Nettle Cultivation Practices—From Open Field to Modern Hydroponics: A Case Study of Specialized Metabolites

Abstract

:1. Introduction

2. Nutritional Aspects of Nettle

3. Functional Properties and Use of Nettle

4. Cultivation of Nettle—From Open Field to Hydroponics

5. Possibilities and Challenges of Hydroponic Nettle Cultivation

5.1. Nutrient Solution Management

5.2. Suitable Hydroponics Techniques for Nettle Cultivation

5.3. Management of Hydroponic Techniques Affecting SM in Plants

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ozola, B.; Augspole, I.; Duma, M. Pigments content in different processed edible wild plants. In Proceedings of the 13th Baltic Conference on Food Science and Technology “Food, Nutrition, Well-Being”, Jelgava, Latvia, 2–3 May 2019; pp. 204–209. [Google Scholar] [CrossRef]

- Demir, E.; Turfan, N.; Özer, H.; Üstün, N.Ş.; Pekşen, A. Nutrient and bioactive substance contents of edible plants grown naturally in Salipazari (Samsun). Acta Sci. Pol.-Hortorum Cultus 2020, 19, 151–160. [Google Scholar] [CrossRef]

- Grauso, L.; De Falco, B.; Lanzotti, V.; Motti, R. Stinging nettle, Urtica dioica L.: Botanical, phytochemical and pharmacological overview. Phytochem. Rev. 2020, 19, 1341–1377. [Google Scholar] [CrossRef]

- Guil-Guerrero, J.L.; Torija-Isasa, M.E. Fatty acid profiles of Mediterranean wild edible plants. In Mediterranean Wild Edible Plants, 1st ed.; Sánchez-Mata, M.C., Tardío, J., Eds.; Springer: New York, NY, USA, 2016; pp. 173–186. [Google Scholar] [CrossRef]

- Bergquist, S.Å.; Gertsson, U.E.; Knuthsen, P.; Olsson, M.E. Flavonoids in baby spinach (Spinacia oleracea L.): Changes during plant growth and storage. J. Agric. Food Chem. 2005, 53, 9459–9464. [Google Scholar] [CrossRef] [PubMed]

- Radman, S.; Fabek, S.; Žutić, I.; Benko, B.; Toth, N. Stinging nettle cultivation in floating hydropon. Contemp. Agric. 2014, 63, 215–223. [Google Scholar]

- Đurović, S.; Pavlić, B.; Šorgić, S.; Popov, S.; Savić, S.; Petronijević, M.; Radojković, M.; Cvetanović, A.; Zeković, Z. Chemical composition of stinging nettle leaves obtained by different analytical approaches. J. Funct. Foods 2017, 32, 18–26. [Google Scholar] [CrossRef]

- Kregiel, D.; Pawlikowska, E.; Antolak, H. Urtica spp.: Ordinary plants with extraordinary properties. Molecules 2018, 23, 1664. [Google Scholar] [CrossRef] [Green Version]

- Upton, R. Stinging nettles leaf (Urtica dioica L.): Extraordinary vegetable medicine. J. Herb. Med. 2013, 3, 9–38. [Google Scholar] [CrossRef]

- Di Virgilio, N.; Papazoglou, E.G.; Jankauskiene, Z.; Di Lonardo, S.; Praczyk, M.; Wielgusz, K. The potential of stinging nettle (Urtica dioica L.) as a crop with multiple uses. Ind. Crops Prod. 2015, 68, 42–49. [Google Scholar] [CrossRef]

- De Vico, G.; Guida, V.; Carella, F. Urtica dioica (Stinging Nettle): A neglected plant with emerging growth promoter/immunostimulant properties for farmed fish. Front. Physiol. 2018, 9, 285. [Google Scholar] [CrossRef]

- Garcìa, L.M.; Ceccanti, C.; Negro, C.; De Bellis, L.; Incrocci, L.; Pardossi, A.; Guidi, L. Effect of Drying Methods on Phenolic Compounds and Antioxidant Activity of Urtica dioica L. Leaves. Horticulturae 2021, 7, 10. [Google Scholar] [CrossRef]

- Repajić, M.; Cegledi, E.; Zorić, Z.; Pedisić, S.; Elez Garofulić, I.; Radman, S.; Palčić, I.; Dragović-Uzelac, V. Bioactive Compounds in Wild Nettle (Urtica dioica L.) Leaves and Stalks: Polyphenols and Pigments upon Seasonal and Habitat Variations. Foods 2021, 10, 190. [Google Scholar] [CrossRef] [PubMed]

- Stanojević, L.P.; Stanković, M.Z.; Cvetković, D.J.; Cakić, M.D.; Ilić, D.P.; Nikolić, V.D.; Stanojević, J.S. The effect of extraction techniques on yield, extraction kinetics, and antioxidant activity of aqueous-methanolic extracts from nettle (Urtica dioica L.) leaves. Sep. Sci. Technol. 2016, 51, 1817–1829. [Google Scholar] [CrossRef]

- Đurović, S.; Zeković, Z.; Šorgić, S.; Popov, S.; Vujanović, M.; Radojković, M. Fatty acid profile of stinging nettle leaves: Application of modern analytical procedures for sample preparation and analysis. Anal. Methods 2018, 10, 1080–1087. [Google Scholar] [CrossRef]

- Biesiada, A.; Kucharska, A.; Sokół-Łętowska, A.; Kuś, A. Effect of the Age of Plantation and Harvest Term on Chemical Composition and Antioxidant Avctivity of Stinging Nettle (Urtica dioica L.). Ecol. Chem. Eng. A 2010, 17, 1061–1068. [Google Scholar]

