Mining Plan Optimization of Multi-Metal Underground Mine Based on Adaptive Hybrid Mutation PSO Algorithm

Abstract

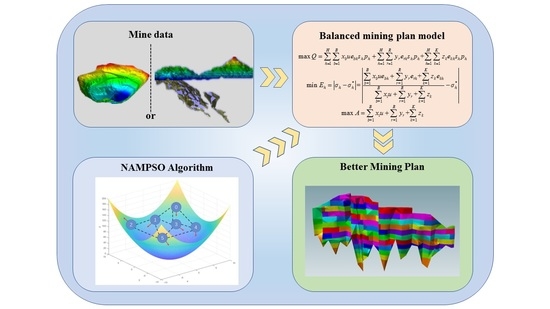

:1. Introduction

2. Balanced Mining Plan Model

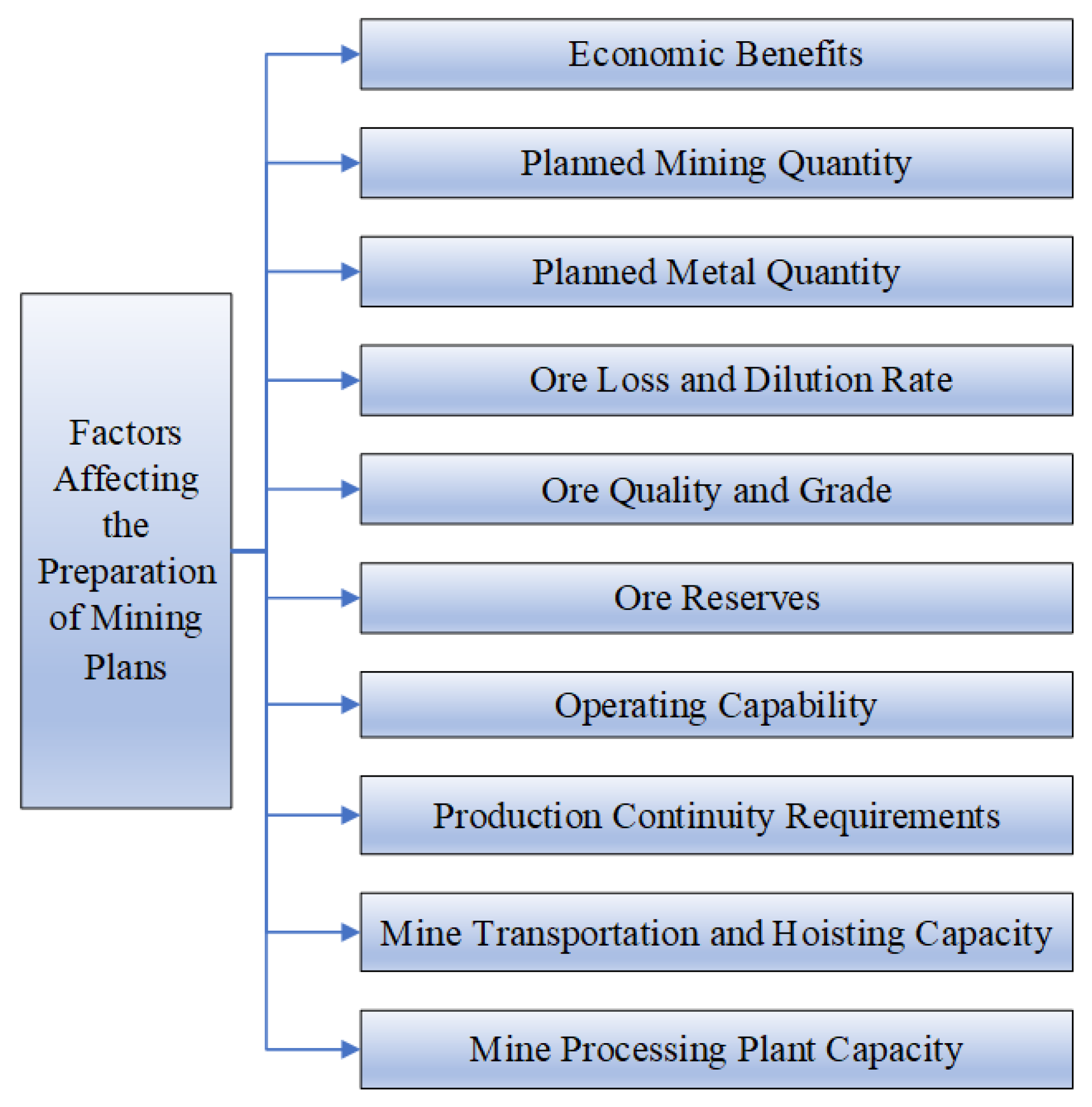

2.1. Model Analysis

- (1)

- Economic efficiency: when mining in the market economy, the first factor to consider is the economic factors, that is, to ensure that the mining enterprise can obtain a better economic benefit.

- (2)

- The planned quantity of mining: for mining enterprises to carry out normal operations, mining plans must be able to ensure the mine’s subsequent production of ore demand.

- (3)

- Planned metal quantity: for mines with metal quantity as the production target, the quantity of ore mined should be guaranteed to meet the requirements of metal quantity for production and processing.

- (4)

- Ore loss and dilution ratios: in the process of balanced mining in underground metal mines, ore loss and dilution ratios must be controlled in order to ensure the maximization of the comprehensive benefits of the enterprise and the maximization of resource recovery and utilization.

- (5)

- Ore quality and grade: due to the variability of mineral resources endowment, there are differences in quality and grade of ore per mining site; therefore, the development of the extraction plan needs to take full account of such differences and achieve the requirements of the extracted ore in terms of quality and grade through reasonable planning.

- (6)

- Ore reserves: to achieve balanced mining, the development of the extraction plan must take into account the limits of the ore reserve of each mineral deposit and mine excavation.

- (7)

- Operating capability: mining enterprises need to have a full understanding of the existing production technology conditions of the mine, production equipment, and the ability and quality of operators when formulating the extraction plan.

- (8)

- Production continuity requirements: once the mine is established, it must ensure that production activities can be carried out continuously and steadily; therefore, the mine’s mining plan must consider the ore reserves of the mineral deposit, cutting, retrieval, and preparation for mining to ensure that the mine production activities can be carried out continuously and steadily.

