Concept Evaluation of Radical Short–Medium-Range Aircraft with Turbo-Electric Propulsion

Abstract

:1. Introduction

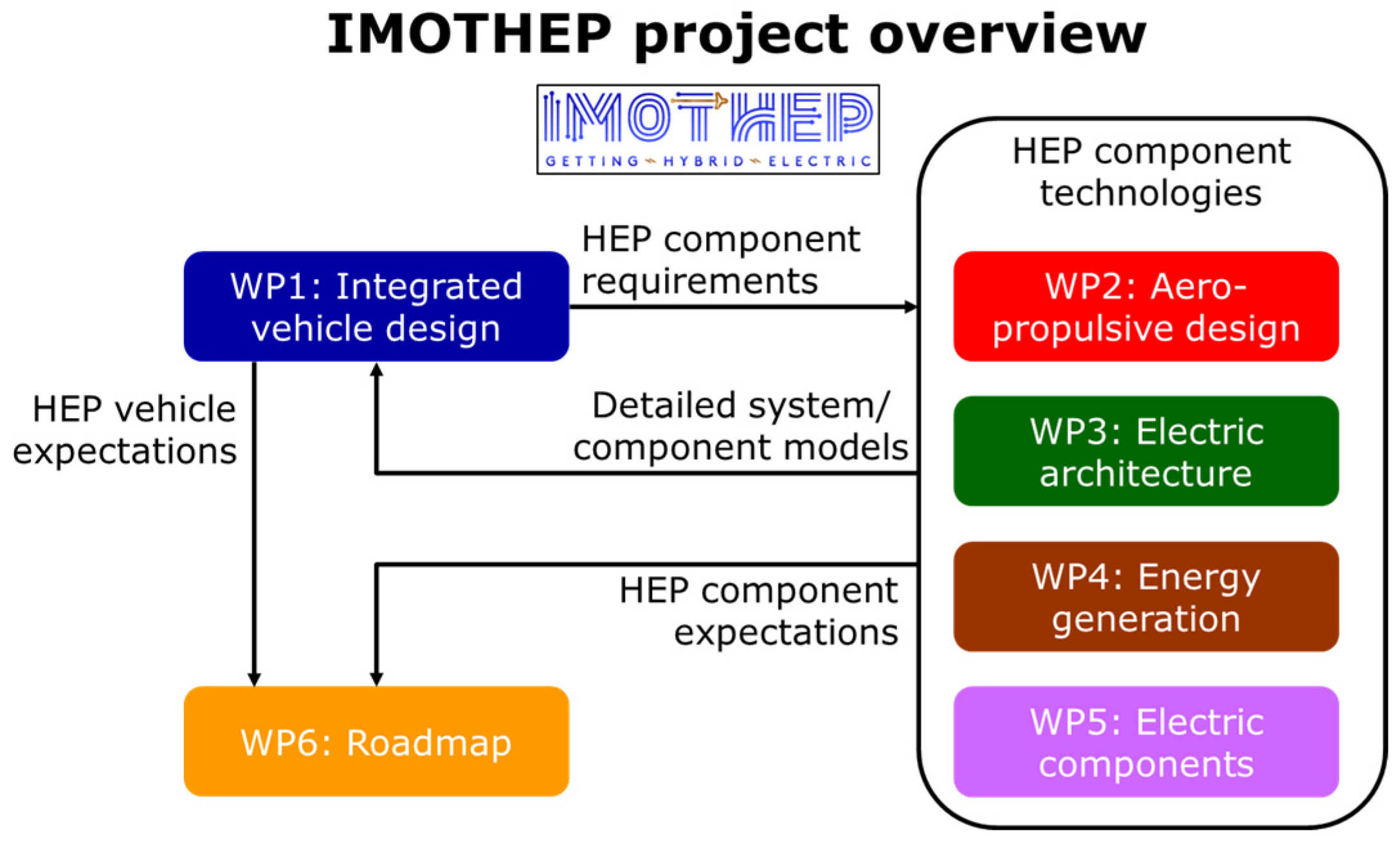

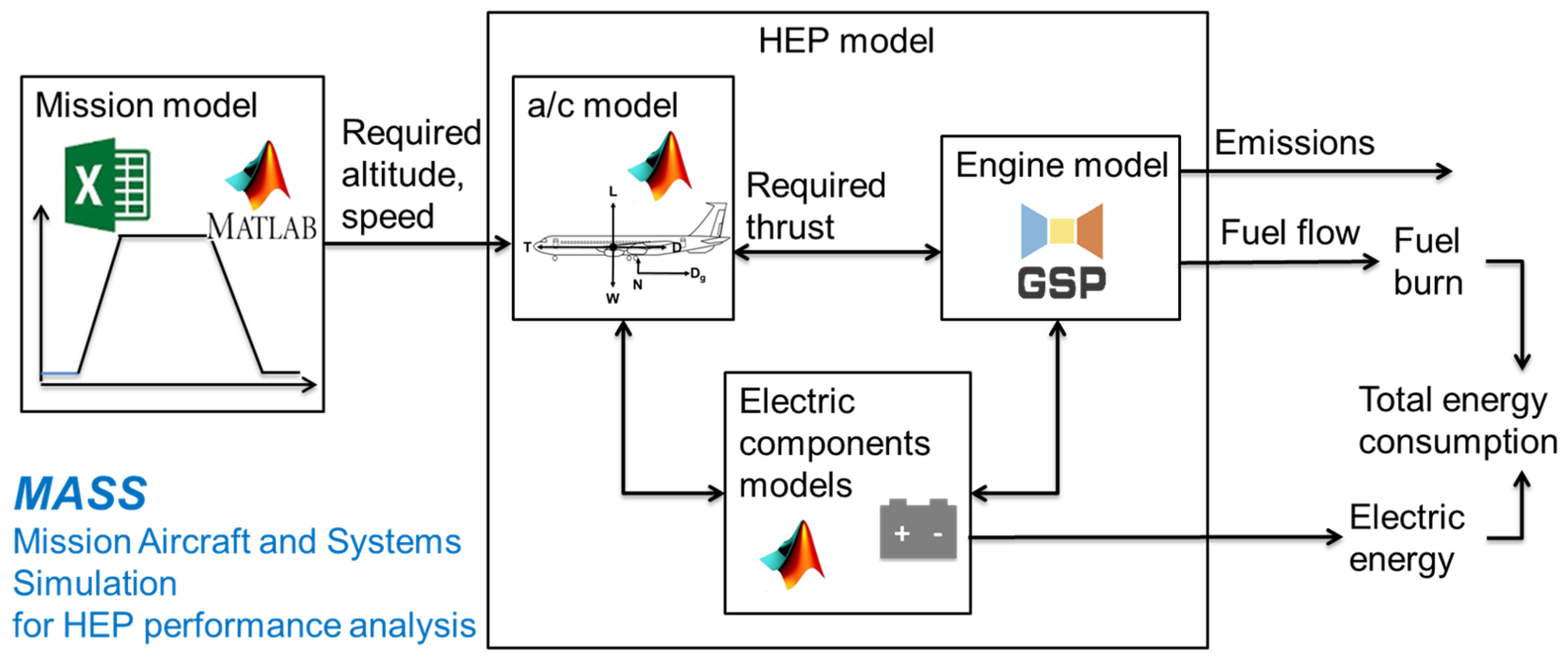

2. IMOTHEP Project Context

3. Modeling and Analysis Methods and Assumptions

- Payload:

- ○

- According to the TLARs, the design payload is 150 PAX@106 kg = 15,900 kg. The maximum payload is 20,000 kg = 189 PAX@106 kg, which is only used in some specific evaluations of the SMR configurations. A design payload of 150 PAX@106 kg = 15,900 kg will be used in all SMR evaluations.

- Range:

- ○

- The typical-range mission at design payload is evaluated, in which the distance on the ground between take-off and landing is 800 NM (1482 km).

- Atmosphere:

- ○

- In all the mission evaluations, the international standard atmosphere (ISA) [10] is assumed.

- Take-off and landing:

- ○

- In all the mission evaluations, take-off and landing are assumed at airports on sea level. Landing is assumed with idle engines; reverse thrust in landing is not considered.

- Taxi:

- ○

- The mission evaluation includes taxiing at airports, in which the taxi definitions given in CeRAS [11] are adopted: taxi-out is defined as 540 s of taxiing at a constant speed of 30 kts (15.4 m/s), yielding 8.33 km, and taxi-in is defined as 300 s of taxiing at a constant speed of 30 kts (15.4 m/s), yielding 4.63 km. The total taxi distance results in 12.96 km and will be used in all SMR evaluations.

- Fuel burn:

- ○

- The actual mission fuel burn figure that is calculated in NLR’s mission evaluation is the “Block-off/Block-on fuel”, i.e., trip fuel + taxi fuel. Here, trip fuel is the fuel consumption from brake release on take-off at the departure aerodrome to the landing touchdown at the destination, and taxi fuel is the fuel consumption during taxi-out and taxi-in. The “Block-off/Block-on fuel” will be evaluated in all the SMR-RAD evaluations of NLR.

- Reserve fuel:

- ○

- The definitions given in CeRAS for reserve fuel are as follows: reserve fuel is the sum of contingency fuel, alternate fuel, final reserve fuel, additional fuel and extra fuel, i.e., total fuel on board, minus trip fuel and taxi fuel. The reserve fuel needed for the SMR missions is calculated as follows: 5% contingency for the nominal mission fuel burn, go around, followed by 200 NM diversion at 15,000 ft altitude and 30 min hold at 1500 ft altitude.

- Cruise:

- ○