- Radman, S.; Javornik, M.; Žutić, I.; Opačić, N.; Benko, B. Impact of different nutrient solution composition on stinging nettle growth and mineral content. In Proceedings of the VIII South-Eastern Europe Symposium on Vegetables and Potatoes 1320, Ohrid, North Macedonia, 24–26 September 2021; Acta Horticulturae: Leuven, Belgium, 2021; pp. 157–166. [Google Scholar] [CrossRef]

- Basu, A.; Basu, S.K.; Sengupta, R.; Asif, M.; Li, X.; Li, Y.; Hirani, A.; Zandi, P.; Sajad, M.; Solorio-Sánchez, F.; et al. Important Plant-Based Phytonutrients. Phytonutr. Improv. Crops 2017, 1, 1–82. [Google Scholar]

- Maggini, R.; Kiferle, C.; Pardossi, A. Hydroponic production of medicinal plants. In Medicinal Plants: Antioxidant Properties, Traditional Uses and Conservation Strategies; Pereira, A.D.M., Ed.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2014; pp. 91–116. [Google Scholar]

- Pagliarulo, C.L.; Hayden, A.L.; Giacomelli, G.A. Potential for greenhouse aeroponic cultivation of Urtica dioica. In Proceedings of the VII International Symposium on Protected Cultivation in Mild Winter Climates: Production, Pest Management and Global Competition 659, Acta Horticulturae 2004, Kissimmee, FL, USA, 25 November 2004; pp. 61–66. [Google Scholar] [CrossRef]

- Nicola, S.; Hoeberechts, J.; Fontana, E. Ebb-and-flow and floating systems to grow leafy vegetables: A review for rocket, corn salad, garden cress and purslane. In Proceedings of the VIII International Symposium on Protected Cultivation in Mild Winter Climates: Advances in Soil and Soilless Cultivation under 747, Acta Horticulturae 2006, Agadir, Morocco, 31 August 2007; pp. 585–593. [Google Scholar] [CrossRef]

- Honary, H.; Vasundhara, M.; Nuthan, D. Hydroponics and aeroponics as alternative production systems for high-value medicinal and aromatic crops: Present scenario and future prospects. J. Med. Aromat. Plant Sci. 2011, 33, 397–403. [Google Scholar]

- Hayden, A.L. Aeroponic and hydroponic systems for medicinal herb, rhizome, and root crops. HortScience 2016, 41, 536–538. [Google Scholar] [CrossRef] [Green Version]

- Gonnella, M.; Serio, F.; Conversa, G.; Santamaria, P. Production and nitrate content in lamb’s lettuce grown in floating system. Acta Hort. 2004, 644, 61–68. [Google Scholar] [CrossRef]

- Toth, N.; Borošić, J.; Fabek, S.; Benko, B.; Novak, B. Leafy vegetables grown in floating system. In Proceedings of the Book of abstracts of 43rd Croatian and 3rd International Symposium on Agriculture, Opatija, Croatia, 18–21 February 2008; p. 132. [Google Scholar]

- Petrazzini, L.L.; Souza, G.A.; Rodas, C.L.; Emrich, E.B.; Carvalho, J.G.; Souza, R.J. Nutritional deficiency in crisphead lettuce grown in hydroponics. Hortic. Bras. 2014, 32, 310–313. [Google Scholar] [CrossRef] [Green Version]

- Kowalczyk, K.; Niedzińska, M.; Przybył, J.; Metera, A.; Cetner, M.D. The effect of nutrient solution on yield, its quality and the reaction of photosynthetic apparatus of endive (Cichorium endivia) grown in hydroponics. In Proceedings of the VI Balkan Symposium on Vegetables and Potatoes 1142, Acta Horticulturae 2016, Zagreb, Croatia, 31 October 2016; pp. 335–342. [Google Scholar] [CrossRef]

- Radman, S.; Žutić, I.; Fabek, S.; Toth, N.; Benko, B.; Čoga, L. Influence of propagation method and fertilization on chemical composition and yield of stinging nettle. In Proceedings of the 51st Croatian & 11th International Symposium on Agriculture, Opatija, Hrvatska, 15–18 February 2016; pp. 192–196. [Google Scholar]

- Conversa, G.; Bonasia, A.; Lazzizera, C.; Elia, A. Soilless Cultivation System, Electrical Conductivity of Nutrient Solution, and Growing Season on Yield and Quality of Baby-Leaf Oak-Leaf Lettuce. Agronomy 2021, 11, 1220. [Google Scholar] [CrossRef]

- Rutto, L.K.; Ansari, M.S.; Brandt, M. Biomass yield and dry matter partitioning in greenhouse-grown stinging nettle under different fertilization regimes. HortTechnology 2012, 22, 751–756. [Google Scholar] [CrossRef]

- Adhikari, B.M.; Bajracharya, A.; Shrestha, A.K. Comparison of nutritional properties of Stinging nettle (Urtica dioica) flour with wheat and barley flours. Food Sci. Nutr. 2016, 4, 119–124. [Google Scholar] [CrossRef] [PubMed]

- Zeipiņa, S.; Alsiņa, I.; Lepse, L. Stinging nettle–the source of biologically active compounds as sustainable daily diet supplement. Res. Rural Dev. 2014, 20, 34–38. [Google Scholar]

