Development of Quinoa Value Chain to Improve Food and Nutritional Security in Rural Communities in Rehamna, Morocco: Lessons Learned and Perspectives

Abstract

:1. Introduction

2. Results

2.1. New High Yielding Chenopodium Quinoa Cultivars Introduction

2.2. Quinoa Seed Processing

2.2.1. Harvest and Postharvest Machines

2.2.2. Quinoa Transformation Pathway

2.2.3. Shelling Impacts on the Nutritional and Antinutritional Aspect of Quinoa Seeds

2.3. Quinoa Import

2.4. Economic Analysis of Quinoa Seed Production

2.4.1. Quinoa vs. Traditional Cereals: Production Cost and Net Margin

2.4.2. Quinoa Production Cost Breakdown

2.4.3. Sensitivity Analysis of Net Margin vs. Production Cost, Grain Yield and Sale Price

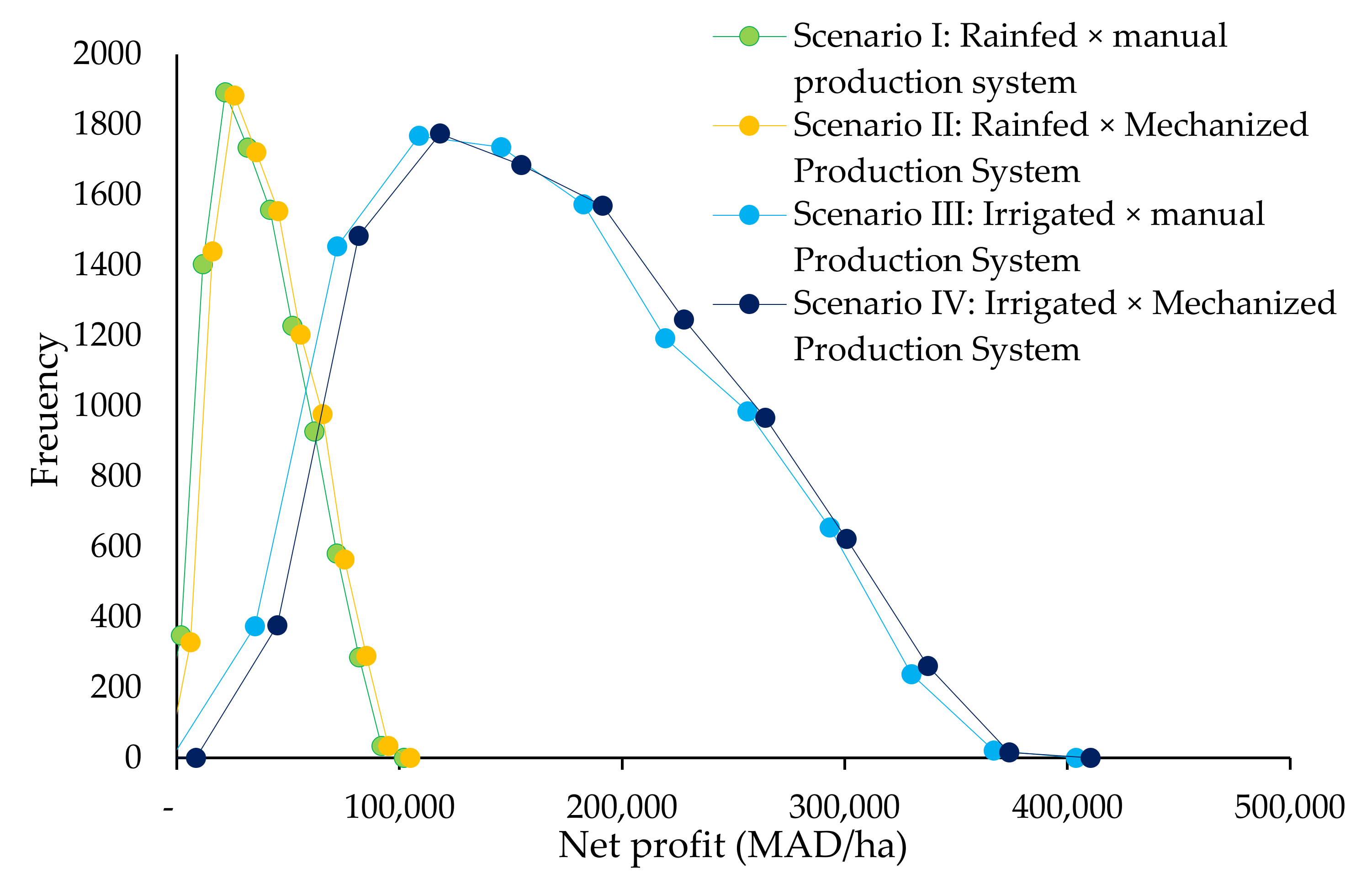

2.4.4. Monte Carlo Simulation Analysis (10,000 Iterations)

2.4.5. Cost Breakdown of Quinoa Based Products

2.5. SWOT Analysis of the Quinoa Value Chain in Morocco

2.6. Lessons Learned

2.7. Perspectives of Development

3. Discussion

4. Materials and Methods

4.1. Study Area

4.2. Soil and Water Analysis

4.3. Tested Cultivars

4.4. Trial Installation

4.4.1. At the Farm Level

4.4.2. At the UM6P Experimental Farm

4.5. Agronomic Practices and Seed Yield Determination

4.6. Seed Pearling

4.7. Chemical Analysis

4.7.1. Nutrient Analysis

- After weighing. harvested samples were ground to a fine powder using the FOSS CT 293 Cyclotec grinder (Fisher Scientific, Canada).

