Abstract

Small living organisms such as lizards possess naturally built functional surface textures that enable them to walk or climb on versatile surface topographies. Bio-mimicking the surface characteristics of these geckos has enormous potential to improve the accessibility of modern robotics. Therefore, gecko-inspired adhesives have significant industrial applications, including robotic endoscopy, bio-medical cleaning, medical bandage tapes, rock climbing adhesives, tissue adhesives, etc. As a result, synthetic adhesives have been developed by researchers, in addition to dry fibrillary adhesives, elastomeric adhesives, electrostatic adhesives, and thermoplastic adhesives. All these adhesives represent significant contributions towards robotic grippers and gloves, depending on the nature of the application. However, these adhesives often exhibit limitations in the form of fouling, wear, and tear, which restrict their functionalities and load-carrying capabilities in the natural environment. Therefore, it is essential to summarize the state of the art attributes of contemporary studies to extend the ongoing work in this field. This review summarizes different adhesion mechanisms involving gecko-inspired adhesives and attempts to explain the parameters and limitations which have impacts on adhesion. Additionally, different novel adhesive fabrication techniques such as replica molding, 3D direct laser writing, dip transfer processing, fused deposition modeling, and digital light processing are encapsulated.

1. Introduction

Scientific expeditions have identified exceptional properties in living organisms that help them to perform outstanding tasks. Frogs, for instance, have a highly regular toe pad microstructure which facilitates them to stick easily to wet surfaces [1]. Spiders generate a glue-coated thread from their posterior abdomen to capture the prey [2]. On the other hand, geckos, such as lizard geckos and tokay geckos, climb on vertical surfaces without slipping, using their unique toe pads [3]. By gaining insights from the physiological properties of these biological creatures, scientists have developed smart synthetic materials with unique characteristics. The evolution of such synthetic materials has enabled researchers to replicate the surface properties of biological creatures, leading to an interdisciplinary field called biomimetics.

The origin of biomimetics can be dated back to 1950, when it was indicated that designs from biological creatures could be transferred to produce technologies in the form of machines, materials, and novel concepts that would be useful for humans [4]. Among these biological creatures, geckos have inspired researchers to develop synthetic materials over the past two decades. Autumn et al. [5] conducted one of the earliest studies in 2000 which laid the foundation for fabricating different synthetic adhesives inspired by gecko adhesion. Since then, considerable research has been conducted in the field of gecko-based adhesives [6,7,8]. The fabrication process, development, and design of these adhesives have been the primary focus areas for researchers to develop adhesive technology with high load-bearing capabilities and minimal fouling.

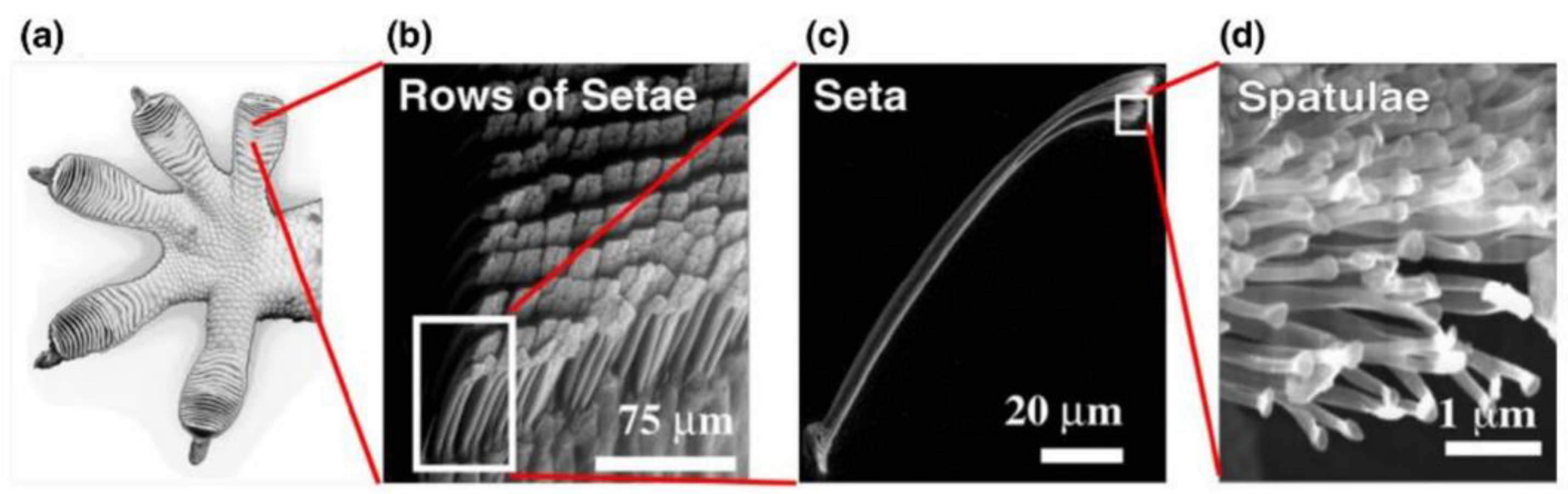

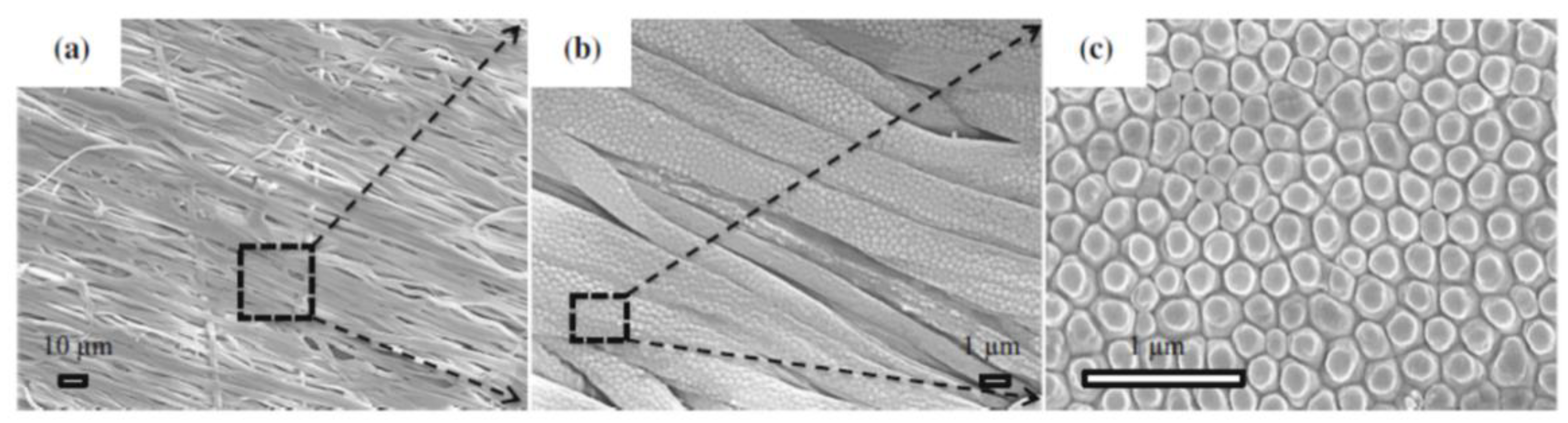

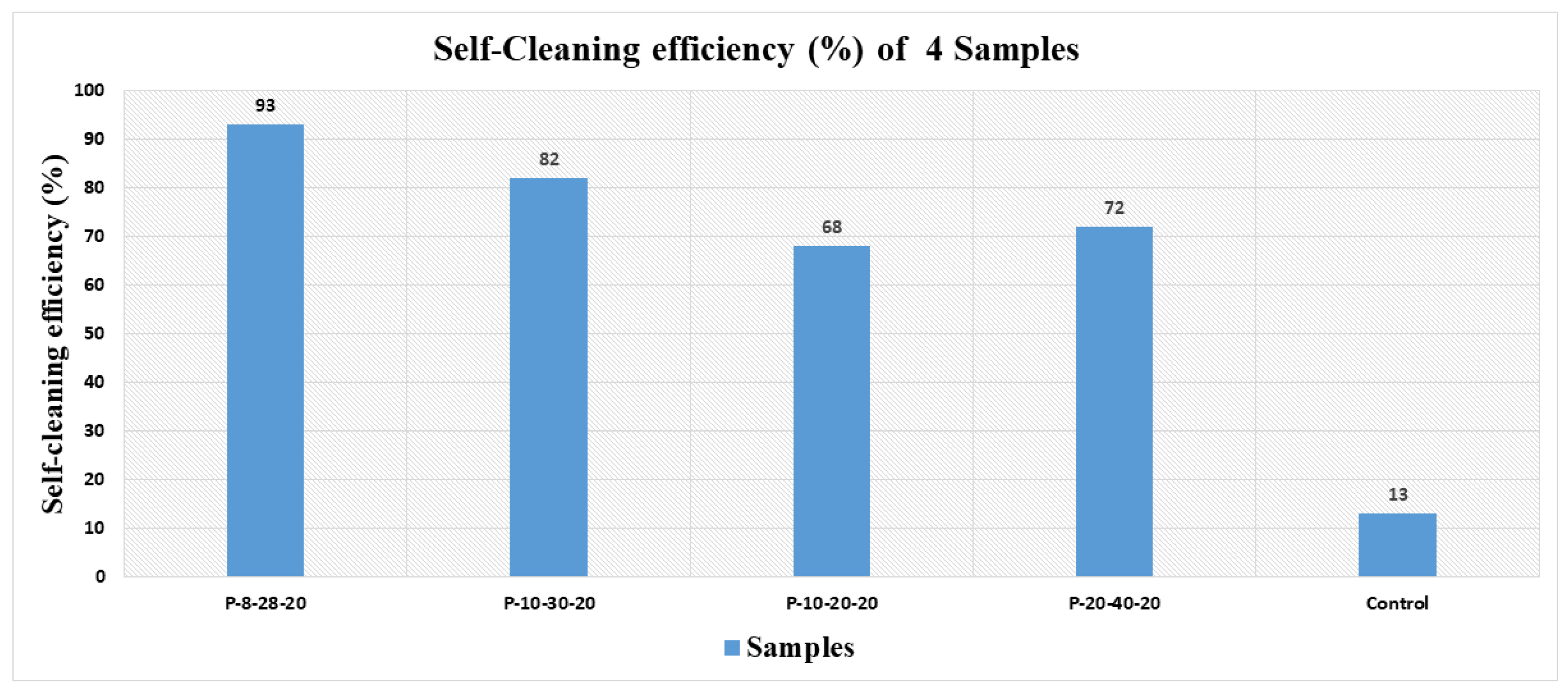

Geckos can walk or climb on a plane as well as vertical surfaces without slipping, using a quick attachment and detachment mechanism. The gecko toepad is composed of millions of hair-like structures called setae, which are composed of β keratin protein [9]. The attachment and detachment mechanism of gecko is controlled by the gecko’s foot morphology [10]. Figure 1 shows the hierarchical structure of the gecko’s toepad, consisting of macro-, meso-, and microstructures. The gecko toepads are sticky due to the hierarchical microstructures consisting of high-aspect-ratio lamellar shafts that act as smart adhesives [11]. The adhesive mechanism is actuated through the lamellar shafts, composed of millions of setae. These setae structures enable attractive van der Waal forces which help with adhesion. One setae structure is approximately 100 µm in length and 5 µm in diameter, and the tip of these individual setae branches into 100–1000 nanostructures known as spatulae. When the spatulae come in contact with any surface, they distort to provide a large contact area and generate a molecular contact which converts weak van der Waal forces into enormous attractive forces, sufficient for geckos to climb [12].

Figure 1.

Hierarchical structure of a gecko toepad: (a) lamellar structures; (b) rows of setae; (c) tip of one single setae; (d) spatulae image. Reprinted with permission from [9]. 2018, Springer.

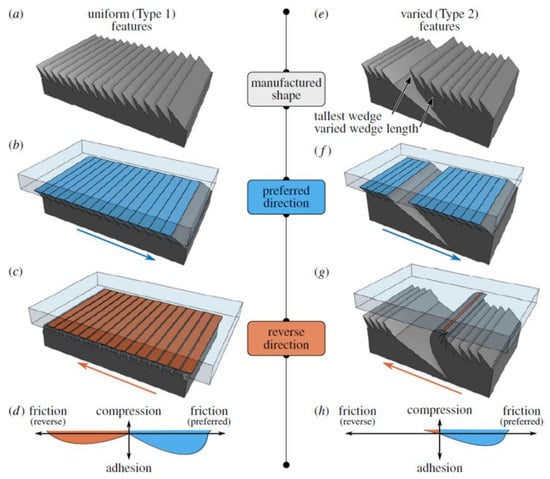

The hierarchical structure of the gecko toepads enables them to generate a frictional force that helps them carry their body weight during rapid locomotion [13]. It has been observed that adhesion increases with humidity, but the adhesion decreases when the toes are completely immersed in a fluid. Studies have shown that under sultry weather conditions, the adhesive pads of geckos can modify their hydrophobicity to increase their adhesion and control frictional forces [14,15]. Experiments have revealed that the front two feet of a gecko are able to develop frictional forces of around 20 N, and each seta can have a mean shear force of 6.2 N, with a maximum shear force of 194 N [16]. Another important attribute of gecko adhesion is high reversible adhesion and friction. During reverse adhesion, a peeling mechanism makes it possible for the rapid detachment of gecko toes. Theoretical and experimental studies have shown that setae on gecko feet are angled, showing anisotropy features in their adhesion and friction forces when they stick and dislocate in reverse directions [16]. In attachment mode, the setae bend down and stick to the substrate surface so that the toes have high adhesion and friction. Similarly, when in detachment mode, gecko toes peel off the surface where the setae bend back to decrease both adhesion and friction. The friction force between two adhesive surfaces () based on gecko adhesion is given by Equation (1) [16]:

where is normal load, is the coefficient of friction, is the actual contact area, and is the shear strength. The first term, , in the equation defines the friction forces, and the second term, , in the equation represents the adhesion and real contact area. Usually, for gecko adhesion, the friction forces are low compared with the adhesive forces. Equation (1) indicates that the adhesive forces play an important role in defining the friction forces for efficient gecko adhesion. Thus, to realize the application of the gecko adhesion mechanism, it is necessary to study the various adhesives and adhesion mechanisms employed by state-of-the-art gecko-based robots and their corresponding artificial adhesives.

Gecko-inspired adhesives provide relatively (compared with other adhesives) many advantages such as lower power consumption, suitability to a broader range of materials, relatively safer to use, can be scaled with the area, and hence carry higher loads [17]. These adhesives can adapt to surfaces of varying roughness, enhance the contact area, and provide required adhesion. Additionally, these adhesives can be employed in special environments such as space. Some of these adhesives are directional in nature, i.e., they are controllable to be turned on and off as and when required. Due to their anisotropic behavior, some of these adhesives can be disengaged with lower forces for specific applications [18]. The properties mentioned above make gecko-inspired adhesives suitable for various robotic applications, such as wall-climbing robots [19], manipulators [20], and space robots [21], to name a few.

The novelty of this review is that it explains about the importance of both water and humidity on gecko adhesion, in addition to the significance of surface roughness on adhesives. Here, there are many examples cited with novel fabrication techniques for synthetic adhesives. The following sections discuss adhesion mechanisms related to natural geckos, factors affecting them, various adhesion mechanisms upon which gecko-based artificial adhesives are fabricated, and recent progress in this field (Figure 2).

Figure 2.

A brief pictorial representation of the major topics discussed.

2. Adhesion Mechanisms of Some Climbing Robots and Gecko-Inspired Robots

At the prior stage of gecko-inspired robotics research, two types of adhesion mechanisms were commonly used, namely, suction adhesion, and magnetic adhesion. Suction adhesion is one of the oldest adhesion mechanisms, designed for wall-climbing robots. In this mechanism, the robot carries a pump to create a vacuum inside the adhesive cups that can be pressed against any smooth surface [22]. However, this mechanism remains inoperable on porous, cracked, and rough surfaces due to the chances of air leakage [23]. In addition, a considerable amount of time and power was required to produce sufficient vacuum in order to generate realistic adhesion force under the suction mechanism. Therefore, the robot’s locomotion slowed down significantly, which has limited the contemporary use of the suction adhesion mechanism under natural environments [24].

