Start-Up Strategy-Based Resilience Optimization of Onsite Monitoring Systems Containing Multifunctional Sensors

Abstract

:1. Introduction

2. Resilience Analysis of Onsite Monitoring Systems

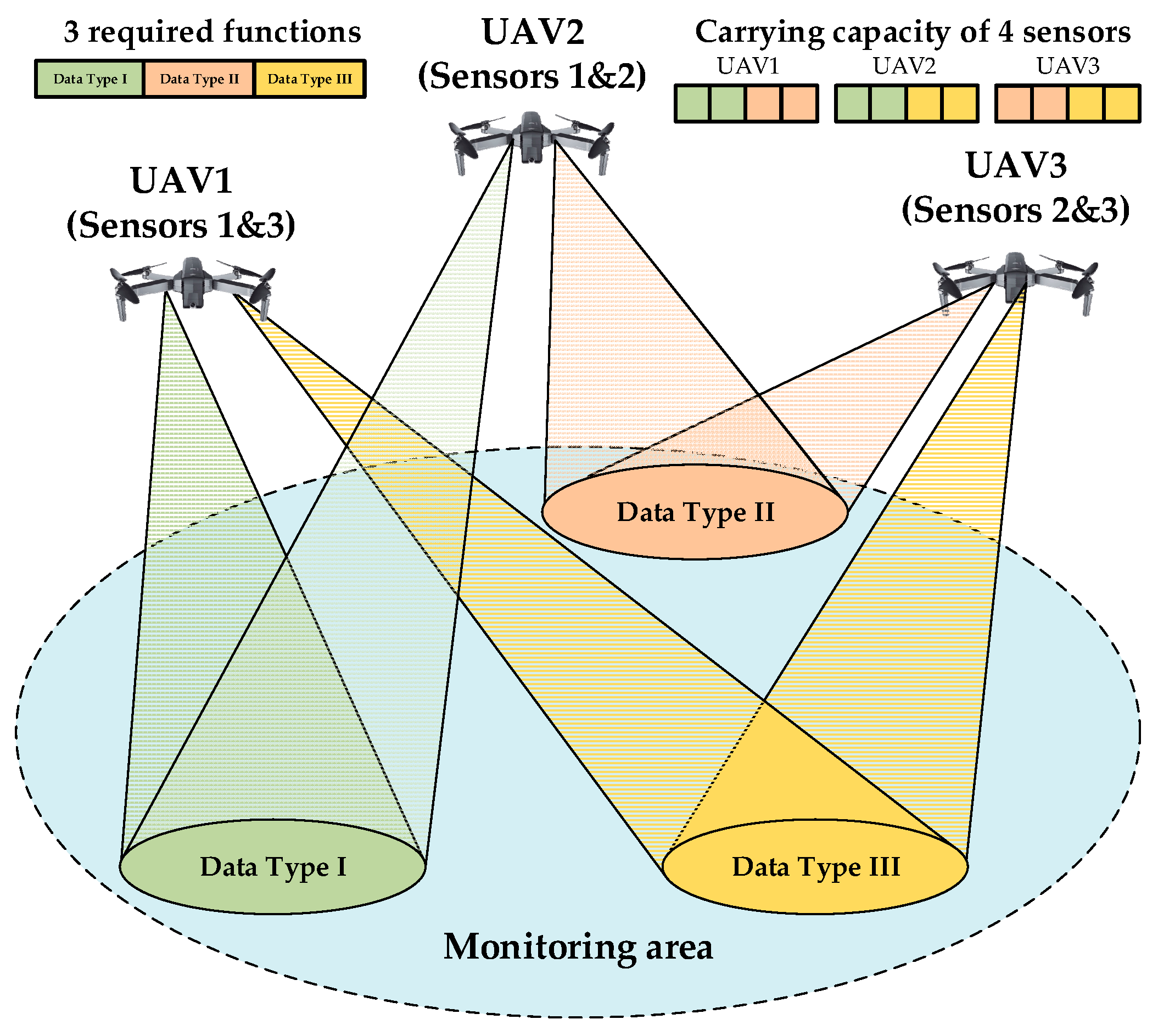

2.1. Onsite Monitoring Systems Containing Multifunctional Sensors

2.2. Assumptions of OMSs

- In a multifunctional system, the failure of one component does not affect the failure of other components, and a functional failure does not affect the failure of another function in the same component.

- The failure of one component can cause all the functions of this component to be activated regardless of the conditions of the functions.

- If any function of a component is activated, the component is used.

- If no components can provide one of the required functions, the system will fail.

- Considering that sensors are electronic components, the lifetime of the components and their functions follow exponential distributions.

- Information on hazardous events, including the occurrence time and effect of events on components and their functions, is known, and the failure rates of the affected components or functions are larger.