- (9)

- Mine transportation and hoisting capacity: Most of the waste rock and all the ore produced by underground metal mines rely on haulage and hoisting equipment to transport and hoist. The production capacity of the mine must be matched with the transport and hoisting capacity of the mine.

- (10)

- Mine processing plant capacity: in order to avoid the long-term backlog of mined ore, resulting in increased mining production costs or affecting underground mining operations, the total output of ore during the planning period is generally required to be on par with the processing capacity of the plant.

2.2. Model Building

2.2.1. Model Assumptions

- (1)

- The mining method assumed for the model is room-and-pillar mining. The mine development system has been completed before the preparation of the mining plan, and the mining plan constructed in this paper mainly includes the output of each mineral deposit and the mining cut of each block during the planning period.

- (2)

- The ore reserves, the grade of each metallic element in the ore, and the content of contaminants in each mineral deposit (including the mined room, the mined pillar, the mined and cut room, the mined and cut pillar, and the complete block that has not yet been mined) have all been proven.

- (3)

- The planned mineral deposits should be capable of simultaneous mining operations.

2.2.2. Model Parameters Definition

2.2.3. Objective Functions

2.2.4. Constraints

2.3. Optimized Solution

3. Materials and Methods

3.1. Basic Particle Swarm Optimization Algorithm

3.2. Optimization Strategies

3.2.1. Nonlinear Dynamic Decreasing Inertia Weighting Strategy

3.2.2. Dynamic Learning Factor Strategy

3.2.3. Adaptive Variation Probability and Global Optimal Hybrid Mutation Strategy

| Algorithm 1: Mut1. |

| begin |

| if rand < 0.5 |

| else |

| end |

| ); |

| end |

| − 0.5)); |

| ); |

| end |

| end |

3.2.4. Worst Personal-Best Position Adaptive Wavelet Mutation Strategy

3.3. Algorithm Steps

- Step 1.

- (Initialization): set the current number of iterations , the maximum number of iterations , the population size N, the dimensionality of the search space M, and the initial position and velocity of each particle generated randomly.

- Step 2.

- (Optimal update): the velocity and current position of each particle are updated according to Equations (10), (11) and (13)–(15), and the value of the fitness function is calculated for each particle.

- Step 3.

- (Individual Optimal Update): for each particle , if the current fitness function value is better than the individual historical optimal position , update the individual optimal .

- Step 4.

- (Global Optimal Update): for each particle , if the current fitness function value is better than the global optimal position , the global optimal is updated.

- Step 5.

- Calculate the aggregation degree and the variation probability of the particle population according to Equation (16); if , mutate according to the mutation strategies Mut1 and Mut2 in Section 3.2.3 and Section 3.2.4.

- Step 6.

- Calculate the particle fitness and update and .

- Step 7.

- and return to step 2 until t reaches the set maximum number of iterations and stop.

- Step 8.

- The optimal result is output, and the algorithm is finished.

3.4. Construction of the Fitness Evaluation Function

4. Engineering Applications and Results Analysis

4.1. Mine Engineering Overview and Basic Data

4.2. Balanced Mining Model Parameters

- (1)

- Excavated blocks = 9, Mine pillars = 8, Mine rooms = 13.

- (2)

- Production ore quantity factor for block mining preparation works = 4.2 t/m, Quantity of ore contained in 1 m of mining preparation = 166.7 t/m.

- (3)

- Quantity factor of prepared mining blocks/ during the plan period = 1.

- (4)

- Maximum mining capacity: = 25,000 t, = 25,000 t, = 180 m.

- (5)

- Metal types = 3, Average quarterly ore output = 20,000 t, Maximum underground hoisting capacity quarterly = 35,000 t.

- (6)

- Gold concentrate contains gold price (metal price) = 235,000 Yuan/kg, antimony concentrate contains antimony price (metal price) = 29,700 Yuan/t (antimony concentrate valuation coefficient is 0.6), tungsten concentrate contains tungsten price = 150,000 Yuan/t. The quarterly revenue required by the enterprise can be calculated according to the quarterly metal quantity task as = 22,488,750.

4.3. Algorithm Parameter Setting

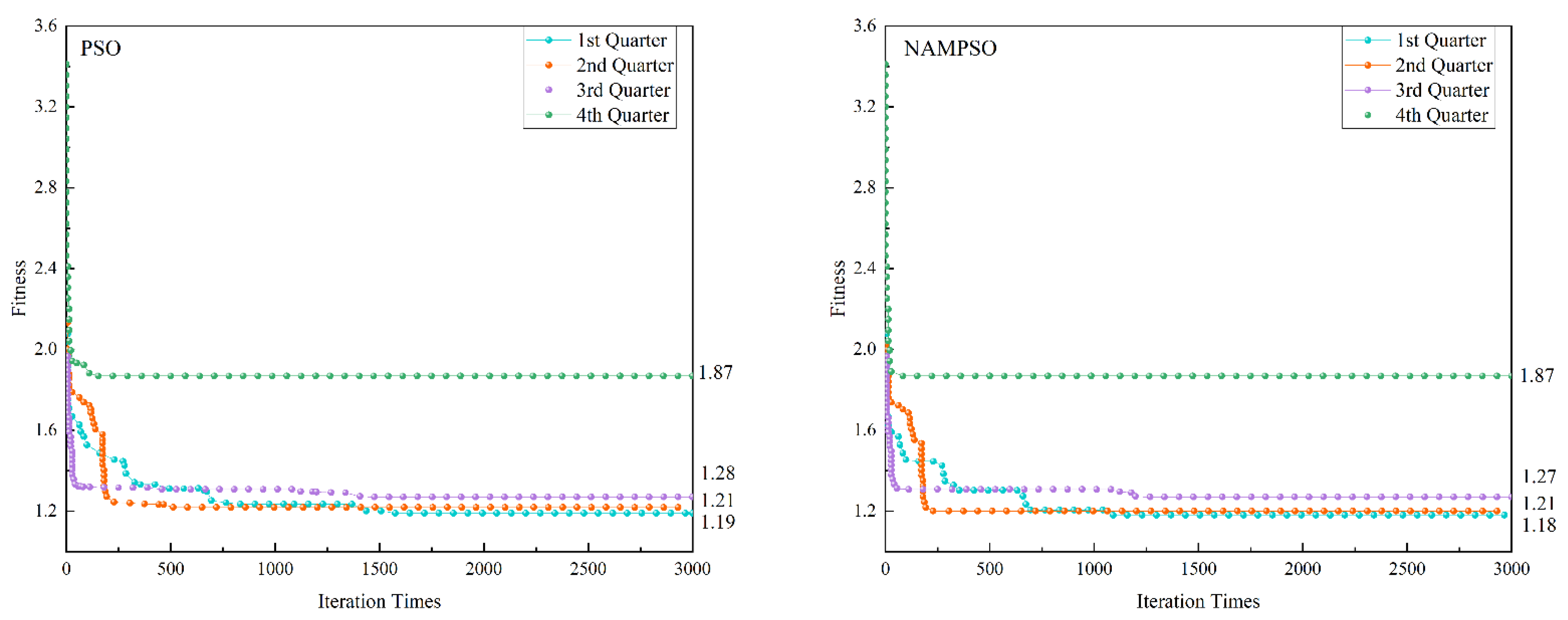

4.4. Engineering Example Simulation

4.5. Analysis of Results

- (1)

