Wet Etching-Based WO3 Patterning for High-Performance Neuromorphic Electrochemical Transistors

Abstract

:1. Introduction

2. Materials and Methods

3. Results

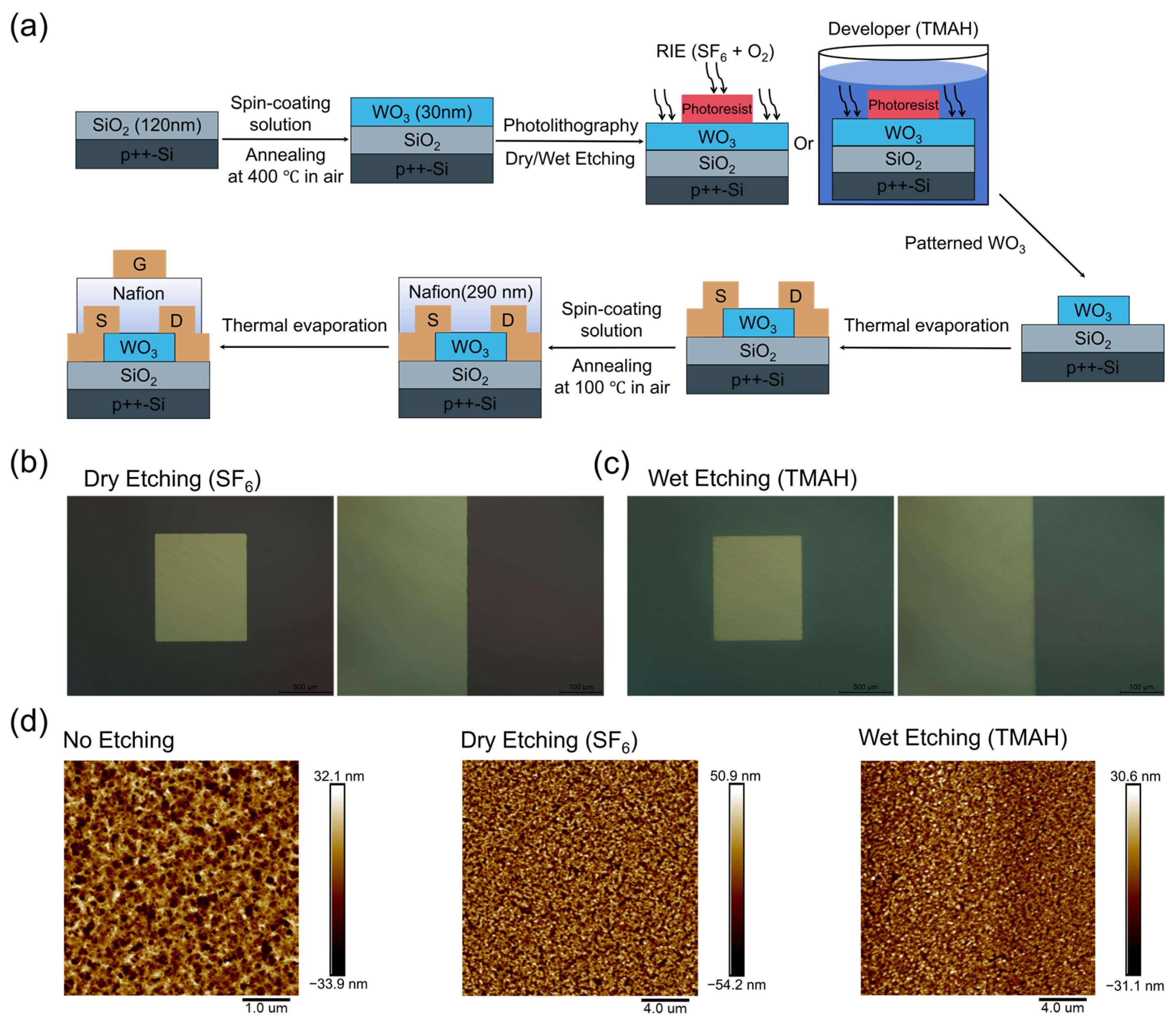

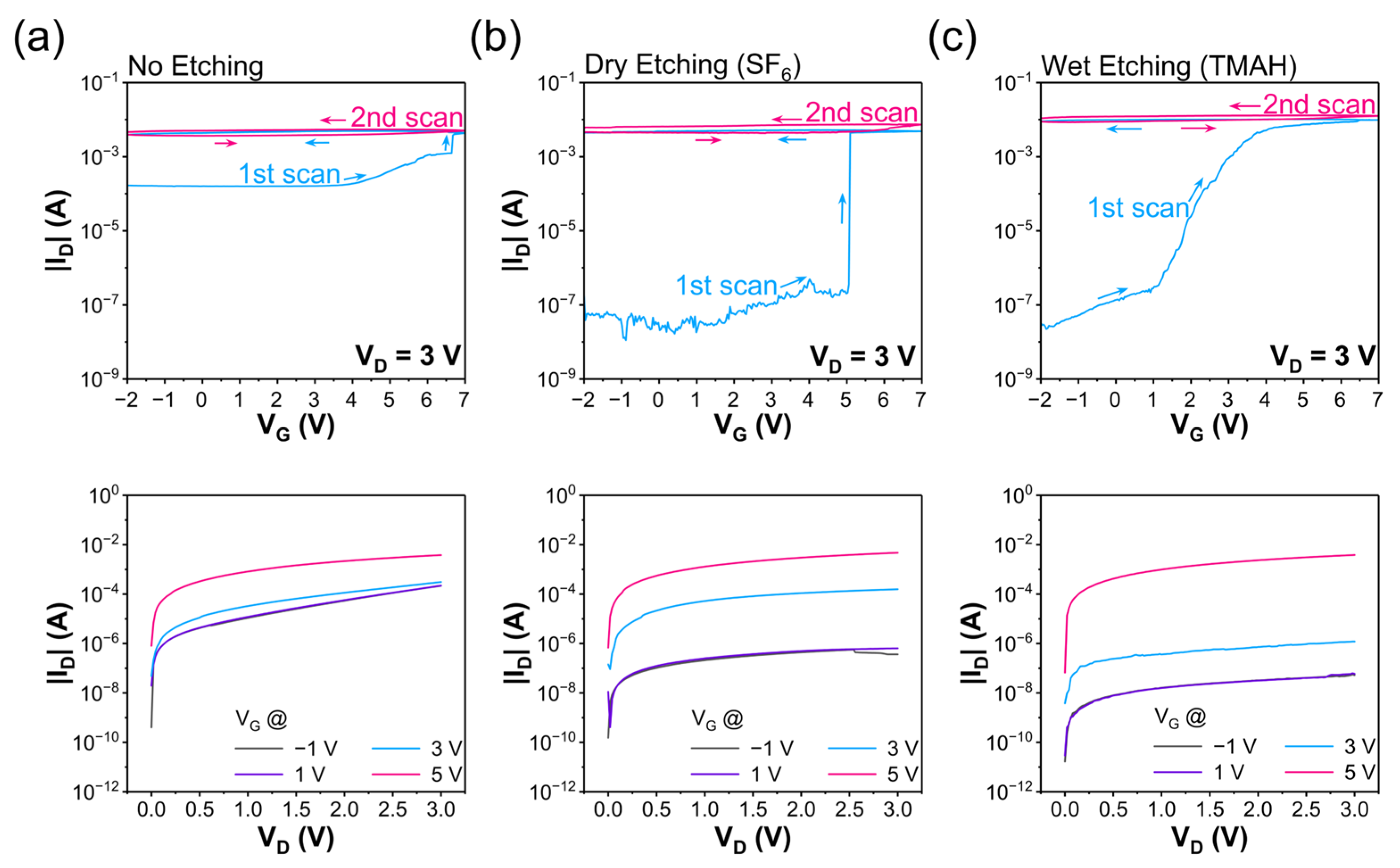

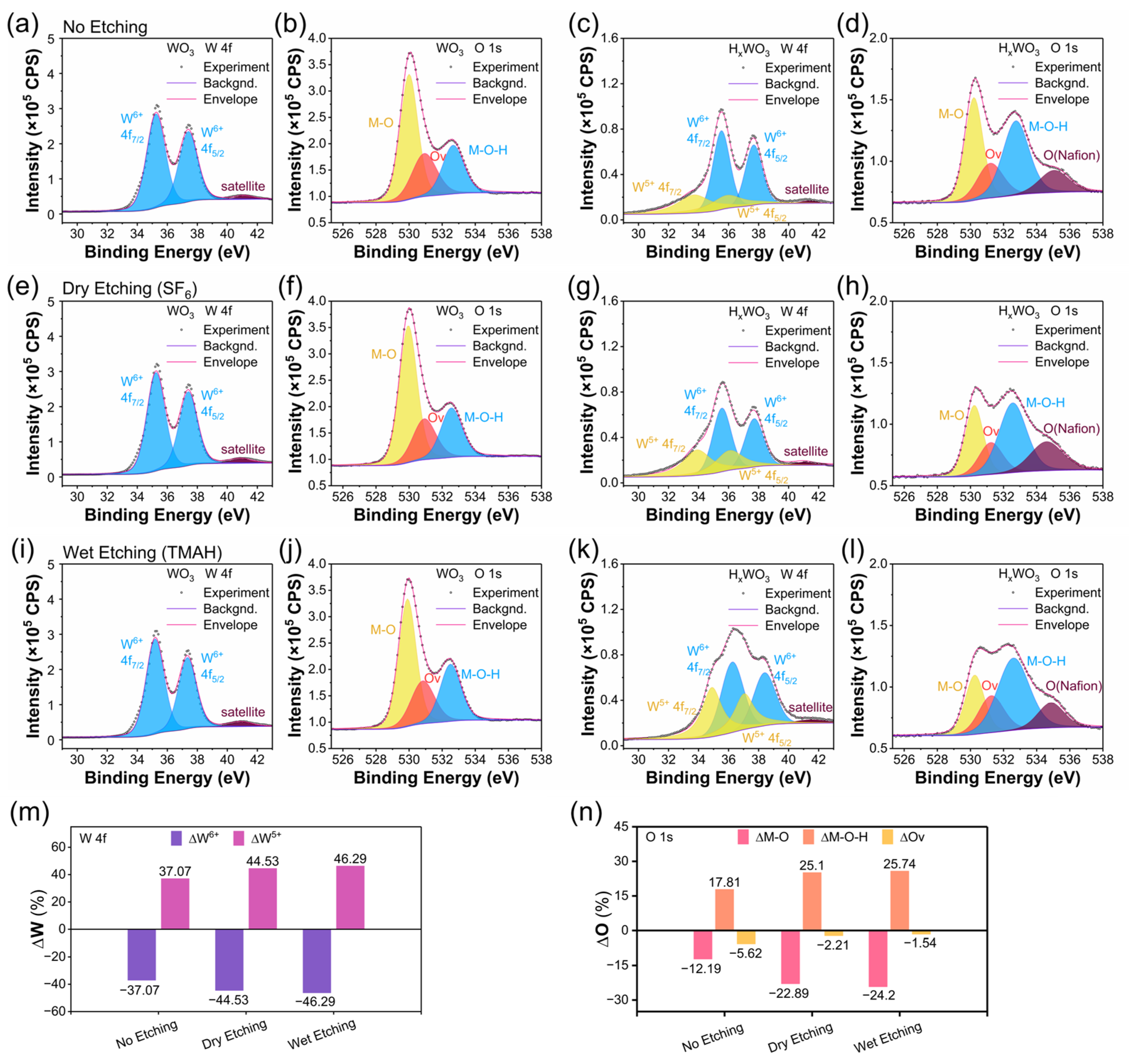

3.1. Comparison of Different Etching Methods

3.2. Long-Term and Short-Term Memory in WO3 ECTs

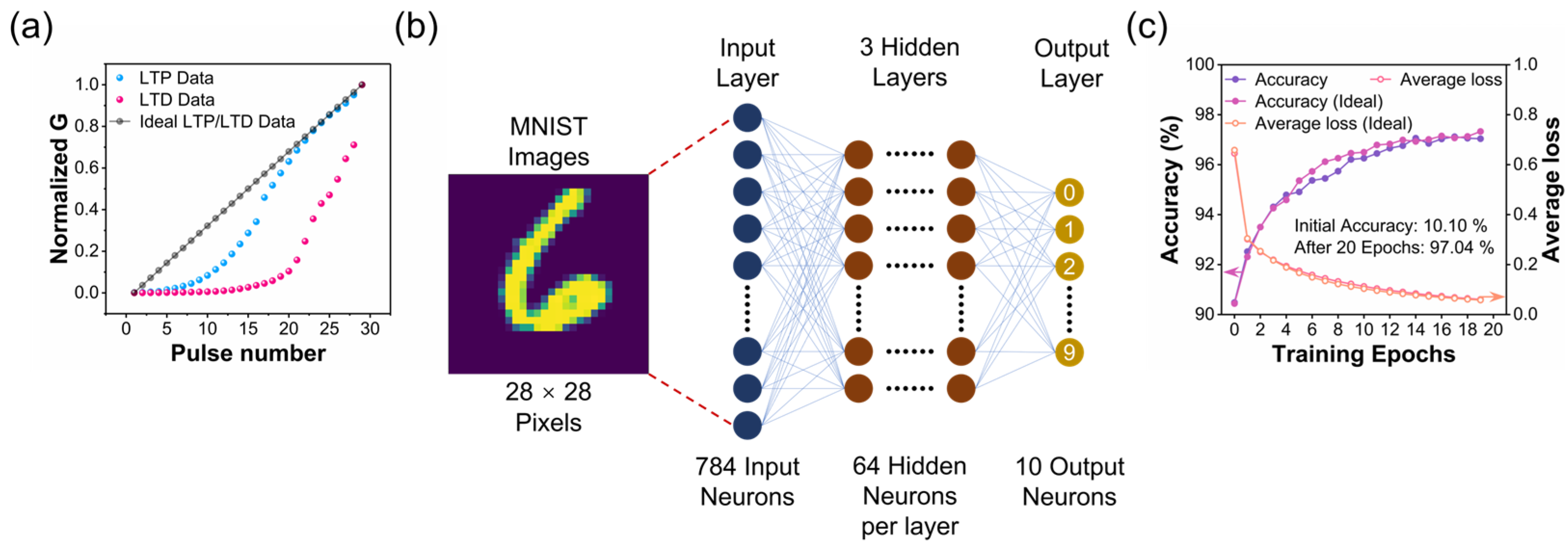

3.3. Simulated ANN for Image Recognition

