Precise Modeling and Analysis of Aviation Power System Reliability via the Aviation Power System Reliability Probability Network Model

Abstract

:1. Introduction

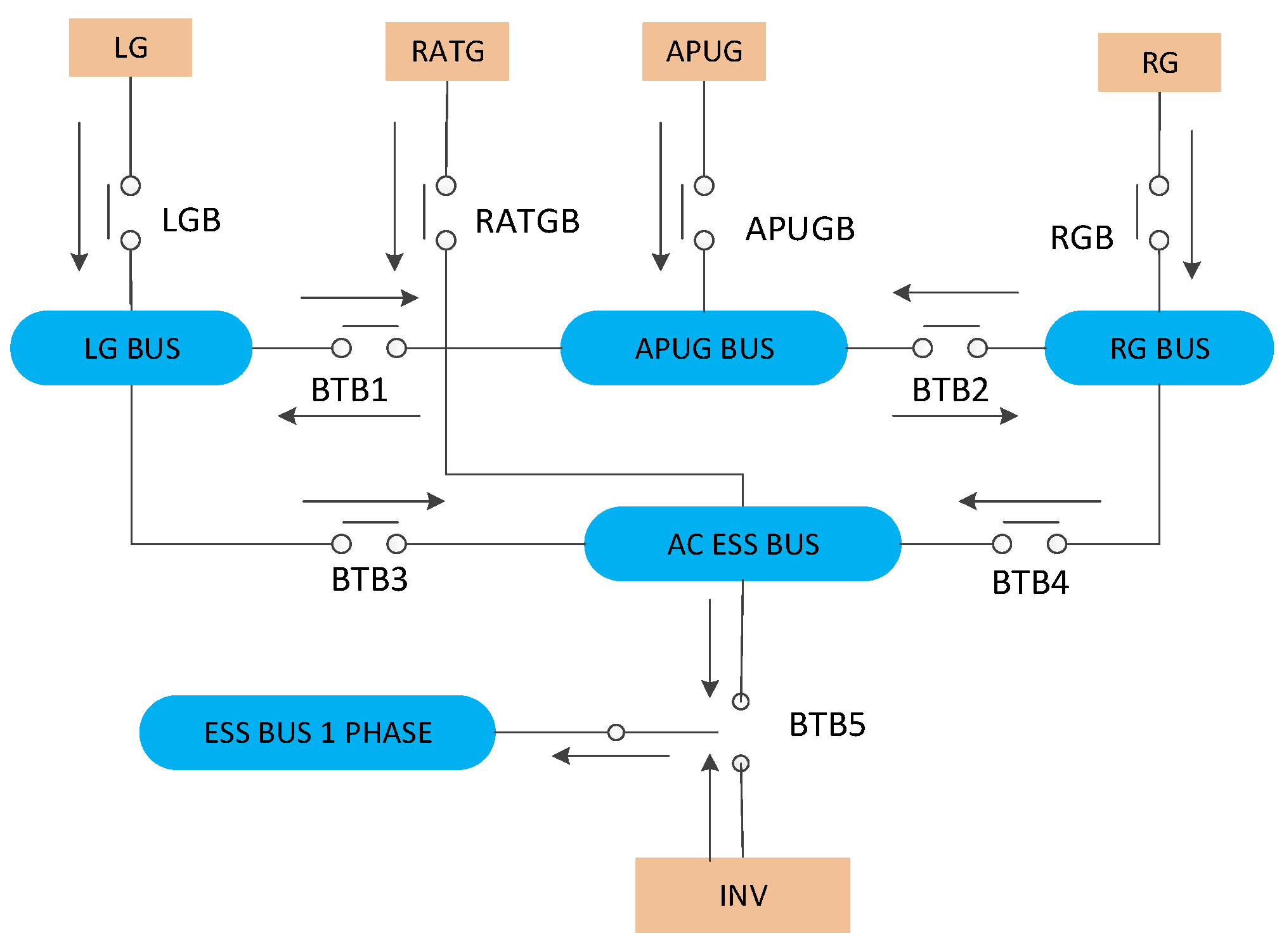

2. System Structure of the APS

2.1. Typical Structure and Function Logic of the APS

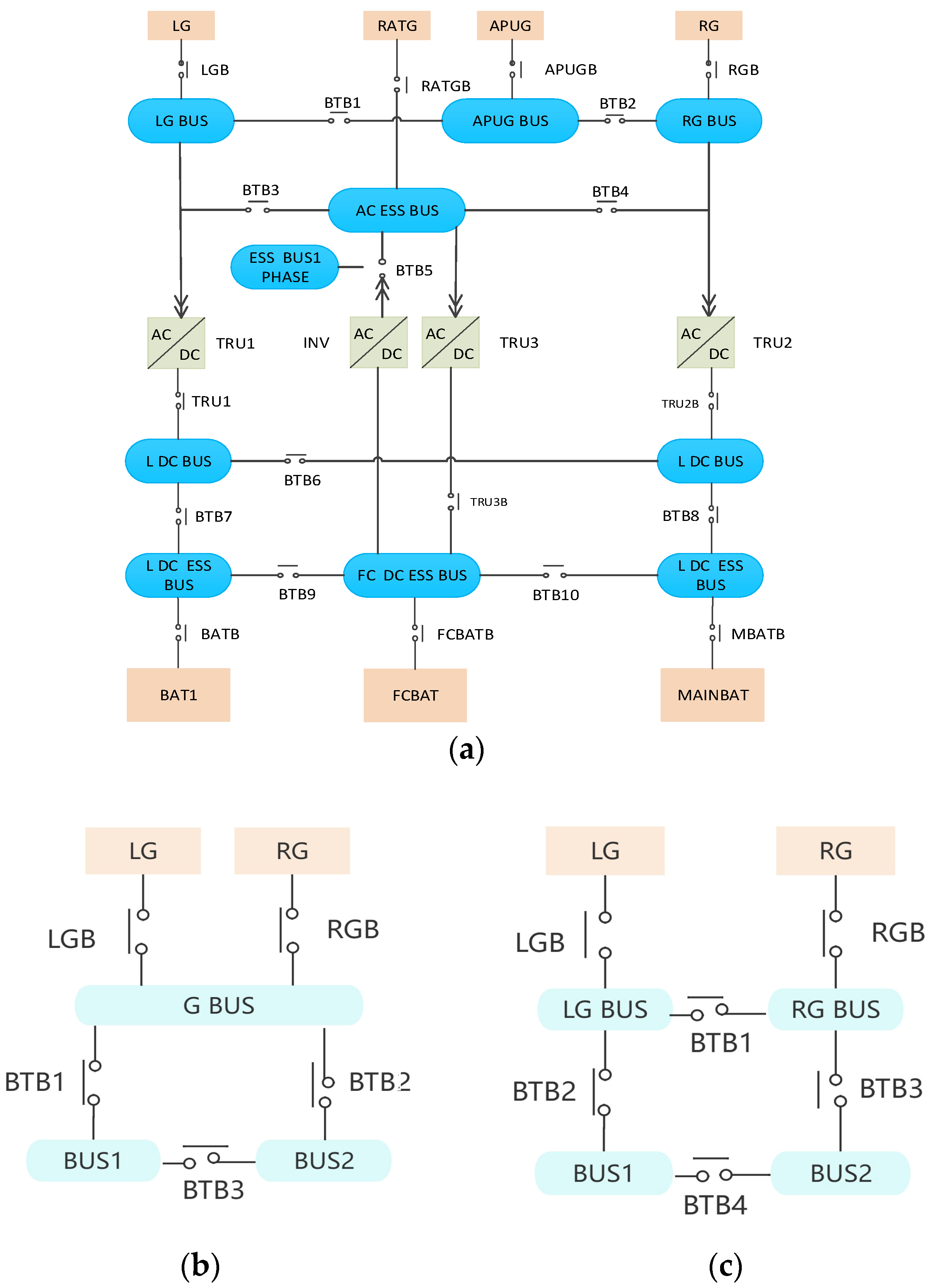

2.2. Three Basic Types of the APS Structure

- (1)

