Perovskite Solar Cells and Thermoelectric Generator Hybrid Array Feeding a Synchronous Reluctance Motor for an Efficient Water Pumping System

Abstract

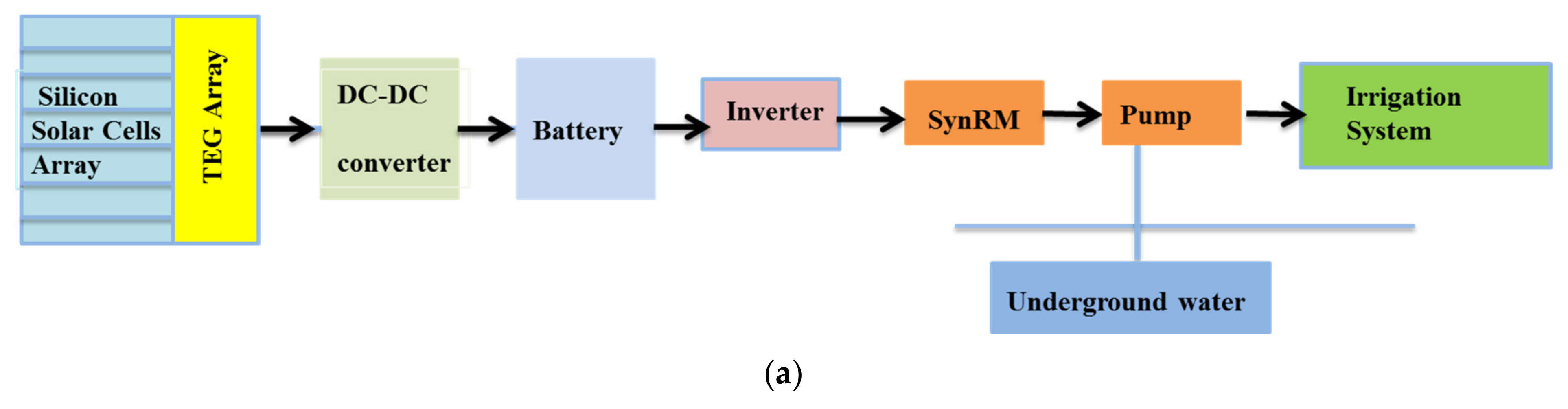

:1. Introduction