- As shown in Figure 4, in terms of mining quantity, the actual mining quantity of each quarter and year in the balanced mining plan is slightly higher than the planned mining quantity, which can meet the annual mining quantity target specified by the enterprise. At the same time, the proportion of mining quantity in each quarter is 26%, 25%, 24%, and 25%, respectively, which meets the requirement of balanced mining.

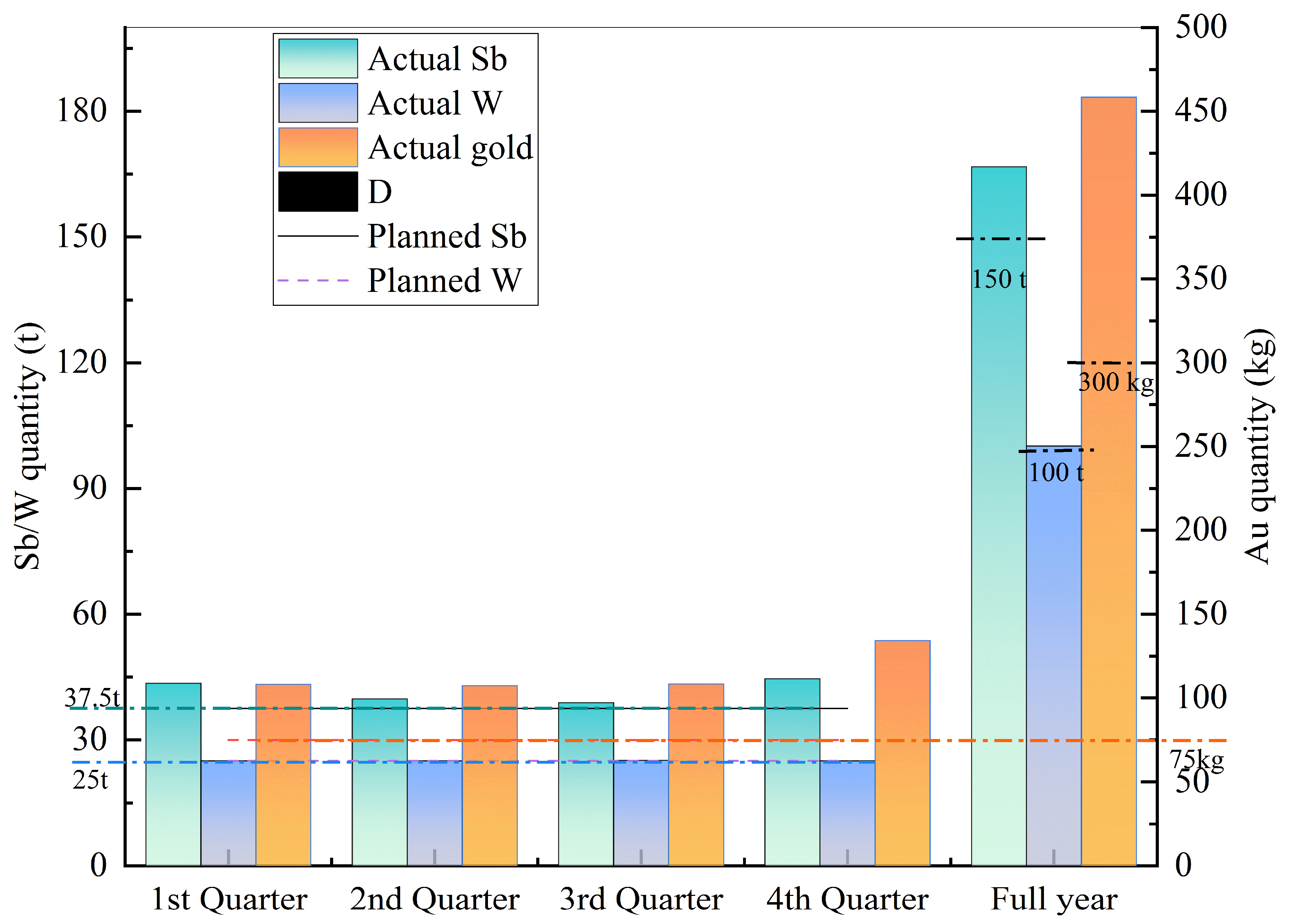

- (2)

- As shown in Figure 5, in terms of the production of gold, antimony, and tungsten, the actual production for each quarter and year in the extraction plan given in this paper is slightly higher or equal to the planned production, which fully meets the annual metal production target set by the enterprise. The percentages of gold production in each quarter are 24%, 23%, 24%, and 29%, respectively; the percentages of antimony production in each quarter are 26%, 24%, 23%, and 27%, respectively; and the percentages of tungsten production in each quarter are 25%, 25%, 25%, and 25%, respectively. From the absolute uniform distribution of tungsten production in each quarter, it can be seen that the algorithm takes the achievement of tungsten production as one of the key conditions when searching for the optimal mining plan, which fully meets the metal content constraint requirement of the model, and because the grade of tungsten is relatively the lowest among the three metals in the ore of each mining site, the value of tungsten is relatively the lowest among the three metals, and the recovery rate of tungsten beneficiation is also the lowest.

