Last Word in Last-Mile Logistics: A Novel Hybrid Multi-Criteria Decision-Making Model for Ranking Industry 4.0 Technologies

Abstract

:1. Introduction

- The newly developed hybrid mathematical model;

- Model application to solving the defined problem;

- Consideration of a wide range of alternatives and criteria.

2. Literature Review

2.1. Application of MCDM Methods in Logistics

2.2. Last-Mile Logistics

2.3. Industry 4.0 Technologies in Last-Mile Logistics

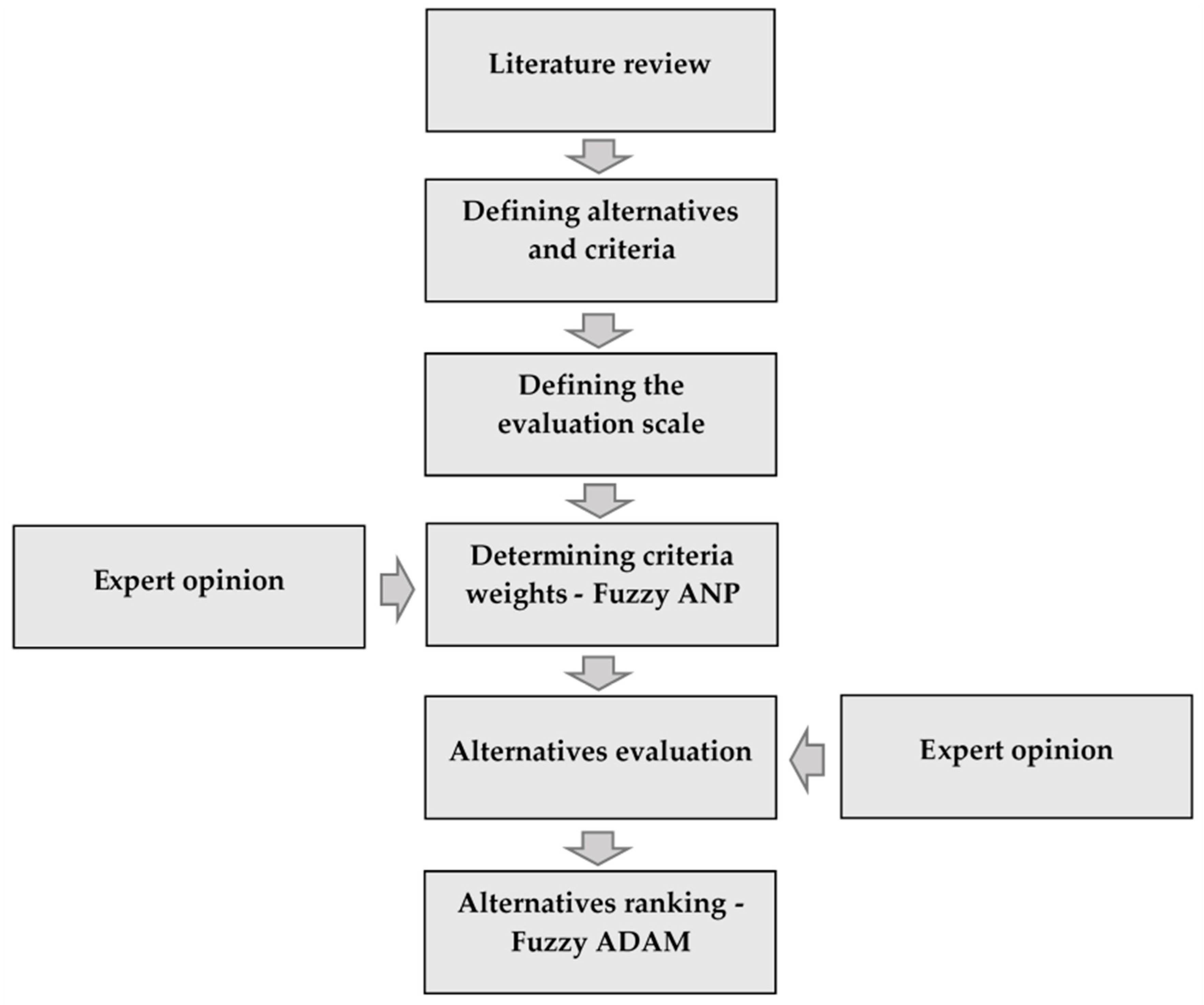

3. Methodology

4. Methodology Application for the Selection of I4.0 Technology for LML

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| C11 | C12 | C13 | C14 | C15 | C16 | C17 | C21 | C22 | C23 | C24 | C31 | C32 | C33 | C34 | C35 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C11 | + | + | + | + | + | + | + | + | + | + | + | + | + | + | ||

