Determining the Proper Force Parameters for Robotized Pipetting Devices Used in Automated Polymerase Chain Reaction (PCR) †

Abstract

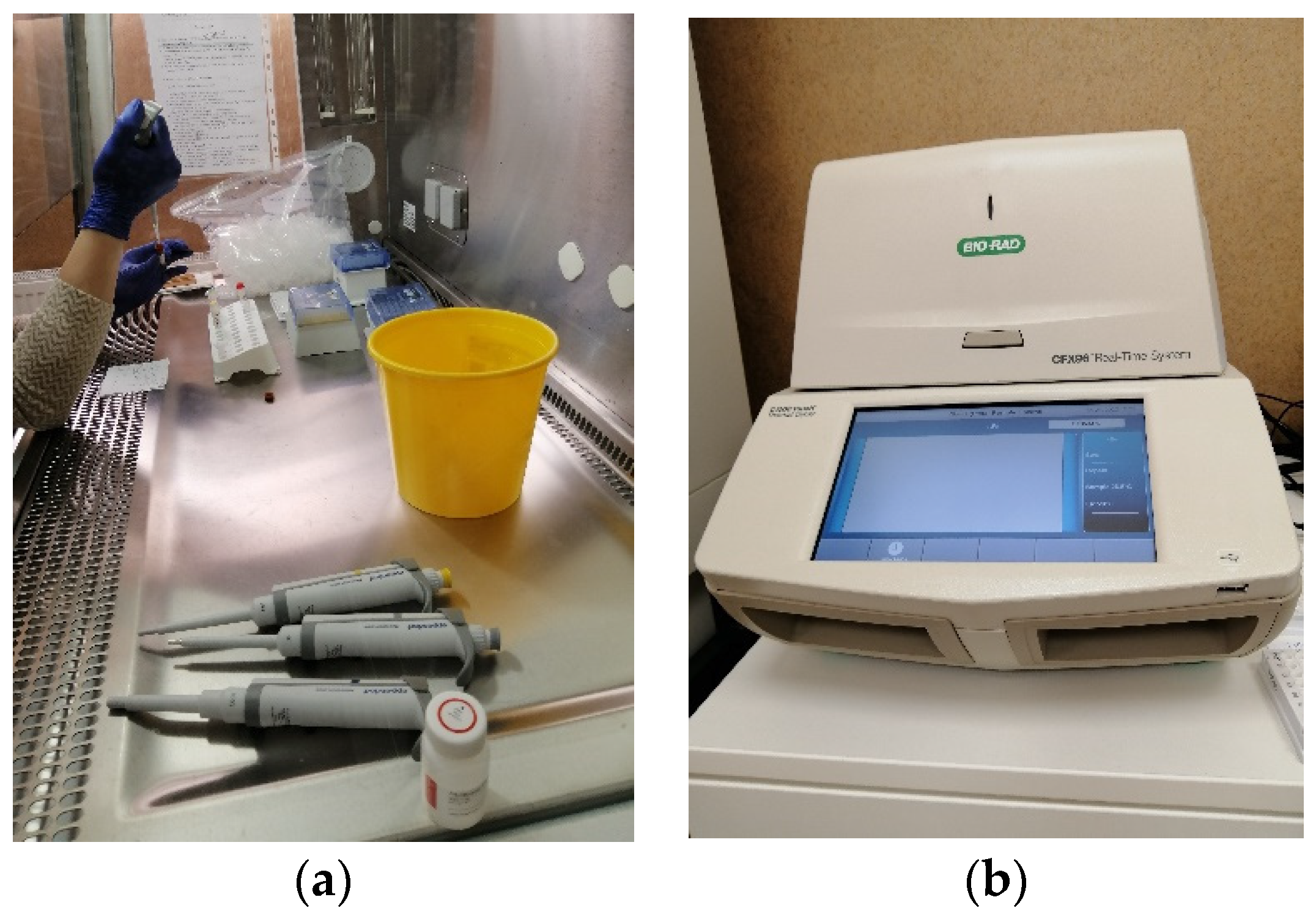

1. Introduction