- (3)

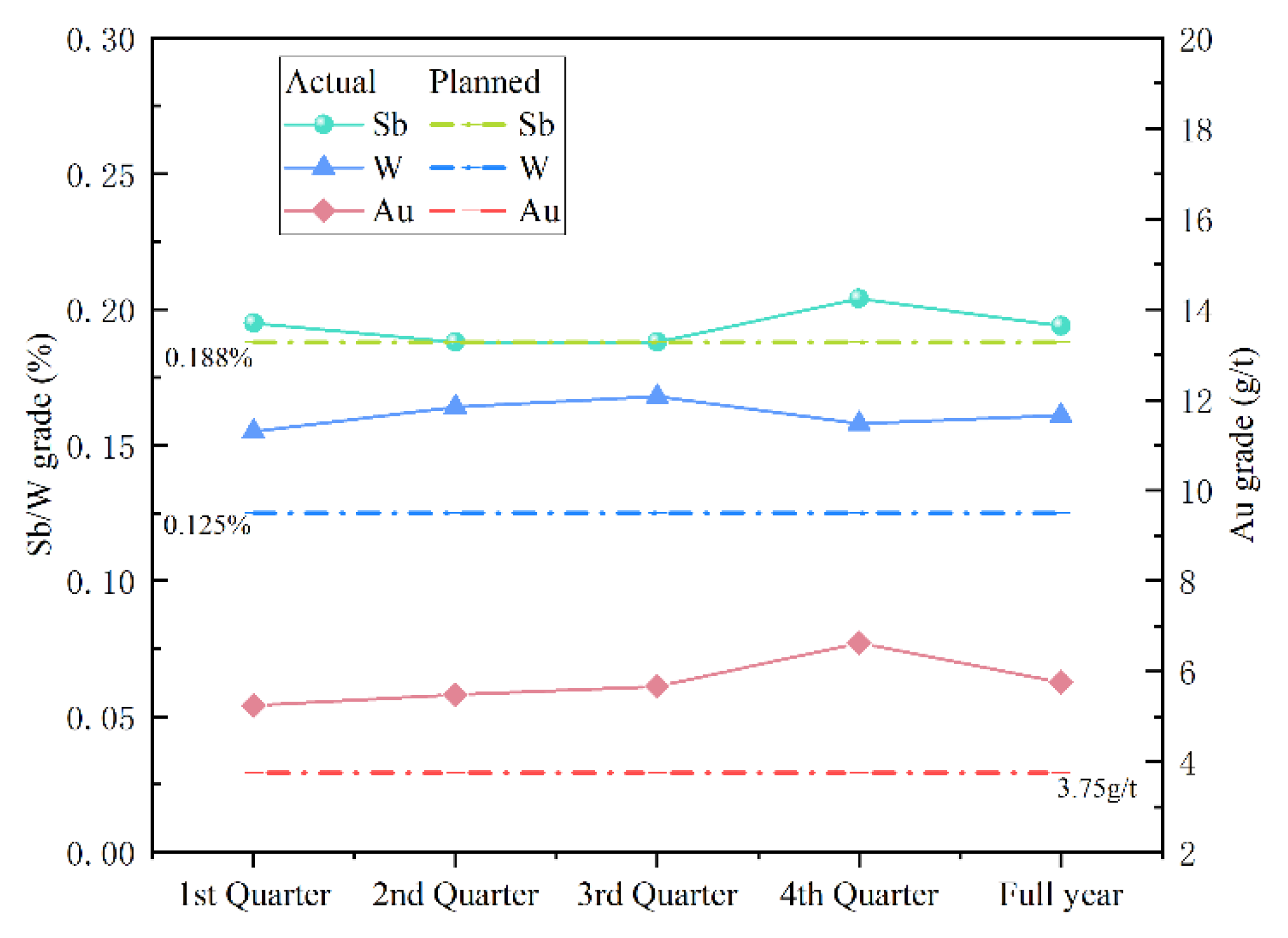

- As shown in Figure 6, the average grade of gold and tungsten is higher than the planned ore grade, the average grade of gold and tungsten in the ore mined in each quarter is basically balanced, and the average grade of antimony in the ore mined in each quarter is basically the same as the planned grade. Therefore, the mining plan searched by the method of this paper achieves the balance of the ore grade, and the ore grade fluctuation is small.

- (4)