2. The Proposed System Components

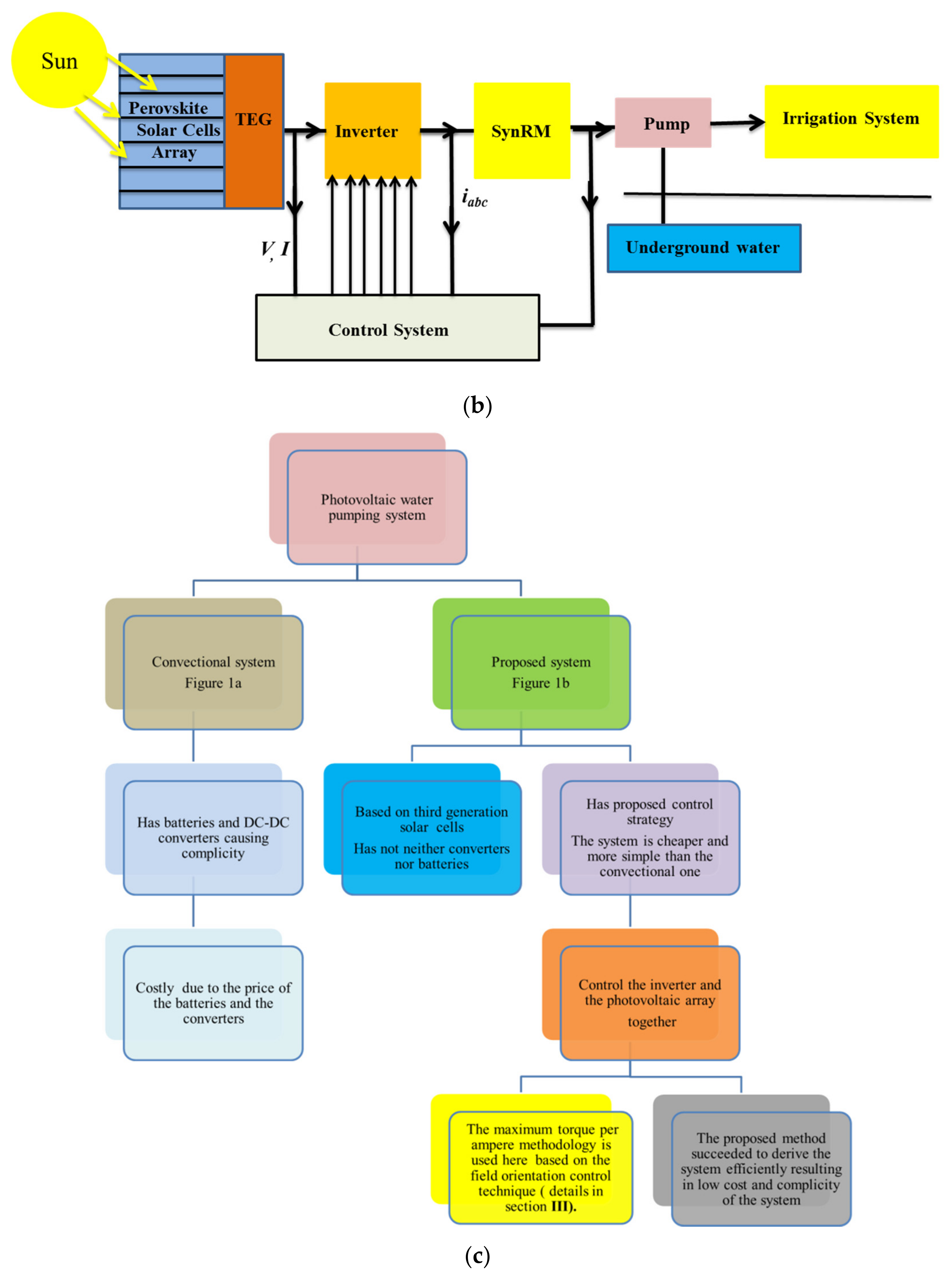

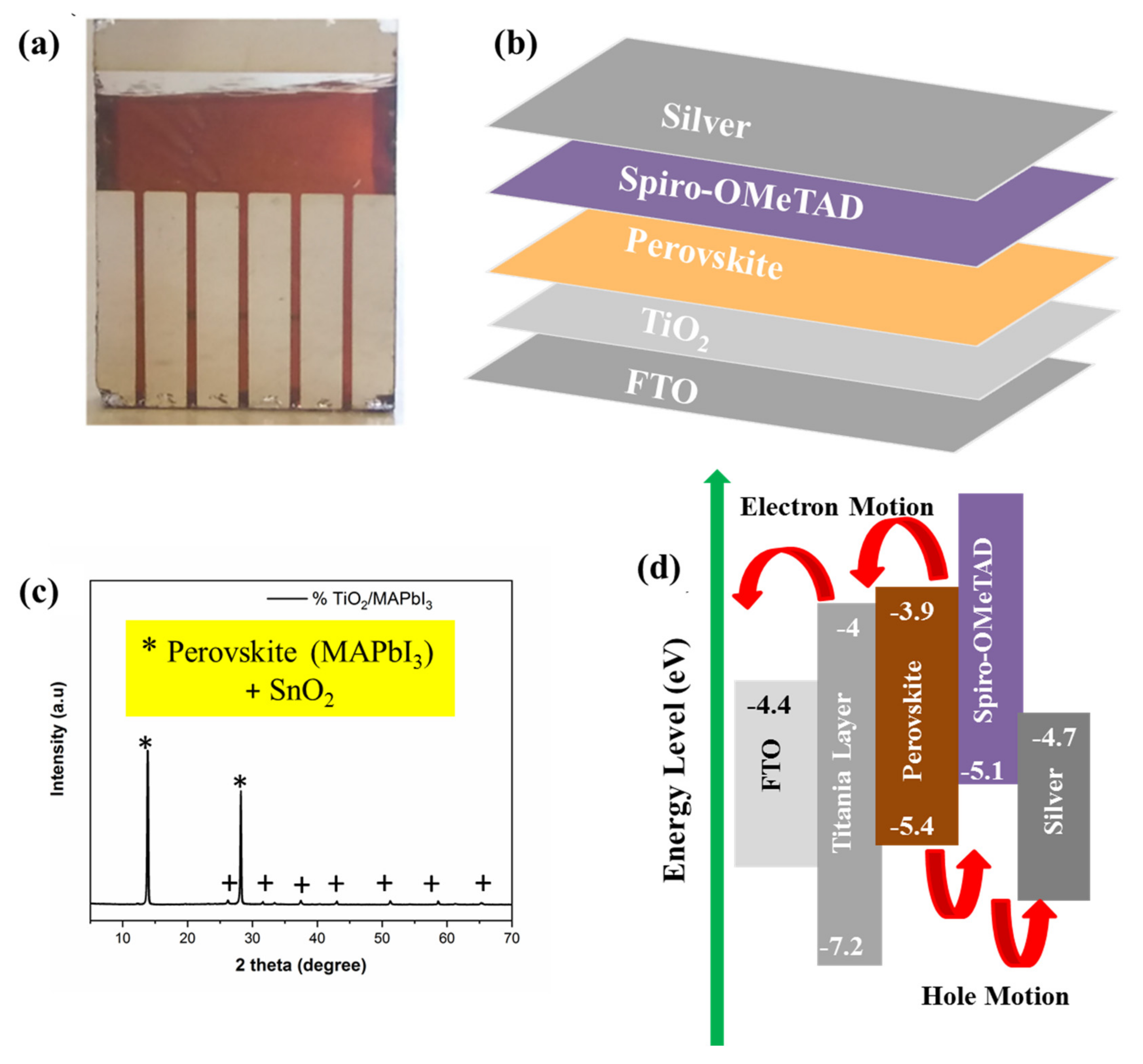

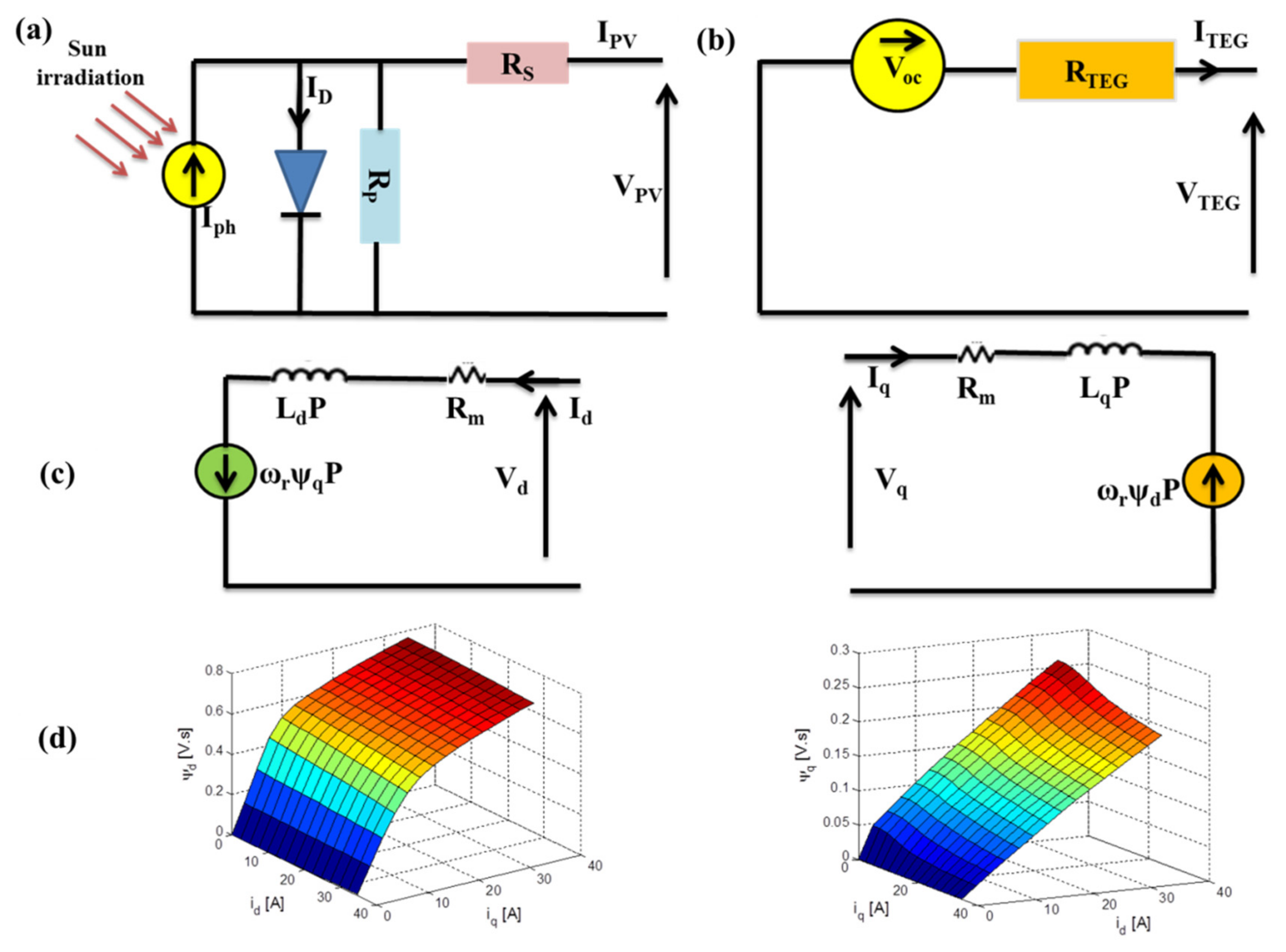

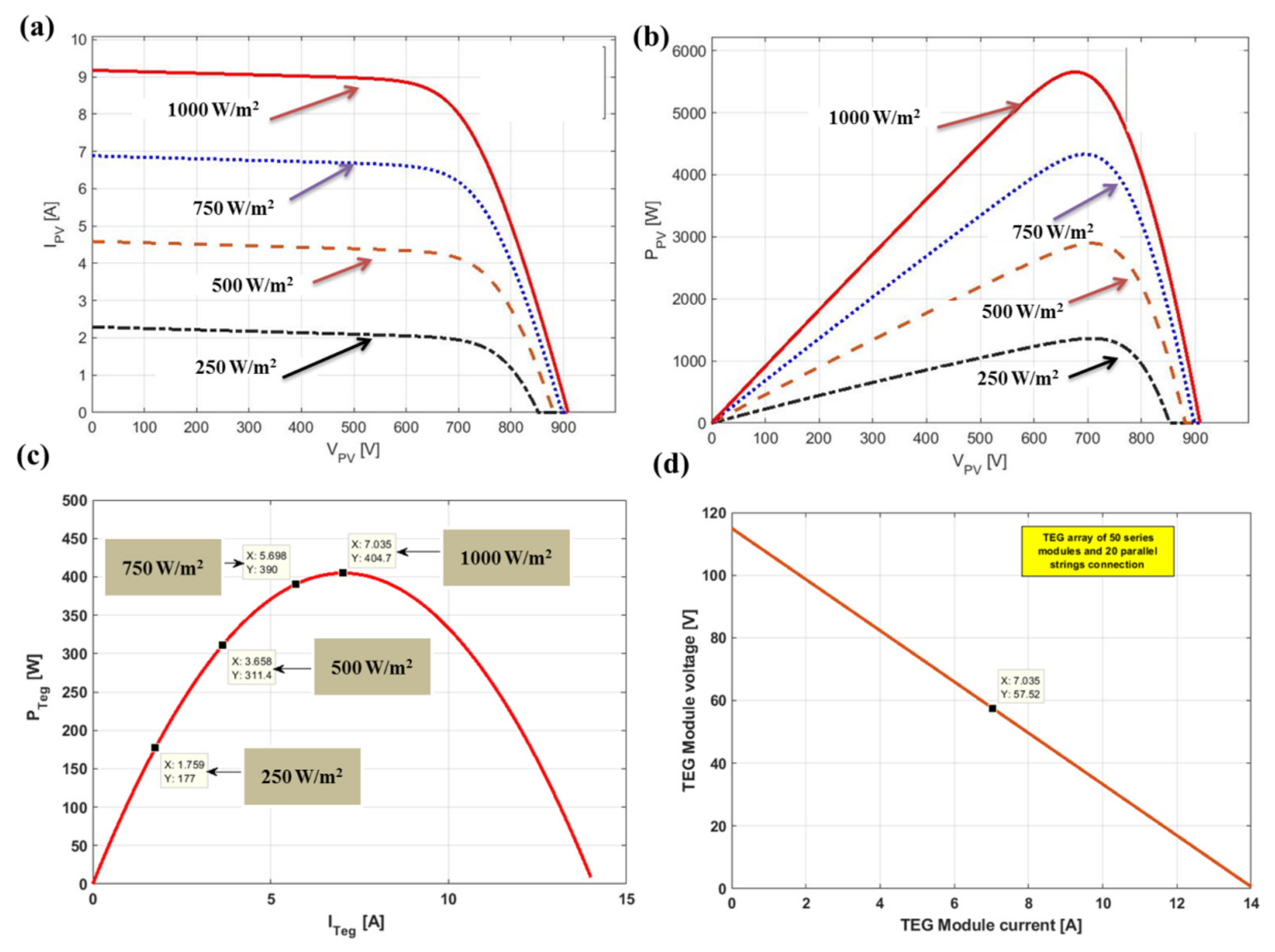

2.1. Perovskite Solar Cell Fabrication and Modeling