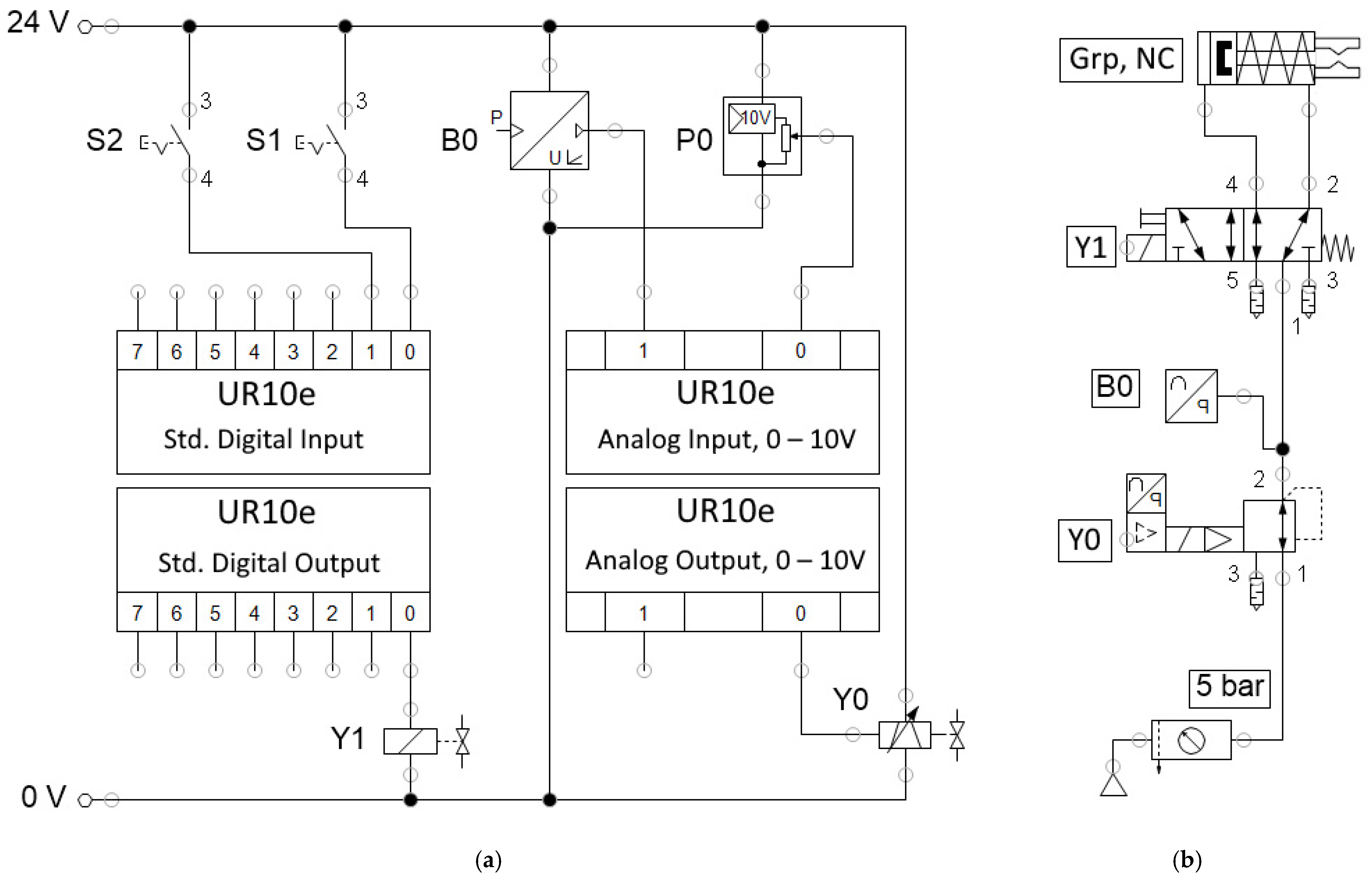

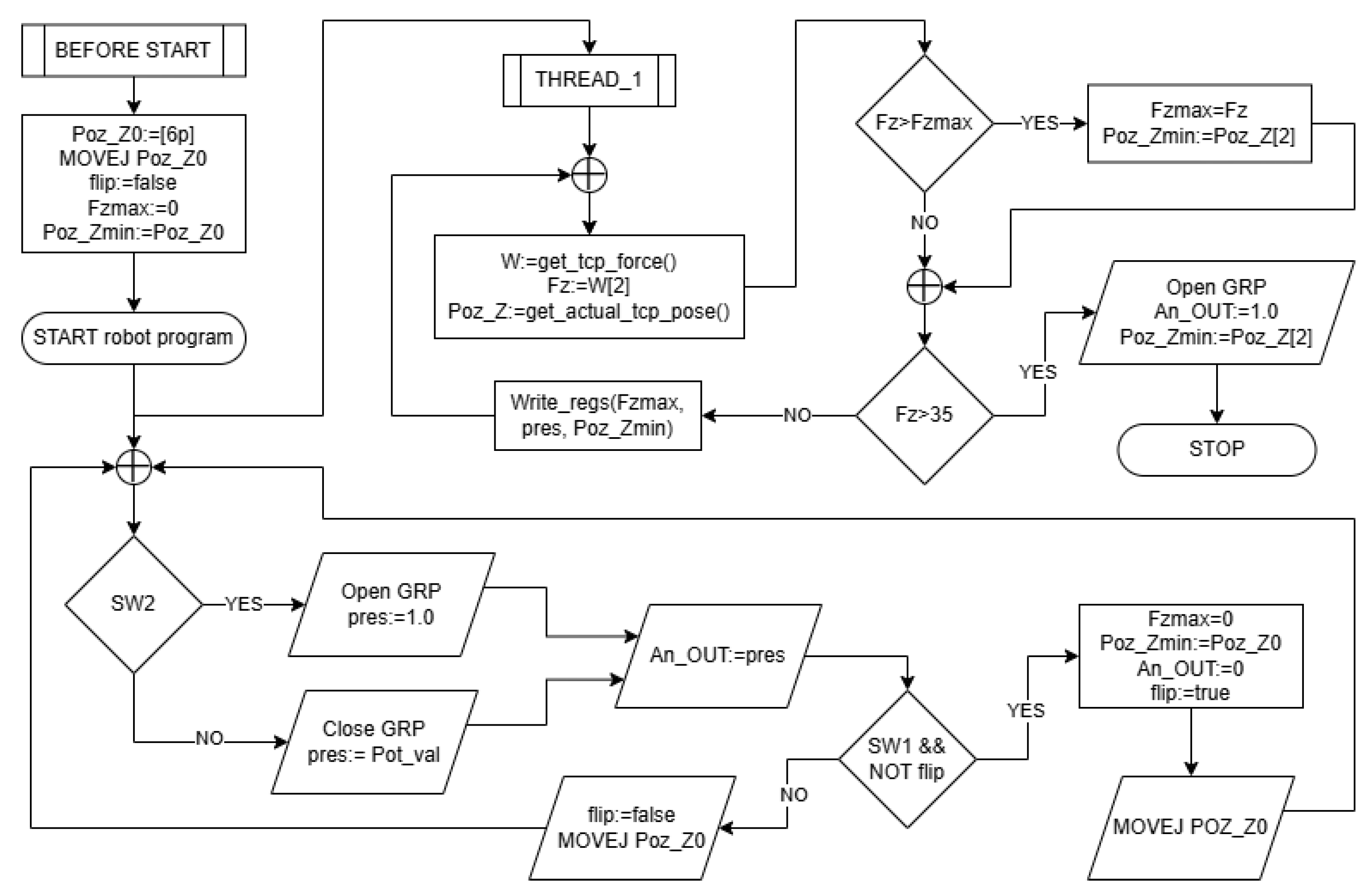

2. Materials and Methods

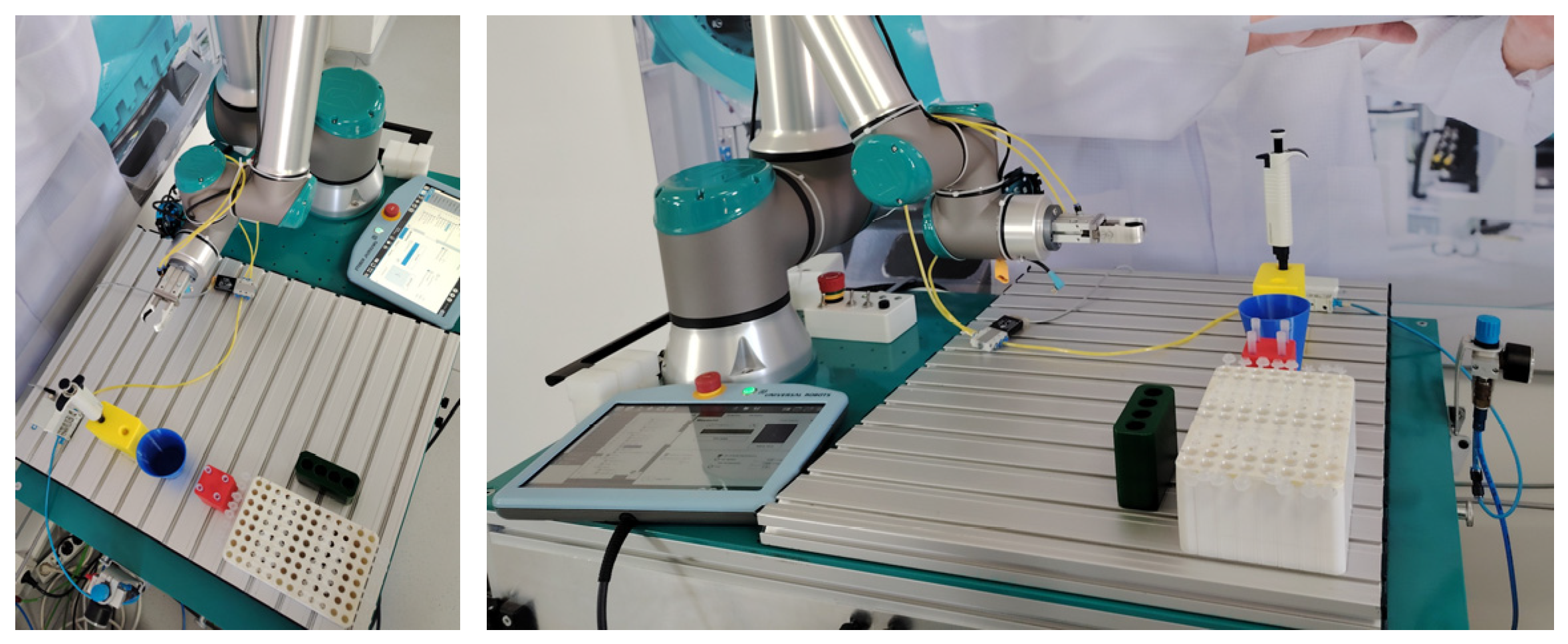

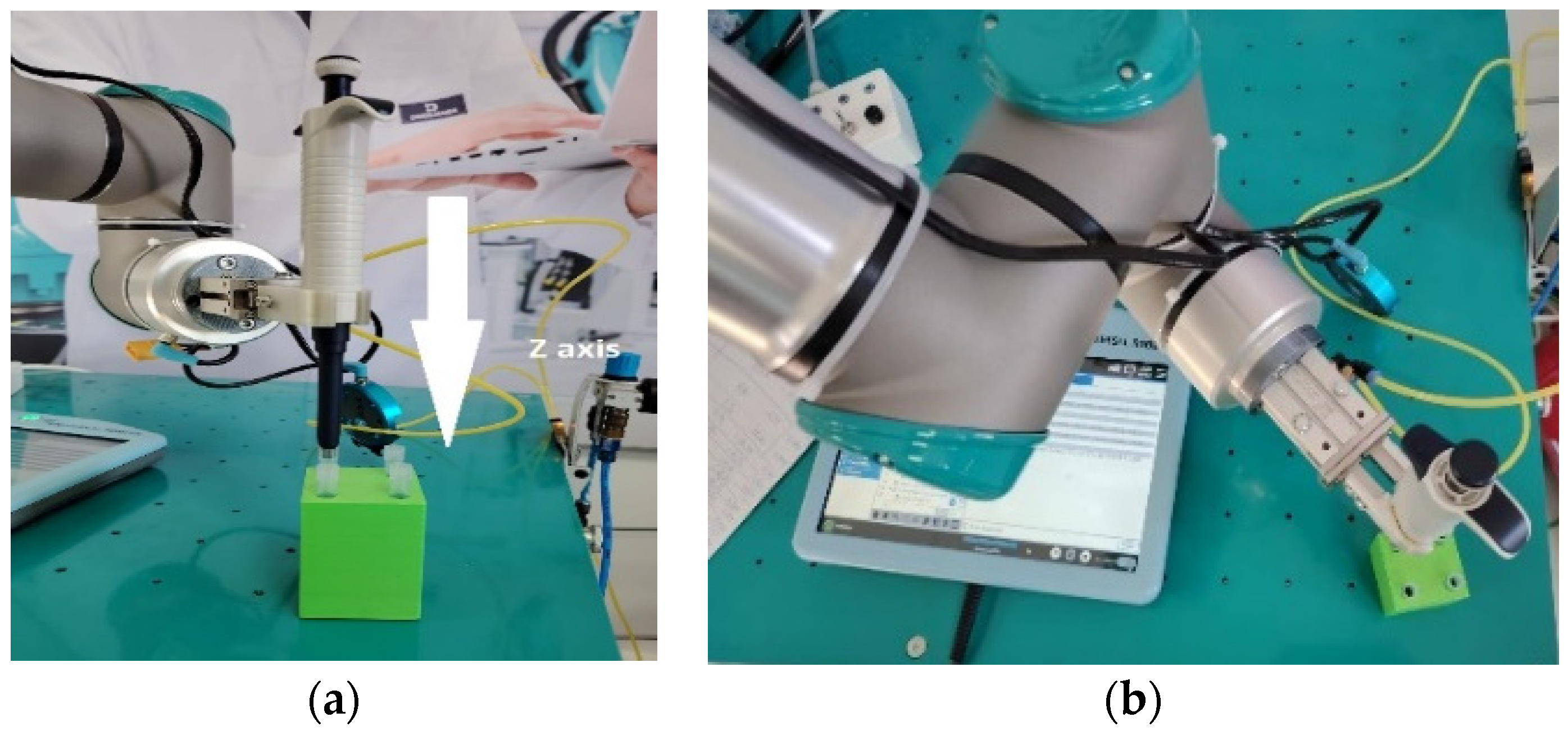