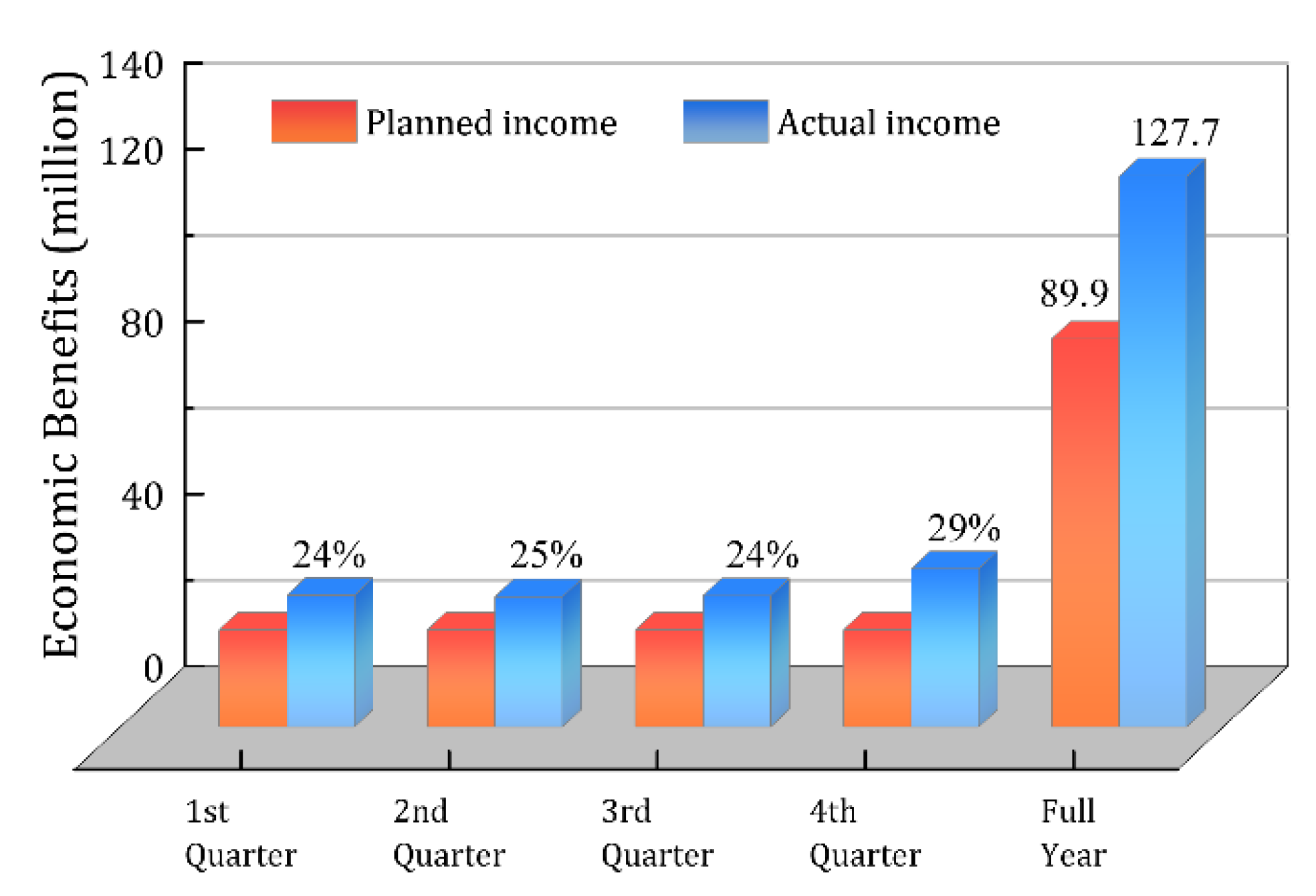

- As shown in Figure 7, in terms of economic benefits, the annual economic benefits of the extraction plan given in this paper increased by 41.88% compared to the planned economic benefits. The actual production of each quarter and year is slightly higher than the planned production, and the production of each metal also meets the requirements, so the economic benefits of each quarter and year are necessarily higher than the planned economic benefits, and the actual benefits of each quarter account for 24%, 23%, 24%, and 29%, respectively, and in general, the economic benefits of each quarter are balanced and stable, which can well fulfill the benefit targets given by the company.

- (5)

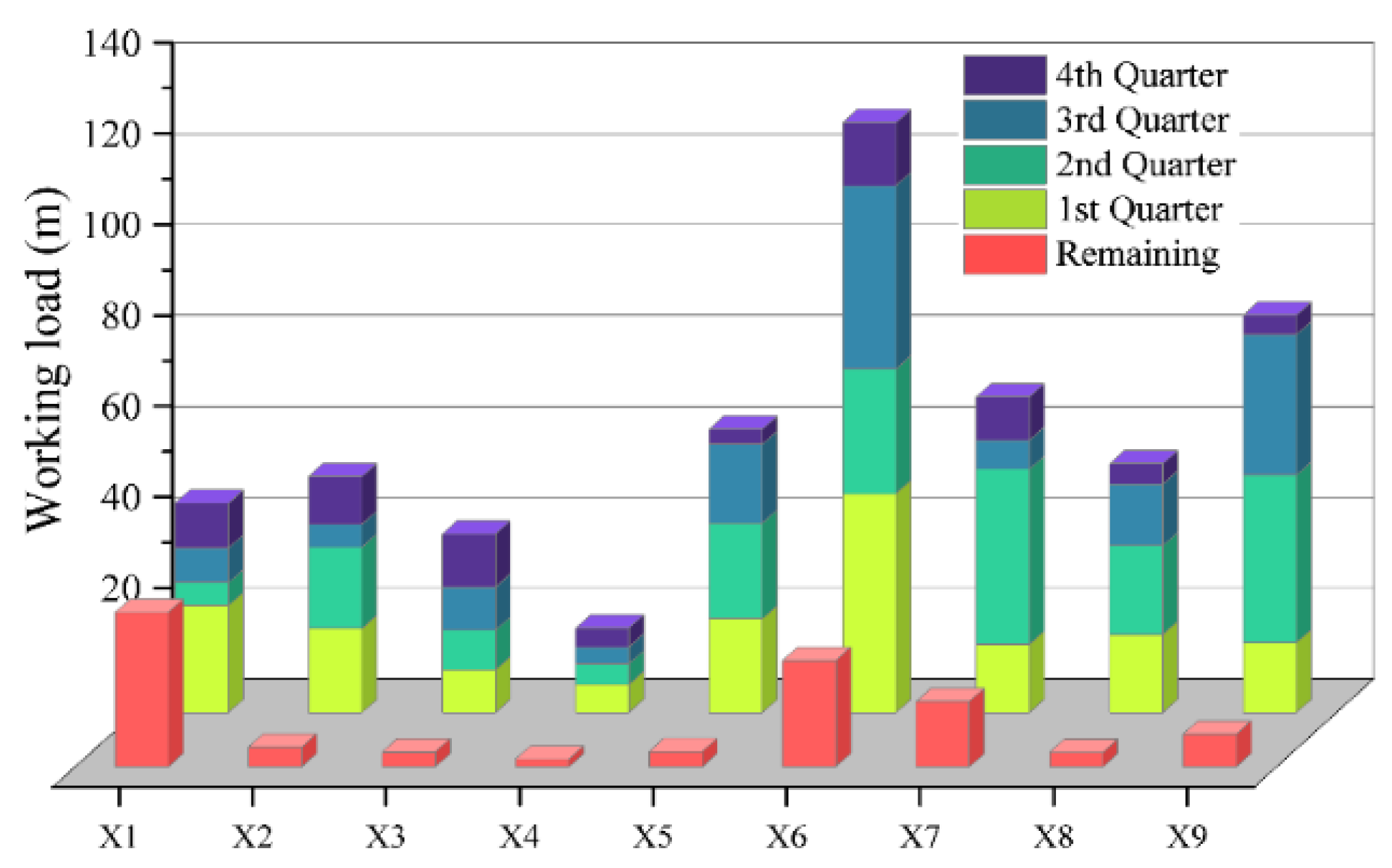

- As shown in Figure 8, in terms of mining balance, in order to seek the quarterly quantity of ore production that satisfies each constraint, the quantity of ore mined from each mineral deposit (including the mine room and pillar) varies each quarter, which reflects the equilibrium process of ore matching. Through four quarters of mining, the ore reserves of each mining field are basically depleted, and in actual production the ore reserves of the mining field can be considered as the end of mining when they are below a certain value. After one year of mining, most of the 21 recovery mining fields involved in the plan can be considered as completed. In order to ensure that mine production can be carried out continuously, it is necessary to adhere to the principle of balanced mining and excavation with excavation first. In this paper, the mining plan is formulated mainly through the balance between the recovery quantity and mining preparation quantity to ensure the continuity of production, as shown in Figure 9. This paper contains nine mining preparation fields, each of which has a different footage of excavation in each quarter, and the reason for this is that the quantity of ore production from each mining preparation project also must meet the production constraints. After four quarters of mining preparation work, the nine mining preparation fields are basically finished and can be used as back mining fields for the next year, which can ensure the continuous progress of production work in the next year.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Model parameters definition | |