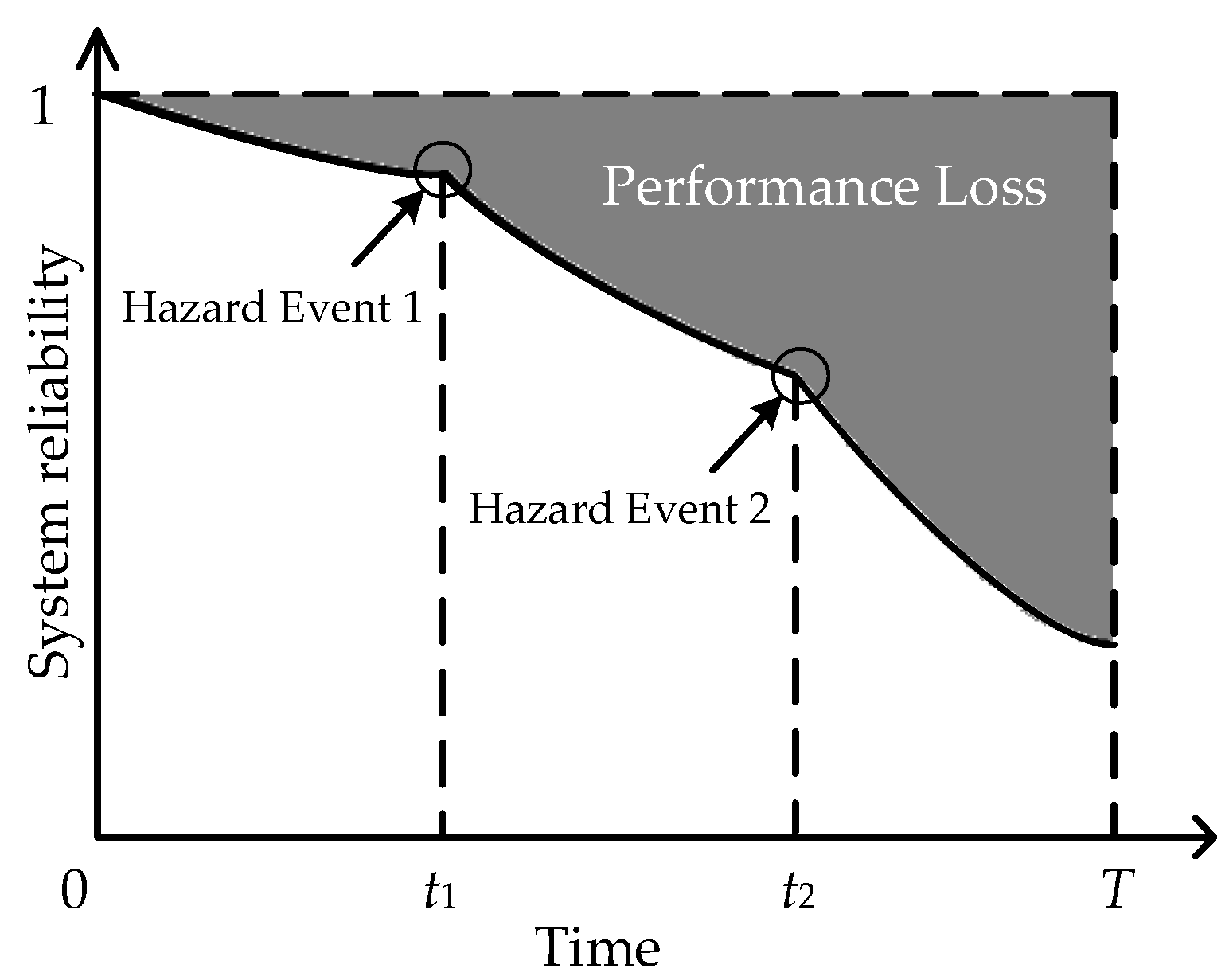

2.3. Resilience Evaluation of OMSs

2.3.1. Real-Time Reliability Analysis of OMSs

- The OMS states were defined. For an OMS containing m components with n required functions, indicates that function j in component i is initially selected in the start-up strategy; otherwise, . All possible system states can be represented by a matrix, which includes the initial selection of functions, where the redundancy levels represents the redundancy levels of function j in component i, and indicates that the function is lost. Once all elements in column j in the redundancy level part are 0, the system fails because no component can provide the required functions.

- Generate all possible states of the OMS based on a two-step iterative method. Set all the non-zero redundancy levels as one and generate all the system states based on the start-up strategy. Then, consider the combination of real redundancy levels to enumerate all the system states.

- Evaluation of transition rates between different states: To better analyze the transition probability between the different states, the transition rates from state u to state v can be divided into four situations. Situation 1 indicates that state u cannot be transferred to state v by considering the failure of a function or a component, and the transition rates in Situation 1 are 0. Situation 2 indicates that state u can be transferred to state v by considering the failure of a component, and the transition rates are the failure rates of the components. Situation 3 indicates that state u can transfer to state v by considering the failure of a function, and the transition rates are the product of the function’s failure rate and its redundancy levels under state u. Situation 4 indicates that state u can transfer to state v by considering the failure of a component or a function whose redundancy level is 1 for state u, and the transition rates are the sum of the function’s failure rate and the component’s failure rate. In summary, the transition rate can be determined using the above four situations, and . The transition rate matrix is represented by all .

- Calculation of real-time system reliability: Let contain all the system states, and let be the set of all the working states. The probability that the system state is u at time t can be denoted as or . According to the Kolmogorov equations, , and the probability of all states can be obtained using . Therefore, the system reliability of OMS can be evaluated by the sum of the probabilities that the system is in the working states, as shown in Equation (1).

