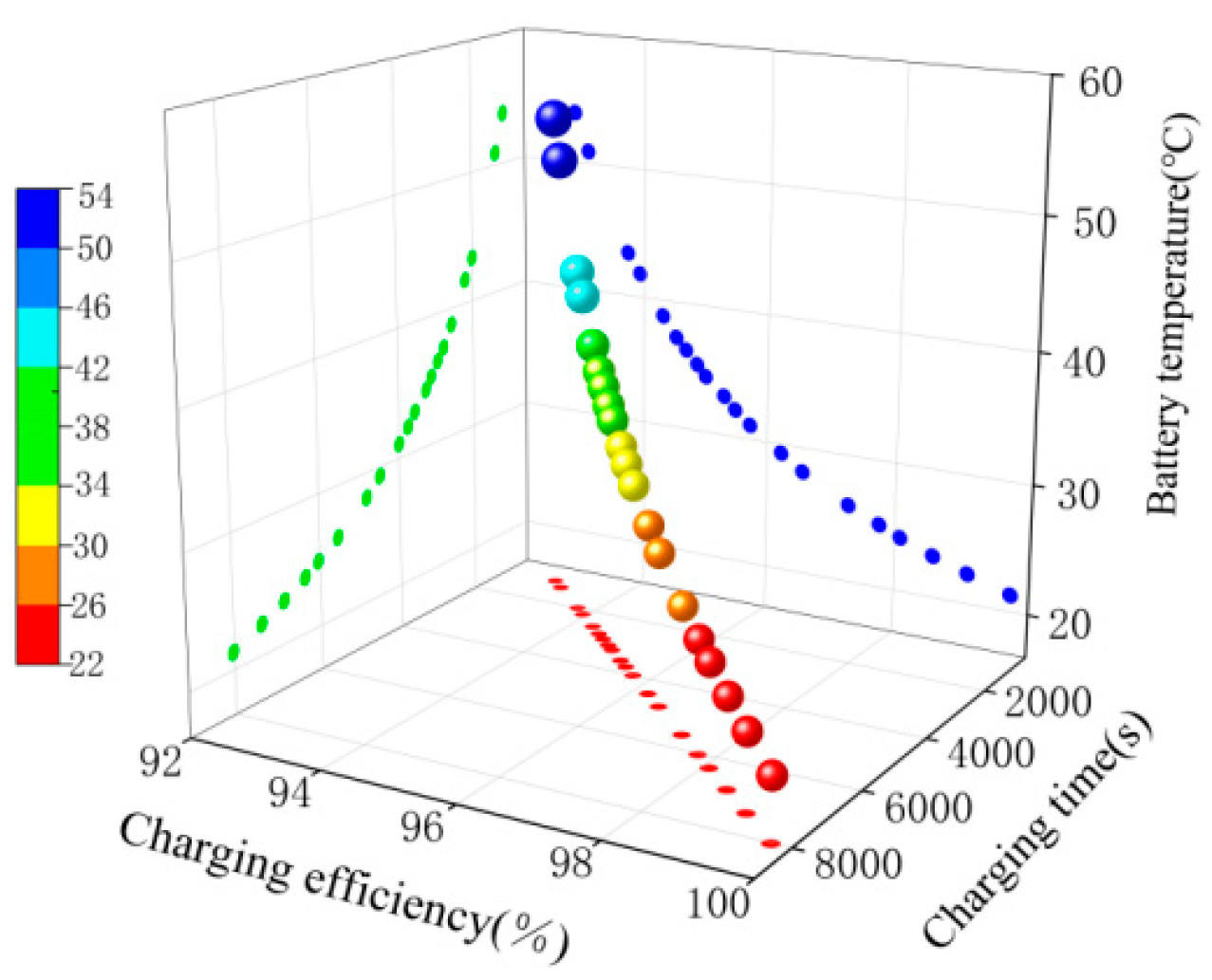

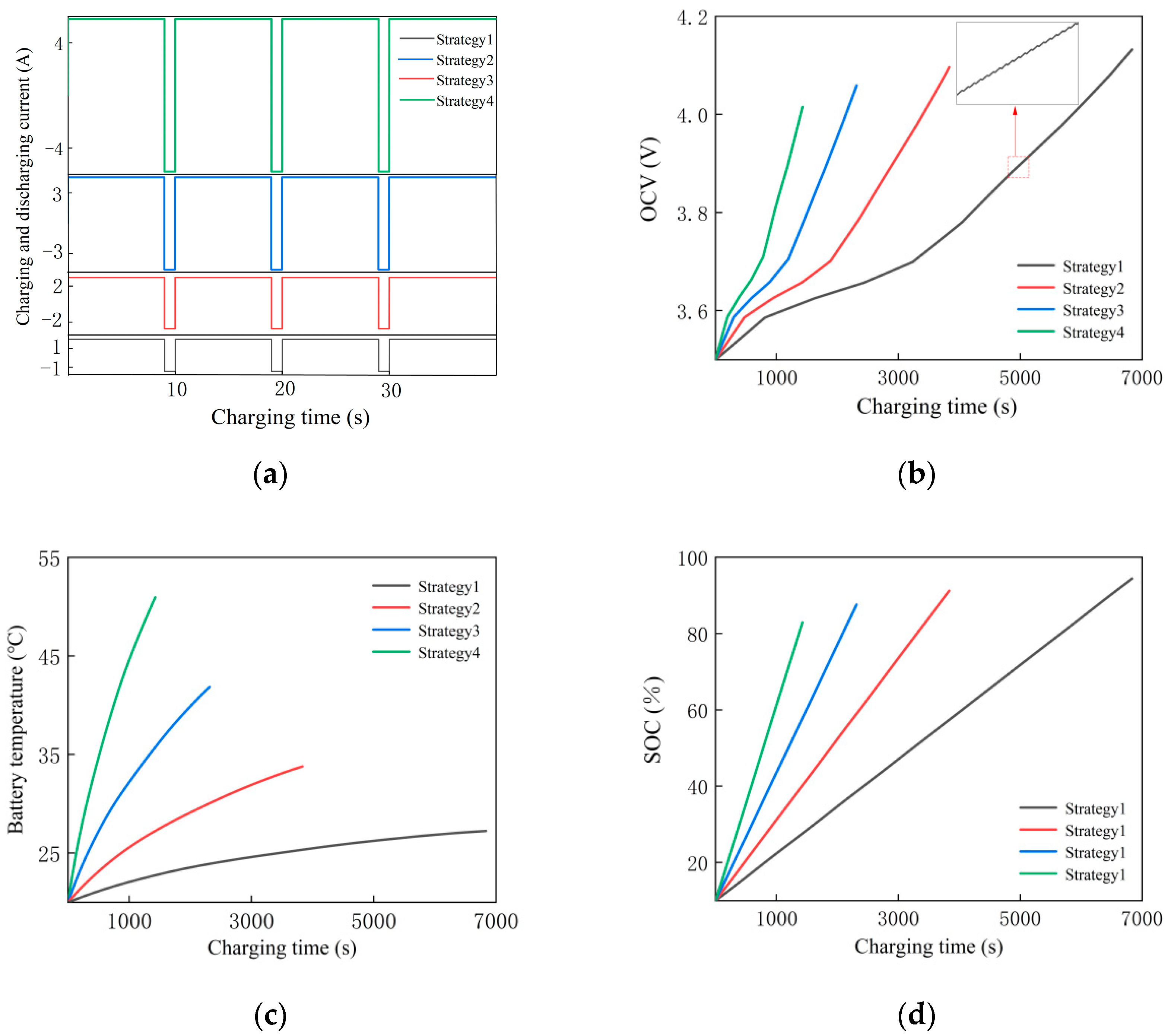

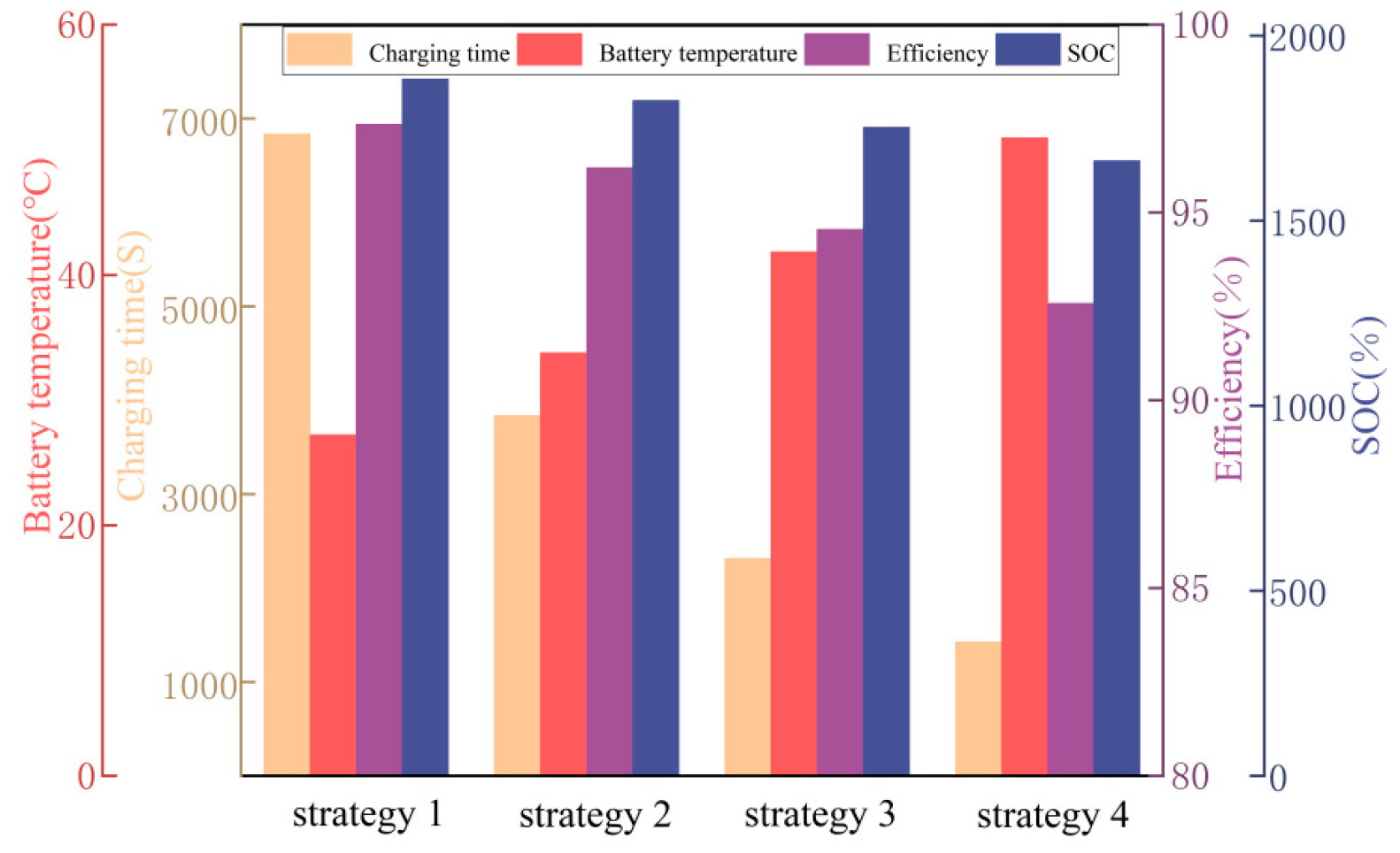

Optimization Strategy for Negative Pulsed-Current Charging

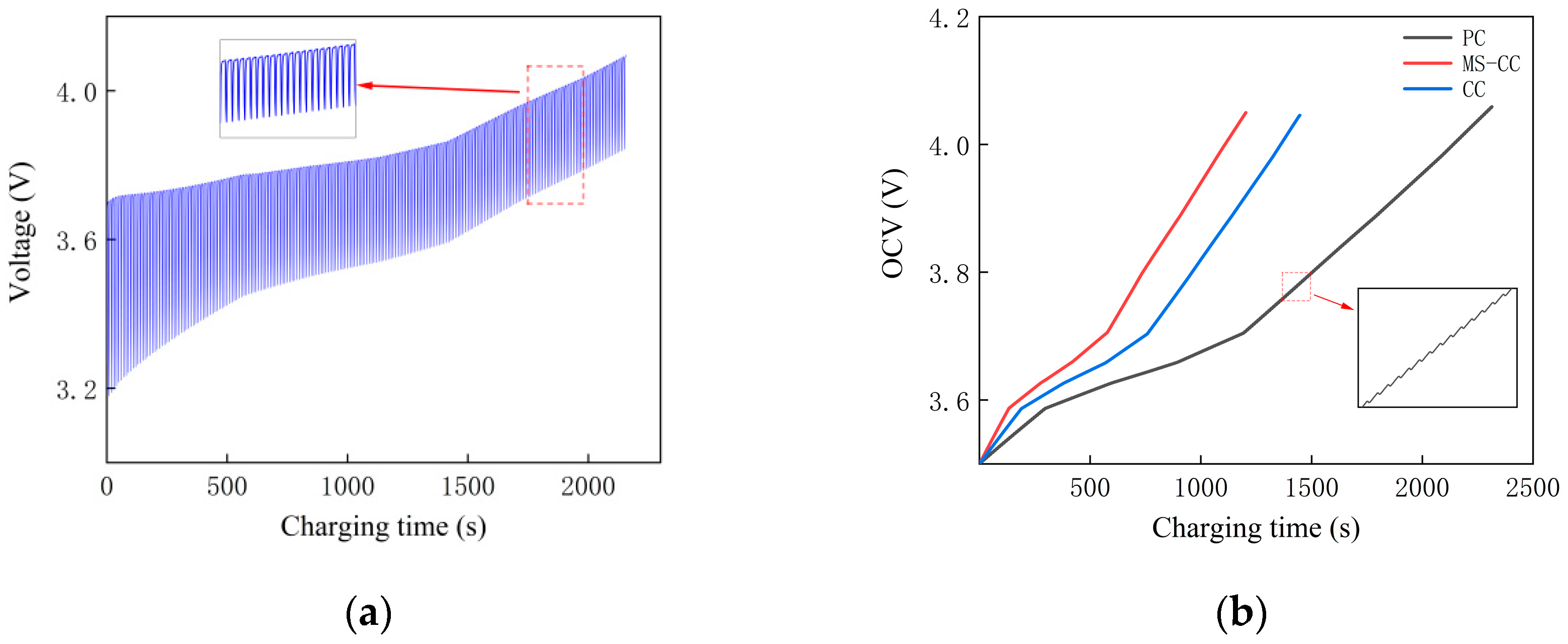

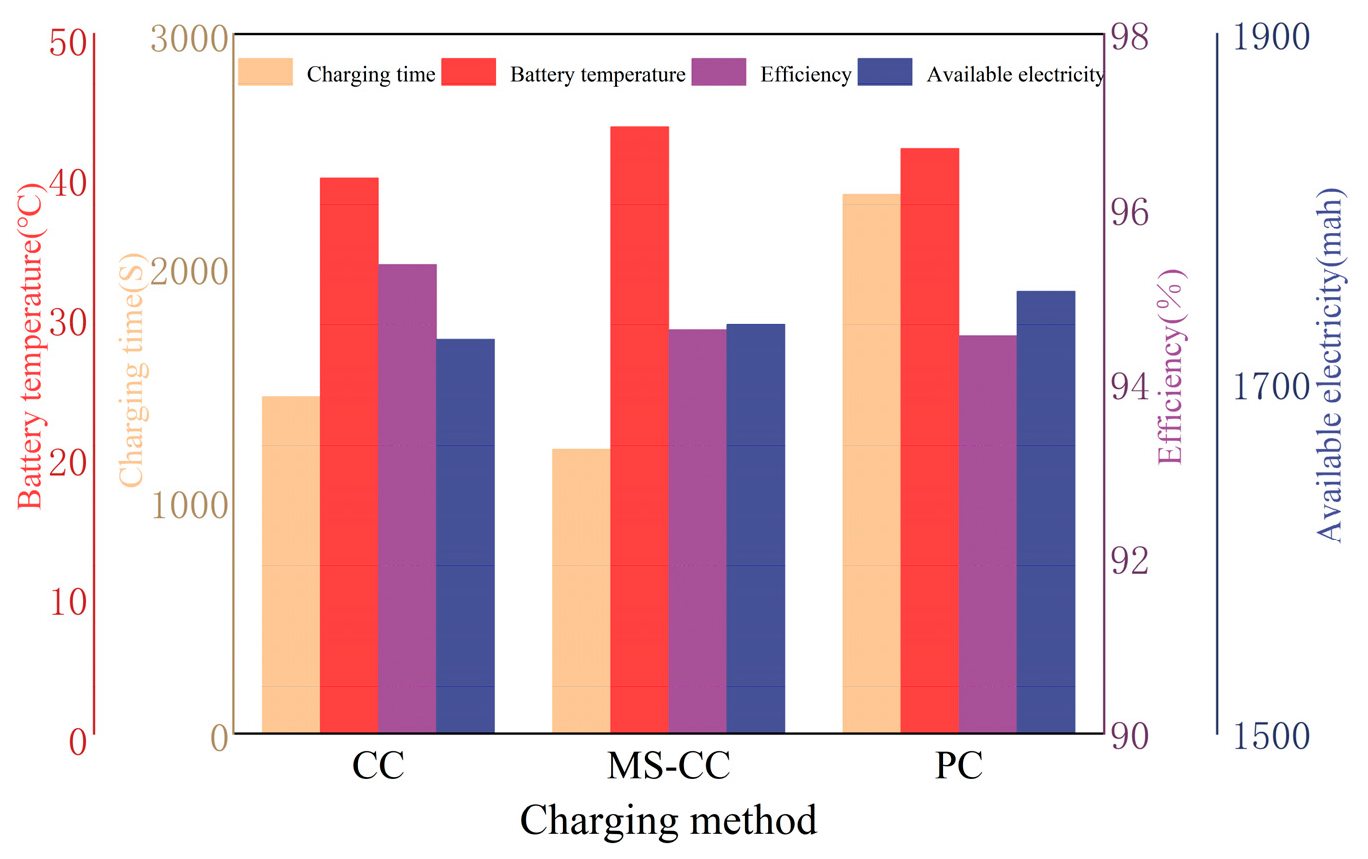

5. Comparison of the CC, PC, and MS-CC Charging Strategy

6. Conclusions

- The proposed charging strategy can effectively charge the battery