1. Introduction

Tigernut or ‘chufa’ (

Cyperus esculentus var.

sativa) is a tropical sedge that produces edible tubers commercially traded as nuts. The tubers are chewy and have a sweet taste with a nutty flavor like coconut or almond [

1,

2]. Common names vary widely among cultures around the world. Both the plant and the tubers are called several names including aki-Hausa, atadwe, aya, chufa, earth or ground almond, earth chestnut, earth nut, edible galingale, edible rush, ofio, rushnut, tigernuts, tiger nutsedge, yellow nutgrass, yellow nutsedge, zulu nut, etc. [

1,

2,

3]. Tigernut is a perennial that reproduces asexually through tuberous growth but can also reproduce sexually, albeit more rarely. Unlike the weedy form of the species known as yellow nutsedge in North America, which flowers readily in the field, the cultivated tigernut rarely flowers under New Jersey (NJ) conditions [personal observations]. Plant height ranges from 30–110 cm depending on soil fertility conditions and the plant thrives in moist loamy, sandy loam, and loamy sand soils (unpublished reports).

Tigernut has been cultivated since ancient times. It has been grown in North Africa, especially Egypt and the surrounding areas, for centuries [

4]. The tubers have been found in the tombs of Pharaohs of pre-dynastic times, about 6000 years ago [

5], and are thought to be a part of the diet of our Paleo-ancestors [

6]. A recent Oxford University publication reported that tigernuts were indeed a part of the diet of early man around the Pleistocene Epoch and consisted of about 80% of the diet [

7].

The tubers have moderate protein content (6–9%), high in lipids (28–35%) [

8,

9], and high in energy (400 kcal/100 g) [

8] compared to sweet potatoes (100 kcal/100 g), another tropical tuber crop species. Tigernut-tubers can be ground into flour to be used in baking products and make an excellent wheat flour substitute for those with Celiac disease, or those seeking a gluten-free diet [

1,

10,

11]. The tigernut oil shares a similar fatty acid profile to olive oil with high (up to 73%) monounsaturated fatty acids [

12,

13]. Oleic acid is the most abundant fatty acid in tigernut tubers and has been implicated in the reduction of heart disease, diabetes, and cancer [

14,

15,

16]. Vanillin has been found in roasted tigernut oil and is a favorable and marketable quality as it adds to the overall aroma of the oil [

13] Tigernut oil could serve as a natural alternative source of vanillin or aromatic food flavoring [

17]. Tubers are also high in vitamins C and E [

18]. In addition to all these benefits, tigernuts also contain more than the adult FAO/WHO requirements for daily protein intake [

19] and more than the requirements for 17 out of 20 amino acids. Tigernuts have low amounts of (or completely lack) the essential amino acids asparagine, glutamine, and tryptophan [

19]. In West and North Africa and in Spain, tigernut tubers are fermented and squeezed to produce the “

horchata de leche” or “

horchata de chufa”, a popular beverage in Spain and North Africa. Recent review papers and research articles described the possible use of tigernut tuber as a source of a natural anticancer drug [

20] and as an aphrodisiac [

21].

The global market for tigernut has increased significantly since 2015. Among the top 10 importing countries, importation of tigernut on average increased by 27.9% between 2015 and 2020, with an overall import value of

$1.82 B in 2020 [

22]. The United States, China, and Germany are the three leading importers of tigernuts with each country having an import share of 30.7, 16.5, and 8.7%, respectively [

22]. The United States spent

$660.5 M in 2020 on tigernut importation (

Table 1). To combat the ongoing shortages from soybean importation for vegetable oil, in 2019 Cheng [

23] reported that China may shift to tigernut production as a substitute for soybean.

In the United States, wild tigernut, popularly known as yellow nutsedge, is considered a difficult weed to manage in vegetable and field crops as well as in home or recreational lawns and turf [

24,

25,

26]. The weedy characteristics of yellow nutsedge make it highly productive and desirable to be considered as a biofuel alternative or for other applications. There is limited cultivation in some southern states primarily directed at feeding the tubers to turkeys [

27] or using them as bait for fishing [

28,

29]. The several good qualities of tigernuts and the rising economic value on the global market, make it a highly desirable crop to integrate into the agricultural economy of NJ and the mid-Atlantic for maximum benefits. The objective of this paper is to highlight the results of studies conducted at Rutgers University, New Brunswick, NJ, USA between 2008 and 2021 to evaluate the performance of tigernut selections in the hoop house and their adaptation to field cultivation in NJ.

