Effects of Equivalent-Oxide-Thickness and Fin-Width Scaling on In0.53Ga0.47As Tri-Gate Metal-Oxide-Semiconductor-Field-Effect-Transistors with Al2O3/HfO2 for Low-Power Logic Applications

Abstract

:1. Introduction

2. Materials and Methods

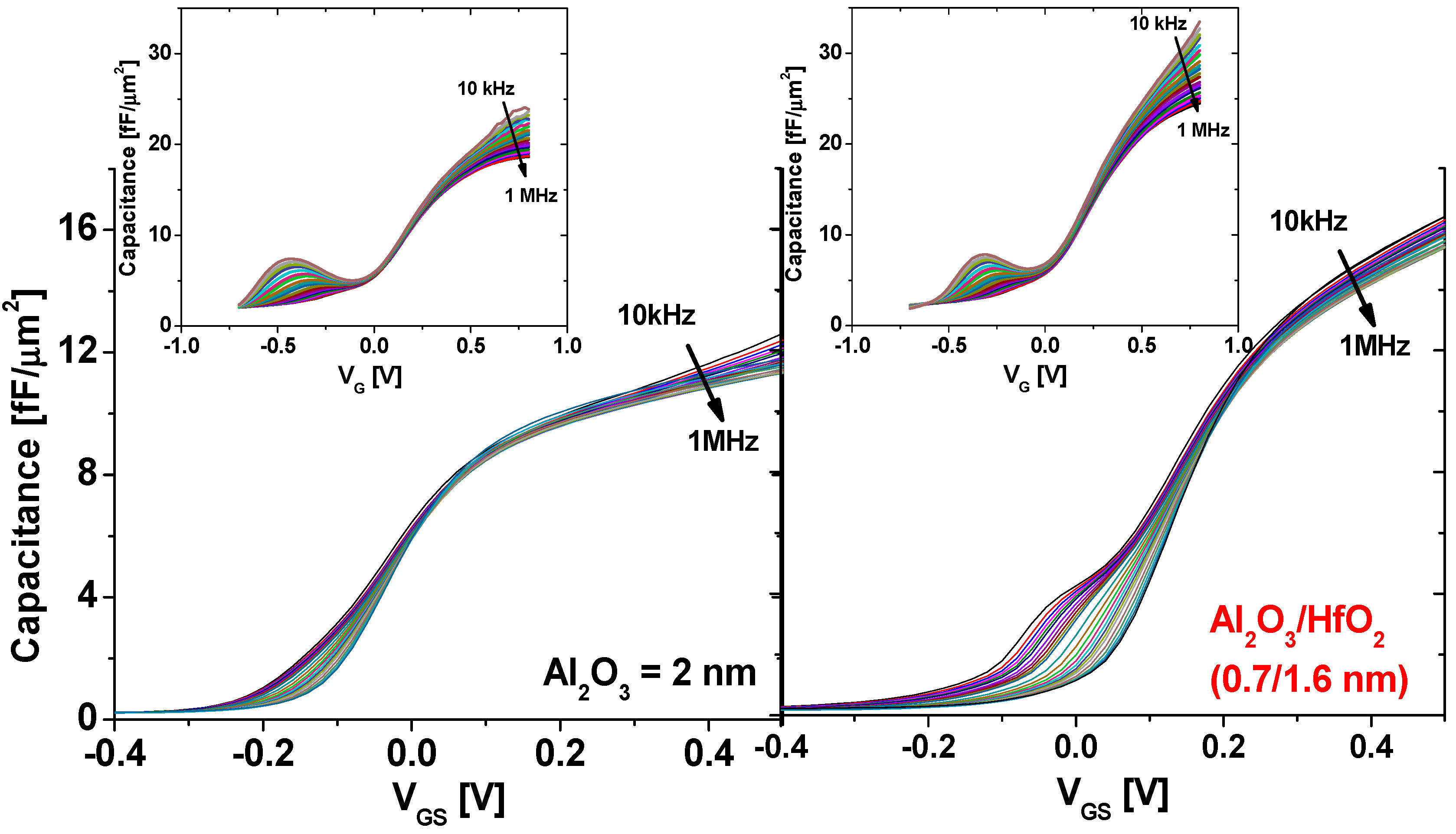