| C12 | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | |

| C13 | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | |

| C14 | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | |

| C15 | + | + | + | + | + | + | + | + | + | + | + | + | + | |||

| C16 | + | + | + | + | + | + | + | + | + | + | + | + | ||||

| C17 | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | |

| C21 | + | + | + | + | ||||||||||||

| C22 | + | + | + | + | ||||||||||||

| C23 | + | + | + | + | + | + | + | + | + | + | + | + | + | |||

| C24 | + | + | + | + | + | + | ||||||||||

| C31 | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | |

| C32 | + | + | + | + | + | + | + | |||||||||

| C33 | + | + | + | + | + | + | + | + | ||||||||

| C34 | + | + | + | + | + | + | + | + | ||||||||

| C35 | + | + | + | + | + | + | + |

References

- Salecl, R. The Tyranny of Choice; Profile Books: London, UK, 2011. [Google Scholar]

- Aldui, D.J.J.; Pome, G.P.C.; Díaz, M.F.C.; Flores, J.C.Q. Industry 4.0 and last mile logistics, new challenges and approaches: A bibliometric review. In Proceedings of the 3rd Asia Pacific International Conference on Industrial Engineering and Operations Management, Johor Bahru, Malaysia, 13–15 September 2022. [Google Scholar]

- Wang, C.N.; Chung, Y.C.; Wibowo, F.D.; Dang, T.T.; Nguyen, N.A.T. Sustainable Last mile Delivery Solution Evaluation in the Context of a Developing Country: A Novel OPA–Fuzzy MARCOS Approach. Sustainability 2023, 15, 12866. [Google Scholar] [CrossRef]

- Silva, V.; Amaral, A.; Fontes, T. Towards Sustainable Last-mile Logistics: A Decision-Making Model for Complex Urban Contexts. Sustain. Cities Soc. 2023, 96, 104665. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Uztürk, D. A Hybrid Methodology for Last-mile Delivery Strategy and Solution Selection at Smart Cities. In Transactions on Engineering Technologies; Springer: Singapore, 2021; pp. 217–231. [Google Scholar]

- Kostrzewski, M.; Abdelatty, Y.; Eliwa, A.; Nader, M. Analysis of Modern vs. Conventional Development Technologies in Transportation-the Case Study of a Last-mile Delivery Process. Sensors 2022, 22, 9858. [Google Scholar] [CrossRef] [PubMed]

- Cornell, A.; Kloss, B.; Presser, D.J.; Reidel, R. Drones Take to the Sky, Potentially Disrupting Last-Mile Delivery. McKinsey & Company. Available online: https://www.mckinsey.com/industries/aerospace-and-defense/our-insights/future-air-mobility-blog/drones-take-to-the-sky-potentially-disrupting-last-mile-delivery (accessed on 13 June 2024).

- Garg, V.; Niranjan, S.; Prybutok, V.; Pohlen, T.; Gligor, D. Drones in Last-Mile Delivery: A Systematic Review on Efficiency, Accessibility, and Sustainability. Transp. Res. D Transp. Environ. 2023, 123, 103831. [Google Scholar] [CrossRef]

- Ferrari, A.; Mangano, G.; Carlin, A. Socio-economic variables driving 4.0 projects in last-mile logistics. In Proceedings of the Summer School Francesco Turco, Bergamo, Italy, 8–10 September 2021. [Google Scholar]

- Sharma, V.P.; Prakash, S.; Singh, R. What Prevents Sustainable Last-mile Delivery in Industry 4.0? An Analysis and Decision Framework. Sustainability 2022, 14, 16423. [Google Scholar] [CrossRef]

- Ordoobadi, S.M. Application of ANP Methodology in Evaluation of Advanced Technologies. J. Manuf. Technol. Manag. 2012, 23, 229–252. [Google Scholar] [CrossRef]

- Krstić, M.; Agnusdei, G.P.; Tadić, S.; Kovač, M.; Miglietta, P.P. A Novel Axial-Distance-Based Aggregated Measurement (ADAM) Method for the Evaluation of Agri-Food Circular-Economy-Based Business Models. Mathematics 2023, 11, 1334. [Google Scholar] [CrossRef]

- Tadić, S.; Veljović, M.; Krstić, M.; Zečević, S. Application of industry 4.0 technologies in home delivery: A review. J. Appl. Eng. Sci. 2023, 21, 928–939. [Google Scholar] [CrossRef]

- Żak, J.; Węgliński, S. The Selection of the Logistics Center Location Based on MCDM/A Methodology. Transp. Res. Procedia 2014, 3, 555–564. [Google Scholar] [CrossRef]