by optimizing the three objective functions of charging time, charging efficiency, and battery temperature increase;

- In this study, the NSGA-II algorithm was employed to screen the generated charging current sequence through non-dominating sorting and crowding, making it challenging to directly determine the fitness of multi-objective problems. An appropriate charging current magnification is determined depending on the emphasis on different objective functions, resulting in a Pareto optimal solution set;

- The PC charging strategy proposed in this study can balance the internal polarization phenomenon of lithium batteries and significantly enhance the battery’s acceptance of electrical energy. Furthermore, the increase in temperature is lower than that of the MS-CC charging mode. A comparative analysis was conducted between the PC and CC charging capacities at charging rates of 0.5C, 1C, 1.5C, 2C, 2.5C, and 3C. The results demonstrated that the PC charging mode could improve the battery’s charging capacity as the charging rate increased under a 3C charging rate or less.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Patel, M.; Mishra, K.; Banerjee, R.; Chaudhari, J.; Kanchan, D.K.; Kumar, D. Fundamentals, recent developments and prospects of lithium and non-lithium electrochemical rechargeable battery systems. J. Energy Chem. 2023, 81, 221–259. [Google Scholar] [CrossRef]

- He, L.E.; Gu, Z.H.; Zhang, Y.; Jing, H.D.; Li, P.P. Review on Thermal Management of Lithium-Ion Batteries for Electric Vehicles: Advances, Challenges, and Outlook. Energy Fuels 2023, 37, 4835–4857. [Google Scholar] [CrossRef]