- The moisture content was measured by drying 100 g of sample at 105 °C for 48 h

- Crude protein was determined using Kjeldahl (Buchi, Switzerland, AACC 46–10) method with a conversion factor of 6.25. Micronutrients were determined after sample mineralization.

- Representative samples (0.25 g) were digested with 7.5 mL of HNO3 acid in the DigiPrep System (SCP SCIENCE, France) during two hours at 100 °C.

- After digestion. the solutions were filtered through 45 µm filters. and the filtrates were diluted to 50 mL with deionized water and acidified (2% HNO3) in order to undergo the analysis by ICP-OES using Agilent technologies 5110 ICP-OES (Agilent, United States of America) for the elements P. K. Mg. Ca. Cu. Mn. Fe. Zn and B.

4.7.2. Saponin Analysis

4.8. Farmer’s Survey

- Field operation costs;

- Plowing: deep. superficial;

- Organic amendment: quantity. application;

- Irrigation system: purchase. installation;

- Seeds: quantity. price;

- Sowing: manual. seeder;

- Irrigation: workforce. energy;

- Fertilization: manual. fertigation;

- Weeding: manual. chemical;

- Phytosanitary treatment: insecticide. fungicide;

- Harvest: manual. mechanical;

- Other operations;

- Post-harvest operation costs;

- Yield;

- Panicle drying;

- Threshing: Mechanical. Manual;

- Cleaning: Mechanical. Manual;

- Washing: Mechanical. Manual;

- Seed drying;

- Weighing and packaging;

- Labeling;

- Other operations.

4.9. Sensitivity Analysis and Monte Carlo Simulations

4.10. Valorization Cooperative’s Survey

4.11. Quinoa Import Data

4.12. Statistical Analysis

5. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bazile, D.; Jacobsen, S.E.; Verniau, A. The global expansion of quinoa: Trends and limits. Front. Plant Sci. 2016, 7, 622. [Google Scholar]

- Bazile, D.; Bertero., H.D.; Nieto., C. (Eds.) Estado del Arte de la Quinua en el Mundo en 2013; FAO: Rome, Italy; CIRAD: Montpellier, France, 2014; 724p, Available online: http://www.fao.org/3/a-i4042s/index.html (accessed on 16 November 2020).

- Lavini, A.; Pulvento, C.; d’Andria, R.; Riccardi, M.; Choukr-Allah, R.; Belhabib, O.; Yazar, A.; İncekaya, Ç.; Metin Sezen, S.; Qadir, M.; et al. Quinoa’s potential in the Mediterranean region. J. Agron. Crop Sci. 2014, 200, 344–360. [Google Scholar]

- Choukr-Allah, R.; Nanduri, K.R.; Hirich, A.; Shahid, A.; Alshankiti, A.; Toderich, K.; Gill., S.; Rahman, B. Quinoa for Marginal Environments: Toward Future Food and Nutritional Security in MENA and Central Asia Regions. Front. Plant Sci. 2016, 7, 346. [Google Scholar] [CrossRef] [Green Version]

- Benlhabib, O.; Jacobsen, S.E.; Jellen, R.; Maughan, J.; Choukrallah, R.; Oussible, M. Status of quinoa production and research in Morocco. In State of the Art Report on Quinoa around the World in 2013; Bazile, D., Bertero, H.D., Nieto, C., Eds.; FAO. CIRAD: Santiago, Chile, 2015; pp. 478–491. [Google Scholar]

- Brakez, M.; El Brik, K.; Daoud, S.; Harrouni, M.C. Performance of chenopodium quinoa under salt stress. In Developments in Soil Salinity Assessment and Reclamation. Springer: Dordrecht, The Netherlands, 2013; pp. 463–478. [Google Scholar]

- Hirich, A.; Jelloul, A.; Choukr-Allah, R.; Jacobsen, S.E. Saline water irrigation of quinoa and chickpea: Seedling rate. stomatal conductance and yield responses. J. Agron. Crop Sci. 2014, 200, 378–389. [Google Scholar]

- Fghire, R.; Wahbi, S.; Anaya, F.; Issa Ali, O.; Benlhabib, O.; Ragab, R. Response of quinoa to different water management strategies: Field experiments and SALTMED model application results. Irrig. Drain. 2015, 64, 29–40. [Google Scholar]

- Filal, K.; Hirich, A.; Benlhabib, O.; Choukr-Allah, R.; Ragab, R. Yield and dry matter simulation using the SALTMED model for five quinoa (Chenopodium quinoa) accessions under deficit irrigation in South Morocco. Irrig. Drain. 2017, 66, 340–350. [Google Scholar]

- Hirich, A.; Choukr-Allah, R.; Jacobsen, S.E. Deficit irrigation and organic compost improve growth and yield of quinoa and pea. J. Agron. Crop Sci. 2014, 200, 390–398. [Google Scholar]

- Hirich, A.; Choukr-Allah, R.; Jacobsen, S.E. Quinoa in Morocco–effect of sowing dates on development and yield. J. Agron. Crop Sci. 2014, 200, 371–377. [Google Scholar]