Comparatively, magnetic adhesion is a faster and more efficient mechanism when involving actuators [22]. In this mechanism, a permanent magnet is utilized to assist the robot’s locomotion on any ferromagnetic surface through integrated wheels [25]. Shen et al. [26] fabricated a wall-climbing robot in 2006 based on the magnetic adhesion mechanism. The benefit of this robot model was that it could carry a load of at least 30 kg. Magnetic adhesion mechanisms have also been preferred for nuclear power plant inspection systems [27]. In addition, they can be employed on any ferromagnetic surface. However, the greatest limitation of magnetic adhesion is its inability to operate on nonferromagnetic surfaces, which has greatly limited its usage in advanced applications [23].

Due to the limitations of suction and magnetic adhesion, researchers have explored alternative adhesion mechanisms, such as dry fibrillary adhesion, elastomeric adhesion, electrostatic adhesion, and thermoplastic adhesion, to name a few for gecko-inspired robots. Researchers have been investigating these mechanisms significantly for the last two decades.

In Table 1, a summary of these mechanisms with their applications is presented based on the literature. These mechanisms are discussed in detail in the subsequent sections.

Table 1.

Examples of synthetic adhesives employing different adhesion mechanisms.

2.1. Dry Fibrillary Adhesion

In dry fibrillary adhesion, surfaces can stick to smooth substrates but cannot stick to rough surfaces due to smaller contact areas and higher stress concentrations [48]. However, the flexibility of the fibers on rough surfaces can be enhanced by modifying their aspect ratio. The modified fibers provide enhanced contact area and adhesion, but their tensile strength may be reduced [49]. The improved contact area and adhesion are due to extended fibrils which increase the van der Waals interactions with the surface. In this context, some dry fibrillary gecko-based adhesives were employed historically, which included pressure-sensitive adhesives (PSAs). PSAs have fibrillary structures with a soft flowing layer which generates a large van der Waals attraction force to the surface [50]. Even though PSAs can provide sufficient adhesion to help robots climb efficiently on vertical surfaces [29,30], they require an extra support layer of soft foam for adhesion on rough surfaces [35]. PSAs also require a considerable amount of preload in the normal direction for efficient adhesion and detachment [32]. These factors, in addition to fouling, have limited the usage of PSA for climbing robots [32]. Hence, new adhesives with microstructured geometries (fibrillary structures) needed to be developed. Krahn et al. [28] introduced a novel ‘timing belt-based climbing platform (TBCP) robot’ in 2011, which did not require a preload for climbing vertical or horizontal surfaces. In addition, a fibrillary dry adhesive was developed for this robot with mushroom-shaped caps using polymethyl methacrylate (PMMA) and polydimethylsiloxane (PDMS) for smoother attachment and detachment purposes (Table 1). This robot could easily climb on vertical glass and painted steel surfaces. The robot could also traverse both horizontal and vertical surfaces with a speed of 3.4 cm/s.

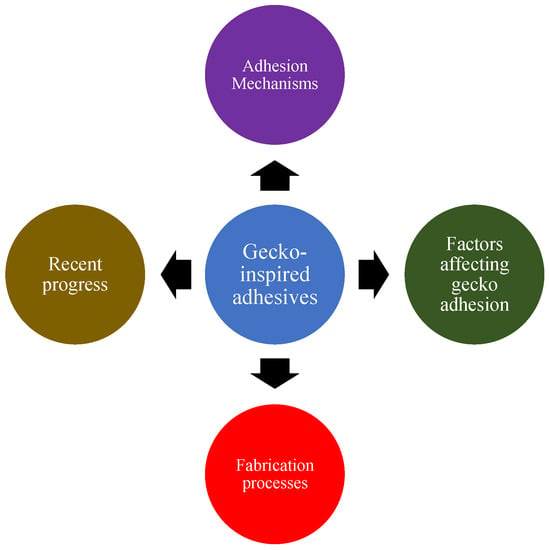

Previously, it was discovered that gecko toes could stick to surfaces efficiently despite high bulk material stiffness (almost 2 GPa for β keratin) [11]. This is due to the hierarchy of microstructure consisting of lamellae, setae, and spatulae, which reduces the effective stiffness of the entire gecko footpad structure. Thus, the entire system acts as a tacky material without fouling, and the microstructures further diffuse the load by dividing contact surfaces. Since this discovery, many artificial dry adhesive materials have been fabricated using perpendicular multi-wall carbon nanotubes (CNTs) and polymer fibers. In addition, in order for a material to be considered tacky, its effective modulus should be less than 100 kPa [8,11]. These “tack criteria” are satisfied by PSAs made from viscoelastic materials. Even though these structural materials are non-flexible and hydrophobic, they are delicate and require high normal loads for efficient attachment and detachment. Although CNT- and polymer–fiber-based adhesives sometimes lack anti-fouling properties, they can be manually cleaned and reused. Micro-structured elastomer tapes are an example of such adhesives [29,31]. The contrasting features of adhesives prepared from polymers and CNTs are presented in Table 2.

Table 2.

Contrasting features of polymer-based adhesives and CNT adhesives [51].

In addition to the effective stiffness and the effective modulus of adhesive microstructures, the size and form of contacting elements are important parameters for maintaining adhesion [33,52,53]. For a specific loading direction, special tip microstructural geometry can reduce the stress concentration up to 50-fold times and improve the adhesion of each fiber [32]. A smaller scaled tip geometry needs smaller deformation energy and produces good stress distribution on contacting surfaces. Hence, sensitivity to tip geometry pertaining to small-scaled structures is lower. However, for larger-scaled features, tip geometry is significant and influences adhesion in addition to the stress distribution. If soft material is used for the tip geometry on a larger-scale structure, it decreases both the deformation energy and shape sensitivity. However, this will increase the probability of fouling on the tips as well as the sticking of adjacent tips. Therefore, it is beneficial to have a small tip geometry of microstructures.

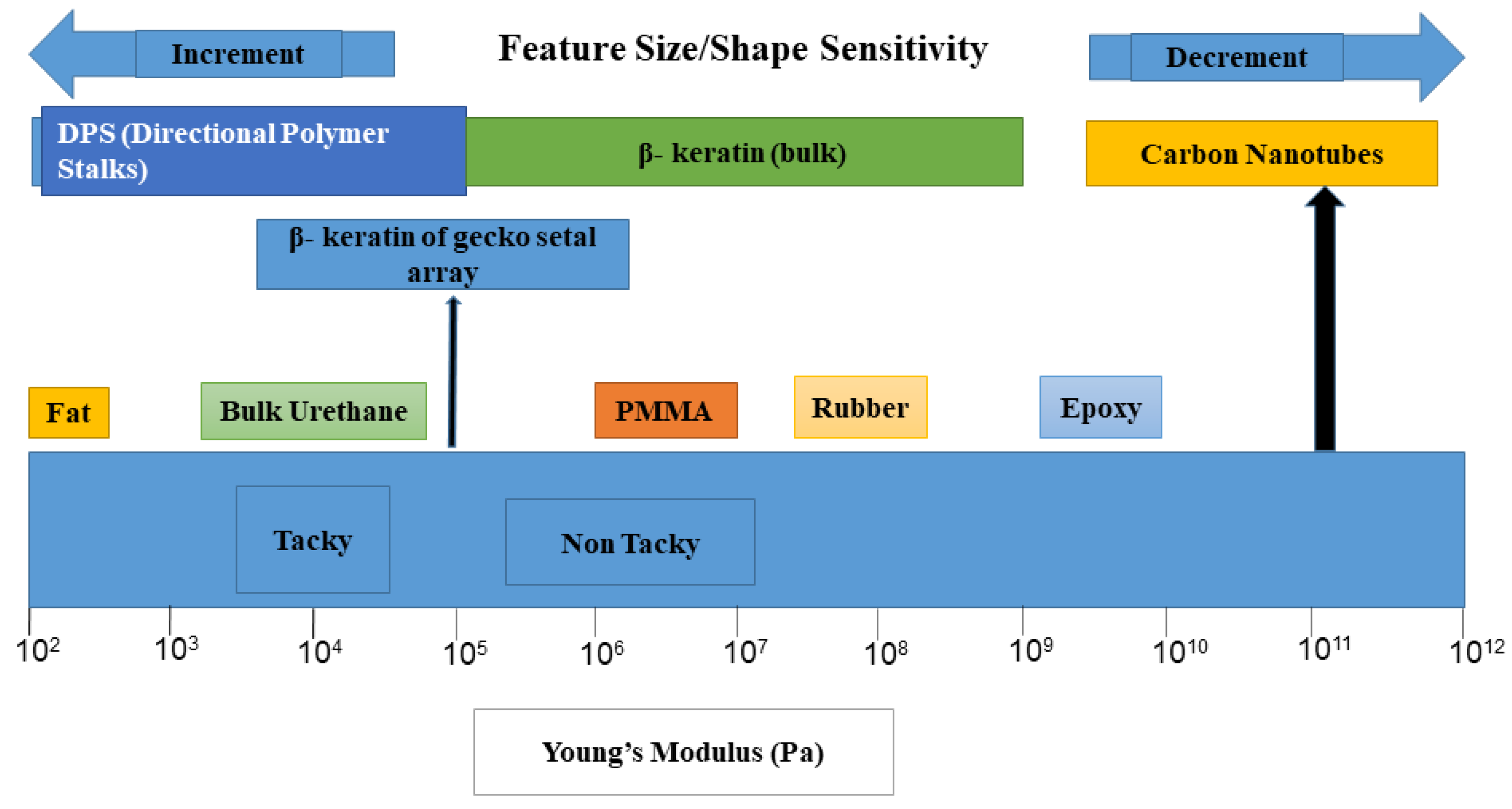

In addition to microstructures, fibrillary structures reduce the rigidness of bulk materials in order to make the adhesive tacky. Geckos apply β keratin for their adhesive structures, which supports this theory [32]. Based on the mentioned ‘tacky’ principle, Kim et al. [32] developed a robot named “Sticky Bot” which employed hierarchical fibrillary microstructures in its adhesion system (Figure 3). The robot’s feet comprised directional polymer stalk (DPS) adhesives manufactured from PU. The benefits of this robot were:

Figure 3.

Shape sensitivity is shown for various materials. Young’s modulus range of various materials and feature size of the distal end of multiple structures. Adapted with permission from [32]. 2008, IEEE Xplore.

- It could stick on surfaces with varying roughness from micrometer to centimeter scale;

- It could attach and detach from surfaces easily by controlling tangential forces during directional adhesion;

- It employed force control, which functioned with body compliance along with the oriented adhesive to regulate tangential forces of the foot.

The disadvantage of this model was the fouling of the DPS over time. The fabrication of better adhesives with refined fibrillary structures might solve the limitation in the near future.