2.3.2. Resilience Definition for OMSs

2.4. Resilience Properties of OMSs

2.4.1. Monotonic Analysis of System Resilience

2.4.2. Changes in System Resilience as the Number of Hazardous Events Increases

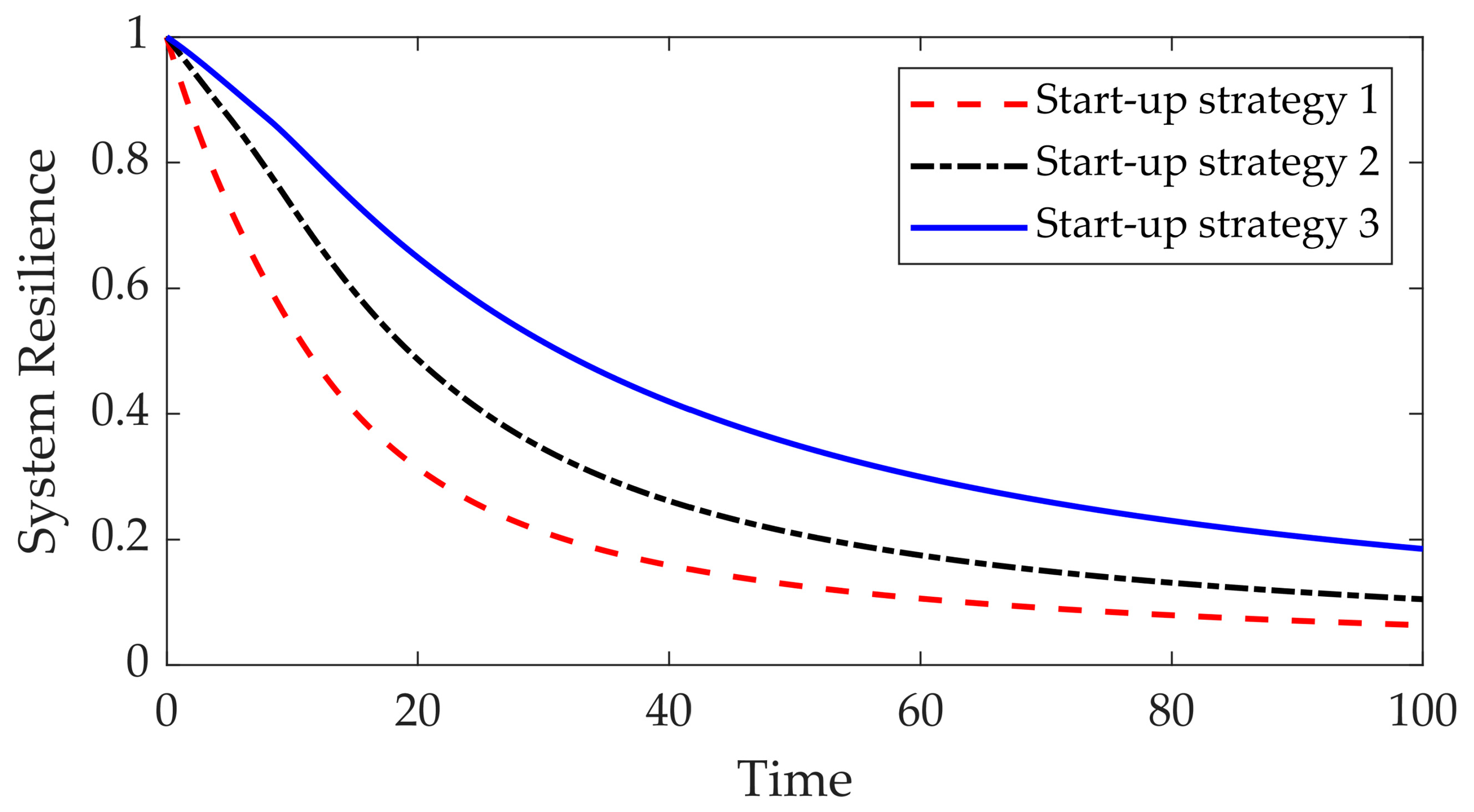

2.4.3. Changes in System Resilience as Start-Up Strategy Adjusts

3. Resilience-Oriented Start-Up Strategy Optimization of Onsite Monitoring Systems

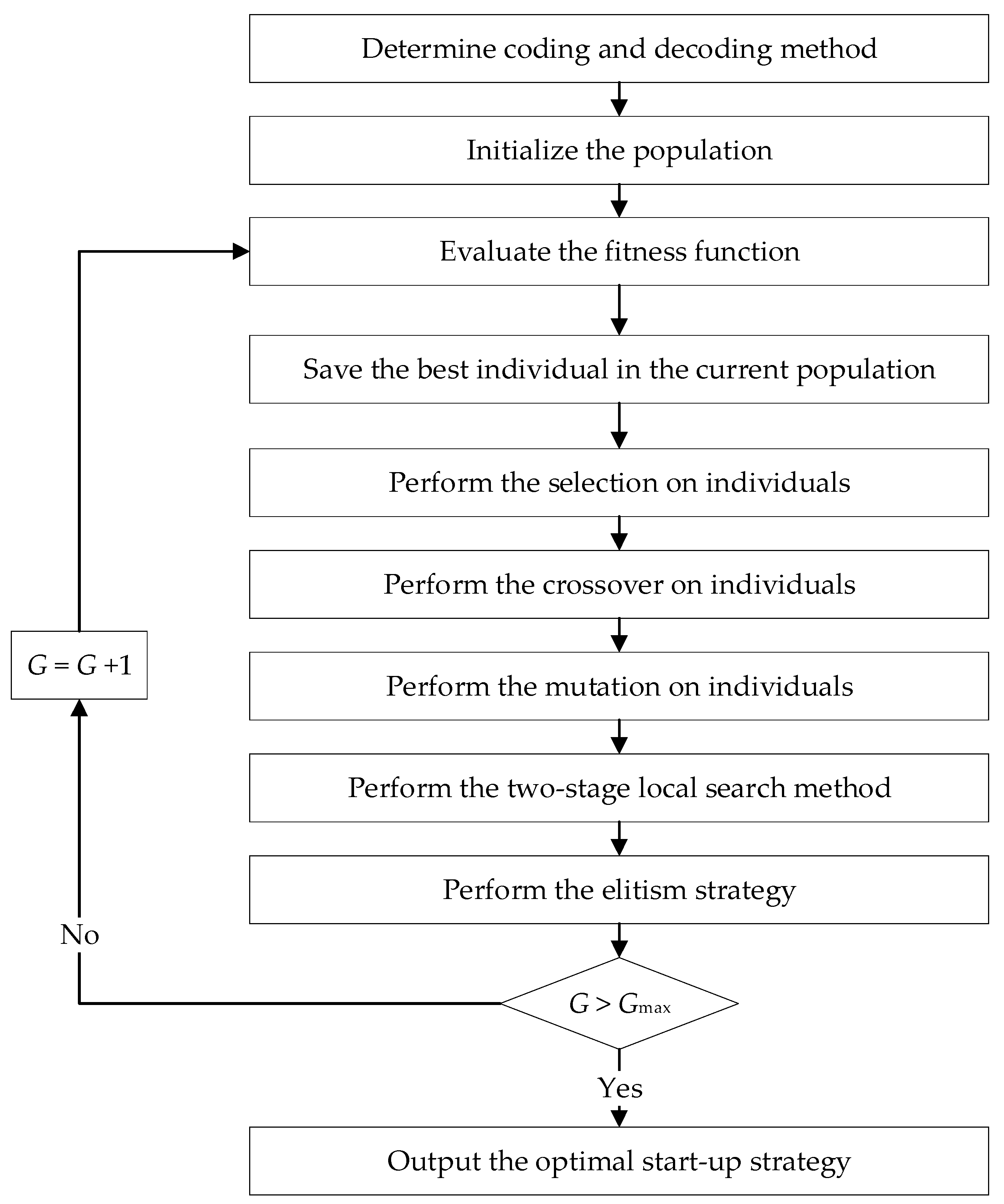

4. Solving Algorithm

4.1. Two-Stage Local Search Method

- Choose the function with minimum resilience reduction when removing its redundant function by one.

- Choose the function with maximum resilience increase when adding its redundant function by one.

- Determine the component i* with the maximum improvement of system resilience by .

- Find the component with the maximum improvement in system resilience by adjusting the start-up strategy of function j according to .

- Determine the function of the component by maximizing the improvement in system resilience by .