- Hirich, A.; Choukr-Allah, R.; Jacobsen, S.E. The combined effect of deficit irrigation by treated wastewater and organic amendment on quinoa (Chenopodium quinoa Willd.) productivity. Desal. Water Treat 2014, 52. [Google Scholar]

- Abugoch James., L.E. Quinoa (Chenopodium quinoa Willd.): Composition. chemistry. nutritional and functional properties. Adv. Food Nutr. Res. 2009, 58, 1–31. [Google Scholar]

- Graf, B.L.; Rojas-Silva, P.; Rojo, L.E.; Delatorre-Herrera, J.; Baldeón, M.E.; Raskin, I. Innovations in health value and functional food development of quinoa (Chenopodium quinoa Willd.). Compr. Rev. Food Sci. Food Saf. 2015, 14, 431–445. [Google Scholar]

- Sezgin, A.C.; Sanlier, N. A new generation plant for the conventional cuisine: Quinoa (Chenopodium quinoa Willd.). Trends Food Sci. Technol. 2019, 86, 51–58. [Google Scholar]

- El Hazzam, K.; Hafsa, J.; Sobeh, M.; Mhada, M.; Taourirte, M.; El Kacimi, K.; Yasri, A. An Insight into Saponins from Quinoa (Chenopodium quinoa Willd): A Review. Molecules 2020, 25, 1059. [Google Scholar]

- Statista. Average Price of Quinoa Worldwide from 2010 to 2019 (in U.S. Dollars per Kilogram). Statista Databas. 2020. Available online: https://www.statista.com/statistics/520974/average-price-of-quinoa-worldwide/#:~:text=Average%20global%20price%20of%20quinoa%202010%2D2019&text=The%20global%20average%20price%20of.U.S.%20dollars%20on%20average%20worldwide (accessed on 20 November 2020).

- Codex Alimentarius. Codex Standard for Quinoa—CXS 333—2019. FAO: Roma, Italy, 2019; pp. 2–4. [Google Scholar]

- Rafik, S.; Chaoui, M.; Assabban, Y.; Jazi, S.; Choukr-Allah, R.; El Gharouss, M.; Hirich, A. Quinoa value chain. adoption. and market assessment in Morocco. Environ. Sci. Poll. Res. 2020, 1–12. [Google Scholar]

- Geerts, S.; Dirk, R.; Magali, G.; Vacher, J.; Mamani, R.; Mendoza, J.; Huanca, R.; Morales, B.; Miranda, R.; Cusicanqui, J.; et al. Introducing deficit irrigation to stabilize yields of quinoa (Chenopodium quinoa Willd.). Eur. J. Agron. 2008, 28, 427–436. [Google Scholar]

- Barzegar, A.R.; Yousefi, A.; Daryashenas, A. The effect of addition of different amounts and types of organic materials on soil physical properties and yield of wheat. Plant Soil 2002, 247, 295–301. [Google Scholar]

- Chung, R.S.; Wang, C.H.; Wang, C.W.; Wang, Y.P. Influence of organic matter and inorganic fertilizer on the growth and nitrogen accumulation of corn plants. J. Plant Nutr. 2000, 23, 297–311. [Google Scholar]

- Quiroga, A.; Funaro, D.; Noellemeyer, E.; Peinemann, N. Barley yield response to soil organic matter and texture in the Pampas of Argentina. Soil Till. Res. 2006, 90, 63–68. [Google Scholar]

- Timsina, J. Can organic sources of nutrients increase crop yields to meet global food demand? Agronomy 2018, 8, 214. [Google Scholar]

- Konishi, Y.; Hirano, S.; Tsuboi, H.; Wada, M. Distribution of minerals in quinoa (Chenopodium quinoa Willd.) seeds. Biosci. Biotechnol. Biochem. 2004, 68, 231–234. [Google Scholar]

- D’Amico, S.; Jungkunz, S.; Balasz, G.; Foeste, M.; Jekle, M.; Tömösköszi, S.; Schoenlechner, R. Abrasive milling of quinoa: Study on the distribution of selected nutrients and proteins within the quinoa seed kernel. J. Cereal Sci. 2019, 86, 132–138. [Google Scholar]

- Varriano-Marston, E.; DeFrancisco, A. Ultrastructure of quinoa fruit (Chenopodium quinoa Willd). Food Struct. 1984, 3, 9. [Google Scholar]

- Präger, A.; Munz, S.; Nkebiwe, P.M.; Mast, B.; Graeff-Hönninger, S. Yield and quality characteristics of different Quinoa (Chenopodium quinoa Willd.) cultivars grown under field conditions in southwestern Germany. Agronomy 2018, 8, 197. [Google Scholar]

- Hirano, S.; Konishi, Y. Nutritional characteristics within structural part of quinoa seeds. J. Jpn. Soc. Nutr. Food Sci. 2003, 56, 283–289. [Google Scholar]

- Mhada, M.; Metougui, M.L.; El Hazzam, K.; El Kacimi, K.; Yasri, A. Variations of Saponins. Minerals and Total Phenolic Compounds Due to Processing and Cooking of Quinoa (Chenopodium quinoa Willd.) Seeds. Foods 2020, 9, 660. [Google Scholar] [CrossRef]

