Towards a State of Health Definition of Lithium Batteries through Electrochemical Impedance Spectroscopy

Abstract

1. Introduction

- Time domain-based methods, in which a pulse current is used to evaluate the IR value like, for example, in [37], which investigates the battery IRs with current pulses at different SOC values in the range between 90% and 10% for a cycle and calendar life test.

- Frequency domain-based methods, in which EIS measurements at different scan frequencies are used to obtain an impedance spectrum and to estimate its variation with the aging of the cells. For instance, in [38,39,40], these methods are used to construct a dataset for Machine Learning-based battery prognostic techniques or aging modeling of different Lithium-ion cells’ technologies.

2. Materials and Methods

2.1. Device under Test (DUT)

2.2. Testing Procedure

- The first battery is discharged using a fast Constant Current profile at a 3C-rate (i.e., 7.5 A current).

- The second battery is discharged using a nominal Constant Current at a 1C-rate (i.e., 2.5 A current).

2.3. Experimental Setup

- A Laboratory Battery Test System (LBT 5V-30A) by Arbin (Arbin Instruments, College Station, TX, USA): a bi-directional power supply capable of charging and discharging simultaneously and, with different methodologies, up to 16 channels. The system can collect data with a maximum log frequency of 100 Hz and a resolution of 24 bits. The maximum current and voltage rates allowed are 30 A and 5 V, respectively.

- A Gamry Interface 5000E EIS instrument (Gamry Instruments, Warminster, PA, USA): it can perform EIS measurements in a range between 10 μHz and 100 kHz when integrated with the LBT system.

- A 21084HC Datalogger by Arbin (Arbin Instruments, College Station, TX, USA): it is connected to the external case of the batteries with T-type thermocouples. This has the aim of monitoring the overheating of the cells, in order to avoid the temperature increasing above the safety thresholds.

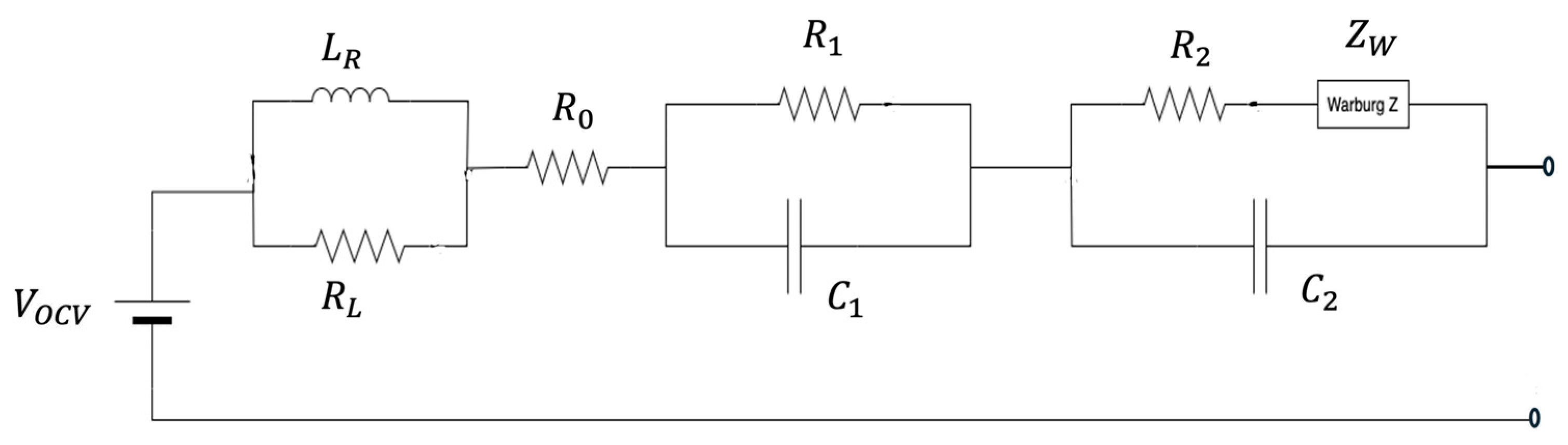

2.4. Equivalent Circuit Model Used

- A resistance, R0, to indicate the DC IR of the battery.

- An RL element to represent the Ohmic-Inductive behavior at high-frequency.

- Two RC elements to describe the different effects of Charge Transfer Losses and SEI degradation in the intermediate frequencies that generally generate one or two arches in impedance spectra, depending on the chemistry and SOC of the battery.

- A Warburg element, modeled as , that describes a linear trend at lower frequencies, due to diffusion mechanisms.