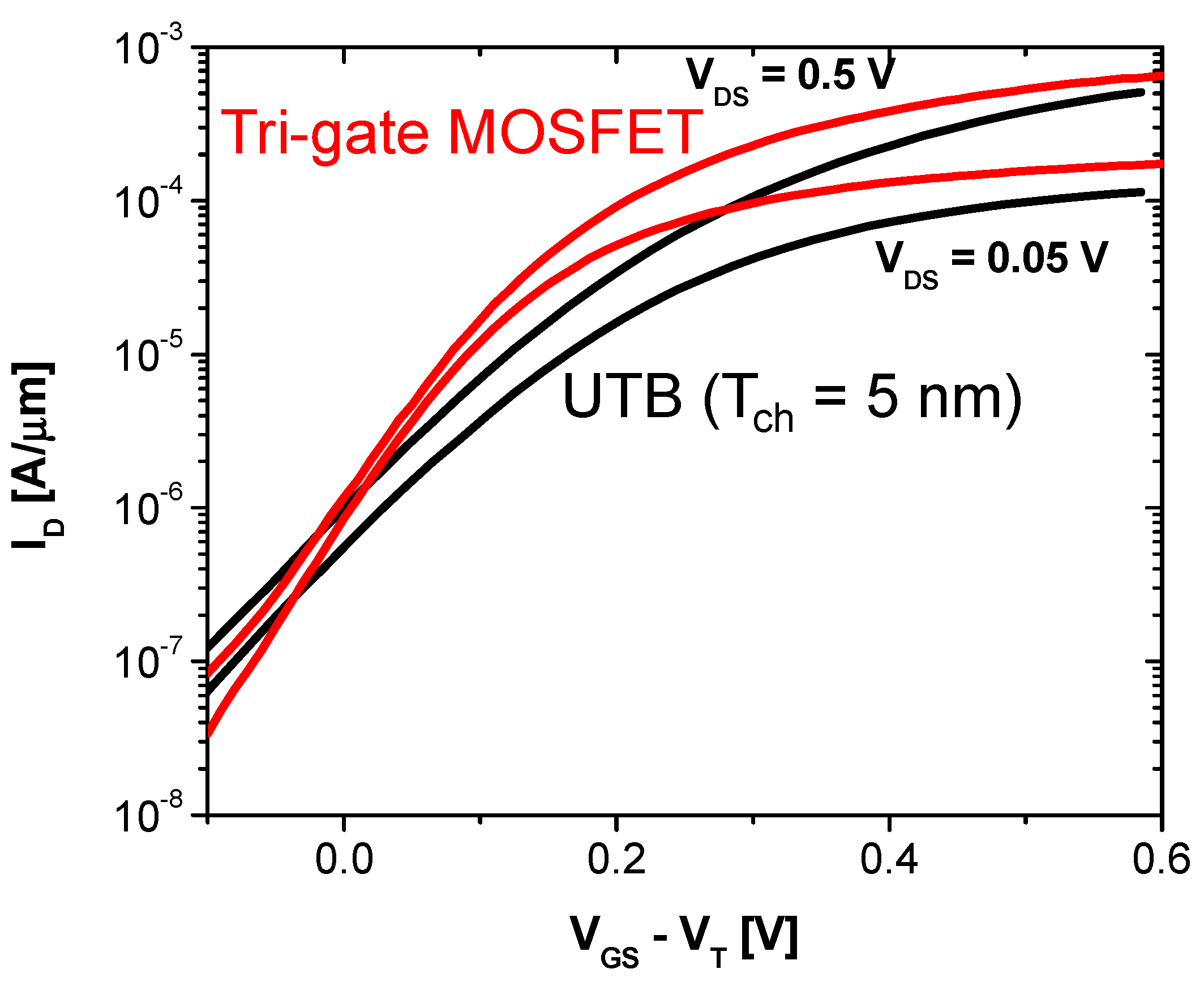

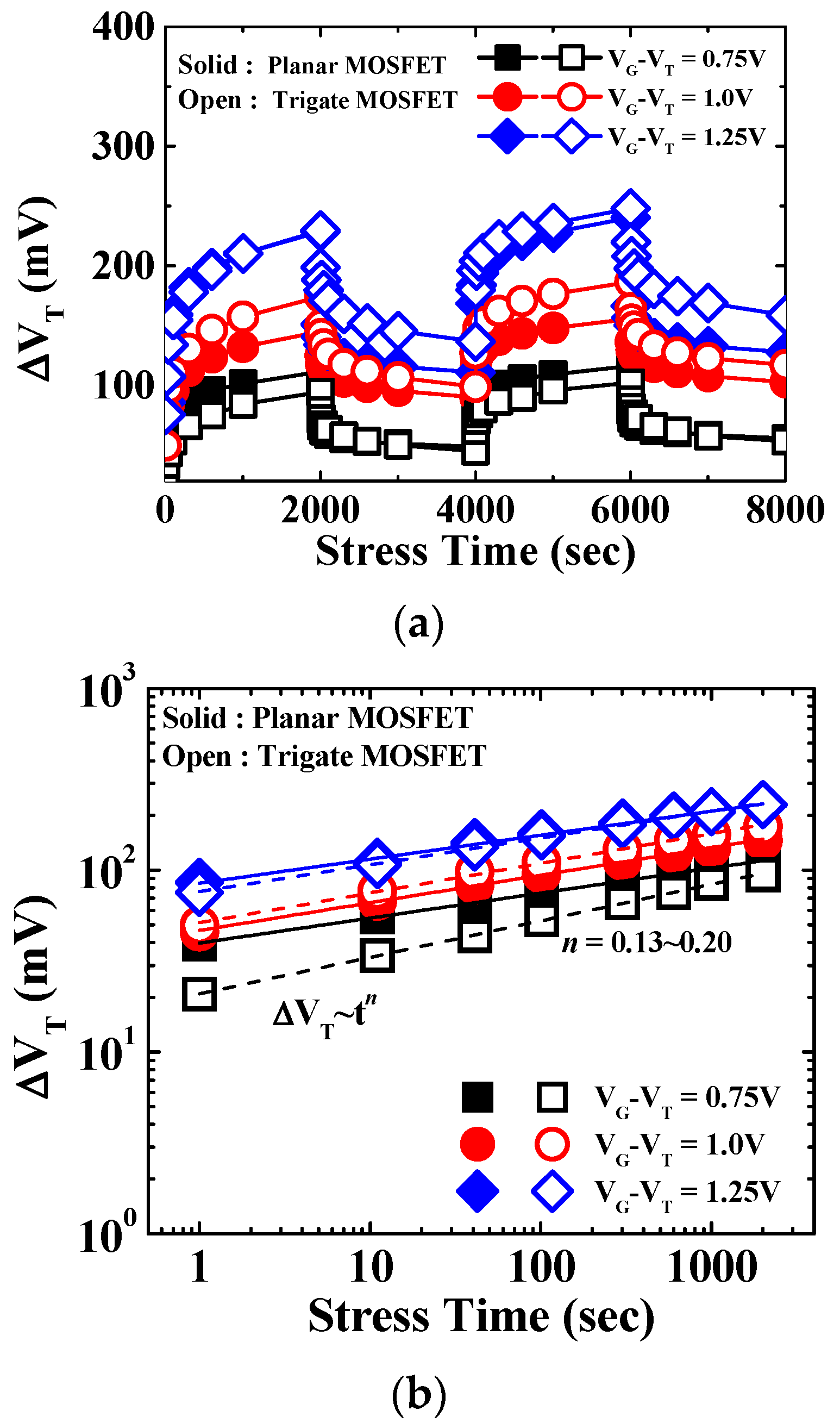

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Del Alamo, J.A. Nanometre-scale electronics with III–V compound semiconductors. Nature 2011, 479, 317–323. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.C.; Wang, W.E.; Brammertz, G.; Meuris, M.; Heyns, M. Electrical study of sulfur passivated In0.53Ga0.47As MOS capacitor and transistor with ALD Al2O3 as gate insulator. Microelectron. Eng. 2009, 86, 1554–1557. [Google Scholar] [CrossRef]