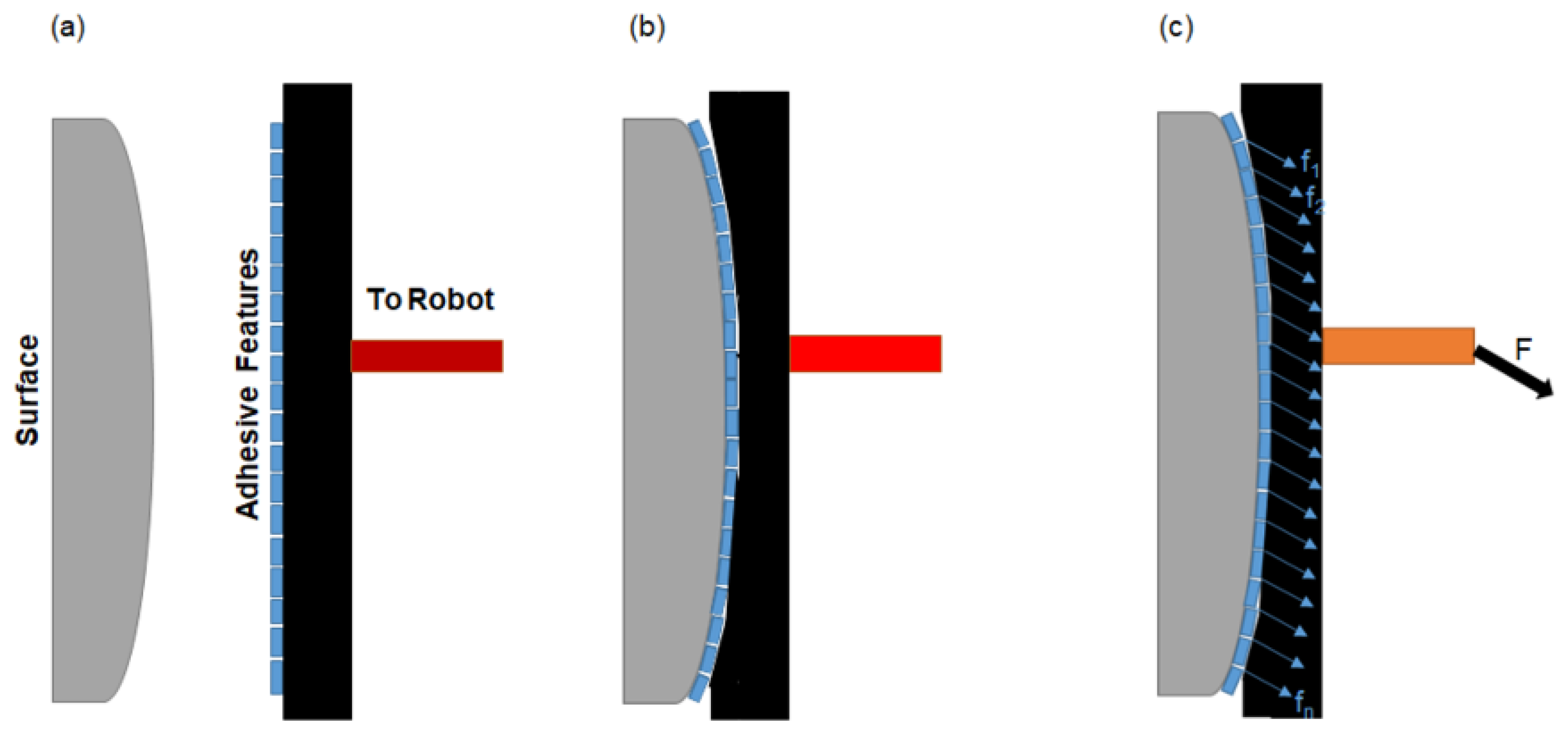

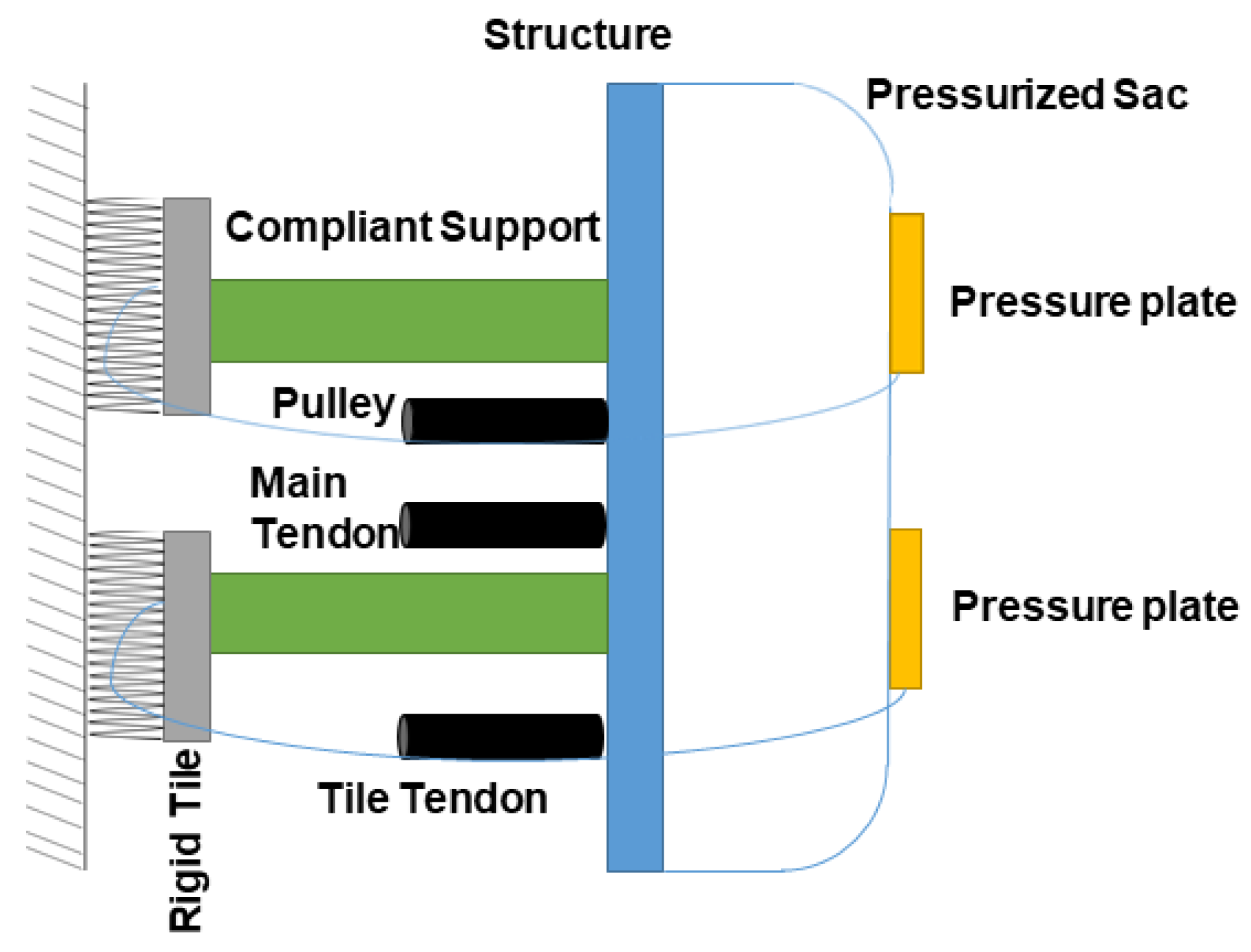

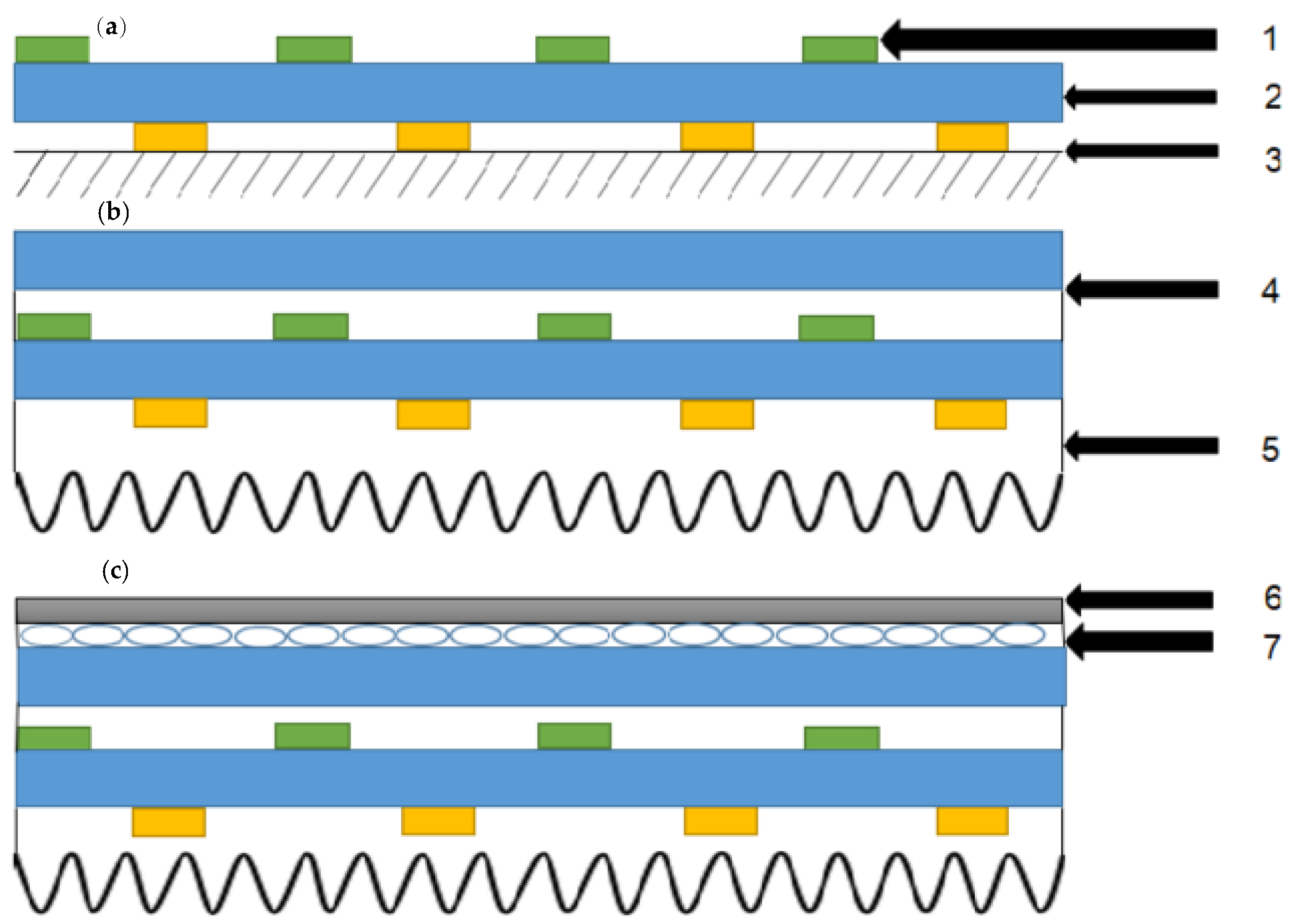

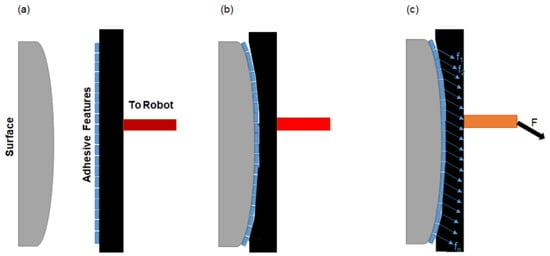

Although many investigations have been carried out on dry fibrillary adhesives since their inception, most of these investigations have been performed on precisely oriented materials and smaller sample sizes. Only a limited amount of research is available on materials with a larger area and larger load that could maintain sufficient adhesion [54,55]. Moreover, there has not been much work conducted with the accurate positioning and application of load. The majority of practical robots employing microstructured dry adhesives could not attain the same level of adhesion compared with those of standard test experiments [32,36,56]. This limitation might be counteracted by employing a bigger gecko-based robot foot. However, if a larger foot is designed, it will be tough to supply the necessary adhesion because the length of the foot will extend, causing the mass and the contact area to increase [34]. In order to climb and carry a payload for a bigger robot, it is necessary that the amount of adhesion attained must be similar to that obtained from standard tests. Furthermore, the adhesive must be able to adjust load variation as well as a deviation in alignment. To overcome this drawback, Hawkes et al. [34] proposed two distinct mechanisms with identical capabilities. In the first mechanism, an adhesive tile, a tendon-like string, and an adaptable support were assessed and compared with that of a standard test sample (Figure 4). The second mechanism employed many independent tiles into an array which was tested and compared with a single tile mechanism. For a gecko-inspired adhesive to be able to work under inaccurate orientation, varying load, and large surface area, two designs were proposed [34]. The first design demonstrated full contact of the adhesive features with the surface (Figure 4a). Every distinct microstructure of the adhesive should make contact with the surface so as to be able to produce maximum adhesion (Figure 4b). The second design proposed that every distinct microstructure of the adhesive must encounter the same load distribution (Figure 4c). As shown in Figure 5, the functional components of the robot used for this experiment were (a) rigid tile backing, (b) compliant support, (c) tendons, (d) pulley, and (e) pressurized sac. For a particular direction, the adhesion was sufficient to help the robot attach and detach from surfaces easily.

Figure 4.

(a) Model explaining the design requirements; (b) all distinct microstructures of the adhesive in contact with the surface; (c) all distinct microstructure of the adhesive experience uniform load. Adapted with permission from [34]. 2012, IEEE Xplore.

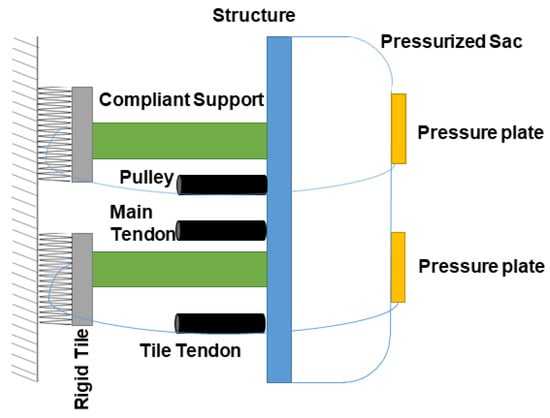

Figure 5.

Functional components of the proposed robot by Hawkes et al. Adapted with permission from [34]. 2012, IEEE Xplore.

In Figure 5, the compliant support provides full contact with all tiles while preload is applied. Tile tendons pass from the center of each tile to a pressurized sac, which ensures that each tile obtains a similar loading force. The resultant of single forces pass through the structure and into the main tendon [34].

Murphy et al. [19] later designed and fabricated a robot named Wallbot II. In this model, footpads were fabricated using PU. The fibers had dimensions of 57 µm in stem diameter, tip diameter of 114 µm, and length of 113 µm. A 2.8 mm of soft foam, with a stiffness of 676 N/m, was inserted amongst the foot and fibrillary adhesive pad (Table 1). This was beneficial because it increased the conformity to the footpad and reduced misalignment within the fibers and surface. As a result, consistent load could be obtained during preloading of the robot. The robot could climb vertical surfaces with high surface roughness. Additionally, the surface roughness was sufficient to stop the robot from adhering to the surface if it had flat, unstructured adhesive pads. This robot was able to carry a payload which was more than its body weight. Due to the fibrous footpads, the consumption of power could be lowered, and the climbing speed of the robot could also be enhanced.

2.2. Elastomeric Adhesion

With the advancements in science, researchers have fabricated synthetic polymers. These polymers are often termed “elastomers”. Elastomeric adhesives are natural or synthetic materials possessing wonderful peel strength but low shear strength [57]. Their resilience provides good fatigue and impact properties. These materials are mainly of four types: (1) tapes, (2) gels, (3) flat elastomer adhesives, and (4) fibrillar elastomer adhesives [36,58]. Applications of elastomeric adhesion are relatively new. The elastomeric adhesion mechanism is usually applicable when the surface roughness is less than a few micrometers. The benefit of this type of mechanism is its energy efficiency, noiseless operation, and applicability to a variety of smooth surfaces (on account of intermolecular-force-based adhesion), even in a vacuum. Due to intermolecular-force-dependent adhesion, elastomers are able to function over different surfaces and environments [58]. Researchers observed that dry elastomers stick to a given surface roughness when compressed perpendicularly to the substrate. The adhesion force developed by this mechanism is approximately 100 KPa [59,60,61]. When the adhesive material sticks properly to the surface, it can remain attached to the surface for a longer duration without any additional power requirement. For efficient vibration-free detachment, these elastomers are expected to peel off similarly to gecko foot hair [6,62,63]. The main disadvantage of elastomer-based adhesives is that they can easily be dirtied. The dirt or contamination on these adhesives can be removed by cleaning their surface with alcohol or acetone to regain adhesion [58]. Unver et al. [36] proposed a robot attachment technique using a soft dry elastomer named Vytalflex-10 (V-10) (Table 1). The surface roughness of this elastomer was approximately a few micrometers. V-10 elastomers have been successfully validated as an effective adhesive material for rough surfaces in previous research [36]. The researchers fabricated a tank-like robot employing non-patterned elastomer adhesive treads, which were in the form of curved wheels. The adhesion force of this elastomer was directly proportional to the contact area; thus, the adhesion force could be extensively increased by designing the wheel as a tread shape which increased the contact area. The adhesive force on this elastomer was a function of the contact area and could be improved by widening the track width or by increasing the number of wheels in parallel. Applying multiple tread shapes on the robot, it was found that the robot could carry various payloads, perform easy transitions, steer easily, and move around for many tasks. The robot could also be stopped on a vertical glass surface without consuming any power for a considerable time [36]. However, the major challenge of this robot was frequent fouling of the adhesive tread wheels.

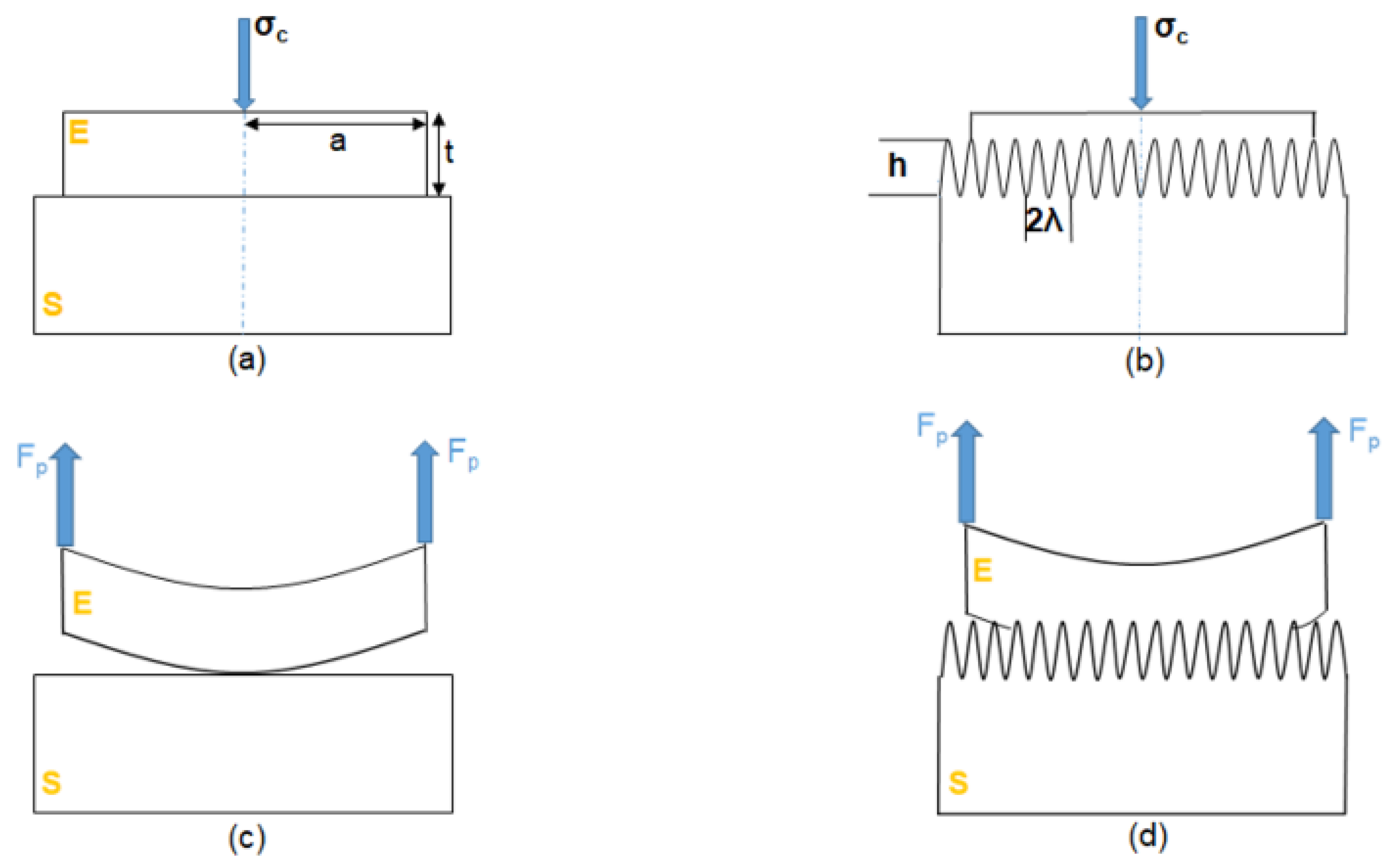

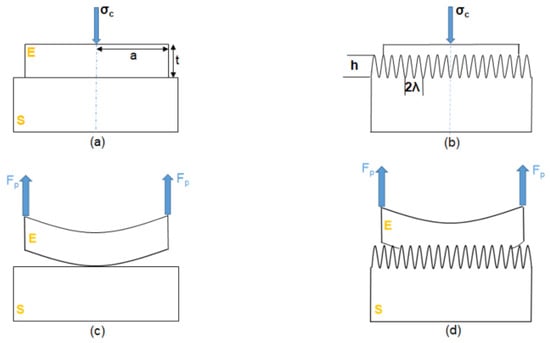

Hansen and Autumn [64] showed that fouled gecko foot hairs can recover around 50% of shear adhesion after making contact with many dry and clean surfaces. Lee and Fearing [65] assessed the contact-based self-cleaning of hard polymer adhesive fiber arrays that were contaminated. They found that these adhesives can recover around 30% of shear adhesion after touching clean surfaces [65]. Kim et al. [66] experimented and highlighted that fouled soft elastomer arrays could be washed with a drop of water, and this could help them to recover almost 100% of adhesion. However, this self-cleaning mechanism of these elastomer fibers led to only 20% to 30% adhesion recovery in actual experimentations, which was a major drawback. In another study, Unver et al. [58] utilized non-patterned elastomers as adhesives for attachment purposes (Table 1). Their model provided higher adhesion for the designed robot. It was also observed that these elastomer-based adhesives were able to perform better on smooth surfaces compared with rough surfaces (Figure 6). Furthermore, in order to align the robot footpads better, a foam material was used, which helped to obtain higher preload, and correspondingly, better adhesion [58].