3. Results

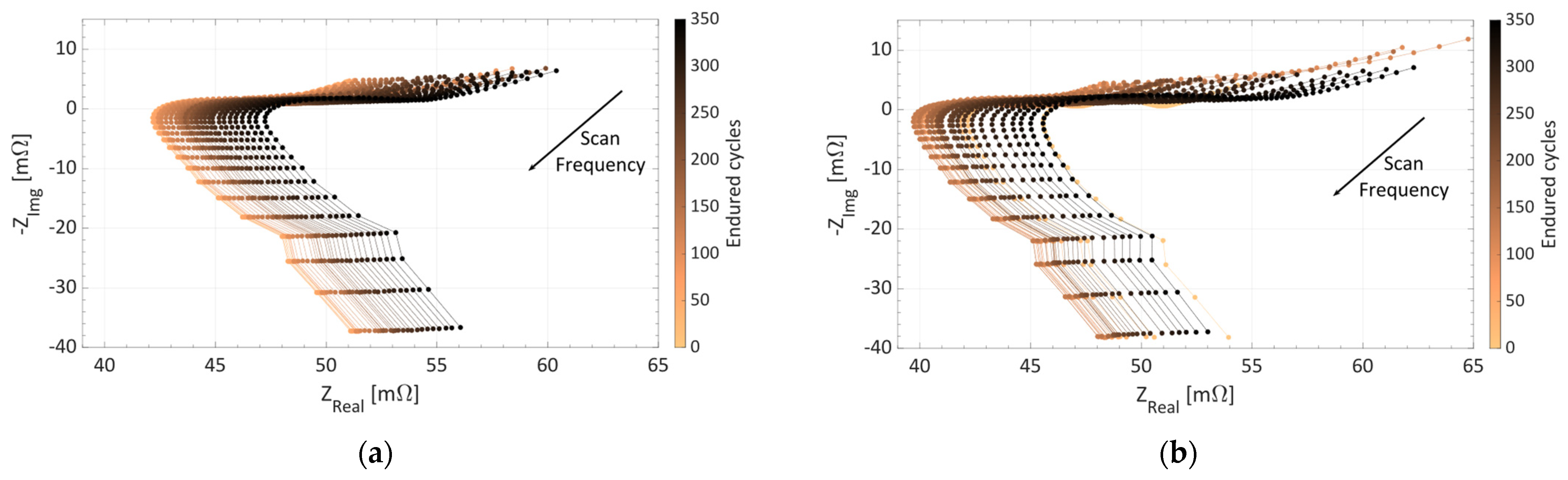

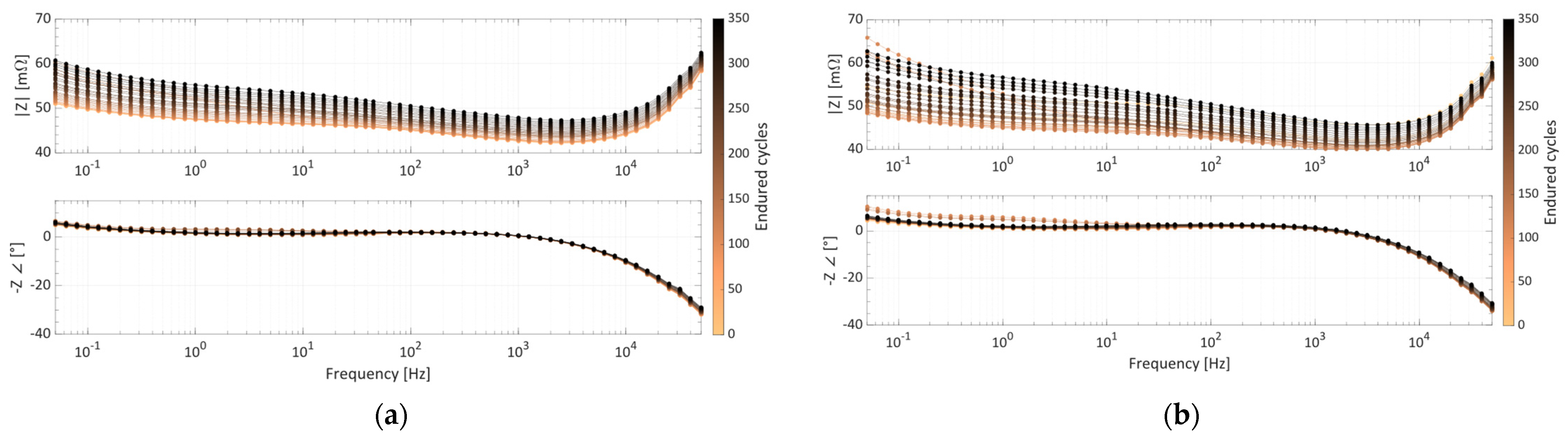

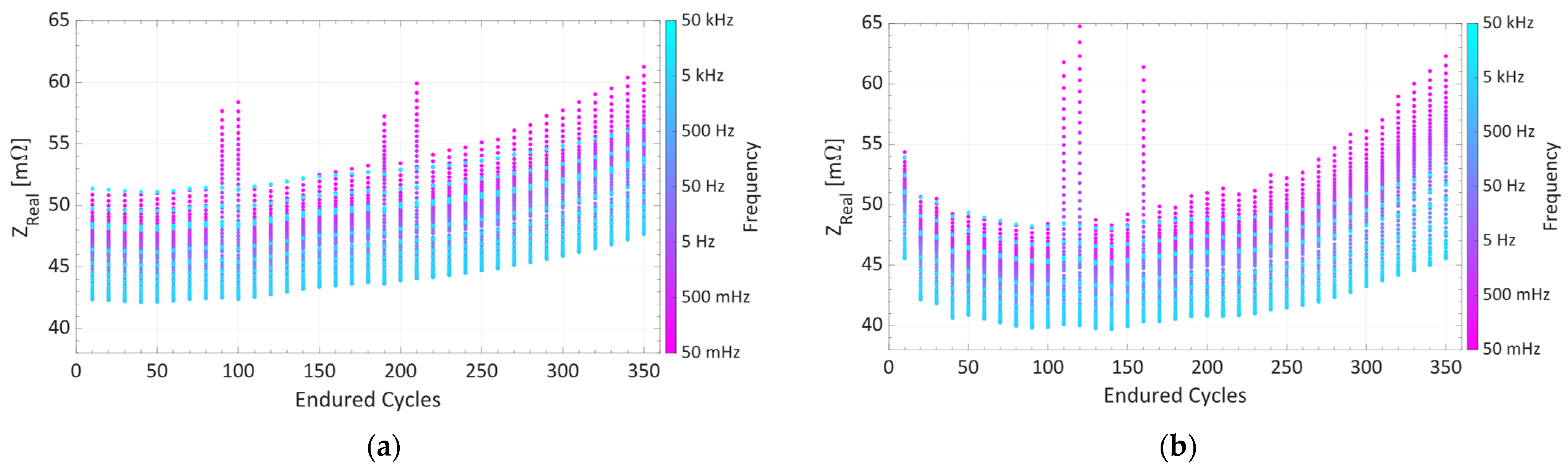

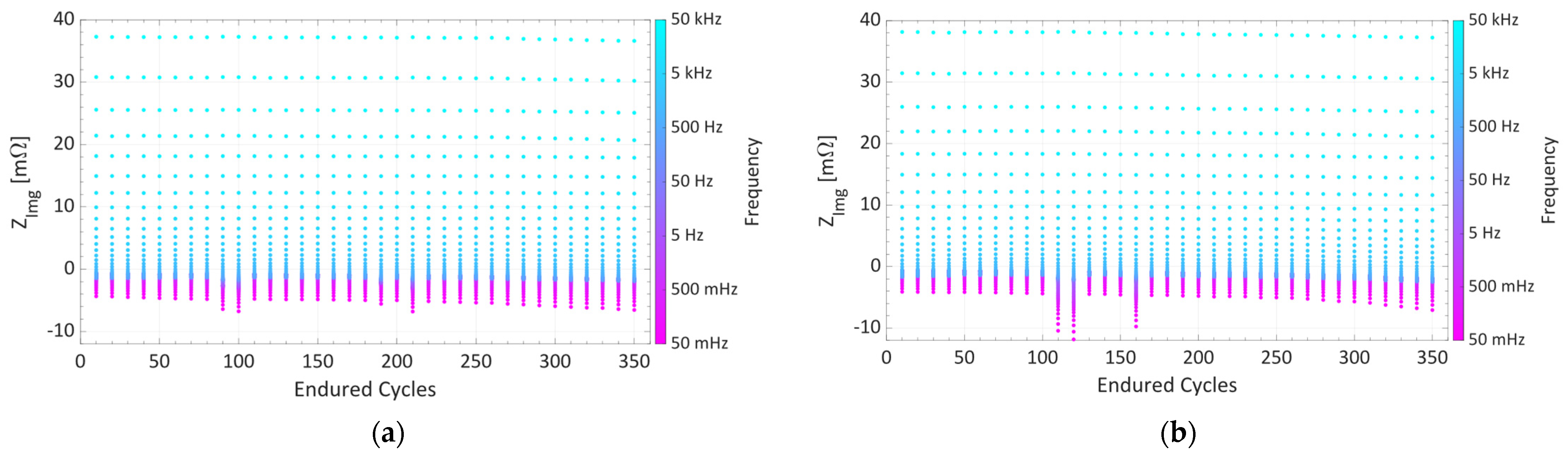

3.1. Impedance Spectrum Analysis

- After 150 cycles, the maximum module variation is 1.89 mΩ for the first cell and 1.75 mΩ for the second one.