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ielmini, D.; Ambrogio, S. Emerging neuromorphic devices. Nanotechnology 2020, 31, 092001. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Zhang, T.; Yang, Y.; Huang, R. A comprehensive review on emerging artificial neuromorphic devices. Appl. Phys. Rev. 2020, 7, 011312. [Google Scholar] [CrossRef]

- Boahen, K. A neuromorph’s prospectus. Comput. Sci. Eng. 2017, 19, 14–28. [Google Scholar] [CrossRef]

- Wang, T.; Meng, J.; Zhou, X.; Liu, Y.; He, Z.; Han, Q.; Li, Q.; Yu, J.; Li, Z.; Liu, Y.; et al. Reconfigurable neuromorphic memristor network for ultralow-power smart textile electronics. Nat. Commun. 2022, 13, 7432. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, P.; Gao, Z.; Wen, D. Artificial Tactile Sensing Neuron with Tactile Sensing Ability Based on a Chitosan Memristor. Adv. Sci. 2024, 11, 2308610. [Google Scholar] [CrossRef] [PubMed]

- Park, S.-O.; Hong, S.; Sung, S.-J.; Kim, D.; Seo, S.; Jeong, H.; Park, T.; Cho, W.J.; Kim, J.; Choi, S. Phase-change memory via a phase-changeable self-confined nano-filament. Nature 2024, 628, 293–298. [Google Scholar] [CrossRef] [PubMed]

- Burr, G.W.; Breitwisch, M.J.; Franceschini, M.; Garetto, D.; Gopalakrishnan, K.; Jackson, B.; Kurdi, B.; Lam, C.; Lastras, L.A.; Padilla, A.; et al. Phase change memory technology. J. Vac. Sci. Technol. B 2010, 28, 223–262. [Google Scholar] [CrossRef]

