Role of Partial Flexibility on Flow Evolution and Aerodynamic Power Efficiency over a Turbine Blade Airfoil

Abstract

:1. Introduction

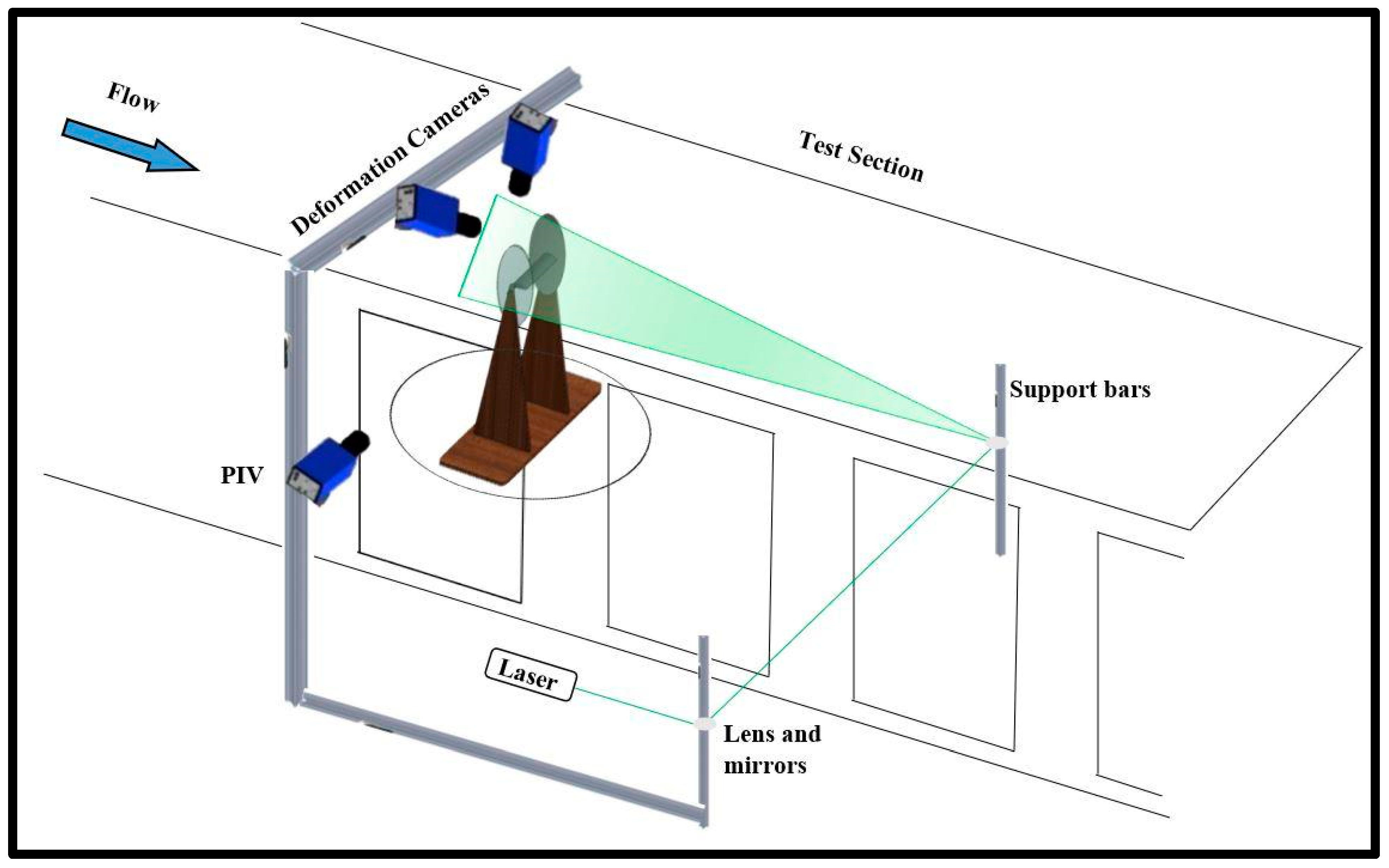

2. Experimental Setup

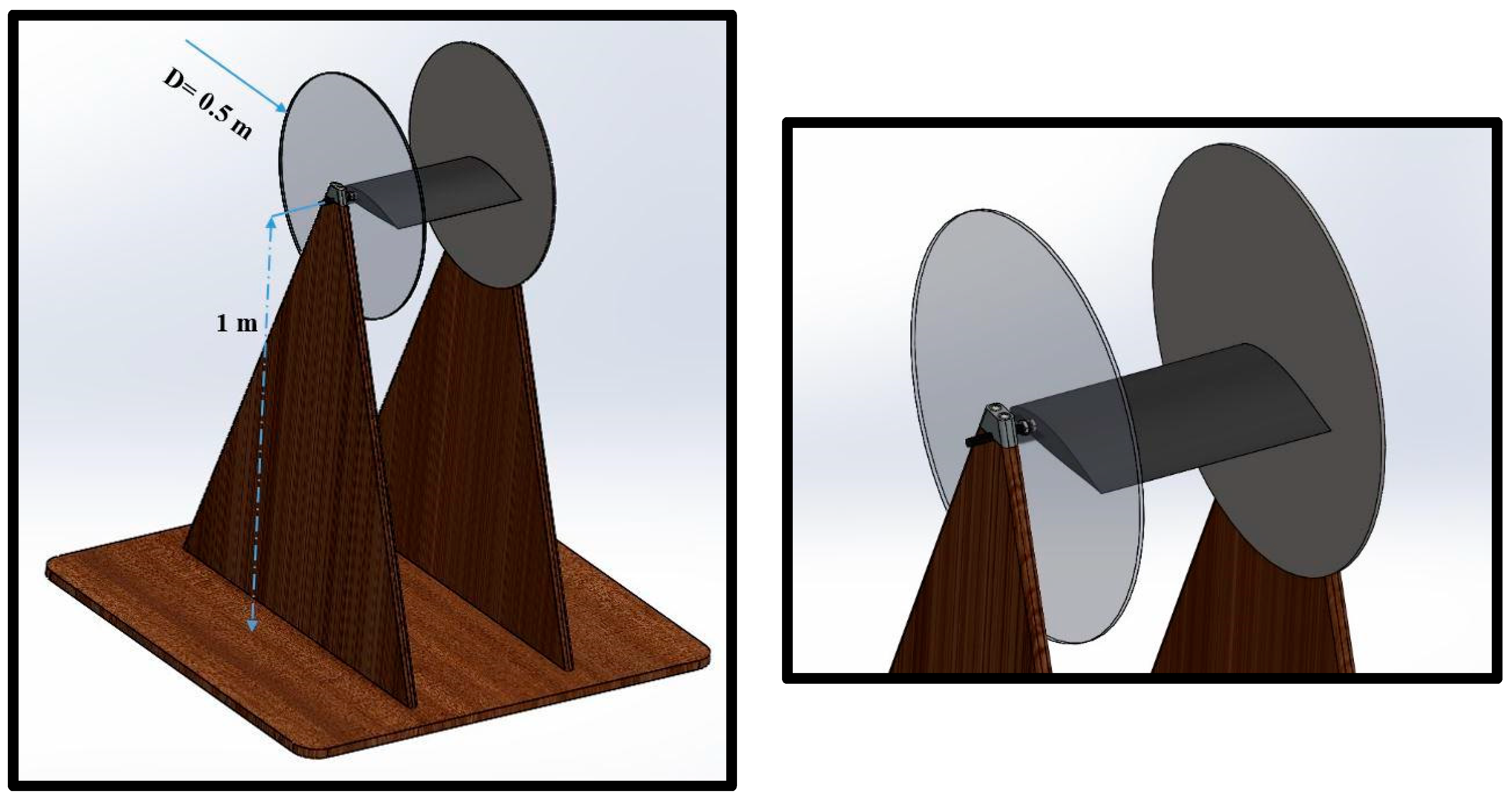