- Gómez-Caravaca, A.M.; Iafelice, G.; Verardo, V.; Marconi, E.; Caboni, M.F. Influence of pearling process on phenolic and saponin content in quinoa (Chenopodium quinoa Willd). Food Chem. 2014, 157, 157–174. [Google Scholar]

- Yazar, A.; Incekaya, Ç.; Sezen, S.S.; Tkin, T. Quinoa experimentation and production in Turkey. 586 Chapter 6.1.4. In State of the Art Report on Quinoa around the World in 2013; Bazile, D., Bertero, H.D., Nieto, C., Eds.; FAO. CIRAD: Santiago, Chile, 2013; pp. 466–477. [Google Scholar]

- Mercado, W.; Ubillus, K. Characterization of producers and quinoa supply chains in the Peruvian regions of Puno and Junin. Sci. Agropecu. 2017, 8, 251–265. [Google Scholar]

- Parker-Gibson. N. Quinoa: Catalyst or Catastrophe? J. Agric. Food Inf. 2015, 16, 113–122.

- Ali, O.I.; Fghire, R.; Anaya, F.; Benlhabib, O.; Wahbi, S. Physiological and morphological responses of two quinoa cultivars (Chenopodium quinoa Willd.) to drought stress. Gesunde Pflanz. 2019, 71, 123–133. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop evapotranspiration-Guidelines for computing crop water requirements. In FAO Irrigation and Drainage Paper 56; United Nations Food and Agriculture Organization; United Nations Food and Agriculture Organization: Rome, Italy, 1998; Volume 300, p. D05109. [Google Scholar]

- Gianna, V.; Montes, J.; Calandri, E.; Guzman, C. Impact of Several Variables on the Microwave Extraction of Chenopodium quinoa Willd Saponins. Int. J. Food Sci. Technol. 2012, 47, 1593–1597. [Google Scholar] [CrossRef]

- Fiallos-Jurado, J.; Pollier, J.; Moses, T.; Arendt, P.; Barriga-Medina, N.; Morillo, E.; Arahana, V.; Torres, M.; Goossens, A.; Leon-Reyes, A. Saponin Determination. Expression Analysis and Functional Characterization of Saponin Biosynthetic Genes in Chenopodium quinoa Leaves. Plant Sci. 2016, 250, 188–197. [Google Scholar] [CrossRef]

- McCabe, C.; Paulden, M.; Awotwe, I.; Sutton, A.; Hall, P. One-Way Sensitivity Analysis for Probabilistic Cost-Effectiveness Analysis: Conditional Expected Incremental Net Benefit. Pharm. Econ. 2020, 38, 135–141. [Google Scholar]

- Fairchild, K.W.; Misra, L.; Shi, Y. Using Triangular Distribution for Business and Finance Simulations in Excel. J. Financ. Educ. 2016, 42, 313–336. [Google Scholar]

- Office de Change. Morocco Import Statistic. Available online: https://services.oc.gov.ma/DataBase/CommerceExterieur/requete.htm (accessed on 15 November 2020).

| Trial Conditions | Treatments | Seed Yield (t·ha−1) of Tested Varieties | |||||||

|---|---|---|---|---|---|---|---|---|---|

| ICBA-Q1 | ICBA-Q2 | ICBA-Q3 | ICBA-Q4 | ICBA-Q5 | Titicaca | Puno | Bulk Seeds | ||

| Cultivars performance trial under controlled experimental conditions | 1.94 b | 3.40 a | 3.89 a | 1.90 b | 1.47 b | 1.63 b | |||

| Organic amendment trial under controlled experimental conditions | 0 T/ha | 2.20 a | 3.16 a | ||||||

| 5 T/ha compost | 2.34 a | 2.10 b | |||||||

| 10 T/ha compost | 2.43 a | 2.05 b | |||||||

| 20 T/ha compost | 2.31 a | 2.40 b | |||||||

| 10 T/ha manure | 2.94 ab | 1.87 b | |||||||

| 20 T/ha manure | 2.50 a | 2.23 b | |||||||

| 40 T/ha manure | 4.40 b | 2.60 ab | |||||||

| Trials under farm conditions | Rainfed | 0.74 a | 0.90 a | 0.71 a | 0.51 a | 0.63 a | 0.54 a | ||

| Irrigated without manure | 2.34 a | 2.91 a | 1.72 ab | 1.55 ab | 2.70 a | 0.85 b | |||

| Irrigated with manure | 3.31 a | 3.65 a | 1.78 b | 1.69 b | 3.26 a | 1.04 b | |||

| Plant height (cm) | |||||||||

| Cultivars performance trial under controlled experimental conditions | 125.73 a | 136.38 a | 123.18 a | 92.40 b | 79.92 b | 96.28 b | |||

| Organic amendment trial under controlled experimental conditions | 0 T/ha | 97.35 a | 75.75 a | ||||||

| 5 T/ha compost | 96.64 a | 74.72 a | |||||||

| 10 T/ha compost | 101.93 a | 81.97 a | |||||||

| 20 T/ha compost | 104.83 a | 84.94 a | |||||||

| 10 T/ha manure | 103.51 a | 76.61 a | |||||||

| 20 T/ha manure | 108.43 a | 88.72 a | |||||||

| 40 T/ha manure | 117.06 a | 86.11 a | |||||||

| Trials under farm conditions | Rainfed | 50.83 a | 52.16 a | 52.83 a | 46.05 a | 46.77 a | 42.83 a | ||