- At the end of the test, the maximum variation ranges are 9.71 mΩ and 14.38 mΩ, respectively.

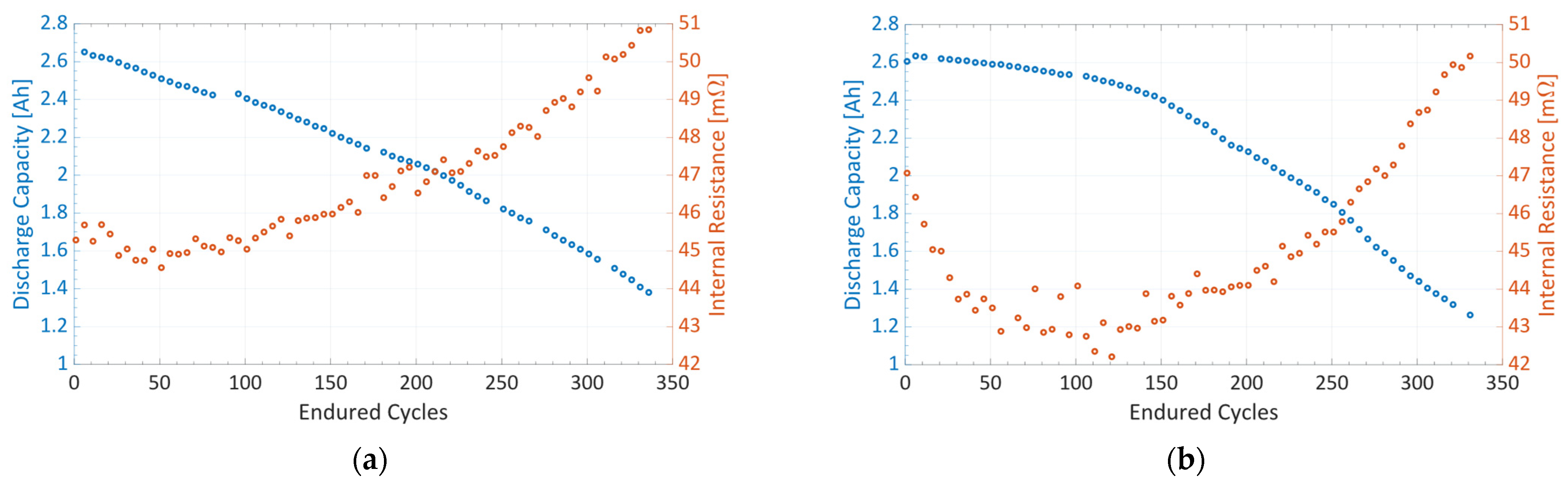

3.2. Discharge Capacity vs. Internal Resistance

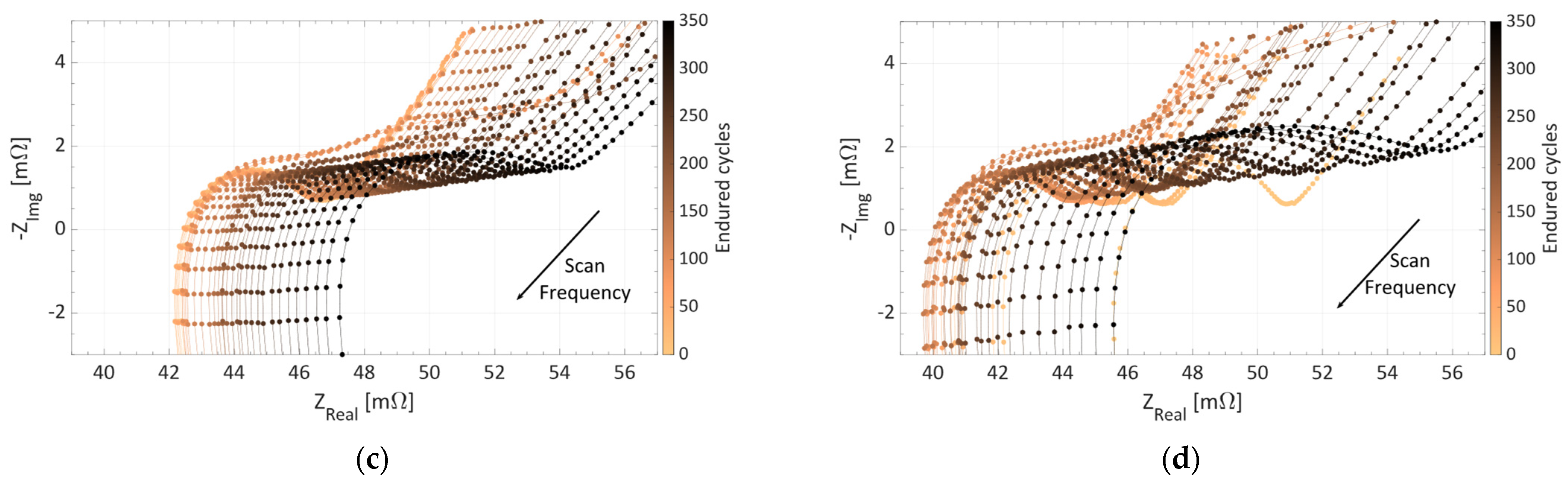

3.3. Differences in Each Region’s Trend at Different SOH Conditions

- New cell condition.

- Minimum Impedance Condition ().

- 80% SOH condition, the most common definition of End Of Life (EOL) conditions derived from automotive standards.

- 70% SOH condition, which is a valid alternative for the EOL in alternative fields.

- End of the test (i.e., 350 cycles, which represents approximately 50% SOH).

- In the Warburg zone, the linear trend’s slope decreases in a monotonic way for both the cells tested. The total percentage reduction results equal to 13.32%, for the fast discharged battery and 28.24%, for the cell aged under nominal conditions. It is important to emphasize that the most significant decrease in the diffusion coefficient is collocated in the portion of the cells’ life between 70% SOH and the end of the test.

- The mid-frequency (MF) arc’s size follows the behavior of the impedance, with a decreasing trend until the condition, to then increase with the rest of the cycles. The more significant variations in the central arc are seen for the 1C-rate discharged battery that passes from the 5.5633 mΩ width at the initial condition to the value of 10.0368 mΩ at the end of the test.