- Lin, D.; Brammertz, G.; Sioncke, S.; Fleischmann, C.; Delabie, A.; Martens, K.; Bender, H.; Conard, T.; Tseng, W.H.; Lin, J.C.; et al. Enabling the high-performance InGaAs/Ge CMOS: A common gate stack solution. In Proceedings of the 2009 IEEE International Electron Devices Meeting (IEDM), Baltimore, MD, USA, 7–9 December 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 1–4. [Google Scholar]

- Heyns, M.; Alian, A.; Brammertz, G.; Caymax, M.; Chang, Y.C.; Chu, L.K.; De Jaeger, B.; Eneman, G.; Gencarelli, F.; Groeseneken, G.; et al. Advancing CMOS beyond the Si roadmap with Ge and III/V devices. In Proceedings of the 2011 International Electron Devices Meeting, Washington, DC, USA, 5–7 December 2011; IEEE: Piscataway, NJ, USA, 2011; Volume 3, pp. 13.1.1–13.1.4. [Google Scholar]

- Takagi, S.; Iisawa, T.; Tezuka, T.; Numata, T.; Nakaharai, S.; Hirashita, N.; Moriyama, Y.; Usuda, K.; Toyoda, E.; Dissanayake, S.; et al. Carrier-Transport-Enhanced Channel CMOS for Improved Power Consumption and Performance. IEEE Trans. Electron Devices 2008, 55, 21–39. [Google Scholar] [CrossRef]

- Son, S.-W.; Park, J.-H.; Baek, J.-M.; Kim, J.S.; Kim, D.-K.; Shin, S.H.; Banerjee, S.K.; Lee, J.-H.; Kim, T.-W.; Kim, D.-H. Performance and carrier transport analysis of In0.7 Ga0.3 As quantum-well MOSFETs with Al2O3 /HfO2 gate stack. Solid State Electron. 2016, 123, 63–67. [Google Scholar] [CrossRef]

- Chidambaram, T.; Veksler, D.; Madisetti, S.; Yakimov, M.; Tokranov, V.; Oktyabrsky, S. InGaAs Inversion Layer Mobility and Interface Trap Density From Gated Hall Measurements. IEEE Electron Device Lett. 2016, 37, 1547–1550. [Google Scholar] [CrossRef]

- Netsu, S.; Hellenbrand, M.; Zota, C.B.; Miyamoto, Y.; Lind, E. A Method for Determining Trap Distributions of Specific Channel Surfaces in InGaAs Tri-Gate MOSFETs. IEEE J. Electron Devices Soc. 2018, 6, 408–412. [Google Scholar] [CrossRef]

- Engel-Herbert, R.; Hwang, Y.; Stemmer, S. Quantification of trap densities at dielectric/III–V semiconductor interfaces. Appl. Phys. Lett. 2010, 97, 062905. [Google Scholar] [CrossRef] [Green Version]

- Engel-Herbert, R.; Hwang, Y.; Chobpattana, V.; Stemmer, S. Correct determination of trap densities at high-k/III-V interfaces. In Proceedings of the CS MANTECH Conference, New Orleans, LA, USA, 13–16 May 2013; pp. 185–188. [Google Scholar]

- Veksler, D.; Bersuker, G.; Morassi, L.; Yum, J.H.; Verzellesi, G.; Wang, W.; Kirsch, P.D. Extraction of interfacial state density in high-k/III-V gate stacks: Problems and solutions. In Proceedings of the IEEE Nano Materials and Device Conference, Beijing, China, 5–8 August 2013; pp. 1–2. [Google Scholar]

- Chang, C.-H.; Chiou, Y.-K.; Chang, Y.-C.; Lee, K.-Y.; Lin, T.-D.; Wu, T.-B.; Hong, M.; Kwo, J. Interfacial self-cleaning in atomic layer deposition of HfO2 gate dielectric on In0.15Ga0.85As. Appl. Phys. Lett. 2006, 89, 242911. [Google Scholar] [CrossRef]