| Irrigated without manure | 115.66 ab | 127.5 a | 107.58 ab | 137.5 a | 87.66 b | 70.85 b | |||

| Irrigated with manure | 109.25 bc | 131.9 a | 121.75 b | 122.75 b | 92.91 c | 79.75 c | |||

| Dry Matter (g·plant−1) | |||||||||

| Cultivars performance trial under controlled experimental conditions | 82.83 b | 171.47 a | 95.70 b | 41.40 b | 82.54 b | 77.19 b | |||

| Organic amendment trial under controlled experimental conditions | 0 T/ha | 101.32 b | 75.62 a | ||||||

| 5 T/ha compost | 113.33 ab | 58.85 b | |||||||

| 10 T/ha compost | 119.65 ab | 56.66 b | |||||||

| 20 T/ha compost | 100.16 | 61.24 ab | |||||||

| 10 T/ha manure | 133.05 a | 55.29 b | |||||||

| 20 T/ha manure | 94.61 b | 61.48 ab | |||||||

| 40 T/ha manure | 137.94 a | 43.66 c | |||||||

| 1000 Seed Weight (g) | |||||||||

| Cultivars performance trial under controlled experimental conditions | 2.66 ab | 2.58 ab | 2.76 ab | 3.55 a | 1.73 b | 2.47 ab | |||

| Organic amendment trial under controlled experimental conditions | 0 T/ha | 5.2 a | 3.9 b | ||||||

| 5 T/ha compost | 6.5 a | 6.0 a | |||||||

| 10 T/ha compost | 5.5 a | 4.6 ab | |||||||

| 20 T/ha compost | 5.4 a | 6.1 a | |||||||

| 10 T/ha manure | 5.1 a | 5.2 ab | |||||||

| 20 T/ha manure | 5.7 a | 4.5 ab | |||||||

| 40 T/ha manure | 6.7 a | 5.6 ab | |||||||

| Machines | Description | Capacity | |

|---|---|---|---|

| Combined harvester | The cereal’s combined harvester was used to harvest quinoa with few adaptations at sieves levels to match quinoa seed size | 1.5 ha·hr−1 |  |

| Thresher | The machine can be powered by an electric or a diesel engine. It adopts axial-flow roller | 200 kg·hr−1 |  |

| Winnower | Threshing quinoa panicles results in a mixture of grains, small residues and chaffs. The mechanical winnowing consists of using a winnowing fan that creates wind that blows away the lighter chaff, while the heavier grains fall back down for recovery. | 150 kg·hr−1 |  |

| Sheller (pearling machine) | It is equipped with two motors, the first one is designed to turn a drum with a rotation speed of 750 rpm. The second one is more powerful (3000 rpm) and designed to extract the fine dust produced during the pearling process. The rotating drum is made of 80 cm long perforated inox steel and has 6 baffles distributed throughout the drum. | 200 kg·hr−1 |  |

| Cultivar | Products | Protein Content (%) | C (%) | K (%) | Mg (%) | Na (%) | P (%) | Ca (%) | Fe (mg/kg) | Zn (mg/kg) | Cu (mg/kg) | Mn (mg/kg) | Moisture (%) | Ash Content (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Puno | Raw seed | 14.42 | 44.70 | 0.98 | 0.17 | 0.09 | 0.28 | 0.17 | 57.35 | 20.54 | 5.91 | 28.22 | 8 | 3.74 |

| Processed seed | 15.39 | 44.35 | 0.53 | 0.14 | 0.06 | 0.31 | 0.09 | 61.55 | 22.30 | 4.21 | 19.73 | 7 | 2.30 | |

| Quinoa Bran | 14.99 | 46.48 | 5.67 | 0.36 | 0.11 | 0.10 | 0.55 | 101.64 | 180.85 | 13.78 | 83.78 | 7 | 18.00 | |

| Titicaca | Raw seed | 14.47 | 43.61 | 1.33 | 0.19 | 0.09 | 0.35 | 0.12 | 67.79 | 30.30 | 5.76 | 32.80 | 6 | 3.80 |

| Processed seed | 18.83 | 43.98 | 0.72 | 0.18 | 0.06 | 0.43 | 0.10 | 51.22 | 30.94 | 5.49 | 23.97 | 6 | 2.67 | |

| Quinoa Bran | 12.65 | 42.60 | 8.87 | 0.43 | 0.23 | 0.19 | 0.51 | 521.23 | 61.98 | 6.75 | 109.95 | 6 | 17.31 | |

| ICBA-Q5 | Raw seed | 12.18 | 40.40 | 1.74 | 0.20 | 0.09 | 0.18 | 0.10 | 46.51 | 26.38 | 2.48 | 32.09 | 7 | 4.85 |

| Processed seed | 11.07 | 40.20 | 1.38 | 0.16 | 0.09 | 0.18 | 0.05 | 33.99 | 27.63 | 3.80 | 28.11 | 7 | 3.50 | |

| Quinoa Bran | 14.61 | 39.36 | 6.64 | 0.77 | 0.18 | 0.19 | 0.54 | 249.04 | 68.23 | 6.02 | 110.91 | 7 | 16.69 |