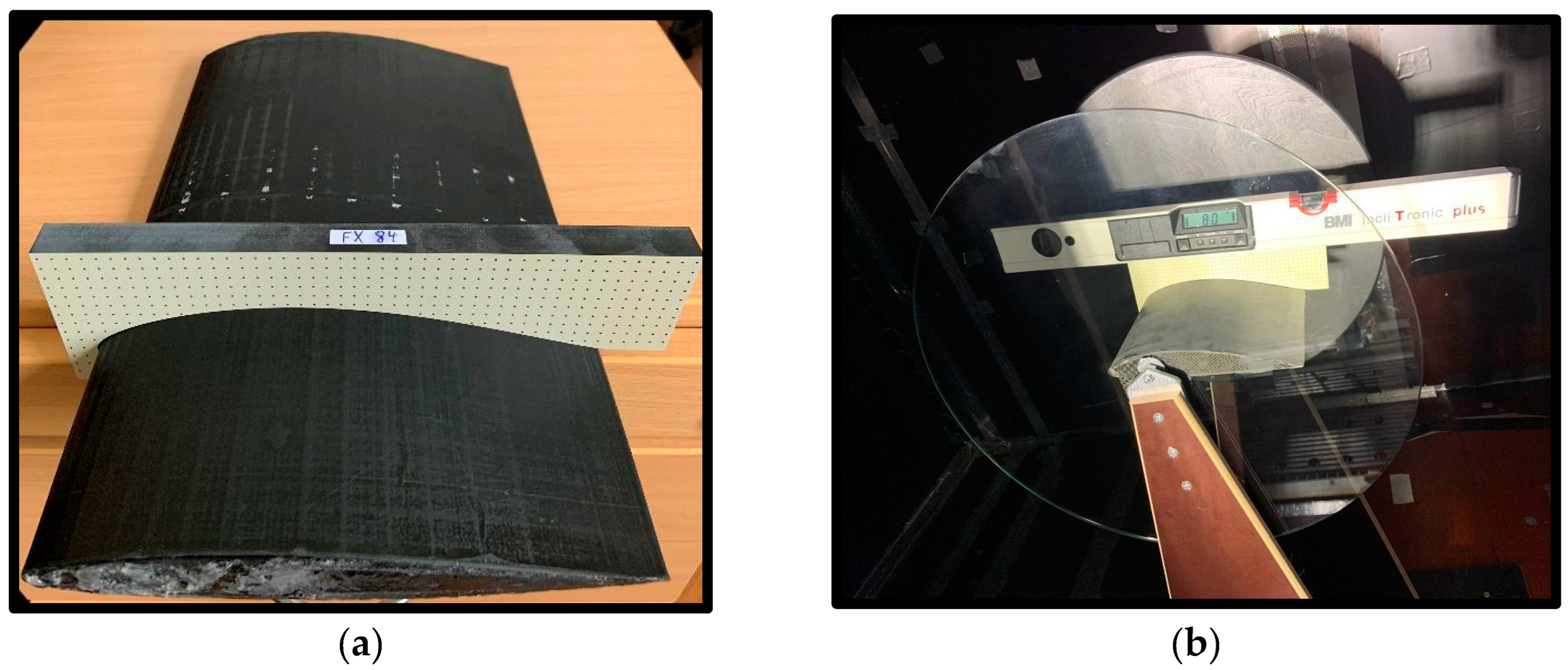

2.1. Test Model

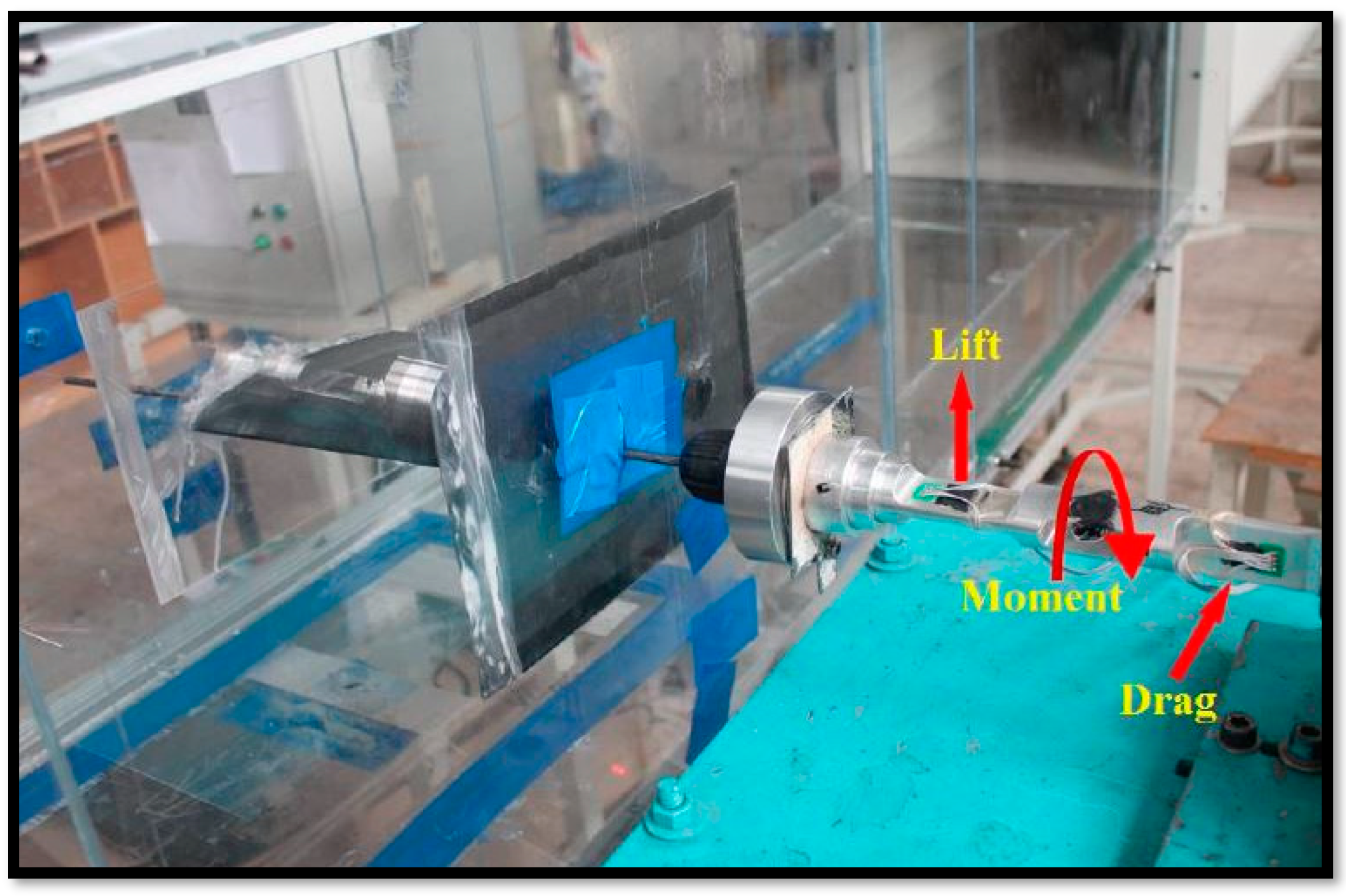

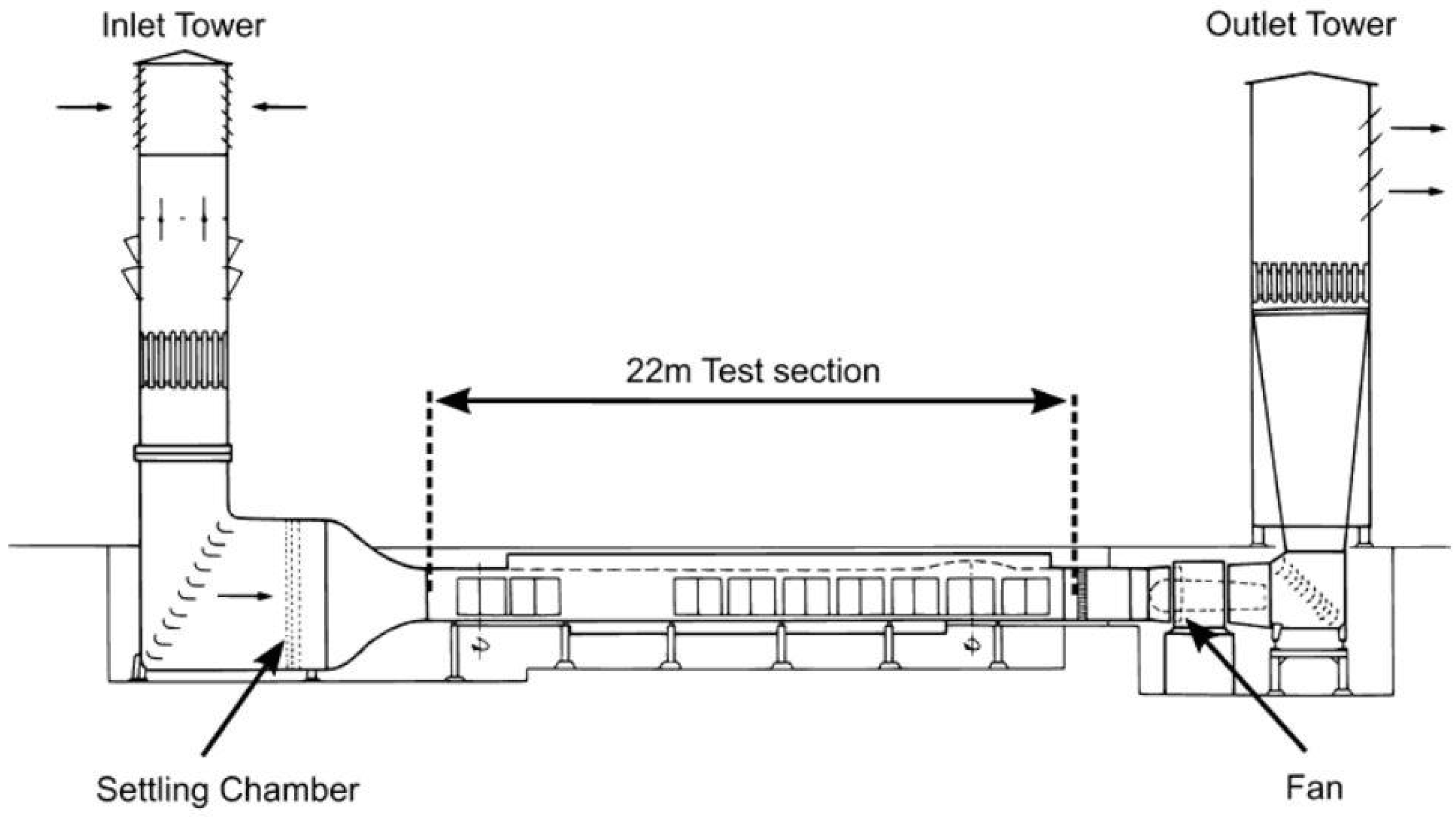

2.2. Experimental Techniques and Apparatus

3. Experimental Results and Discussion

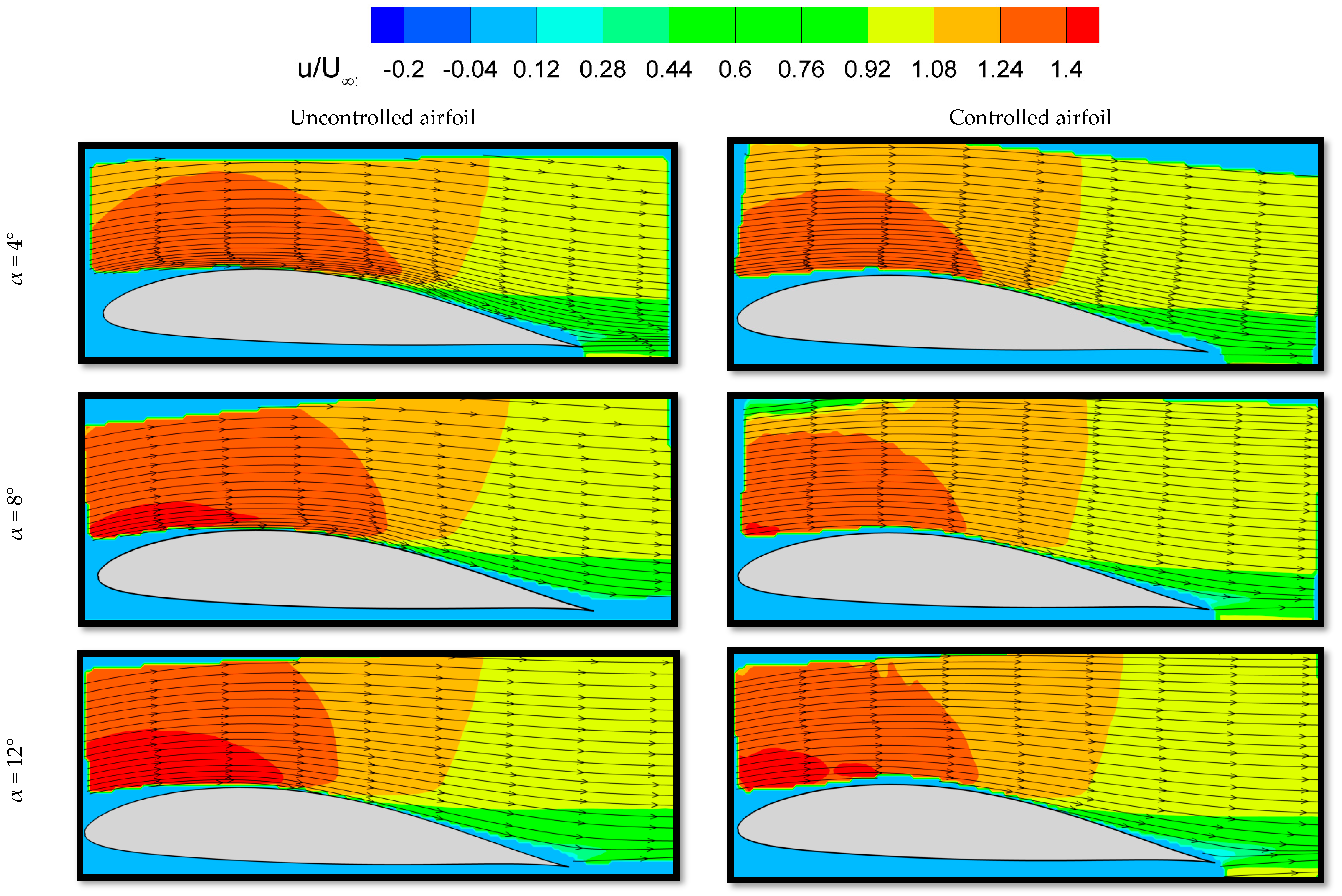

