Gate Current and Snapback of 4H-SiC Thyristors on N+ Substrate for Power-Switching Applications

Abstract

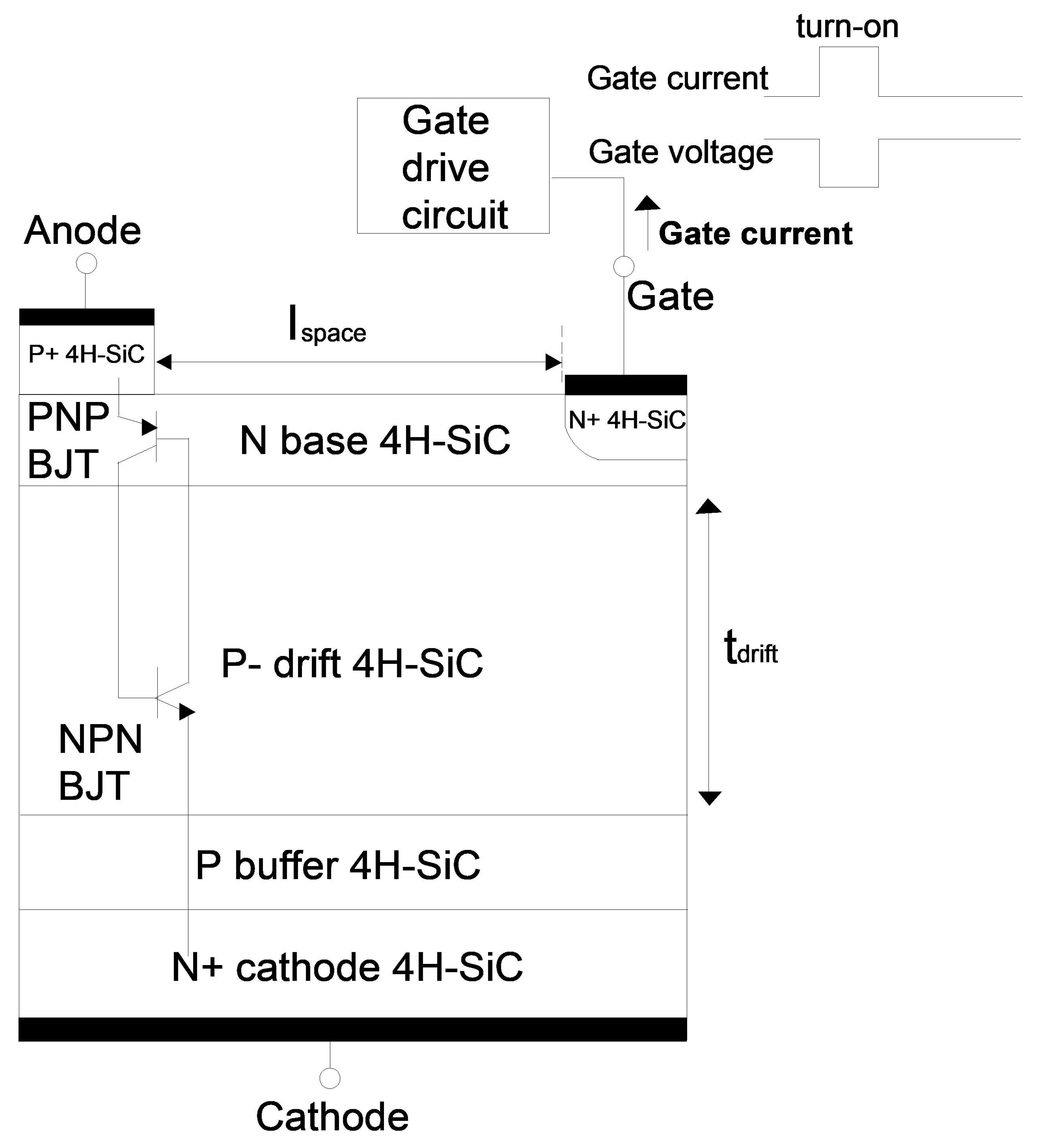

:1. Introduction

2. Numerical Methods

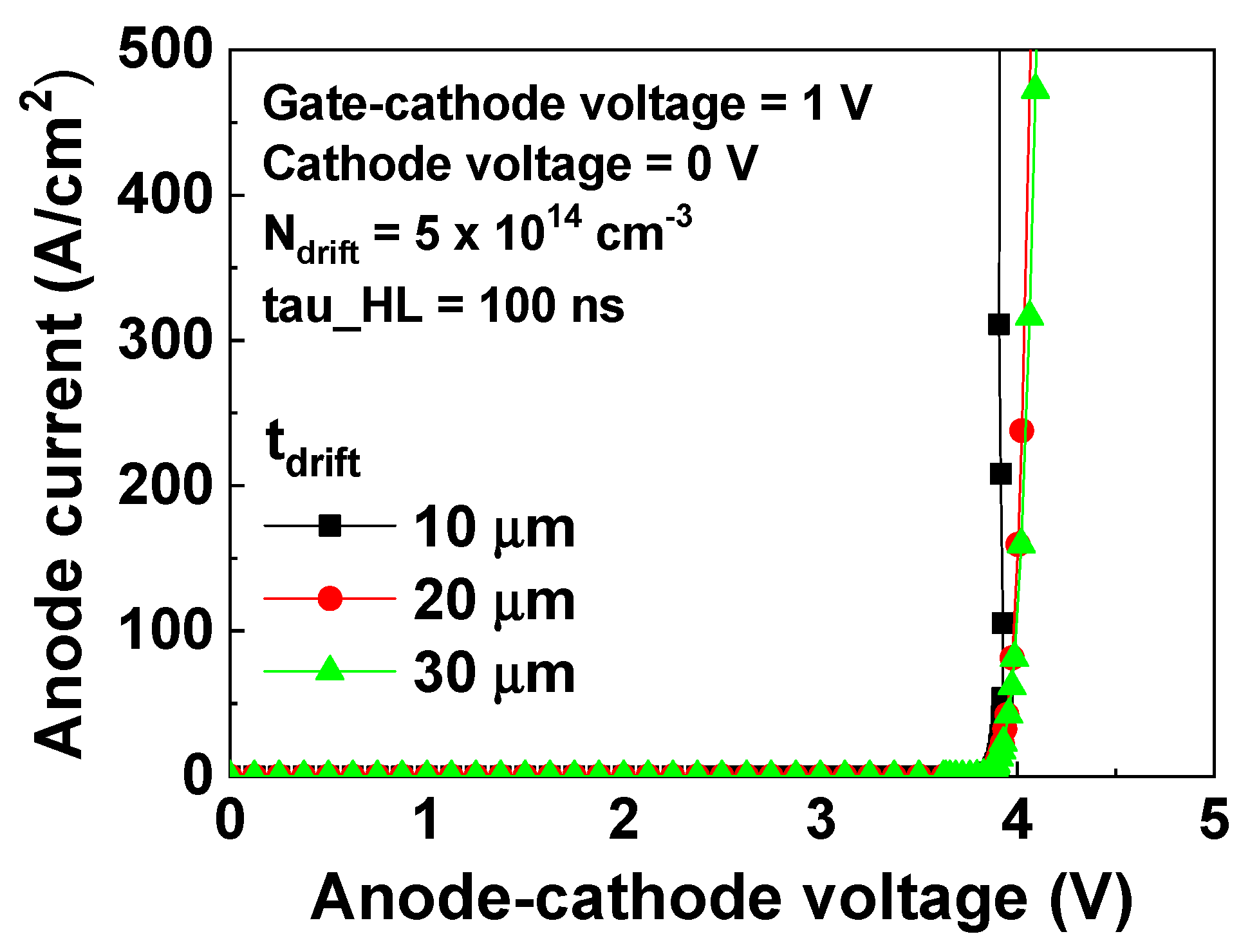

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Huang, A.Q. Power semiconductor devices for smart grid and renewable energy systems. Proc. IEEE 2017, 105, 2019–2047. [Google Scholar] [CrossRef]

- Choi, U.-M.; Blaabjerg, F.; Lee, K.-B. Study and handling methods of power IGBT module failures in power electronic converter systems. IEEE Trans. Power Electron. 2015, 30, 2517–2533. [Google Scholar] [CrossRef]

- Vobecký, J.; Schulze, H.-J.; Streit, P.; Niedernostheide, F.-J.; Botan, V.; Przybilla, J.; Kellner-Werdehausen, U.; Bellini, M. Silicon thyristors for ultrahigh power (GW) applications. IEEE Trans. Electron Devices 2017, 64, 760–768. [Google Scholar] [CrossRef]

- Liu, G.; Tuttle, B.R.; Dhar, S. Silicon carbide: A unique platform for metal-oxide-semiconductor physics. Appl. Phys. Rev. 2015, 2, 021307. [Google Scholar] [CrossRef]

- She, X.; Huang, A.Q.; Lucía, Ó.; Ozpineci, B. Review of silicon carbide power devices and their applications. IEEE Trans. Ind. Electron. 2017, 64, 8193–8205. [Google Scholar] [CrossRef]

- Kimoto, T.; Yonezawa, Y. Current status and perspectives of ultrahigh-voltage SiC power devices. Mater. Sci. Semicon. Proc. 2018, 78, 43–56. [Google Scholar] [CrossRef]

- Kimoto, T. Material science and device physics in SiC technology for high-voltage power devices. Jpn. J. Appl. Phys. 2015, 54, 040103. [Google Scholar] [CrossRef]