- Rutto, L.K.; Xu, Y.; Ramirez, E.; Brandt, M. Mineral properties and dietary value of raw and processed stinging nettle (Urtica dioica L.). Int. J. Food Sci. 2013, 2013, 857120. [Google Scholar] [CrossRef] [Green Version]

- Çolak, S.; Çömlekcioğlu, N.; Aygan, A. Investigation of antioxidant and antimicrobial activities of Urtica dioica plant extracts. In Proceedings of the 3rd International Eurasian Conference on Biological and Chemical Sciences (EurasianBioChem 2020), Ankara, Turkey, 19–20 March 2020; p. 137. [Google Scholar]

- Kukrić, Z.Z.; Topalić-Trivunović, L.N.; Kukavica, B.M.; Matoš, S.B.; Pavičić, S.S.; Boroja, M.M.; Savić, A.V. Characterization of antioxidant and antimicrobial activities of nettle leaves (Urtica dioica L.). Acta Period. Technol. 2012, 43, 257–272. [Google Scholar] [CrossRef]

- Joshi, B.C.; Mukhija, M.; Kalia, A.N. Pharmacognostical review of Urtica dioica L. Int. J. Green Pharm. 2014, 8, 201. [Google Scholar] [CrossRef]

- Shonte, T.T.; Duodu, K.G.; De Kock, H.L. Effect of drying methods on chemical composition and antioxidant activity of underutilized stinging nettle leaves. Heliyon 2020, 6, e03938. [Google Scholar] [CrossRef]

- Paulauskienė, A.; Tarasevičienė, Ž.; Laukagalis, V. Influence of Harvesting Time on the Chemical Composition of Wild Stinging Nettle (Urtica dioica L.). Plants 2021, 10, 686. [Google Scholar] [CrossRef]

- Rafajlovska, V.; Kavrakovski, Z.; Simonovska, J.; Srbinoska, M. Determination of protein and mineral contents in stinging nettle. Qual. Life 2013, 7, 7. [Google Scholar] [CrossRef] [Green Version]

- Radman, S.; Žutić, I.; Fabek, S.; Žlabur, J.Š.; Benko, B.; Toth, N.; Čoga, L. Influence of nitrogen fertilization on chemical composition of cultivated nettle. Emir. J. Food Agric. 2015, 27, 889–896. [Google Scholar] [CrossRef] [Green Version]

- Radman, S. Influence of Nitrogen Fertilization and Cultivation Methods on the Chemical Composition of Stinging Nettle (Urtica dioica L.). Ph.D. Thesis, Faculty of Agriculture, University of Zagreb, Zagreb, Croatia, 2015. [Google Scholar]

- Chrubasik, J.E.; Roufogalis, B.D.; Wagner, H.; Chrubasik, S.A. A comprehensive review on nettle effect and efficacy profiles, Part I: Herba urticae. Phytomedicine 2007, 14, 423–435. [Google Scholar] [CrossRef] [PubMed]

- Biesiada, A.; Wołoszczak, E.; Sokόł-Łętowska, A.; Kucharska, A.Z.; Nawirska-Olszańska, A. The effect of nitrogen form and dose on yield, chemical composition and antioxidant activity of stinging nettle (Urtica dioica L.). Herba Pol. 2009, 55, 84–93. [Google Scholar]

- Carvalho, A.R.; Costa, G.; Figueirinha, A.; Liberal, J.; Prior, J.A.; Lopes, M.C.; Batista, M.T. Urtica spp.: Phenolic composition, safety, antioxidant and anti-inflammatory activities. Food Res. Int. 2017, 99, 485–494. [Google Scholar] [CrossRef] [PubMed]

- Francišković, M.; Gonzalez-Pérez, R.; Orčić, D.; Sanchez de Medina, F.; Martínez-Augustin, O.; Svirčev, E.; Mimica-Dukić, N. Chemical Composition and Immuno-Modulatory Effects of Urtica dioica L.(Stinging Nettle) Extracts. Phytother. Res. 2017, 31, 1183–1191. [Google Scholar] [CrossRef]

- Gül, S.; Demirci, B.; Başer, K.H.C.; Akpulat, H.A.; Aksu, P. Chemical composition and in vitro cytotoxic, genotoxic effects of essential oil from Urtica dioica L. Bull. Environ. Contam. Toxicol. 2012, 88, 666–671. [Google Scholar] [CrossRef]

- Otles, S.; Yalcin, B. Phenolic compounds analysis of root, stalk, and leaves of nettle. Sci. World J. 2012, 2012, 564367. [Google Scholar] [CrossRef] [Green Version]

- Grevsen, K.; Fretté, X.; Christensen, L.P. Concentration and composition of flavonol glycosides and phenolic acids in aerial parts of stinging nettle (Urtica dioica L.) are affected by high nitrogen fertilization and by harvest time. Eur. J. Hortic. Sci. 2008, 73, 20–27. [Google Scholar]

- AlShuwayeb, M.H.; Al-Khatib, A.J. Molecular and chemical therapeutic features of Urtica species. Eur. Sci. J. 2013, 9, 253–261. [Google Scholar]

- Gülçin, I.; Küfrevioǧlu, Ö.İ.; Oktay, M.; Büyükokuroǧlu, M.E. Antioxidant, antimicrobial, antiulcer and analgesic activities of nettle (Urtica dioica L.). J. Ethnopharmacol. 2004, 90, 205–215. [Google Scholar] [CrossRef]