| Scenarios | Production System | Yield (kg/ha) | Production Cost (MAD/kg) | Production Cost (MAD/ha) | Net Margin (MAD/ha) |

|---|---|---|---|---|---|

| Quinoa Rainfed: Scenario I (manual); Scenario II (mechanized) | Manual | 500 | 26.8 | 13,400 | 21,100 |

| Mechanized | 500 | 19.3 | 9650 | 28,850 | |

| Quinoa Irrigated with organic amendment and fertilization: Scenario III (manual); Scenario IV (mechanized) | Manual | 2000 | 16.2 | 32,195 | 101,805 |

| Mechanized | 2000 | 11.1 | 22,445 | 111,555 | |

| Barley under rainfed conditions | Mechanized | 2000 | 1.5 | 3097 | 3072 |

| Wheat under rainfed conditions | Mechanized | 3000 | 1.3 | 3914 | 6366 |

| Operation | Description | Unit | Production Scenario | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rainfed × Manual (Objective Yield: 500 kg/ha) | Rainfed × Mechanized (Objective Yield: 500 kg/ha) | Irrigated with Fertilization × Manual (Objective Yield: 2000 kg/ha) | Irrigated with Fertilization × Mechanized (Objective Yield: 2000 kg/ha) | |||||||||||

| Qty | Unit Cost | Total Cost | Qty | Unit Cost | Total Cost | Qty | Unit Cost | Total Cost | Qty | Unit Cost | Total Cost | |||

| Ploughing and soil preparation | Deep | Hour | 4 | 200 | 800 | 4 | 200 | 800 | 4 | 200 | 800 | 4 | 200 | 800 |

| Shallow | Hour | 2 | 150 | 300 | 2 | 150 | 300 | 2 | 150 | 300 | 2 | 150 | 300 | |

| Fight against bird’s attack | Manual | Day | 15 | 100 | 1500 | 15 | 100 | 1500 | 15 | 100 | 1500 | 15 | 100 | 1500 |

| Sowing | Manual/ seeder | Day /Hour | 3 | 100 | 300 | 1 | 250 | 250 | 3 | 100 | 300 | 1 | 250 | 250 |

| Irrigation and fertigation (energy, depreciation, and fertilizers) | Ha | 1 | 11795 | 11,795 | 1 | 11,795 | 11,795 | |||||||

| Thinning and weeding | First | Day | 10 | 100 | 1000 | 10 | 100 | 1000 | 10 | 100 | 1000 | 10 | 100 | 1000 |

| Second | Day | 10 | 100 | 1000 | 10 | 100 | 1000 | 10 | 100 | 1000 | 10 | 100 | 1000 | |

| Harvest | Manual | Day | 30 | 100 | 3000 | 30 | 100 | 3000 | ||||||

| Threshing | Manual | Day | 20 | 100 | 2000 | 20 | 100 | 2000 | ||||||

| Seed cleaning | Manual | Day | 15 | 100 | 1500 | 45 | 100 | 4500 | ||||||

| Seed washing | Manual | Day | 10 | 100 | 1000 | 30 | 100 | 3000 | ||||||

| Drying and sieving | Manual | Day | 10 | 100 | 1000 | 30 | 100 | 3000 | ||||||

| Harvest and threshing (combined) | Mechanized | Ha | 1 | 1800 | 1800 | 1 | 1800 | 1800 | ||||||

| Seed pearling | Mechanized | Kg | 500 | 6 | 3000 | 2000 | 2 | 4000 | ||||||

| Total (MAD) | 13,400 | 9650 | 32,195 | 22,445 | ||||||||||

| Scenario | Yield (kg·ha−1) | Price (MAD/kg) | Total Cost(MAD/ha) |

|---|---|---|---|

| Scenario I: Rainfed × manual production system | 219.50 | 29.40 | 33,500 |

| Scenario II: Rainfed × Mechanized Production System | 148.51 | 19.90 | 33,500 |

| Scenario III: Irrigated × manual Production System | 485.00 | 16.25 | 101,505 |

| Scenario IV: Irrigated × Mechanized Production System | 339.48 | 11.37 | 134,000 |