- Open-loop Configuration (Similar to Radial Configuration): As shown in Figure 1b (excluding contactor BTB3), the power in an open-loop grid is transmitted to power busbars or electrical equipment through a single channel. This configuration is structurally simple but has relatively low reliability as the power supply to electrical equipment will be lost in the case of a fault in the supply channel.

- (2)

- Closed-loop Configuration (Similar to Looped Configuration): As depicted in Figure 1b (including contactor BTB3), a closed-loop grid connects load busbars BUS1 and BUS2 through the closed BTB3, forming a “box”-shaped closed-loop structure. This configuration allows load busbars or loads to obtain power from multiple channels, achieving redundant power supply and significantly improving power supply reliability. Closed-loop grids are commonly used in parallel power supply systems.

- (3)

- Hybrid Configuration (Similar to Interconnected Configuration): As illustrated in Figure 1c, a hybrid grid combines the characteristics of open-loop and closed-loop grids. Under normal conditions, BTB1 and BTB4 are open. When a generator or contactor fails, causing power loss to a certain busbar, the corresponding contactor will close, enabling a dual-redundancy fault-tolerant power supply through a grid reconfiguration. This configuration further enhances the reliability and fault tolerance of the power supply system through flexible grid structure changes.

2.3. Redundancy and Fault-Tolerant Power Supply Requirements

3. Construction Method of APS-RPNM

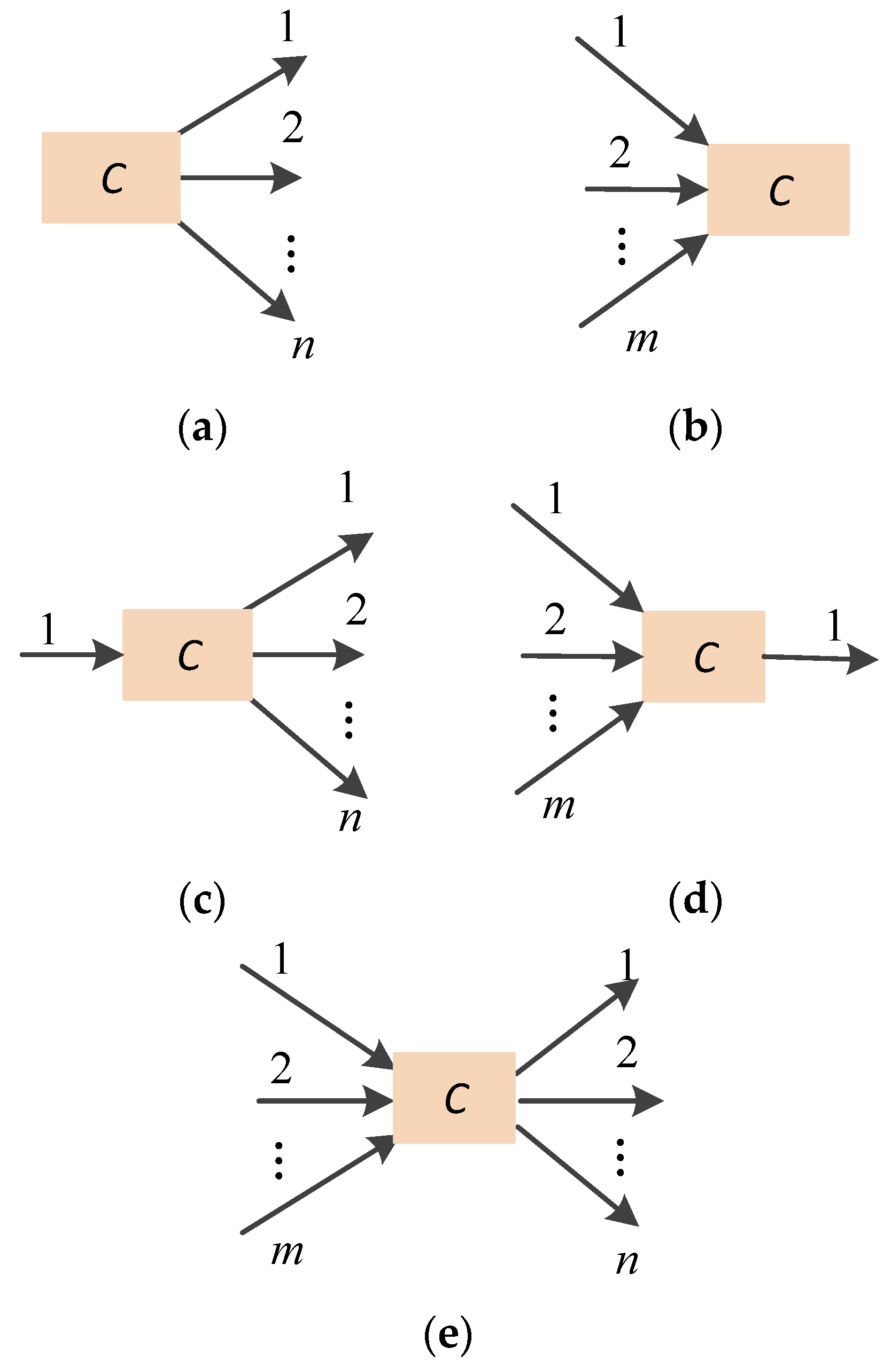

3.1. Five Types of Structure of the Components of an APS

- (1)

- None-Input-to-Multiple-Output (NIMO) structure, where m = 0 and n ≥ 1, indicating that component C receives no direct input but supplies current to multiple outputs.

- (2)

- Multiple-Input-to-None-Output (MINO) structure, where m ≥ 1 and n = 0, implying that component C receives current from multiple sources but does not directly output it to any component.

- (3)

- Single-Input-to-Multiple-Output (SIMO) structure, with m = 1 and n ≥ 1, signifying that component C has a single input source and distributes current to multiple outputs.

- (4)

- Multiple-Input-to-Single-Output (MISO) structure, where m ≥ 2 and n = 1, meaning component C receives current from multiple sources but directs it to a single output.