- Si, M.; Su, C.-J.; Jiang, C.; Conrad, N.J.; Zhou, H.; Maize, K.D.; Qiu, G.; Wu, C.-T.; Shakouri, A.; Alam, M.A.; et al. Steep-slope hysteresis-free negative capacitance MoS2 transistors. Nat. Nanotechnol. 2018, 13, 24–28. [Google Scholar] [CrossRef]

- Gao, L.; Hu, B.-L.; Wang, L.; Cao, J.; He, R.; Zhang, F.; Wang, Z.; Xue, W.; Yang, H.; Li, R.-W. Intrinsically elastic polymer ferroelectric by precise slight cross-linking. Science 2023, 381, 540–544. [Google Scholar] [CrossRef]

- van de Burgt, Y.; Lubberman, E.; Fuller, E.J.; Keene, S.T.; Faria, G.C.; Agarwal, S.; Marinella, M.J.; Alec Talin, A.; Salleo, A. A non-volatile organic electrochemical device as a low-voltage artificial synapse for neuromorphic computing. Nat. Mater. 2017, 16, 414–418. [Google Scholar] [CrossRef]

- Tang, J.; Bishop, D.; Kim, S.; Copel, M.; Gokmen, T.; Todorov, T.; Shin, S.; Lee, K.T.; Solomon, P.; Chan, K.; et al. ECRAM as Scalable Synaptic Cell for High-Speed, Low-Power Neuromorphic Computing. In Proceedings of the 2018 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 1–5 December 2018. [Google Scholar] [CrossRef]

- Yang, C.-S.; Shang, D.-S.; Liu, N.; Fuller, E.J.; Agrawal, S.; Talin, A.A.; Li, Y.-Q.; Shen, B.-G.; Sun, Y. All-Solid-State Synaptic Transistor with Ultralow Conductance for Neuromorphic Computing. Adv. Funct. Mater. 2018, 28, 1804170. [Google Scholar] [CrossRef]

- Milewska, A.; Świerczek, K.; Tobola, J.; Boudoire, F.; Hu, Y.; Bora, D.K.; Mun, B.S.; Braun, A.; Molenda, J. The nature of the nonmetal–metal transition in LixCoO2 oxide. Solid State Ion. 2014, 263, 110–118. [Google Scholar] [CrossRef]

- Speulmanns, J.; Kia, A.M.; Kühnel, K.; Bönhardt, S.; Weinreich, W. Surface-Dependent Performance of Ultrathin TiN Films as an Electrically Conducting Li Diffusion Barrier for Li-Ion-Based Devices. ACS Appl. Mater. Interfaces 2020, 12, 39252–39260. [Google Scholar] [CrossRef]

- Huang, J.; Wu, K.; Xu, G.; Wu, M.; Dou, S.; Wu, C. Recent progress and strategic perspectives of inorganic solid electrolytes: Fundamentals, modifications, and applications in sodium metal batteries. Chem. Soc. Rev. 2023, 52, 4933–4995. [Google Scholar] [CrossRef]

- Yang, C.S.; Shang, D.S.; Liu, N.; Shi, G.; Shen, X.; Yu, R.C.; Li, Y.Q.; Sun, Y. A Synaptic Transistor based on Quasi-2D Molybdenum Oxide. Adv. Mater. 2017, 29, 1700906. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, Y.; Li, L.; Mou, X.; Peng, H.; Shen, S.; Wang, M.; Xiao, K.; Ji, S.-H.; Yi, D.; et al. Nanoscale multistate resistive switching in WO3 through scanning probe induced proton evolution. Nat. Commun. 2023, 14, 3950. [Google Scholar] [CrossRef]

- Yao, X.; Klyukin, K.; Lu, W.; Onen, M.; Ryu, S.; Kim, D.; Emond, N.; Waluyo, I.; Hunt, A.; del Alamo, J.A.; et al. Protonic solid-state electrochemical synapse for physical neural networks. Nat. Commun. 2020, 11, 3134. [Google Scholar] [CrossRef]

- Tran, D.M.; Son, J.W.; Ju, T.-S.; Hwang, C.; Park, B.H. Dopamine-Regulated Plasticity in MoO3 Synaptic Transistors. ACS Appl. Mater. Interfaces 2023, 15, 49329–49337. [Google Scholar] [CrossRef]