Figure 6.

Attachment and detachment process involved in a soft flat elastomer robot foot with radius ‘a’ and thickness ‘t’. (a) Attachment of Vytaflex elastomer (E) to a smooth surface (S) when a compressive pre-load of σc is applied; (b) attachment of Vytaflex elastomer to a rough surface, with amplitude ‘h’ and roughness wavelength ‘λ’; (c) detachment process of Vytaflex elastomer from a smooth surface when a tensile force, Fp, is applied; (d) detachment process of Vytaflex elastomer from a rough surface when a tensile force, Fp, is applied. Adapted with permission from [58]. 2009, IEEE Xplore.

Advanced elastomers have recently been introduced by researchers. Amongst them, silicon elastomers possess a wide range of applications in robotics. Continuous investigations have been ongoing to interpret the connections between silicon’s structure and its mechanical properties. It was observed that the low surface energy of silicon elastomers substantially limited the possible modifications [37,38]. Simaite et al. [39] examined 11 different elastomers (Table 3) and explained their adhesive properties. It was observed that metal oxide particles in elastomers increased adhesion. Therefore, excessively doped elastomers used to fabricate the microstructured adhesives worked better relative to unstructured, flat adhesives. Additionally, it was noted that the adhesion of unstructured elastomers was dependent on bulk dissipation. However, for structured adhesives, the adhesion relied on interface toughness. It was proven that microstructured adhesives were more effective on rough substrates. Moreover, it highlighted that the important parameters to explain adhesion strength in both unstructured and structured adhesives are mechanical properties such as elastic modulus, E, loss factor, tanδ, and surface properties such as work performed due to adhesion, WA, free surface energy, γeff, and root-mean-square roughness, RRMS. Amongst these parameters, loss factor is a mathematical term which is defined as the ratio of energy loss to that of the sum of energy loss and strain energy of the adhesive [67]. It varies with the shear modulus of the adhesive.

Table 3.

Elastomers and their curing conditions. MR, mixing ratio; CT, curing temperature; Ct, curing time; CT2, secondary curing temperature; Ct2, secondary curing time [39].

2.3. Electrostatic Adhesion

Electrostatic adhesion is an electrically compliant adhesion mechanism that requires creating electrostatic charges on a wall surface, employing a power supply connected to a specific electrode panel [40]. This electrode panel consists of at least two sets of non-dependent electrodes at different potentials. When alternate positive and negative charges are developed on adjoining electrodes, electric fields are set up on the wall surface. This causes electrostatic adhesion between the electrode panel and the wall surface. The advantage of this process is that it can be used to carry a light load in gecko-inspired robots. It utilizes less power and can provide adjustability to various wall surfaces. Chen proposed a gecko-inspired robot that worked on the basis of electrostatic adhesive force [40]. In this model, the base of the adhesive footpad was composed of polyimide film (PI) with a specific thickness. On this PI film, electrodes fabricated from copper with specific thickness were deposited (Table 1). This entire material was covered by another PI film with a similar thickness to the base material. Due to the pliability of copper and PI film, the adhesive footpad could easily detach from the conforming surface, and buckle during attachment. On top of the footpad, a layer comprising six bendable plastic bars was employed and positioned in radial directions. This helped the footpad conform to the surface efficiently, as well as keep its shape during attachment and detachment. From the experiment, it was observed that the robot made with this electrostatic adhesive could walk as well as turn on the vertical glass surface. The maximum speed obtained from this robot was 2 cm/s, and the highest angle to which it could turn was 30°.

When a large voltage potential is applied across electrodes, fixed in a dielectric medium, an electrostatic field is created, which consequently creates adhesive force [68]. The benefit of this type of adhesion is that it is applicable to both conducting as well as non-conducting surfaces [43]. The degree of electrostatic adhesion relies on voltage potential, electrode geometry (breadth, thickness, and pattern), insulator thickness, and substrate permittivity [69]. The magnitude of the adhesive force is directly proportional to the voltage applied and substrate permittivity. Additionally, decreasing insulator thickness or breadth between the electrodes increases adhesive forces. For conductive surfaces, electrons are free to move towards positive electrodes and form electron holes under negative electrodes. However, for non-conductive surfaces, the electric field polarizes the substrate’s molecules, thereby creating an attraction force [69].

Electrostatic adhesives can be a game-changer in space conditions, where ferromagnetic materials are rare, pressure-sensitive adhesives do not work properly, and the suction phenomenon does not work due to the absence of an atmosphere. They can be utilized for both vacuum and non-vacuum applications [70]. There have been attempts to create other electrostatic adhesives by various researchers. One method was creating an electrode pattern with polyethylene terephthalate (PET) and later coating it by spraying it with a thin layer of resin as an insulator [41] (Table 1). This method mainly worked well on smooth surfaces due to the thin layer of resin-coated surfaces, which increased electric field strength. However, the electrostatic adhesives were unable to stick to rough surfaces, which was its main disadvantage. A different method of creating electrostatic adhesives was using metal or carbon traces stuffed between mylar sheets [42] (Table 1). This method enabled the adhesive to partially stick to the surface. On the other hand, Ruffatto et al. [44] fabricated a new electrostatic adhesive, which involved implanting a copper- and nickel-coated conductive mesh inside a soft silicone dielectric (Table 1). The mesh here was chemically etched with a ferric chloride solution in order to create an electric pattern. It was observed that this process produced a highly adaptable electrostatic adhesive pad possessing good surface friction properties. This process allowed the adhesive pad to stick to micron level rough surfaces, thereby creating a large contact area. Dadkhah et al. [43] used a similar fabrication process to produce a better adhesive by employing a copper-clad kapton (PI film) instead of nickel-coated mesh.

For a long time, researchers have been trying to develop new manufacturing techniques in order to produce artificial microstructured adhesives. Synthetic fibrillary adhesives employ multiple structures to engage with a surface in order to reduce crack propagation and also to improve surface adaptability [43]. Few of these adhesive use nonsymmetric or directional microstructure hairs that create a large real area of contact when loaded in a specific direction. Furthermore, if the load is made opposite, the adhesives release from the surface with almost no force. A new field of research which is still in the nascent stage is the combination of electrostatic adhesives along with microstructured adhesives, which results in an even stronger adhesive [43]. In this regard, Berengueres et al. [71] inserted electrodes inside the dry adhesive microstructures, but the electric field could not disperse into the substrate [44,71]. In another study, Krahn et al. [72] used silicon to prepare a non-directional fibrillary adhesive, which exhibited better properties. However, this material oxidized rapidly. Furthermore, Ruffato et al. [73] tried fabricating a microstructured adhesive into the surface of an electrostatic adhesive. This electrostatic parameter provided a normal adhesion force which helped the adhesive stick to the surface properly. The benefit of the microstructured adhesive was that it provided a fit to micro-scale features, reduced crack propagation, and resulted in a larger surface contact area. This combination of electrostatic adhesives and microstructural fibrillary adhesives improved efficiency over different materials and surface roughnesses.

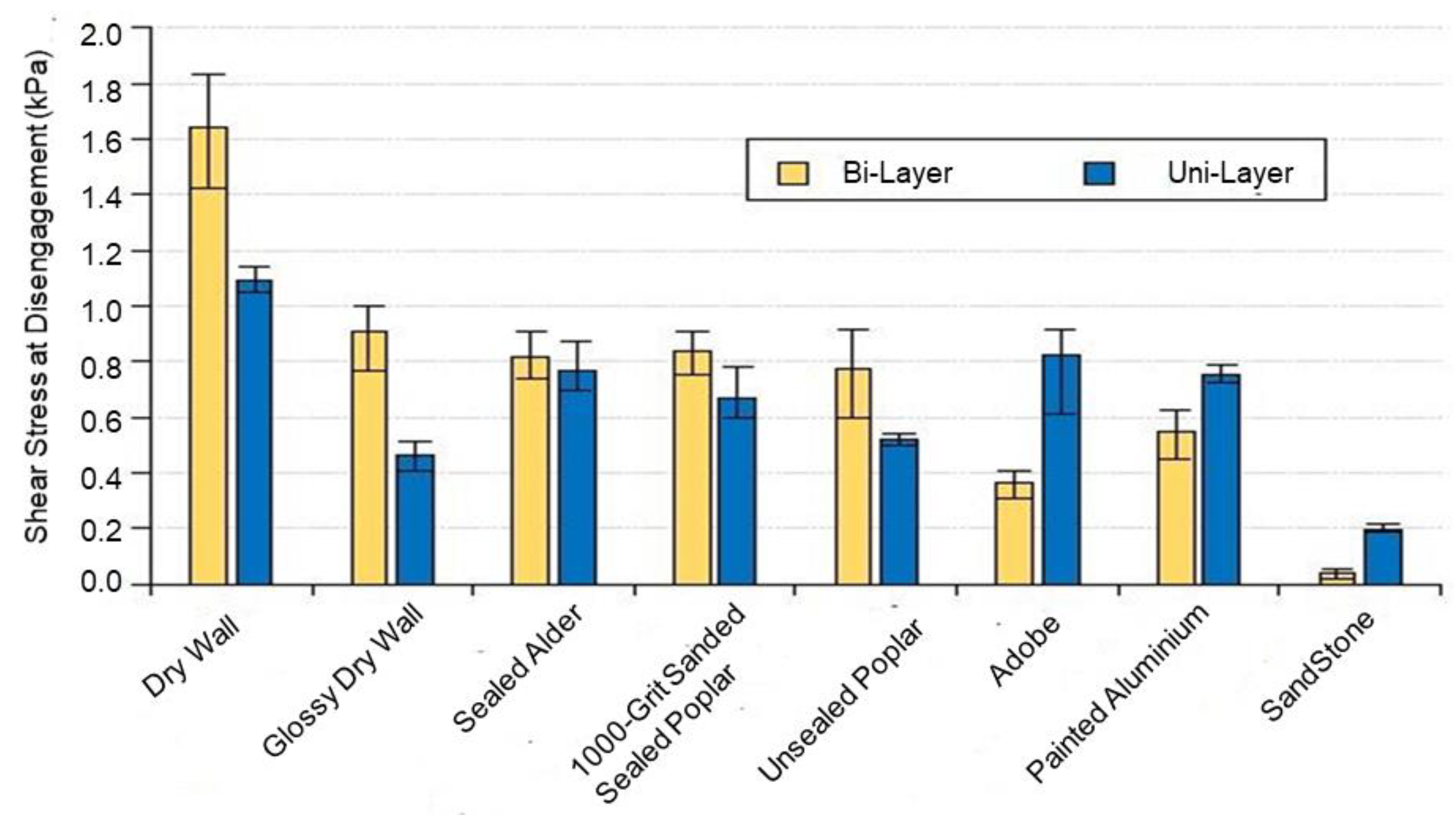

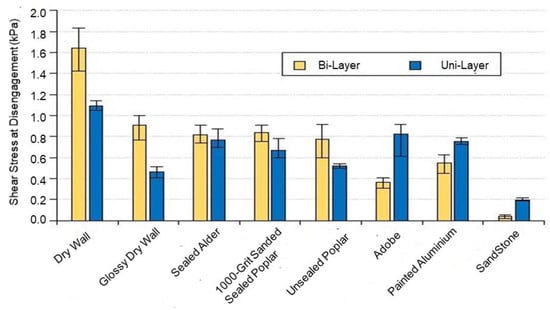

Dadkhah et al. [43] fabricated a new electrostatic adhesive on eight different materials, as shown in Figure 7. A novel fabrication method known as the bi-layer technique was employed here to manufacture the electrostatic adhesive. The bi-layer is fabricated by setting positive and negative electrodes on opposite sides of a kapton film. The positive electrode is clubbed between two kapton film layers. The bi-layer technique has an advantage over the uni-layer technique, in that it provides more output and is resistant to short circuits. From the experiment, it was observed that shear stress was significantly better when the adhesive detached from the substrate in a bi-layer compared with a conventional electrostatic-designed adhesive. The new adhesive using a bi-layer could improve the adhesion properties of the microstructures.

Figure 7.

A chart showing experimental results of shear stress obtained using the bi-layer method and uni-layer method applied on different substrates. Adapted with permission from [43]. 2018, Elsevier.

There are many cases where robots are required to operate in difficult-to-reach regions, with a lesser amount of energy available. Generally, it takes more energy for a robot to remain in a constant position, compared with when it is in motion [18]. Ruffatto et al. [18] developed a novel wall-climbing robot which employed a hybrid electrostatic adhesive to perform the assigned tasks, for an extended time duration. They developed a less power-consuming electrostatic anchoring device coupled with a surface layer of gecko-based adhesives that were able to repeat anchoring, ranging from a few seconds to longer than five weeks. An adaptable foam material was introduced here, between a stiff plate and adhesive surface, in order to allow the adhesive to attach effectively and carry a large shear force. A dielectric material was selected, which did not deteriorate over five weeks of operation compared with other conventional materials. To design the electrostatic adhesive and pad size, optimum materials were investigated. To design the pad size, the limitations of payload mass were determined based on anchor dimension and adhesive potential. Amongst the material to be selected (Table 4) for dielectric film insulators, PI was considered a popular choice due to its better temperature stability, greater breakdown resistance, optimum dielectric constant, and high water absorption property [18]. However, there was a limitation to this material. It was found that PI film adhesive material deteriorated while exposed to a large electric field.

Table 4.

Comparison of materials that could be used as dielectric film insulator [18].

Based on data from Table 4, polyethylene terephthalate (PET) and polyethylenenaphthalate (PEN), were considered as feasible alternative materials for adhesive fabrication. The advantage of PET and PEN was that they exhibited greater adhesive pressure without deteriorating during the extended duration. Polyphenylene sulfide (PPS) was difficult to obtain, and hence, not considered. To decrease power consumption, an electronic switch circuit was used in this study. In addition, a layer of silicone foam was employed to assist the anchor. In addition to the foam, a magnesium metal bracket was used behind the foam, to help distribute load uniformly across the footpad, as shown in Figure 8.

Figure 8.

The fabrication process of fabricated hybrid adhesive anchor: (a) Metal is deposited giving the required electrode shape on the substrate (consisting of 1, 2, and 3); (b) A layer of PEN film over the positive electrode acts as an insulator. Putting gecko-inspired adhesive on the front surface finishes the adhesive pad (consisting of 4 and 5); (c) fabrication of full anchor is achieved by employing a foam-backed magnesium bracket (consisting of 6 and 7). Adapted with permission from [18]. 2018, IEEE Xplore.