- Tadić, S.; Krstić, M.; Roso, V.; Brnjac, N. Dry Port Terminal Location Selection by Applying the Hybrid Grey MCDM Model. Sustainability 2020, 12, 6983. [Google Scholar] [CrossRef]

- Jusufbašić, A. MCDM Methods for Selection of Handling Equipment in Logistics: A Brief Review. Spec. Eng. Man. Sci. 2023, 1, 13–24. [Google Scholar] [CrossRef]

- Ulutaş, A.; Karaköy, Ç. An Analysis of the Logistics Performance Index of EU Countries with an Integrated MCDM Model. Econ. Bus. Rev. 2019, 5, 49–69. [Google Scholar] [CrossRef]

- Prakash, C.; Barua, M.K. A Combined MCDM Approach for Evaluation and Selection of Third-Party Reverse Logistics Partner for Indian Electronics Industry. Sustain. Prod. Consum. 2016, 7, 66–78. [Google Scholar] [CrossRef]

- Tadić, S.; Zečević, S.; Krstić, M. A Novel Hybrid MCDM Model Based on Fuzzy DEMATEL, Fuzzy ANP and Fuzzy VIKOR for City Logistics Concept Selection. Expert Syst. Appl. 2014, 41, 8112–8128. [Google Scholar] [CrossRef]

- Kovač, M.; Tadić, S.; Krstić, M.; Veljović, M. A Methodology for Planning City Logistics Concepts Based on City-Dry Port Micro-Consolidation Centres. Mathematics 2023, 11, 3347. [Google Scholar] [CrossRef]

- Hien, D.N.; Thanh, N.V. Optimization of cold chain logistics with fuzzy MCDM model. Processes 2022, 10, 947. [Google Scholar] [CrossRef]

- Tadić, S.; Krstić, M.; Veljović, M.; Kovač, M. Selection of the starting point of e-order delivery using ADAM method. In Proceedings of the 50th International Symposium on Operational Research, SYM-OP-IS 2023, Tara, Serbia, 18–21 September 2023. [Google Scholar]

- Amchang, C.; Song, S.H. Locational preference of last-mile delivery centres: A case study of Thailand parcel delivery industry. J. Ind. Distrib. Bus. 2018, 9, 7–17. [Google Scholar] [CrossRef]

- Wang, C.N.; Cao, T.B.O.; Dang, T.T.; Nguyen, N.A.T. Third-Party Logistics Provider Selection in the Industry 4.0 Era by Using a Fuzzy AHP and Fuzzy MARCOS Methodology. IEEE Access 2024, 12, 67291–67313. [Google Scholar] [CrossRef]

- Krstić, M.; Tadić, S.; Kovač, M.; Roso, V.; Zečević, S. A Novel Hybrid MCDM Model for the Evaluation of Sustainable Last-mile Solutions. Math. Probl. Eng. 2021, 2021, 5969788. [Google Scholar] [CrossRef]

- Nur, F.; Alrahahleh, A.; Burch, R.; Babski-Reeves, K.; Marufuzzaman, M. Last-mile Delivery Drone Selection and Evaluation Using the Interval-Valued Inferential Fuzzy TOPSIS. J. Comput. Des. Eng. 2020, 7, 397–411. [Google Scholar] [CrossRef]

- Kovač, M.; Tadić, S.; Krstić, M.; Bouraima, M.B. Novel Spherical Fuzzy MARCOS Method for Assessment of Drone-Based City Logistics Concepts. Complexity 2021, 2021, 2374955. [Google Scholar] [CrossRef]

- Tadić, S.; Radovanović, L.J.; Krstić, M.; Veljović, M. Study of barriers for the use of drones in the last-mile logistics. In Proceedings of the 2nd International Conference on Advances in Traffic and Communication Technologies, ATCT, Sarajevo, Bosnia and Herzegovina, 18 May 2023. [Google Scholar]

- Miškić, S.; Tadić, S.; Stević, Ž.; Krstić, M.; Roso, V. A Novel Hybrid Model for the Evaluation of Industry 4.0 Technologies’ Applicability in Logistics Centers. J. Math. 2023, 2023, 3532862. [Google Scholar] [CrossRef]

- Nila, B.; Roy, J. Analysing the Key Success Factors of Logistics Center 4.0 Implementation Using Improved Pythagorean Fuzzy DEMATEL Method. Arab. J. Sci. Eng. 2023, 2023, 1–23. [Google Scholar] [CrossRef]

- Ferraro, S.; Cantini, A.; Leoni, L.; De Carlo, F. Sustainable Logistics 4.0: A Study on Selecting the Best Technology for Internal Material Handling. Sustainability 2023, 15, 7067. [Google Scholar] [CrossRef]