- Jevasuwan, W.; Urabe, Y.; Maeda, T.; Miyata, N.; Yasuda, T.; Yamada, H.; Hata, M.; Taoka, N.; Takenaka, M.; Takagi, S. Initial Processes of Atomic Layer Deposition of Al2O3 on InGaAs: Interface Formation Mechanisms and Impact on Metal-Insulator-Semiconductor Device Performance. Materials 2012, 5, 404–414. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Timm, R.; Head, A.R.; Yngman, S.; Knutsson, J.V.; Hjort, M.; McKibbin, S.R.; Troian, A.; Persson, O.; Urpelainen, S.; Knudsen, J.; et al. Self-cleaning and surface chemical reactions during hafnium dioxide atomic layer deposition on indium arsenide. Nat. Commun. 2018, 9, 1412. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hinkle, C.L.; Sonnet, A.M.; Vogel, E.M.; McDonnell, S.; Hughes, G.J.; Milojevic, M.; Lee, B.; Aguirre-Tostado, F.S.; Choi, K.J.; Kim, H.C.; et al. GaAs interfacial self-cleaning by atomic layer deposition. Appl. Phys. Lett. 2008, 92, 071901. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.-W.; Koh, D.; Kwon, H.; Shin, C.-S.; Park, W.-K.; Shin, S.H.; Cho, Y.; Ko, D.-H.; Hill, R.J.W.; Maszara, W.P.; et al. In0.7 Ga0.3 As quantum well MOSFETs with Al2O3/HfO2 toward subthreshold swing of ∼60 mV/dec. Appl. Phys. Express 2014, 7, 074201. [Google Scholar] [CrossRef]

- Kim, T.-W.; Koh, D.-H.; Shin, C.-S.; Park, W.-K.; Orzali, T.; Hobbs, C.; Maszara, W.P.; Kim, D.-H. Lg = 80-nm Trigate Quantum-Well In0.53 Ga0.47 as Metal–Oxide–Semiconductor Field-Effect Transistors With Al2O3/HfO2 Gate-Stack. IEEE Electron Device Lett. 2015, 36, 223–225. [Google Scholar] [CrossRef]

- Crupi, G.; Schreurs, D.M.M.; Rakin, J.P.; Caddemi, A. A comprehensive review on microwave FinFET modeling for progressing beyond the state of art. Solid State Electron. 2013, 80, 81–95. [Google Scholar] [CrossRef]

- Crupi, G.; Schreurs, D.M.M.; Rakin, J.P.; Caddemi, A. Effects of Gate-Length Scaling on Microwave MOSFET Performance. Electronics 2017, 6, 62. [Google Scholar] [CrossRef] [Green Version]

- Takagi, S.I.; Toriumi, A.; Iwase, M.; Tango, H. On the universality of inversion layer mobility in Si MOSFETs: Part I—Effects of substrate impurity concentration. IEEE Trans. Electron Devices 1994, 41, 2357–2362. [Google Scholar] [CrossRef]

- Kim, T.-W.; Kim, D.-H.; Koh, D.-H.; Hill, R.J.W.; Lee, R.T.P.; Wong, M.H.; Cunningham, T.; del Alamo, J.A.; Banerjee, S.K.; Oktyabrsky, S.; et al. ETB-QW InAs MOSFET with scaled body for improved electrostatics. In Proceedings of the 2012 International Electron Devices Meeting, San Francisco, CA, USA, 10–13 December 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 32.3.1–32.3.4. [Google Scholar]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.-W. Effects of Equivalent-Oxide-Thickness and Fin-Width Scaling on In0.53Ga0.47As Tri-Gate Metal-Oxide-Semiconductor-Field-Effect-Transistors with Al2O3/HfO2 for Low-Power Logic Applications. Electronics 2020, 9, 29. https://doi.org/10.3390/electronics9010029

Kim T-W. Effects of Equivalent-Oxide-Thickness and Fin-Width Scaling on In0.53Ga0.47As Tri-Gate Metal-Oxide-Semiconductor-Field-Effect-Transistors with Al2O3/HfO2 for Low-Power Logic Applications. Electronics. 2020; 9(1):29. https://doi.org/10.3390/electronics9010029

Chicago/Turabian StyleKim, Tae-Woo. 2020. "Effects of Equivalent-Oxide-Thickness and Fin-Width Scaling on In0.53Ga0.47As Tri-Gate Metal-Oxide-Semiconductor-Field-Effect-Transistors with Al2O3/HfO2 for Low-Power Logic Applications" Electronics 9, no. 1: 29. https://doi.org/10.3390/electronics9010029