2.2. Thermoelectric Generator Modeling

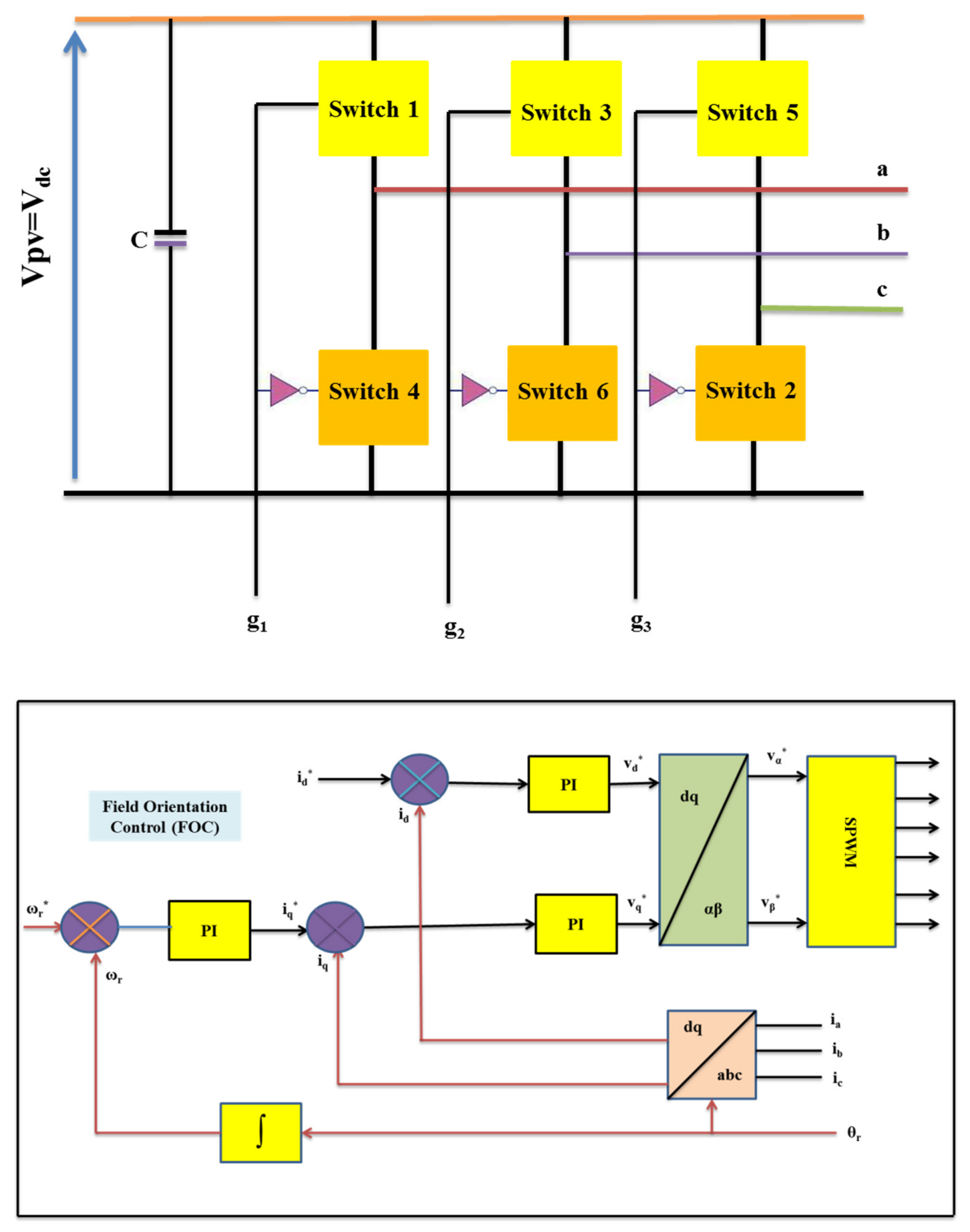

2.3. Modeling of the Three-Phase Inverter

2.4. The Three-Phase SynRM Model

2.5. Centrifugal Pump Modeling

3. The Proposed Control Strategy