In Figure 8, 1 represents a set of shadow masks during the electron beam evaporation process; 2 represents a magnet; 3 represents a stiff base plate on which the shadow mask and base plate rest; 4 represents an extra PEN film layer which acts as an insulator; 5 represents spin-coated silicone on a microstructured wax mold; 6 represents a metal bracket for constant load distribution covering the pad; and 7 represents a layer of silicon closed cell foam to help the anchor adjust to surface irregularities [18]. From the experiment, adhesive force in a normal direction was studied on different surfaces, such as drywall, polished wood, glass, and aluminum. The highest adhesion was observed on wood, followed by aluminum, then glass, and the lowest adhesion was obtained on drywall. This study explained that when electrostatic adhesives were coupled with gecko-inspired adhesives, the combined adhesive acted as a less-power-consuming anchoring device, which could also reorient itself as per requirements. Song et al. [74] performed experiments and model analyses through which the contribution of electrostatic force emerging from setae adhesion of gecko was studied. In the experiment, they observed that by touching the substrates with only 1/70th of the foot area, geckos formed tribocharge at their toes with a density of 277 pC/mm2. This helped in the formation of electrostatic attractions of 4.4 mN/mm2. From this result, they estimated that triboelectrification adhesion could be approximately 1% of total adhesion. Next, the model analyses performed at the gecko’s spatula level showed similar outputs that electrostatic force may be approximately 3% of total adhesion. This lower amount of electrostatic force explained the reason why geckos find it challenging walking on these substrates (such as Teflon), where tribocharge can easily develop, but developing van der Waals forces is problematic.

2.4. Thermoplastic Adhesion

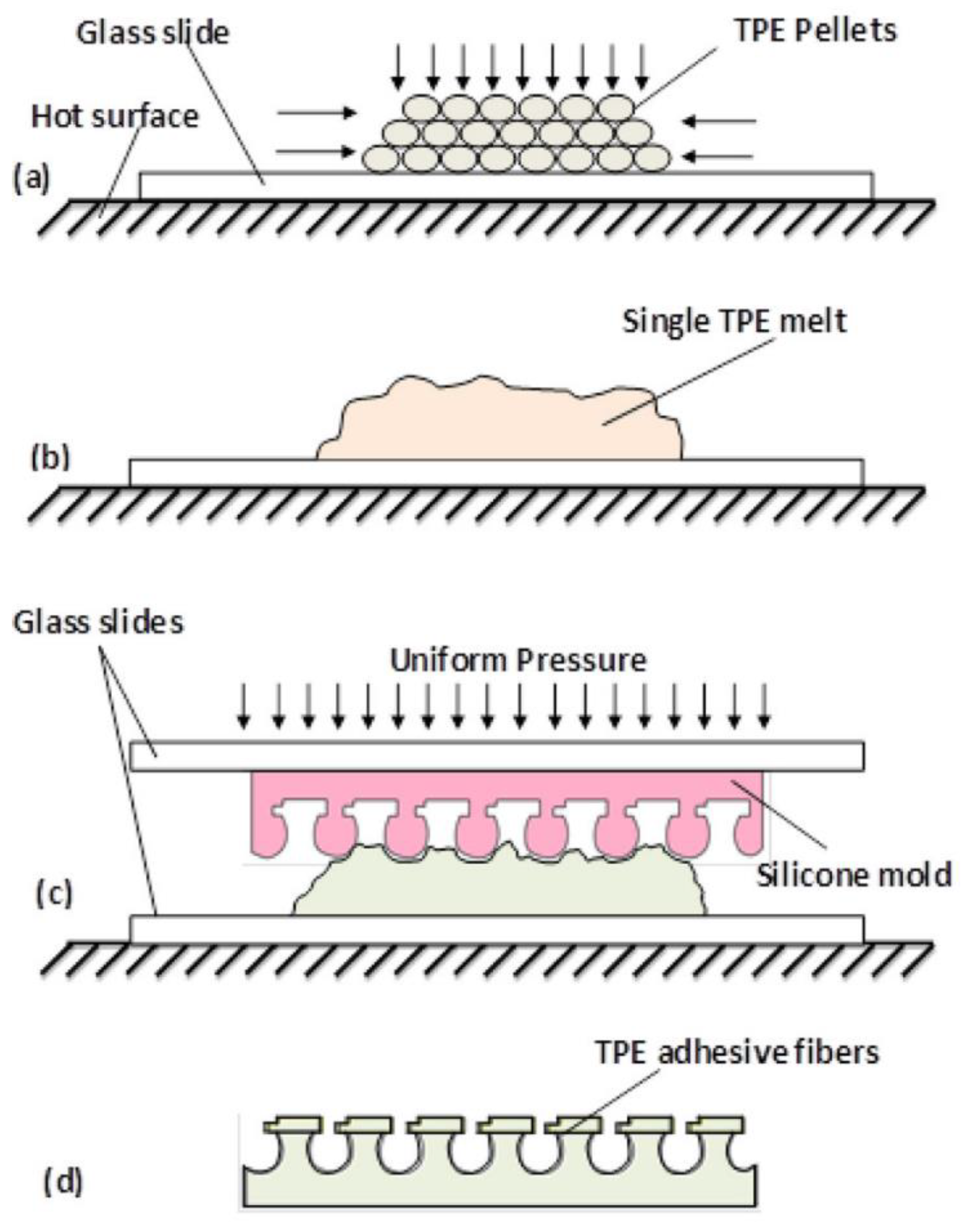

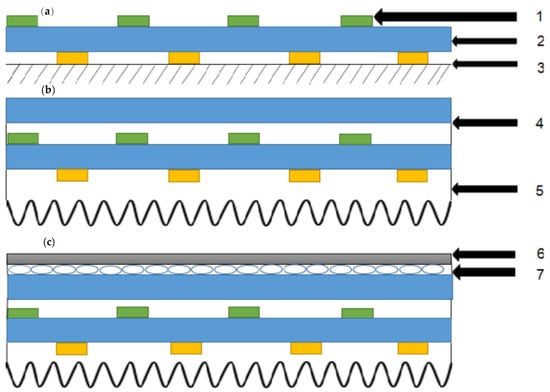

Thermoplastic adhesion is a mechanism which takes place on polymers that melt above a specific unique temperature and solidify upon cooling [75]. Taking inspiration from geckos, many synthetic adhesives possessing thermoplastic nature have been developed by researchers [46]. Generally, PDMS and PU elastomers have been used in order to fabricate dry adhesives [53,76,77]. However, the thermosetting nature of these materials is a disadvantage due to their more material costs, the repeated need for vacuum degassing, and higher curing times [45]. Khaled et al. [45] established poly (styrene–ethylene/butylene–styrene) (SEBS) thermoplastic elastomers possessing directional and non-directional performance, as a substitute material to PDMS and polyurethane (PU) for the development of dry adhesives (Table 1). The benefit of these materials is that they are less contaminated due to oligomer transfer and are also suitable for mass production. In this experiment, oligomer transfer was analyzed on PDMS, PU, and SEBS thermoplastic elastomer, which was in contact with an inflexible surface. Mushroom-shaped dry adhesives were developed from thermoplastic elastomers using a thermocompression molding process. As shown in Figure 9, SEBS was prepared by incorporating solid kraton pellets to a specific volume of hexane solution. Isotropic and anisotropic adhesive specimens were fabricated from SEBS by thermocompression molding.

Figure 9.

Fabrication process of SEBS thermoplastic elastomer performed by thermocompression modeling: (a) SEBS thermoplastic elastomers (SEBS-TPE) lying on a glass slide melted using slight pressure; (b) formation of a single SEBS-TPE melt; (c) a silicone mold placed on the single SEBS-TPE melt with desired force; (d) the silicone mold, SEBS-TPE melt, and glass slide are removed from the hot plate and allowed to cool. Later, TPE adhesive fibers are formed. Reprinted with permission from [45]. 2014, ACS.

Surface fouling tests using X-ray photoelectron spectroscopy (XPS) revealed that both PDMS and PU carried small amounts of oligomers, but kraton thermoplastic did not exhibit any detectable oligomer of it. In their study, two forms of thermoplastic elastomer dry adhesives, i.e., isotropic and anisotropic, were contrasted with polyurethane (PU). The benefit of this thermocompression molding of the thermoplastic elastomer process was that it could produce adhesive relatively more quickly, involving cheaper costs of the base material, and negligible oligomer transfer.

In a different study, Zhang et al. [47] studied the thermoplastic property of a commercially available product named SU-8. They used a combination of conventional photolithography (CPL) and capillary force lithography (CFL) techniques to prepare hierarchical micropillar arrays with different aspect ratios of a single PDMS polymer mold by harnessing the thermoplastic and photosensitive nature of SU-8. The developed material was highly cross-linked, possessing high thermal and mechanical strength. By regulating the film thickness of SU-8 on a substrate, various micropillar arrays with different aspect ratios were developed. In this study, because of SU-8′s thermoplastic and photosensitive nature, various hierarchical structures were fabricated by combining CPL and CFL. The limitation of this model was when the micropillars became excessively tall, damage was observed due to the capillary force.

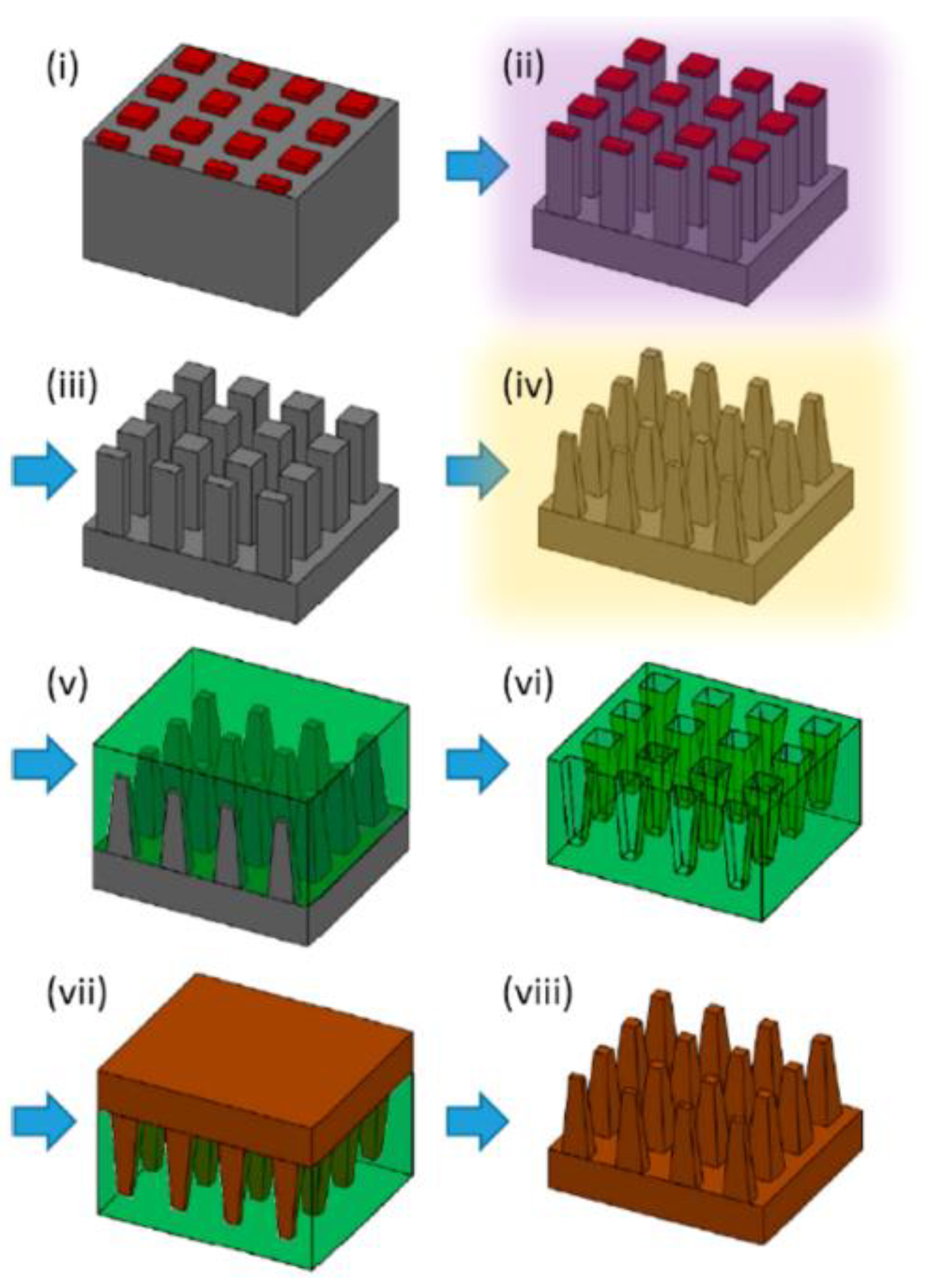

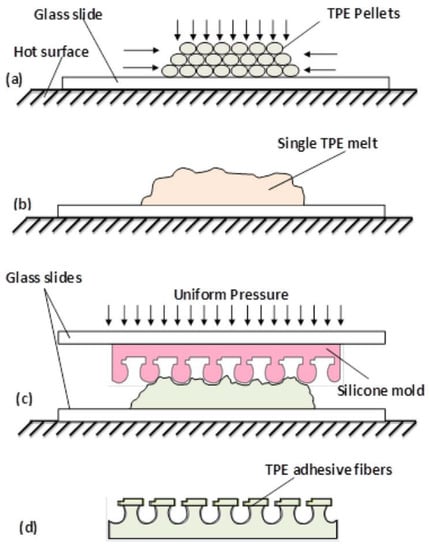

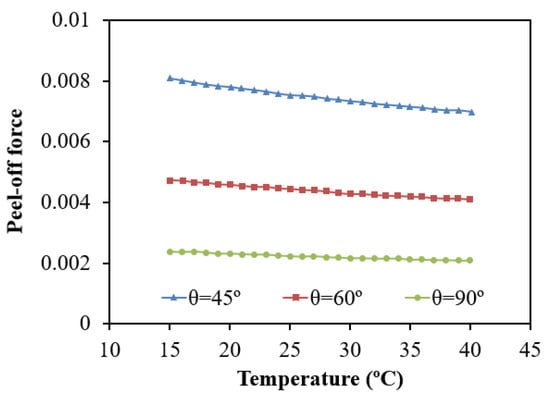

The attachment manner of artificial adhesives is delicate for the geometric dimensions of microstructures which constitute fibrillary surfaces. The main factors which influence the adhesion, friction, and mechanical behavior of individual fibers of an adhesive are the fiber aspect ratio [78,79], tilting angle [80,81], tip shape [82,83], and hierarchy [84,85]. Usually, synthetic adhesives possess a higher aspect ratio or are thermoplastic in nature. These materials are fabricated by molding from lithographically defined hard templates or by soft lithography techniques [86,87]. However, there is one geometric aspect that could not be regulated by the above method, which was sidewall tapering of the fibers. Kim et al. [46] studied this property and tried to improve its working. They introduced a procedure that could command over the lateral tapering of microfibers. Later, this tapering was replicated by low-density polyethylene (LDPE) thermoplastic to analyze the effect of macro-friction, as shown in Figure 10. They observed that the tapering angle plays an important role in thermoplastic adhesives, which can significantly improve adhesion (Table 1). It was observed that the etching procedure tapered and thinned the micropillars, but at the same time, the pillars also shortened in height. If the etching solution was diluted by water, then the tapering angle of the pillars decreased. Utilizing these reduced taper angles of pillars, different shapes could be fabricated as shown in Figure 10.

Figure 10.

Fabrication process of tapered square silicon pillar template and their copy imprinted on an LDPE thermoplastic: (i) photoresist pattern process; (ii) deep reactive ion etching; (iii) removal of photoresist; (iv) hydrofluoric/nitric/acetic acid etching; (v) polycarbonate film molding; (vi) template peel off; (vii) LDPE film mold; (viii) dissolution of template in methylene chloride. Reprinted with permission from [46]. 2014, ACS.

Hoang et al. [88] designed a soft robotic gripper whose work performance was improved by adding an elastomeric gecko-inspired adhesive and a thermo responsive variable stiffness filament. The results from the experiments performed here show that the gripper’s holding force improved by 655% and the pull-out force improved by 507%. The materials used for this study were cheaper and could find potential applications where gentle grasping, as well as high load capacity, are required. Table 5 summarizes some gecko-inspired materials used for the fabrication of adhesives, in addition to their advantages, disadvantages, and applications.

Table 5.

Summary of some commonly used gecko-inspired materials for adhesive fabrication.