2.1. Robotic Testing Work Cell

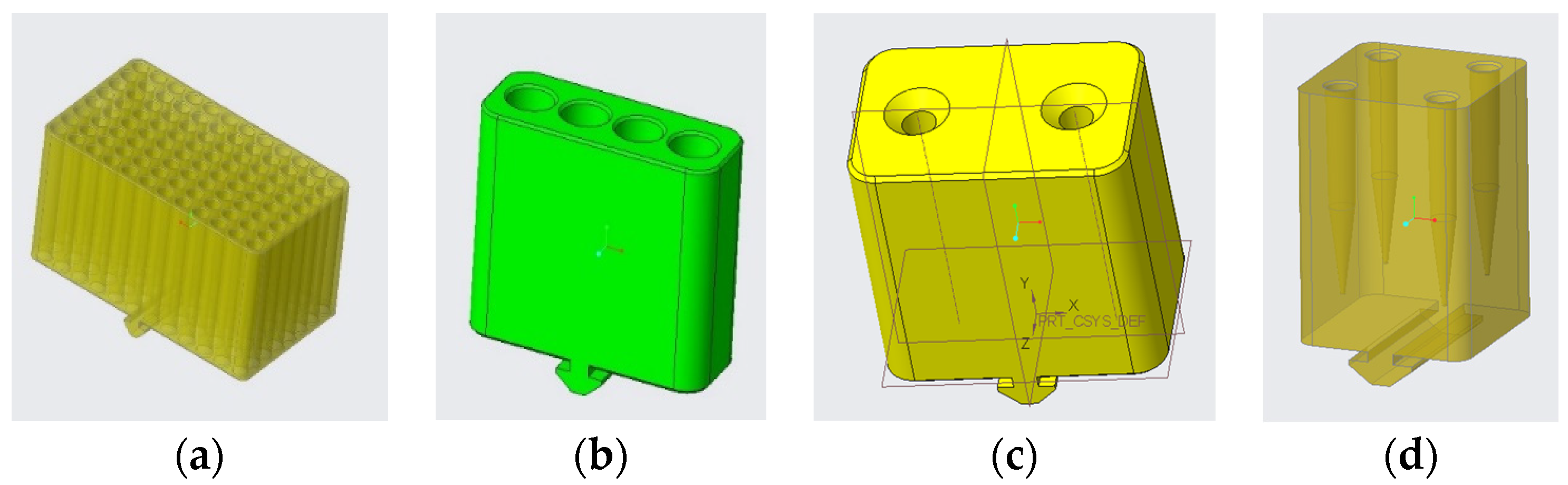

2.2. Three-Dimensional Modeling of the Components for the Experimental Setup

- A holder for the manipulated pipette;

- A holder with multiple locations for the tips;

- support for tubes with reagents;

- A holder for the elution tubes;

- A recycling cup for discarded tips;

- A gripper assembly for manipulating the pipette.