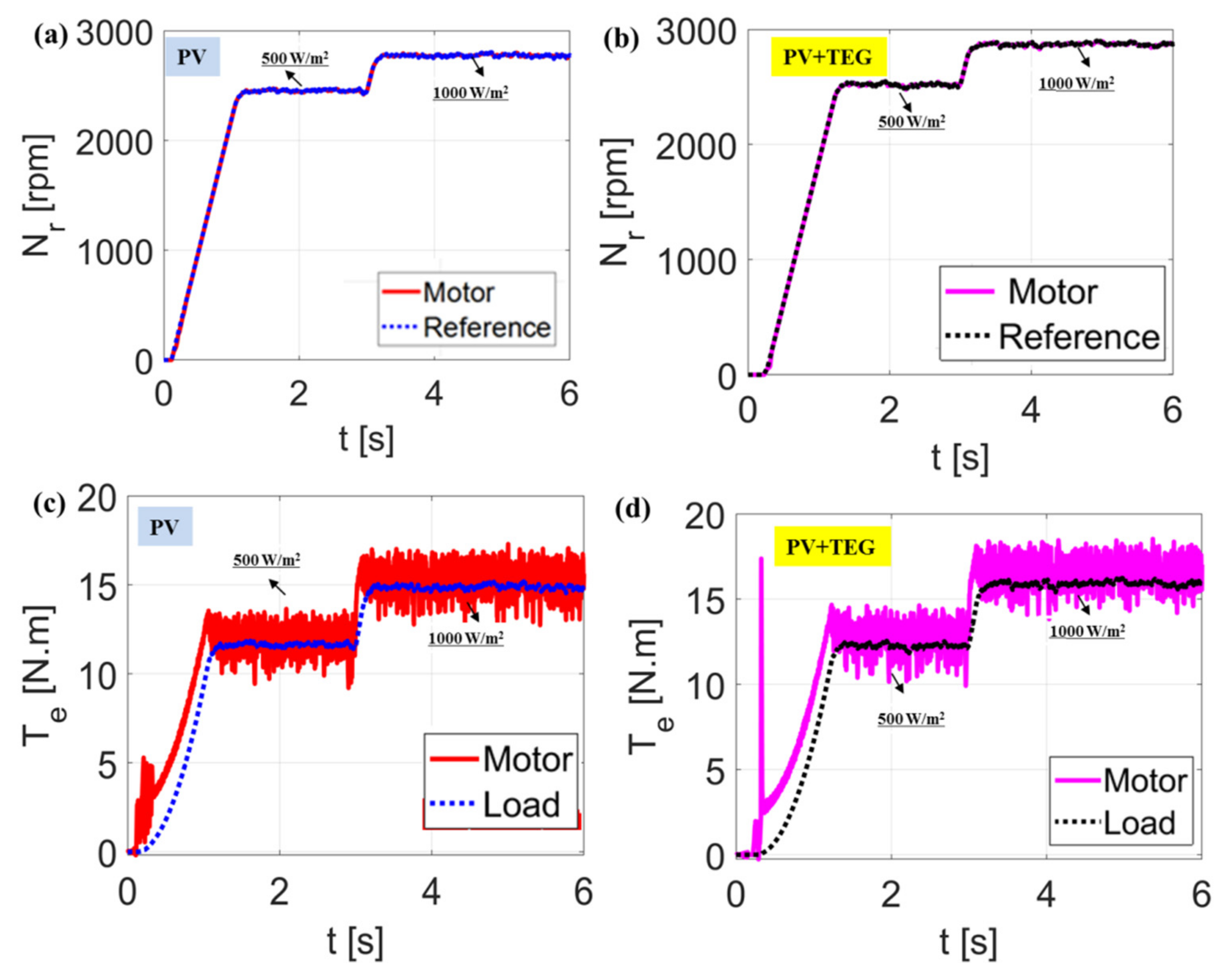

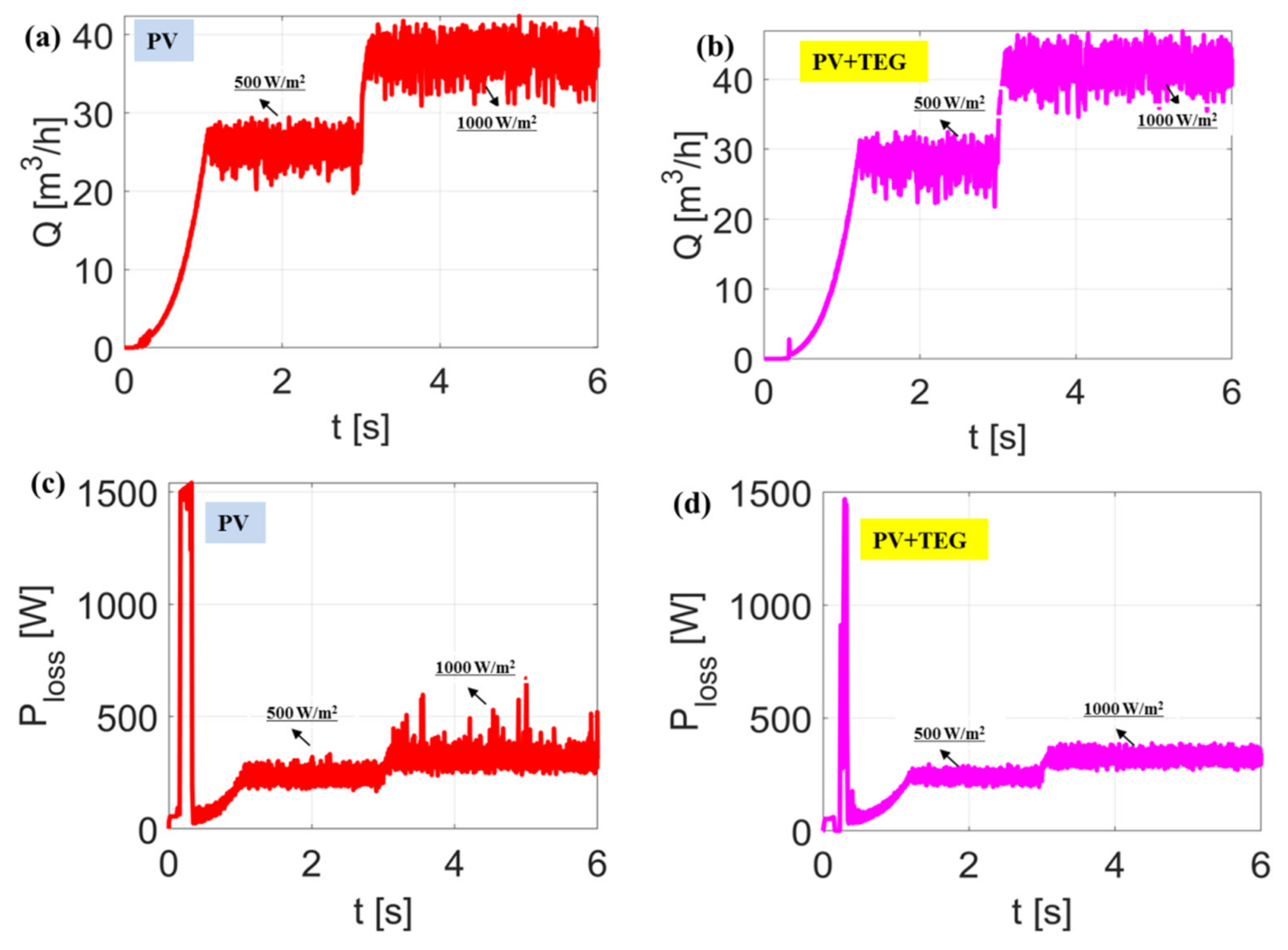

4. The Complete Proposed Pumping System Performance

5. Economic Analysis

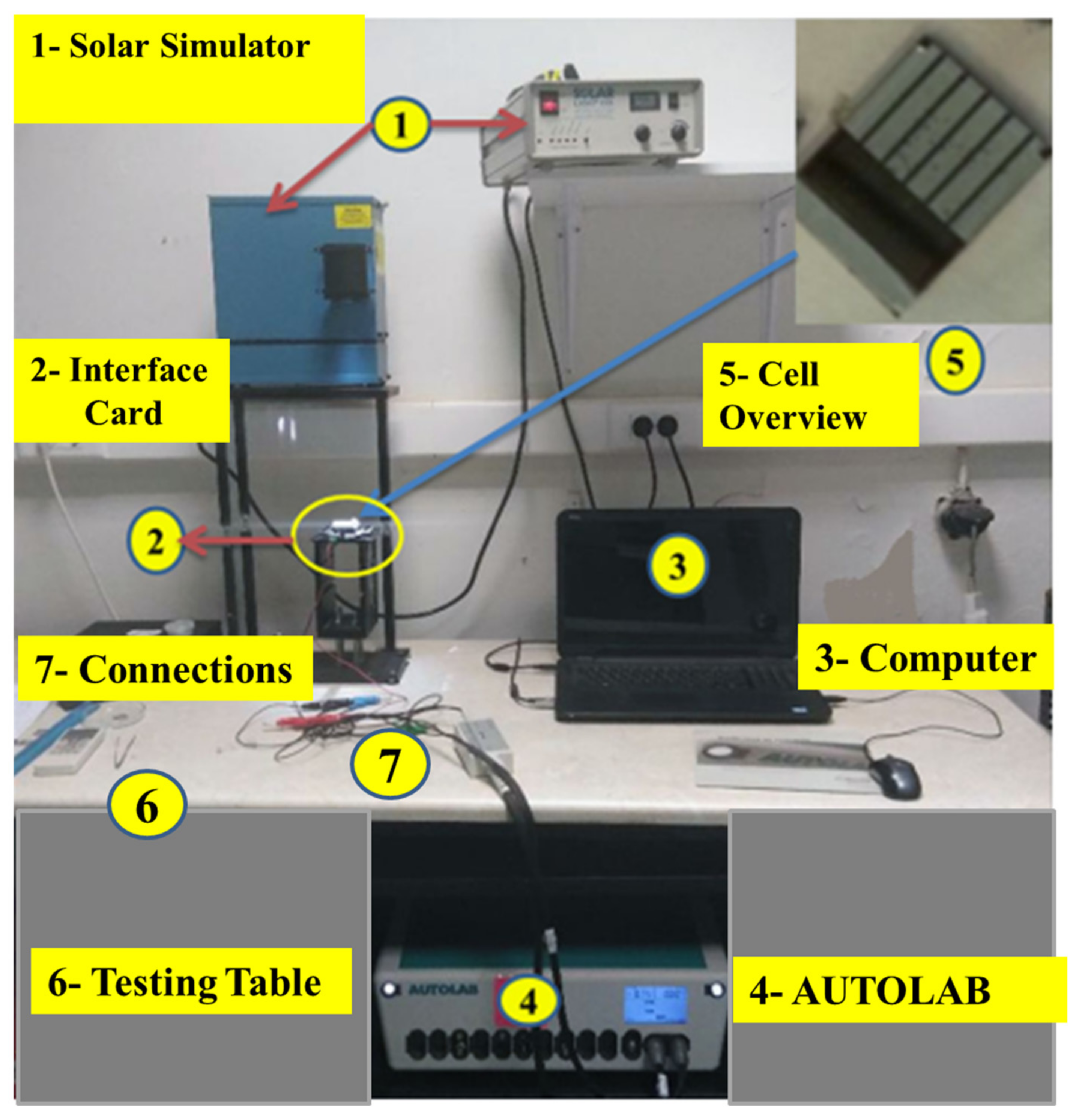

6. Experimental Confirmation

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Verma, V.; Kane, A.; Singh, B. Complementary performance enhancement of PV energy system through thermoelectric generation. Renew. Sustain. Energy Rev. 2016, 58, 1017–1026. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Rahim, N.A.A.; Rahim, N.A.; Selvaraj, J.A.L. Progress in solar PV technology: Research and achievement. Renew. Sustain. Energy Rev. 2013, 20, 443–461. [Google Scholar] [CrossRef]