- Krstić, M.; Agnusdei, G.P.; Miglietta, P.P.; Tadić, S.; Roso, V. Applicability of Industry 4.0 Technologies in the Reverse Logistics: A Circular Economy Approach Based on COmprehensive Distance Based RAnking (COBRA) Method. Sustainability 2022, 14, 5632. [Google Scholar] [CrossRef]

- Jharkharia, S.; Shankar, R. Selection of Logistics Service Provider: An Analytic Network Process (ANP) Approach. Omega 2007, 35, 274–289. [Google Scholar] [CrossRef]

- Guimarães, J.L.d.S.; Salomon, V.A.P. ANP Applied to the Evaluation of Performance Indicators of Reverse Logistics in Footwear Industry. Procedia Comput. Sci. 2015, 55, 139–148. [Google Scholar] [CrossRef]

- Tavana, M.; Yazdani, M.; Di Caprio, D. An Application of an Integrated ANP–QFD Framework for Sustainable Supplier Selection. Int. J. Logist. 2017, 20, 254–275. [Google Scholar] [CrossRef]

- Peker, I.; Baki, B.; Tanyas, M.; Murat Ar, I. Logistics Center Site Selection by ANP/BOCR Analysis: A Case Study of Turkey. J. Intell. Fuzzy Syst. 2016, 30, 2383–2396. [Google Scholar] [CrossRef]

- Göncü, K.K.; Çetin, O. A Decision Model for Supplier Selection Criteria in Healthcare Enterprises with Dematel ANP Method. Sustainability 2022, 14, 13912. [Google Scholar] [CrossRef]

- Osintsev, N.; Rakhmangulov, A.; Baginova, V. Evaluation of Logistic Flows in Green Supply Chains Based on the Combined Dematel-Anp Method. Facta Univ. Ser. Mech. Eng. 2021, 19, 473. [Google Scholar] [CrossRef]

- Jiang, P.; Hu, Y.-C.; Yen, G.-F.; Jiang, H.; Chiu, Y.-J. Using a Novel Grey DANP Model to Identify Interactions between Manufacturing and Logistics Industries in China. Sustainability 2018, 10, 3456. [Google Scholar] [CrossRef]

- Onut, S.; Tuzkaya, U.R.; Torun, E. Selecting Container Port via a Fuzzy ANP-Based Approach: A Case Study in the Marmara Region, Turkey. Transp. Policy 2011, 18, 182–193. [Google Scholar] [CrossRef]

- Cui, X.; Wang, F.; Li, X.; Zhang, Y.; Yu, S. A Fuzzy-ANP Approach to Cooperation Risk Evaluation of Virtual Logistics Enterprise. In Proceedings of the 2007 IEEE International Conference on Automation and Logistics, Jinan, China, 18–21 August 2007. [Google Scholar]

- Aghaee, M.; Aghaee, R. Selection of Logistics Personnel by Using and Hybrid Fuzzy DEMATEL and Fuzzy ANP. Int. Res. J. Manag. Sci. 2016, 4, 14–22. [Google Scholar]

- Büyüközkan, G.; Çifçi, G. A Novel Hybrid MCDM Approach Based on Fuzzy DEMATEL, Fuzzy ANP and Fuzzy TOPSIS to Evaluate Green Suppliers. Expert Syst. Appl. 2012, 39, 3000–3011. [Google Scholar] [CrossRef]

- Senturk, S.; Erginel, N.; Binici, Y. Interval Type-2 Fuzzy Analytic Network Process for Modelling a Third-party Logistics (3PL) Company. J. Mult.-Valued Log. Soft Comput. 2017, 28, 311–333. [Google Scholar]

- Zayat, W.; Kilic, H.S.; Yalcin, A.S.; Zaim, S.; Delen, D. Application of MADM Methods in Industry 4.0: A Literature Review. Comput. Ind. Eng. 2023, 177, 109075. [Google Scholar] [CrossRef]

- Aballay, C.; Quezada, L.; Sepúlveda, C. Model for Technology Selection in the Context of Industry 4.0 Manufacturing. Processes 2023, 11, 2905. [Google Scholar] [CrossRef]

- Yadav, S.; Singh, S.P. An Integrated Fuzzy-ANP and Fuzzy-ISM Approach Using Blockchain for Sustainable Supply Chain. J. Enterp. Inf. Manag. 2021, 34, 54–78. [Google Scholar] [CrossRef]

- Shardeo, V.; Patil, A.; Madaan, J. Critical Success Factors for Blockchain Technology Adoption in Freight Transportation Using Fuzzy ANP–Modified TISM Approach. Int. J. Inf. Technol. Decis. Mak. 2020, 19, 1549–1580. [Google Scholar] [CrossRef]