- Li, Y.; Lu, J.; Shang, D.; Liu, Q.; Wu, S.; Wu, Z.; Zhang, X.; Yang, J.; Wang, Z.; Lv, H.; et al. Oxide-Based Electrolyte-Gated Transistors for Spatiotemporal Information Processing. Adv. Mater. 2020, 32, 2003018. [Google Scholar] [CrossRef]

- Sahu, M.C.; Jena, A.K.; Mallik, S.K.; Roy, S.; Sahoo, S.; Ajimsha, R.S.; Misra, P.; Sahoo, S. Reconfigurable Low-Power TiO2 Memristor for Integration of Artificial Synapse and Nociceptor. ACS Appl. Mater. Interfaces 2023, 15, 25713–25725. [Google Scholar] [CrossRef]

- Xu, H.; Shang, D.; Luo, Q.; An, J.; Li, Y.; Wu, S.; Yao, Z.; Zhang, W.; Xu, X.; Dou, C.; et al. A low-power vertical dual-gate neurotransistor with short-term memory for high energy-efficient neuromorphic computing. Nat. Commun. 2023, 14, 6385. [Google Scholar] [CrossRef] [PubMed]

- Vemuri, R.S.; Engelhard, M.H.; Ramana, C.V. Correlation between Surface Chemistry, Density, and Band Gap in Nanocrystalline WO3 Thin Films. ACS Appl. Mater. Interfaces 2012, 4, 1371–1377. [Google Scholar] [CrossRef]

- Xie, D.; Liang, X.; Geng, D.; Wu, Q.; Liu, C. An Enhanced Synaptic Plasticity of Electrolyte-Gated Transistors through the Tungsten Doping of an Oxide Semiconductor. Electronics 2024, 13, 1485. [Google Scholar] [CrossRef]

- Hjelm, A.; Granqvist, C.G.; Wills, J.M. Electronic structure and optical properties of WO3, LiWO3, NaWO3, and HWO3. Phys. Rev. B 1996, 54, 2436–2445. [Google Scholar] [CrossRef]

- Talin, A.A.; Li, Y.; Robinson, D.A.; Fuller, E.J.; Kumar, S. ECRAM Materials, Devices, Circuits and Architectures: A Perspective. Adv. Mater. 2023, 35, 2204771. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; An, F.; Qian, J.; Wu, Y.; Sloan, L.L.; Pidaparthy, S.; Zuo, J.-M.; Cao, Q. CMOS-compatible electrochemical synaptic transistor arrays for deep learning accelerators. Nat. Electron. 2023, 6, 292–300. [Google Scholar] [CrossRef]

- Johnson, N.R.; George, S.M. WO3 and W Thermal Atomic Layer Etching Using “Conversion-Fluorination” and “Oxidation-Conversion-Fluorination” Mechanisms. ACS Appl. Mater. Interfaces 2017, 9, 34435–34447. [Google Scholar] [CrossRef]

- Su, X.; Li, Y.; Jian, J.; Wang, J. In situ etching WO3 nanoplates: Hydrothermal synthesis, photoluminescence and gas sensor properties. Mater. Res. Bull. 2010, 45, 1960–1963. [Google Scholar] [CrossRef]

- Shi, P.; Wang, D.; Yu, T.; Xing, R.; Wu, Z.; Yan, S.; Wei, L.; Chen, Y.; Ren, H.; Yu, C.; et al. Solid-state electrolyte gated synaptic transistor based on SrFeO2.5 film channel. Mater. Des. 2021, 210, 110022. [Google Scholar] [CrossRef]

- Jang, J.W.; Park, S.; Burr, G.W.; Hwang, H.; Jeong, Y.H. Optimization of Conductance Change in Pr1–xCaxMnO3-Based Synaptic Devices for Neuromorphic Systems. IEEE Electron Device Lett. 2015, 36, 457–459. [Google Scholar] [CrossRef]