- (5)

- Multiple-Input-to-Multiple-Output (MIMO) structure, characterized by m ≥ 2 and n ≥ 2, indicating that component C both receives current from and supplies current to multiple components simultaneously.

3.2. Mapping Rules for Components to the Nodes of APS-RPNM

- (1)

- In the NIMO structure, if component C functions normally, it does not affect the working state of its output components. However, if component C fails, all of its output components will fail to operate properly.

- (2)

- In the MINO structure, due to the independence of component failures, if component C is in a fault state, it cannot function regardless of whether its input components are capable of providing normal current to C. Conversely, when C is in a non-fault state, it operates normally if any of its input components are capable of supplying current; otherwise, if none of the input components can provide current to C, it remains inoperable even though component C is not faulty.

- (3)

- In the MISO and SIMO structures, although the number of inputs and outputs of component C differs from that in the MINO scenario, the functional/fault logic remains identical (where, when C is in state 1 or 2, it cannot provide input current to its output components). Therefore, for component C in these two structures, the same three-state node and conditional probability distribution as in case (2) are constructed.

- (4)

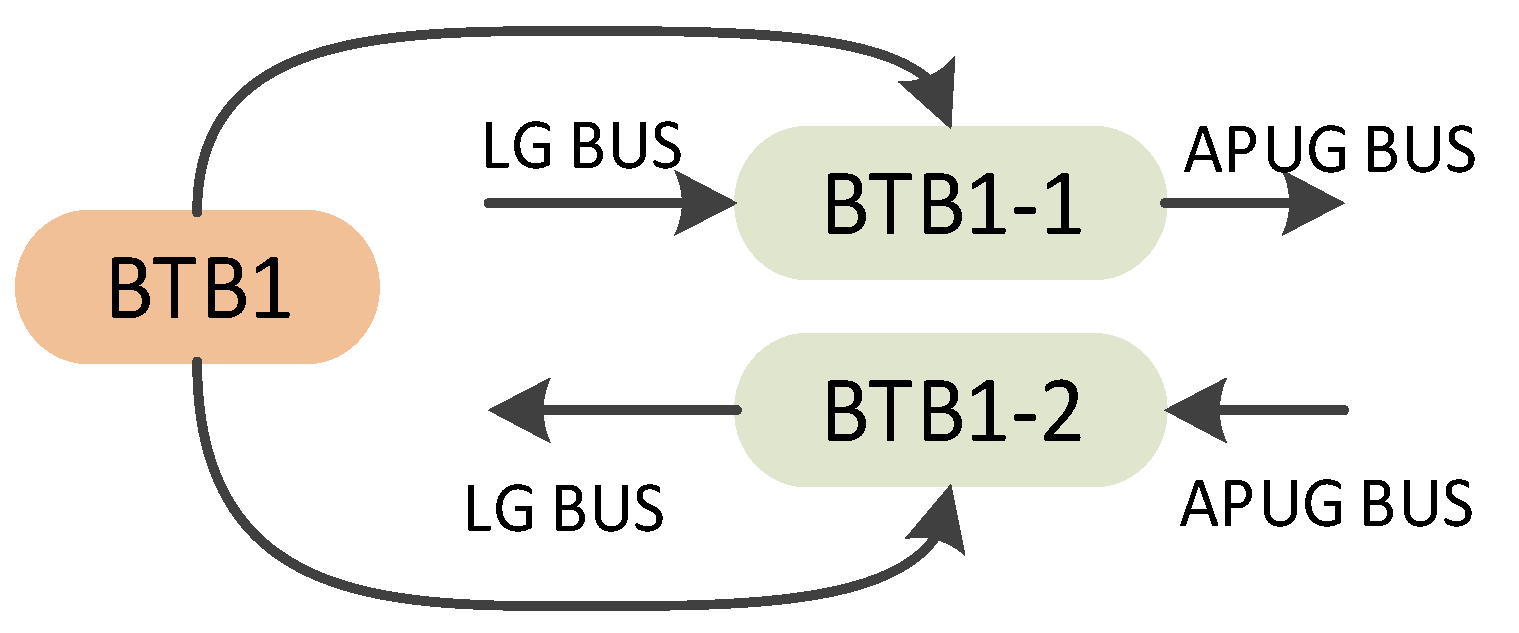

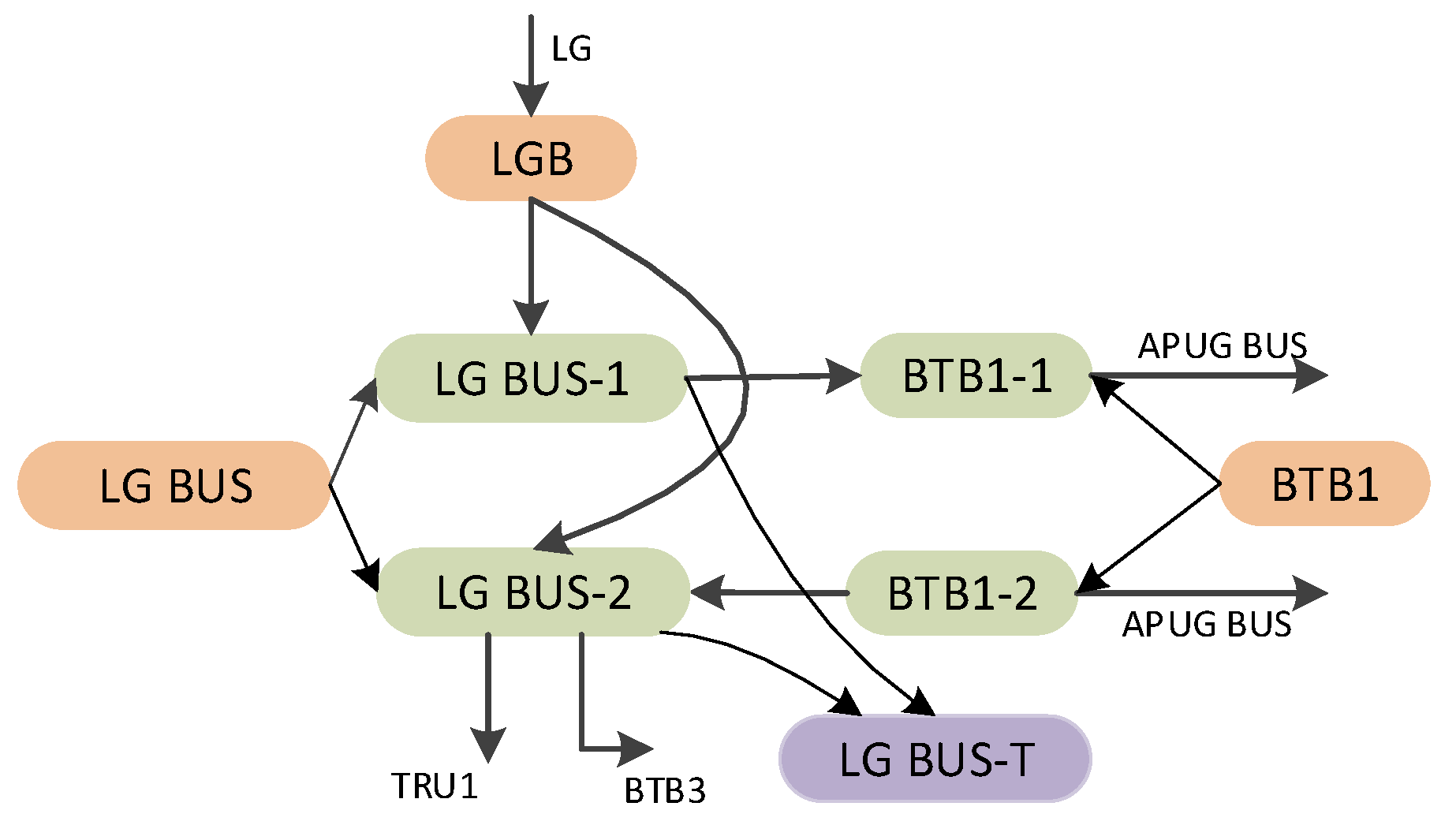

- In the MIMO structure, for component C, the input components powering its i-th output component may be different from those powering its j-th output component. For example, considering the LGBUS component in Figure 1, it exhibits a 3:2 structure or configuration, with three outputs and two input components. Specifically, both BTB3 and TRU1 are powered by the same input components, namely LGB and BTB1, whereas BTB1 is solely powered by LGB (refer to Figure 3).

- When s = 1, all pathways are the same, and the grandparent nodes of each output component are identical. Therefore, constructing a three-state node C can accurately represent the function/failure logic between component C and its input/output components.

- When 2 ≤ s ≤ n, there exist different pathways for component C. The grandparent nodes of output components on different pathways are necessarily distinct. Hence, the key to constructing the corresponding node for component C in this case lies in accurately describing these s different pathways.

- When component C fails, the pathway represented by C-k becomes non-functional, unable to transmit power to the output component on that pathway.

- If component C is operational and at least one input component on pathway k is working, the pathway represented by C-k can transmit power to its output component.