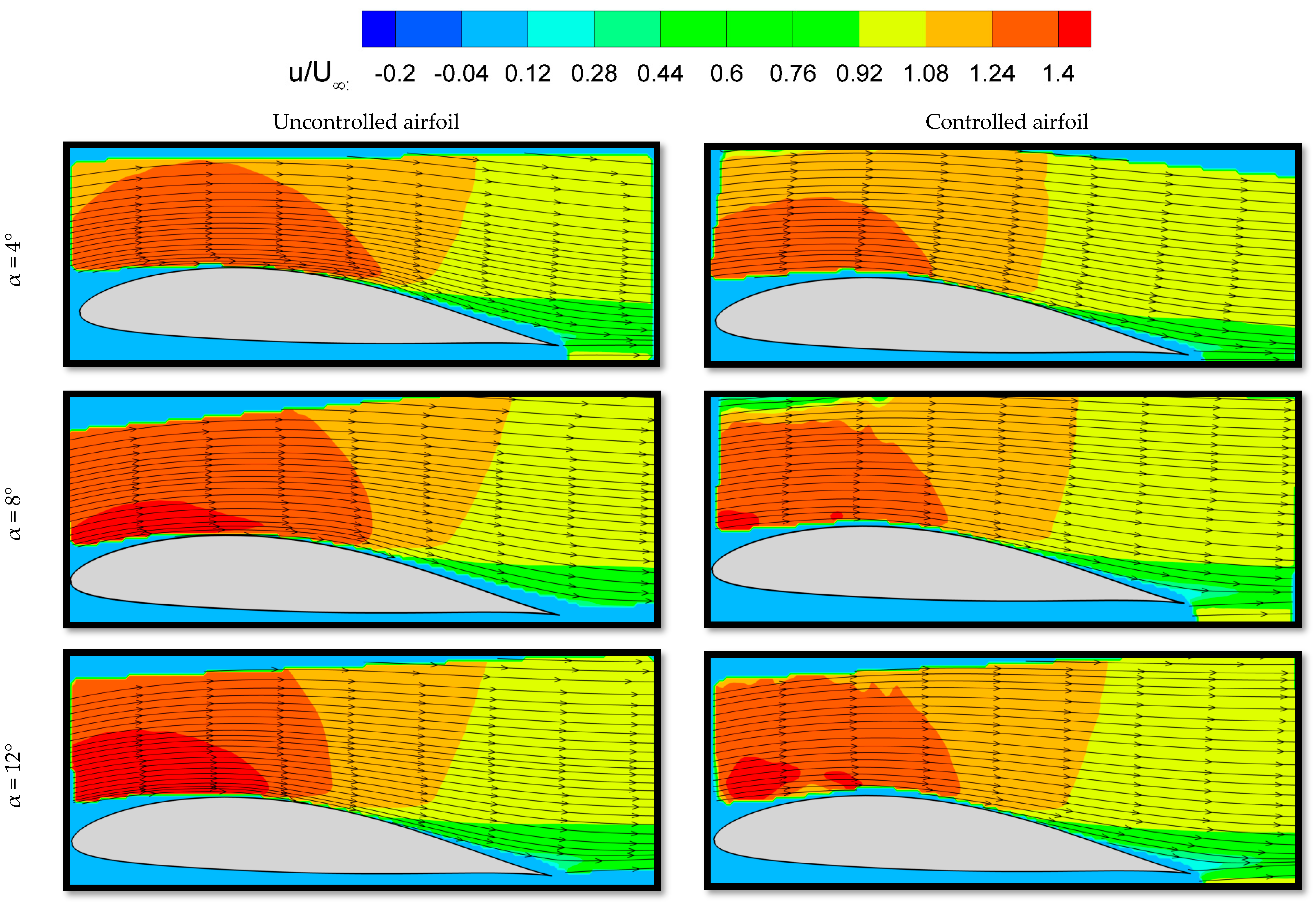

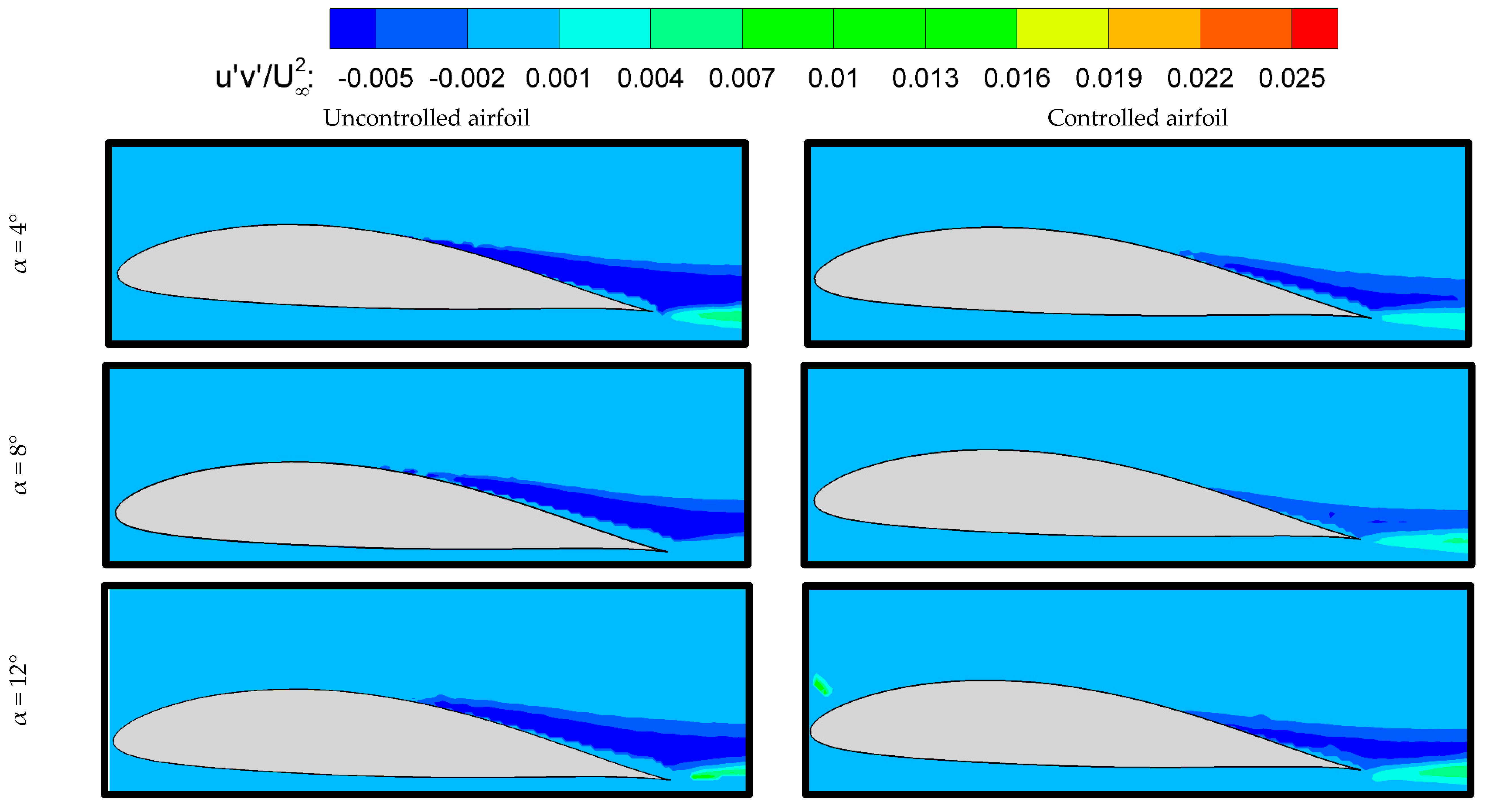

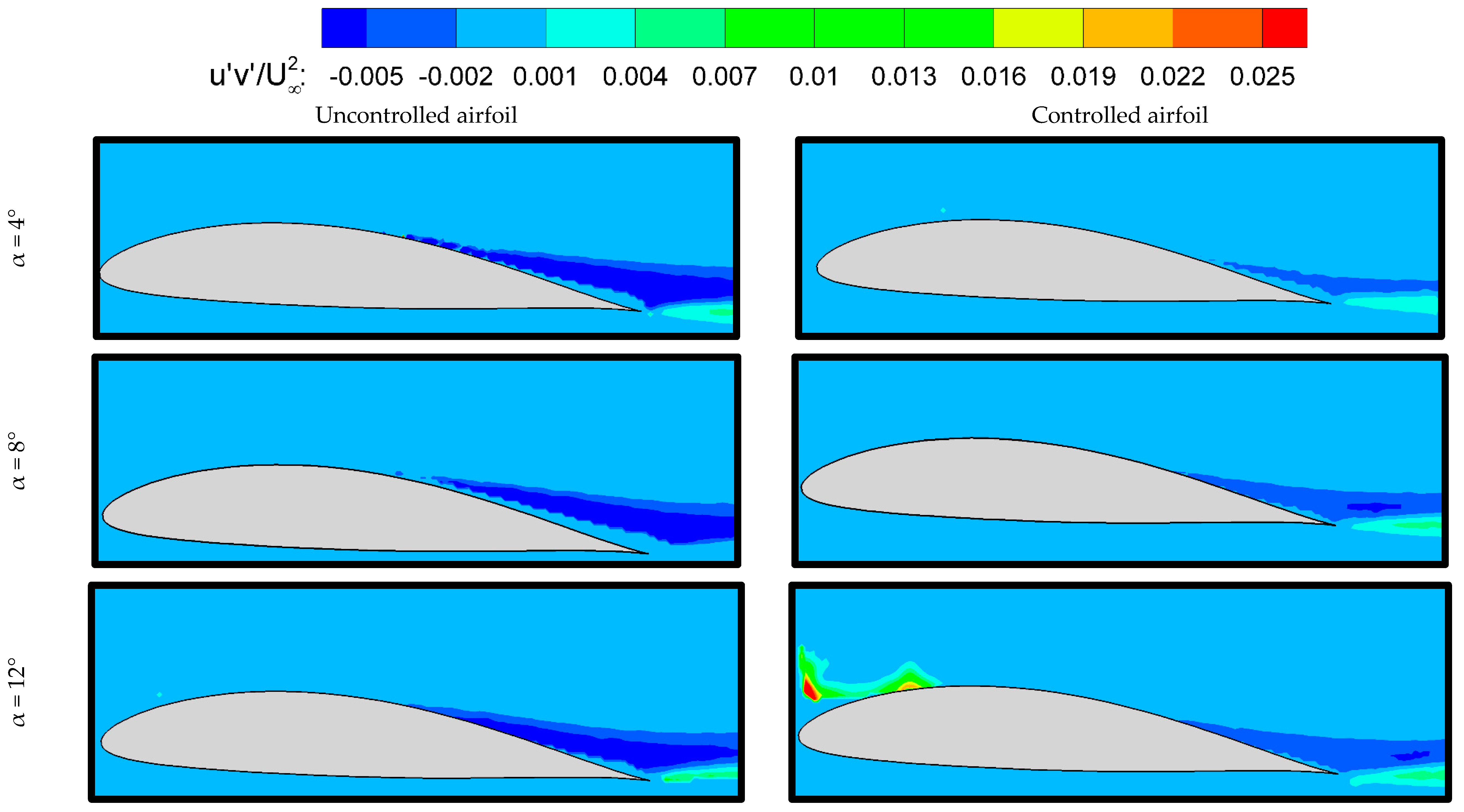

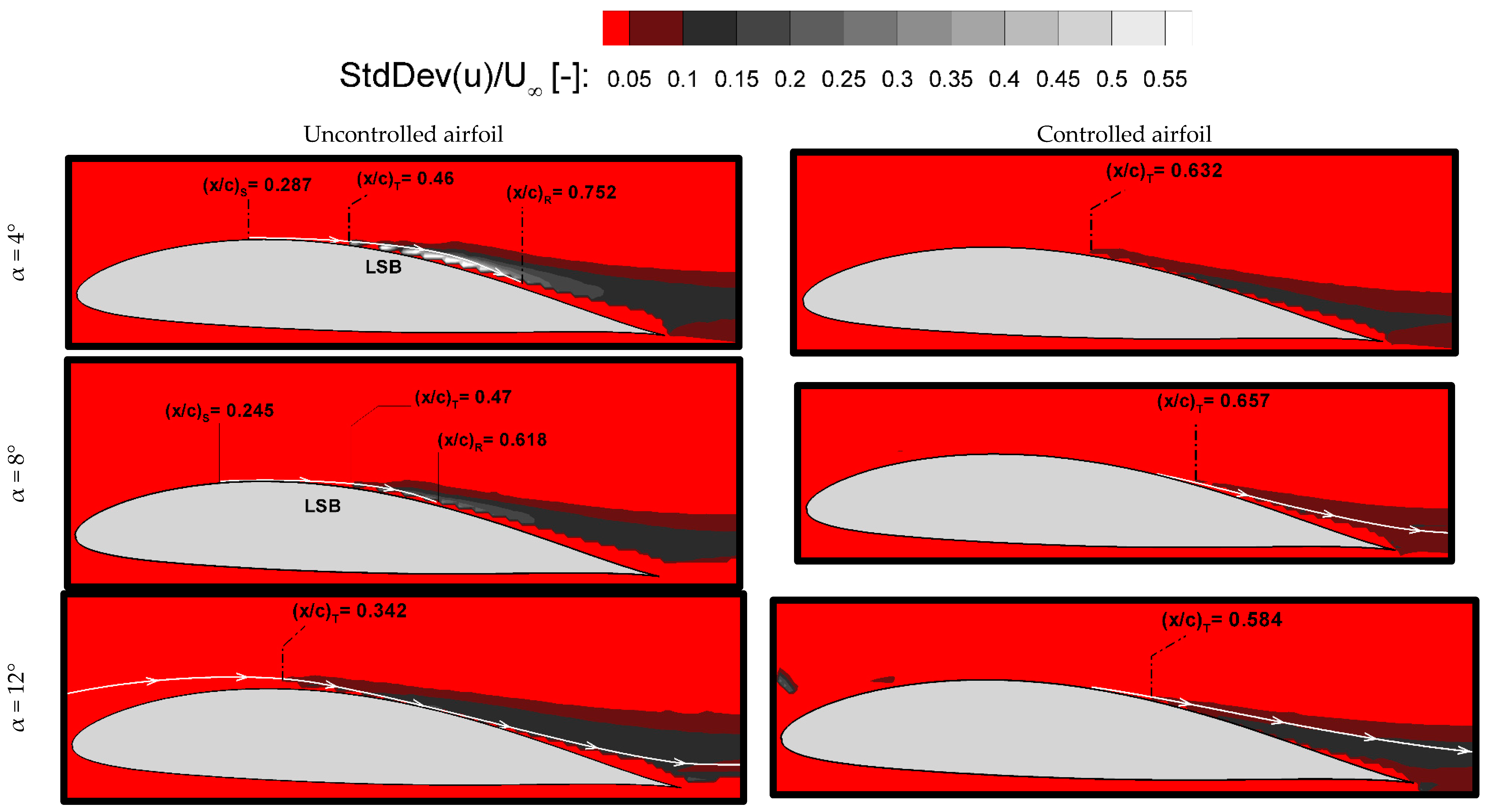

3.1. PIV Results

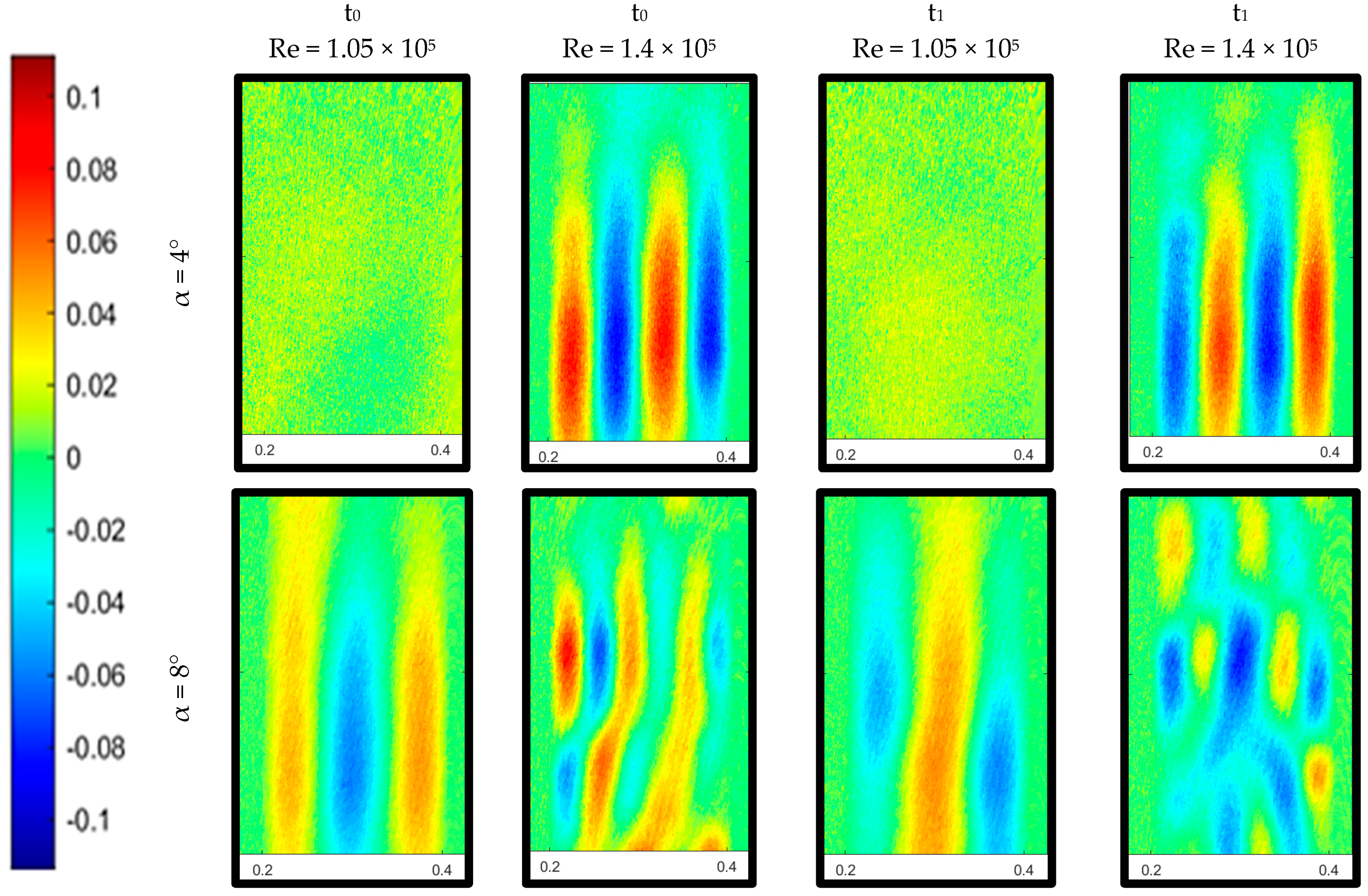

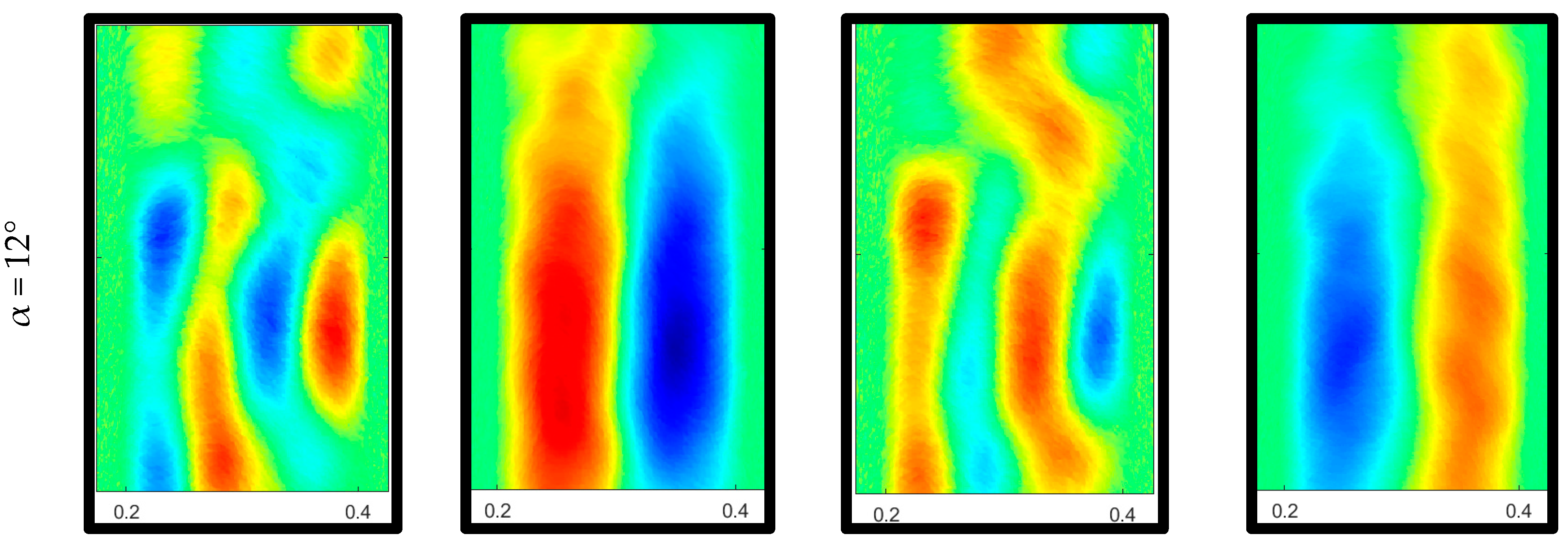