- Wang, I.T.; Chang, C.-C.; Chiu, L.-W.; Chou, T.; Hou, T.-H. 3D Ta/TaOx/TiO2/Ti synaptic array and linearity tuning of weight update for hardware neural network applications. Nanotechnology 2016, 27, 365204. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Shi, P.; Xing, R.; Xing, Y.; Ge, Y.; Wei, L.; Wang, D.; Zhao, L.; Yan, S.; Chen, Y. Quasi-two-dimensional α-molybdenum oxide thin film prepared by magnetron sputtering for neuromorphic computing. RSC Adv. 2022, 12, 17706–17714. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Guo, K.; Shen, X.; Ning, H.; Liang, H.; Zhong, J.; Xu, W.; Tang, B.; Yao, R.; Peng, J. Physical Simulation Model of WO3 Electrochromic Films Based on Continuous Electron-Transfer Kinetics and Experimental Verification. ACS Appl. Mater. Interfaces 2021, 13, 4768–4776. [Google Scholar] [CrossRef]

- Bathe, S.R.; Patil, P.S. Titanium doping effects in electrochromic pulsed spray pyrolysed WO3 thin films. Solid State Ion. 2008, 179, 314–323. [Google Scholar] [CrossRef]

- Karbalaei Akbari, M.; Ramachandran, R.K.; Detavernier, C.; Hu, J.; Kim, J.; Verpoort, F.; Zhuiykov, S. Heterostructured plasmonic memristors with tunable opto-synaptic functionalities. J. Mater. Chem. C 2021, 9, 2539–2549. [Google Scholar] [CrossRef]

- He, Y.; Nie, S.; Liu, R.; Shi, Y.; Wan, Q. Indium–Gallium–Zinc–Oxide Schottky Synaptic Transistors for Silent Synapse Conversion Emulation. IEEE Electron Device Lett. 2019, 40, 139–142. [Google Scholar] [CrossRef]

- Zhou, J.; Wan, C.; Zhu, L.; Shi, Y.; Wan, Q. Synaptic Behaviors Mimicked in Flexible Oxide-Based Transistors on Plastic Substrates. IEEE Electron Device Lett. 2013, 34, 1433–1435. [Google Scholar] [CrossRef]

- Han, C.; Han, X.; Han, J.; He, M.; Peng, S.; Zhang, C.; Liu, X.; Gou, J.; Wang, J. Light-Stimulated Synaptic Transistor with High PPF Feature for Artificial Visual Perception System Application. Adv. Funct. Mater. 2022, 32, 2113053. [Google Scholar] [CrossRef]

- Gong, Y.; Wang, Y.; Li, R.; Yang, J.-Q.; Lv, Z.; Xing, X.; Liao, Q.; Wang, J.; Chen, J.; Zhou, Y.; et al. Tailoring synaptic plasticity in a perovskite QD-based asymmetric memristor. J. Mater. Chem. C 2020, 8, 2985–2992. [Google Scholar] [CrossRef]

- Zucker, R.S.; Regehr, W.G. Short-Term Synaptic Plasticity. Annu. Rev. Physiol. 2002, 64, 355–405. [Google Scholar] [CrossRef]

- Zinebi, F.; Russell, R.T.; McKernan, M.; Shinnick-Gallagher, P. Comparison of paired-pulse facilitation of AMPA and NMDA synaptic currents in the lateral amygdala. Synapse 2001, 42, 115–127. [Google Scholar] [CrossRef] [PubMed]

- Brenes, A.J. Calculating and Reporting Coefficients of Variation for DIA-Based Proteomics. J. Proteome Res. 2024, 23, 5274–5278. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.Y.; Peng, X.; Yu, S. NeuroSim+: An integrated device-to-algorithm framework for benchmarking synaptic devices and array architectures. In Proceedings of the 2017 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–6 December 2017. [Google Scholar] [CrossRef]

- Mohanty, H.N.; Tsuruoka, T.; Mohanty, J.R.; Terabe, K. Proton-Gated Synaptic Transistors, Based on an Electron-Beam Patterned Nafion Electrolyte. ACS Appl. Mater. Interfaces 2023, 15, 19279–19289. [Google Scholar] [CrossRef] [PubMed]

- Nowshin, F.; Yi, Y. Memristor-based Deep Spiking Neural Network with a Computing-In-Memory Architecture. In Proceedings of the 2022 23rd International Symposium on Quality Electronic Design (ISQED), Santa Clara, CA, USA, 6–7 April 2022. [Google Scholar] [CrossRef]