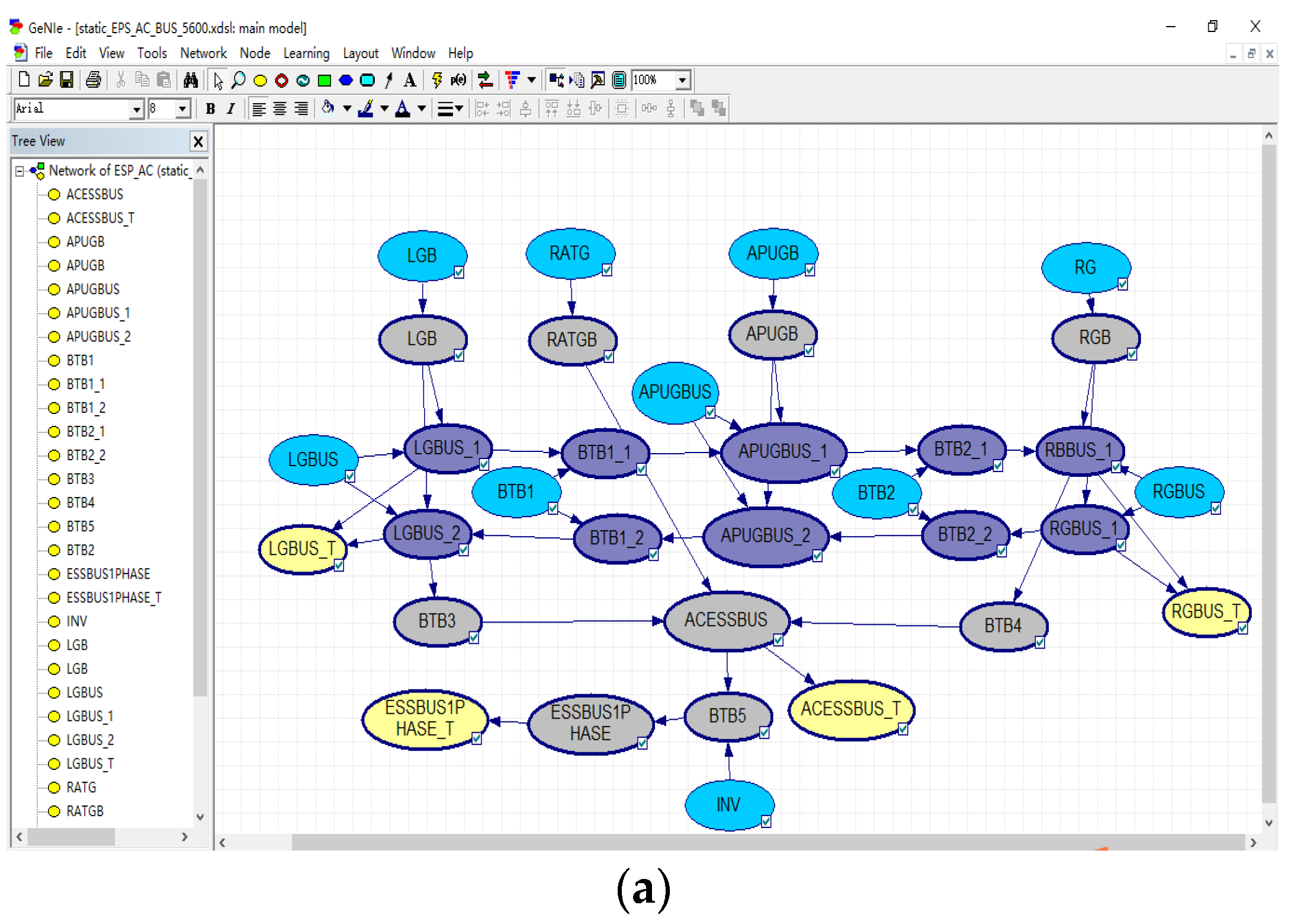

3.3. Construction of an Equivalent APS-RPNM

4. Case Study

4.1. Construct the Equivalent APS-RPNM

4.1.1. Constructing Nodes Based on Component Structures

4.1.2. Determining Parent Nodes

4.1.3. Identifying the Target Nodes

4.1.4. Determining Conditional Probability Distributions for Nodes

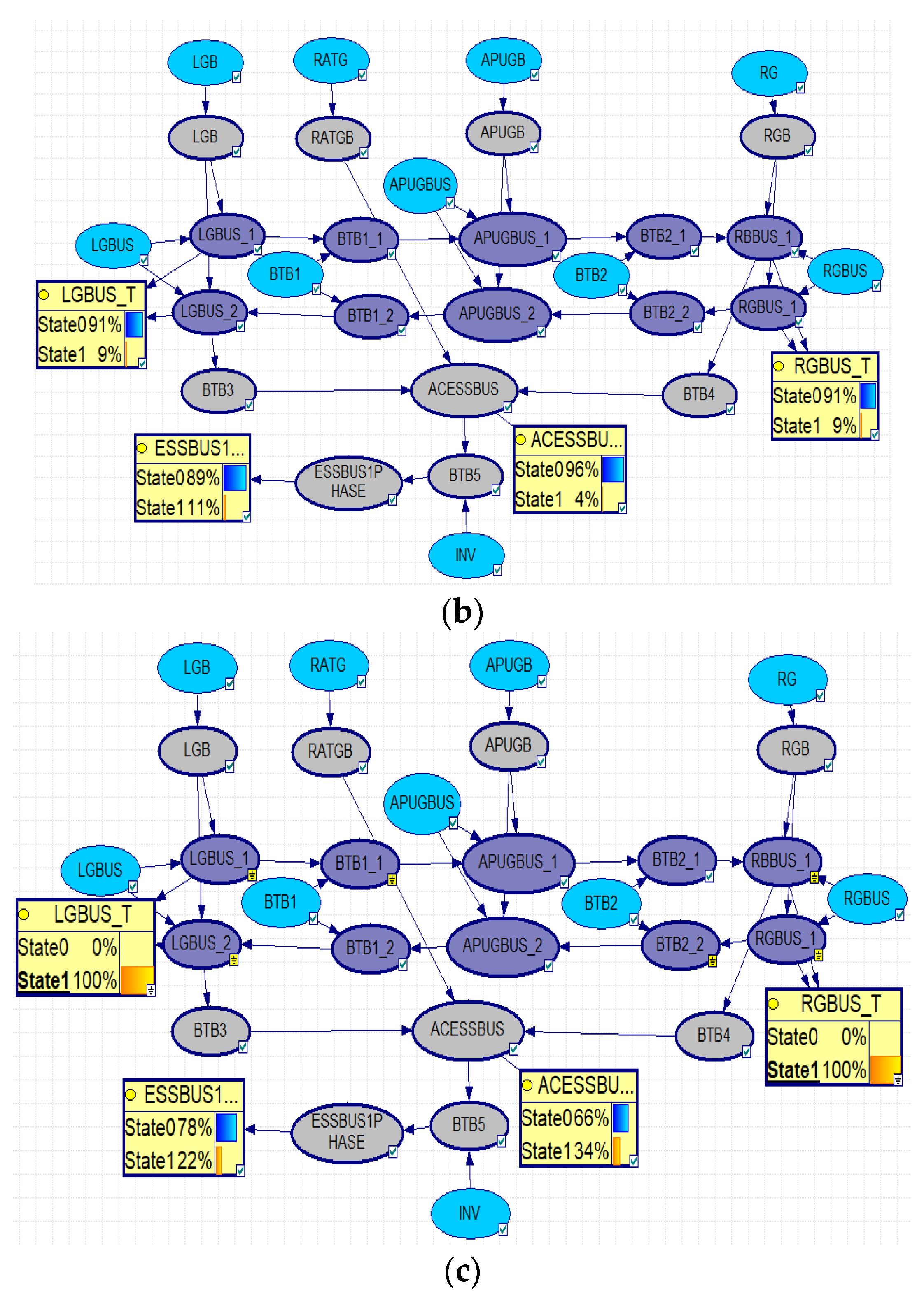

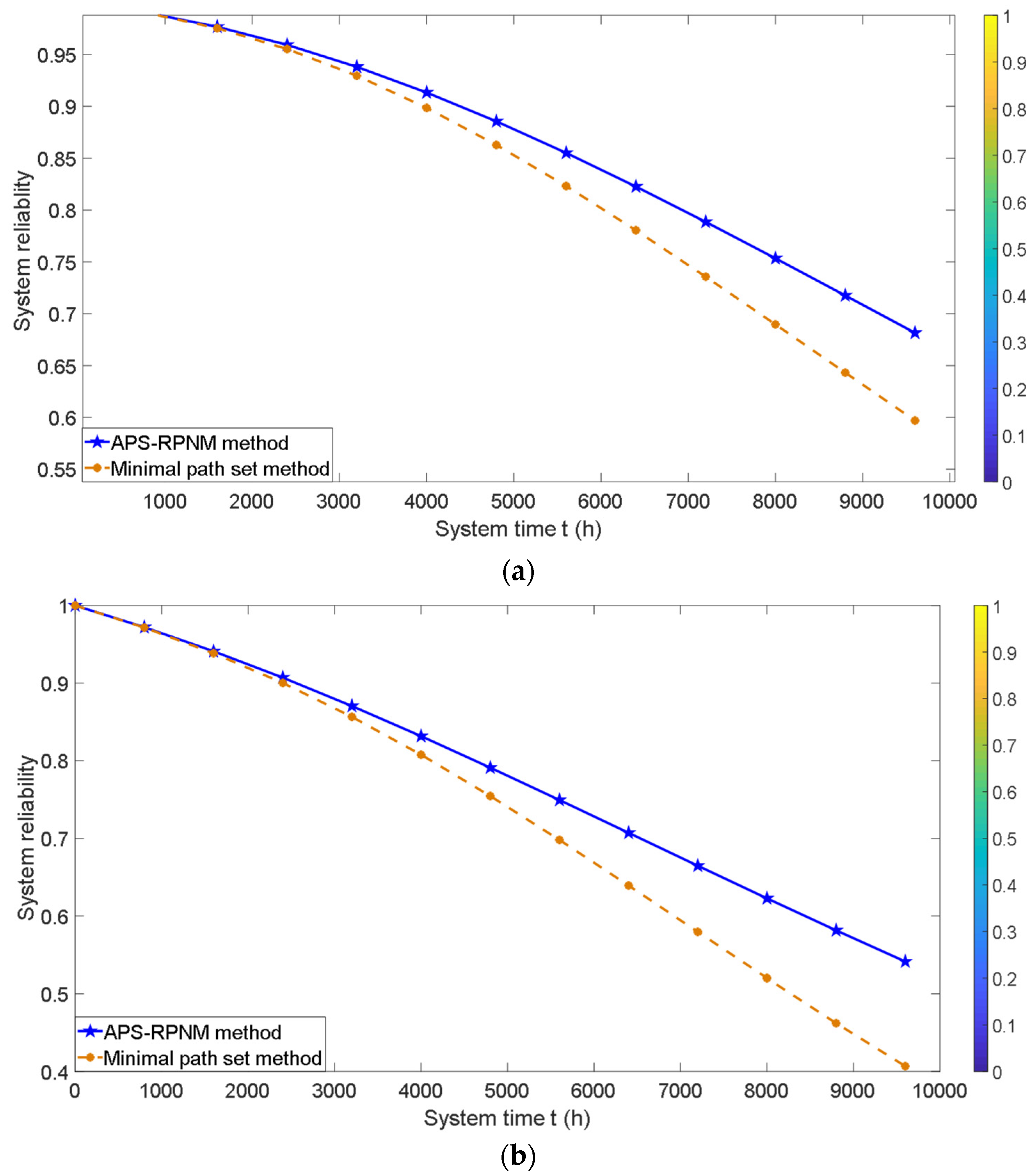

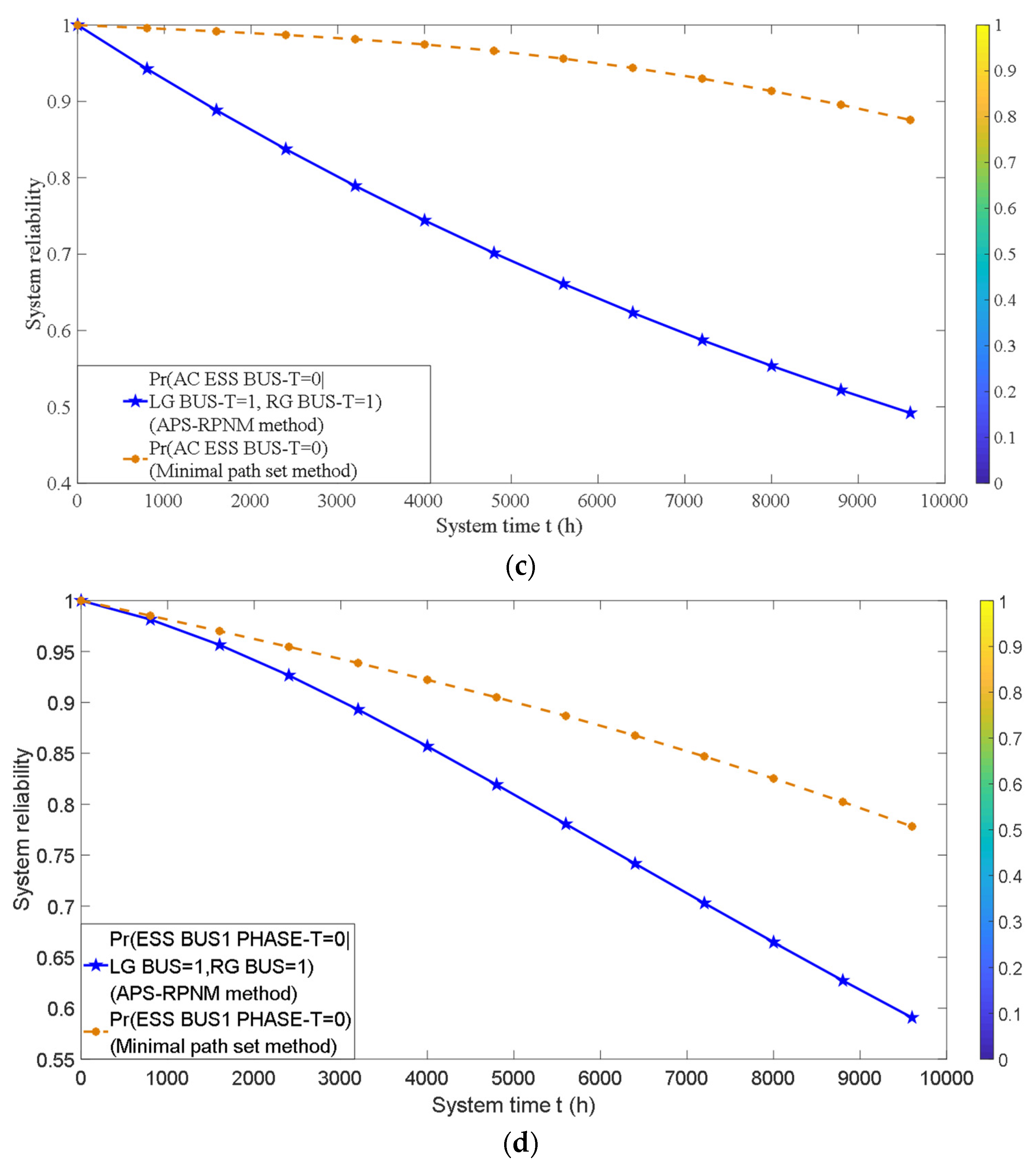

4.2. System Reliability Calculation and Analysis

4.2.1. Reliability Analysis Results Based on APS-RPNM

Calculation of Power Supply Reliability

Analysis of Power Supply Dependency

4.2.2. Reliability Analysis Results Based on Minimal Path Sets

4.3. Analysis of the Power Supply Reliability Results

4.3.1. Model Structure Analysis

4.3.2. Analysis of Computational Efficiency

4.3.3. Analysis of Power Supply Dependence between Different Load Points

4.3.4. Main Contributions of This Proposed APS-RPNM

- (i)

- Significant improvement in model accuracy and consistency: By constructing a probabilistic network model that closely corresponds to the system structure schematic, this paper successfully visualizes the functional/fault logic and probability data originally hidden in the schematic. This modeling approach not only greatly improves the accuracy of the model but also ensures its consistency with the actual operation of the system, laying a solid foundation for subsequent reliability analysis.

