Mathematical Modeling for Robot 3D Laser Scanning in Complete Darkness Environments to Advance Pipeline Inspection

Abstract

1. Introduction

2. Materials and Methods/Theoretical Concepts

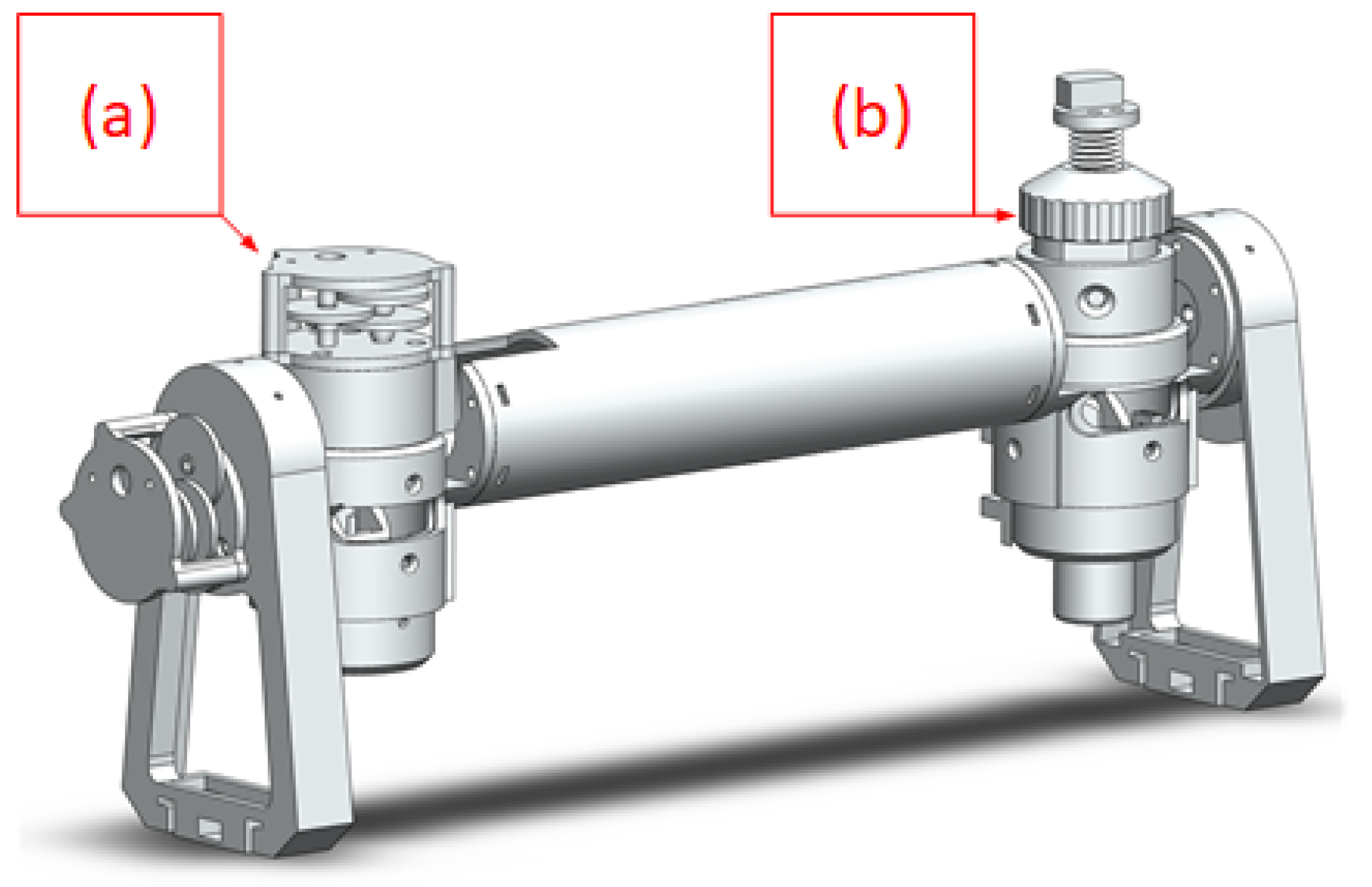

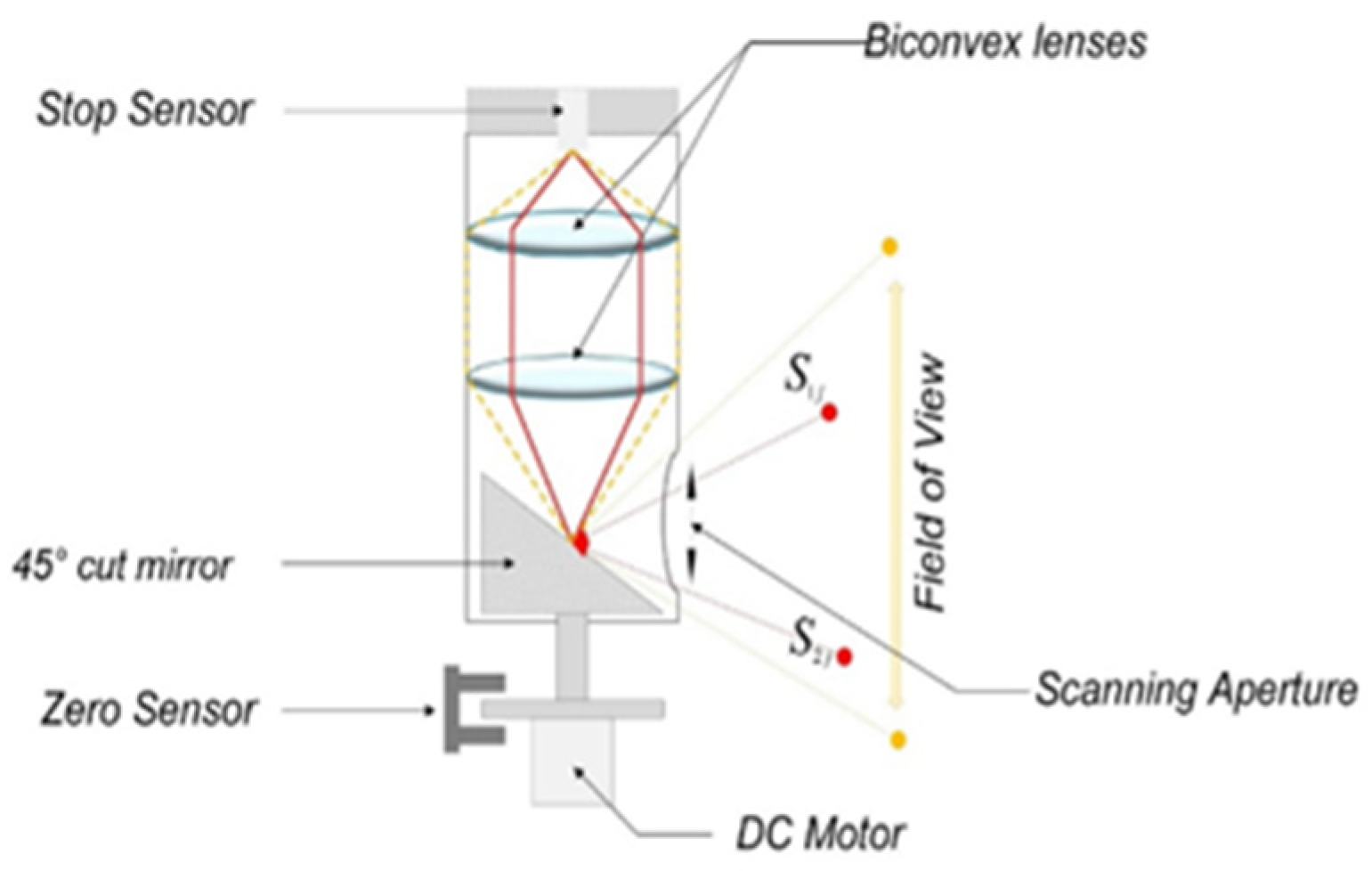

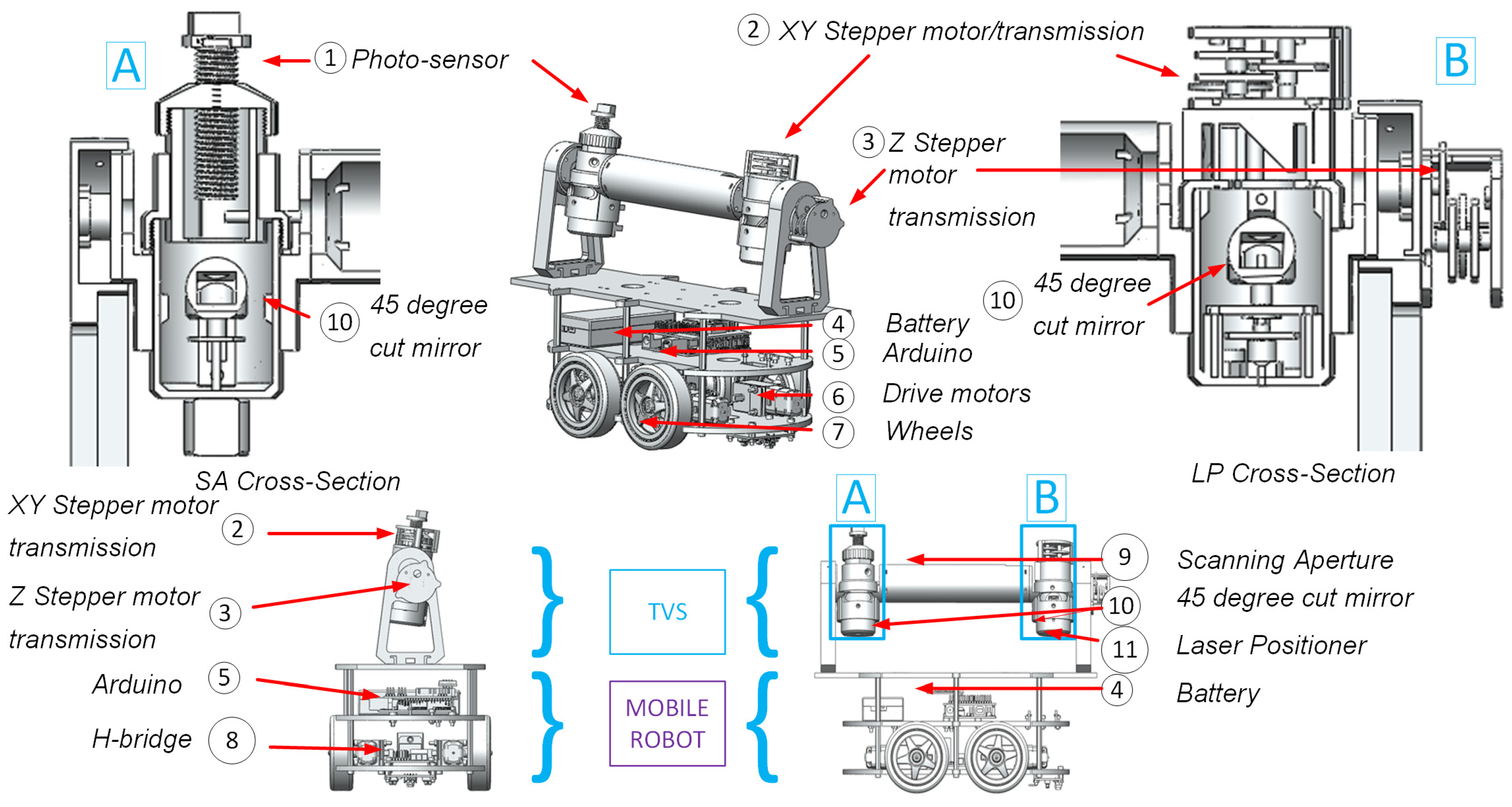

2.1. Scanning System

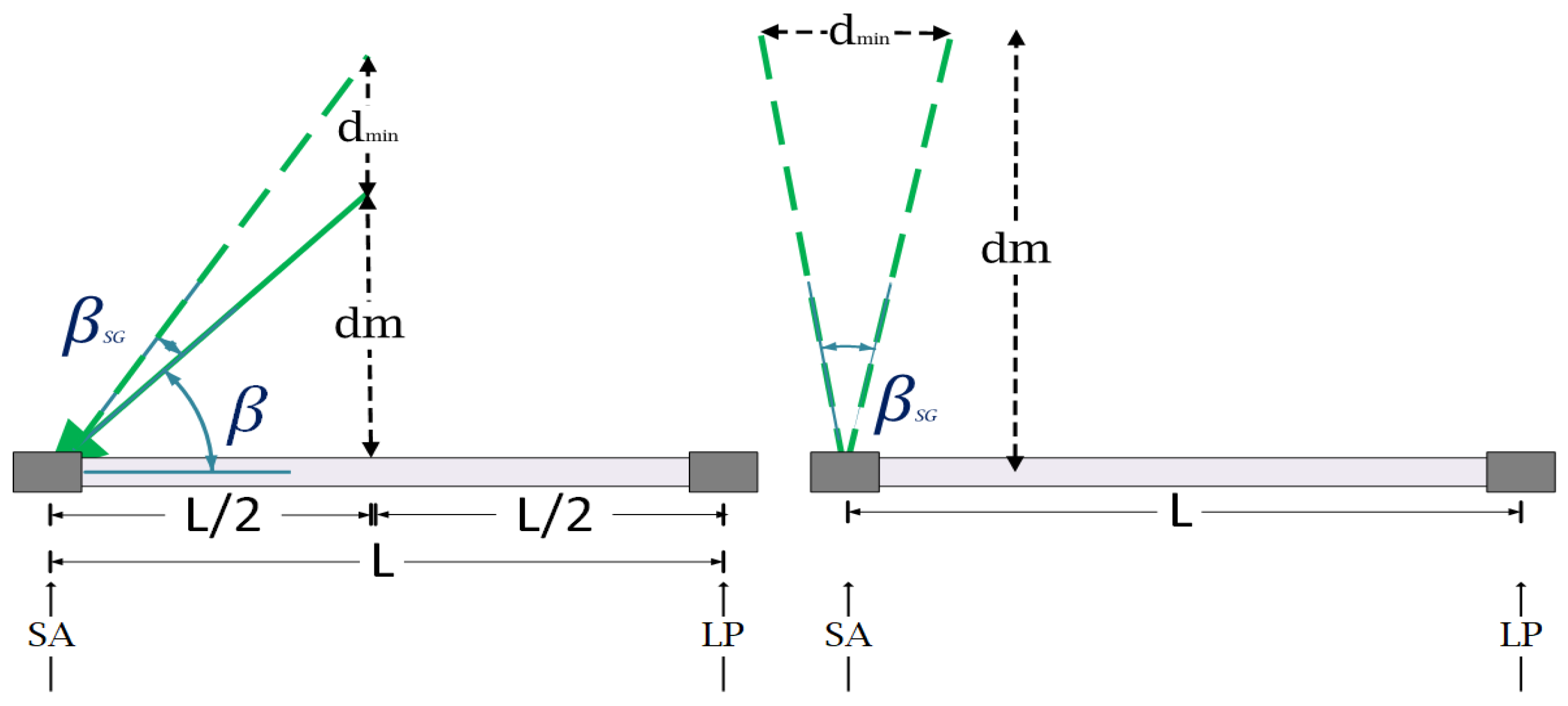

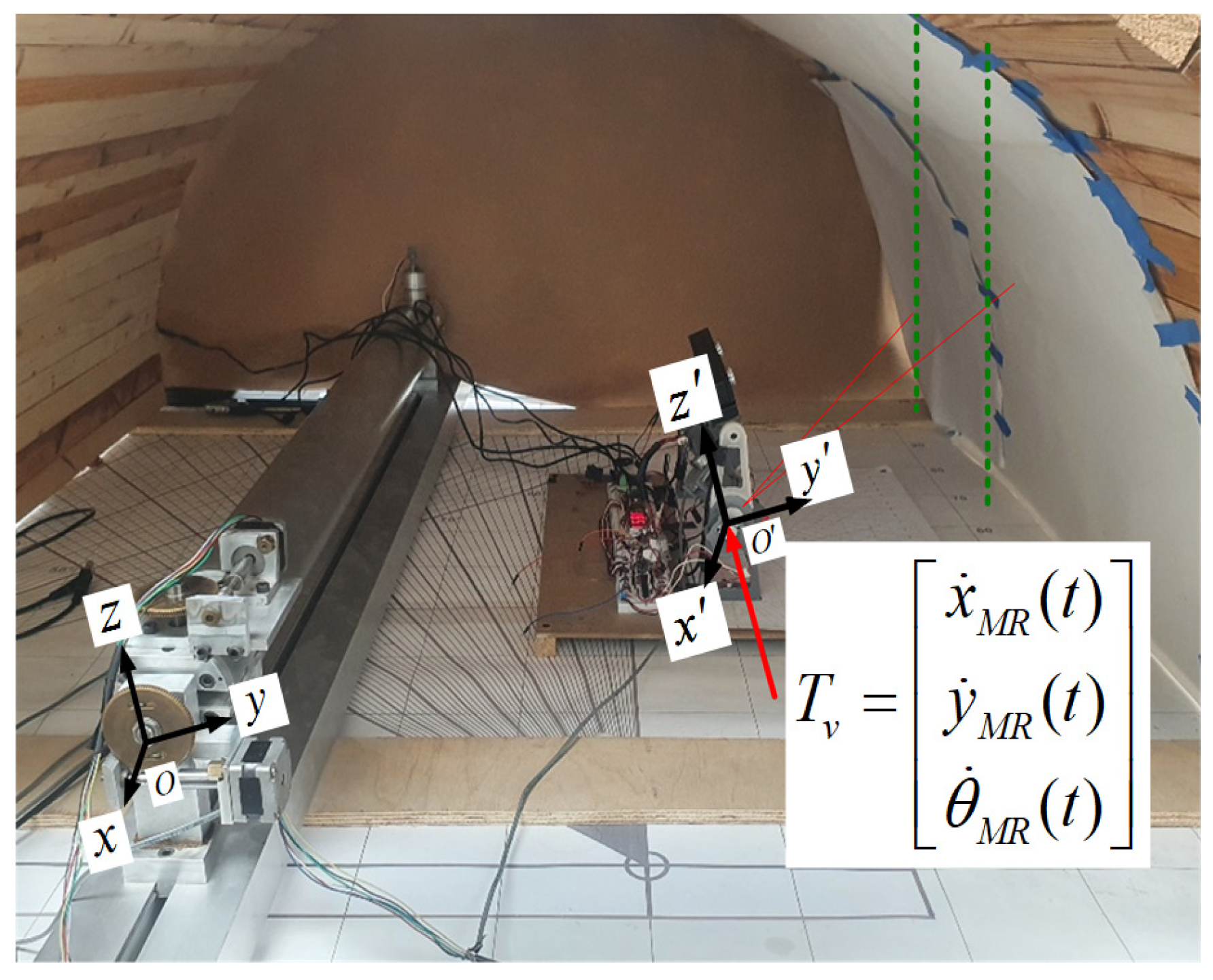