3. Factors Affecting Gecko Toe Adhesion

In real life, geckos’ dwell on a variety of environmental conditions, such as deserts and tropical forests, consisting of surfaces that are often hot, wet, and experience humid conditions. Considerable studies have worked to understand the mechanics of gecko adhesion, but the majority have been performed under highly controlled laboratory surfaces. Less information is available about how surrounding factors such as wet conditions, humid conditions, and surface roughness impact the adhesive abilities of geckos in their natural habitat. Hence, it is necessary to study how environmental factors impact the natural adhesion capabilities of geckos. This study becomes more useful when fabricating gecko-inspired synthetic adhesives that are expected to work better in real environmental conditions. The next section explains in detail a few important parameters that affect gecko adhesion in real surroundings. In this section, different parameters that impact the adhesion of geckos are explained.

3.1. Influence of Temperature and Humidity on Gecko Toe Adhesion

When fully submerged under water, geckos exhibit a loss of adhesive capability due to lower van der Waals forces between their toes and a substrate. Thus, examining the effect of temperature and relative humidity on gecko adhesion is useful for the design of gecko-inspired adhesives. This would help synthetic fabricated adhesives to be able to work under real environmental conditions. To date, substantial experiments have been carried out to investigate the effect of temperature on gecko adhesion [89,90]. However, the experimental data sometimes provided erratic results. Peng et al. [91] mentioned that one study had shown that the adhesion force of geckos constantly reduces with increasing temperature, within the temperature range of their natural habitat (17–40 °C). However, the possibility of fabricating temperature-independent gecko-based adhesive was also presented in the literature [89].

Niewiarowski et al. [92] summarized the temperature consequence of gecko adhesion performed by Stark et al. [93] in 2016. The former research group mentioned that the result of temperature on gecko adhesion was complex, and felt that the relationship between temperature and relative humidity should be considered. They explained three major limitations of gecko-based synthetic adhesives: (a) insufficient theory and data on the mechanics of synthetic adhesives under non-ideal situations (wet, dirty, and rough surfaces); (b) lack of understanding of the contribution by natural gecko-inspired adhesive materials such as skin and lipids as unique compared with their structure; and (c) insufficient qualitative and quantitative data on the working of live geckos on natural substrates. Addressing these limitations will open up more applications for gecko-based synthetic adhesives.

Some of the important parameters that significantly contribute to gecko adhesion are contact van der Waals forces [94], electrification [95], and capillary forces [13]. Considerable research has been conducted on van der Waals force and capillary forces, although not much on contact electrification. All these parameters need to be studied under relative humidity (RH) to better understand gecko adhesion in non-ideal situations [92]. Lab-related research to understand gecko-based adhesion has been limited to major surface types such as smooth, dry, clean glass, or plastic. However, to better understand gecko adhesion, the effects of surface roughness comprising real surfaces differing in many length scales should be analyzed under wet conditions. Theory and lab studies have focused on the impact of control roughness on the surface adhesion and design of gecko-inspired adhesive, especially related to safety factors [52,84]. The safety factor is the capacity of a system to work higher than normal limits; for a gecko system, this needs to be studied under wet conditions. Gecko setae are naturally hydrophobic in certain conditions; it is very difficult to have a permanent superhydrophobic gecko toe. Badge et al. [96] performed an experiment in which a thick permanent hydrophobic coating was applied to gecko setae. The setae were later found to be superhydrophobic indefinitely and without any change [96]. Stark et al. [93] carried out several studies and analyzed the results of temperature and humidity on adhesion in a gecko-inspired synthetic adhesive. They established that the reaction of humidity must be considered in the study of temperature-dependent adhesion. Adhesion was found to be dependent on humidity, but only when the surrounding temperature was low [90]. Provided that the temperature effect is not considered, Huber et al. [97] and Sun et al. [98] experimentally observed the adhesion force of gecko seta (spatula) increasing with the rise in relative humidity. Puthoff et al. [99] further experimentally analyzed the impact of surrounding humidity on gecko setae and claimed that due to the wetting of gecko setae, there was a rise in adhesion force. In this same study, they discovered that an increase in RH results in softening of the setae as well as viscoelastic damping, which helps to increase adhesion. Tan et al. [100] studied the impact of RH on the adhesion of gecko-inspired nanopillar arrays. The nanopillar arrays were fabricated with PS material, where the array tips were shaped into spatula and T-shaped geometries. A superficial layer, softened by water from the humid environment was obtained on the nanopillars. This layer formed a kind of “soft shell-stiff core” geometric structure. This core structure reduced the stress distribution at the interface of each nanopillar and contributed to the enhancement of normal adhesion. In another study, Leckband et al. [101] showed that the water-repelling property of a lipid–protein monolayer is not a natural property of that surface. Moreover, this property is controlled by the surroundings [101]. They assumed that proteins on the surface experienced variation in compliance when exposed to a highly humid or wet medium, which helped in repelling water. Based on a similar experiment, Pesika et al. [14] carried out a study in which keratin protein imbibed setae of the gecko exhibited hydrophilic properties by varying the compliance of surface proteins. The study showed that the adhesion force of the gecko rose with humidity due to the increase in surface energy. However, adhesion force is reduced when the gecko setae are fully submerged in water due to the decrement of van der Waals forces.

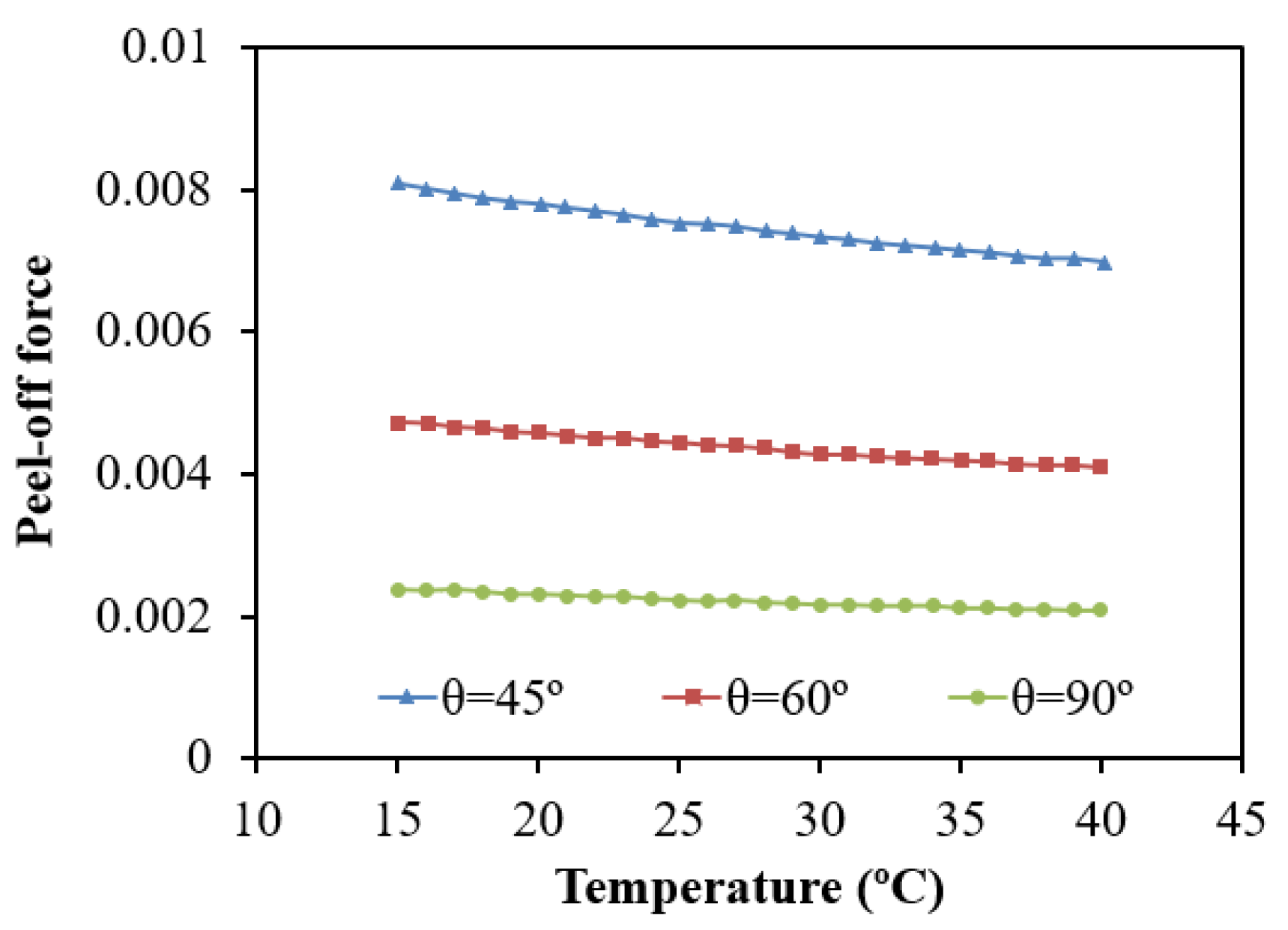

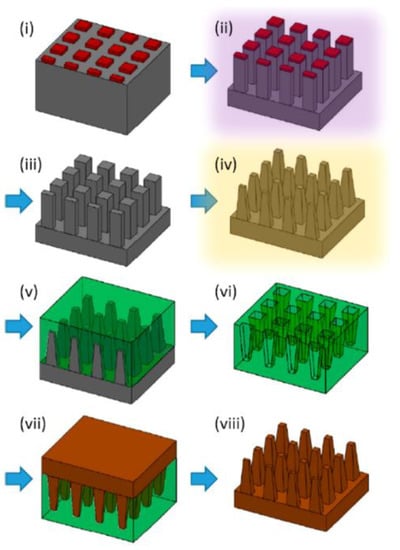

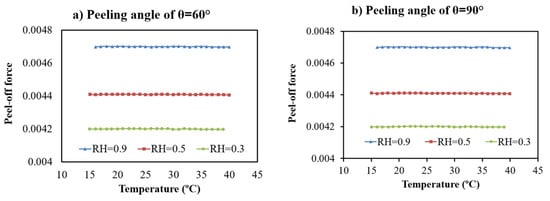

To analyze the better impact of temperature and RH on gecko adhesion, Peng et al. [91] developed a theoretical model for understanding the peel-off force of a synthetic gecko spatula material under individual surrounding humidity and individual temperature conditions. The same study was performed under combined surrounding humidity as well as temperature conditions. In this study, a theoretical model of a nanofilm connected to a stiff substrate was taken for analysis purposes. The peel-off force, F, as a function of the peeling angle, θ, was taken into consideration for the analysis (Figure 11 and Figure 12).

Figure 11.

Effect of peel-off force when compared with temperature under different peel-off angles. Adapted with permission from [91]. 2017, IOP Science.

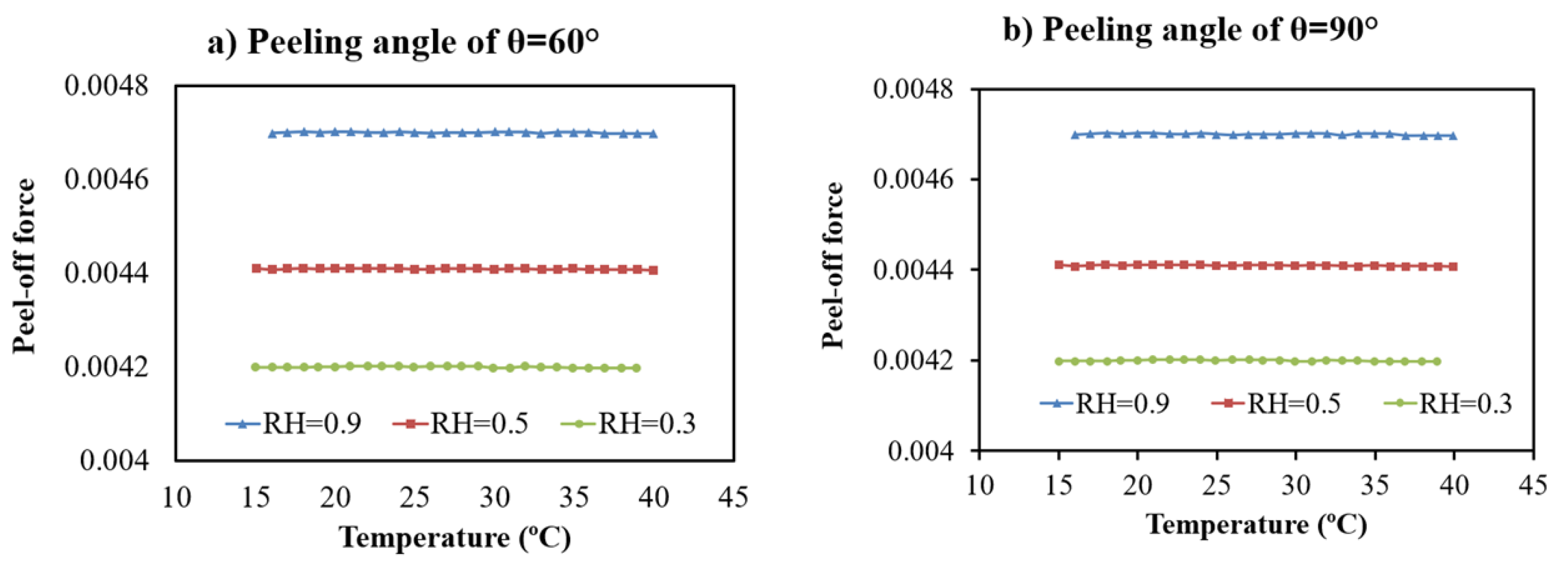

Figure 12.

Peel-off force (F) against temperature at three different relative humidity levels for two different peeling angles (a) θ = 60° and (b) θ = 90°. Adapted with permission from [91]. 2017, IOP Science.

Figure 11 indicated that with an increase in peel-off angle (θ), there was a decrease in peel-off force (F) when surrounding humidity was not taken into consideration.

Figure 12 shows higher peeling off force at lower peeling off angles, under the consideration of three different RH levels. In both cases, a higher peel-off force (F) was observed to correspond to higher RH. In addition, for constant relative humidity, peel-off force is not much concerned with temperature. The study exhibited that effect of temperature only on interface adhesion is not clear when RH is constant. However, the effect of RH only on interface adhesion is important when the temperature is constant. Furthermore, if surrounding humidity is not constant, then the combined impact of both RH and temperature is needed to be studied, due to the temperature-dependent nature of relative humidity. The results from this study could help researchers to design temperature- or humidity-controlled sensors for gecko-inspired robots. The second important parameter that needs to be understood for gecko-inspired adhesive capability is the surface roughness to which the gecko clings. Section 3.2 explains the impact of surface roughness on gecko adhesion.

3.2. Importance of Surface Roughness on Gecko Adhesion

Geckos can climb and walk on different surfaces. Adhesion studies performed on geckos highlight the influence of various levels of surface substrate roughness on macroscopic as well as microscopic scales [102]. In addition to adhesion, frictional forces are an important factor pertaining to geckos. A minimum frictional force can be distinguished for a specific range of surface roughness values due to which geckos can stick to a surface.

When analyzing the adhesion of an elastic body to a rough substrate, two parameters need to be understood: (a) attractive contact due to adhesion energy, and (b) non-attractive interconnection due to the formation of elastic strain energy during contact [102]. The implication of surface roughness on adhesion for gecko reptiles has been studied by researchers. In order to understand the impact of roughness on adhesion between two elastic bodies, an experiment was carried out by Fuller et al. [103]. Similar experiments had been carried out on geckos by Persson et al. [35] and Peressadko et al. [104], who tested rubber balls pressing against hard rough substrates. The tests highlighted that a net pull-off force could be computed from surface roughness power spectra secured from a measured surface height profile. This case presented an understanding of the adhesion mechanism for geckos, which could be assessed in two experiments: (a) calculation of the adhesion of a single gecko hair by atomic force microscopy (AFM), and (b) the inspection of live geckos sticking to surfaces of various surface roughnesses [102]. Huber et al. [102] carried out the above experiments to understand the impact of surface roughness on the adhesion of geckos to bulk materials as well as nanomaterials. The experiments were carried out at a certain room temperature and relative humidity. For the AFM experiment, nine dissimilar surfaces were marked according to increased root-mean-square (RMS) roughness. On the other hand, for checking the sticking ability of geckos to surfaces with various surface roughnesses, asperity sizes were created for the test in a range between 0.3 µm and 12 µm. It was observed that on surfaces with a nominal asperity size of 0.3 µm, geckos were not able to stick to the surface. On the other hand, increasing the asperity size to 1 µm, it was observed that lizards could stick to surfaces only for a while because their toes were slipping off after some time. Then, on further increasing the asperity size to 12 µm, geckos could stick to the surface for about five minutes. Generally, for bulk material, it has been observed that if surface roughness is incremented, then there is a decrement in adhesive force [103]. However, in the present experiment, for nanoscale, it was observed that the adhesive force of a gecko spatula decreased for intermediate RMS roughness varying from 100 nm to 300 nm. However, above and below this intermediate RMS roughness value, it was found that the detachment force increased. These data corresponded with those of live geckos, which are able to stick to substrates with high and low roughness [102]. This highlights the fact that when single spatulae are considered, geckos could stick to very smooth or very rough surfaces, but failed with intermediate roughness surfaces. This concept is useful to fabricate artificial gecko-inspired adhesives based on surface roughness.