- (ii)

- Innovation in computational efficiency: Compared to traditional methods that require calculating the power supply reliability of each load busbar individually, the method proposed in this paper achieves a significant improvement in computational efficiency by processing all busbar calculations in parallel within the same model. Especially when dealing with large and complex power supply networks containing many busbars, the advantages of this method become more apparent, providing strong support for rapid decision-making in practical applications.

- (iii)

- Comprehensive strengthening of system dependency analysis capabilities: Traditional methods often have shortcomings in dealing with dependency between power supply paths, while the method proposed in this paper successfully solves this problem by integrating the functional/fault logic of all components into the same model. This not only makes the analysis of the overall system reliability more accurate but also allows for accurate calculations of the relevant conditional probabilities in complex scenarios such as emergency power supply conditions, providing a more comprehensive theoretical support for the reliability design and optimization of the system.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schäfer, A.W.; Barrett, S.R.; Doyme, K.; Dray, L.M.; Gnadt, A.R.; Self, R.; O’Sullivan, A.; Synodinos, A.P.; Torija, A.J. Technological, economic and environmental prospects of all-electric aircraft. Nat. Energy 2019, 4, 160–166. [Google Scholar] [CrossRef]

- Borghei, M.; Ghassemi, M. Insulation materials and systems for more-and all-electric aircraft: A review identifying challenges and future research needs. IEEE Trans. Transp. Electrif. 2021, 7, 1930–1953. [Google Scholar] [CrossRef]

- Sahoo, S.; Zhao, X.; Kyprianidis, K. A review of concepts, benefits, and challenges for future electrical propulsion-based aircraft. Aerospace 2020, 7, 44. [Google Scholar] [CrossRef]

- Schefer, H.; Fauth, L.; Kopp, T.H.; Mallwitz, R.; Friebe, J.; Kurrat, M. Discussion on electric power supply systems for all electric aircraft. IEEE Access 2020, 8, 84188–84216. [Google Scholar] [CrossRef]

- Ebersberger, J.; Hagedorn, M.; Lorenz, M.; Mertens, A. Potentials and comparison of inverter topologies for future all-electric aircraft propulsion. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 5264–5279. [Google Scholar] [CrossRef]

- Ye, X.I.; Savvarisal, A.; Tsourdos, A.; Zhang, D.; Jason, G.U. Review of hybrid electric powered aircraft, its conceptual design and energy management methodologies. Chin. J. Aeronaut. 2021, 34, 432–450. [Google Scholar]