- For the high-frequency (HF) region, it is possible to notice a different progression in linear trends’ slopes for the two batteries. In fact, while for the second battery, the variations in the slope follow the impedance behavior, the other cell exhibits a decreasing progression. This is probably due to the higher impedance values at the high frequency shown by the first cell.

| Condition | IR [mΩ] | Warburg Zone Slope | MF Arc Width [mΩ] | HF Zone Slope |

|---|---|---|---|---|

| New Cell | 42.7 | 0.9433 | 4.7744 | −3.6568 |

| 42.4 | 0.9214 | 4.7452 | −3.6688 | |

| 80% SOH | 43.9 | 0.9163 | 4.9993 | −3.6369 |

| 70% SOH | 44.8 | 0.8952 | 5.4978 | −3.6262 |

| End of Test | 47.5 | 0.8176 | 7.1494 | −3.5999 |

| Condition | IR [mΩ] | Warburg Zone Slope | MF Arc Width [mΩ] | HF Zone Slope |

|---|---|---|---|---|

| New Cell | 45.9 | 1.0847 | 5.5633 | −3.9735 |

| Zmin | 40.2 | 0.9773 | 4.6964 | −3.9635 |

| 80% SOH | 41.1 | 0.9213 | 6.3300 | −4.1198 |

| 70% SOH | 43.7 | 0.8763 | 7.8592 | −4.2398 |

| End of Test | 45.9 | 0.7784 | 10.0368 | −4.3426 |

4. Discussion

5. Conclusions

- The cycle aging of the battery affects the various regions of the impedance spectrum differently, with more significant variations visible on the mid-frequency arc and the low-frequency linear zone.

- A quicker aging impact caused by a faster discharge profile of the cell has been discovered in the “first life stage” (until 80% SOH is reached) of a Li–Mn battery, with a higher overall impedance and an approximately linear capacity drop.