2.2. Mechanical Analysis and Kinematics Modeling

2.2.1. Mechanical Analysis

2.2.2. Kinematics Modeling/Orientation Detection

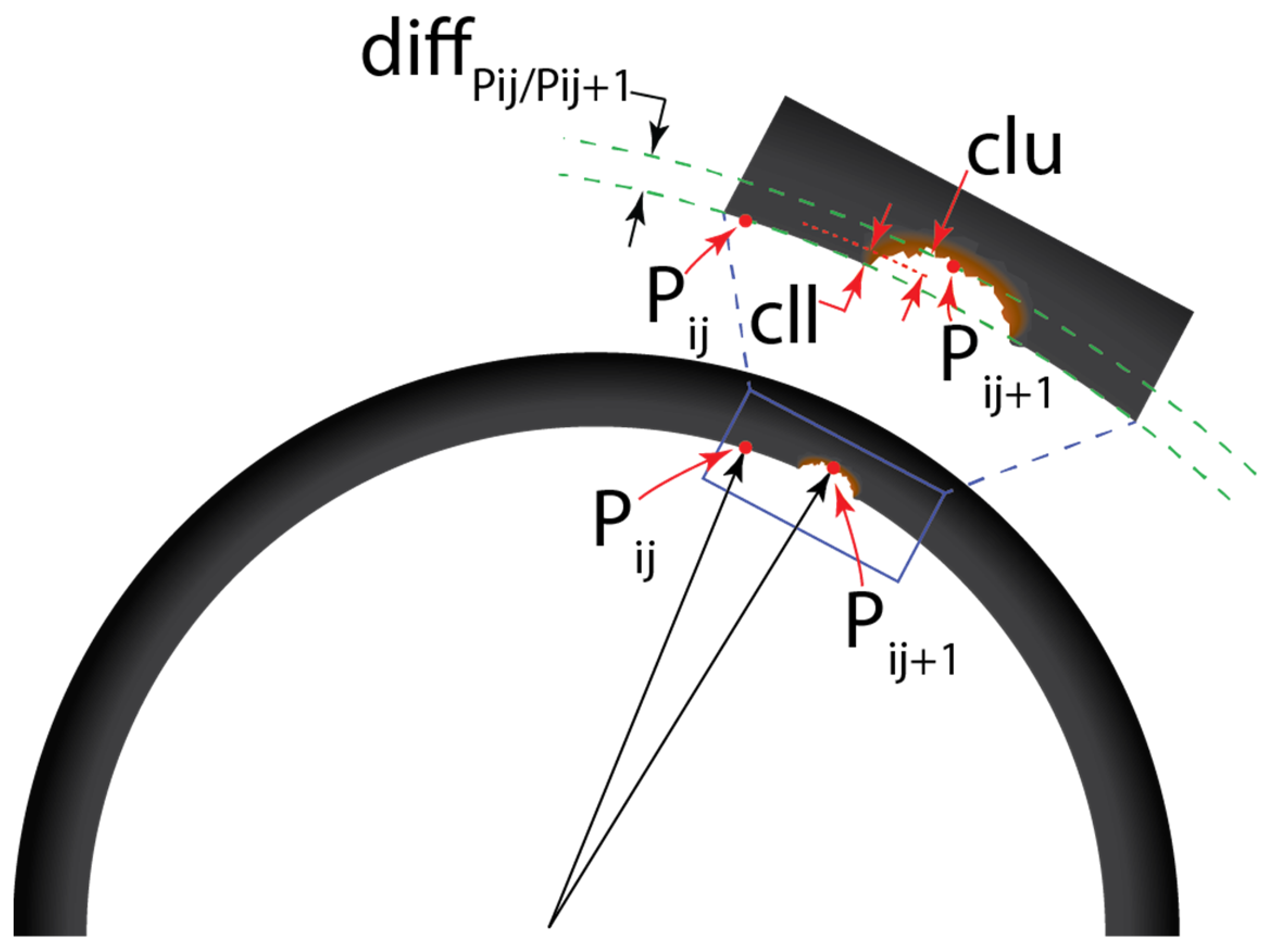

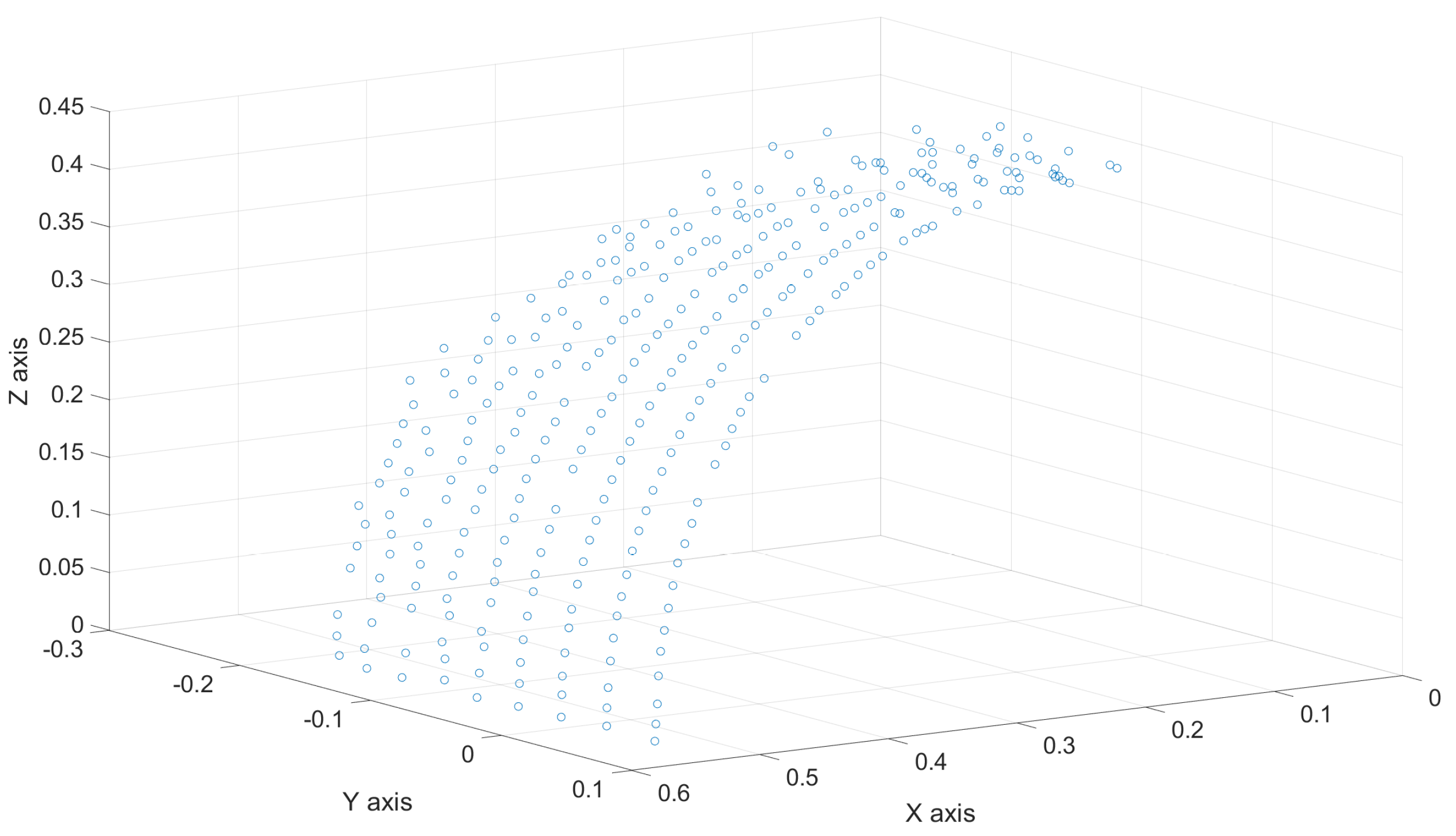

3. Point Cloud Scanning Methodology to Determine Pipe’s Surface

3.1. Control Principle Workflow

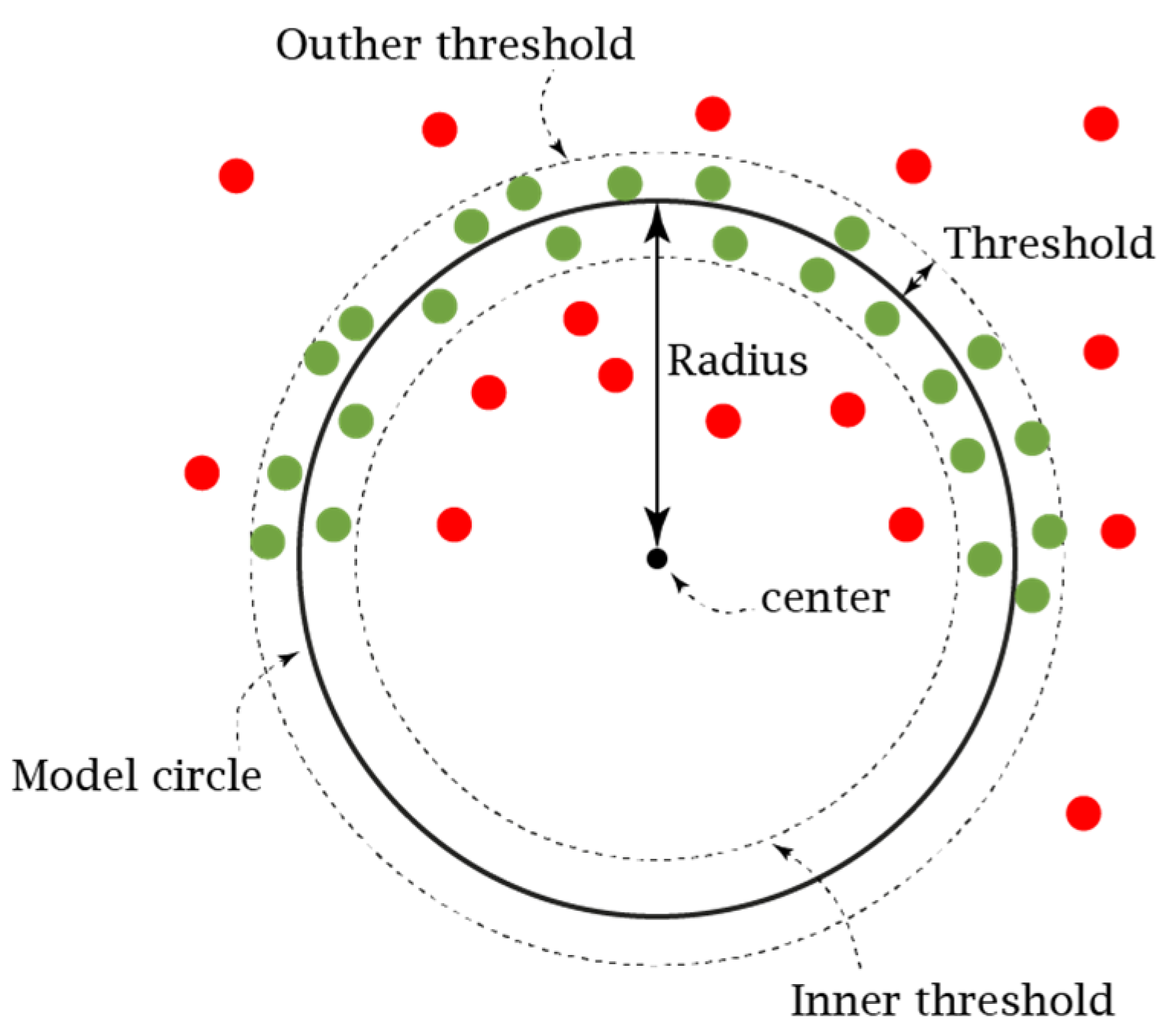

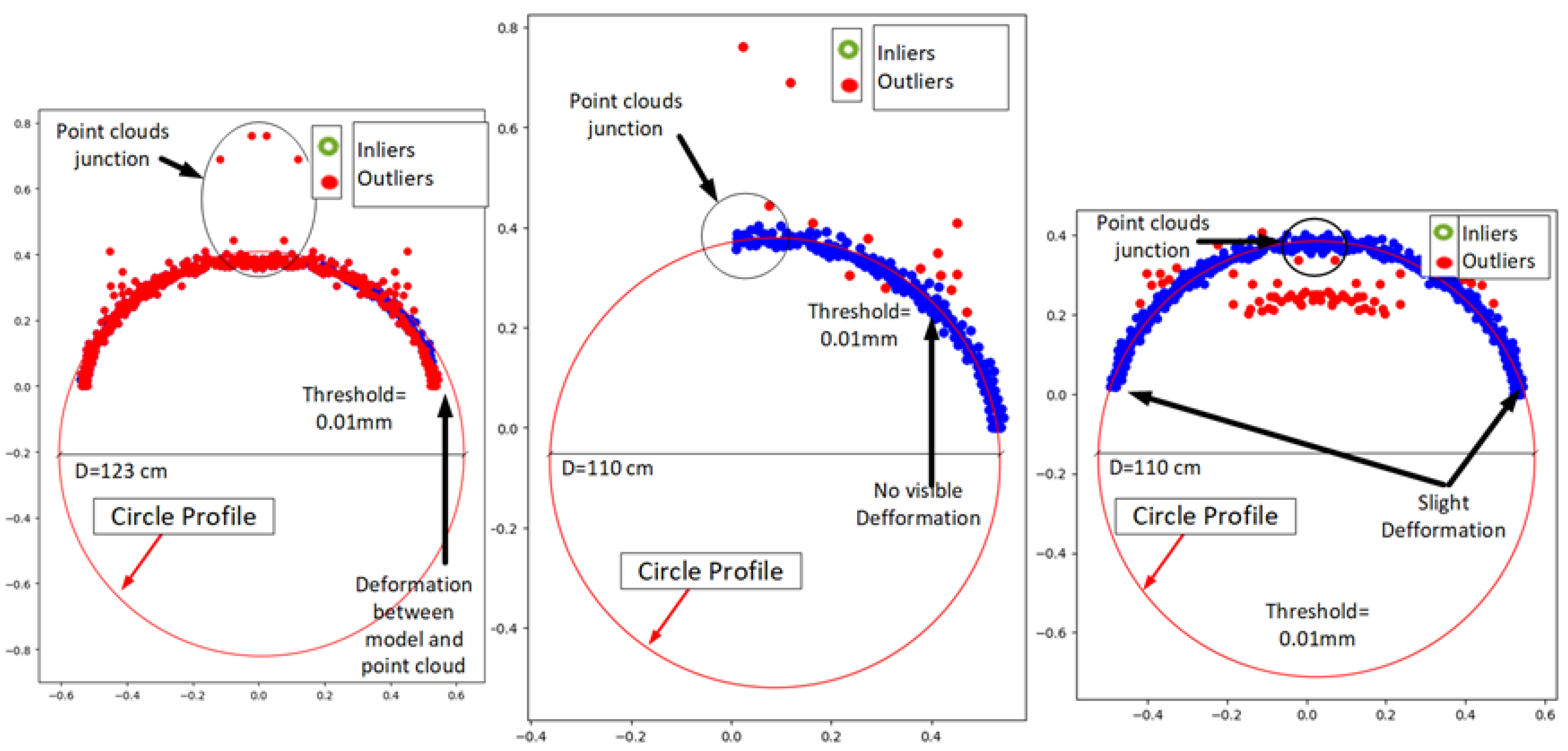