- Bugryniec, P.J.; Resendiz, E.G.; Nwophoke, S.M.; Khanna, S.; James, C.; Brown, S.F. Review of gas emissions from lithium-ion battery thermal runaway failure—Considering toxic and flammable compounds. J. Energy Storage 2024, 87, 111288. [Google Scholar] [CrossRef]

- Huang, X.R.; Liu, W.J.; Acharya, A.B.; Meng, J.H.; Teodorescu, R.; Stroe, D.I. Effect of Pulsed Current on Charging Performance of Lithium-Ion Batteries. IEEE Trans. Ind. Electron. 2022, 69, 10144–10153. [Google Scholar] [CrossRef]

- Waseem, M.; Ahmad, M.; Parveen, A.; Suhaib, M. Battery technologies and functionality of battery management system for EVs: Current status, key challenges, and future prospectives. J. Power Sources 2023, 580, 233349. [Google Scholar] [CrossRef]

- Cho, S.Y.; Lee, I.O.; Baek, J.I.; Moon, G.W. Battery Impedance Analysis Considering DC Component in Sinusoidal Ripple-Current Charging. IEEE Trans. Ind. Electron. 2016, 63, 1561–1573. [Google Scholar] [CrossRef]

- Shuangming, D.; Penglai, D. Adaptive charging strategy for lithium batteries based on differential voltage platforms. Energy Storage Sci. Technol. 2023, 12, 1561–1573. [Google Scholar]

- Zhao, D.; Chen, M.B.; Lv, J.; Lei, Z.G.; Song, W.J. Multi-objective optimization of battery thermal management system combining response surface analysis and NSGA-II algorithm. Energy Conv. Manag. 2023, 292, 117374. [Google Scholar] [CrossRef]

- Tian, J.Q.; Li, S.Q.; Liu, X.H.; Yang, D.; Wang, P.; Chang, G.Y. Lithium-ion battery charging optimization based on electrical, thermal and aging mechanism models. Energy Rep. 2022, 8, 13723–13734. [Google Scholar] [CrossRef]

- He, J.H.; Meng, J.K.; Huang, Y.H. Challenges and recent progress in fast-charging lithium-ion battery materials. J. Power Sources 2023, 570, 232965. [Google Scholar] [CrossRef]

- Reisecker, V.; Flatscher, F.; Porz, L.; Fincher, C.; Todt, J.; Hanghofer, I.; Hennige, V.; Linares-Moreau, M.; Falcaro, P.; Ganschow, S.; et al. Effect of pulse-current-based protocols on the lithium dendrite formation and evolution in all-solid-state batteries. Nat. Commun. 2023, 14, 2432. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.R. Design of Duty-Varied Voltage Pulse Charger for Improving Li-Ion Battery-Charging Response. IEEE Trans. Ind. Electron. 2009, 56, 480–487. [Google Scholar] [CrossRef]

- Chen, L.R. A design of an optimal battery pulse charge system by frequency-varied technique. IEEE Trans. Ind. Electron. 2007, 54, 398–405. [Google Scholar] [CrossRef]

- Aryanfar, A.; Brooks, D.; Merinov, B.V.; Goddard, W.A.; Colussi, A.J.; Hoffmann, M.R. Dynamics of Lithium Dendrite Growth and Inhibition: Pulse Charging Experiments and Monte Carlo Calculations. J. Phys. Chem. Lett. 2014, 5, 1721–1726. [Google Scholar] [CrossRef] [PubMed]

- Acosta, L.N.; Garaventta, G.; Levi, M.; Aurbach, D.; Flexer, V. Pulsed Charging Protocols with Non-Zero Relaxation Time for Lithium-Ion Batteries. J. Electrochem. Soc. 2022, 169, 100519. [Google Scholar] [CrossRef]

- Ou, S.-Y.; Tian, J.-H.; Yang, C.-Y. Design and implementation of a DSP-based fast charger for Li-ion battery. In Proceedings of the 2011 IEEE Ninth International Conference on Power Electronics and Drive Systems, Singapore, 5–8 December 2011; pp. 809–812. [Google Scholar]