- The definition given in CeRAS for SMR cruise conditions is a Mach 0.78 flight speed at an initial altitude of 35 kft (10.7 km). This altitude is applied to the REF and BAS configurations. The 0HEP and RAD configurations will fly at their optimal altitude (between 12 and 13 km).

- Power offtake (PTO):

- ○

- The mechanical power offtake from the low-pressure turbine (LPT) shaft, for the power supply to non-propulsive on-board systems like pumps and generators, is taken into account. CeRAS applies a fixed PTO of 52 kW per engine. This value (104 kW in total) will be used in all the SMR-RAD evaluations of NLR.

- Bleed offtake:

- ○

- Bleed air offtake from the low-pressure and high-pressure compressors (LPC, HPC), for the power supply to non-propulsive on-board systems like the ECS and IPS, are taken into account. CeRAS applies a fixed bleed offtake of 0.98 kg/s per engine. This value (1.96 kg/s in total) will be used in all the SMR-RAD evaluations of NLR.

- Design range:

- ○

- A configuration is designed that is able to fulfil a mission with a range of 2750 NM (i.e., 5093 km) at the design payload (i.e., 15,900 kg).

- Design mission:

- ○

- An Initial Cruise Altitude (ICA) of 33 kft (10.06 km) at ISA + 10 conditions is fulfilled: this is assumed to be fulfilled by a cruise altitude of 35 kft (10.7 km) under ISA conditions, which is used in all design missions, which is, given density, approximately equivalent to 33 kft (10.06 km) at ISA + 10.

- Take-off field length (TOFL):

- ○

- Must be lower than 2200 m under ISA + 15 conditions: this is assumed to be fulfilled by the approximately equivalent TOFL of less than 2000 m under ISA conditions, which is used in all missions.

- Climb time:

- ○

- Must be lower than 35 min from 1500 ft (0.46 km) to 33 kft (10.06 km) under ISA + 10 conditions: this is assumed to be fulfilled by an approximately equivalent climb time of less than 35 min from 1500 ft (0.46 km) to 35 kft (10.7 km) under ISA conditions, which is used in all missions.

- Approach speed:

- ○

- Must be lower than 138 kts (71 m/s) in all missions.

- Landing distance:

- ○

- Must be lower than 1800 m in all missions.

- Typical range:

- ○

- 800 NM (1482 km) under the default cruise conditions (800 NM @ Mach 0.78, 35 kft (10.7 km); CeRAS [11]).

- Additional typical-range missions are defined:

- ○

- Default cruise conditions for max payload (20 t (20,000 kg) @ Mach 0.78, 35 kft (10.7 km)).