- Ghassemi, M.; Barzkar, A.; Saghafi, M. All-Electric NASA N3-X aircraft electric power systems. IEEE Trans. Transp. Electrif. 2022, 8, 4091–4104. [Google Scholar] [CrossRef]

- Kolly, J.M.; Panagiotou, J.; Czech, B.A. The Investigation of a Lithium-Ion Battery Fire Onboard a Boeing 787 by the US National Transportation Safety Board; Safety Research Corporation of America: Dothan, AL, USA, 2013; pp. 1–18. [Google Scholar]

- Pandian, G.; Pecht, M.; Enrico, Z.I.; Hodkiewicz, M. Data-driven reliability analysis of Boeing 787 Dreamliner. Chin. J. Aeronaut. 2020, 33, 1969–1979. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, Y.; Hu, X.; Gao, X.; Li, S.; Li, Y. Reliability Uncertainty Analysis Method for Aircraft Electrical Power System Design Based on Variance Decomposition. Appl. Sci. 2022, 12, 2857. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, X.; Cai, Y.; Yang, M.; Li, S.; Li, Y. Reliability evaluation for aviation electric power system in consideration of uncertainty. Energies 2020, 13, 1175. [Google Scholar] [CrossRef]

- Harikumaran, J.; Buticchi, G.; Migliazza, G.; Madonna, V.; Giangrande, P.; Costabeber, A.; Wheeler, P.; Galea, M. Failure modes and reliability oriented system design for aerospace power electronic converters. IEEE Open J. Ind. Electron. Soc. 2020, 2, 53–64. [Google Scholar] [CrossRef]

- Enrico, Z.I.; Mengfei, F.A.; Zhiguo, Z.E.; Rui, K.A. Application of reliability technologies in civil aviation: Lessons learnt and perspectives. Chin. J. Aeronaut. 2019, 32, 143–158. [Google Scholar]

- Yaramasu, A.; Cao, Y.; Liu, G.; Wu, B. Aircraft electric system intermittent arc fault detection and location. IEEE Trans. Aerosp. Electron. Syst. 2015, 51, 40–51. [Google Scholar] [CrossRef]

- Cano, T.C.; Castro, I.; Rodríguez, A.; Lamar, D.G.; Khalil, Y.F.; Albiol-Tendillo, L.; Kshirsagar, P. Future of electrical aircraft energy power systems: An architecture review. IEEE Trans. Transp. Electrif. 2021, 7, 1915–1929. [Google Scholar] [CrossRef]

- Ramabhotla, S.; Bayne, S.; Giesselmann, M. Reliability optimization using fault tree analysis in the grid connected mode of microgrid. In Proceedings of the 2016 IEEE Green Technologies Conference (GreenTech), Kansas City, MO, USA, 6–8 April 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 136–141. [Google Scholar]

- Yazdi, M.; Zarei, E. Uncertainty handling in the safety risk analysis: An integrated approach based on fuzzy fault tree analysis. J. Fail. Anal. Prev. 2018, 18, 392–404. [Google Scholar] [CrossRef]

- Boussahoua, B.; Elmaouhab, A. Reliability analysis of electrical power system using graph theory and reliability block diagram. In Proceedings of the 2019 Algerian Large Electrical Network Conference (CAGRE), Algiers, Algeria, 26–28 February 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Zhang, Y.; Kurtoglu, T.; Tumer, I.Y.; O’Halloran, B. System-Level Reliability Analysis for Conceptual Design of Electrical Power Systems. In Proceedings of the Conference on Systems Engineering Research (CSER), Redondo Beach, CA, USA, 15–16 April 2011. [Google Scholar]

- Zhang, B. Applying Reliability Analysis to Design Electric Power Systems for More-Electric Aircraft. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2014. [Google Scholar]

- Zhao, Y.; Wu, H.; Cai, J.; Shi, X. Reliability analysis for electric power systems of more-electric aircraft based on the minimal path set. J. Comput. Methods Sci. Eng. 2019, 19, 1017–1026. [Google Scholar] [CrossRef]

- Zhao, Y.; Che, Y.; Lin, T.; Wang, C.; Liu, J.; Xu, J.; Zhou, J. Minimal cut sets-based reliability evaluation of the more electric aircraft power system. Math. Probl. Eng. 2018, 2018, 9461823. [Google Scholar] [CrossRef]

- Cai, L.; Zhang, L.; Yang, S.; Wang, L. Reliability assessment and analysis of large aircraft power distribution systems. Acta Aeronaut. Astronaut. Sin. 2011, 32, 1488–1496. [Google Scholar]

- Xu, Q.; Xu, Y.; Tu, P.; Zhao, T.; Wang, P. Systematic reliability modelling and evaluation for on-board power systems of more electric aircrafts. IEEE Trans. Power Syst. 2019, 34, 3264–3273. [Google Scholar] [CrossRef]

- Raveendran, V.; Andresen, M.; Liserre, M. Improving onboard converter reliability for more electric aircraft with lifetime-based control. IEEE Trans. Ind. Electron. 2019, 66, 5787–5796. [Google Scholar] [CrossRef]

- Lawhorn, D.; Rallabandi, V.; Ionel, D.M. Scalable graph theory approach for electric aircraft power system optimization. In Proceedings of the 2019 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), Indianapolis, IN, USA, 22–24 August 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–5. [Google Scholar]

- Recalde, A.A.; Atkin, J.A.; Bozhko, S.V. Optimal design and synthesis of MEA power system architectures considering reliability specifications. IEEE Trans. Transp. Electrif. 2020, 6, 1801–1818. [Google Scholar] [CrossRef]

- Chwa, J.; Ameri, A.; Mozumdar, M. Improving reliability of aircraft electric power distribution system. In Proceedings of the 2014 IEEE Green Energy and Systems Conference (IGESC), Long Beach, CA, USA, 24–24 November 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 61–66. [Google Scholar]

- Bajaj, N.; Nuzzo, P.; Sangiovanni-Vincentelli, A. Optimal architecture synthesis for aircraft electrical power systems (EPS). In Proceedings of the 2014 Berkeley EECS Annual Research Symposium, Berkeley, CA, USA, 13 February 2014. [Google Scholar]

- Gupta, N.; Swarnkar, A.; Niazi, K.R. Distribution network reconfiguration for power quality and reliability improvement using Genetic Algorithms. Int. J. Electr. Power Energy Syst. 2014, 54, 664–671. [Google Scholar] [CrossRef]

- Tajudin, A.I.; Abd Samat, A.A.; Saedin, P.; Mohamad Idin, M.A. Application of Artificial Bee Colony Algorithm for Distribution Network Reconfiguration. Appl. Mech. Mater. 2015, 785, 38–42. [Google Scholar] [CrossRef]

- Boicea, V.A. Distribution grid reconfiguration through Simulated Annealing and Tabu Search. In Proceedings of the International Symposium on Advanced Topics in Electrical Engineering, Bucharest, Romania, 23–25 March 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 563–568. [Google Scholar]