| Quinoa Product | Inputs | Description | Cost (MAD/kg) | % | |

|---|---|---|---|---|---|

| Quinoa Couscous | Raw material | Quinoa semolina | 21 | 28.14% | 80.40% |

| Quinoa flour | 39 | 52.26% | |||

| Salt | 0.004 | 0.01% | |||

| Water | Washing | 0.02 | 0.03% | 0.04% | |

| Processing | 0.002 | 0.00% | |||

| Women’s labor force | Sorting | 5 | 6.70% | 13.57% | |

| Hydration | 5 | 6.70% | |||

| Packaging | 0.12 | 0.17% | |||

| Energy | Electricity | 0.05 | 0.08% | 0.48% | |

| Gas | 0.3 | 0.40% | |||

| Transportation | 1 | 1.34% | 1.34% | ||

| Packaging | 1 kg package | 1.46 | 1.96% | 1.96% | |

| Depreciation | Dryer | 1.64 | 2.20% | 2.22% | |

| Heat-sealing machine | 0.01 | 0.01% | |||

| Total | 74.62 | 100% | 100% | ||

| Quinoa flour | Raw material (Quinoa seeds) | 50 | 87.66% | ||

| Washing water | 0.019 | 0.03% | |||

| Energy | 0.436 | 0.77% | |||

| Labor force | 1.073 | 1.88% | |||

| Packaging | 2.975 | 5.22% | |||

| Transport | 0.951 | 1.67% | |||

| Depreciation | 1.580 | 2.77% | |||

| Total | 57.03 | 100% | |||

| Quinoa processed seeds 1 kg | Raw material (Quinoa seeds) | 50 | 85.65% | ||

| Washing water | 0.02 | 0.03% | |||

| Energy | 0.45 | 0.78% | |||

| Labor force | 2.12 | 3.64% | |||

| Packaging | 3.12 | 5.34% | |||

| Transport | 1 | 1.71% | |||

| Depreciation | 1.65 | 2.83% | |||

| Total | 58.37 | 100% | |||

| Strengths | Weaknesses |

In terms of cultivation:

| At the production level:

|

| Opportunities | Threats |

|

|

| Lesson Learned | Action Taken/Needed |

|---|---|

| At the Farm Level | |

| First. more awareness should be raised among farmers. relevant government entities. private sector and general public about the economic benefits of quinoa and its potential as an alternative crop tolerant to stress and soil–climate conditions of the Rehamna region. | Several training sessions were organized for farmers. women cooperatives and extension agents about quinoa cultivation and its virtues. |

| In a process of introducing new crop such as quinoa. more technical and economic information is needed to dispel the hesitations of some farmers who are faithful to their usual practices. | Several extension material and brochures about quinoa including a farmer practical guide about quinoa cultivation were produced and shared with farmers and extension agents during organized trainings and workshops. |

| At the level of production techniques: In spite of the important peasant know-how. quinoa remains a new crop and therefore obeys a logic of adoption. which means categories of progressive farmers (willing to take risk). neutrals (those who see no objection to the introduction of quinoa) and recalcitrant (who are unwilling to question their crop rotation plan). In the first two categories. even a light training in production techniques is necessary. | Field trials conducted by students can serve as a demonstration platform before generalization. The agricultural advisers (institutional partners of the project. ONCA) should act as a link between the results of the experiments and the introduction of quinoa into the farms. |

| One of the constraints limiting quinoa production is the labor costs. which are estimated by farmers to be excessive compared to the margin generated by the sale of quinoa. | Mechanization of cropping practices is necessary to reduce labor cost including sowing. harvest. threshing. seed pearling and even packaging. Individual small farmers cannot afford those tools. thus. farmer’s organization in cooperatives or associations is considered a judicious option to acquire mechanized tools to be used collectively by the adhered farmers. Several mechanized tools including threshing. winnowing. pearling and seed washing have been locally manufactured and provided to several cooperatives. |

| Farmers in the Rehamna region usually use the harvested seeds to be sown in the next season for several years. which led to a loss of genetic performance of the initially introduced lines and therefore low germination rate and low performance are usually occurred. | Five introduced varieties (ICBA Q1–Q5) have been registered in the national germplasm catalogue and transferred to a local seed production farm (Benrim Farm) to sustain the production of high quality and homogeneous variety seeds. |

| In most of farms. quinoa is produced under an organic mode (without application of chemicals) but without certification. Therefore. organic certification is a good option to better valorize quinoa seeds in Morocco and to target international market that require such as certified products (e.g., European market). | The first group of organic quinoa producers has been created in Rehamna in 2018 formed in a first stage by 5 farmers and received organic certification in 2019. |

| At the Valorization Level (Women Cooperatives) | |

| Seed pearling and saponin removal remains the most critical post-harvest operation as the final quinoa seed quality depends on this step. In most of the cases seed pearling is performed manually. which increase the cost without reaching the saponin content threshold (0.12%) recommended by the CODEX [18]. | A pearling machine or sheller (described in the Harvest and Postharvest machines section) has been locally manufactured and preliminary results show good performance of the machine in removing saponin. Several shellers have been distributed to several farmer’s and women’s cooperatives. |

| The breakdown of quinoa-based product processing costs shows that raw materials account for more than 80% of the total costs. followed by labor. | • The reduction in the cost of raw materials can be achieved by a combination of several practices:

|

| Weak organization of the women cooperatives linked to several administrative issues mainly due to poor management of the unit. poor distribution of responsibilities. lack of operation’s records. weak coordination. opportunism. decision making. etc. | Training about best practices for cooperative governance and management has been delivered to several women cooperative members to build their managerial and leadership capacity. |

| At the Market Level | |

| The application of high prices of imported quinoa showcased in supermarkets with small quantities to the locally produced quinoa seeds constitutes a bottleneck in the quinoa marketing in Morocco. Pricing strategy should consider the price of similar products based on other cereal (e.g. couscous). import price. the production cost and the willingness price of the Moroccan consumer. The current price of locally produced quinoa seeds remains high as perceived by the Moroccan consumer. | A marketing study was performed in order to determine the psychological price of quinoa in Morocco [19]. The study indicates that the Moroccan consumer is willing to pay 4–5 USD for one kilogram of processed quinoa seeds. |

| Promotion and communication around quinoa products and virtues in Morocco still needs to be further developed. | Several promotion and communication activities were organized to showcase quinoa products including:

|

| There is a need to develop a specific and unified packaging labeled “Quinoa Rehamna” for all beneficiaries involved in the project including the “gluten free” and “organic” label. | A branding and visual identity document about “Quinoa Rehamna” brand has been elaborated and shared with relevant stakeholders. |

| For the moment. quinoa producers only commercialize their production at local fairs. weekly rural markets. cereal markets. healthy and organic food shops and individual clients (consumers. restaurants. etc.). Quinoa producers in Morocco could not market their products in the local supermarkets due to a lack of a sanitary certificate for quinoa seed processing and transformation. |

|

| Value Chain Component | Development Actions | Involved Actors |

|---|---|---|

| Agricultural inputs supply |

|

|

| Quinoa production |

|

|

| Quinoa transformation and valorization |

|

|

| Marketing and distribution |

|

|

| Consumption |

|

|

| Research and development | Further research and development activities are needed in the following subjects:

|

|

| Parameter | Unit | At UM6P Experimental Station Level | At Farm Level | Analysis Method | |

|---|---|---|---|---|---|

| Granulometric composition | Clay | % | 32.15 | 6.03 | NF X 31-107 |

| Silt | % | 26.45 | 23.54 | NF X 31-108 | |

| Sand | % | 42.34 | 70.46 | NF X 31-109 | |

| pH-water | 8.38 | 7.9 | NF ISO 10390 | ||

| Electric Conductivity (EC) 1/5 at 25 °C | mS·cm−1 | 0.19 | 0.1 | NF ISO 11265 | |

| Total limestone (CaCO3) | % | 4.83 | 0.2 | NF EN ISO 10693 | |

| Organic matter | % | 1.07 | 0.8 | NF ISO 14235 | |

| Phosphorus (P2O5) | Mg·kg−1 | 17.15 | 43.45 | NF ISO 11263 | |

| Potassium (K2O) | Mg·kg−1 | 455.45 | 216 | NFX 31-108 | |

| Ammonium (NH4+) | Mg·kg−1 | 6.45 | 10.25 | NFX 31-109 | |

| Nitrate (NO3−) | Mg·kg−1 | 7.91 | 12.50 | NFX 31-110 | |

| Parameter | Unit | At UM6P Experimental Station Level | At Farm Level | Method | ||

|---|---|---|---|---|---|---|

| pH | 9.28 | 7.91 | NM ISO 10523 | |||

| Electric conductivity at 25 °C | mS·cm−1 | 2.50 | 1.44 | IM ISO 7888 | ||

| Dry extract | g.l−1 | 1.60 | 0.92 | NM 03.7.027 | ||

| Cations | ||||||

| Potassium (K+) | meq.l−1 | 0.22 | 0.01 | Continuous Flow Analysis (CFA) | ||

| Sodium (Na+) | 14.67 | 5.40 | Continuous Flow Analysis (CFA) | |||

| Calcium (Ca2+) | 3.50 | 2.31 | Continuous Flow Analysis (CFA) | |||

| Magnesium (Mg2+) | 6.80 | 6.45 | Continuous Flow Analysis (CFA) | |||

| Anions | ||||||

| Chloride (Cl−) | meq.l−1 | 17.44 | 7.17 | Continuous Flow Analysis (CFA) | ||

| Carbonate (CO32−) | 2.40 | 0.17 | NM ISO 9963-1 | |||

| Bicarbonate (HCO3−) | 2.60 | 0.77 | NM ISO 9963-2 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hirich, A.; Rafik, S.; Rahmani, M.; Fetouab, A.; Azaykou, F.; Filali, K.; Ahmadzai, H.; Jnaoui, Y.; Soulaimani, A.; Moussafir, M.; et al. Development of Quinoa Value Chain to Improve Food and Nutritional Security in Rural Communities in Rehamna, Morocco: Lessons Learned and Perspectives. Plants 2021, 10, 301. https://doi.org/10.3390/plants10020301

Hirich A, Rafik S, Rahmani M, Fetouab A, Azaykou F, Filali K, Ahmadzai H, Jnaoui Y, Soulaimani A, Moussafir M, et al. Development of Quinoa Value Chain to Improve Food and Nutritional Security in Rural Communities in Rehamna, Morocco: Lessons Learned and Perspectives. Plants. 2021; 10(2):301. https://doi.org/10.3390/plants10020301

Chicago/Turabian StyleHirich, Abdelaziz, Sifeddine Rafik, Mohamed Rahmani, Amira Fetouab, Fatima Azaykou, Kaoutar Filali, Hayatullah Ahmadzai, Younes Jnaoui, Aziz Soulaimani, Mariam Moussafir, and et al. 2021. "Development of Quinoa Value Chain to Improve Food and Nutritional Security in Rural Communities in Rehamna, Morocco: Lessons Learned and Perspectives" Plants 10, no. 2: 301. https://doi.org/10.3390/plants10020301

APA StyleHirich, A., Rafik, S., Rahmani, M., Fetouab, A., Azaykou, F., Filali, K., Ahmadzai, H., Jnaoui, Y., Soulaimani, A., Moussafir, M., El Gharous, M., Karboune, S., Sbai, A., & Choukr-Allah, R. (2021). Development of Quinoa Value Chain to Improve Food and Nutritional Security in Rural Communities in Rehamna, Morocco: Lessons Learned and Perspectives. Plants, 10(2), 301. https://doi.org/10.3390/plants10020301