- Parida, B.; Iniyan, S.; Goic, R. A review of solar photovoltaic technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Attivissimo, F.; di Nisio, A.; Lanzolla, A.M.L.; Paul, M. Feasibility of a photovoltaic–thermoelectric generator: Performance analysis and simulation results. IEEE Trans. Instrum. Meas. 2015, 64, 1158–1169. [Google Scholar] [CrossRef] [Green Version]

- Babu, C.; Ponnambalam, P. The theoretical performance evaluation of hybrid PV TEG system. Energy Convers. Manag. 2018, 173, 450–460. [Google Scholar] [CrossRef]

- Hasanuzzaman, M.; Malek, A.B.M.A.; Islam, M.M.; Pandey, A.K.; Rahim, N.A. Global advancement of cooling technologies for PV systems: A review. Sol. Energy 2016, 137, 25–45. [Google Scholar] [CrossRef]

- Lin, J.; Liao, T.; Lin, B. Performance analysis and load matching of a photovoltaic–thermoelectric hybrid system. Energy Convers. Manag. 2015, 105, 891–899. [Google Scholar] [CrossRef]

- Benlarbi, K.; Mokrani, L.; Nait-Said, M.S. A fuzzy global efficiency optimization of a photovoltaic water pumping system. Sol. Energy 2004, 77, 203–216. [Google Scholar] [CrossRef]

- Nabil, M.; Allam, S.M.; Rashad, E.M. Modeling and design considerations of a photovoltaic energy source feeding a synchronous reluctance motor suitable for pumping systems. Ain Shams Eng. J. 2012, 3, 375–382. [Google Scholar] [CrossRef] [Green Version]

- Nabil, M.; Allam, S.M.; Rashad, E.M. Performance improvement of a photovoltaic pumping system using a synchronous reluctance motor. Electr. Power Compon. Syst. 2013, 41, 447–464. [Google Scholar] [CrossRef]

- Solar Cells Efficiency Map. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 27 June 2022).

- Balis, N.; Zaky, A.A.; Perganti, D.; Kaltzoglou, A.; Sygellou, L.; Katsaros, F.; Stergiopoulos, T.; Kontos, A.G.; Falaras, P. Dye Sensitization of Titania Compact Layer for Efficient and Stable Perovskite Solar Cells. ACS Appl. Energy Mater. 2018, 1, 6161–6171. [Google Scholar] [CrossRef]

- Gkini, K.; Verykios, A.; Balis, N.; Kaltzoglou, A.; Papadakis, M.; Adamis, K.S.; Armadorou, K.-K.; Soultati, A.; Drivas, C.; Gardelis, S.; et al. Enhanced Organic and Perovskite Solar Cell Performance through Modification of the Electron-Selective Contact with a Bodipy−Porphyrin Dyad. ACS Appl. Mater. Interfaces 2020, 12, 1120–1131. [Google Scholar] [CrossRef]

- Gkini, K.; Balis, N.; Papadakis, M.; Verykios, A.; Skoulikidou, M.; Drivas, C.; Kennou, S.; Golomb, M.; Walsh, A.; Coutsolelos, A.G.; et al. Manganese porphyrin interface engineering in perovskite solar cells. ACS Appl. Energy Mater. 2020, 3, 7353–7363. [Google Scholar] [CrossRef]

- Zaky, A.A.; Christopoulos, E.; Gkini, K.; Arfanis, M.K.; Sygellou, L.; Kaltzoglou, A.; Stergiou, A.; Tagmatarchis, N.; Balis, N.; Falaras, P. Enhancing efficiency and decreasing photocatalytic degradation of perovskite solar cells using a hydrophobic copper-modified titania electron transport layer. Appl. Catal. B Environ. 2021, 284, 119714. [Google Scholar] [CrossRef]

- Zaky, A.A.; Ibrahim, M.N.; Rezk, H.; Christopoulos, E.; El Sehiemy, R.A.; Hristophorou, E.; Kladas, A.; Sergeant, P.; Falaras, P. Energy Efficiency Improvement of Water Pumping System Using Synchronous Reluctance Motor Fed by Perovskite Solar Cells. Int. J. Energy Res. 2020, 44, 11629–11642. [Google Scholar] [CrossRef]

- Zaky, A.A.; Balis, N.; Gkini, K.; Athanasekou, C.; Kaltzoglou, A.; Stergiopoulos, T.; Falaras, P. Dye Engineered Perovskite Solar Cells under Accelerated Thermal Stress and Prolonged Light Exposure. ChemistrySelect 2020, 5, 4454–4462. [Google Scholar] [CrossRef]

- Zaky, A.A.; El Sehiemy, R.A.; Rashwan, Y.I.; El Hossieni, M.A.; Gkini, K.; Kladas, A.; Falaras, P. Optimal Performance Emulation of PSCs using the Elephant Herd Algorithm Associated with Experimental Validation, Electronic and Photonic Devices and Systems section. ECS J. Solid State Sci. Technol. 2019, 8, Q249–Q255. [Google Scholar] [CrossRef]