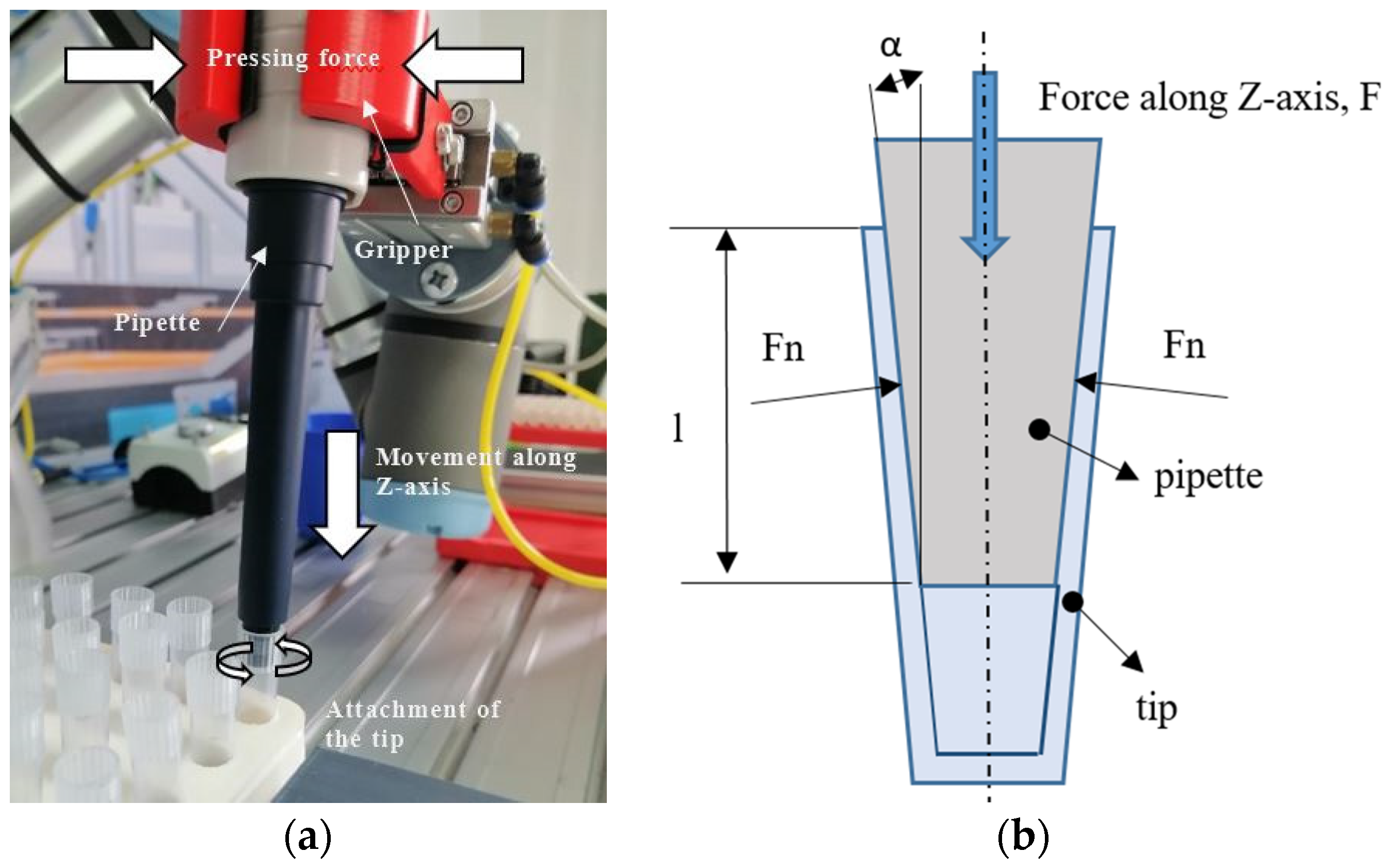

3. Determining the Pipette’s Proper Clamping Force

3.1. Defining of Clamping Force

3.2. Test Setup for Measuring Forces

3.3. Gripper Design

- –

- The pipette must be gripped in the same position and orientation every time.

- –

- The pipette holding force must be appropriate for the operation to be carried out.

- –

- Excessive forces from any direction (but especially from Z-travel—the work direction) must be avoided by quickly releasing the pipette.

- –

- The pipette must remain in a gripped state (low force) upon the failure or shut-off of compressed air components.

- –

- Supplemental future mechanisms for operating the pipette must be accounted for.

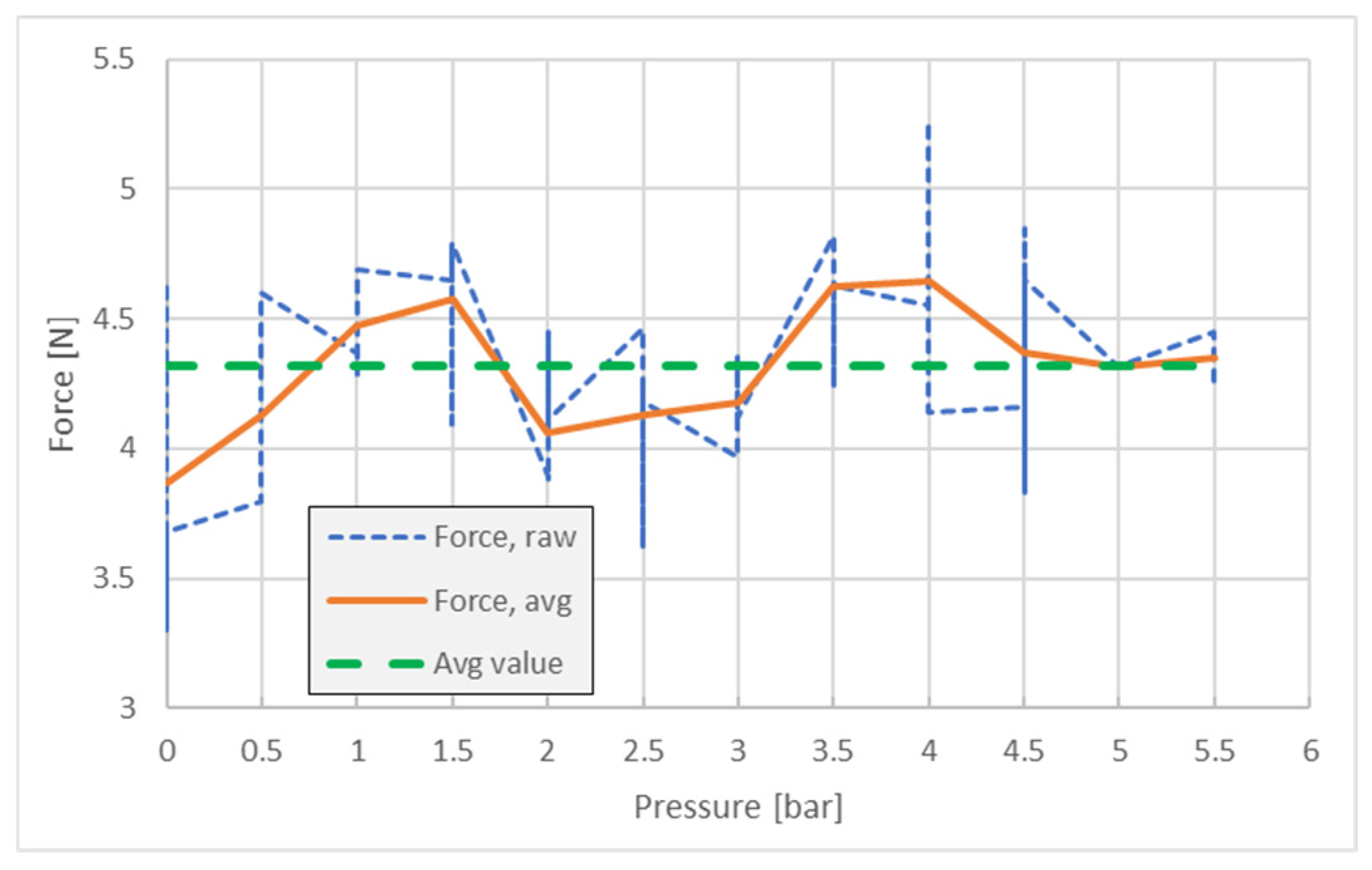

3.4. First Experiment—Pipette Holding Force

First Experiment—Results

3.5. Second Experiment—Tip Holding Force

- –

- The tip must remain attached to the pipette after lifting and positioning the assembly.

- –

- The tip must not leak any of its collected (water) content for at least 30 s.

- –

- The tip must be released by pressing the dedicated pipette button, with an ergonomically accepted finger force of 10–25 N.

- –

- The tip must not crack or deform at its assembly collar or at its narrow open end.