- Peko, I.; Gjeldum, N.; Bilić, B. Application of AHP, fuzzy AHP and PROMETHEE method in solving additive manufacturing process selection problem. Teh. Vjesn. 2018, 25, 453–461. [Google Scholar] [CrossRef]

- Ransikarbum, K.; Khamhong, P. Integrated Fuzzy Analytic Hierarchy Process and Technique for Order of Preference by Similarity to Ideal Solution for Additive Manufacturing Printer Selection. J. Mater. Eng. Perform. 2021, 30, 6481–6492. [Google Scholar] [CrossRef]

- Tadić, S.; Krstić, M.; Veljović, M.; Čokorilo, O.; Milovanović, M. Risk Analysis of the Use of Drones in City Logistics. Mathematics 2024, 12, 1250. [Google Scholar] [CrossRef]

- Kalem, A.; Tadić, S.; Krstić, M.; Čabrić, N.; Branković, N. Performance Evaluation of Railway Infrastructure Managers: A Novel Hybrid Fuzzy MCDM Model. Mathematics 2024, 12, 1590. [Google Scholar] [CrossRef]

- Krstić, M.; Tadić, S.; Jolović, M. Evaluation of Transshipment Technologies in Intermodal Terminals: A Hybrid FSWARA-ADAM Approach. J. Organ. Technol. Entrep. 2024, 2, 27–38. [Google Scholar] [CrossRef]

- Sangkhiew, N.; Pornsing, C.; Ohmori, S.; Watanasungsuit, A. An Integrated fuzzy AHP-TOPSIS for the Last Mile Delivery Mode Selection. Sci. Technol. Asia 2022, 27, 265–280. [Google Scholar]

- Tadić, S.; Veljović, M. Home delivery: Concept and characteristics. Int. J. Traffic Transp. Eng. 2020, 10, 519–533. [Google Scholar] [CrossRef]

- Lim, S.F.W.; Jin, X.; Srai, J.S. Consumer-driven e-commerce: A literature review, design framework, and research agenda on last-mile logistics models. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 308–332. [Google Scholar] [CrossRef]

- Olsson, J.; Hellström, D.; Pålsson, H. Framework of Last-mile Logistics Research: A Systematic Review of the Literature. Sustainability 2019, 11, 7131. [Google Scholar] [CrossRef]

- Chopra, S. Designing the Distribution Network in a Supply Chain. Transp. Res. Part E Logist. Trans. Rev. 2003, 39, 123–140. [Google Scholar] [CrossRef]

- Halldórsson, Á.; Wehner, J. Last-mile Logistics Fulfilment: A Framework for Energy Efficiency. Res. Transp. Bus. Manag. 2020, 37, 100481. [Google Scholar] [CrossRef]

- Agatz, N.A.H.; Fleischmann, M.; van Nunen, J.A.E.E. E-Fulfillment and Multi-Channel Distribution—A Review. Eur. J. Oper. Res. 2008, 187, 339–356. [Google Scholar] [CrossRef]

- Daduna, J.R.; Lenz, B. Online shopping and changes in mobility. In Distribution Logistics: Advanced Solutions to Practical Problems; Fleischmann, B., Ed.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 65–84. [Google Scholar]

- Dablanc, L.; Giuliano, G.; Holliday, K.; O’Brien, T. Best Practices in Urban Freight Management: Lessons from an International Survey. Transp. Res. Rec. 2013, 2379, 29–38. [Google Scholar] [CrossRef]

- Harrington, T.S.; Singh Srai, J.; Kumar, M.; Wohlrab, J. Identifying Design Criteria for Urban System ‘Last-mile’ Solutions—A Multi-Stakeholder Perspective. Prod. Plan. Control 2016, 27, 456–476. [Google Scholar] [CrossRef]

- Ding, Z. Evaluating Different Last-Mile Logistics Solutions: A Case Study of SF Express. Master’s Thesis, University of Gävle, Gävle, Sweden, 2014. [Google Scholar]

- Tadić, S.; Veljović, M. Home delivery: A framework for structuring. Int. J. Traffic Transp. Eng. 2021, 11, 30–74. [Google Scholar] [CrossRef]

- Krstić, M.; Tadić, S.; Zečević, S. Technological solutions in logistics 4.0. Ekon. Preduzeća 2021, 69, 385–401. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A Systematic Review towards a New Logistics System. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Wang, K. Logistics 4.0 solution-new challenges and opportunities. In Proceedings of the 6th International Workshop of Advanced Manufacturing and Automation, IWAMA, Kunming, China, 10–11 November 2016. [Google Scholar]