- Under nominal discharge conditions, a sensible change in the degradation trend in the “second life phase” (after 80% SOH threshold) has been discovered, with higher impacts on the mid-frequency degradation mechanisms and on the reduction in the diffusion coefficient in the Warburg region.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- D’Emilia, G.; Gaspari, A.; Natale, E.; Adduce, G.; Vecchiarelli, S. All-Around Approach for Reliability of Measurement Data in the Industry 4.0. IEEE Instrum. Meas. Mag. 2021, 24, 30–37. [Google Scholar] [CrossRef]

- D’Emilia, G.; Gaspari, A.; Natale, E. Mechatronics Applications of Measurements for Smart Manufacturing in an Industry 4.0 Scenario. IEEE Instrum. Meas. Mag. 2019, 22, 35–43. [Google Scholar] [CrossRef]

- Catelani, M.; Ciani, L.; Bartolini, A.; Del Rio, C.; Guidi, G.; Patrizi, G. Reliability Analysis of Wireless Sensor Network for Smart Farming Applications. Sensors 2021, 21, 7683. [Google Scholar] [CrossRef] [PubMed]

- Singh, K.; Singh, Y.; Barak, D.; Yadav, M. Evaluation of Designing Techniques for Reliability of Internet of Things (IoT). Int. J. Eng. Trends Technol. 2023, 71, 102–118. [Google Scholar] [CrossRef]

- Da Silva, F.S.T.; Da Costa, C.A.; Crovato, C.D.P.; Da Rosa Righi, R. Looking at energy through the lens of Industry 4.0: A systematic literature review of concerns and challenges. Comput. Ind. Eng. 2020, 143, 106426. [Google Scholar] [CrossRef]

- Ghookabloo, M.; Fathi, M. Industry 4.0 and opportunities for energy sustainability. J. Clean. Prod. 2021, 295, 126427. [Google Scholar]

- Scharl, S.; Praktiknjo, A. The Role of a digital industry 4.0 in a renewable energy system. Int. J. Energy Res. 2019, 43, 3891–3904. [Google Scholar] [CrossRef]

- Iturrino-Garcia, C.; Patrizi, G.; Bartolini, A.; Ciani, L.; Paolucci, L.; Luchetta, A.; Grasso, F. An Innovative Single Shot Power Quality Disturbance Detector Algorithm. IEEE Trans. Instrum. Meas. 2022, 71, 2517210. [Google Scholar] [CrossRef]

- Bayindir, R.; Colak, I.; Fulli, G.; Demirtas, K. Smart grid technologies and applications. Renew. Sustain. Energy Rev. 2016, 66, 499–516. [Google Scholar] [CrossRef]

- Tan, K.M.; Babu, T.S.; Ramachandaramurthy, V.K.; Kasinathan, P.; Solanki, S.G.; Raveendran, S.K. Empowering smart grid: A comprehensive review of energy storage technology and application with renewable energy integration. J. Energy Storage 2021, 39, 102591. [Google Scholar] [CrossRef]

- Alotaibi, I.; Abido, M.A.; Khalid, M.; Savkin, A.V. A Comprehensive Review of Recent Advances in Smart Grids: A Sustainable Future with Renewable Energy Resources. Energies 2020, 13, 6269. [Google Scholar] [CrossRef]

- Tong, B.; Song, Z.; Wu, H.; Wang, X.; Feng, W.; Zhou, Z.; Zhang, H. Ion transport and structural design of lithium-ion conductive solid polymer electrolytes: A perspective. Mater. Futures 2022, 1, 042103. [Google Scholar] [CrossRef]

- Zhao, Q.; Sun, K.; Wang, X.; Wang, Q.; Wang, J. Examining green-sustainable approaches for recycling of lithium-ion batteries. DeCarbon 2024, 3, 100034. [Google Scholar] [CrossRef]

- Armand, M.; Axmann, P.; Bresser, D.; Copley, M.; Edström, K.; Ekberg, C.; Guyomard, D.; Lestriez, B.; Novák, P.; Petranikova, M.; et al. Lithium-ion batteries—Current state of the art and anticipated developments. J. Power Sources 2020, 479, 228708, ISSN 0378-7753. [Google Scholar] [CrossRef]

- Dunn, B.; Kamath, H.; Tarascon, J.-M. Electrical energy storage for the grid: A battery of choices. Science 2011, 334, 928–935. [Google Scholar] [CrossRef] [PubMed]

- Bresser, D.; Moretti, A.; Varzi, A.; Passerini, S. The role of batteries for the successful transition to renewable energy sources. In Encyclopedia of Electrochemistry: Batteries, 1st ed.; Wiley-VCH: Weinheim, Germany, 2020; pp. 3–11. [Google Scholar]

- Wang, A.G. Battery energy storage system: The key of future smart grid. In Proceedings of the 2016 IEEE International Conference on Pervasive Computing and Communication Workshops (PerCom Workshops), Sydney, NSW, Australia, 14–18 March 2016; p. 1. [Google Scholar] [CrossRef]

- Yudhistira, R.; Khatiwada, D.; Sanchez, F.A. Comparative life cycle assessment of lithium-ion and lead-acid batteries for grid energy storage. J. Clean. Prod. 2022, 358, 131999. [Google Scholar] [CrossRef]