- –

- The tip should be reusable for at least one more operation under the same conditions (although this will never happen in the lab as the tips are disposable, it is a qualitative indicator of the mechanical stress applied to the tip).

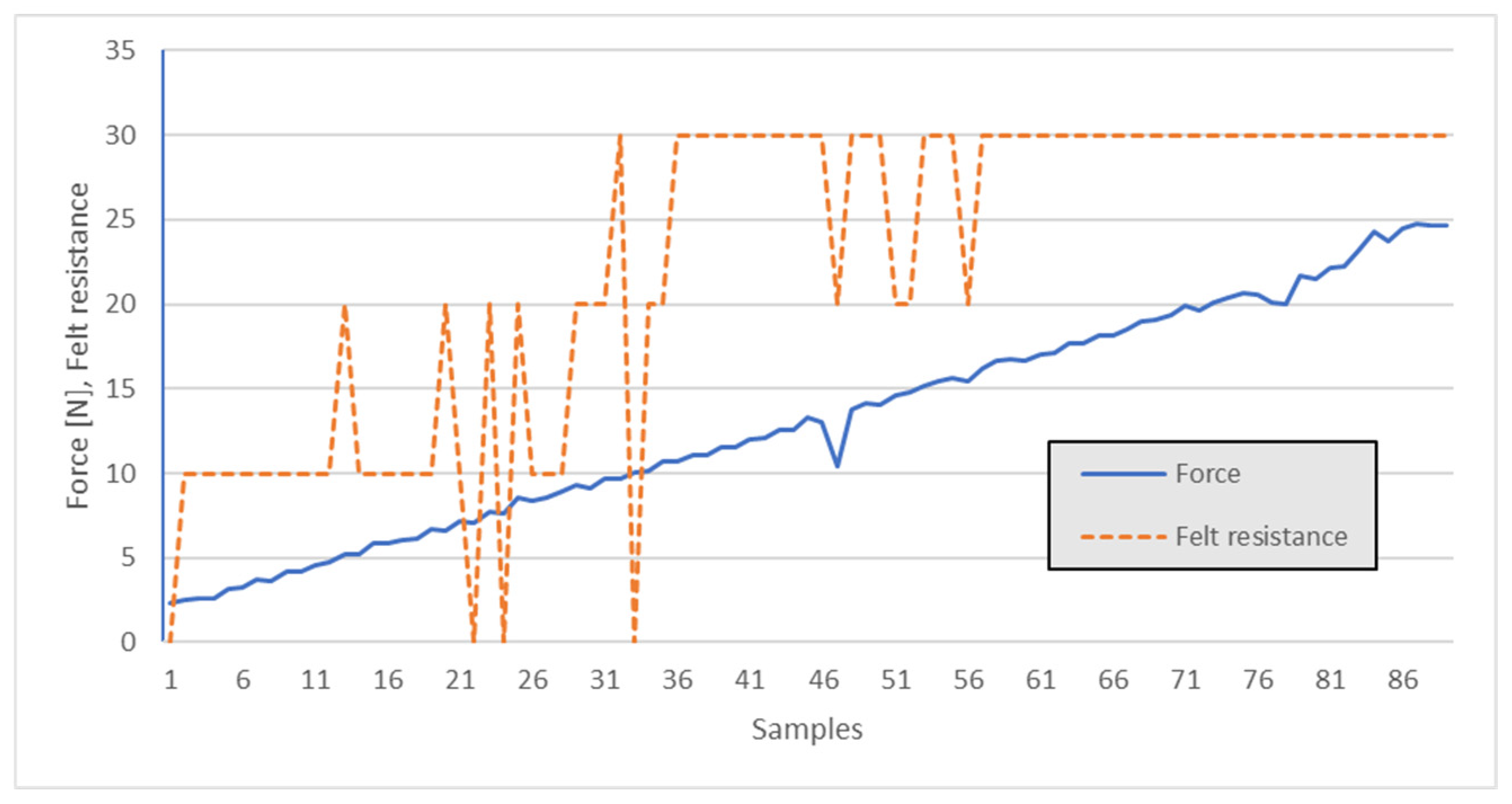

Second Experiment—Results

4. Discussion and Future Work

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Worsfold, P.; Townshend, A.; Poole, C. (Eds.) Encyclopedia of Analytical Science; Elsevier Ltd.: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Mei, X.; Lee, H.C.; Diao, K.Y.; Huang, M.; Lin, B.; Liu, C.; Xie, Z.; Ma, Y.; Robson, P.M.; Chung, M.; et al. Artificial intelligence-enabled rapid diagnosis of patients with COVID-19. Nat. Med. 2020, 26, 1224–1228. [Google Scholar] [CrossRef]

- Hamet, P.; Tremblay, J. Artificial intelligence in medicine. Metabolism 2017, 69 (Suppl.), S36–S40. [Google Scholar] [CrossRef]

- Available online: https://www.genome.gov/genetics-glossary/DNA-Replication (accessed on 4 November 2024).

- Yang, K.; Gan, Y.; Cao, Y.; Yang, J.; Wu, Z. Optimization of 3D Tolerance Design Based on Cost-Quality-Sensitivity Analysis to the Deviation Domain. Automation 2023, 4, 123–150. [Google Scholar] [CrossRef]

- Martínez, D.S.; Carlos, A.J.; Gomez-Donoso, F. A new automatic method for demoulding plastic parts using an intelligent robotic system. Int. J. Adv. Manuf. Technol. 2023, 129, 3109–3121. [Google Scholar] [CrossRef]

- Erebak, S.; Kasimoğlu, N. Nurses’ Robot Use Self-Efficacy: Mediation Effect in The Relationship Between Robot Anxiety and Preference of Automation Levels. J. Ege Univ. Nurs. Fac. 2024, 40, 47–56. [Google Scholar] [CrossRef]

- Tatsumi, N.; Okuda, K.; Tsuda, I. A new direction in automated laboratory testing in Japan: Five years of experience with total laboratory automation system management. Clin. Chim. Acta 1999, 290, 93–108. [Google Scholar] [CrossRef]