- Jose, R.N.C.; Antonio, P.P.R.; Astrid, S.M.J. Evaluation of the Feasibility of Implementing 4.0 Industry Technologies in the Last-mile Processes Case: Logistic Operators of the Department of Atlántico. In Proceedings of the 2020 15th Iberian Conference on Information Systems and Technologies (CISTI), Seville, Spain, 24–27 June 2020; pp. 1–8. [Google Scholar]

- Kolasińska-Morawska, K.; Sułkowski, Ł.; Buła, P.; Brzozowska, M.; Morawski, P. Smart Logistics—Sustainable Technological Innovations in Customer Service at the Last-mile Stage: The Polish Perspective. Energies 2022, 15, 6395. [Google Scholar] [CrossRef]

- Li, X.; Gong, L.; Liu, X.; Jiang, F.; Shi, W.; Fan, L.; Gao, H.; Li, R.; Xu, J. Solving the Last Mile Problem in Logistics: A Mobile Edge Computing and Blockchain-based Unmanned Aerial Vehicle Delivery System. Concurr. Comput. 2022, 34, e6068. [Google Scholar] [CrossRef]

- Chen, K.-W.; Xie, M.-R.; Chen, Y.-M.; Chu, T.-T.; Lin, Y.-B. DroneTalk: An Internet-of-Things-Based Drone System for Last mile Drone Delivery. IEEE Trans. Intell. Transp. Syst. 2022, 23, 15204–15217. [Google Scholar] [CrossRef]

- Yaqiong, L.V.; Lei, T.U.; Lee, C.K.; Xin, T.A.N.G. IoT based omni-channel logistics service in industry 4.0. In Proceedings of the 2018 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Singapore, 31 July–2 August 2018. [Google Scholar]

- Markovic, M.; Jacobs, N.; Dryja, K.; Edwards, P.; Strachan, N.J.C. Integrating Internet of Things, Provenance, and Blockchain to Enhance Trust in Last Mile Food Deliveries. Front. Sustain. Food Syst. 2020, 4, 563424. [Google Scholar] [CrossRef]

- Demir, M.; Turetken, O.; Ferwom, A. Blockchain and IoT for Delivery Assurance on Supply Chain (BIDAS). In Proceedings of the 2019 IEEE International Conference on Big Data (Big Data), Los Angeles, CA, USA, 9–12 December 2019; pp. 5213–5222. [Google Scholar]

- Wanganoo, L.; Patil, A. Preparing for the Smart Cities: IoT Enabled Last mile Delivery. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 4 February–9 April 2020; pp. 1–6. [Google Scholar]

- Slabinac, M. Innovative Solutions for a “Last-mile” Delivery—A European Experience. In Proceedings of the 15th International Scientific Conference Business Logistics in Modern Management, Osijek, Croatia, 15 October 2015. [Google Scholar]

- Engesser, V.; Rombaut, E.; Vanhaverbeke, L.; Lebeau, P. Autonomous Delivery Solutions for Last mile Logistics Operations: A Literature Review and Research Agenda. Sustainability 2023, 15, 2774. [Google Scholar] [CrossRef]

- Fehling, C.; Saraceni, A. Technical and Legal Critical Success Factors: Feasibility of Drones & AGV in the Last mile-Delivery. Res. Transp. Bus. Manag. 2023, 50, 101029. [Google Scholar] [CrossRef]

- Jucha, P. Use of Artificial Intelligence in Last Mile Delivery. SHS Web Conf. 2021, 92, 04011. [Google Scholar] [CrossRef]

- Rosendorff, A.; Hodes, A.; Fabian, B. Artificial intelligence for last mile logistics—Procedures and architecture. Online J. Appl. Knowl. Manag. 2021, 9, 46–61. [Google Scholar] [CrossRef]

- Song, X.; Yang, S.; Huang, Z.; Huang, T. The application of artificial intelligence in electronic commerce. J. Phys. Conf. Ser. 2019, 1302, 032030. [Google Scholar] [CrossRef]

- Engelhardt, M.; Seeck, S.; Geier, B. Artificial Intelligence in Urban Last Mile Logistics—Status Quo, Potentials and Key Challenges. In Dynamics in Logistics; Springer International Publishing: Cham, Switzerland, 2022; pp. 275–289. ISBN 9783031053580. [Google Scholar]

- Feng, Z. Constructing Rural E-Commerce Logistics Model Based on Ant Colony Algorithm and Artificial Intelligence Method. Soft Comput. 2020, 24, 7937–7946. [Google Scholar] [CrossRef]

- Naclerio, A.G.; De Giovanni, P. Blockchain, Logistics and Omnichannel for Last Mile and Performance. Int. J. Logist. Manag. 2022, 33, 663–686. [Google Scholar] [CrossRef]