- Lee, S.; Kim, S.; Kang, H.J.; Kim, H.W.; Seok, O.; Moon, J.H.; Bahng, W.; Kim, H.J.; Ha, M.W. Effect of sweeping direction on the capacitance−voltage behavior of sputtered SiO2/4H-SiC metal-oxide semiconductors after nitric oxide post-deposition annealing. Phys. Scr. 2019, 94, 125811. [Google Scholar] [CrossRef]

- Lee, S.; Kim, Y.S.; Kang, H.J.; Kim, H.; Ha, M.W.; Kim, H.J. Effects of post-deposition annealing on sputtered SiO2/4H-SiC metal-oxide-semiconductor. Solid-State Electron. 2018, 139, 115–120. [Google Scholar] [CrossRef]

- Seok, O.; Kim, H.W.; Moon, J.H.; Bahng, W. High-voltage LDIMOSFETs on HPSI 4H-SiC substrate with dual field plates. Phys. Scr. 2019, 94, 76–96. [Google Scholar] [CrossRef]

- Asllani, B.; Morel, H.; Phung, L.V.; Planson, D. 10 kV silicon carbide pin diodes—from design to packaged component characterization. Energies 2019, 12, 4566. [Google Scholar] [CrossRef] [Green Version]

- Kimoto, T.; Yamada, K.; Niwa, H.; Suda, J. Promise and challenges of high-voltage SiC bipolar power devices. Energies 2016, 9, 908. [Google Scholar] [CrossRef] [Green Version]

- Qin, H.; Mo, Y.; Xun, Q.; Zhang, Y.; Dong, Y. A digital-controlled SiC-based solid state circuit breaker with soft switch-off method for DC power system. Electronics 2019, 8, 837. [Google Scholar] [CrossRef] [Green Version]

- Xu, C.; Ma, Q.; Xu, P.; Cui, T. Shaping SiC MOSFET voltage and current transitions by intelligent control for reduced EMI generation. Electronics 2019, 8, 508. [Google Scholar] [CrossRef] [Green Version]

- Tiku, D. dc power transmission. IEEE Power Energy Mag. 2014, 12, 76–96. [Google Scholar] [CrossRef]

- Veilleux, E.; Ooi, B.T. Multiterminal HVDC with thyristor power-flow controller. IEEE Trans. Power Del. 2012, 27, 1205–1212. [Google Scholar] [CrossRef]

- Kim, C.K.; Sood, V.K.; Jang, G.S.; Lim, S.J.; Lee, S.J. HVDC Transmission: Power Conversion Applications in Power Systems; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; pp. 149–159. [Google Scholar]

- Shah, P.B.; Jones, K.A. Simulated Turn-Off of 4H-SiC gate turn-off thyristors with gate electrodes on the p-base or the n-base. IEEE Electron Device Lett. 1999, 20, 577–579. [Google Scholar] [CrossRef] [Green Version]

- Huang, A.Q.; Zhang, B. Comparing SiC switching power devices: MOSFET, NPN transistor and GTO thyristor. Solid-State Electron. 2000, 44, 325–340. [Google Scholar] [CrossRef]

- Cao, L.; Li, B.; Zhao, J.H. Characterization of 4H-SiC gate turn-off thyristor. Solid-State Electron. 2000, 44, 347–352. [Google Scholar] [CrossRef]

- Li, Y.; Huang, A.Q.; Motto, K. Experimental and numerical study of the emitter turn-off thyristor (ETO). IEEE Trans. Power Electron. 2000, 15, 561–574. [Google Scholar] [CrossRef]

- Wang, J.; Huang, A.Q. Design and characterization of high-voltage silicon carbide emitter turn-off thyristor. IEEE Trans. Power Electron. 2009, 24, 1189–1197. [Google Scholar] [CrossRef]

- Song, X.; Huang, A.Q.; Lee, M.; Peng, C.; Cheng, L.; O’Brien, H.; Ogunniyi, A.; Scozzie, C.; Palmour, J. 22 kV SiC emitter turn-off (ETO) thyristor and its dynamic performance including SOA. In Proceedings of the 27th International Symposium Power Semiconductor Devices & ICs, Hong Kong, China, 10–14 May 2015; pp. 277–280. [Google Scholar]

- Song, X.; Huang, A.Q.; Lee, M.C.; Peng, C. Theoretical and Experimental Study of 22 kV SiC Emitter Turn-OFF (ETO) Thyristor. IEEE Trans. Power Electron. 2017, 32, 6381–6393. [Google Scholar] [CrossRef]

- Sugawara, Y.; Takayama, D.; Asano, K.; Agarwal, A.K.; Ryn, S.; Palmour, J.; Ogate, S. 12.7kV ultra high voltage SiC commutated gate turn-off thyristor: SICGT. In Proceedings of the 16th International Symposium Power Semiconductor Devices & ICs, Kitakyushu, Japan, 24–27 May 2004; pp. 365–368. [Google Scholar]