- Salkuti, S.R. Energy Storage Technologies for Smart Grid: A Comprehensive Review. Majlesi J. Electr. Eng. 2020, 14, 39–48. [Google Scholar]

- Zubi, G.; Dufo-Lopez, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Patrizi, G.; Picano, B.; Catelani, M.; Fantacci, R.; Ciani, L. Validation of RUL Estimation Method for Battery Prognostic under Different Fast-Charging Conditions. In Proceedings of the 2022 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Ottawa, ON, Canada, 16–19 May 2022. [Google Scholar]

- Rahimi-Eichi, H.; Ojha, U.; Baronti, F.; Chow, M.-Y. Battery Management System: An Overview of Its Application in the Smart Grid and Electric Vehicles. IEEE Ind. Electron. Mag. 2013, 7, 4–16. [Google Scholar] [CrossRef]

- Catelani, M.; Ciani, L.; Grasso, F.; Patrizi, G.; Reatti, A. Remaining Useful Life Estimation for Electric Vehicle Batteries Using a Similarity-Based Approach. In Proceedings of the 2022 IEEE International Workshop on Metrology for Automotive (MetroAutomotive), Modena, Italy, 4–6 July 2022; pp. 82–87. [Google Scholar]

- Yang, S.; Zhang, C.; Jiang, J.; Zhang, W.; Zhang, L.; Wang, Y. Review on state-of-health of lithium-ion batteries: Characterizations, estimations and applications. J. Clean. Prod. 2021, 314, 128015. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Li, D.; Wang, K. State-of-health estimation of lithium-ion batteries based on electrochemical impedance spectroscopy: A review. Prot. Control Mod. Power Syst. 2023, 8, 41. [Google Scholar] [CrossRef]

- Patrizi, G.; Catelani, M.; Ciani, L.; Song, Y.; Liu, D. A Multi-Channel Deep-Learning Prediction Algorithm for Battery State-of-Health Indicator. In Proceedings of the 2023 IEEE International Conference on Metrology for eXtended Reality, Artificial Intelligence and Neural Engineering (MetroXRAINE), Milano, Italy, 25–27 October 2023; pp. 816–821. [Google Scholar]

- Dubarry, M.; Baure, G.; Ansean, D. Perspective on state-of-health determination in lithium-ion batteries. J. Electrochem. Energy Convers. Storage 2020, 17, 044701. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, J.; Qin, C.; Lu, L.; Han, X.; Ouyang, M. A novel capacity estimation method based on charging curve sections for lithium-ion batteries in electric vehicles. Energy 2019, 185, 361–371. [Google Scholar] [CrossRef]

- Kim, I.-S. A Technique for Estimating the State of Health of Lithium Batteries Through a Dual-Sliding-Mode Observer. IEEE Trans. Power Electron. 2010, 25, 1013–1022. [Google Scholar] [CrossRef]

- Liu, G.; Ouyang, M.; Lu, L.; Li, J.; Han, X. Online estimation of lithium-ion battery remaining discharge capacity through differential voltage analysis. J. Power Sources 2015, 274, 971–989. [Google Scholar] [CrossRef]

- Berecibar, M.; Garmendia, M.; Gandiaga, I.; Crego, J.; Villarreal, I. State of health estimation algorithm of LiFePO4 battery packs based on differential voltage curves for battery management system application. Energy 2016, 103, 784–796. [Google Scholar] [CrossRef]

- He, J.; Wei, Z.; Bian, X.; Yan, F. State-of-Health Estimation of Lithium-Ion Batteries Using Incremental Capacity Analysis Based on Voltage–Capacity Model. IEEE Trans. Transp. Electrif. 2020, 6, 417–426. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Zhang, L.; Zou, C.; Dorrell, D.D. State-of-health estimation for Li-ion batteries by combing the incremental capacity analysis method with grey relational analysis. J. Power Sources 2019, 410–411, 106–114, ISSN 0378-7753. [Google Scholar] [CrossRef]

- Ansean, D.; Garcia, V.M.; Gonzalez, M.; Blanco-Viejo, C.; Viera, J.C.; Pulido, Y.F.; Sanchez, L. Lithium-ion battery degradation indicators via incremental capacity analysis. IEEE Trans. Ind. Appl. 2019, 55, 2992–3002. [Google Scholar] [CrossRef]

- Chen, L.; Lu, Z.; Lin, W.; Li, J.; Pan, H. A new state-of-health estimation method for lithium-ion batteries through the intrinsic relationship between ohmic internal resistance and capacity. Measurements 2018, 116, 586–595. [Google Scholar] [CrossRef]