It has been learned that there are very scant data available on the surface roughness characteristics of surface layers utilized by geckos for climbing. In reality, natural surfaces differ in roughness over distances ranging from seven to eight orders of magnitude [105]. The statistical tool of RMS has been used to indicate roughness for comparing different results. However, the limitation of this tool is that it makes the surface variation discrete in the landscape of a 3D surface into one entity which hinders analyses of important variations with respect to contact mechanics theory. Therefore, it is important to obtain quantitative data which can help realize the abilities of geckos sticking to different surfaces possessing dissimilar roughness values [106]. One of the reasons why geckos have fascinated researchers is their ability to stick on rough, dry, dirty, wet, and smooth surfaces, in spite of the fact that approximately 40% of gecko species do not possess an adhesive system [106]. Geckos are found to generally stick to natural surfaces such as flower petals, leaves, rocks, sand, etc., which have varied surface roughness values. However, most contemporary research on developing gecko-inspired adhesives is for very smooth surfaces. This is to develop artificial adhesives for applications in cleaning building surfaces or climbing smooth surfaces in the form of gloves and shoes. For example, Stanford’s Stickybot and DARPA Z Man project supports the fact that the major challenges in the fabrication of gecko-inspired adhesives are those related to highly smooth surfaces [106]. However, the contact mechanics of these artificial adhesive systems are dependent on the contact area, i.e., smooth and clean surfaces; in reality, geckos can easily stick to these smooth surfaces. The roughness of natural surfaces on which geckos stick and crawl differs so widely from atomistic to millimeter length [104]. Hence, how variations in surface roughness affect wild natural geckos has not been studied in detail. How fibrillary adhesives found in geckos create strong adhesion while adjusting variation in surface roughness at different lengths of scales is yet not understood clearly [107]. Niewiaroski et al. [106] tried to generate an analogy which can provide a new direction of study. They reported that ecologists had faced two significant problems in understanding the effect of the thermal environment on geckos: (a) how to prototype heat exchange between surrounding and geckos, and (b) the procedure to calculate temperature during heat exchange [106]. Hence, they developed a physical heat-based model based on thermal ecology to better study the impact of surface roughness on gecko adhesion. Usually, a physical model in thermal ecology is a copy of the gecko with similar size, shape, conductive, convective, and radiative heat exchange rates. This model is generally prepared from a hollow metal cast painted to complement the reflectivity of the live gecko, providing the model with an equilibrium temperature that is almost equal to that of the live gecko. In this model, PDMS is used to create a prototype of the physical model. This model was expected to interact with real surroundings, similar to the way natural geckos behave. From the adhesion tests performed on this model, it was observed that the adhesive force of the model was identical to that of the force produced by natural geckos. To understand this model better, it is also important to analyze its surface mechanics and the results obtained should be similar to those of natural geckos. This model provides future insights into testing fibrillary adhesives on model rough surfaces. Ye et al. [108] employed the reversible adhesive characteristics of gallium (Ga)-based liquid metal coatings to enhance the adhesion, reduce vulnerability to non-optimal conditions, and increase the maximum–minimum adhesion ratio (switching ratio) of PDMS adhesives. They controlled the phase change of Ga and found that it can be used as a new strong adhesive, possessing two adhesive states: (a) a high adhesion state (solid) and (b) a low adhesion state (liquid). It was observed that the maximum adhesion and the switching ratio were dependent on the roughness of the substrate. The results showed that the Ga-based coating method could be used as a potential adhesive for rough surfaces under both dry and wet conditions. Drotlef et al. [109] fabricated gecko-inspired skin adhesive films composed of elastomeric microfibers decorated with conformal and mushroom-shaped vinyl siloxane (VS) tips for wearable sensors. Here, it was shown that crosslinking of the VS tips helped in obtaining strong skin adhesion to the multiscale roughness of the skin. It was also observed that the fabricated adhesive could attach to other complex topographies over a wide range of surface roughnesses under both dry and wet conditions. Tan et al. [110], combining the adhesive advantages of gecko setae and creeper root, fabricated a switchable fibrillar adhesive. This adhesive consisted of PU as the backing layer and graphene/shape memory polymer (GSMP) as the pillar array. It was observed that the photothermal effect of graphene modified the GSMP pillars into a viscoelastic state which enabled enhanced adhesion on surfaces over a wide range of roughness. Controlling the phase state of the GSMP pillar helped in switching between high and low adhesion states conveniently.

4. Gecko-Inspired Adhesives and Related Fabrication Processes

Understanding the function of the natural gecko adhesion mechanism helps in deciding different materials as potential artificial adhesives inspired by geckos. It also provides insights to explore different fabrication techniques of artificial adhesives inspired by geckos. In Section 4.1, various gecko-inspired synthetic adhesives, their conventional fabrication methods, and a few recent fabrication techniques employed to develop them are discussed.

4.1. Conventional Fabrication Methods

Gecko-inspired adhesive was first fabricated in the early 2000s. It was observed that van der Waals forces are one of the major components in gecko adhesion. Van der Waals forces are the main mechanism of gecko’s setae adhesion; therefore, the adhesive force is more dependent on the size of the setal tips rather than the nature of its material.

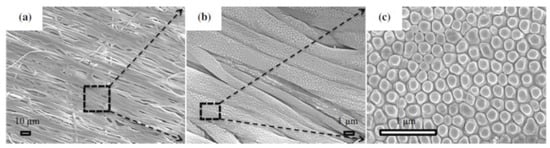

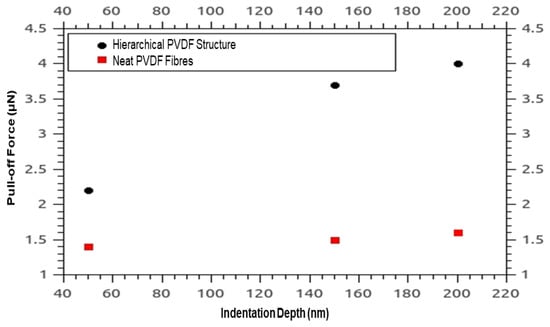

Since 2000, different strategies have been developed to fabricate gecko-inspired adhesives. One of the initial studies on fabricating the nanoscale adhesion properties of gecko-inspired adhesives was performed by casting polyester resin [111]. Since then, various techniques have been employed to fabricate dry adhesives with modification of the adhesive material. Amongst them, micro/nanoscale casting and gas phase growth are the most remarkable. The number of studies performed using the gas phase fabrication method is relatively smaller than the casting method. This is because the gas phase method is expensive and requires a higher process temperature (greater than 700 °C) [87]. Geim et al. [112] fabricated a polymide-based foot hair array employing oxygen plasma technology and electron beam lithography. It was observed that the array could withstand a load of 40 g; however, the adhesion within itself was found to reduce the contact area as well as its durability. Gorb et al. [113] studied mushroom-shaped fibrillar structures developed by the injection mold method. The observations from their study were that the peel strength and the pull-off force of the mushroom-shaped structures were much higher than those of flat structures.

In addition, experiments have attempted to fabricate gecko hierarchical structures using various top-down and bottom-up approaches or combining both of them (hybrid methods) [114]. Apart from these, some of the other traditional fabrication methods were chemical vapor deposition, lithography, dip transfer method, and multi-step molding. Yurdumakan et al. [115] employed a chemical vapor deposition technique to form gecko-inspired adhesive tape on high-density carbon nanotubes. It was observed that the structures developed from this adhesive exhibited good adhesion forces at the nanometer level, and this force was 200 times greater than that of a single gecko hair. Aksak et al. produced microfiber arrays fabricated by a micromolding process [80]. The benefit of this process was that it enabled the fabrication of fibers in a non-vertical orientation. Greiner et al. [84] employed a combination of soft lithography and multi-step photolithography to fabricate hierarchical structures. They observed that the adhesion of fibrillar structures did not benefit from extra levels of hierarchy when experimented against planar surfaces. Jeong et al. [116] employed a two-step ultraviolet (UV)-supported capillary molding procedure to fabricate micro- and nanoscale hierarchical polymeric hairs. For fabricating the adhesive, the researchers employed an angled etching technique to produce slanted nano-holes in the adhesive. They further observed that by controlling the etching conditions, various nano-hairs could be fabricated with customized geometry.

The other classical fabrication techniques are casting and nano-molding. For the former technique, dry adhesive designs are fabricated by producing molds out of various materials. In the nano-molding process, a template is used with high-aspect-ratio micro- or nanoscale features in addition to curable liquid polymers. Procedures to develop a template were (a) the usage of an atomic force microscope to indent a wax surface by molding with silicone rubber, (b) the fabrication of a nano porous membrane, and (c) to selectively cure a liquid polymer exposed to ultraviolet light. This method was useful, but not meant for large-scale production. With progress over time, researchers experimented with new fabrication methods for fabricating superior adhesives.

4.2. Advanced Fabrication Methods

In order to overcome the limitations of conventional fabrication methods, researchers have developed many advanced fabrication techniques. Amongst them, two-step photolithography and deep reactive ion etching to fabricate adhesive templates are some of the recent techniques. Here, a fabricated template possessing compliant microstructures can then significantly modify its adhesive properties. Fabricated compliant fiber structure in close contact with the surface helps in the enhancement of adhesion. Some factors which were thought to impact the sticking nature of fibrillary adhesives are mentioned below [107].

(a) Stiffness of fiber: Autumn’s research group conducted studies to analyze the elastic behavior of gecko setae. The study revealed the elastic nature was due to the mechanical properties of the β keratin. Peattie et al. [117] explained that natural materials like β keratin were fruitful only when they are in fiber shape. Additionally, rigid fibers can be firmly packed instead of becoming concentrated mass [118]. This enhances adhesion simply by increasing the number of contact points. Thus, the stiffness of the fabricated adhesives is expected to exhibit similar behavior.

(b) The aspect ratio of fiber: Lin et al. (2011) showed that the effective modulus of fibers possessing a large aspect ratio can reduce with the bulk modulus of the fiber material [119] (Figure 3). The limitations of obtaining the optimum aspect ratio are due to complications in the fabrication processes.

(c) End geometry of fiber: The end geometry of fibers plays an important role in the nature of adhesion. Thus far, many experiments have been carried out on fibrillary pillars with various end shapes. Arzt et al. [79] showed that better adhesion could be obtained by reducing the radius of a fiber and raising the fiber length by employing a process known as ‘contact splitting’. Especially, mushroom-shaped pillars exhibited the highest pull-off force. Flat, spherical configurations yielded a lower adhesion force. Concave form end geometries exhibited the worst performance [120].

(d) Slanted fiber: Slanted fibers with a high aspect ratio exhibited anisotropic shear adhesion. This feature is beneficial for artificial dry adhesives [121].

(e) Environmental factor: In order to understand the effect of environmental factors on fiber structures, many studies have been carried out. Factors such as surface roughness, interfacial air entrapment, and fiber configuration have been studied to understand their impact on adhesion [122,123].

Table 6 highlights some of the recent synthetic materials used for the fabrication of gecko-inspired adhesives.

Table 6.

Enumeration of new adhesive material and their application.

Kang et al. [124] performed an experiment where mushroom-shaped microstructures from PDMS were developed on a bio-inspired dry adhesive. The microstructures were prepared by a simple molding method. In this experiment, the de-attachment process of the adhesive was conducted by a twisting method. The twisting process was obtained by implementing a shear force at the end of the developed dry adhesive, which resulted in easy detachment. To understand the process better, the factors of detachment were experimentally observed by contrasting the detachment force, total torque, and time required for detachment. Furthermore, all these factors were dependent on the adhesive width, as well as the angular momentum of twisting. This study recommends the detachment of dry adhesives by the twisting method rather than the traditional peeling off method (Table 6).

Silicone elastomers have been found to have various applications in different technologies such as robotics, [134,135] wearable electronic devices [136,137], and microfluidics [138,139], to name a few. Due to lesser surface energy, silicon is unable to interact with other surfaces easily. In order to improve the interaction of the silicon surface, a chemical process such as oxygen plasma has been employed by researchers [125]. Although the oxygen plasma process results in the development of strong siloxane bonds, the plasma has been found to also damage the PDMS foundation by reducing its mechanical strength. To overcome this drawback, Simaite et al. [125] studied the cross-linking reaction of PDMS as a silicon–silicon bonding enhancer for developing advanced gecko-inspired adhesives. It was found that these materials could be used to bond even after one week of molding (Table 6). It was also shown that increasing the cross-linking density at the interface could enhance the adhesion strength of these gecko-based adhesives.

Gwon et al. [140] employed a 3D printing method along with an additional polymer coating to fabricate direction gecko-inspired directional adhesive pads for grippers. Conventional 3D printing methods for fabricating directional adhesives have limitations in terms of tip size and surface roughness. The adhesive fabricated by this group of researchers not only compensated for these limitations, but was also observed to enhance the adhesion force. Additionally, when the adhesive was contaminated with dust, if cleaned with water or sticky material, it helped in restoring 95% of its normal adhesion force.

Busche et al. [141] fabricated an anisotropic dry gecko-inspired adhesive microstructure for the capture of space debris. The adhesive structures were fabricated using adaptable 3D printing with a two-photon polymerization process and replicated it with space-rated polydimethylsiloxane (PDMS). The fabricated adhesives exhibited a normal adhesion force of 1100 mN/cm2 and an anisotropic factor of 7.5, which was much higher than that previously developed adhesives for space applications. This study is useful for fabricating mass-producible adhesives pertaining to space applications where high anisotropy of the holding force is required. Researchers are further exploring new 3D printing methods to fabricate gecko-inspired adhesives that can provide enhanced performance.

5. Recent Progress of Gecko-Based Adhesives and Fabrication Techniques

Recent progress on gecko-based adhesives and their fabrication techniques has been classified into three types in this study for the convenience of readers. The classifications are:

(1) Switchable gecko-inspired adhesives;

(2) Shape-memory-property-inspired adhesives;

(3) Miscellaneous fabrication techniques.

5.1. Progress of Switchable Gecko-Inspired Synthetic Adhesives

Switchable bio-inspired adhesives have received significant attention from contemporary researchers. Northen et al. [142] attempted to create an adhesive from a composite consisting of a sticky polymer and magnetic nickel cantilevers. Increasing or decreasing the magnetic field led to variations in cantilever alignment. This ultimately improved the adhesive performance of the composite. He et al. [143] fabricated a polyvinyl chloride (PVC)-based switchable electro-active adhesive. It was noticed that the PVC showed switchable adhesion when treated under an electric potential. The switchable PVC-based adhesive was observed to exhibit greater adhesion force and response speed when compared with a reversible adhesive. Li et al. [144] fabricated a three-layer adhesive from TPU that exhibited switchable adhesion on non-flat surfaces. By adjusting the voltage, the adhesive was able to exhibit an enhanced adhesive force by 1 or 2 orders of magnitude relative to conventional adhesive structures. The adhesive was successfully employed in a gecko-inspired gripper for transportation activities. In another study, Paretkar et al. [145] proved that applying mechanical load on fibrillary hair structures, which produces reversible buckling, can lead to a reduction in adhesion on elastomeric pillars. Del Campo et al. [120] employed a liquid crystal elastomer which enabled an array of pillars to move nearer or far away. This allowed the formation or prevention of adhesive contact. Jeong et al. [146] fabricated a wrinkled PDMS adhesive, which could achieve attachment and detachment by stretching. This process was feasible due to variations in the alignment of the adhesive caused by changes in the fluctuation of wrinkles [146].