- Li, F.; Zuo, W.; Zhou, K.; Li, Q.Q.; Huang, Y.H.; Zhang, G.D. State-of-charge estimation of lithium-ion battery based on second order resistor-capacitance circuit-PSO-TCN model. Energy 2024, 289, 130025. [Google Scholar] [CrossRef]

- Amanor-Boadu, J.M.; Guiseppi-Elie, A.; Sánchez-Sinencio, E. Search for Optimal Pulse Charging Parameters for Li-Ion Polymer Batteries Using Taguchi Orthogonal Arrays. IEEE Trans. Ind. Electron. 2018, 65, 8982–8992. [Google Scholar] [CrossRef]

- Keil, P.; Jossen, A. Charging protocols for lithium-ion batteries and their impact on cycle life-An experimental study with different 18650 high-power cells. J. Energy Storage 2016, 6, 125–141. [Google Scholar] [CrossRef]

- Liu, J.; Yadav, S.; Salman, M.; Chavan, S.; Kim, S.C. Review of thermal coupled battery models and parameter identification for lithium-ion battery heat generation in EV battery thermal management system. Int. J. Heat Mass Transfer 2024, 218, 124748. [Google Scholar] [CrossRef]

- Wang, J.A.; Yang, K.; Sun, S.Y.; Ma, Q.Y.; Yi, G.; Chen, X.; Wang, Z.; Yan, W.; Liu, X.H.; Cai, Q.; et al. Advances in thermal-related analysis techniques for solid-state lithium batteries. InfoMat 2023, 5, e12401. [Google Scholar] [CrossRef]

- Maleki, H.; Al Hallaj, S.; Selman, J.R.; Dinwiddie, R.B.; Wang, H. Thermal properties of lithium-ion battery and components. J. Electrochem. Soc. 1999, 146, 947. [Google Scholar] [CrossRef]

- Liu, Z.T.; Li, K.N.; Zhang, W.L.; Xie, Y.; Liu, J.Y.; Sun, L.D.; Zan, J.M. Research on safe charging strategy of lithium-ion battery based on three-electrode equivalent circuit model. J. Energy Storage 2023, 72, 108563. [Google Scholar] [CrossRef]

- Doerr, B.; Qu, Z.D. A First Runtime Analysis of the NSGA-II on a Multimodal Problem. IEEE Trans. Evol. Comput. 2023, 27, 1288–1297. [Google Scholar] [CrossRef]

| Parameter | Value Range | Unit |

|---|---|---|

| [1, 6] | A | |

| [1, 6] | A | |

| 9 | s | |

| 1 | s | |

| SOC | [10, 100] | % |

| T | [20, 60] | °C |

| [90, 100] | % | |

| [3.4, 4.2] | V |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Wang, S.; Wang, Z.; Xu, G. Investigation of Lithium-Ion Battery Negative Pulsed Charging Strategy Using Non-Dominated Sorting Genetic Algorithm II. Electronics 2024, 13, 2178. https://doi.org/10.3390/electronics13112178

Huang Y, Wang S, Wang Z, Xu G. Investigation of Lithium-Ion Battery Negative Pulsed Charging Strategy Using Non-Dominated Sorting Genetic Algorithm II. Electronics. 2024; 13(11):2178. https://doi.org/10.3390/electronics13112178

Chicago/Turabian StyleHuang, Yixuan, Shenghui Wang, Zhao Wang, and Guangwei Xu. 2024. "Investigation of Lithium-Ion Battery Negative Pulsed Charging Strategy Using Non-Dominated Sorting Genetic Algorithm II" Electronics 13, no. 11: 2178. https://doi.org/10.3390/electronics13112178

APA StyleHuang, Y., Wang, S., Wang, Z., & Xu, G. (2024). Investigation of Lithium-Ion Battery Negative Pulsed Charging Strategy Using Non-Dominated Sorting Genetic Algorithm II. Electronics, 13(11), 2178. https://doi.org/10.3390/electronics13112178