3.2. Segmentation Using the RANSAC-Modified Algorithm

4. Experimental Evaluation

4.1. Considerations

4.1.1. Surface Sensor Suite Validation/Scanning Circular

4.1.2. Measurements Validation

4.1.3. Performance Evaluation with Existing Technologies

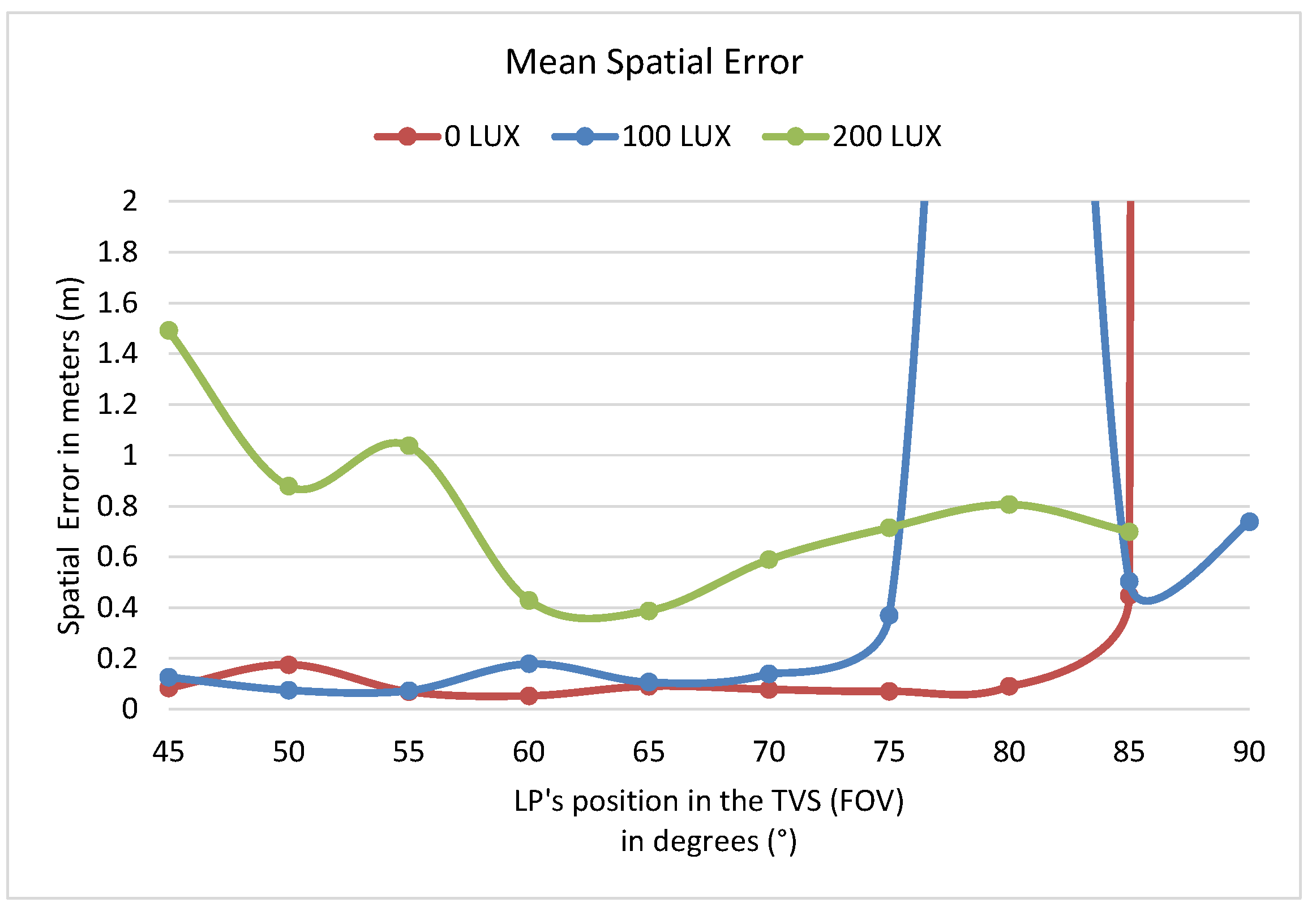

4.2. Measurements under Different Light Conditions

4.3. Workspace

4.4. Acquisition Algorithm Validation-Data Acquisition in Motion