2. Materials and Methods

2.1. Tigernut Tuber Sources

Between 2008 and 2019, tigernut tubers obtained from African markets around New Brunswick, NJ and commercial stores in New York (NY) and NJ were raised in hoop house nurseries to compare growth and productivity. Tubers were separated based on size, color, and shape and identified based on tuber source.

Table 2 describes the tigernut selections used in the hoop house and field studies between 2008 and 2021.

2.2. Hoop House Studies

The GH, MV, and SK selections (

Table 2) were the first set of tigernuts procured in 2008 from African markets in central NJ and evaluated in the hoop house at Rutgers Horticultural Farm 3 (RH3), 67 Ryders Lane, East Brunswick, NJ. These were followed in 2010 by selections NG1, NG2, NG3, and NG4 (

Table 2) also procured in African markets in central NJ. Selections OG and T-USA (

Table 2) purchased online from Organic Gemini, LLC (Brooklyn, NY, USA) and Tigernut USA, LLC (Hamilton, NJ, USA) were added to the germplasm in 2014 and 2019, respectively.

The 6 × 12 m2 hoop house used for growing tigernuts was covered with a clear double layer tube greenhouse film (6 mil gauge from Greenhouse Megastore), which was replaced every three years to sustain maximum sunlight penetration. Regulated heating units were provided to keep the hoop house above 18.3 °C during the cold months between November and May. The heating units were switched off between June and October when the ambient temperature ranged between 23.9 and 37.8 °C. Dehumidifiers were provided to regulate the relative humidity between 75 and 90% year-round. During the short daylight period between November and April, supplemental lighting was supplied using four regular incandescent lamps (Philips 65-Watt Incandescent BR30 Flood Light Bulb Soft White [2700 K]) arranged centrally approximately 2.4-m overhead and 3-m apart along the length of the hoop house. The lights were programmed to be on for 14-h per 24-h cycle. Plants were raised on 0.75-m tall 1.2 × 2.40-m2 metal benches arranged to allow free passage between benches for plant management and data collection. The hoop house was connected to the public water system for plant irrigation.