5.2. Progress on Shape-Memory-Property-Inspired Adhesives

Shape memory polymers (SMPs) have drawn researcher’s interest to fabricate artificial adhesives inspired by geckos due to their advantages such as lightweight, lower cost, the capability of recovering from strain, and good insulating behavior. SMPs possess the unique property where, upon the application of external parameters such as light or temperature, material properties can vary. Reddy et al. [147] experimented with a shape memory thermoplastic elastomer, Tecoflex 72D, where they could vary the adhesive performance of the polymer. The experiment showed that not only was the shape memory effect effective at the microscale, but it was effective even on surfaces that possessed switchable adhesion. Furthermore, research has been undertaken to develop superhydrophobic surfaces with SMP. However, developing a superhydrophobic surface with shape memory property is difficult. Geckos have a unique ability to unfold their toe pad and that varies adhesion properties. Based on this, Wang et al. [148] tried to create a film by putting a layer of column structured PU possessing super hydrophobicity (S-PU) on a shape memory polyurethane cellulose nanofiber (PU-CNF) substrate. This could act like hair structures of the gecko toe. The advantage of PU-CNF is that they can act similarly to gecko toe pad muscles and help the film to regain initial shapes. As a result, by varying the film shape, the hydrophobicity of the surface could be modulated.

Dry adhesives usually exhibit poor adhesion in underwater conditions. Many experiments have been conducted by immersing adhesives under water. Park et al. [149] fabricated a thermosensitive SMP adhesive and assessed its adhesion performance at different submerged conditions (underwater, saltwater, and oil). This thermosensitive SMP exhibited high adhesion strength of 18 atm measured underwater. This experiment explained that shape memory properties were one of the main factors for the high adhesion of this SMP exhibited in submerged conditions.

Researchers also fabricated a patterned adhesion system with switchable adhesion using a combination of SMP and shape memory alloy (SMA). Elmar kroner [150] fabricated one such pressure switchable system (PSS) with bio-inspired adhesives. It was observed in the PSS system that with a low preload that the tips of the pillar could form close contact, resulting in a high adhesive force during detachment. However, if a higher preload was provided, this would result in elastic bending of the pillars [145,151]. This bending exhibits a strong moment on the pillar tip, causing partial detachment. Again, if the load is released, the pillars can only form partial contact between the tip and the probe. It has been observed that this partial contact exhibits lower adhesion [152]. Therefore, controlled misalignment of surface patterns with the help of an external stimulus could possibly give rise to attachment and detachment in the adhesive properties of bio-inspired adhesives.

Superhydrophobic surfaces with various fluid adhesive properties are dependent on contrasting surfaces with dissimilar microstructures. Shao et al. [153] tried developing an SMP from PU, acting as a switchable surface, which can transform between isotropic/anisotropic super-wetting natures. It could also change its behavior from superhydrophobic to hydrophobic property, and vice versa. By varying the microstructures of the SMP, two different types of surfaces could be obtained. The surface possessing intact microstructure arrays exhibited good self-cleaning properties as well as low water adhesive force. This was similar to the lotus surface [154]. The other surface, consisting of compressed microstructures, exhibited high adhesive force, and this was similar to the rose-leaf model [5]. These models are being further investigated with ongoing research.

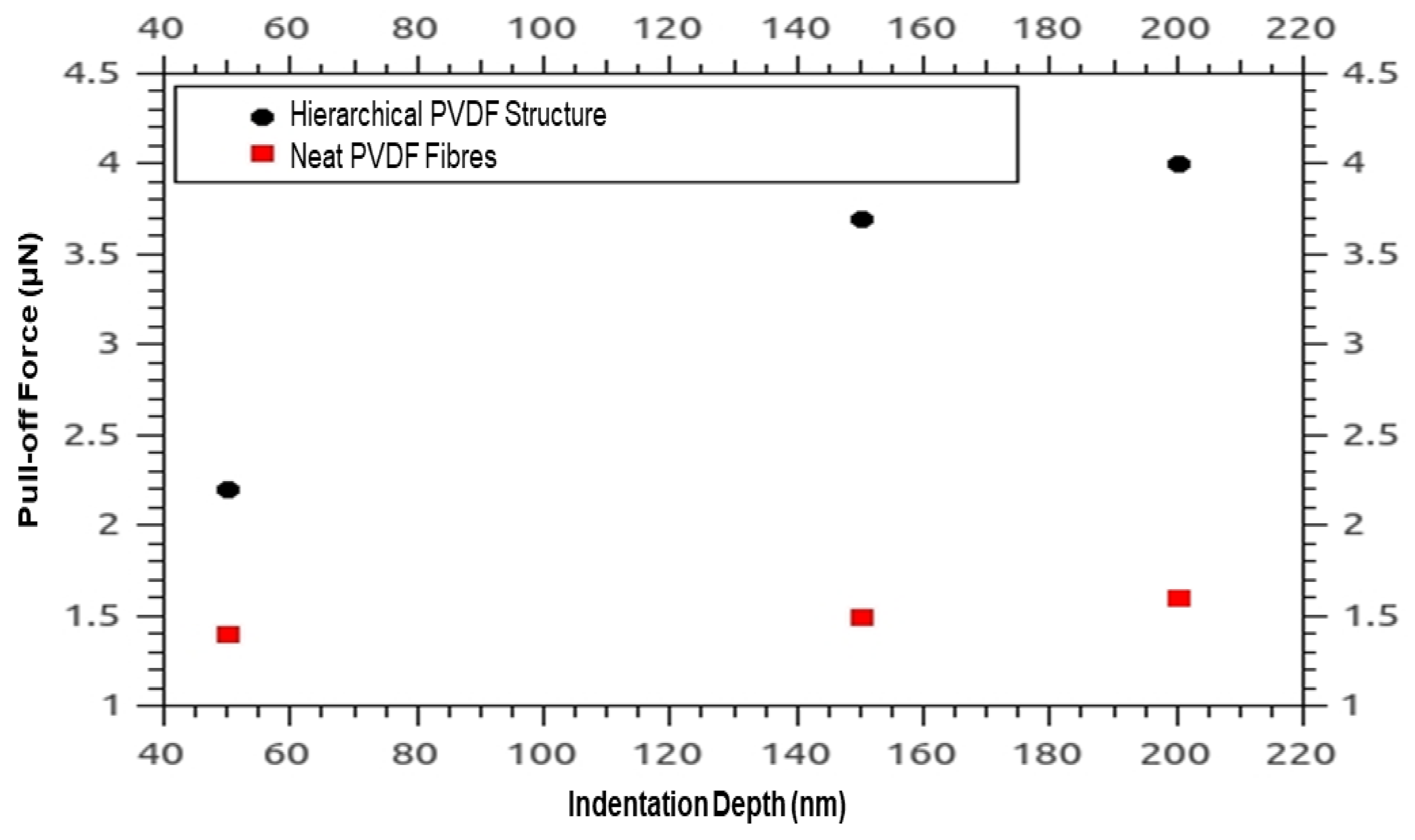

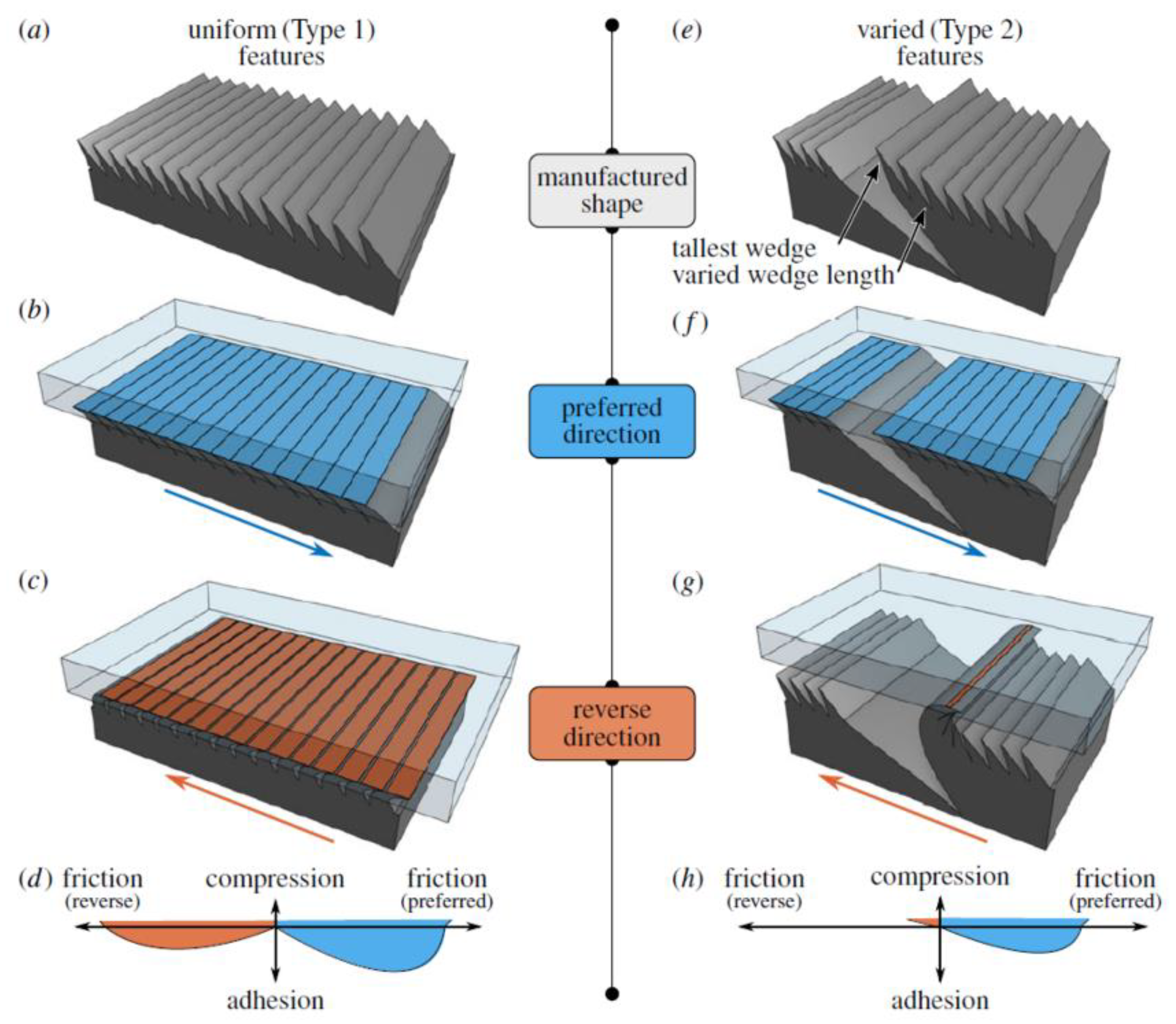

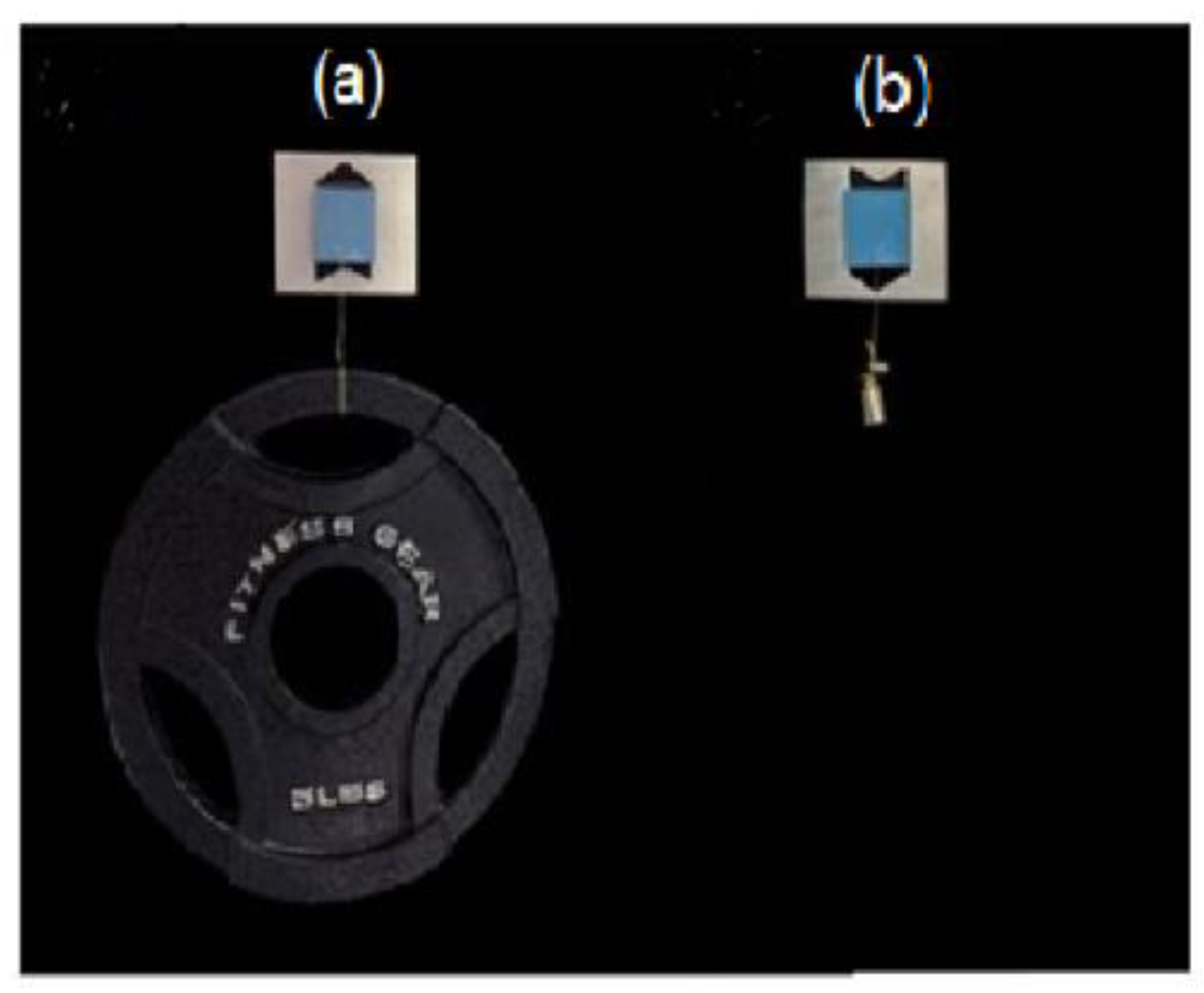

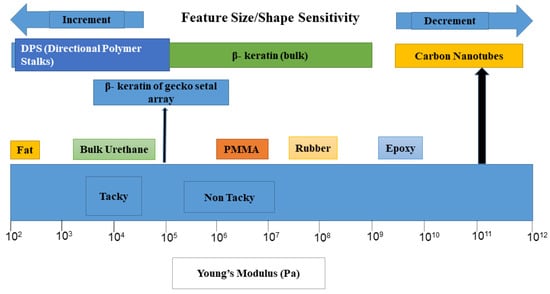

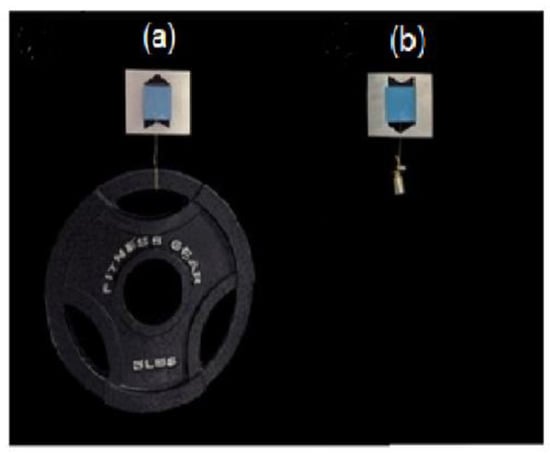

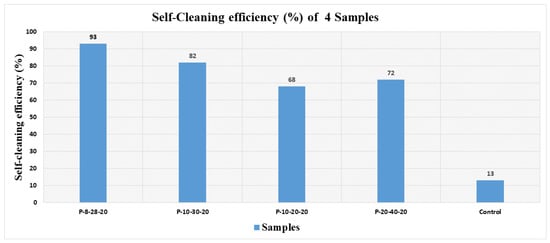

5.3. Progress on Miscellaneous Fabrication Techniques