5. Conclusions

Prototype and Further Applications

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shukla, A.; Karki, H. Application of Robotics in Onshore Oil and Gas Industry-A Review Part I. Rob. Auton. Syst. 2016, 75, 490–507. [Google Scholar] [CrossRef]

- Abubakar, S.A.; Mori, S.; Sumner, J. A Review of Factors Affecting SCC Initiation and Propagation in Pipeline Carbon Steels. Metals 2022, 12, 1397. [Google Scholar] [CrossRef]

- Sergiyenko, O.; Hernandez, W.; Tyrsa, V.; Cruz, L.F.D.; Starostenko, O.; Peña-Cabrera, M. Remote Sensor for Spatial Measurements by Using Optical Scanning. Sensors 2009, 9, 5477–5492. [Google Scholar] [CrossRef] [PubMed]

- Sergiyenko, O.Y.; Tyrsa, V.V. 3D Optical Machine Vision Sensors with Intelligent Data Management for Robotic Swarm Navigation Improvement. IEEE Sens. J. 2021, 21, 11262–11274. [Google Scholar] [CrossRef]

- Básaca-Preciado, L.C.; Sergiyenko, O.Y.; Rodríguez-Quinonez, J.C.; García, X.; Tyrsa, V.V.; Rivas-Lopez, M.; Hernandez-Balbuena, D.; Mercorelli, P.; Podrygalo, M.; Gurko, A.; et al. Optical 3D Laser Measurement System for Navigation of Autonomous Mobile Robot. Opt. Lasers Eng. 2014, 54, 159–169. [Google Scholar] [CrossRef]