- Iurilli, P.; Brivio, C.; Wood, V. On the use of electrochemical impedance spectroscopy to characterize and model the aging phenomena of lithium-ion batteries: A critical review. J. Power Sources 2021, 505, 229860. [Google Scholar] [CrossRef]

- Kabitz, S.; Bernhard, J.; Ecker, M.; Yurdagel, Y.; Emmermacher, B.; Andrè, D.; Mitsch, T.; Uwe, D. Cycle and calendar life study of a graphite|LiNi1/3Mn1/3Co1/3O2 Li-ion high energy system. Part A: Full cell characterization. J. Power Sources 2013, 239, 572–583. [Google Scholar] [CrossRef]

- Li, Y.; Maleki, M.; Banitaan, S. State of health estimation of lithium-ion batteries using EIS measurement and transfer learning. J. Energy Storage 2023, 73, 109185. [Google Scholar] [CrossRef]

- Choi, W.; Shin, H.C.; Kim, J.M.; Choi, J.Y.; Yoon, W.S. Modeling and Applications of Electrochemical Impedance Spectroscopy (EIS) for Lithium-ion Batteries. J. Electrochem. Sci. Technol. 2020, 11, 1–13. [Google Scholar] [CrossRef]

- Estaller, J.; Kersten, A.; Kuder, M.; Mashayek, A.; Buberger, J.; Thirlinger, T.; Eckerle, R.; Weyh, T. Battery Impedance Modeling and Comprehensive Comparisons of State-Of-The-Art Cylindrical 18650 Battery Cells considering Cells’ Price, Impedance, Specific Energy and C-Rate. In Proceedings of the 2021 IEEE International Conference on Environment and Electrical Engineering and 2021 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Bari, Italy, 7–10 September 2021; pp. 1–8. [Google Scholar]

- Datasheet: Li-Mn Battery Specification Model IMR18650, 1st ed.; Consulted on February; Shenzhen Fest Technology Co. Ltd.: Shenzhen, China, 2024.

- Catelani, M.; Ciani, L.; Corti, F.; Laschi, M.; Patrizi, G.; Reatti, A.; Vangi, D. Experimental Characterization of Hybrid Supercapacitor Under Different Operating Conditions Using EIS Measurements. IEEE Trans. Instrum. Meas. 2024, 73, 3503210. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Wang, Z.; Jiang, Y.; Wen, G.; Gao, P.; Zhu, Y. Electrochemical impedance spectroscopy study of lithium-rich material 0.5Li2MnO3·0.5LiNi1/3Co1/3Mn1/3O2 in the first two charge-discharge cycles. Electrochim. Acta 2019, 310, 136–145. [Google Scholar] [CrossRef]

- Keefe, A.S.; Buteau, S.; Hill, I.G.; Dahn, J.R. Temperature Dependent EIS Studies Separating Charge Transfer Impedance from Contact Impedance in Lithium-Ion Symmetric Cells. J. Electrochemic. Soc. 2019, 166, A3272. [Google Scholar] [CrossRef]

| Discharge Rate | Discharge Capacity Function Slope [Ah/Cycle] | |

|---|---|---|

| 3C-rate | −0.0033 | |

| 1C-rate | −0.0014 (until 150th cycle) | −0.0064 (150th–end) |

| Discharge Rate | IR Function Slope [mΩ/Cycle] | |

| 3C-rate | −0.0182 (until 50th cycle) | 0.0199 (50th–end) |

| 1C-rate | −0.0457 (until 80th cycle) | 0.0282 (80th–end) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patrizi, G.; Canzanella, F.; Ciani, L.; Catelani, M. Towards a State of Health Definition of Lithium Batteries through Electrochemical Impedance Spectroscopy. Electronics 2024, 13, 1438. https://doi.org/10.3390/electronics13081438

Patrizi G, Canzanella F, Ciani L, Catelani M. Towards a State of Health Definition of Lithium Batteries through Electrochemical Impedance Spectroscopy. Electronics. 2024; 13(8):1438. https://doi.org/10.3390/electronics13081438

Chicago/Turabian StylePatrizi, Gabriele, Fabio Canzanella, Lorenzo Ciani, and Marcantonio Catelani. 2024. "Towards a State of Health Definition of Lithium Batteries through Electrochemical Impedance Spectroscopy" Electronics 13, no. 8: 1438. https://doi.org/10.3390/electronics13081438

APA StylePatrizi, G., Canzanella, F., Ciani, L., & Catelani, M. (2024). Towards a State of Health Definition of Lithium Batteries through Electrochemical Impedance Spectroscopy. Electronics, 13(8), 1438. https://doi.org/10.3390/electronics13081438