- One engine inoperative (OEI):

- ○

- The SMR configurations are able to fulfil a mission with one engine inoperative at maximum take-off mass (MTOM), including take-off (TO) and climb until 15 kft (4.6 km) at a climb rate greater than 100 ft/min (0.51 m/s).

- CL: The values of CL during the mission that are found from the MASS simulations should always remain below the maximum possible CL value. Because the current conceptual modeling does not include high-fidelity methods to calculate the maximum possible CL value, we estimate this value from the A320neo aircraft characteristics and mission specifications. This maximum possible CL value occurs in the low speed mission segments of take-off and landing.

- ○

- For rotation at take-off, the speed of A320neo shall be 150 kts (77.2 m/s) or more [13]. For straight-and-level flight at the MTOM (i.e., 79 t (79,000 kg) for the A320neo in REF), this leads to CL = (MTOM × g)/(Swing × 1/2ρv2) = 1.73. For the rotation, we assume that 10% extra lift is needed for a change in the flight path angle, yielding max(CL) = 1.9.

- ○

- For landing, we assume a final approach speed for A320neo of at least 131.5 kts (67.6 m/s) at maximum landing mass (MLM = 67,400 kg [13]. For straight-and-level flight, this leads to max(CL) = (MLM × g)/(Swing × 1/2ρv2) = 1.92. The SMR TLARs require an approach speed vapp < 138 kts (71 m/s), so vapp = 137 kts (70.5 m/s) is used in all missions.

- ○

- With these estimated max(CL) values, the variations in the wing area (i.e., the key design variable) shall be made such that the design constraint CL < max(CL) is always fulfilled.

- ○

- Fn (net thrust force): The maximum take-off thrust of 120 kN per engine according to the CFM-LEAP-1A type certificate [12] shall never be exceeded.

- N1 (low-pressure spool rotational speed): N1 shall remain below 101% of the maximum design speed according to the CFM-LEAP-1A type certificate [12].

- TT4 (high pressure turbine inlet temperature): TT4 shall remain below 1850 K.

4. Design Evaluations for SMR-REF

- For a SMR-REF configuration that is feasible for the design range of 2750 NM@35 kft (5093 km@10.7 km), the wing area cannot be reduced below 123 m2. The critical case is the SMR-DAS failure case “OEI at TO with MTOM”. For this SMR-REF configuration, the total mission fuel burn for the typical 800 NM mission is 4838 kg.

5. Design Evaluations for SMR-BAS

2035 Technology Assumptions

- 2035 in comparison to 2014 turbofan engine assumptions:

- ○

- A thrust-specific fuel consumption (TSFC) reduction of 7% in comparison to the 2014 CFM-LEAP-1A engine has been implemented in the SMR-BAS models, accounting mainly for the expected fan propulsive efficiency improvements (In [14], a TSFC reduction of 10% was accounted for. However, new discussions with engine specialists in the IMOTHEP project resulted in a lower reduction of 7%).

- ○

- Thrust-over-weight ratio (T/W) +3.7% in comparison to A320neo: Apply a 3.7% reduction in engine mass, i.e., ~0.037 × 3000 kg = 111 kg per engine, so a 222 kg decreased mOE has been implemented in the SMR-BAS models.

- ○

- Wetted area to be adjusted: Because UHBR engines have a larger fan diameter but a shorter length, the change in the nacelle wetted area is a bit speculative. Therefore, no change in the nacelle wetted area has been implemented in the SMR-BAS models.

- 2035 in comparison to 2014 component mass assumptions:

- ○

- Wing mass −10%: i.e., ~0.1 × 8800 kg = an 880 kg decreased mOE has been implemented in the SMR-BAS models.

- ○

- Fuselage mass −5%: ~0.05 × 8800 kg = a 440 kg decreased mOE has been implemented in the SMR-BAS models.

- ○

- Landing gear mass −15%: ~0.15 × 2200 kg = a 330 kg decreased mOE has been implemented in the SMR-BAS models.

- ○

- Pylons mass −5%: ~0.05 × 650 kg = 32.5 kg per pylon, so a 65 kg decreased mOE has been implemented in the SMR-BAS models.

- ○

- Furniture mass −25%: ~0.25 × 2440 kg = a 610 kg decreased mOE has been implemented in the SMR-BAS models.

- 2035 in comparison to 2014 aerodynamics assumptions:

- ○

- +3.3% on L/D (lift over drag): A 3% reduction applied to CD has been implemented in the SMR-BAS models.

- ○

- −5% on CD0 (zero-lift drag coefficient) of the wing: A decrease in CD0 by 5% has been implemented in the SMR-BAS models.

- ○

- −50% on CDw (wave drag coefficient): A decrease in CDw by 50% has been implemented in the SMR-BAS models.

- ○

- −10% on CDi (induced drag coefficient): A decrease in CDi by 10% has been implemented in the SMR-BAS models.

- The 2035 technology assumptions yield a total mass reduction at the aircraft level (i.e., total decreased mOE) of 2547 kg.

- For the SMR-BAS configuration, the wing area can be reduced to 107 m2. The critical case for this SMR-BAS configuration with a reduced wing area of 107 m2 is the mission evaluation for the SMR-DAS of the maximum payload (20,000 kg). For this SMR-BAS configuration, the total mission fuel burn for a typical mission is 3927 kg.