3.2. Deformation Results

3.3. The Results of Aerodynamic Force Measurement

4. Conclusions

- -

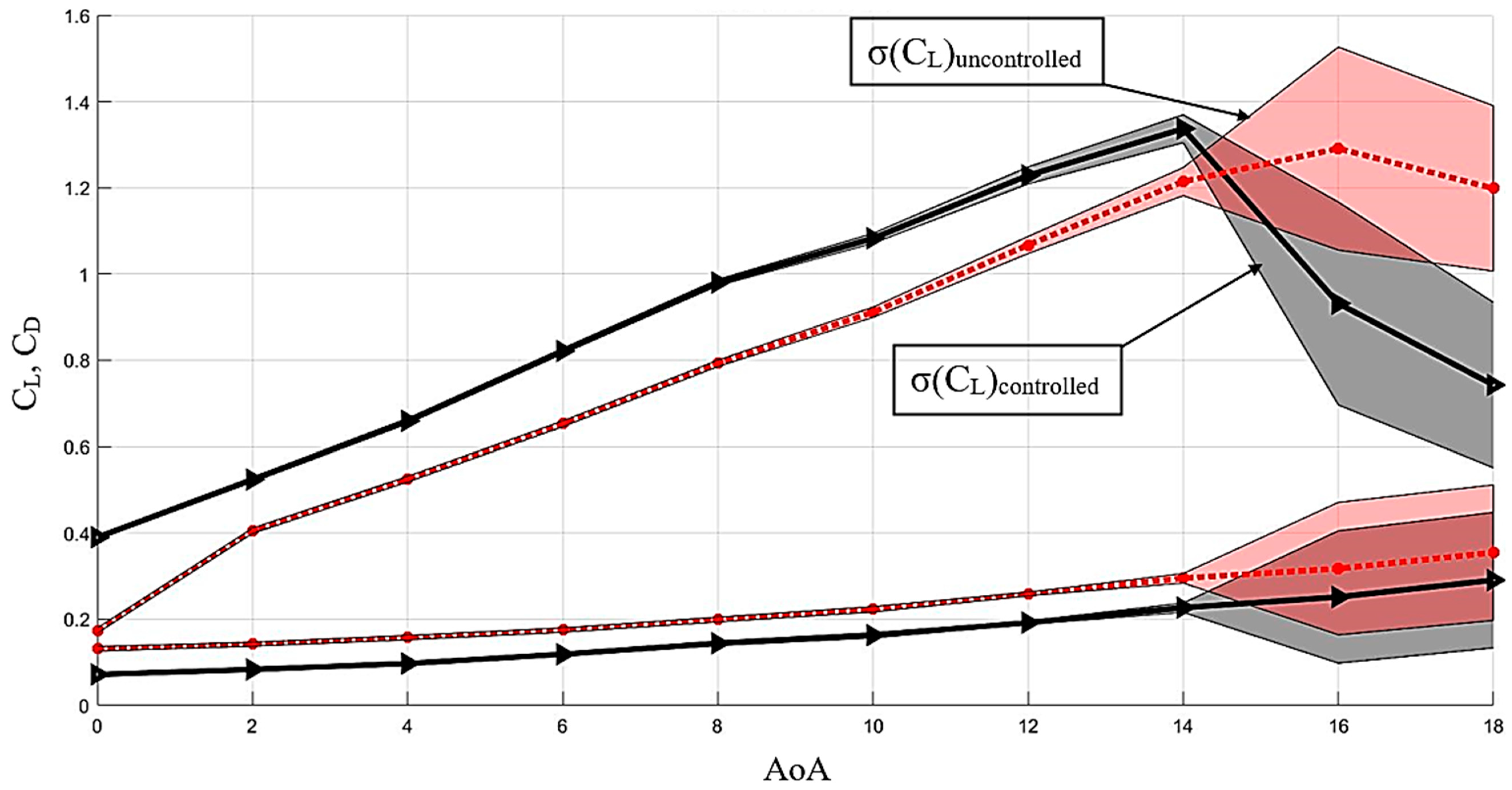

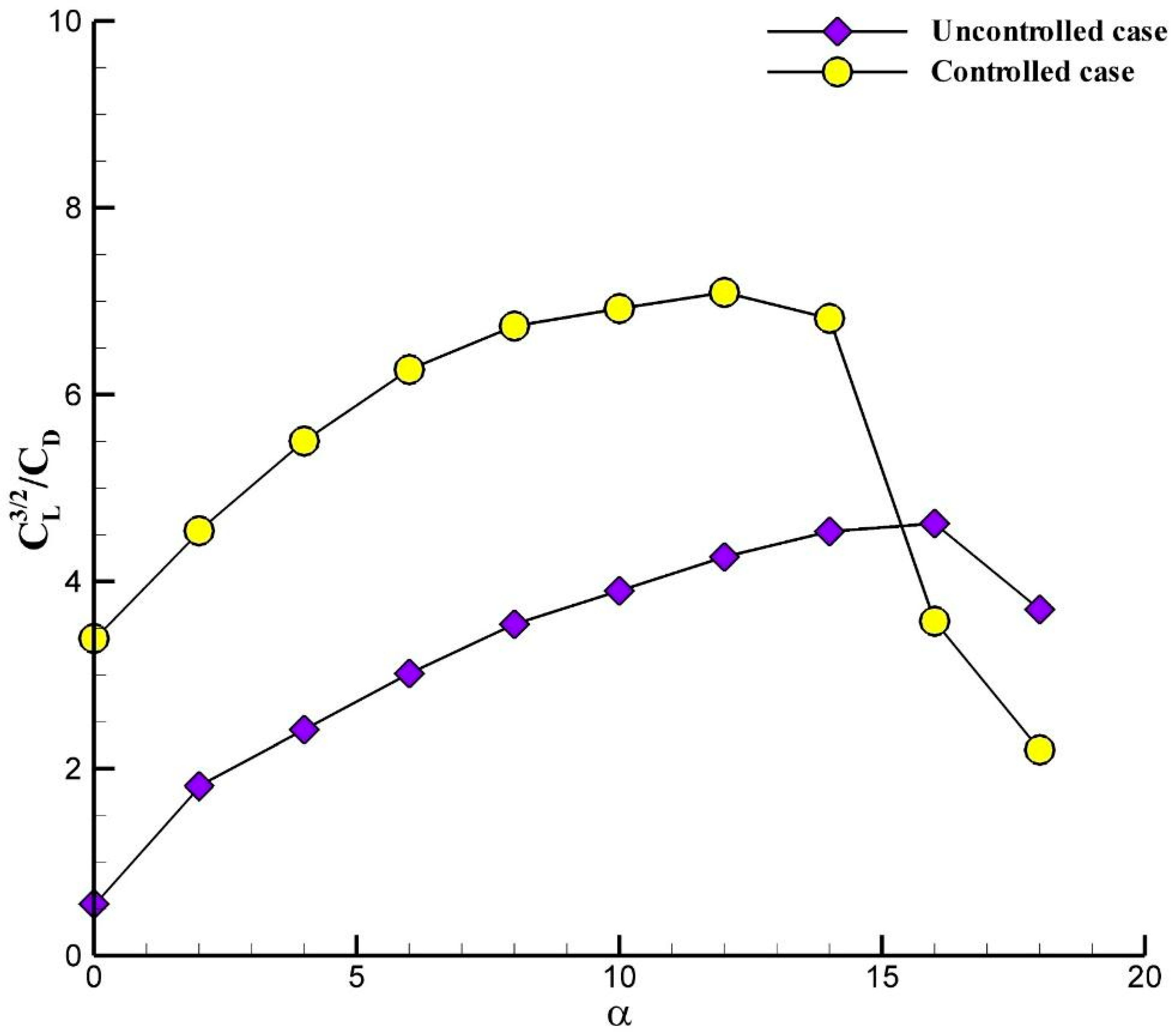

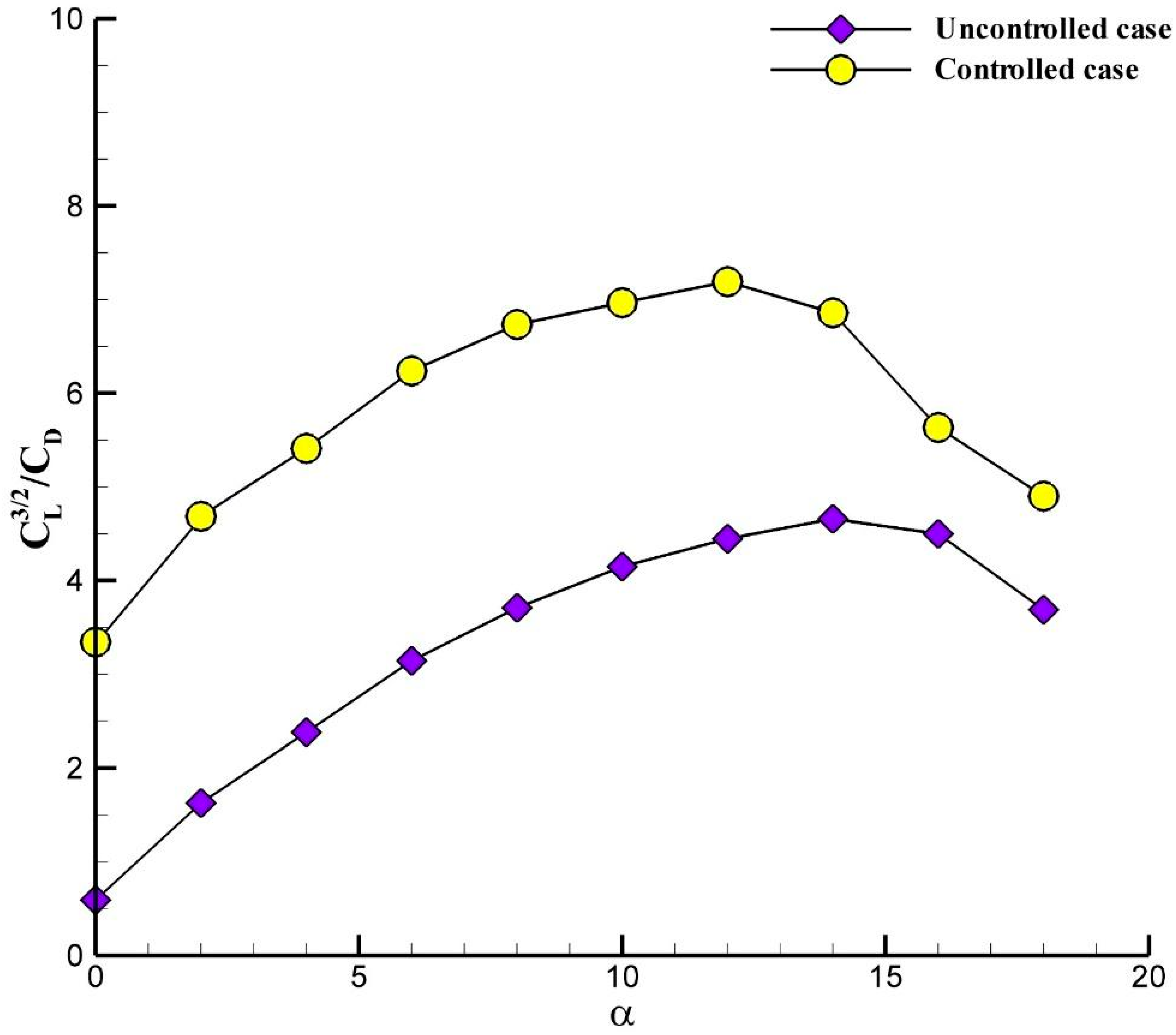

- The use of the flexible membrane significantly hampered the development of the LSB. Improvement of CL,max was provided at the level of around 4.65% and 8.73% at Re = 1.05 × 105 and Re = 1.4 × 105, respectively. This indicated that aerodynamic performance was remarkably increased, resulting in the presence of more energy output under the same conditions. This can be seen from the aerodynamic power efficiency. While the maximum aerodynamic power efficiency was 4.5 at both Reynolds numbers, this value increased to 7 in the controlled case.