- Santos-Sanchez, J.O.; Rojas-Casas, M.A.; Sergiyenko, O.; Rodriguez-Quinonez, J.C.; Flores-Fuentes, W.; Sepulveda-Valdez, C.; Alaniz-Plata, R.; Tyrsa, V.; Mercorelli, P. Analysis of the Construction of an Autonomous Robot to Improve Its Energy Efficiency When Traveling through Irregular Terrain. In Proceedings of the IECON 2022—48th Annual Conference of the IEEE Industrial Electronics Society, Brussels, Belgium, 17–20 October 2022. [Google Scholar] [CrossRef]

- Alaniz-Plata, R.; Sergiyenko, O.; Flores-Fuentes, W.; Tyrsa, V.V.; Rodríguez-Quiñonez, J.C.; Sepúlveda-Valdez, C.A.; Andrade-Collazo, H.; Mercorelli, P.; Lindner, L. ROS and Stereovision Collaborative System. In Optoelectronic Devices in Robotic Systems; Springer: Cham, Switzerland, 2022; pp. 71–113. [Google Scholar] [CrossRef]

- Sergiyenko, O. Optoelectronic Devices in Robotic Systems; Springer: Cham, Switzerland, 2022; ISBN 9783031097911. [Google Scholar]

- Sepulveda-Valdez, C.; Sergiyenko, O.; Tyrsa, V.; Flores-Fuentes, W.; Rodriguez-Quinonez, J.C.; Murrienta-Rico, F.N.; Miranda-Vega, J.E.; Mercorelli, P.; Kolendovska, M. Geometric Analysis of a Laser Scanner Functioning Based on Dynamic Triangulation. In Proceedings of the 2020 IEEE 29th International Symposium on Industrial Electronics (ISIE), Delft, The Netherlands, 17–19 June 2020; pp. 1398–1403. [Google Scholar] [CrossRef]

- Real-Moreno, O.; Castro-Toscano, M.J.; Rodríguez-Quiñonez, J.C.; Hernández-Balbuena, D.; Flores-Fuentes, W.; Rivas-Lopez, M. Implementing K-Nearest Neighbor Algorithm on Scanning Aperture for Accuracy Improvement. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 3182–3186. [Google Scholar] [CrossRef]

- Sepulveda-Valdez, C.; Sergiyenko, O.; Alaniz-Plata, R.; Núñez-López, J.A.; Tyrsa, V.; Flores-Fuentes, W.; Rodriguez-Quiñonez, J.C.; Mercorelli, P.; Kolendovska, M.; Kartashov, V.; et al. Laser Scanning Point Cloud Improvement by Implementation of RANSAC for Pipeline Inspection Application. In Proceedings of the IECON 2023—49th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 16–19 October 2023; pp. 1–6. [Google Scholar]

- PEMEX Base de Datos Institucional|Estadísticas Operativas Seleccionadas. Available online: https://ebdi.pemex.com/bdi/bdiController.do?action=cuadro&cvecua=MESTADOP (accessed on 16 November 2022).

- Mathieson, W.L.; Croft, P.; Wuttig, F.J. Infrastructure Adaptions to Changing Permafrost Conditions—Three Case Studies along the Trans Alaska Pipeline System. In Proceedings of the Geo-Congress 2020: Geotechnical Earthquake Engineering and Special Topics, Minneapolis, MN, USA, 25–28 February 2020; pp. 913–925. [Google Scholar]

- Shukla, A.; Xiaoqian, H.; Karki, H. Autonomous Tracking of Oil and Gas Pipelines by an Unmanned Aerial Vehicle. In Proceedings of the 2016 IEEE 59th International Midwest Symposium on Circuits and Systems (MWSCAS), Abu Dhabi, United Arab Emirates, 16–19 October 2016. [Google Scholar]

- Kim, J.H.; Sharma, G.; Iyengar, S.S. FAMPER: A Fully Autonomous Mobile Robot for Pipeline Exploration. In Proceedings of the 2010 IEEE International Conference on Industrial Technology, Via del Mar, Chile, 14–17 March 2010; pp. 517–523. [Google Scholar] [CrossRef]

- Roslin, N.S.; Anuar, A.; Jalal, M.F.A.; Sahari, K.S.M. A Review: Hybrid Locomotion of in-Pipe Inspection Robot. Procedia Eng. 2012, 41, 1456–1462. [Google Scholar] [CrossRef]

- Gunatilake, A.; Piyathilaka, L.; Tran, A.; Vishwanathan, V.K.; Thiyagarajan, K.; Kodagoda, S. Stereo Vision Combined with Laser Profiling for Mapping of Pipeline Internal Defects. IEEE Sens. J. 2021, 21, 11926–11934. [Google Scholar] [CrossRef]

- Latif, J.; Shakir, M.Z.; Edwards, N.; Jaszczykowski, M.; Ramzan, N.; Edwards, V. Review on Condition Monitoring Techniques for Water Pipelines. Measurement 2022, 193, 110895. [Google Scholar] [CrossRef]

- Tan, K.; Cheng, X. Correction of Incidence Angle and Distance Effects on TLS Intensity Data Based on Reference Targets. Remote Sens. 2016, 8, 251. [Google Scholar] [CrossRef]

- Lopez, M.R.; Sergiyenko, O.Y.; Tyrsa, V.V.; Perdomo, W.H.; Cruz, L.F.D.; Balbuena, D.H.; Burtseva, L.P.; Hipolito, J.I.N. Optoelectronic Method for Structural Health Monitoring. Struct. Health Monit. 2009, 9, 105–120. [Google Scholar] [CrossRef]

- MX344504 Sistema Optico de Triangulacion Dinamica Para la Medicion de Angulos y Coordenadas en un Espacio Tridimensional. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=MX152798571&recNum=1&maxRec=2&office=&prevFilter=&sortOption=Pub+Date+Desc&queryString=FP%3A%28Sistema+AND+Triangulacion+AND+Dinamica%29&tab=NationalBiblio (accessed on 5 June 2024).