| Indices | Definition |

| number of mining preparation blocks within the orebody model | |

| number of mining rooms within the orebody model | |

| number of mine pillar rooms within the orebody model | |

| number of metal types | |

| Parameters | |

| Mining preparation work for block b, meter | |

| Ore reserves in the mine room r, ton | |

| Ore reserves in the mine pillar k, ton | |

| Maximum block mining preparation capacity, meter/a plan period | |

| Maximum mine room recovery capacity, ton/a plan period | |

| Maximum mine pillar recovery capacity, ton/a plan period | |

| Quantity factor of prepared mining blocks during the plan period,1~2 | |

| Ore production during the plan period, ton | |

| Maximum hoisting capacity of underground hoisting equipment, ton | |

| Enterprise revenue during the plan period, yuan | |

| The price of the h ore produced during the plan period, yuan/ton | |

| Quantity of ore contained in 1 meter of mining preparation, ton/meter | |

| Production ore quantity factor for block mining preparation works, ton/meter | |

| mineral processing recovery rate of h metal, % | |

| Minimum requirements for h metal production during the plan period, ton | |

| The average grade of h metal in the production ore | |

| The grade required by the enterprise for h metal in the ore | |

| The average grade of h metal in the mining preparation blocks b, mine room r mine pillar k, % | |

| Variables | |

| Mining preparation work for block b in the mining plan, meter/a period | |

| Recovery of ore quantity in mine room r of the mining plan, ton/a period | |

| Recovery of ore quantity in mine pillar k of the mining plan, ton/a period | |

References

- Zhu, M.; Sun, J.; Liu, W.; Zhang, A.; Zhou, H.; Ai, L.; Peng, J.; Jia, Y.; Wang, L. Mining Plan Optimization Based on Linear Programming in Shirengou Iron Mine. In Proceedings of the Manufacturing Systems Engineering; Yang, G., Ed.; Trans Tech Publications Ltd.: Durnten-Zurich, Switzerland, 2012; Volume 429, p. 206. [Google Scholar]

- Musingwini, C. Presidential Address: Optimization in Underground Mine Planning-Developments and Opportunities. J. S. Afr. Inst. Min. Metall. 2016, 116, 809–820. [Google Scholar] [CrossRef] [Green Version]

- Kumral, M.; Sari, Y.A. Underground Mine Planning for Stope-Based Methods. In Proceedings of the 2nd International Conference on Earth Science, Mineral, and Energy; Prasetya, J.D., Cahyadi, T.A., Muangthai, I., Widodo, L.E., Ardian, A., Syafrizal, S., Rahim, R., Eds.; American Institute of Physics: Melville, NY, USA, 2020; Volume 2245, p. 030014. [Google Scholar]

- Sundar, D.K.; Acharya, D. Blast Schedule Planning and Shiftwise Production Scheduling of an Opencast Iron Ore Mine. Comput. Ind. Eng. 1995, 28, 927–935. [Google Scholar] [CrossRef]

- Chanda, E. An Application of Integer Programming and Simulation to Production Planning for a Stratiform Ore Body. Min. Sci. Technol. 1990, 11, 165–172. [Google Scholar] [CrossRef]

- Carlyle, W.M.; Eaves, B.C. Underground Planning at Stillwater Mining Company. Interfaces 2001, 31, 50–60. [Google Scholar] [CrossRef]

- Dagdelen, K.; Topal, E.; Kuchta, M. Linear Programming Model Applied to Scheduling of Iron Ore Production at the Kiruna Mine, Sweden; Mine Planning and Equipment Selection 2000; Routledge: London, UK, 2018. [Google Scholar]

- Nehring, M.; Topal, E.; Knights, P. Dynamic Short Term Production Scheduling and Machine Allocation in Underground Mining Using Mathematical Programming. Min. Technol. 2010, 119, 212–220. [Google Scholar] [CrossRef]

- Leite, A.; Dimitrakopoulos, R. Stochastic Optimisation Model for Open Pit Mine Planning: Application and Risk Analysis at Copper Deposit. Min. Technol. 2013, 116, 109–118. [Google Scholar] [CrossRef]

- Nehring, M.; Topal, E. Production Schedule Optimisation in Underground Hard Rock Mining Using Mixed Integer Programming. Australas. Inst. Min. Metall. 2007, 7, 169–175. [Google Scholar] [CrossRef]

- Guo, Q.; Zhang, Z.; Li, Z.; Liu, K.; Liu, H. Mining Method Optimization Based on Fuzzy Comprehensive Evaluation. In Proceedings of the Sustainable Development of Natural Resources; Pts 1–3; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2013; Volume 616–618, pp. 365–369. [Google Scholar]

- Huang, S.; Li, G.; Ben-Awuah, E.; Afum, B.O.; Hu, N. A Robust Mixed Integer Linear Programming Framework for Underground Cut-and-Fill Mining Production Scheduling. Int. J. Min. Reclam. Environ. 2020, 34, 397–414. [Google Scholar] [CrossRef]

- Dimitrakopoulos, R.; Ramazan, S. Stochastic Integer Programming for Optimising Long Term Production Schedules of Open Pit Mines: Methods, Application and Value of Stochastic Solutions. Min. Technol. 2013, 117, 155–160. [Google Scholar] [CrossRef]

- Weintraub, A.; Pereira, M.; Schultz, X. A Priori and A Posteriori Aggregation Procedures to Reduce Model Size in MIP Mine Planning Models. Electron. Notes Discret. Math. 2009, 30, 297–302. [Google Scholar] [CrossRef]

- Newman, A.M.; Kuchta, M. Using Aggregation to Optimize Long-Term Production Planning at an Underground Mine. Eur. J. Oper. Res. 2007, 176, 1205–1218. [Google Scholar] [CrossRef]

- Terblanche, S.E.; Bley, A. An Improved Formulation of the Underground Mine Scheduling Optimisation Problem When Considering Selective Mining. ORiON 2015, 31, 1–16. [Google Scholar] [CrossRef]