6. Design Evaluations for SMR-0HEP

6.1. SMR-0HEP Aerodynamic Characterization

6.2. SMR-0HEP Design Evaluations

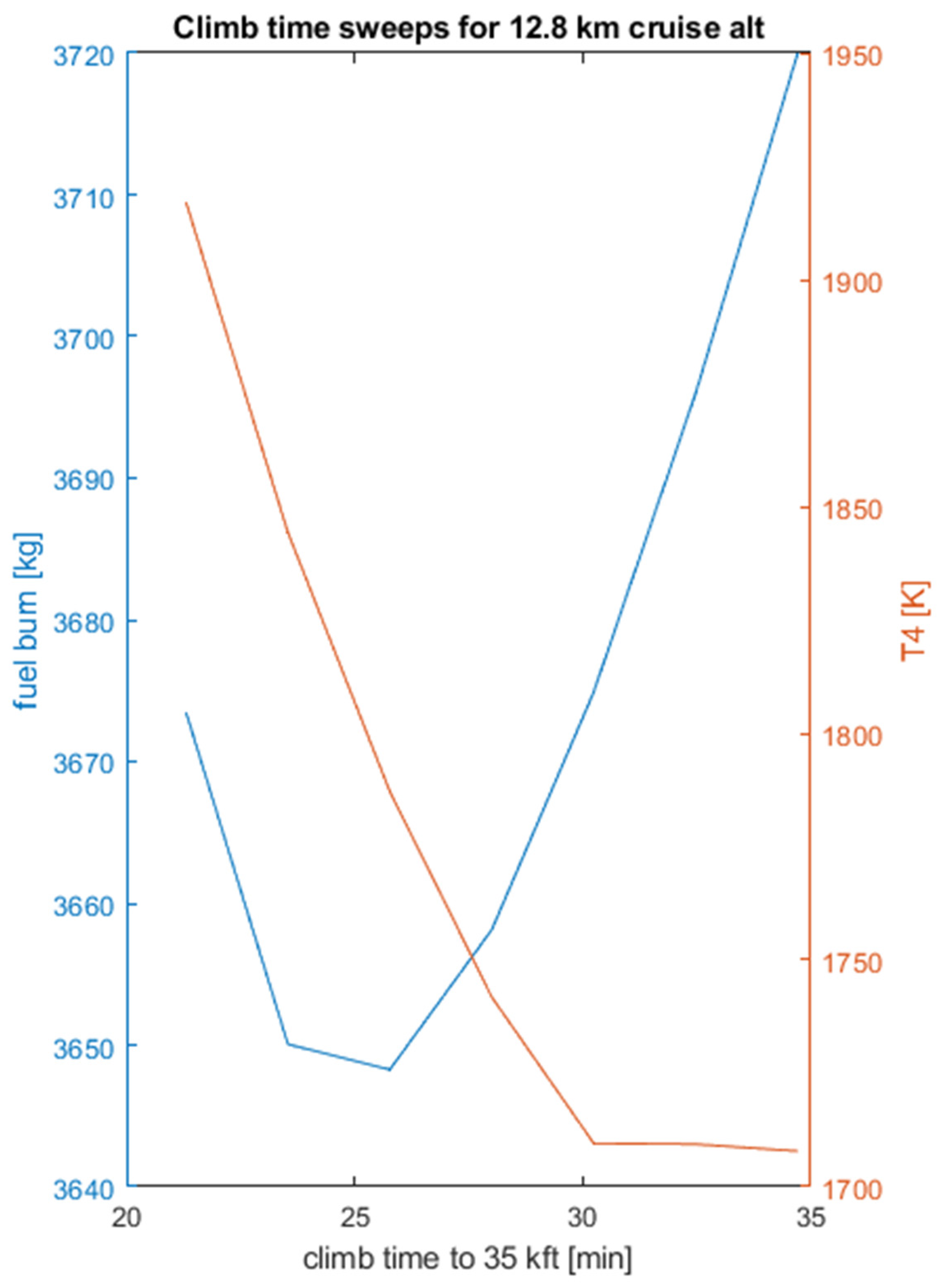

- Updated: For the SMR-0HEP configuration with an unchanged wing area of 268.6 m2, which is feasible for the design range of 2750 NM@41 kft (5093 km@12.6 km), the maximum CL required during landing for a maximum-payload (20,000 kg) mission is max(CL) = 0.70. It is assumed that this max(CL) value can be achieved with the high-lift systems installed in the SMR-0HEP configuration. The critical case is mission evaluation for the SMR-DAS for the maximum payload (20,000 kg). For this SMR-0HEP configuration, the total mission fuel burn for a typical mission is 3581 kg.