4.2. TLSGA Procedures

5. Numerical Experiments

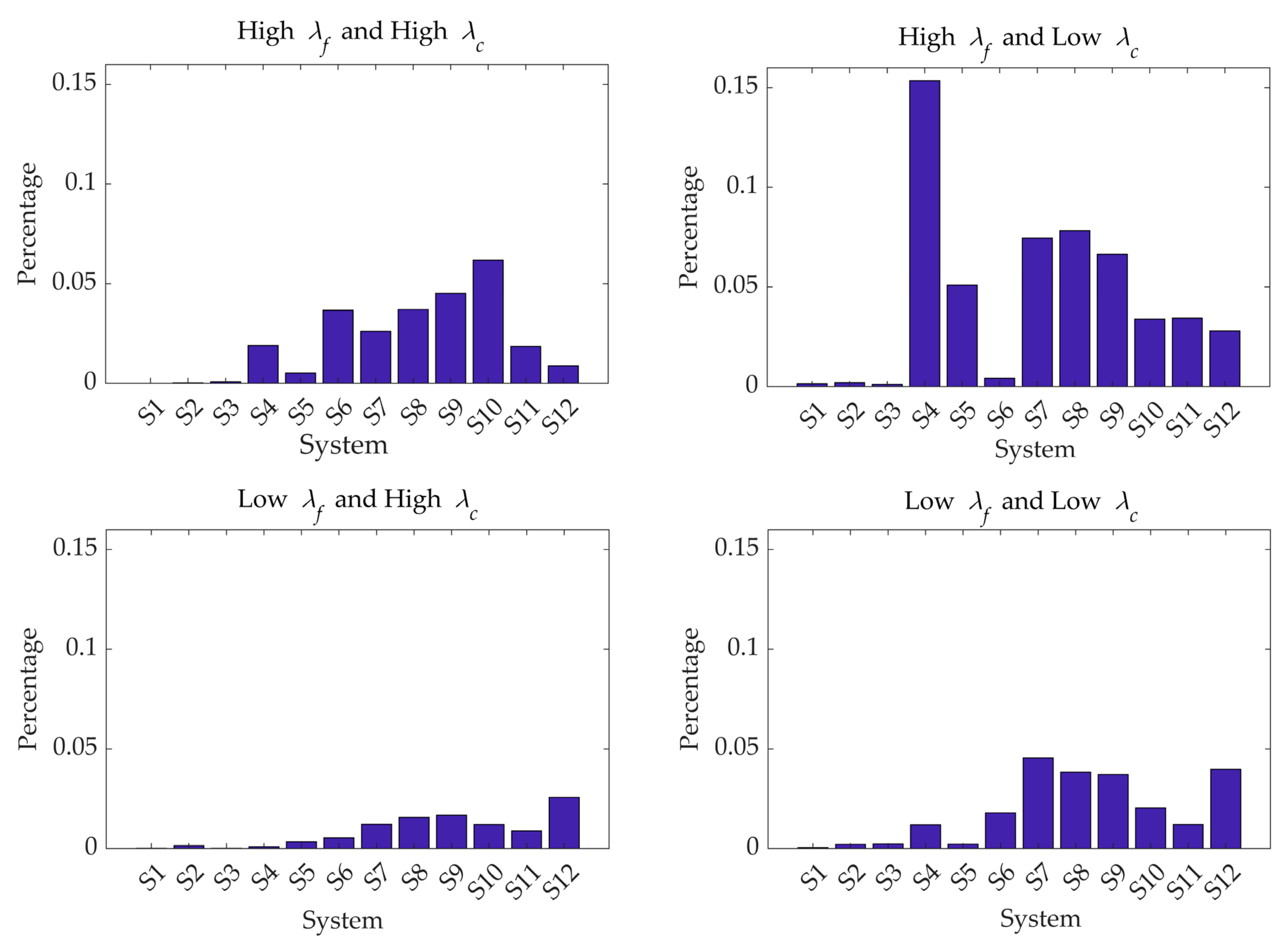

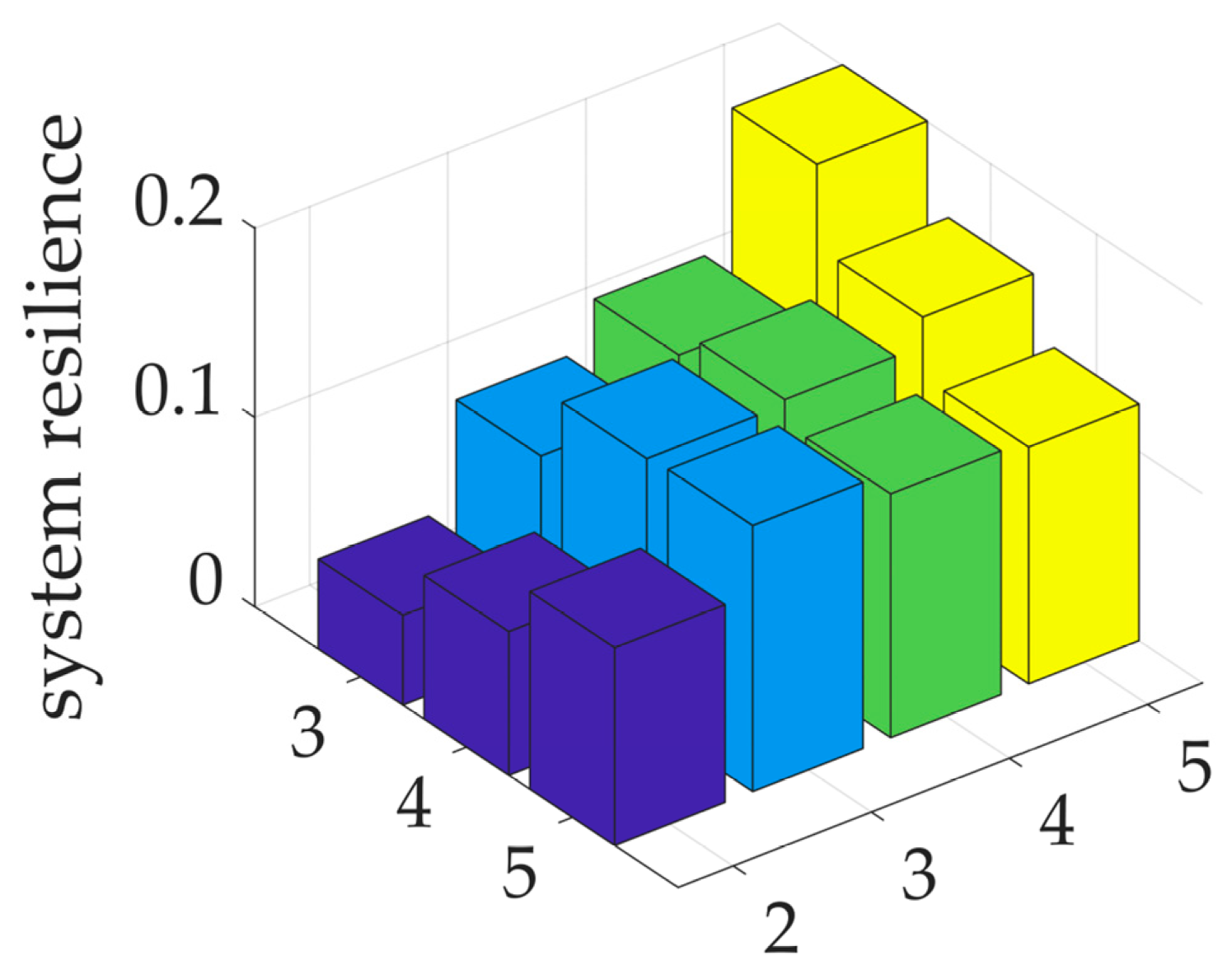

5.1. Performance Comparison between TLSGA and GA

5.1.1. Experimental Design

5.1.2. Experimental Results

5.2. Numerical Case for Onsite Monitoring Systems

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Z.; Li, X.; Li, H. Multifunction Transformer With Adjustable Magnetic Stage Based on Nanocomposite Semihard Magnets. IEEE Trans. Ind. Electron. 2020, 67, 4226–4234. [Google Scholar] [CrossRef]

- Adam, T.J.; Liao, G.; Petersen, J.; Geier, S.; Finke, B.; Wierach, P.; Kwade, A.; Wiedemann, M. Multifunctional Composites for Future Energy Storage in Aerospace Structures. Energies 2018, 11, 335. [Google Scholar] [CrossRef]

- Liu, Y.-L.; Shi, Y.; Yang, C.-L. Two-Dimensional MoSSe/g-GeC van Der Waals Heterostructure as Promising Multifunctional System for Solar Energy Conversion. Appl. Surf. Sci. 2021, 545, 148952. [Google Scholar] [CrossRef]

- Guo, X.; Xue, Z.; Zhang, Y. Manufacturing of 3D multifunctional microelectronic devices: Challenges and opportunities. NPG Asia Mater. 2019, 11, 29. [Google Scholar] [CrossRef]