- Yao, P.; Wu, H.; Gao, B.; Tang, J.; Zhang, Q.; Zhang, W.; Yang, J.J.; Qian, H. Fully hardware-implemented memristor convolutional neural network. Nature 2020, 577, 641–646. [Google Scholar] [CrossRef] [PubMed]

- Burr, G.W.; Shelby, R.M.; Sebastian, A.; Kim, S.; Kim, S.; Sidler, S.; Virwani, K.; Ishii, M.; Narayanan, P.; Fumarola, A.; et al. Neuromorphic computing using non-volatile memory. Adv. Phys. X 2017, 2, 89–124. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, P.; Xing, R.; Yu, T.; Zhao, L.; Wei, L.; Wang, D.; Yan, S.; Tian, Y.; Bai, L.; et al. Flexible Mott Synaptic Transistor on Polyimide Substrate for Physical Neural Networks. Adv. Electron. Mater. 2022, 8, 2200078. [Google Scholar] [CrossRef]

- Su, D.; Liang, X.; Geng, D.; Wu, Q.; Liu, B.; Liu, C. An Artificial Neural Network Based on Oxide Synaptic Transistor for Accurate and Robust Image Recognition. Micromachines 2024, 15, 433. [Google Scholar] [CrossRef]

| Pulse Width/Number | Gmax/Gmin | AR | |

|---|---|---|---|

| 50 ms | 259.0 | 0.67 | |

| 100 ms | 1731.1 | 0.68 | |

| 200 ms | 3192.4 | 0.89 | |

| 0.63 | |||

| 15p + 15d | 259.0 | 0.67 | |

| 30p + 30d | 859.2 | 0.58 | |

| 50p + 50d | 3652.0 | 0.31 |

| Channel | Electrolyte | Ion Type | On-Off Ratio | Conductance Retention Time | Recognition Accuracy | Ref. |

|---|---|---|---|---|---|---|

| MoO3 | H2SO4 | H+ | ~2 | 50 s | - | [16] |

| Nb2O5 | LixSiO2 | Li+ | ~20 | 103 s | - | [20] |

| VO2 | CsClO4 | H+ | ~2 | 4 × 103 s | 98% | [49] |

| In2O3 | Al2O3 | H+ | ~3 | 120 s | 85% | [50] |

| WO3 | ZrO2 | H+ | ~20 | 103 s | 93% | [27] |

| IZO | Nafion | H+ | ~2.5 | 103 s | 84% | [45] |

| WO3 | Nafion | H+ | ~107 | - | - | [18] |

| WO3 | Nafion | H+ | ~105 | 103 s | 97% | Our work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Chen, S.; Fu, S.; Han, S.; Zhang, L.; Zhang, Y.; Wang, M.; Liu, C.; Liang, X. Wet Etching-Based WO3 Patterning for High-Performance Neuromorphic Electrochemical Transistors. Electronics 2025, 14, 1183. https://doi.org/10.3390/electronics14061183

Zhang L, Chen S, Fu S, Han S, Zhang L, Zhang Y, Wang M, Liu C, Liang X. Wet Etching-Based WO3 Patterning for High-Performance Neuromorphic Electrochemical Transistors. Electronics. 2025; 14(6):1183. https://doi.org/10.3390/electronics14061183

Chicago/Turabian StyleZhang, Liwei, Sixing Chen, Shaoming Fu, Songjia Han, Li Zhang, Yu Zhang, Mengye Wang, Chuan Liu, and Xiaoci Liang. 2025. "Wet Etching-Based WO3 Patterning for High-Performance Neuromorphic Electrochemical Transistors" Electronics 14, no. 6: 1183. https://doi.org/10.3390/electronics14061183

APA StyleZhang, L., Chen, S., Fu, S., Han, S., Zhang, L., Zhang, Y., Wang, M., Liu, C., & Liang, X. (2025). Wet Etching-Based WO3 Patterning for High-Performance Neuromorphic Electrochemical Transistors. Electronics, 14(6), 1183. https://doi.org/10.3390/electronics14061183