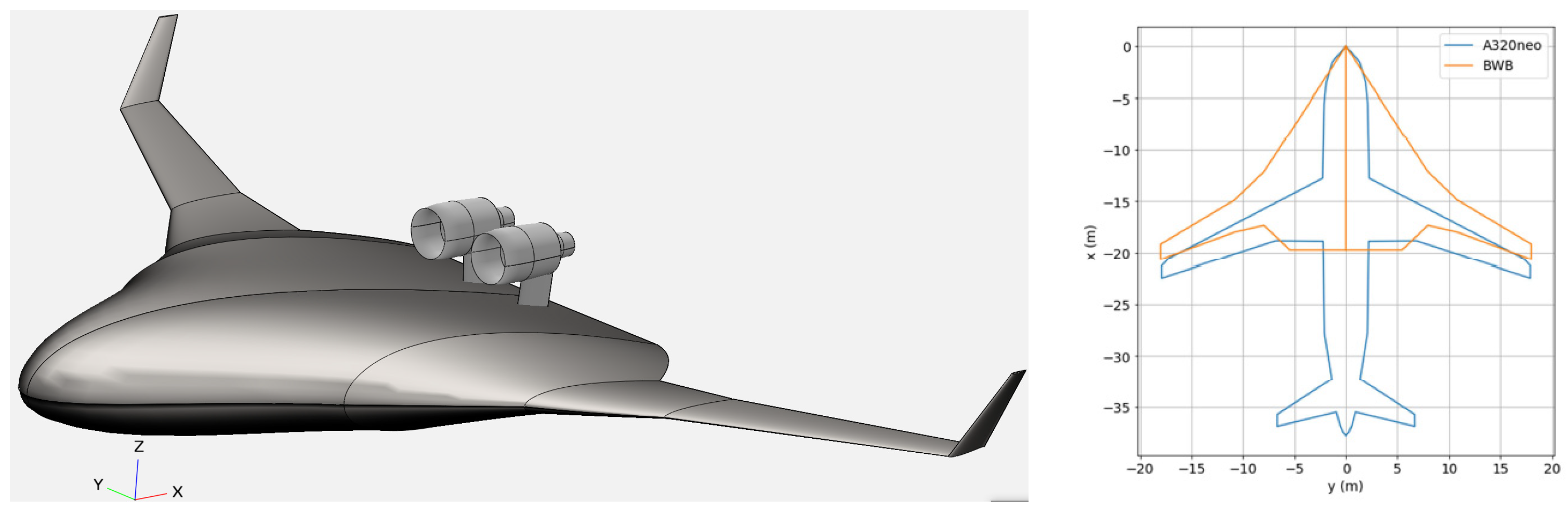

7. Design Evaluations for SMR-RAD

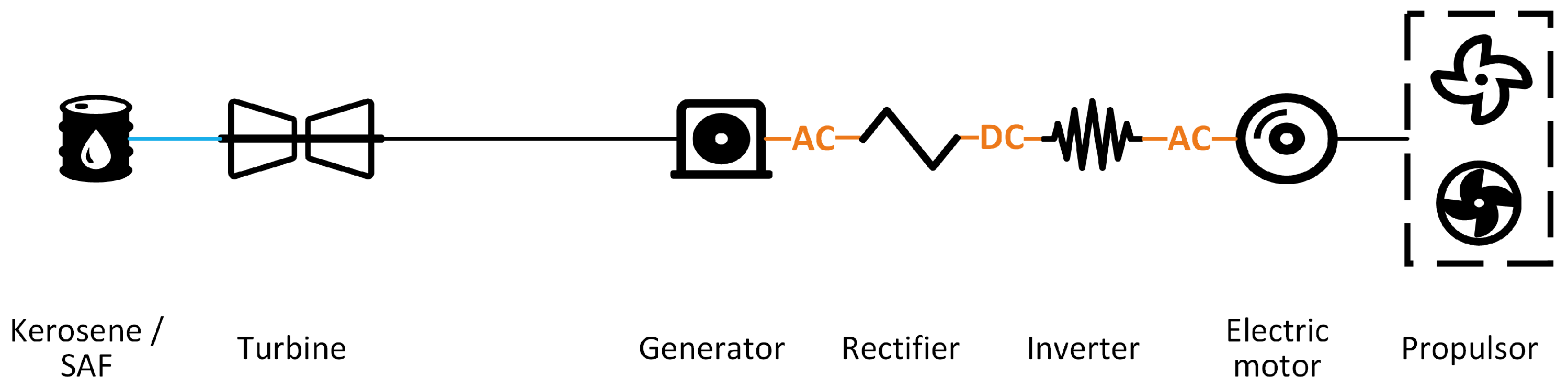

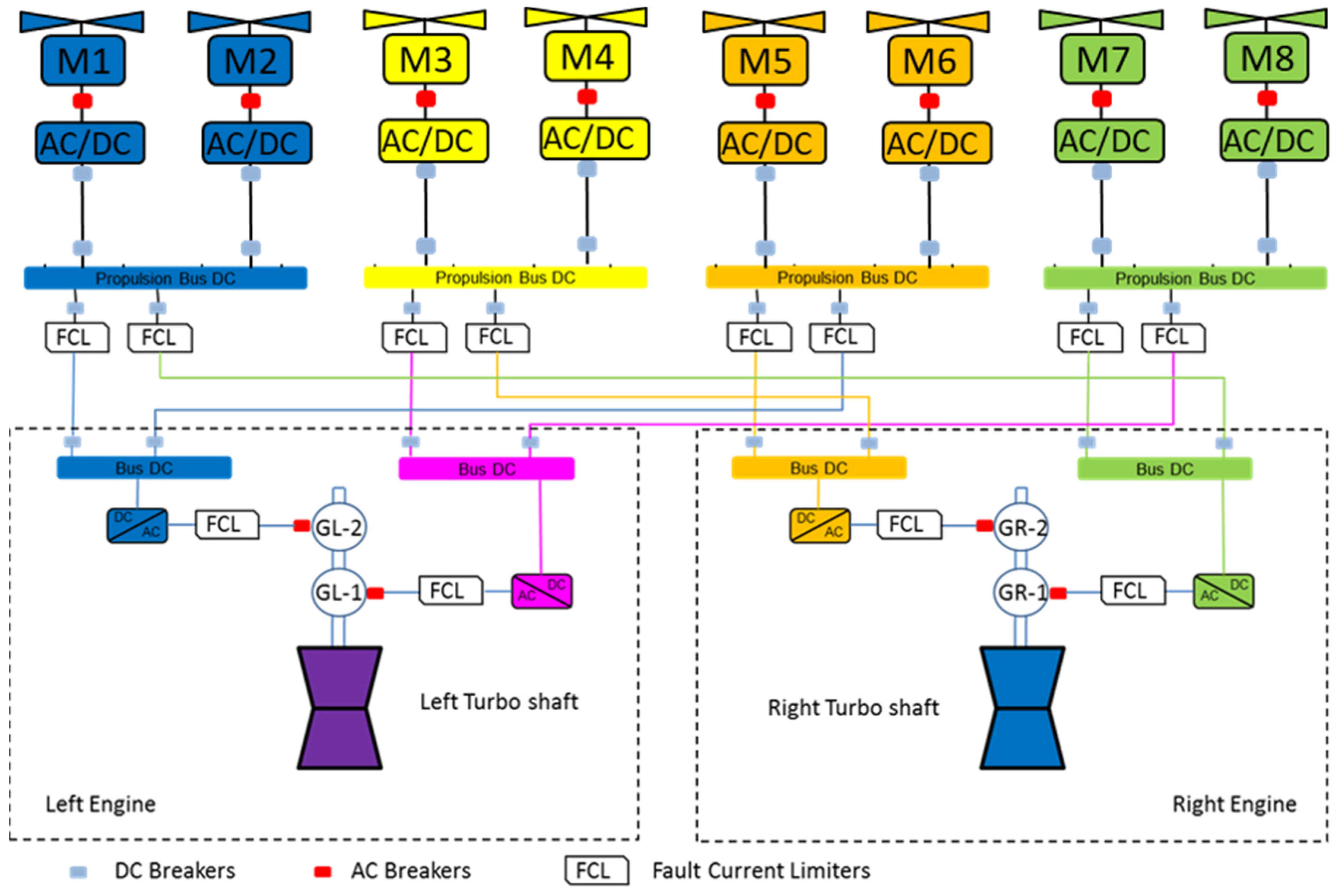

7.1. Turbo-Electric Architecture for SMR-RAD

7.2. Aerodynamic Effects for SMR-RAD

7.3. Propulsion System Mass Estimations

7.4. Energetic Efficiencies of the Propulsion System

7.5. Electric Components Models

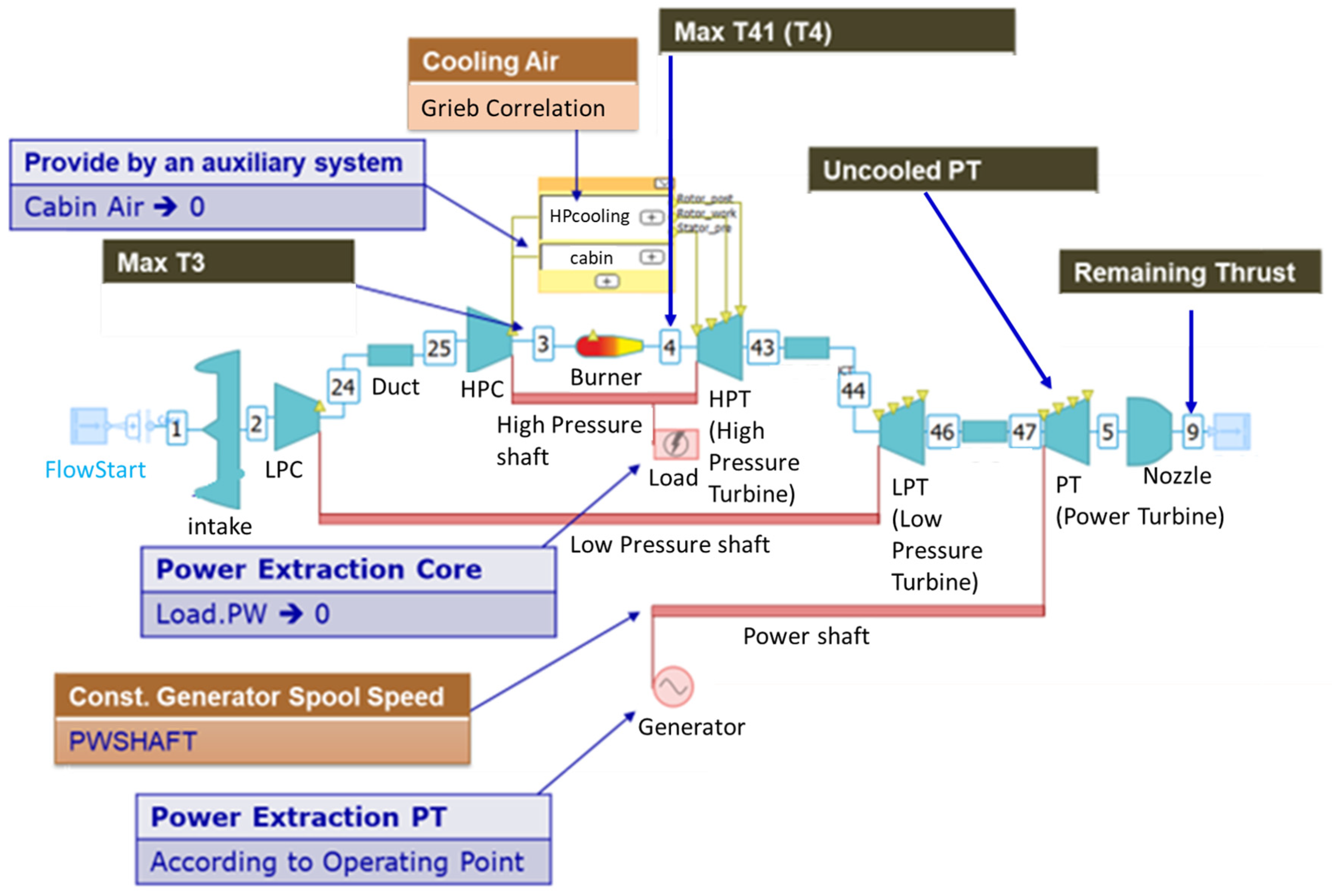

7.6. Turbo-Generator Model

- The resulting total change in the system mass at the aircraft level is estimated at −980 kg, i.e., a reduction of 980 kg.

- The total electric power requirement for all the non-propulsive systems is estimated at 350 kW during the whole flight.

7.7. Ducted Fan Modeling

7.8. SMR-RAD Longitudinal Stability

7.9. SMR-RAD Sizing and Performance Results

8. Discussion

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ANN | Artificial Neural Network |

| BAS | Baseline |

| BLI | Boundary-Layer Ingestion |

| BWB | Blended-Wing-Body |

| CeRAS | Central Reference Aircraft Data System |

| CON | Conservative |

| CS | Cooling System |

| CS2 | Clean Sky 2 |

| DEP | Distributed Electric Propulsion |

| DF | Ducted Fan |

| EG | Electric Generator |

| EIS | Entry Into Service |