- Modarresi-Chahardehi, A.; Ibrahim, D.; Fariza-Sulaiman, S.; Mousavi, L. Screening antimicrobial activity of various extracts of Urtica dioica. Rev. Biol. Trop. 2012, 60, 1567–1576. [Google Scholar] [CrossRef] [Green Version]

- Di Venere, D.; Gatto, M.A.; Ippolito, A.; Bianco, V.V. Antimicrobial potential of wild edible herbaceous species. In Mediterranean Wild Edible Plants, 1st ed.; Sánchez-Mata, M.C., Tardío, J., Eds.; Springer: New York, NY, USA, 2016; pp. 233–252. [Google Scholar] [CrossRef]

- Tardío, J.; de Cortes Sánchez-Mata, M.; Morales, R.; Molina, M.; García-Herrera, P.; Morales, P.; Boussalah, N. Ethnobotanical and Food Composition Monographs of Selected Mediterranean Wild Edible Plants, 1st ed.; Sánchez-Mata, M.C., Tardío, J., Eds.; Springer: New York, NY, USA, 2016; pp. 273–470. [Google Scholar] [CrossRef]

- Petrović, J.V.; Alagić, S.Č.; Tošić, S.B.; Šteharnik, M.M.; Bugarin, M.M.; Stevanović, Z.O. The content of heavy metals in the aerial parts of the common nettle and sun spurge from Oštrelj (municipality of Bor): A contribution to the examinations of plant biomonitoring and phytoremediation potentials. Zaštita Mater. 2019, 60, 105–111. [Google Scholar] [CrossRef]

- Viktorova, J.; Jandova, Z.; Madlenakova, M.; Prouzova, P.; Bartunek, V.; Vrchotova, B.; Lovecka, P.; Musilova, L.; Macek, T. Native phytoremediation potential of Urtica dioica for removal of PCBs and heavy metals can be improved by genetic manipulations using constitutive CaMV 35S promoter. PLoS ONE 2016, 11, e0167927. [Google Scholar] [CrossRef] [PubMed]

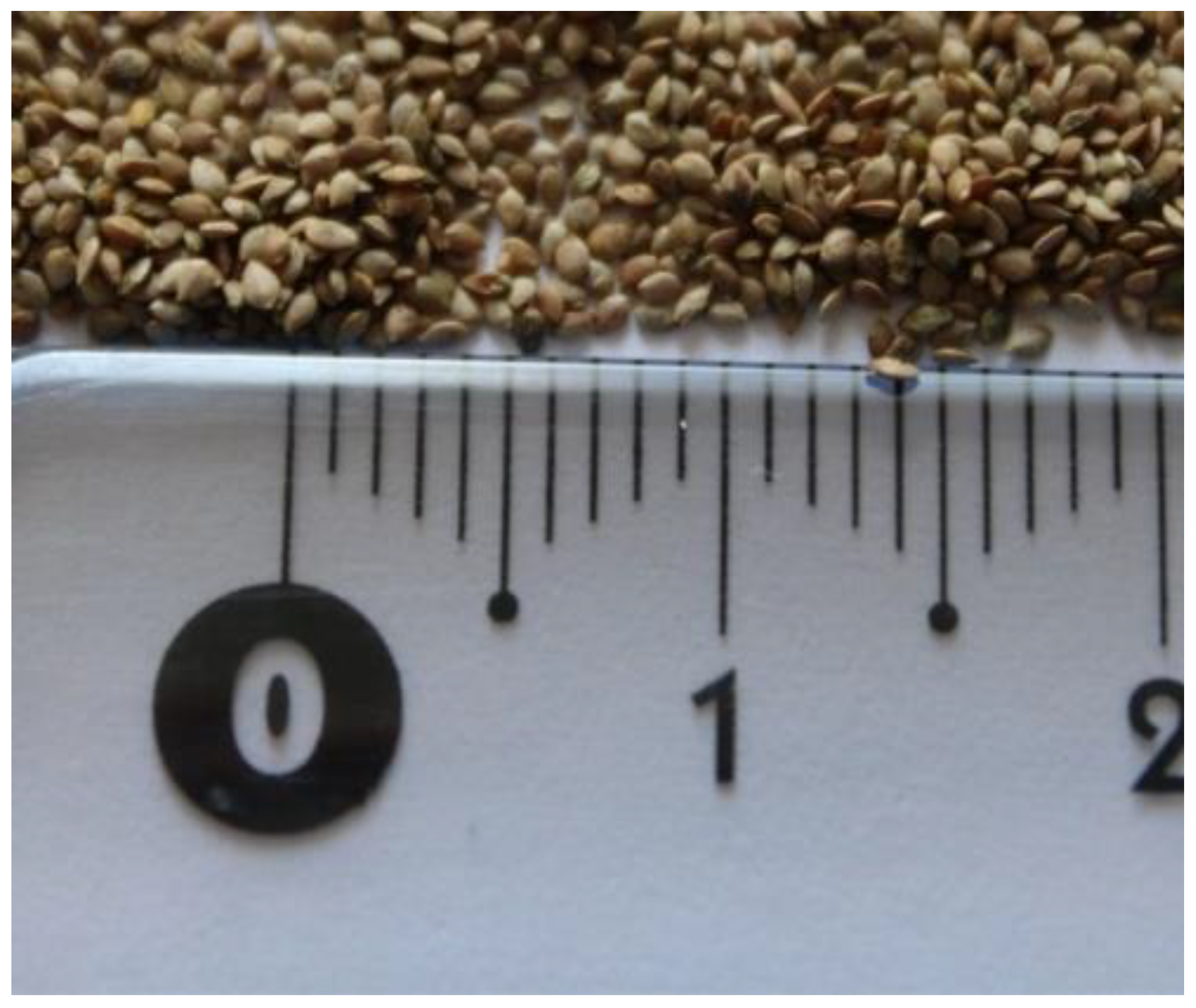

- Radman, S.; Žutić, I.; Fabek, S.; Frkin, A.; Benko, B.; Toth, N. Utjecaj temperature i svjetla na klijavost sjemena koprive. In Proceedings of the 50th Croatian & 10th International Symposium on Agriculture, Opatija, Croatia, 16–20 February 2015; p. 271. [Google Scholar]