- Andrade, M.A.B.; Ramos, T.S.; Adamowski, J.C.; Marzo, A. Contactless pick-and-place of millimetric objects using inverted near-field acoustic levitation. Appl. Phys. Lett. 2020, 116, 054104. [Google Scholar] [CrossRef]

- Jiang, L.; Wu, Z.; Xu, X.; Zhan, Y.; Jin, X.; Wang, L.; Qiu, Y. Opportunities and challenges of artificial intelligence in the medical field: Current application, emerging problems, and problem-solving strategies. J. Int. Med. Res. 2021, 49, 03000605211000157. [Google Scholar] [CrossRef]

- Holland, L.L.; Smith, L.L.; Blick, K.E. Total laboratory automation can help eliminate the laboratory as a factor in emergency department length of stay. Am. J. Clin. Pathol. 2006, 125, 765–770. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, Y.; Ju, J.; Lu, E. Design and Experimental Test of Rope-Driven Force Sensing Flexible Gripper. Sensors 2024, 24, 6407. [Google Scholar] [CrossRef] [PubMed]

- Scimmi, L.S.; Melchiorre, M.; Troise, M.; Mauro, S.; Pastorelli, S. A Practical and Effective Layout for a Safe Human-Robot Collaborative Assembly Task. Appl. Sci. 2021, 11, 1763. [Google Scholar] [CrossRef]

- Seaberg, R.S.; Stallone, R.O.; Statland, B.E. The role of total laboratory automation in a consolidated laboratory network. Clin. Chem. 2000, 46, 751–756. [Google Scholar] [CrossRef] [PubMed]

- Neha, F.; Bhati, D.; Shukla, D.K.; Amiruzzaman, M. ChatGPT: Transforming Healthcare with AI. AI 2024, 5, 2618–2650. [Google Scholar] [CrossRef]

- Ferraris, C.; Amprimo, G.; Pettiti, G. Computer Vision and Image Processing in Structural Health Monitoring: Overview of Recent Applications. Signals 2023, 4, 539–574. [Google Scholar] [CrossRef]

- Anil Al, G.; Estrela, P.; Martinez-Hernandez, U. Towards an intuitive human-robot interaction. In Proceedings of the 2020 IEEE International Conference on Multisensor Fusion and Integration for Intelligent Systems (MFI), Virtual Conference, 14–16 September 2020. [Google Scholar]

- Kucuk, S.; Bingul, Z. Robot workspace optimization basedon a novel local and global performance index. In Proceedings of the IEEE International Symposium on Industrial Electronics, ISIE, Dubrovnik, Croatia, 20–23 June 2005; pp. 1593–1598. [Google Scholar]

- Asif, S.; Webb, P. Realtime Calibration of an Industrial Robot. Appl. Syst. Innov. 2022, 5, 96. [Google Scholar] [CrossRef]

- Sarosh, P.; Tarek, S. Manipulator Performance Measures—A Comprehesive Literature Survey. J. Intell. Robot Syst. 2015, 77, 547–570. [Google Scholar] [CrossRef]

- Kot, T.; Bobovský, Z.; Vysocký, A.; Krys, V.; Šafarík, J.; Ružarovský, R. Method for Robot Manipulator Joint Wear Reduction by Finding the Optimal Robot Placement in a Robotic Cell. Appl. Sci. 2021, 11, 5398. [Google Scholar] [CrossRef]

- Jiang, P.; Oaki, J.; Ishihara, Y.; Ooga, J. Multiple-Object Grasping Using a Multiple-Suction-Cup Vacuum Gripper in Cluttered Scenes. Robotics 2024, 13, 85. [Google Scholar] [CrossRef]

- Bezzini, R.; Bassani, G.; Avizzano, C.A.; Filippeschi, A. Design and Experimental Evaluation of Multiple 3D-Printed Reduction Gearboxes for Wearable Exoskeletons. Robotics 2024, 13, 168. [Google Scholar] [CrossRef]

- Zhang, J.; Wan, W.; Tanaka, N.; Fujita, M.; Takahashi, K.; Harada, K. Integrating a Pipette Into a Robot Manipulator With Uncalibrated Vision and TCP for Liquid Handling. IEEE Trans. Autom. Sci. Eng. 2024, 21, 5503–5522. [Google Scholar] [CrossRef]

- Shah, J.A.; Saleh, J.H.; Hoffman, J.A. Review and Synthesis of Considerations in Architecting Heterogeneous Teams of Humans and Robots for Optimal Space Exploration. IEEE Trans. Syst. MAN Cybern. Part C Appl. Rev. 2007, 37, 779–793. [Google Scholar] [CrossRef]

- Filippeschi, P.; Griffa, C.; Avizzano, A. Kinematic Optimization for the Design of a Collaborative Robot End-Effector for Tele-Echography. Robotics 2021, 10, 8. [Google Scholar] [CrossRef]

- Florian, D.C.; Odziomek, M.; Ock1, C.L.; Chen, H.; Guelcher, S.A. Principles of computer controlled linear motion applied to an open source afordable liquid handler for automated micropipetting. Sci. Rep. 2020, 10, 13663. [Google Scholar] [CrossRef]

- Trudeau, M.; Skinner, N. Demonstration of LC-MS Nitrosamine Impurity Quantification Performance Using Automated Sample Preparation with the Andrew+ Pipetting Robot; 720007134; Waters Corporation: Milford MA, USA, 2021. [Google Scholar]

- Tai, K.; El-Sayed, A.R.; Shahriari, M.; Biglarbegian, M.; Mahmud, S. State of the Art Robotic Grippers and Applications. Robotics 2016, 5, 11. [Google Scholar] [CrossRef]

- Fantoni, G.; Santochi, M.; Dini, G.; Tracht, K.; Scholz-Reiter, B.; Fleischer, J.; Lien, T.K.; Seliger, G.; Reinhart, G.; Franke, J.; et al. Grasping devices and methods in automated production processes. CIRP Ann. Manuf. Technol. 2014, 63, 679–701. [Google Scholar] [CrossRef]

- Jin, H.L.; Delgado-Martinez, I.; Chen, H.Y. Customizable Soft Pneumatic Chamber-Gripper Devices for Delicate Surgical Manipulation. J. Med. Devices 2014, 8, 044504. [Google Scholar]