- -

- Its positive effects were twofold when aerodynamic lift curves were investigated regionally: (i) at the pre-stall region, membrane material ensured a positive role in terms of increasing aerodynamic performance, and (ii) at the post-stall region, aerodynamic flow-induced vibrations were enormously diminished.

- -

- Not only did the local flexibility affect the formation of the LSB, but also caused the location of the transition phenomenon to alter, providing the occurrence earlier.

- -

- In addition to aerodynamic lift coefficient improvement, the drag coefficient was enormously reduced, resulting in increased power efficiency.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation | |

| LSB | Laminar Separation Bubble |

| MAVs | Micro aerial vehicles |

| UAVs | Unmanned aerial vehicles |

| APG | Adverse pressure gradient |

| CFD | Computational fluid dynamics |

| UDF | User-defined function |

| AoA | Angle of attack |

| LES | Large eddy simulation |

| PIV | Particle image velocimetry |

| LFM | Local flexible membrane |

| PE | Power efficiency |

| TKE | Turbulence kinetic energy |

| AWM | Atmospheric wind tunnel |

| Subscripts | |

| L | Lift |

| D | Drag |

| max | Maximum |

| L, max | Maximum lift |

| Symbols | |

| Re | Reynolds number |

| c | Chord length |

| s | Span length |

| μ | Dynamic viscosity |

| R | Universal gas constant |

| FL | Lift force |

| FD | Drag force |

| CL | Lift coefficient |

| CD | Drag coefficient |

| α | Angle of attack |

| E | Young’s modulus |

| CL,max | Maximum lift coefficient |

| ρ | Air density |

| ρm | Flexible membrane density |

| U∞ | Velocity of potential flow |

| σ | Standard deviation |

| Tu | Turbulence level |

| uı | Velocity component at direction-x |

| vı | Velocity component at direction-y |

References

- Su, R.; Gao, Z.; Chen, Y.; Zhang, C.; Wang, J. Large-eddy simulation of the influence of hairpin vortex on pressure coefficient of an operating horizontal axis wind turbine. Energy Convers. Manag. 2022, 267, 115864. [Google Scholar] [CrossRef]

- Karasu, İ.; Sahin, B.; Tasci, M.O.; Akilli, H. Effect of yaw angles on aerodynamics of a slender delta wing. J. Aerosp. Eng. 2019, 32, 04019074. [Google Scholar] [CrossRef]

- Miao, W.; Liu, Q.; Xu, Z.; Yue, M.; Li, C.; Zhang, W. A comprehensive analysis of blade tip for vertical axis wind turbine: Aerodynamics and the tip loss effect. Energy Convers. Manag. 2022, 253, 115140. [Google Scholar] [CrossRef]

- Liu, Q.; Miao, W.; Bashir, M.; Xu, Z.; Yu, N.; Luo, S.; Li, C. Aerodynamic and aeroacoustic performance assessment of a vertical axis wind turbine by synergistic effect of blowing and suction. Energy Convers. Manag. 2022, 271, 116289. [Google Scholar] [CrossRef]

- Karasu İ Genç, M.S.; Açıkel, H.; Akpolat, M.T. An experimental study on laminar separation bubble and transition over an aerofoil at low Reynolds number. In Proceedings of the 30th AIAA Applied Aerodynamics Conference, AIAA-2012-3030, New Orleans, LA, USA, 25–28 June 2012. [Google Scholar]

- Durhasan, T.; Karasu, İ. Dye visualization over double delta wing with various kink angles. J. Vis. 2019, 22, 669–681. [Google Scholar] [CrossRef]

- Demir, H.; Genç, M.S. An experimental investigation of laminar separation bubble formation on flexible membrane wing. Eur. J. Mech. -B/Fluids 2017, 65, 326–338. [Google Scholar] [CrossRef]

- Koca, K.; Genç, M.S.; Özkan, R. Mapping of laminar separation bubble and bubble-induced vibrations over a turbine blade at low Reynolds numbers. Ocean Eng. 2021, 239, 109867. [Google Scholar] [CrossRef]

- Karasu, İ. Flow control over a diamond-shaped cylinder using slits. Exp. Therm. Fluid Sci. 2020, 112, 109992. [Google Scholar] [CrossRef]

- Collis, S.S.; Joslin, R.D.; Seifert, A.; Theofilis, V. Issues in active flow control: Theory, control, simulation, and experiment. Prog. Aerosp. Sci. 2004, 40, 237–289. [Google Scholar] [CrossRef]

- Ghosh, S.; Choi, J.I.; Edwards, J.R. Numerical simulations of effects of micro vortex generators using immersed-boundary methods. AIAA J. 2010, 48, 92–103. [Google Scholar] [CrossRef]

- Igarashi, T.; Terachi, N. Drag reduction of flat plate normal to airstream by flow control using a rod. J. Wind. Eng. Ind. Aerodyn. 2002, 90, 359–376. [Google Scholar] [CrossRef]

- Attie, C.; ElCheikh, A.; Nader, J.; Elkhoury, M. Performance enhancement of a vertical axis wind turbine using a slotted deflective flap at the trailing edge. Energy Convers. Manag. 2022, 273, 116388. [Google Scholar] [CrossRef]

- Genç, M.S.; Kaynak, Ü. Control of flow separation and transition point over an aerofoil at low Re number using simultaneous blowing and suction. In Proceedings of the 19th AIAA Computational Fluid Dynamics, AIAA-3672, San Antonio, TX, USA, 22–25 June 2009. [Google Scholar]

- Genç, M.S. Control of Low Reynolds Number Flow over Aerofoils and Investigation of Aerodynamic Performance. Ph.D. Thesis, Graduate School of Natural and Applied Sciences, Erciyes University, Kayseri, Turkey, 2009. [Google Scholar]

- Chakroun, W.; Al-Mesri, I.; Al-Fahad, S. Effect of Surface Roughness on the Aerodynamic Characteristics of a Symmetrical Airfoil. Wind Eng. 2004, 28, 547–564. [Google Scholar] [CrossRef]

- Miao, X.; Zhang, Q.; Wang, L.; Jiang, H.; Qi, H. Application of riblets on turbine blade endwall secondary flow control. J. Propuls. Power 2015, 31, 1578–1585. [Google Scholar] [CrossRef]

- Özden, K.S.; Karasu, İ.; Genç, M.S. Experimental investigation of the ground effect on a wing without/with trailing edge flap. Fluid Dyn. Res. 2020, 52, 045504. [Google Scholar] [CrossRef]

- Genç, M.S.; Ozisik, G.; Kahraman, N. Investigation of aerodynamics performance of NACA00-12 aerofoil with plain. ISI BILIM TEK DERG-J. Therm. Sci. Technol. 2008, 28, 1–8. [Google Scholar]

- Sedighi, H.; Akbarzadeh, P.; Salavatipour, A. Aerodynamic performance enhancement of horizontal axis wind turbines by dimples on blades: Numerical investigation. Energy 2020, 195, 117056. [Google Scholar] [CrossRef]

- Seo, S.H.; Hong, C.H. Performance improvement of airfoils for wind blade with the groove. Int. J. Green Energy 2016, 13, 34–39. [Google Scholar] [CrossRef]

- Hansen, K.L.; Kelso, R.M.; Dally, B.B. Performance variations of leading-edge tubercles for distinct airfoil profiles. AIAA J. 2011, 49, 185–194. [Google Scholar] [CrossRef]

- Ni, Z.; Su, T.C.; Dhanak, M. An empirically-based model for the lift coefficients of twisted airfoils with leading-edge tubercles. AIP Adv. 2018, 8, 045123. [Google Scholar] [CrossRef]

- Johari, H.; Henoch, C.; Custodio, D.; Levshin, A. Effects of leading-edge protuberances on airfoil performance. AIAA J. 2007, 45, 2634–2642. [Google Scholar] [CrossRef]

- Malipeddi, A.K.; Mahmoudnejad, N.; Hoffmann, K.A. Numerical analysis of effects of leading-edge protuberances on aircraft wing performance. J. Aircr. 2012, 49, 1336–1344. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Zhuang, M. Improvement of the aerodynamic performance of vertical axis wind turbines with leading-edge serrations and helical blades using CFD and Taguchi method. Energy Convers. Manag. 2018, 177, 107–121. [Google Scholar] [CrossRef]