- Stepanović, B.; Radanović, D.; Turšić, I.; Nemčević, N.; Ivanec, J. Uzgoj Ljekovitog i Aromatičnog Bilja; Jan-Spider: Pitomača, Croatia, 2009; pp. 243–245. [Google Scholar]

- An Official Website of the European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32002R0563 (accessed on 20 December 2021).

- Başgel, S.; Erdemoğlu, S.B. Determination of mineral and trace elements in some medicinal herbs and their infusions consumed in Turkey. Sci. Total Environ. 2006, 359, 82–89. [Google Scholar] [CrossRef] [PubMed]

- Tomasi, N.; Pinton, R.; Dalla Costa, L.; Cortella, G.; Terzano, R.; Mimmo, T.; Scampicchio, M.; Cesco, S. New ‘solutions’ for floating cultivation system of ready-to-eat salad: A review. Trends Food Sci. Technol. 2015, 46, 267–276. [Google Scholar] [CrossRef]

- Fernández, J.A.; Orsini, F.; Baeza, E.; Oztekin, G.B.; Muñoz, P.; Contreras, J.; Montero, J.I. Current trends in protected cultivation in Mediterranean climates. Eur. J. Hortic. Sci. 2018, 83, 294–305. [Google Scholar] [CrossRef] [Green Version]

- Savvas, D.; Gruda, N. Application of soiless culture techologies in the modern greenhouse industry—A review. Eur. Hortic. Sci. 2018, 83, 280–293. [Google Scholar] [CrossRef]

- Nguyen, N.T.; McInturf, S.A.; Mendoza-Cózatl, D.G. Hydroponics: A versatile system to study nutrient allocation and plant responses to nutrient availability and exposure to toxic elements. J. Vis. Exp. JoVE 2016, 113, e54317. [Google Scholar] [CrossRef]

- Resh, H.M. Hydroponic Food Production: A Definitive Guidebook for the Advanced Home Gardner and the Commercial Hydroponic Grower, 7th ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Massa, D.; Magán, J.J.; Montesano, F.F.; Tzortzakis, N. Minimizing water and nutrient losses from soilless cropping in southern Europe. Agric. Water Manag. 2020, 241, 106395. [Google Scholar] [CrossRef]

- Šic Žlabur, J.; Radman, S.; Fabek Uher, S.; Opačić, N.; Benko, B.; Galić, A.; Samirić, P.; Voća, S. Plant Response to Mechanically-Induced Stress: A Case Study on Specialized Metabolites of Leafy Vegetables. Plants 2021, 10, 2650. [Google Scholar] [CrossRef]

- Hasan, M.; Bashir, T.; Ghosh, R.; Lee, S.K.; Bae, H. An overview of LEDs’ effects on the production of bioactive compounds and crop quality. Molecules 2017, 22, 1420. [Google Scholar] [CrossRef] [Green Version]

- Rouphael, Y.; Kyriacou, M.C.; Petropoulos, S.A.; De Pascale, S.; Colla, G. Improving vegetable quality in controlled environments. Sci. Hortic. 2018, 234, 275–289. [Google Scholar] [CrossRef]

- Körner, O.; Challa, H. Process-based humidity control regime for greenhouse crops. Comput. Electron. Agric. 2003, 39, 173–192. [Google Scholar] [CrossRef]

- Vox, G.; Teitel, M.; Pardossi, A.; Minuto, A.; Tinivella, F.; Schettini, E. Sustainable greenhouse systems. In Sustainable Agriculture: Technology, Planning and Management; Nova Publishers: New York, NY, USA, 2010; pp. 1–79. [Google Scholar]

- Shavrukov, Y.; Genc, Y.; Hayes, J. The use of hydroponics in abiotic stress tolerance research. In Hydroponics—A Standard Methodology for Plant Biological Researches, 1st ed.; Toshiki, A., Ed.; InTech: Rijeka, Croatia, 2012; pp. 39–66. [Google Scholar] [CrossRef]

- Sonneveld, C.; Voogt, W. Plant nutrition in future greenhouse production. In Plant Nutrition of Greenhouse Crops; Springer: Dordrecht, The Netherlands, 2009; pp. 393–403. [Google Scholar]

- Benton Jones, J., Jr. Complete Guide for Growing Plants Hydroponically; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

- Marschner, P. Marschner’s Mineral Nutrition of Higher Plants, 3rd ed.; Academic Press Elsevier: London, UK; Waltham, MA, USA; San Diego, CA, USA, 2012. [Google Scholar]

- Van Delden, S.H.; Nazarideljou, M.J.; Marcelis, L.F. Nutrient solutions for Arabidopsis thaliana: A study on nutrient solution composition in hydroponics systems. Plant Methods 2020, 16, 72. [Google Scholar] [CrossRef]