| EPU | Electric Propulsion Unit |

| EM | Electric Motor |

| FPR | Fan Pressure Ratio |

| GSP | Gas Turbine Simulation Program |

| HEP | Hybrid Electric Propulsion |

| HPT | High-Pressure Turbine |

| IMOTHEP | Investigation and Maturation of Technologies for Hybrid Electric Propulsion |

| ISA | International Standard Atmosphere |

| MASS | Mission, Aircraft and Systems Simulation |

| MLM | Maximum Landing Mass |

| MTOM | Maximum Take-Off Mass |

| mOE | Operating Empty Mass |

| mTO | Take-Off Mass |

| OEI | One Engine Inoperative |

| PSFC | Power-Specific Fuel Consumption |

| PTO | Power Offtake |

| RAD | Radical |

| REG | Regional |

| REF | Reference |

| SMR | Short–Medium-Range |

| SMR-DAS | SMR Design Assumptions |

| SMR-DOCs | SMR Design Optimization Constraints |

| TAS | True Air Speed |

| TE | Turbo Electric |

| TLARs | Top Level Aircraft Requirements |

| TO | Take-Off |

| TRL | Technology Readiness Level |

| TSFC | Thrust-Specific Fuel Consumption |

| TS | Turbo Shaft |

References

- Brelje, B.; Martins, J.R.R.A. Electric, Hybrid, and Turboelectric Fixed-Wing Aircraft: A Review of Concepts, Models, and Design Approaches. Prog. Aerosp. Sci. 2019, 104, 1–19. [Google Scholar] [CrossRef]