- Núñez-Lónez, J.A.; Sergiyenko, O.; Alaniz-Plata, R.; Sepulveda-Valdez, C.; Peréz-Landeros, O.M.; Tyrsa, V.; Flores-Fuentes, W.; Rodriguez-Quiñonez, J.C.; Murrieta-Rico, F.N.; Mercorelli, P.; et al. Advances in Laser Positioning of Machine Vision System and Their Impact on 3D Coordinates Measurement. In Proceedings of the IECON 2023—49th Annual Conference of the IEEE Industrial Electronics Society, Singapore, Singapore, 16–19 October 2023; pp. 1–6. [Google Scholar]

- Latoui, A.; Hossine Daachi, M.E. Implementation of Q-Learning Algorithm on Arduino: Application to Autonomous Mobile Robot Navigation in COVID-19 Field Hospitals. In Proceedings of the International Conference on Electrical, Computer, and Energy Technologies, ICECET 2021, Cape Town, South Africa, 9–10 December 2021. [Google Scholar]

- Febbo, R.; Flood, B.; Halloy, J.; Lau, P.; Wong, K.; Ayala, A. Autonomous Vehicle Control Using a Deep Neural Network and Jetson Nano. In Proceedings of the ACM International Conference Proceeding Series, Portland, OR, USA, 26 July 2020; Association for Computing Machinery: New York, NY, USA, 2020; pp. 333–338. [Google Scholar]

- Vespoli, S.; Guizzi, G.; Converso, G.; Popolo, V.; Tedesco, A. An Electrical DC Motor Equivalent Circuit Testbed for the Battery Prognostic Health and Management. In Proceedings of the 2019 IEEE International Workshop on Metrology for Industry 4.0 and IoT, MetroInd 4.0 and IoT 2019—Proceedings, Naples, Italy, 4–6 June 2019; pp. 108–111. [Google Scholar]

- Singh, S.; Weeber, M.; Birke, K.P. Advancing Digital Twin Implementation: A Toolbox for Modelling and Simulation. In Proceedings of the Procedia CIRP, Gulf of Naples, Italy, 1 January 2021; Elsevier: Amsterdam, The Netherlands, 2021; Volume 99, pp. 567–572. [Google Scholar]

- Wang, Z.; Cao, Q.; Luan, N.; Zhan, L. Development of an Autonomous In-Pipe Robot for Offshore Pipeline Maintenance. Ind. Rob. 2010, 37, 177–184. [Google Scholar] [CrossRef]

- Hernandez, W.; de Vicente, J.; Sergiyenko, O.Y.; Fernández, E. Improving the Response of Accelerometers for Automotive Applications by Using LMS Adaptive Filters: Part II. Sensors 2010, 10, 952–962. [Google Scholar] [CrossRef] [PubMed]

- Nayak, A.; Pradhan, S.K. Design of a New In-Pipe Inspection Robot. Procedia Eng. 2014, 97, 2081–2091. [Google Scholar] [CrossRef]

- Capula Colindres, S.; Méndez, G.T.; Velázquez, J.C.; Cabrera-Sierra, R.; Angeles-Herrera, D. Effects of Depth in External and Internal Corrosion Defects on Failure Pressure Predictions of Oil and Gas Pipelines Using Finite Element Models. Adv. Struct. Eng. 2020, 23, 3128–3139. [Google Scholar] [CrossRef]

- Nguyen, A.; Le, B. 3D Point Cloud Segmentation: A Survey. In Proceedings of the 2013 6th IEEE Conference on Robotics, Automation and Mechatronics (RAM), Manila, Philippines, 12–15 November 2013; pp. 225–230. [Google Scholar] [CrossRef]

- Schnabel, R.; Wahl, R.; Klein, R. Efficient RANSAC for Point-cloud Shape Detection. In Computer Graphics Forum; Blackwell Publishing Ltd.: Oxford, UK, 2007; Volume 26, pp. 214–226. [Google Scholar] [CrossRef]

- Martínez-Otzeta, J.M.; Rodríguez-Moreno, I.; Mendialdua, I.; Sierra, B. RANSAC for Robotic Applications: A Survey. Sensors 2022, 23, 327. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Hu, Q.; Ai, M. Point Cloud Registration Based on One-Point RANSAC and Scale-Annealing Biweight Estimation. IEEE Trans. Geosci. Remote Sens. 2021, 59, 9716–9729. [Google Scholar] [CrossRef]

- Fischler, M.A.; Bolles, R.C. Random Sample Consensus: A Paradigm for Model Fitting with Applications to Image Analysis and Automated Cartography. Commun. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

| Failure | Defect Location | Code | Dimensions |

|---|---|---|---|

| Corrosion | Internal | 1 | 0.2–0.8 mm |

| Weld Failure | Internal | 2 | 10 mm |

| Perforation | Internal/External | 3 | - |

| Crack | Internal/External | 4 | 10–30 mm |

| Manufacturing Defects | Internal | 5 | 10–100 mm |

| Deformation | Internal/External | 6 | >20 mm |

| Failure | Defect Location | Probability |

|---|---|---|

| Corrosion | Internal | High |

| Weld Failure | Internal | Small |

| Perforation | Internal/External | Medium |

| Crack | Internal/External | Medium |

| Manufacturing Defects | Internal | Small |

| Fracture | Internal | Medium |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sepulveda-Valdez, C.; Sergiyenko, O.; Tyrsa, V.; Mercorelli, P.; Rodríguez-Quiñonez, J.C.; Flores-Fuentes, W.; Zhirabok, A.; Alaniz-Plata, R.; Núñez-López, J.A.; Andrade-Collazo, H.; et al. Mathematical Modeling for Robot 3D Laser Scanning in Complete Darkness Environments to Advance Pipeline Inspection. Mathematics 2024, 12, 1940. https://doi.org/10.3390/math12131940

Sepulveda-Valdez C, Sergiyenko O, Tyrsa V, Mercorelli P, Rodríguez-Quiñonez JC, Flores-Fuentes W, Zhirabok A, Alaniz-Plata R, Núñez-López JA, Andrade-Collazo H, et al. Mathematical Modeling for Robot 3D Laser Scanning in Complete Darkness Environments to Advance Pipeline Inspection. Mathematics. 2024; 12(13):1940. https://doi.org/10.3390/math12131940

Chicago/Turabian StyleSepulveda-Valdez, Cesar, Oleg Sergiyenko, Vera Tyrsa, Paolo Mercorelli, Julio C. Rodríguez-Quiñonez, Wendy Flores-Fuentes, Alexey Zhirabok, Ruben Alaniz-Plata, José A. Núñez-López, Humberto Andrade-Collazo, and et al. 2024. "Mathematical Modeling for Robot 3D Laser Scanning in Complete Darkness Environments to Advance Pipeline Inspection" Mathematics 12, no. 13: 1940. https://doi.org/10.3390/math12131940

APA StyleSepulveda-Valdez, C., Sergiyenko, O., Tyrsa, V., Mercorelli, P., Rodríguez-Quiñonez, J. C., Flores-Fuentes, W., Zhirabok, A., Alaniz-Plata, R., Núñez-López, J. A., Andrade-Collazo, H., Miranda-Vega, J. E., & Murrieta-Rico, F. N. (2024). Mathematical Modeling for Robot 3D Laser Scanning in Complete Darkness Environments to Advance Pipeline Inspection. Mathematics, 12(13), 1940. https://doi.org/10.3390/math12131940