- Chelpanov, I.B.; Kolpashnikov, S.N. Problems with the mechanics of industrial robot grippers. Mech. Mach. Theory 1983, 18, 295–299. [Google Scholar] [CrossRef]

- Rateni, R.; Cianchetti, M.; Ciuti, G.; Menciassi, A.; Laschi, C. Design and Development of a soft robotic gripper for manipulation in minimally invasive surgery: A proof of concept. Meccanica 2015, 50, 2855–2863. [Google Scholar] [CrossRef]

- Bosse, S.; Hogreve, S.; Tracht, K. Design of a Mechanical Gripper with an Integrated Smart Sensor Network for Multi-Axial Force Sensing and Perception of Environment. In Proceedings of the Smart Systems Integration Conference, Zürich, Switzerland, 21–22 March 2012. [Google Scholar]

- Sandu, M.O.; Gruescu, C.M.; Lovasz, E.C.; Ciupe, V. Synthesis of an Automation System for the PCR (Polymerase Chain Reaction) Samples Preparation Process. In Proceedings of SYROM 2022 & ROBOTICS 2022: 13th IFToMM International Symposium on Science of Mechanisms and Machines & XXV International Conference on Robotics; Book Series Mechanism and Machine Science; Spinger: Cham, Switzerland, 2022; Volume 127, pp. 389–396. [Google Scholar]

- Sandu, M.O.; Gruescu, C.M.; Kristof, R.; Sticlaru, C.; Ciupe, V.; Lovasz, E.C. Experimental Approach on the Force for Robotic Pipetting in Automated PCR (Polymerase Chain Reaction). In Mechanism Design for Robotics. MEDER 2024. Mechanisms and Machine Science; Lovasz, E.C., Ceccarelli, M., Ciupe, V., Eds.; Springer: Cham, Switzerland, 2024; Volume 166. [Google Scholar] [CrossRef]

- Available online: https://www.universal-robots.com/ro/produse/robot-ur10e/ (accessed on 4 November 2024).

- Available online: https://www.witeg.de/en/products/liquid-handling/pipetting/microliter-pipettes/microliter-pipettes-witopet-economy-fix-single-channel?number=5401910 (accessed on 4 November 2024).

- Fleischer, H.; Drews, R.R.; Janson, J.; Reddy, B.; Patlolla, C.; Chu, X.; Klos, M.; Thurow, K. Application of a Dual-Arm Robot in Complex Sample Preparation and Measurement Processes. J. Lab. Autom. 2016, 21, 671–681. [Google Scholar] [CrossRef]

- Ellwood, R.; Raatz, A.; Hesselbach, J. Vision and Force Sensing to Decrease Assembly Uncertainty. In Precision Assembly Technologies and Systems; Springer: Berlin/Heidelberg, Germany, 2010; pp. 123–130. [Google Scholar]

- Available online: https://www.smcpneumatics.com/MHZ2-20CN.html (accessed on 4 November 2024).

- Available online: https://www.festo.com/ro/ro/a/8046299/ (accessed on 4 November 2024).

- International Standard ISO 9409-1, Manipulating industrial robots–Mechanical interfaces–Part 1: Plates. Available online: https://cdn.standards.iteh.ai/samples/36578/348a837664f444bc83e2902c7a5acf4c/ISO-9409-1-2004.pdf (accessed on 4 November 2024).

| Item | Function | Signal | Values | Type |

|---|---|---|---|---|

| S1, S2 | Branch selectors for program loops | Digital input | 24 V | NO switches, manual act |

| P0 | Gripping force command | Analog input | 0–10 V | Potentiometer, manual act |

| B0 | Gripping pressure feedback | Analog input | 0–10 V | Pressure sensor, part of Y0 |

| Y0 | Gripping force control | Analog output | 0–10 V | Proportional pressure regulator |

| Y1 | Open/close gripper | Digital output | 24 V | Directional control solenoid valve |

| Grp | Pipette gripper | Compressed air | 0–10 bar | NC, spring-loaded, air gripper |

| No Resistance | Really Easy | Easy | Good |

|---|---|---|---|

| 0 | 10 | 20 | 30 |

| Robot Force | 10–14 s | 15–29 s | 30–59 s | Over 60 s | Total Samples |

|---|---|---|---|---|---|

| 10.1–15.0 N | 5 | 1 | 3 | 14 | 20 |

| 15.1–20.0 N | 0 | 0 | 4 | 16 | 20 |

| 20.1–25.0 N | 0 | 0 | 1 | 19 | 20 |

| 25.1–30.0 N | 0 | 0 | 0 | 10 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sandu, M.-O.; Ciupe, V.; Gruescu, C.-M.; Kristof, R.; Sticlaru, C.; Tulcan, E.-G. Determining the Proper Force Parameters for Robotized Pipetting Devices Used in Automated Polymerase Chain Reaction (PCR). Robotics 2025, 14, 2. https://doi.org/10.3390/robotics14010002

Sandu M-O, Ciupe V, Gruescu C-M, Kristof R, Sticlaru C, Tulcan E-G. Determining the Proper Force Parameters for Robotized Pipetting Devices Used in Automated Polymerase Chain Reaction (PCR). Robotics. 2025; 14(1):2. https://doi.org/10.3390/robotics14010002

Chicago/Turabian StyleSandu, Melania-Olivia, Valentin Ciupe, Corina-Mihaela Gruescu, Robert Kristof, Carmen Sticlaru, and Elida-Gabriela Tulcan. 2025. "Determining the Proper Force Parameters for Robotized Pipetting Devices Used in Automated Polymerase Chain Reaction (PCR)" Robotics 14, no. 1: 2. https://doi.org/10.3390/robotics14010002

APA StyleSandu, M.-O., Ciupe, V., Gruescu, C.-M., Kristof, R., Sticlaru, C., & Tulcan, E.-G. (2025). Determining the Proper Force Parameters for Robotized Pipetting Devices Used in Automated Polymerase Chain Reaction (PCR). Robotics, 14(1), 2. https://doi.org/10.3390/robotics14010002