- Salem, K.A.; Palaia, G.; Quarta, A.A. Review of hybrid-electric aircraft technologies and designs: Critical analysis and novel solutions. Prog. Aerosp. Sci. 2023, 141, 100924. [Google Scholar] [CrossRef]

- Xie, Y.; Savvarisal, A.; Tsourdos, A.; Zhang, D.; Gu, J. Review of hybrid electric powered aircraft, its conceptual design and energy management methodologies. Chin. J. Aeronaut. 2021, 34, 432–450. [Google Scholar] [CrossRef]

- Jansen, R.; Kiris, C.C.; Chau, T.; Machado, L.M.; Duensing, J.C.; Mirhashemi, A.; Chapman, J.; French, B.D.; Miller, L.; Litt, J.S.; et al. Subsonic Single Aft Engine (SUSAN) Transport Aircraft Concept and Trade Space Exploration. In Proceedings of the AIAA SciTech 2022 Forum, San Diego, CA, USA & Virtual, 3–7 January 2022. [Google Scholar] [CrossRef]

- IMOTHEP Project. Available online: https://www.imothep-project.eu/ (accessed on 9 June 2024).

- Eurocontrol, Aviation Outlook 2050, Main Report. April 2022. Available online: https://www.eurocontrol.int/sites/default/files/2022-04/eurocontrol-aviation-outlook-2050-main-report.pdf (accessed on 9 June 2024).

- Clean Sky 2 JU. Clean Sky 2 Technology Evaluator, First Global Assessment 2020, Technical Report. May 2021. Available online: https://cleansky.paddlecms.net/sites/default/files/2021-10/TE-FGA-TR_en.pdf (accessed on 9 June 2024).

- Lammen, W.F.; Vankan, W.J. Energy Optimization of Single Aisle Aircraft with Hybrid Electric Propulsion. In Proceedings of the AIAA SciTech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. NLR-TP-2020-114. [Google Scholar] [CrossRef]

- GSP. Available online: https://www.gspteam.com/ (accessed on 9 June 2024).

- ISO 2533:1975; Standard Atmosphere. International Organization for Standardization: Geneva, Switzerland, 1975.

- CeRAS-Central Reference Aircraft Data System. Available online: https://www.ilr.rwth-aachen.de/cms/ilr/forschung/projekte/abgeschlossene-projekte/~mtvz/ceras/?lidx=1 (accessed on 9 June 2024).

- European Aviation Safety Agency (EASA). Type-Certificate Data Sheet: No. E.110 for Engine LEAP-1A & LEAP-1 C Series Engines. 2018. Available online: https://www.easa.europa.eu/en/document-library/type-certificates/engine-cs-e/easae110-leap-1a-leap-1c-series-engines (accessed on 13 June 2024).

- Airbus A320 Aircraft Characteristics Airport and Maintenance Planning AC, AIRBUS S.A.S. Customer Services, Technical Data Support and Services 31707 Blagnac Cedex FRANCE, Rev: Apr 01/20. Available online: https://www.airbus.com/sites/g/files/jlcbta136/files/2021-11/Airbus-Commercial-Aircraft-AC-A320.pdf (accessed on 13 June 2024).

- Vankan, W.J.; Lammen, W.F.; Defoort, S. Conceptual design study for a radical short-medium range hybrid aircraft. In Proceedings of the 9th EUCASS, Lille, France, 27 June–1 July 2022. [Google Scholar] [CrossRef]

- Schmollgruber, P.; Donjat, D.; Ridel, M.; Cafarelli, I.; Atinault, O.; François, C.; Paluch, B. Multidisciplinary Design and performance of the ONERA Hybrid Electric Distributed Propulsion concept DRAGON. In Proceedings of the AIAA SciTech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar] [CrossRef]

- Gauvrit-Ledogar, J.; Tremolet, A.; Brevault, L. Blended Wing Body Design. In Aerospace System Analysis and Optimization in Uncertainty; Springer Optimization and Its Applications 156; Springer Nature Switzerland AG: Cham, Switzerland, 2020. [Google Scholar]

- NLR ENFLOW/ENSOLV. Available online: https://www.nlr.org/research-infrastructure/high-performance-computing/ (accessed on 9 June 2024).

- MATLAB. Available online: https://nl.mathworks.com/help/deeplearning/ref/fitnet.html (accessed on 9 June 2024).

- Felder, J.L. NASA Glenn Research Center, “NASA Hybrid Electric Propulsion Systems Structures,” Presentation to the Committee on September 1, 2015. Available online: https://nap.nationalacademies.org/read/23490/chapter/7 (accessed on 13 June 2024).

- Aalbers, V.J.E.; van Muijden, J. Low-fidelity Aerodynamic Integration of Distributed Electric Propulsion on a Blended Wing Body including Boundary Layer Ingestion. In Proceedings of the 9th European Conference for Aeronautics and Aerospace Sciences (EUCASS), Lille, France, 27 June–1 July 2022. [Google Scholar]

- Lammen, W.F.; Vankan, W.J. Conceptual design of a blended wing body aircraft with distributed electric propulsion. In Proceedings of the MEA 2021—More Electric Aircraft Conference, Bordeaux, Talence, France, 20–21 October 2021. NLR-TP-2021-510. [Google Scholar]

- Van, E.N.; Defoort, S.; Ridel, M.; Donjat, D.; Viguier, C.; Gerada, D.; Gerada, C. Design and performance evaluation of a full turboelectric distributed electric propulsion aircraft: Preliminary results of EU project IMOTHEP. In Proceedings of the EUCASS 2022, Lille, France, 27 June–1 July 2022. [Google Scholar]

- Schneider, B. Virtualization of the DLR turbine test facility NG-TURB. In Proceedings of the Deutscher Luft- und Raumfahrtkongress 2020, Cologne, Germany, 1–3 September 2020. [Google Scholar] [CrossRef]