- Mckinnon, A. The Possible Impact of 3D Printing and Drones on Last mile Logistics: An Exploratory Study. Built Environ. 2016, 42, 617–629. [Google Scholar] [CrossRef]

- Demir, E.; Eyers, D.; Huang, Y. Competing through the Last Mile: Strategic 3D Printing in a City Logistics Context. Comput. Oper. Res. 2021, 131, 105248. [Google Scholar] [CrossRef]

- Saaty, T.L.; Takizawa, M. Dependence and Independence: From Linear Hierarchies to Nonlinear Networks. Eur. J. Oper. Res. 1986, 26, 229–237. [Google Scholar] [CrossRef]

- Rahmani, A.; Lotf, H.; Rostamy-Malkhalifeh, F.; Allahviranloo, M. A New Method for Defuzzifcation and Ranking of Fuzzy Numbers Based on the Statistical Beta Distribution. Adv. Fuzzy Syst. 2016, 2016, 6945184. [Google Scholar]

- Campbell, T.; Williams, C.; Ivanova, O.; Garrett, B. Could 3D Printing Change the World? Technologies, Potential, and Implications of Additive Manufacturing; Atlantic Council: Washington, DC, USA, 2011. [Google Scholar]

- Ransikarbum, K.; Kim, N. Importance of Multi-objective Evaluation in 3D Printing. In Industrial Strategies and Solutions for 3D Printing: Applications and Optimization; Vanaei, H.R., Khelladi, S., Tcharkhtchi, A., Eds.; John Wiley & Sons: New York, NY, USA, 2024; pp. 105–128. [Google Scholar]

- DHL, Robotics in Logistics: A DPDHL Perspective on Implications and Use Cases for The Logistics Industry. Available online: https://www.thehive-network.com/wp-content/uploads/2017/03/DHL_RoboticsInLogistics.pdf (accessed on 17 June 2024).

- Zhou, Z.; Chen, E.; Wu, F.; Chang, Z.; Xing, L. Multi-Satellite Scheduling Problem with Marginal Decreasing Imaging Duration: An Improved Adaptive Ant Colony Algorithm. Comput. Ind. Eng. 2023, 176, 108890. [Google Scholar] [CrossRef]

- Chang, Z.; Punnen, A.P.; Zhou, Z.; Cheng, S. Solving Dynamic Satellite Image Data Downlink Scheduling Problem via an Adaptive Bi-Objective Optimization Algorithm. Comput. Oper. Res. 2023, 160, 106388. [Google Scholar] [CrossRef]

- Chang, Z.; Zhou, Z.; Li, R.; Xiao, H.; Xing, L. Observation Scheduling for a State-of-the-Art SAREOS: Two Adaptive Multi-Objective Evolutionary Algorithms. Comput. Ind. Eng. 2022, 169, 108252. [Google Scholar] [CrossRef]

- Chang, Z.; Chen, Y.; Yang, W.; Zhou, Z. Mission Planning Problem for Optical Video Satellite Imaging with Variable Image Duration: A Greedy Algorithm Based on Heuristic Knowledge. Adv. Space Res. 2020, 66, 2597–2609. [Google Scholar] [CrossRef]

- Chen, E.; Zhou, Z.; Li, R.; Chang, Z.; Shi, J. The Multi-Fleet Delivery Problem Combined with Trucks, Tricycles, and Drones for Last-Mile Logistics Efficiency Requirements under Multiple Budget Constraints. Transp. Res. Part E Logist. Trans. Rev. 2024, 187, 103573. [Google Scholar] [CrossRef]

- Kückelhaus, M.; Zeiler, K. Big Data in Logistics: A DHL Perspective on How to Move Beyond the Hype; DHL Customer Solutions & Innovation Represented by Martin Wegner: Troisdorf, Germany, 2013. [Google Scholar]

- Zheng, Z.; Xie, S.; Dai, H.; Chen, X.; Wang, H. An Overview of Blockchain Technology: Architecture, Consensus, and Future Trends. In Proceedings of the 2017 IEEE International Congress on Big Data (BigData Congress), Boston, MA, USA, 11–14 December 2017. [Google Scholar]

- Ding, Y.; Jin, M.; Li, S.; Feng, D. Smart Logistics Based on the Internet of Things Technology: An Overview. Int. J. Logist. 2021, 24, 323–345. [Google Scholar] [CrossRef]

- Chang, S.-C.; Chang, H.-H.; Lu, M.-T. Evaluating Industry 4.0 Technology Application in SMEs: Using a Hybrid MCDM Approach. Mathematics 2021, 9, 414. [Google Scholar] [CrossRef]