- Balis, N.; Zaky, A.A.; Athanasekou, C.; Silva, A.M.T.; Sakellis, E.; Vasilopoulou, M.; Stergiopoulos, T.; Kontos, A.G.; Falaras, P. Investigating the Role of Reduced Graphene Oxide as a Universal Additive in Planar Perovskite Solar Cells. J. Photochem. Photobiol. A Chem. 2020, 386, 112141. [Google Scholar] [CrossRef]

- Zaky, A.A.; Fathy, A.; Rezk, H.; Gkini, K.; Falaras, P.; Abaza, A. A Modified Triple-Diode Model Parameters Identification for Perovskite Solar Cells via Nature-Inspired Search Optimization Algorithms. Sustainability 2021, 13, 12969. [Google Scholar] [CrossRef]

- Ibrahim, M.N.; Sergeant, P.; Rashad, E.M. Relevance of including saturation and position dependence in the inductances for accurate dynamic modeling and control of SynRMs. IEEE Trans. Ind. Appl. 2017, 53, 151–160. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, M.N.F.; Abdel-khalik, A.S.; Rashad, E.M.; Sergeant, P. An improved torque density synchronous reluctance machine with a combined star–delta winding layout. IEEE Trans. Energy Convers. 2018, 33, 1015–1024. [Google Scholar] [CrossRef]

- Available online: https://www.nextbigfuture.com/2019/02/first-commercial-perovskite-solar-late-in-2019-and-the-road-to-moving-the-energy-needle.html (accessed on 27 June 2022).

- Song, Z.; McElvany, C.L.; Phillips, A.B.; Celik, I.; Krantz, P.W.; Watthage, S.C.; Liyanage, G.K.; Apul, D.; Heben, M.J. A technoeconomic analysis of perovskite solar module manufacturing with low-cost materials and techniques. Energy Environ. Sci. 2017, 10, 1297–1305. [Google Scholar] [CrossRef]

- Available online: https://gotecotech.com/a-new-solar-cell-material-could-make-solar-power-dirtcheap/#:~:text=Perovskites%20offer%20a%20great%20combination%20of%20cheaper%20production,20%20cents%20per%20watt%2C%20that%20is%2086%25%20cheaper (accessed on 27 June 2022).

- Ouyang, Z.; Li, D. Design of segmented high-performance thermoelectric generators with cost in consideration. Appl. Energy 2018, 221, 112–121. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://www.tegmart.com/datasheets/TGPR-10W4V-40S.pdf (accessed on 27 June 2022).

- Lyden, S.; Haque, M.E. Maximum Power Point Tracking techniques for photovoltaic systems: A comprehensive review and comparative analysis. Renew. Sustain. Energy Rev. 2015, 52, 1504–1518. [Google Scholar] [CrossRef]

- Heidari, H.; Rassõlkin, A.; Kallaste, A.; Vaimann, T.; Andriushchenko, E.; Belahcen, A.; Lukichev, D.V. A Review of Synchronous Reluctance Motor Drive Advancements. Sustainability 2021, 13, 729. [Google Scholar] [CrossRef]

- Ibrahim, M.N.; Rezk, H.; Al-Dhaifallah, M.; Sergeant, P. Modelling and Design Methodology of an Improved Performance Photovoltaic Pumping System Employing Ferrite Magnet Synchronous Reluctance Motors. Mathematics 2020, 8, 1429. [Google Scholar] [CrossRef]

- Ibrahim, M.N.; Sergeant, P.; Rashad, E.M. Design of low cost and efficient photovoltaic pumping system utilizing synchronous reluctance motor. In Proceedings of the International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017. [Google Scholar]

- Ibrahim, M.N.; Rezk, H.; Al-Dhaifallah, M.; Sergeant, P. Solar array fed synchronous reluctance motor driven water pump: An improved performance under partial shading conditions. IEEE Access 2019, 7, 77100–77115. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaky, A.A.; Ibrahim, M.N.; Taha, I.B.M.; Yousif, B.; Sergeant, P.; Hristoforou, E.; Falaras, P. Perovskite Solar Cells and Thermoelectric Generator Hybrid Array Feeding a Synchronous Reluctance Motor for an Efficient Water Pumping System. Mathematics 2022, 10, 2417. https://doi.org/10.3390/math10142417

Zaky AA, Ibrahim MN, Taha IBM, Yousif B, Sergeant P, Hristoforou E, Falaras P. Perovskite Solar Cells and Thermoelectric Generator Hybrid Array Feeding a Synchronous Reluctance Motor for an Efficient Water Pumping System. Mathematics. 2022; 10(14):2417. https://doi.org/10.3390/math10142417

Chicago/Turabian StyleZaky, Alaa A., Mohamed N. Ibrahim, Ibrahim B. M. Taha, Bedir Yousif, Peter Sergeant, Evangelos Hristoforou, and Polycarpos Falaras. 2022. "Perovskite Solar Cells and Thermoelectric Generator Hybrid Array Feeding a Synchronous Reluctance Motor for an Efficient Water Pumping System" Mathematics 10, no. 14: 2417. https://doi.org/10.3390/math10142417

APA StyleZaky, A. A., Ibrahim, M. N., Taha, I. B. M., Yousif, B., Sergeant, P., Hristoforou, E., & Falaras, P. (2022). Perovskite Solar Cells and Thermoelectric Generator Hybrid Array Feeding a Synchronous Reluctance Motor for an Efficient Water Pumping System. Mathematics, 10(14), 2417. https://doi.org/10.3390/math10142417