- Cai, C.; Zuo, Z.; Morimoto, M.; Maeda, T.; Kamada, Y.; Liu, S. Two-step stall characteristic of an airfoil with a single leading-edge protuberance. AIAA J. 2018, 56, 64–77. [Google Scholar] [CrossRef]

- Corsini, A.; Delibra, G.; Sheard, A.G. On the role of leading-edge bumps in the control of stall onset in axial fan blades. J. Fluids Eng. 2013, 135, 081104. [Google Scholar] [CrossRef]

- Rostamzadeh, N.; Kelso, R.M.; Dally, B.B.; Hansen, K.L. The effect of undulating leading-edge modifications on NACA 0021 airfoil characteristics. Phys. Fluids 2013, 25, 117101. [Google Scholar] [CrossRef]

- Skillen, A.; Revell, A.; Pinelli, A.; Piomelli, U.; Favier, J. Flow over a wing with leading-edge undulations. AIAA J. 2015, 53, 464–472. [Google Scholar] [CrossRef]

- Özden, M.; Genç, M.S.; Koca, K. Investigation of the effect of hidden vortex generator-flap integrated mechanism revealed in low velocities on wind turbine blade flow. Energy Convers. Manag. 2023, 287, 117107. [Google Scholar] [CrossRef]

- Zhao, P.; Jiang, Y.; Liu, S.; Stoesser, T.; Zou, L.; Wang, K. Investigation of fundamental mechanism leading to the performance improvement of vertical axis wind turbines by deflector. Energy Convers. Manag. 2021, 247, 114680. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhao, P.; Stoesser, T.; Wang, K.; Zou, L. Experimental and numerical investigation of twin vertical axis wind turbines with a deflector. Energy Convers. Manag. 2020, 209, 112588. [Google Scholar] [CrossRef]

- Heragy, M.; Kono, T.; Kiwata, T. Investigating the effects of wind concentrator on power performance improvement of crossflow wind turbine. Energy Convers. Manag. 2022, 255, 115326. [Google Scholar] [CrossRef]

- Hosseini, A.; Goudarzi, N. Design and CFD study of a hybrid vertical-axis wind turbine by employing a combined Bach-type and H-Darrieus rotor systems. Energy Convers. Manag. 2019, 189, 49–59. [Google Scholar] [CrossRef]

- Saleem, A.; Kim, M.H. Effect of rotor tip clearance on the aerodynamic performance of an aerofoil-based ducted wind turbine. Energy Convers. Manag. 2019, 201, 112186. [Google Scholar] [CrossRef]

- MacPhee, D.W.; Beyene, A. Performance analysis of a small wind turbine equipped with flexible blades. Renew. Energy 2019, 132, 497–508. [Google Scholar] [CrossRef]

- Genç, M.S. Unsteady aerodynamics and flow-induced vibrations of a low aspect ratio rectangular membrane wing with excess length. Exp. Therm. Fluid Sci. 2013, 44, 749–759. [Google Scholar] [CrossRef]

- Özden, M.; Genç, M.S.; Koca, K. Passive flow control application using single and double vortex generator on S809 wind turbine airfoil. Energies 2023, 16, 5339. [Google Scholar] [CrossRef]

- Lian, Y.; Shyy, W.; Viieru, D.; Zhang, B. Membrane wing aerodynamics for micro air vehicles. Prog. Aerosp. Sci. 2003, 39, 425–465. [Google Scholar] [CrossRef]

- Koca, K.; Genç, M.S.; Ertürk, S. Impact of local flexible membrane on power efficiency stability at wind turbine blade. Renew. Energy 2022, 197, 1163–1173. [Google Scholar] [CrossRef]

- Kang, W.; Zhang, J.Z.; Feng, P.H. Aerodynamic analysis of a localized flexible airfoil at low Reynolds numbers. Commun. Comput. Phys. 2012, 11, 1300–1310. [Google Scholar] [CrossRef]

- Naderi, A.; Mojtahedpoor, M. Numerical solution of unsteady flow on airfoils with local membrane in transient and laminar flows. J. Theor. Appl. Vib. Acoust. 2016, 2, 21–34. [Google Scholar]

- Wang, L.; Cao, S.; Li, Y.; Zhang, J. On synchronization in flow over airfoil with local oscillating flexible surface at high angle of attack using Lagrangian coherent structures. Eur. Phys. J. Spec. Top. 2019, 228, 1515–1525. [Google Scholar] [CrossRef]

- Lou, B.; Ye, S.; Wang, G.; Huang, Z. Numerical and experimental research of flow control on an NACA 0012 airfoil by local vibration. Appl. Math. Mech. 2019, 40, 1–12. [Google Scholar] [CrossRef]

- Koca, K.; Genç, M.S.; Bayır, E.; Soğuksu, F.K. Experimental study of the wind turbine airfoil with the local flexibility at different locations for more energy output. Energy 2022, 239, 121887. [Google Scholar] [CrossRef]

- Koca, K.; Genç, M.S.; Veerasamy, D.; Özden, M. Experimental flow control investigation over suction surface of turbine blade with local surface passive oscillation. Ocean Eng. 2022, 266, 113024. [Google Scholar] [CrossRef]

- Genç, M.S.; Karasu, İ.; Açıkel, H.H. An experimental study on aerodynamics of NACA2415 aerofoil at low Re numbers. Exp. Therm. Fluid Sci. 2012, 39, 252–264. [Google Scholar] [CrossRef]

- Bleischwitz, R.; de Kat, R.; Ganapathisubramani, B. Aspect-ratio effects on aeromechanics of membrane wings at moderate Reynolds numbers. AIAA J. 2015, 53, 780–788. [Google Scholar] [CrossRef]

- Available online: https://www.unibw.de/lrt7-en/equipment/atmospheric-windtunnel (accessed on 25 April 2024).

- Genç, M.S.; Demir, H.; Özden, M.; Bodur, T.M. Experimental analysis of fluid-structure interaction in flexible wings at low Reynolds number flows. Aircr. Eng. Aerosp. Technol. 2021, 93, 1060–1075. [Google Scholar] [CrossRef]

| Design | Suction-Type and Low-Speed |

|---|---|

| Length of test section | ~2.5 m (closed type) |

| Length of tunnel | 13 m |

| Test section | Length (~2.5 m), Height (0.5 m), Width (0.5 m) |

| Motor | Type: DC motor, Power: 15 kW, Frequency: 50 Hz |

| Model | H4, 1000/15A |

| Capacity | 45,000 m3/h, 450 PA |

| Flow velocity | 5 m/s < U < 40 m/s |

| Turbulence level | 0.3% < Tu < ~0.9% |

| Nozzle | Contraction cone: 9:1 |

| Design | Eiffel-Type |

|---|---|

| Test section | Length (22 m), Height (1.85 m), Width (1.85 m) |

| Motor | Type: DC motor, Power: 350 kW |

| Flow velocity | 2 m/s < U < 45 m/s |

| Turbulence level | Tu < 0.5% |

| Nozzle | Contraction: 9 |

| Heating | Inlet: 1.2 MW, Bottom: heated/cooled |

| Parameter | PIV |

|---|---|

| Camera | pco.dimax S4 |

| Sensor resolution, pixels | 2016 × 2016; 2016 × 1100 used |

| Pixel size | 11 μm × 11 μm |

| Laser | Photonics DM150-532-DH (Photonics Industries International, Inc., Ronkonkoma, NY, USA) |

| Light sheet thickness | 2 mm |

| PIV mode | Double Frame |

| Sampling rate, Hz | 1000 |

| Sampling time, s | 2 |

| Seeding particles | DEHS, mean diameter ca. 0.4 µm |

| Parameter | Deformation Measurement |

|---|---|

| Camera | pco.dimax S4 (2 cameras) |

| Sensor resolution, pixels | 2016 × 2016; 2016 × 1100 used |

| Pixel size | 11 μm × 11 μm |

| Illumination | Hardsoft ILM-501CG (HARDsoft Mikroprocessor Systems, Kraków, Poland) |

| Sampling rate, Hz | 1000 |

| Sampling time, s | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koca, K.; Genç, M.S. Role of Partial Flexibility on Flow Evolution and Aerodynamic Power Efficiency over a Turbine Blade Airfoil. Aerospace 2024, 11, 571. https://doi.org/10.3390/aerospace11070571

Koca K, Genç MS. Role of Partial Flexibility on Flow Evolution and Aerodynamic Power Efficiency over a Turbine Blade Airfoil. Aerospace. 2024; 11(7):571. https://doi.org/10.3390/aerospace11070571

Chicago/Turabian StyleKoca, Kemal, and Mustafa Serdar Genç. 2024. "Role of Partial Flexibility on Flow Evolution and Aerodynamic Power Efficiency over a Turbine Blade Airfoil" Aerospace 11, no. 7: 571. https://doi.org/10.3390/aerospace11070571

APA StyleKoca, K., & Genç, M. S. (2024). Role of Partial Flexibility on Flow Evolution and Aerodynamic Power Efficiency over a Turbine Blade Airfoil. Aerospace, 11(7), 571. https://doi.org/10.3390/aerospace11070571