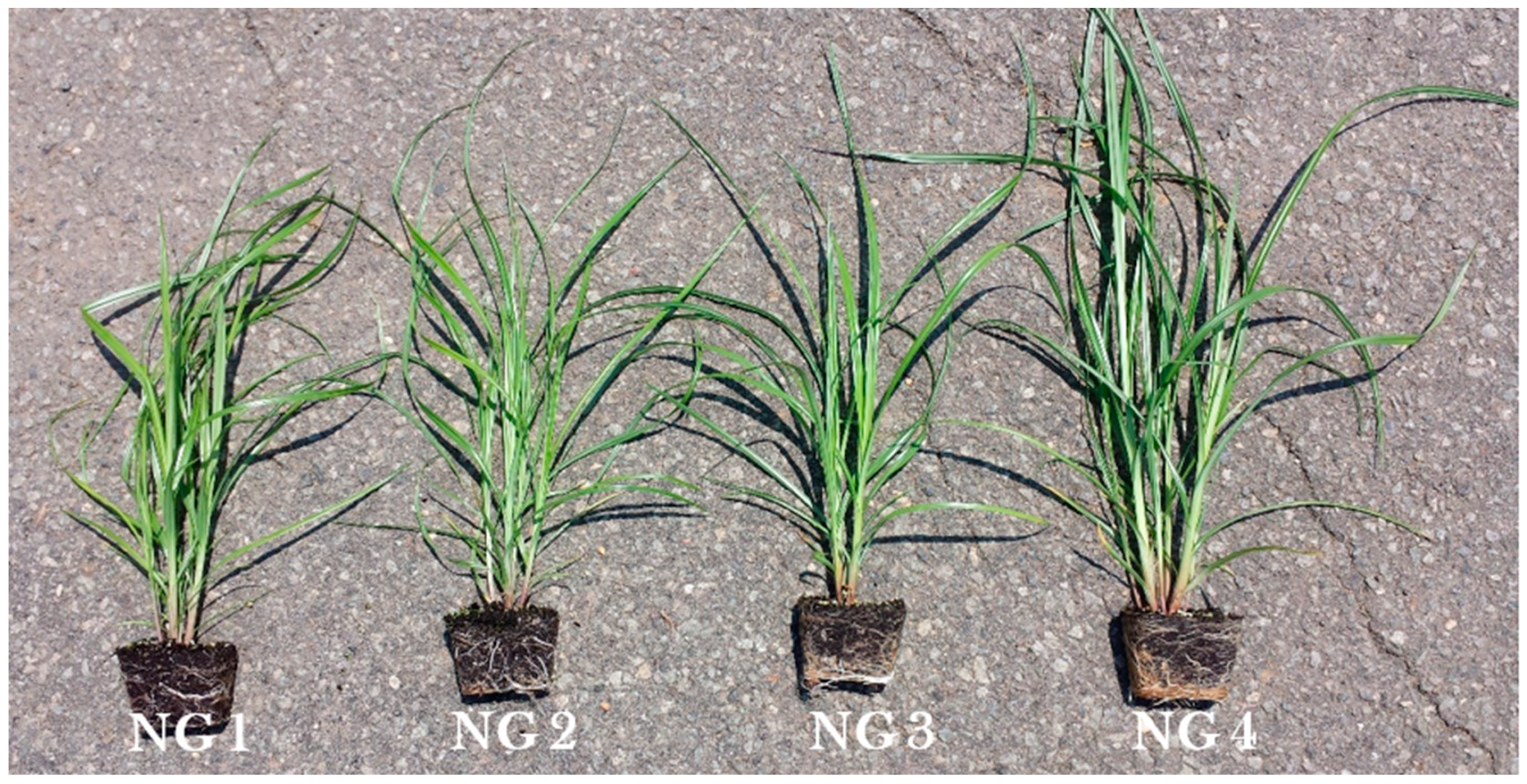

Tigernut plantlets (

Figure 1) were raised in 48-hole black plastic flats filled with the Pro-Mix BX brand (Premier Pro-Mix BX 3.8CF BL White/Black #10380RG–Griffin (

griffins.com) accessed on 27 January 2022). Both the plastic flats and the growth media were procured from the Griffin Greenhouse Supplies Company, Ewing, NJ, USA. A tuber was planted approximately 2.5 cm deep in each hole and watered adequately for four weeks before transplanting the plantlets into 20-cm diameter pots (20-cm tall), which were used for the comparative growth studies of tigernuts in the hoop house. The same media used for raising the tigernut plantlets was used for the plants grown in the 20-cm diameter pots. Peter’s soluble NPK 20-20-20 fertilizer (JR Peters Inc., Allentown, PA, USA) was applied as solution using 30 g/3.75 L (gallon) of water. Application was made at transplanting and at four and eight weeks after transplanting (WATP). At each time of fertilizer application, enough solution was applied until water started to drip at the bottom of the pot. Growth studies continued for 14–16 weeks to allow observation of plant growth habit and collection of foliage and tuber yield data. Data collected included the plant height, number of shoots per pot, foliage fresh and dry weight, number of tubers, tuber fresh weight, and the tuber yield ratio (TYR), which was defined as the tuber fresh weight divided by the foliage dry weight. Tuber distribution in the media was observed before harvesting manually using a 1/4th-inch wide wire screen to separate the tubers from the growth media. Fresh tuber weight was determined after cleaning the tuber under running water and open-air drying for 72–96 h under hoop house conditions. Foliage dry weight was determined by placing the freshly harvested foliage in a dryer set at 40 °C for 72–96 h.

2.3. Field Cultivation Studies

Tigernut may be planted in the field using the tuber directly or plantlets raised in the nursery. Due to significant variability previously observed in tuber sprouting and establishment in the field, the experiments reported in this paper were conducted using plantlets raised in hoop house nursery as described above. The use of plantlets allowed for the relatively uniform plant establishment and growth in the field. Annually, the tigernut nursery was initiated in mid- to late April to raise strong plantlets for transplanting in the field in late May to early June. Between 2014 and 2021, field evaluations of tigernut occurred in three locations in NJ, namely: (a) Rutgers Agricultural Research and Extension Center (RAREC), Bridgeton (southern NJ), (b) HF3, East Brunswick (central NJ), and (c) Specca Farms Pick-Your-Own, Bordentown (SPC-F) (central NJ). Previous observations at HF3 showed that tigernut performed much better under plastic mulch than on bare ground primarily because of suppression of weed interference, moisture conservation, and possibly temperature modulation. For this reason, the experiments reported in this paper were those conducted under black (BPM) and/or white-over-black (WPM) plastic mulch using approximately 4-week-old plantlets (or transplants) raised in the hoop house (

Figure 1).