- Yang, Y.; Vervust, T.; Dunphy, S.; Van Put, S.; Vandecasteele, B.; Dhaenens, K.; Degrendele, L.; Mader, L.; De Vriese, L.; Martens, T.; et al. 3D Multifunctional Composites Based on Large-Area Stretchable Circuit with Thermoforming Technology. Adv. Electron. Mater. 2018, 4, 1800071. [Google Scholar] [CrossRef]

- Akhter, F.; Siddiquei, H.R.; Alahi, M.E.E.; Jayasundera, K.P.; Mukhopadhyay, S.C. An IoT-Enabled Portable Water Quality Monitoring System With MWCNT/PDMS Multifunctional Sensor for Agricultural Applications. IEEE Internet Things J. 2022, 9, 14307–14316. [Google Scholar] [CrossRef]

- Nipa, T.J.; Kermanshachi, S. Resilience measurement in highway and roadway infrastructures: Experts’ perspectives. Prog. Disaster Sci. 2022, 14, 100230. [Google Scholar] [CrossRef]

- Twumasi-Boakye, R.; Sobanjo, J.O. A Computational Approach for Evaluating Post-Disaster Transportation Network Resili-ence. Sustain. Resilient Infrastruct. 2021, 6, 235–251. [Google Scholar] [CrossRef]

- Tari, A.N.; Sepasian, M.S.; Kenari, M.T. Resilience assessment and improvement of distribution networks against extreme weather events. Int. J. Electr. Power Energy Syst. 2021, 125, 106414. [Google Scholar] [CrossRef]

- Almutairi, A.; Collier, Z.A.; Hendrickson, D.; Palma-Oliveira, J.M.; Polmateer, T.L.; Lambert, J.H. Stakeholder Mapping and Disruption Scenarios with Application to Resilience of a Container Port. Reliab. Eng. Syst. Saf. 2019, 182, 219–232. [Google Scholar] [CrossRef]

- Khezeli, M.; Najafi, E.; Molana, M.H.; Seidi, M. A sustainable and resilient supply chain (RS-SCM) by using synchronisation and load-sharing approach: Application in the oil and gas refinery. Int. J. Syst. Sci.-Oper. Logist. 2023, 10, 2198055. [Google Scholar] [CrossRef]

- Nezhadroshan, A.M.; Fathollahi-Fard, A.M.; Hajiaghaei-Keshteli, M. A scenario-based possibilistic-stochastic programming approach to address resilient humanitarian logistics considering travel time and resilience levels of facilities. Int. J. Syst. Sci.-Oper. Logist. 2020, 8, 321–347. [Google Scholar] [CrossRef]

- Sayarshad, H.R. International Trade Resilience with Applied Welfare Economics: An Analysis on Personal Protective Equip-ment. Int. J. Syst. Sci.-Oper. 2023, 10, 2199131. [Google Scholar] [CrossRef]

- Li, X.-Q.; Song, L.-K.; Choy, Y.-S.; Bai, G.-C. Multivariate ensembles-based hierarchical linkage strategy for system reliability evaluation of aeroengine cooling blades. Aerosp. Sci. Technol. 2023, 138, 108325. [Google Scholar] [CrossRef]

- Lamri, M.A.; Abilov, A.; Vasiliev, D.; Kaisina, I.; Nistyuk, A. Application Layer ARQ Algorithm for Real-Time Multi-Source Data Streaming in UAV Networks. Sensors 2021, 21, 5763. [Google Scholar] [CrossRef]

- Meng, X.; Cai, Z.; Si, S.; Duan, D. Analysis of epidemic vaccination strategies on heterogeneous networks: Based on SEIRV model and evolutionary game. Appl. Math. Comput. 2021, 403, 126172. [Google Scholar] [CrossRef]

- Zuo, M. System reliability and system resilience. Front. Eng. Manag. 2021, 8, 615–619. [Google Scholar] [CrossRef]

- Wu, G.; Li, Z.S. Cyber—Physical Power System (CPPS): A review on measures and optimization methods of system resilience. Front. Eng. Manag. 2021, 8, 503–518. [Google Scholar] [CrossRef]

- Huang, G.; Wang, J.; Chen, C.; Qi, J.; Guo, C. Integration of Preventive and Emergency Responses for Power Grid Resilience Enhancement. IEEE Trans. Power Syst. 2017, 32, 4451–4463. [Google Scholar] [CrossRef]

- Ramezankhani, M.; Torabi, S.A.; Vahidi, F. Supply chain performance measurement and evaluation: A mixed sustainability and resilience approach. Comput. Ind. Eng. 2018, 126, 531–548. [Google Scholar] [CrossRef]

- Ferris, T.L.J. A Resilience Measure to Guide System Design and Management. IEEE Syst. J. 2019, 13, 3708–3715. [Google Scholar] [CrossRef]

- Li, Y.; Xie, K.; Wang, L.; Xiang, Y. Exploiting network topology optimization and demand side management to improve bulk power system resilience under windstorms. Electr. Power Syst. Res. 2019, 171, 127–140. [Google Scholar] [CrossRef]

- Kadan, M.; Özkan, G.; Özdemir, M.H. Resilience Measurement System: A Fuzzy Approach. In Intelligent and Fuzzy Techniques: Smart and Innovative Solutions; Springer: Berlin/Heidelberg, Germany, 2021; Volume 1197, pp. 576–581. [Google Scholar]

- Sharma, P.; Chen, Z. Probabilistic Resilience Measurement for Rural Electric Distribution System Affected by Hurricane Events. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2020, 6, 04020021. [Google Scholar] [CrossRef]

- Aldieri, L.; Gatto, A.; Vinci, C.P. Evaluation of energy resilience and adaptation policies: An energy efficiency analysis. Energy Policy 2021, 157, 112505. [Google Scholar] [CrossRef]