- Nehring, M.; Topal, E.; Little, J. A New Mathematical Programming Model for Production Schedule Optimization in Underground Mining Operations. J. S. Afr. Inst. Min. Metall. 2010, 110, 437–446. [Google Scholar] [CrossRef]

- Chowdu, A.; Nesbitt, P.; Brickey, A.; Newman, A.M. Operations Research in Underground Mine Planning: A Review. INFORMS J. Appl. Anal. 2022, 52, 109–132. [Google Scholar] [CrossRef]

- Little, J.; Topal, E. Strategies to Assist in Obtaining an Optimal Solution for an Underground Mine Planning Problem Using Mixed Integer Programming. Int. J. Min. Miner. Eng. 2011, 3, 152–172. [Google Scholar] [CrossRef]

- Hou, J.; Li, G.; Wang, H.; Hu, N. Genetic Algorithm to Simultaneously Optimise Stope Sequencing and Equipment Dispatching in Underground Short-Term Mine Planning under Time Uncertainty. Int. J. Min. Reclam. Environ. 2019, 34, 307–325. [Google Scholar] [CrossRef]

- Otto, E.; Bonnaire, X. A New Strategy Based on GRASP to Solve a Macro Mine Planning. In Proceedings of the International Symposium on Foundations of Intelligent Systems, Prague, Czech Republic, 14–17 September 2009. [Google Scholar]

- O’Sullivan, D.; Newman, A. Extraction and Backfill Scheduling in a Complex Underground Mine. Oper. Res. 2015, 5722, 483–492. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Gu, X.; Liu, Z.; Wang, Q.; Xu, X.; Zheng, M. Production Process Optimization of Metal Mines Considering Economic Benefit and Resource Efficiency Using an NSGA-II Model. Processes 2018, 6, 228. [Google Scholar] [CrossRef] [Green Version]

- Nesbitt, P.; Blake, L.R.; Lamas, P.; Goycoolea, M.; Brickey, A. Underground Mine Scheduling Under Uncertainty. Eur. J. Oper. Res. 2021, 294, 340–352. [Google Scholar] [CrossRef]

- Nwaila, G.T.; Zhang, S.E.; Tolmay, L.C.K.; Frimmel, H.E. Algorithmic Optimization of an Underground Witwatersrand-Type Gold Mine Plan. Nat. Resour. Res. 2021, 30, 1175–1197. [Google Scholar] [CrossRef]

- Campeau, L.-P.; Gamache, M. Short-Term Planning Optimization Model for Underground Mines. Comput. Oper. Res. 2020, 115, 104642. [Google Scholar] [CrossRef]

- Campeau, L.-P.; Gamache, M.; Martinelli, R. Integrated Optimisation of Short- and Medium-Term Planning in Underground Mines. Int. J. Min. Reclam. Environ. 2022, 36, 235–253. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Y.; Bo, L.; Yue, Y.; Wang, Y. Economic Optimal Allocation of Mine Water Based on Two-Stage Adaptive Genetic Algorithm and Particle Swarm Optimization. Sensors 2022, 22, 883. [Google Scholar] [CrossRef]

- Gu, Q.; Liu, Y.; Chen, L.; Xiong, N. An Improved Competitive Particle Swarm Optimization for Many-Objective Optimization Problems. Expert Syst. Appl. 2022, 189, 116118. [Google Scholar] [CrossRef]

- Gu, Q.; Zhang, X.; Chen, L.; Xiong, N. An Improved Bagging Ensemble Surrogate-Assisted Evolutionary Algorithm for Expensive Many-Objective Optimization. Appl. Intell. 2022, 52, 5949–5965. [Google Scholar] [CrossRef]

- Nhleko, A.S.; Musingwini, C. Optimisation of Three-Dimensional Stope Layouts Using a Dual Interchange Algorithm for Improved Value Creation. Minerals 2022, 12, 501. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the Icnn95-International Conference on Neural Networks, Perth, WA, Australia, 27 November 1995. [Google Scholar]

- Li, Z.; Zhu, T. Research on Global-Local Optimal Information Ratio Particle Swarm Optimization for Vehicle Scheduling Problem. In Proceedings of the International Conference on Intelligent Human-Machine Systems & Cybernetics, Hangzhou, China, 23 November 2015. [Google Scholar]

- Yunkai, L.; Yingjie, T.; Zhiyun, O.; Lingyan, W.; Tingwu, X.; Peiling, Y.; Huanxun, Z. Analysis of Soil Erosion Characteristics in Small Watersheds with Particle Swarm Optimization, Support Vector Machine, and Artificial Neuronal Networks. Environ. Earth Sci. 2009, 60, 92–96. [Google Scholar] [CrossRef] [Green Version]

- Dejun, A.E.; Lipengcheng, B.; Pengzhiwei, C.; Oujiaxiang, D. Research of Voltage Caused by Distributed Generation and Optimal Allocation of Distributed Generation. In Proceedings of the 2014 International Conference on Power System Technology (POWERCON), Chengdu, China, 20 October 2014. [Google Scholar]

- Ren, Y.; Liu, S. Modified Particle Swarm Optimization Algorithm for Engineering Structural Optimization Problem. In Proceedings of the International Conference on Computational Intelligence & Security, Hong Kong, China, 15 December 2017. [Google Scholar]

- Shi, Y. A Modified Particle Swarm Optimizer. In Proceedings of the IEEE ICEC Conference, Anchorage, AK, USA, 4 May 1998. [Google Scholar]

- Yong, F.; Teng, G.F.; Wang, A.X.; Yao, Y.M. Chaotic Inertia Weight in Particle Swarm Optimization. In Proceedings of the International Conference on Innovative Computing, Kumamoto, Japan, 5–7 September 2007. [Google Scholar]

- Firs, R.; Malik, A.; Rahman, T.A.; Zaiton, S.; Hashim, M.; Ngah, R.; Malik, R.F. New Particle Swarm Optimizer with Sigmoid Increasing Inertia Weight. Int. J. Comput. Sci. Secur. 2007, 1, 35–44. [Google Scholar]

- Chen, G.; Huang, X.; Jia, J.; Min, Z. Natural Exponential Inertia Weight Strategy in Particle Swarm Optimization. In Proceedings of the World Congress on Intelligent Control & Automation, Dalian, China, 21 June 2006. [Google Scholar]