In 2014, eight tigernut selections, namely GH, MV, NG1, NG2, NG3, NG4, OG, and SK (

Table 2) were compared at RAREC-and HF3-under BPM, and in 2020 and 2021 two selections, namely NG3 and T-USA were compared at SPC-F-under BPM and WPM mulches.

At all locations, soil tests were conducted prior to land preparation to determine the physical and chemical properties including texture, pH, organic matter (OM), N, P, K, Ca, Mg, and trace elements (Cu, Fe, Mn, Zn). Each year, between 15 and 30 May, soils were conventionally plowed and harrowed followed by fertilizer application (using the recommended rates based on soil test results), seedbed preparation (10–15 cm high and 75 cm wide at the top), and the laying of plastic mulch (black or white-over-black supplied by Griffin Farm Supplies, Ewing, NJ, USA) and trickle irrigation lines (also supplied by Griffin Farm Supplies, Ewing, NJ, USA). Distance from the center of one seedbed to the center of the next was 150 cm with a furrow of approximately 75 cm between the seedbeds. All operations were mechanized using standard farm machinery at the New Jersey Agricultural Experiment Station (NJAES).

Experimental plots were 1.5 m long and consisted of five tigernut plantlets spaced 30 cm apart along the center of the seedbed. A spacing of 90 cm separated one plot from the next along the seedbed row. Each year, between 30 May and 10 June, approximately 4-week-old tigernut plantlets were transplanted by placing them (and firmly covering them with soil) in holes made with a simple hand-pushed metallic auger, which drilled carefully through the plastic mulch. Moisture supply was primarily by natural rainfall supplemented with trickle irrigation only as needed.

Weeds that emerged around the tigernut stands were removed manually. In our studies, tigernut plants were relatively free of insect attack or disease interference. For this reason, no insect or disease control treatments were applied. Billbug (Sphenophorus pavullus Gyllenhal) infestations occurred sporadically in a few sites. This soil-borne grub attacked the young shoot at the growth point underground, too late in the season (≥8 weeks after transplanting) to allow any control treatments.

Plants were allowed to senesce and dehydrate before harvesting was initiated and this occurred between mid- to late October in NJ (about 14–16 weeks after planting). For data collection, three plants in the middle of the plot out of five in each experimental plot were harvested for foliar growth and yield determinations. After removing the plastic mulch, plants were dug up with a spade to collect 3–5 cm topsoil at the base of the plant and deposited onto a 1/4th-inch wide wire screen to manually separate tubers from the soil. This procedure was carried out when the soil was relatively dry and never done after a recent rainfall, which would make tuber separation from the soil very difficult (if not impossible). Plant foliage from the three harvested plants cut at ground level was dried in an oven set at 40 °C for 72–96 h for dry weight determination. Tubers were washed thoroughly in running water and air-dried in the hoop house for 72–96 h before measuring the tuber yield.

Figure 2 shows the typical tuber drying process in our studies.

2.4. Experimental Designs and Statistical Analysis

For the hoop house studies, the completely randomized design (CRD) was used, and replications varied between four and six depending on propagule availability. The randomized complete block design (RCBD) was used for all the field studies with three or four replications depending on propagule availability. For both the hoop house and field experiments, data were analyzed using the IBM SPSS Statistics Grad Pack Premium V26.0 and treatment means were separated using the Tukey’s honestly significant difference (HSD) at 5% level of significance.

2.5. Tuber Analysis

Proximate and elemental analyses were carried out to compare the nutritional content of tigernut tubers under black and white plastic mulches at the SPC-F site, in 2020 and 2021. Air-dried tigernut tubers from each treatment (three replications each of NG3 and T-USA selections under black and white-over-black plastic mulch) were packaged carefully and shipped to Brookside Laboratories in New Bremen, Ohio (

https://www.blinc.com/ accessed on 28 January 2022), for proximate and elemental analyses. The analytical protocols for digestible carbohydrates, digestible protein, dietary fiber, total fat, and macro- and micro-nutrients; and references are shown in

Table 3. The data were analyzed using two subsamples from the composite of the three replications of each of the tigernut selections and used as two replications for each treatment.