- Ribeiro, J.P.; Barbosa-Povoa, A. Supply Chain Resilience: Definitions and quantitative modelling approaches—A literature review. Comput. Ind. Eng. 2018, 115, 109–122. [Google Scholar] [CrossRef]

- Ghorbani-Renani, N.; González, A.D.; Barker, K.; Morshedlou, N. Protection-Interdiction-Restoration: Tri-Level Optimization for En-hancing Interdependent Network Resilience. Reliab. Eng. Syst. Saf. 2020, 199, 106907. [Google Scholar] [CrossRef]

- Najarian, M.; Lim, G.J. Optimizing infrastructure resilience under budgetary constraint. Reliab. Eng. Syst. Saf. 2020, 198, 106801. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, Z.; Xu, T.; Cao, X.; Wang, Q.; Cai, Z. Defensive strategy optimization of consecutive-k-out-of-n systems under deterministic external risks. Eksploat. Niezawodn.–Maint. Reliab. 2022, 24, 306–316. [Google Scholar] [CrossRef]

- Liu, X.; Fang, Y.-P.; Zio, E. A Hierarchical Resilience Enhancement Framework for Interdependent Critical Infrastructures. Reliab. Eng. Syst. Saf. 2021, 215, 107868. [Google Scholar] [CrossRef]

- Guo, J.; Du, Q.; He, Z. A method to improve the resilience of multimodal transport network: Location selection strategy of emergency rescue facilities. Comput. Ind. Eng. 2021, 161, 107678. [Google Scholar] [CrossRef]

- Xu, Y.; Liao, H. Reliability Analysis and Redundancy Allocation for a One-Shot System Containing Multifunctional Compo-nents. IEEE Trans. Rel. 2016, 65, 1045–1057. [Google Scholar] [CrossRef]

- Yi, X.-J.; Shi, J.; Mu, H.-N.; Dong, H.-P.; Zhang, Z. Reliability Analysis of Repairable System with Multiple-Input and Multi-Function Component Based on Goal-Oriented Methodology. ASCE-ASME J. Risk Uncert. Engrg. Sys. Part B Mech. Engrg. 2017, 3, 014501. [Google Scholar] [CrossRef]

- Anvarifar, F.; Voorendt, M.Z.; Zevenbergen, C.; Thissen, W. An application of the Functional Resonance Analysis Method (FRAM) to risk analysis of multifunctional flood defences in the Netherlands. Reliab. Eng. Syst. Saf. 2017, 158, 130–141. [Google Scholar] [CrossRef]

- López-Campos, M.; Kristjanpoller, F.; Viveros, P.; Pascual, R. Reliability Assessment Methodology for Massive Manufacturing Using Multi-Function Equipment. Complexity 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Callegari, J.; Silva, M.; de Barros, R.; Brito, E.; Cupertino, A.; Pereira, H. Lifetime evaluation of three-phase multifunctional PV inverters with reactive power compensation. Electr. Power Syst. Res. 2019, 175, 105873. [Google Scholar] [CrossRef]

- Marijnissen, R.; Kok, M.; Kroeze, C.; van Loon-Steensma, J. Re-evaluating safety risks of multifunctional dikes with a probabilistic risk framework. Nat. Hazards Earth Syst. Sci. 2019, 19, 737–756. [Google Scholar] [CrossRef]

- Zhao, J.; Si, S.; Cai, Z.; Liao, H. Time-dependent Reliability Analysis of a Nonrepairable Multifunctional System Containing Multifunctional Components. In Proceedings of the 2020 Asia-Pacific International Symposium on Advanced Reliability and Maintenance Modeling (APARM), Vancouver, BC, Canada, 20–23 August 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Zhou, D.; Sun, C.; Du, Y.-M.; Guan, X. Degradation and reliability of multi-function systems using the hazard rate matrix and Markovian approximation. Reliab. Eng. Syst. Saf. 2020, 218, 108166. [Google Scholar] [CrossRef]

- Hawryluk, M.; Kaszuba, M.; Gronostajski, Z.; Sadowski, P. Systems of supervision and analysis of industrial forging processes. Eksploat. Niezawodn.-Maint. Reliab. 2016, 18, 315–324. [Google Scholar] [CrossRef]

- Yi, X.; Dhillon, B.S.; Shi, J.; Mu, H.; Hou, P. Reliability Optimization Allocation Method for Multifunction Systems with Mul-tistate Units Based on Goal-Oriented Methodology. ASCE-ASME J. Risk Uncert. Engrg. Sys. Part B Mech. Engrg. 2017, 3, 041010. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, L. State-Based Opportunistic Maintenance With Multifunctional Maintenance Windows. IEEE Trans. Reliab. 2021, 70, 1481–1494. [Google Scholar] [CrossRef]

- Shahzad, M.K.; Ding, Y.; Xuan, Y.; Gao, N.; Chen, G. Performance analysis of a novel double stage multifunctional open absorption heat pump system: An industrial moist flue gas heat recovery application. Energy Convers. Manag. 2022, 254, 115224. [Google Scholar] [CrossRef]

- Gharoun, H.; Hamid, M.; Torabi, S.A. An Integrated Approach to Joint Production Planning and Reliability-Based Multi-Level Preventive Maintenance Scheduling Optimization for a Deteriorating System Considering Due-Date Satisfaction. Int. J. Syst. Sci.-Oper. 2022, 9, 489–511. [Google Scholar]

- Gharaei, A.; Amjadian, A.; Shavandi, A. An integrated reliable four-level supply chain with multi-stage products under shortage and stochastic constraints. Int. J. Syst. Sci.-Oper. Logist. 2023, 10, 1958023. [Google Scholar] [CrossRef]