- Toth, N.; Fabek, S.; Benko, B.; Žutić, I.; Stubljar, S.; Zeher, S. Učinak abiotskih čimbenika, gustoće sjetve i višekratne berbe na prinos rige u plutajućem hidroponu. Glas. Zaštite Bilja 2012, 35, 24–34. [Google Scholar]

- Cafuta, D.; Dodig, I.; Cesar, I.; Kramberger, T. Developing a Modern Greenhouse Scientific Research Facility—A Case Study. Sensors 2021, 21, 2575. [Google Scholar] [CrossRef]

- Trejo-Téllez, L.I.; Gómez-Merino, F.C. Nutrient solutions for hydroponic systems. In Hydroponics—A Standard Methodology for Plant Biological Researches; IntechOpen: London, UK, 2012; pp. 1–22. [Google Scholar]

- AlShrouf, A. Hydroponics, aeroponic and aquaponic as compared with conventional farming. Am. Sci. Res. J. Eng. Technol. Sci. (ASRJETS) 2017, 27, 247–255. [Google Scholar]

- Putra, P.A.; Yuliando, H. Soilless culture system to support water use efficiency and product quality: A review. Agric. Agric. Sci. Procedia 2015, 3, 283–288. [Google Scholar] [CrossRef] [Green Version]

- Erken, O.; Oztokat Kuzucu, C.; Cakir, R. Impact of different water supply levels on yield and biochemical ingridients in broccoli. Bulg. J. Agric. Sci. 2013, 19, 1009–1017. [Google Scholar]

- Cukrov, M.; Jerončić, L.; Prelogović, L. Utjecaj Kontroliranog Vodnog Stresa na Sadržaj Bioaktivnih Spojeva u Hidroponskom Uzgoju Rikole (Eruca Sativa Mill.) i Špinata (Spinacia oleracea L.); Graduate Paper Awarded with Rector Award; Faculty of Agronomy, University of Zagreb: Zagreb, Croatia, 2017. [Google Scholar]

- Waraich, E.A.; Ahmad, R.; Ashraf, M.Y. Role of mineral nutrition in alleviation of drought stress in plants. Aust. J. Crop Sci. 2011, 5, 764–777. [Google Scholar]

- Yadav, B.; Jogawat, A.; Rahman, M.D.; Narayan, O. Secondary metabolites in the drought stress tolerance of crop plants: A review. Gene Rep. 2021, 23, 101040. [Google Scholar] [CrossRef]

- Radman, S.; Ćurko, J.; Toth, N.; Fabek, S.; Čoga, L.; Žutić, I.; Benko, B. Lamb’s lettuce mineral content in floating system. Acta Hortic. 2016, 1142, 343–348. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, V.; Shahzad, B.; Ramakrishnan, M.; Sidhu, G.P.S.; Bali, A.S.; Handa, N.; Kapoor, D.; Yadav, P.; Khanna, K.; et al. Photosynthetic Response of Plants Under Different Abiotic Stresses: A Review. J. Plant Growth Regul. 2020, 39, 509–531. [Google Scholar] [CrossRef]

- De Abreu, I.N.; Mazzafera, P. Effect of water and temperature stress on the content of active constituents of Hypericum brasiliense Choisy. Plant Physiol. Biochem. 2005, 43, 241–248. [Google Scholar] [CrossRef] [PubMed]

- Selmar, D.; Kleinwächter, M. Influencing the product quality by deliberately applying drought stress during the cultivation of medicinal plants. Ind. Crops Prod. 2013, 42, 558–566. [Google Scholar] [CrossRef]

- Bloem, E.; Haneklaus, S.; Kleinwächter, M.; Paulsen, J.; Schnug, E.; Selmar, D. Stress-induced changes of bioactive compounds in Tropaeolum majus L. Ind. Crops Prod. 2014, 60, 349–359. [Google Scholar] [CrossRef]

- Ahanger, M.A.; Tomar, N.S.; Tittal, M.; Argal, S.; Agarwal, R.M. Plant growth under water/salt stress: ROS production; antioxidants and significance of added potassium under such conditions. Physiol. Mol. Biol. Plants 2017, 23, 731–744. [Google Scholar] [CrossRef]

| Mineral | Content | Method Used | Cultivation or Wild Harvest Location | Plant Part | Reference |

|---|---|---|---|---|---|

| Ca | 28,605 μg/g | US EPA, 1994 | wild harvested (Serbia) | dried leaves | [7] |

| 853–1050 mg/100 g | unknown | unknown | whole plant | [9] | |

| 3.43% | Nowosielski, 1988 | open field (Poland) | leaves | [16] | |

| 2.15–3.09% | AOAC, 1995 | floating hydroponics (Croatia) | leaves | [17] | |

| 168.77 mg/100 g | AOAC, 2005 | wild harvested (Nepal) | dry leaves powder | [31] | |

| 278–788 mg/100 g | AOAC, 2000 | open field (USA) | shoots before flowering | [33] | |

| 323 mg/100 g | AACC Int., 2000 | open field (South Africa) | leaves | [37] | |

| 3.04% | 71/250/EEC | open field (Lithuania) | leaves | [38] | |

| 2.63–5.09% | AOAC, 1995 | wild harvested (Macedonia) | leaves | [39] | |

| 5.21% | AOAC, 1995 | open field (Croatia) | leaves before flowering | [40] | |

| Fe | 150.97 μg/g | US EPA, 1994 | wild harvested (Serbia) | dried leaves | [7] |