- Agarwal, A.K.; Damsky, B.; Richmond, J.; Krishnaswami, S.; Capell, C.; Ryu, S.H.; Palmour, J.W. The first demonstration of the 1 cm × 1 cm SiC thyristor chip. In Proceedings of the 17th International Symposium Power Semiconductor Devices & ICs, Santa Babara, CA, USA, 23–26 May 2005; pp. 159–162. [Google Scholar]

- Zhou, C.N.; Yue, R.F.; Wang, Y.; Zhang, J.; Dai, G.; Li, J.T. 10-kV 4H-SiC gate turn-off thyristors with space-modulated buffer trench three-step JTE. IEEE Electron Device Lett. 2018, 39, 1199–1202. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, K.; Zhang, L.; Xu, X.; Li, L.; Li, J.; Dai, G. A simple multistep etched termination technique for 4H-SiC GTO thyristors. Solid-State Electron. 2019, 151, 1–5. [Google Scholar] [CrossRef]

- Sung, W.; Huang, A.Q.; Baliga, B.J. Bevel junction termination extension-a new edge termination technique for 4H-SiC high-voltage devices. IEEE Electron Device Lett. 2015, 36, 594–596. [Google Scholar] [CrossRef]

- Atlas and Athena User’s Manual; Silvaco International: Santa Clara, CA, USA, 2009.

- Klaassen, D.B.M. A unified mobility model for device simulation-I. Model equations and concentration dependence. Solid-State Electron. 1992, 35, 953–959. [Google Scholar] [CrossRef]

- Klaassen, D.B.M. A unified mobility model for device simulation-II. Temperature dependence of carrier mobility and lifetime. Solid-State Electron. 1992, 35, 961–967. [Google Scholar] [CrossRef]

- Zakhleniuk, N.A. Nonequilibrium drift-diffusion transport in semiconductors in presence of strong inhomogeneous electric fields. Appl. Phys. Lett. 2006, 89, 252112. [Google Scholar] [CrossRef]

- Shockley, W.; Read, W.T. Statistics of the recombinations of holes and electrons. Phys. Rev. 1952, 87, 835–842. [Google Scholar] [CrossRef]

- Hall, R.N. Electron-hole recombination in germanium. Phys. Rev. 1952, 87, 387. [Google Scholar] [CrossRef]

- Dziewior, J.; Schmid, W. Auger coefficients for highly doped and highly excited silicon. Appl. Phys. Lett. 1977, 31, 346–348. [Google Scholar] [CrossRef]

- Slotboom, J.W.; de Graaf, H.C. Measurements of bandgap narrowing in Si bipolar transistors. Solid-State Electron. 1976, 19, 857–862. [Google Scholar] [CrossRef]

- Goossens, R.J.G.; Beebe, S.; Yu, Z.; Dutton, R.W. An automatic biasing scheme for tracing arbitrarily shaped I-V curves. IEEE Trans. Comput.-Aided Des. Integr. Circuits Syst. 1994, 13, 310–317. [Google Scholar] [CrossRef]

- Hakakeyma, T.; Fukuda, K.; Okumura, H. Physical models for SiC and their application to device simulations of SiC insulated-gate bipolar transistors. IEEE Trans. Electron Devices. 2013, 60, 613–621. [Google Scholar] [CrossRef]

- Hatakeyama, T.; Nishio, J.; Ota, C.; Shinohe, T. Physical modeling and scaling properties of 4H-SiC power devices. In Proceedings of the International Conference Simulation Semiconductor Processes and Devices, Tokyo, Japan, 1–3 September 2005; pp. 171–174. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Seok, O.; Kim, T.; Ha, M.-W. Gate Current and Snapback of 4H-SiC Thyristors on N+ Substrate for Power-Switching Applications. Electronics 2020, 9, 332. https://doi.org/10.3390/electronics9020332

Lee H, Seok O, Kim T, Ha M-W. Gate Current and Snapback of 4H-SiC Thyristors on N+ Substrate for Power-Switching Applications. Electronics. 2020; 9(2):332. https://doi.org/10.3390/electronics9020332

Chicago/Turabian StyleLee, Hojun, Ogyun Seok, Taeeun Kim, and Min-Woo Ha. 2020. "Gate Current and Snapback of 4H-SiC Thyristors on N+ Substrate for Power-Switching Applications" Electronics 9, no. 2: 332. https://doi.org/10.3390/electronics9020332

APA StyleLee, H., Seok, O., Kim, T., & Ha, M.-W. (2020). Gate Current and Snapback of 4H-SiC Thyristors on N+ Substrate for Power-Switching Applications. Electronics, 9(2), 332. https://doi.org/10.3390/electronics9020332