- Chatterjee, A.; Siarry, P. Nonlinear Inertia Weight Variation for Dynamic Adaptation in Particle Swarm Optimization. Comput. Oper. Res. 2006, 33, 859–871. [Google Scholar] [CrossRef]

- Li, H.; Gao, Y. Particle Swarm Optimization Algorithm with Exponent Decreasing Inertia Weight and Stochastic Mutation; IEEE: Manchester, UK, 2009. [Google Scholar]

- Ling, S.H.; Iu, H.C.; Chan, K.Y.; Lam, H.K.; Leung, F. Hybrid Particle Swarm Optimization with Wavelet Mutation and Its Industrial Applications. IEEE Trans. Syst. Man Cybern. 2008, 38, 743. [Google Scholar] [CrossRef] [Green Version]

- Zhai, J.C.; Zhao, Z.; Zhang, P. An Improved Teaching-Learning Based Optimization Algorithm. Comput. Technol. Dev. 2019, 29, 37–41. [Google Scholar] [CrossRef]

| Total Ore Production | 80,000 t | Excavation footage | 480 m |

| Mining Quantity | 78,000 t | Excavation ore quantity | 2000 t |

| Metal | Au | Sb | WO3 |

| Comprehensive Ore Grade | 3.75 g/t | 0.188% | 0.125% |

| Metal Quantity | 300 kg | 150 t | 100 t |

| Mineral Processing Recovery Rate (%) | 89.7 | 97.0 | 70.0 |

| Name | Number | Mining Quantity/Extraction Footage | ||||

|---|---|---|---|---|---|---|

| Au (g/t) | Sb (%) | WO3 (%) | ||||

| Mined pillar | 1314-1 | 1089 t | 7.1 | 0.21 | 0.17 | |

| 1102-1Ⅱ | 2543 t | 10.93 | 0.25 | 0.08 | ||

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | |

| 708-1 | 12,312 t | 6.16 | 0.11 | 0.14 | ||

| Mined room | 508-1 | 25,854 t | 6.97 | 0.23 | 0.16 | |

| 2516-1 | 2709 t | 6.71 | 0.23 | 0.11 | ||

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | |

| 12,514-1 | 5180 t | 5.62 | 0.13 | 0.65 | ||

| Excavated block | 12,520 | 80.1 m | 4.52 | 0.16 | 0.16 | |

| 12,520-1 | 56.3 m | 4.37 | 0.21 | 0.23 | ||

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | |

| 5016 | 94.7 m | 3.25 | 0.00 | 0.00 | ||

| Name | Mining Quantity | |||||

|---|---|---|---|---|---|---|

| Q1 | Q2 | Q3 | Q4 | Full Year | ||

| Mine pillar | 1314-1 | 201.6 | 47.8 | 492.8 | 196.3 | 938.4 |

| 1102-1Ⅱ | 74.7 | 166.0 | 43.0 | 443.6 | 727.3 | |

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | |

| 708-1 | 1151.0 | 3697.0 | 3903.4 | 3439.0 | 12,190.4 | |

| Mine room | 508-1 | 2247.4 | 1808.9 | 850.7 | 11,899.8 | 16,806.8 |

| 2516-1 | 430.7 | 362.8 | 819.7 | 733.0 | 2346.2 | |

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | |

| 12,514-1 | 1261.2 | 1397.7 | 1652.5 | 676.0 | 4987.5 | |

| Total | 22,297.1 | 21,082.3 | 20,751.3 | 22,305.4 | 86,436.1 | |

| Name | Excavation Footage (m) | |||||

|---|---|---|---|---|---|---|

| Q1 | Q2 | Q3 | Q4 | Full Year | ||

| Excavated block | 12,520 | 23.6 | 5.0 | 7.6 | 9.9 | 46.1 |

| 12,520-1 | 18.5 | 17.9 | 5.0 | 10.6 | 51.9 | |

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | |

| 5016 | 15.4 | 36.9 | 30.9 | 4.3 | 87.5 | |

| Total (m) | 174.3 | 179.4 | 134.3 | 72.1 | 560.1 | |

| By-product ore quantity (t) | 731.9 | 753.7 | 564.0 | 302.7 | 2352.3 | |

| Time | Economic Benefits | Total Ore Quantity (t) | Au | Sb | WO3 | |||

|---|---|---|---|---|---|---|---|---|

| Quantity (kg) | Grade (g/t) | Quantity (t) | Grade (%) | Quantity (t) | Grade (%) | |||

| Q1 | 30,498,831.0 | 23,028.9 | 108.3 | 5.244 | 43.5 | 0.195 | 25.0 | 0.155 |

| Q2 | 30,168,711.6 | 21,836.0 | 107.4 | 5.482 | 39.8 | 0.188 | 25.0 | 0.164 |

| Q3 | 30,382,181.5 | 21,315.3 | 108.4 | 5.668 | 38.9 | 0.188 | 25.1 | 0.168 |

| Q4 | 36,643,023.2 | 22,608.1 | 134.3 | 6.623 | 44.6 | 0.204 | 25.0 | 0.158 |

| Full Year | 127,692,747.3 | 88,788.3 | 458.4 | 5.755 | 166.8 | 0.194 | 100.1 | 0.161 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Chen, J.; Yang, S.; Chen, Y. Mining Plan Optimization of Multi-Metal Underground Mine Based on Adaptive Hybrid Mutation PSO Algorithm. Mathematics 2022, 10, 2418. https://doi.org/10.3390/math10142418

Zhao Y, Chen J, Yang S, Chen Y. Mining Plan Optimization of Multi-Metal Underground Mine Based on Adaptive Hybrid Mutation PSO Algorithm. Mathematics. 2022; 10(14):2418. https://doi.org/10.3390/math10142418

Chicago/Turabian StyleZhao, Yifei, Jianhong Chen, Shan Yang, and Yi Chen. 2022. "Mining Plan Optimization of Multi-Metal Underground Mine Based on Adaptive Hybrid Mutation PSO Algorithm" Mathematics 10, no. 14: 2418. https://doi.org/10.3390/math10142418

APA StyleZhao, Y., Chen, J., Yang, S., & Chen, Y. (2022). Mining Plan Optimization of Multi-Metal Underground Mine Based on Adaptive Hybrid Mutation PSO Algorithm. Mathematics, 10(14), 2418. https://doi.org/10.3390/math10142418