- Vankan, W.J.; Lammen, W.F. Parallel hybrid electric propulsion architecture for single aisle aircraft—Powertrain investigation. In Proceedings of the 9th EASN Conference, Athens, Greece, 3–6 September 2019. NLR-TP-2019-358. [Google Scholar]

| TLARs | SMR |

|---|---|

| Design Range | 2750 NM (5093 km) |

| Typical Range | 800 NM (1482 km) |

| Number of PAX (Design Payload) | 150 (15,900 kg) |

| Design Cruise Mach number | 0.78 |

| Seat Pitch | 30 in (0.762 m) |

| Aircraft Component | Improvement Measure | Affected Parameter |

|---|---|---|

| Turbofan engine | Higher BPR, component improvement | TSFC −7% w.r.t. A320neo T/W +3.7% w.r.t. A320neo Wetted area to be adjusted |

| Wing | Lightweight material | Mass −10% w.r.t. 2014 |

| Fuselage | Lightweight material | Mass −5% w.r.t. 2014 |

| Landing gear | Lightweight material | Mass −15% w.r.t. 2014 |

| Pylons | Lightweight material | Mass −5% w.r.t. 2014 |

| Furniture (seats, galleys, catering, …) | Lightweight materials | Mass −25% w.r.t. 2014 |

| Aerodynamics | Morphing wing, turbulent coating, shock control, optimized winglet | +3.3% on L/D −5% on CD0 wing −50% on CDw −10% on CDi (all w.r.t. 2014). |

| SMR-0HEP: | SMR-RAD: |

|---|---|

|

|

| Single CFM-LEAP-1A: total turbofan mass: 2879 kg | Single turboshaft + power turbine: total mass: 700 + 300 kg = 1000 kg |

| Single CFM-LEAP-1A: total nacelle + auxiliary system mass: 1200 kg | Simplified diameter-specific nacelle mass for turboshaft and ducted fan: 200 kg/m Ducted fan diameter: 1.89 m Turboshaft diameter: 1.00 m |

| Single CFM-LEAP-1A: total pylon mass: 625 kg | Simplified pylon mass for turboshaft and ducted fan: (1250 kg)/(10) = 125 kg per pylon |

| Simplified fan rotor mass for ducted fan: 32 kg/m2 fan area | |

| Simplified electric component masses: calculated from powertrain component sizing |

| Parameter | IMOTHEP Loop 2 |

|---|---|

| Electric-motor-specific power [kW/kg] | 13 |

| Electric motor efficiency | 0.98 |

| Converter/inverter-specific power [kVA/kg] | 55.8 |

| Converter/inverter efficiency | 0.99 |

| Cooling-system-specific power [kW/kg] | 1.18 |

| Generator-specific power [kW/kg] | 13 |

| Generator efficiency | 0.99 |

| Cable Type | Description | Length [m] | Nr of Cables | Total Length [m] | Specific Cable Mass [kg/m] | Total Cable Mass [kg] |

|---|---|---|---|---|---|---|

| F1 (AC1) | From EG to converter (bus DC) | 2 | 2 | 4 | 19.5 | 78 |

| F2 (DC1) | From bus DC to propulsion bus DC (EPU core) | 16 | 2 | 32 | 3 | 96 |

| F3 (DC2) | From propulsion bus DC to inverter | 4 | 4 | 16 | 2.25 | 36 |

| F4 (AC2) | From inverter to EM | 2 | 8 | 16 | 2.25 | 36 |

| SMR-REF | SMR-BAS | SMR-0HEP | SMR-RAD | |

|---|---|---|---|---|

| Design 2750 NM | ||||

| Wing area [m2] | 123 | 107 | 269 | 269 |

| mOE [t] | 44.3 | 40.7 | 36.1 | 37.3 |

| mTO [t] | 78.5 | 71.2 | 64.7 | 66.3 |

| max Pshaft [MW] | 19.2 | |||

| max T4 [K] | 1815 | 1769 | 1725 | 1785 |

| max CL@landing (20 t payload) | 0.70 | 0.72 | ||

| Typical mission 800 NM | ||||

| Cruise altitude [km] | 10.7 | 10.7 | 13.2 | 12.8 |

| L/D (mid-flight) | 16.1 | 18.3 | 20.5 | 19.4 |

| Fn [kN] (mid-flight) | 39.6 | 32.4 | 26.5 | 28.7 |

| TSFC [g/kNs] (mid-flight) | 15.5 | 14.8 | 14.8 | 13.98 |

| PSFC [kg/kWh] (mid-flight) | 0.166 | |||

| Reserve fuel [kg] | 2829 | 2381 | 2108 | 2189 |

| Fuel burn [kg] | 4838 | 3927 | 3581 | 3648 |

| Fuel burn relative to REF fuel burn [%] | 100% | 81% | 74% | 75% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vankan, W.J.; Lammen, W.F.; Scheers, E.; Dewitte, P.J.; Defoort, S. Concept Evaluation of Radical Short–Medium-Range Aircraft with Turbo-Electric Propulsion. Aerospace 2024, 11, 477. https://doi.org/10.3390/aerospace11060477

Vankan WJ, Lammen WF, Scheers E, Dewitte PJ, Defoort S. Concept Evaluation of Radical Short–Medium-Range Aircraft with Turbo-Electric Propulsion. Aerospace. 2024; 11(6):477. https://doi.org/10.3390/aerospace11060477

Chicago/Turabian StyleVankan, W. J., W. F. Lammen, E. Scheers, P. J. Dewitte, and Sebastien Defoort. 2024. "Concept Evaluation of Radical Short–Medium-Range Aircraft with Turbo-Electric Propulsion" Aerospace 11, no. 6: 477. https://doi.org/10.3390/aerospace11060477

APA StyleVankan, W. J., Lammen, W. F., Scheers, E., Dewitte, P. J., & Defoort, S. (2024). Concept Evaluation of Radical Short–Medium-Range Aircraft with Turbo-Electric Propulsion. Aerospace, 11(6), 477. https://doi.org/10.3390/aerospace11060477