- Zhao, J.-B.; Hou, P.-Y.; Cai, Z.-Q.; Li, Y.; Guo, P. Research of Mission Success Importance for a Multi-State Repairable k-out-of-n System. Adv. Mech. Eng. 2018, 10, 168781401876220. [Google Scholar] [CrossRef]

- Yodo, N.; Wang, P.; Rafi, M. Enabling Resilience of Complex Engineered Systems Using Control Theory. IEEE Trans. Reliab. 2018, 67, 53–65. [Google Scholar] [CrossRef]

- Nan, C.; Sansavini, G. A quantitative method for assessing resilience of interdependent infrastructures. Reliab. Eng. Syst. Saf. 2017, 157, 35–53. [Google Scholar] [CrossRef]

- Holland, J.H. Genetic algorithms. Sci. Am. 1992, 267, 66–73. [Google Scholar] [CrossRef]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A review on genetic algorithm: Past, present, and future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef]

- Javidi, M.M.; Kermani, F.Z. Utilizing the advantages of both global and local search strategies for finding a small subset of features in a two-stage method. Appl. Intell. 2018, 48, 3502–3522. [Google Scholar] [CrossRef]

- Si, S.; Zhao, J.; Cai, Z.; Dui, H. Recent advances in system reliability optimization driven by importance measures. Front. Eng. Manag. 2020, 7, 335–358. [Google Scholar] [CrossRef]

| References | System Performance Indexes | Optimization Algorithms |

|---|---|---|

| [18] | Integrated response | ✗ |

| [19] | The disaster probability, caused damage, and response measures in grid | Generation decomposition algorithm |

| [20] | Failure time and recovery probability | Segmentation algorithm |

| [21] | Scale function | ✗ |

| [22] | Recovery curve | Network topology optimization |

| [23] | Fuzzy logical relationship | ✗ |

| [24] | Probability for decision making | Monte Carlo simulation algorithm |

| [25] | Energy efficiency and energy security | ✗ |

| [26] | Analog derivation | ✗ |

| [27] | Failure time and recovery rate | ✗ |

| [28] | Examination time and functional level | ✗ |

| [29] | defensive capability | Genetic algorithm |

| [30] | Examination time and functional level | ✗ |

| [31] | Cooperative coverage model | ✗ |

| System # | Component Number m | The Number of Required System Functions n | Carrying Capacity of Component n0 | The Number of Hazardous Events nd |

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 0 |

| 2 | 2 | 3 | 4 | 1 |

| 3 | 2 | 3 | 4 | 2 |

| 4 | 3 | 3 | 2 | 0 |

| 5 | 3 | 3 | 2 | 1 |

| 6 | 3 | 3 | 2 | 2 |

| 7 | 3 | 3 | 4 | 0 |

| 8 | 3 | 3 | 4 | 1 |

| 9 | 3 | 3 | 4 | 2 |

| 10 | 3 | 5 | 4 | 0 |

| 11 | 3 | 5 | 4 | 1 |

| 12 | 3 | 5 | 4 | 2 |

| System # | ||||||||

|---|---|---|---|---|---|---|---|---|

| IN | MRSR | IN | MRSR | IN | MRSR | IN | MRSR | |

| S1 | 50 | 1.0001 | 50 | 1.0015 | 50 | 1.0001 | 50 | 1.0005 |

| S2 | 50 | 1.0002 | 50 | 1.0022 | 50 | 1.0015 | 50 | 1.0023 |

| S3 | 50 | 1.0009 | 50 | 1.0012 | 50 | 1.0002 | 50 | 1.0027 |

| S4 | 50 | 1.0194 | 50 | 1.1854 | 50 | 1.0009 | 49 | 1.0140 |

| S5 | 50 | 1.0064 | 50 | 1.0539 | 49 | 1.0035 | 50 | 1.0023 |

| S6 | 49 | 1.0434 | 50 | 1.0045 | 50 | 1.0070 | 50 | 1.0192 |

| S7 | 47 | 1.0274 | 46 | 1.0868 | 41 | 1.0127 | 49 | 1.0491 |

| S8 | 47 | 1.0398 | 47 | 1.0923 | 47 | 1.0163 | 49 | 1.0409 |

| S9 | 49 | 1.0489 | 48 | 1.0754 | 48 | 1.0175 | 48 | 1.0400 |

| S10 | 49 | 1.0736 | 49 | 1.0362 | 47 | 1.0145 | 44 | 1.0228 |

| S11 | 45 | 1.0211 | 46 | 1.0381 | 48 | 1.0106 | 47 | 1.0135 |

| S12 | 48 | 1.0093 | 46 | 1.0297 | 47 | 1.0321 | 45 | 1.0463 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Zhang, Z.; Liang, M.; Cao, X.; Cai, Z. Start-Up Strategy-Based Resilience Optimization of Onsite Monitoring Systems Containing Multifunctional Sensors. Mathematics 2023, 11, 4023. https://doi.org/10.3390/math11194023

Zhao J, Zhang Z, Liang M, Cao X, Cai Z. Start-Up Strategy-Based Resilience Optimization of Onsite Monitoring Systems Containing Multifunctional Sensors. Mathematics. 2023; 11(19):4023. https://doi.org/10.3390/math11194023

Chicago/Turabian StyleZhao, Jiangbin, Zaoyan Zhang, Mengtao Liang, Xiangang Cao, and Zhiqiang Cai. 2023. "Start-Up Strategy-Based Resilience Optimization of Onsite Monitoring Systems Containing Multifunctional Sensors" Mathematics 11, no. 19: 4023. https://doi.org/10.3390/math11194023