| 227.89 mg/100 g | unknown | unknown | leaf powder | [8] | |

| 2–200 mg/100 g | unknown | unknown | whole plant | [9] | |

| 79.20–89.50 mg/kg | AOAC, 1995 | floating hydroponics (Croatia) | leaves | [17] | |

| 886–3651 mg/kg | AOAC, 1995 | open field (Croatia) | leaves | [28] | |

| 227.89 mg/100 g | AOAC, 2005 | wild harvested (Nepal) | dry leaves powder | [31] | |

| 1.2–3.4 mg/100 g | AOAC, 2000 | open field (USA) | shoots before flowering | [33] | |

| 2.5 mg/100 g | AACC Int., 2000 | open field (South Africa) | leaves | [37] | |

| 224.78 mg/kg | 73/46/EEC | open field, (Lithuania) | leaves | [38] | |

| 2765 ppm | AOAC, 1995 | open field (Croatia) | leaves before flowering | [40] | |

| 145–2717 mg/kg | AOAC, 1995 | open field (Croatia) | leaves before flowering | [41] | |

| Mg | 8699.76 μg/g | US EPA, 1994 | wild harvested (Serbia) | dried leaves | [7] |

| 0.34% | Nowosielski, 1988 | open field (Poland) | leaves | [16] | |

| 0.23–0.48% | AOAC, 1995 | floating hydroponics (Croatia) | leaves | [17] | |

| 104 mg/100 g | AACC Int., 2000 | open field (South Africa) | leaves | [37] | |

| 0.61% | 73/46/EEC | open field, (Lithuania) | leaves | [38] | |

| 2.51–3.56% | AOAC, 1995 | wild harvested (Macedonia) | leaves | [39] | |

| P | 50–265 mg/100 g | unknown | unknown | whole plant | [9] |

| 0.39% | Nowosielski, 1988 | open field (Poland) | leaves | [16] | |

| 0.41–0.49% | AOAC, 1995 | floating hydroponics (Croatia) | leaves | [17] | |

| 82.6 mg/100 g | AACC Int., 2000 | open field (South Africa) | leaves | [37] | |

| 0.82% | 71/393/EEC | open field (Lithuania) | leaves | [38] |

| Specialized Metabolite | Content | Method Used | Cultivation or Wild Harvest Location | Plant Part | Reference |

|---|---|---|---|---|---|

| Total carotenoids | 1.62 mg/g | spectrophotometry | wild harvested (Latvia) | leaves (ethanol extract) | [1] |

| 51.4–74.8 μg/g | Wills et al., 1988 | wild harvested (Spain) | leaves | [4] | |

| 5.47 mg/g | Wellburn, 1994; Dere et al., 1998; Pavlić et al., 2016 | wild harvested (Serbia) | dried leaves (96% ethanol extract) | [7] | |

| 2.95–8 mg/100 g | unknown | unknown | whole plant | [9] | |

| 33.03 mg/100 g | Castro– Puyana et al. (2017) | wild harvested (Croatia) | leaves and stalks | [13] | |

| 1.31 mg/g | Rumiñska et al., 1985 | open field (Poland) | leaves | [16] | |

| 3496.67 μg/g, db | Ranganna (2001) | wild harvested (Nepal) | dry leaves powder | [31] | |

| 0.55 mg/g | spectrophotometry | wild harvested (Latvia) | shoots | [32] | |

| 0.216–0.323 mg/g | Holm, 1954 and Van Wattstein, 1957 | wild harvested (Bosnia and Herzegovina) | leaves | [35] | |

| 15.36 mg/100 g | Strumite et al., 2015 | open field (Lithuania) | leaves | [38] | |

| 0.81–1.01 mg/g | Porra et al., 1989 | open field (Poland) | leaves | [43] | |

| β-carotene | 3.8–5.6 μg/g | Wills et al., 1988 | wild harvested (Spain) | leaves | [4] |

| 5035–7860 IU/100 g | colorimetry | open field (USA) | shoots before flowering | [33] | |

| 58,059 μg/100 g | colorimetry | open field (South Africa) | leaves | [37] | |

| Total chlorophyll | 24.13 mg/g | Wellburn, 1994; Dere et al., 1998; Pavlić et al., 2016 | wild harvested (Serbia) | dried leaves (96% ethanol extract) | [7] |

| 4.8 mg/g | unknown | wild harvested | leaves | [8] | |

| 611.19 mg/100 g | Castro–Puyana et al. (2017) | wild harvested (Croatia) | leaves and stalks | [13] | |

| 9.66 mg/g | Rumiñska et al., 1985 | open field (Poland) | leaves | [16] | |

| 1.02–1.174 mg/g | Holm, 1954 and Van Wattstein, 1957 | wild harvested (Bosnia and Herzegovina) | leaves | [35] | |

| 2.17 mg/g | spectrophotometry | wild harvested (Latvia) | shoots | [32] | |

| 8.03–9.45 mg/g | Porra et al., 1989 | open field (Poland) | leaves | [43] | |

| Chlorophyll a | 5.56 mg/g | spectrophotometer | wild harvested (Latvia) | leaves (ethanol extract) | [1] |

| 16.55 mg/g | Wellburn, 1994; Dere et al., 1998; Pavlić et al., 2016 | wild harvested (Serbia) | dried leaves (96% ethanol extract) | [7] | |

| 0.698–0.882 mg/g | Holm, 1954 and Van Wattstein, 1957 | wild harvested (Bosnia and Herzegovina) | leaves | [35] | |