- Kabir, S.; Papadopoulos, Y. Applications of Bayesian networks and Petri nets in safety, reliability, and risk assessments: A review. Saf. Sci. 2019, 115, 154–175. [Google Scholar] [CrossRef]

- Kiaei, I.; Lotfifard, S. Fault section identification in smart distribution systems using multi-source data based on fuzzy Petri nets. IEEE Trans. Smart Grid 2019, 11, 74–83. [Google Scholar] [CrossRef]

- Guo, P. Research on the Reliability Analyze Methodology of the Complex Aircraft System based on the Petri Net. Adv. Aeronaut. Sci. Eng. 2016, 7, 174–180. [Google Scholar]

- Zhao, X.; Malasse, O.; Buchheit, G. Verification of safety integrity level of high demand system based on Stochastic Petri Nets and Monte Carlo Simulation. Reliab. Eng. Syst. Saf. 2019, 184, 258–265. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, F.; Feng, Y.; Cao, S. A Three-State Space Modeling Method for Aircraft System Reliability Design. Machines 2023, 12, 13. [Google Scholar] [CrossRef]

- Hossain, N.U.; Jaradat, R.; Hosseini, S.; Marufuzzaman, M.; Buchanan, R.K. A framework for modeling and assessing system resilience using a Bayesian network: A case study of an interdependent electrical infrastructure system. Int. J. Crit. Infrastruct. Prot. 2019, 25, 62–83. [Google Scholar] [CrossRef]

- Kong, X.; Wang, J.; Zhang, Z. Reliability analysis of aircraft power system based on Bayesian network and common cause failure. Acta Aeronaut. Astronaut. Sin. 2020, 41, 70–279. [Google Scholar]

- Tang, B.; Yang, S.; Wang, L.; Zhang, H. Commercial aircraft distribution network reconfiguration based on power priority. In Proceedings of the 2016 IEEE 2nd Annual Southern Power Electronics Conference (SPEC), Auckland, New Zealand, 5–8 December 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–5. [Google Scholar]

- Weber, P.; Medina-Oliva, G.; Simon, C.; Iung, B. Overview on Bayesian networks applications for dependency, risk analysis and maintenance areas. Eng. Appl. Artif. Intell. 2012, 25, 671–682. [Google Scholar] [CrossRef]

| Component | Failure Rate (/h) |

|---|---|

| Connector | 1.333300 × 10−5 |

| Gen | 5.555600 × 10−5 |

| Inverter | 9.090900 × 10−5 |

| Busbar | 5.00 × 10−6 |

| LG | R |

|---|---|

| 0 | e−λt = 0.99446 |

| 1 | 1 − e−λt = 0.00554 |

| LG | LGB | Pr(LGB|LG) |

|---|---|---|

| 0 | 0 | e−λt = 0.99867 |

| 0 | 1 | 1 − e−λt = 0.00133 |

| 0 | 2 | 0.0 |

| 0 | 0 | 0.0 |

| 0 | 1 | 1 − e−λt = 0.00133 |

| 0 | 2 | e−λt = 0.99867 |

| LGB | LG BUS | LG BUS-1 | Pr(LG BUS-1|LGB, LG BUS) |

|---|---|---|---|

| 0 | 0 | 0 | 1.0 |

| 0 | 0 | 1 | 0.0 |

| 0 | 1 | 0 | 0.0 |

| 0 | 1 | 1 | 1.0 |

| 1 | 0 | 0 | 0.0 |

| 1 | 0 | 1 | 1.0 |

| … | … | … | … |

| 2 | 1 | 0 | 0.0 |

| 2 | 1 | 1 | 1.0 |

| AC ESS BUS | AC ESS BUS-T | Pr(AC ESS BUS-T|AC ESS BUS) |

|---|---|---|

| 0 | 0 | 1.0 |

| 0 | 1 | 0.0 |

| 1 | 0 | 0.0 |

| 1 | 1 | 1.0 |

| System Time t (h) | Results of the Power Supply Reliability Calculation Based on APS-RPNM | Results of the Power Supply Reliability Calculation Based on the Minimal Path Set | ||||

|---|---|---|---|---|---|---|

| LGBUS | AC ESS BUS | ESS BUS1 PHASE | LGBUS | AC ESS BUS | ESS BUS1 PHASE | |

| 800 | 0.995041 | 0.995986 | 0.985189 | 0.995041 | 0.995986 | 0.985189 |

| 1600 | 0.987677 | 0.991787 | 0.970065 | 0.987677 | 0.991787 | 0.970065 |

| 2400 | 0.977453 | 0.987077 | 0.954606 | 0.977453 | 0.987077 | 0.954606 |

| 3200 | 0.964203 | 0.981481 | 0.938713 | 0.964204 | 0.981481 | 0.938713 |

| 4000 | 0.947966 | 0.974638 | 0.922229 | 0.947966 | 0.974638 | 0.922229 |

| 4800 | 0.928917 | 0.966241 | 0.904974 | 0.928917 | 0.966241 | 0.904974 |

| 5600 | 0.907320 | 0.956060 | 0.886775 | 0.907320 | 0.956060 | 0.886775 |

| System Time t (h) | Time Consumption of Power Supply Reliability Calculation Based on APS-RPNM | Time Consumption of Power Supply Reliability Calculation Based on the Minimal Path Set | ||||

|---|---|---|---|---|---|---|

| LGBUS | AC ESS BUS | ESS BUS1 PHASE | LGBUS | AC ESS BUS | ESS BUS1 PHASE | |

| 800 | <1 | 8 | 10 | 15 | ||

| 1600 | <1 | 8 | 10 | 15 | ||

| 2400 | <1 | 8 | 10 | 15 | ||

| 3200 | <1 | 8 | 10 | 15 | ||

| 4000 | <1 | 8 | 10 | 15 | ||

| 4800 | <1 | 8 | 10 | 15 | ||

| 5600 | <1 | 8 | 10 | 15 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wang, F.; Li, S.; Zhang, Y. Precise Modeling and Analysis of Aviation Power System Reliability via the Aviation Power System Reliability Probability Network Model. Aerospace 2024, 11, 530. https://doi.org/10.3390/aerospace11070530

Wang Y, Wang F, Li S, Zhang Y. Precise Modeling and Analysis of Aviation Power System Reliability via the Aviation Power System Reliability Probability Network Model. Aerospace. 2024; 11(7):530. https://doi.org/10.3390/aerospace11070530

Chicago/Turabian StyleWang, Yao, Fengtao Wang, Shujuan Li, and Yongjie Zhang. 2024. "Precise Modeling and Analysis of Aviation Power System Reliability via the Aviation Power System Reliability Probability Network Model" Aerospace 11, no. 7: 530. https://doi.org/10.3390/aerospace11070530

APA StyleWang, Y., Wang, F., Li, S., & Zhang, Y. (2024). Precise Modeling and Analysis of Aviation Power System Reliability via the Aviation Power System Reliability Probability Network Model. Aerospace, 11(7), 530. https://doi.org/10.3390/aerospace11070530