| 67.29 mg/100 g | Strumite et al., 2015 | open field (Lithuania) | leaves | [38] | |

| Chlorophyll b | 1.84 mg/100 g | spectrophotometer | wild harvested (Latvia) | leaves (ethanol extract) | [1] |

| 7.58 mg/g | Wellburn, 1994; Dere et al., 1998; Pavlić et al., 2016 | wild harvested (Serbia) | dried leaves (96% ethanol extract) | [7] | |

| 0.285–0.320 mg/g | Holm, 1954 and Van Wattstein, 1957 | wild harvested (Bosnia and Herzegovina) | leaves | [35] | |

| 29.14 mg/100 g | Strumite et al., 2015 | open field (Lithuania) | leaves | [38] | |

| Total phenolics | 128.75 mg GAE/g | unknown | unknown | leaf powder | [8] |

| 380.90 mg/100 g | Repajić et al., 2020 | wild harvested (Croatia) | leaves and stalks | [13] | |

| 14.47 mg/g | Slinghart et al., 1977 | open field (Poland) | leaves | [16] | |

| 140 mg GAE/g | Folin–Ciocalteu | wild harvested (Italy) | leaves | [12] | |

| 450.81–539.27 mg GAE/g | Folin–Ciocalteu | unknown (Serbia) | dried leaves (different extraction methods) | [14] | |

| 128.75 mg GAE/g | Ranganna, 2001 | wild harvested (Nepal) | dry leaves powder | [31] | |

| 26.78 mg GAE/g | unknown | wild harvested (Turkey) | USB extract | [34] | |

| 208.37 mg GAE/g | Folin–Ciocalteu | wild harvested (Bosnia and Herzegovina) | leaves | [35] | |

| 118.4 mg GAE/g | Folin–Ciocalteu | open field (South Africa) | leaves | [37] | |

| 8.87 mg GAE/g | Folin–Ciocalteu | open field (Lithuania) | leaves | [38] | |

| 732.49 mg GAE/100 g | Ough and Amerine, 1988 | open field (Croatia) | leaves before flowering | [40] | |

| 22.01–24.94 mg/g | Folin–Ciocalteu | open field (Poland) | leaves | [43] | |

| 7.9 g/100 g | Folin–Ciocalteu | wild harvested (Portugal) | dry aerial parts during flowering | [44] | |

| 28.42 μg/g | Orčić et al., 2014 | wild harvested (Serbia) | herb | [45] | |

| Vitamin C | 20–60 mg/100 g | unknown | unknown | whole plant | [9] |

| 8.4 mg/g | Kampfenkel et al., 1995 | wild harvested (Italy) | leaves | [12] | |

| 0.5–1.1 mg/100 g | AOAC, 2000 | open field (USA | shoots before flowering | [33] | |

| 14.2 mg/100 g | HPLC | open field (South Africa) | leaves | [37] | |

| 8.53 mg/100 g | Latimer, 2016 | open field (Lithuania) | leaves | [38] | |

| 63.75 mg/100 g | AOAC, 2002 | open field (Croatia) | leaves before flowering | [40] | |

| Antioxidant capacity | 60 mg TEAC/g | Brand-Williams et al., 1995 | wild harvested (Italy) | leaves | [12] |

| 26.5 μM Trolox/g | Re et al., 1999 | open field (Poland) | leaves | [16] | |

| 66.3% DPPH | Nuengchamnong et al., 2009 | wild harvested (Nepal) | dry leaves powder | [31] | |

| 0.85% DPPH | DPPH | wild harvested (Bosnia and Herzegovina) | leaves (ethanol extract) | [35] | |

| 65.1% DPPH | Brand-Williams et al., 1995 | open field (South Africa) | leaves | [37] | |

| 70.37% DPPH | Zeipina et al., 2015 | open field (Lithuania) | leaves | [38] | |

| 1936.58 mM Trolox/L | Miller et al., 1993; Re et al., 1999 | open field (Croatia) | leaves before flowering | [40] | |

| 10.95–11.80 μM Trolox/g | Re et al., 1999 | open field (Poland) | leaves | [43] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Opačić, N.; Radman, S.; Fabek Uher, S.; Benko, B.; Voća, S.; Šic Žlabur, J. Nettle Cultivation Practices—From Open Field to Modern Hydroponics: A Case Study of Specialized Metabolites. Plants 2022, 11, 483. https://doi.org/10.3390/plants11040483

Opačić N, Radman S, Fabek Uher S, Benko B, Voća S, Šic Žlabur J. Nettle Cultivation Practices—From Open Field to Modern Hydroponics: A Case Study of Specialized Metabolites. Plants. 2022; 11(4):483. https://doi.org/10.3390/plants11040483

Chicago/Turabian StyleOpačić, Nevena, Sanja Radman, Sanja Fabek Uher, Božidar Benko, Sandra Voća, and Jana Šic Žlabur. 2022. "Nettle Cultivation Practices—From Open Field to Modern Hydroponics: A Case Study of Specialized Metabolites" Plants 11, no. 4: 483. https://doi.org/10.3390/plants11040483

APA StyleOpačić, N., Radman, S., Fabek Uher, S., Benko, B., Voća, S., & Šic Žlabur, J. (2022). Nettle Cultivation Practices—From Open Field to Modern Hydroponics: A Case Study of Specialized Metabolites. Plants, 11(4), 483. https://doi.org/10.3390/plants11040483