- Mahdiraji, H.A.; Zavadskas, E.K.; Skare, M.; Kafshgar, F.Z.R.; Arab, A. Evaluating Strategies for Implementing Industry 4.0: A Hybrid Expert Oriented Approach of BWM and Interval Valued Intuitionistic Fuzzy TODIM. Econ. Res.-Ekon. Istraž. 2020, 33, 1600–1620. [Google Scholar] [CrossRef]

- Kaya, İ.; Erdoğan, M.; Karaşan, A.; Özkan, B. Creating a Road Map for Industry 4.0 by Using an Integrated Fuzzy Multicriteria Decision-Making Methodology. Soft Comput. 2020, 24, 17931–17956. [Google Scholar] [CrossRef]

- Sriram, R.M.; Vinodh, S. Analysis of Readiness Factors for Industry 4.0 Implementation in SMEs Using COPRAS. Int. J. Qual. Reliab. Manag. 2021, 38, 1178–1192. [Google Scholar] [CrossRef]

- Si, J.; Marjanovic-Halburd, L.; Nasiri, F.; Bell, S. Assessment of Building-Integrated Green Technologies: A Review and Case Study on Applications of Multi-Criteria Decision Making (MCDM) Method. Sustain. Cities Soc. 2016, 27, 106–115. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Uztürk, D. Smart Last Mile Delivery Solution Selection for Cities. Available online: http://www.iaeng.org/publication/WCE2019/WCE2019_pp278-284.pdf (accessed on 28 May 2024).

- Alani, M.M.; Alloghani, M. Security Challenges in the Industry 4.0 Era. In Industry 4.0 and Engineering for a Sustainable Future; Springer International Publishing: Cham, Switzerland, 2019; pp. 117–136. ISBN 9783030129521. [Google Scholar]

- Sah, B.; Gupta, R.; Bani-Hani, D. Analysis of Barriers to Implement Drone Logistics. Int. J. Logist. 2021, 24, 531–550. [Google Scholar] [CrossRef]

- Schließmann, A. iProduction, die Mensch-Maschine-Kommunikation in der Smart Factory1. In Handbuch Industrie 4.0 Bd.4; Springer: Berlin/Heidelberg, Germany, 2017; pp. 173–202. ISBN 9783662532539. [Google Scholar]

- Parham, S.; Tamminga, H.J. The adaptation of the logistic industry to the fourth industrial revolution: The role of human resource management. J. Bus. Manag. Soc. Sci. Res. 2018, 7, 179–191. [Google Scholar]

- Arishi, A.; Krishnan, K.; Arishi, M. Machine Learning Approach for Truck-Drones Based Last mile Delivery in the Era of Industry 4.0. Eng. Appl. Artif. Intell. 2022, 116, 105439. [Google Scholar] [CrossRef]

- Villagrán, N.V.; Estevez, E.; Pesado, P.; Marquez, J.D.J. Standardization: A Key Factor of Industry 4.0. In Proceedings of the 2019 Sixth International Conference on eDemocracy & eGovernment (ICEDEG), Quito, Ecuador, 24–26 April 2019; pp. 350–354. [Google Scholar]

- Jamkhaneh, H.B.; Shahin, R.; Tortorella, G.L. Analysis of Logistics 4.0 Service Quality and Its Sustainability Enabler Scenarios in Emerging Economy. Clean. Logist. Supply Chain 2022, 4, 100053. [Google Scholar] [CrossRef]

- Kilibarda, M.; Andrejić, M.; Popović, V. Research in Logistics Service Quality: A Systematic Literature Review. Transport 2019, 35, 224–235. [Google Scholar] [CrossRef]

- Tang, Y.M.; Chau, K.Y.; Kuo, W.T.; Liu, X.X. IoT-Based Information System on Cold-Chain Logistics Service Quality (ICCLSQ) Management in Logistics 4.0. Inf. Syst. Front. 2024, 26, 689–708. [Google Scholar] [CrossRef]

- Boysen, N.; Fedtke, S.; Schwerdfeger, S. Last mile Delivery Concepts: A Survey from an Operational Research Perspective. OR Spectr. 2021, 43, 1–58. [Google Scholar] [CrossRef]

- Rejeski, D.; Zhao, F.; Huang, Y. Research Needs and Recommendations on Environmental Implications of Additive Manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef]

- Rodič, B. Industry 4.0 and the New Simulation Modelling Paradigm. Organizacija 2017, 50, 193–207. [Google Scholar] [CrossRef]

- Tao, F.; Wang, Y.; Zuo, Y.; Yang, H.; Zhang, M. Internet of Things in Product Life-Cycle Energy Management. J. Ind. Inf. Integr. 2016, 1, 26–39. [Google Scholar] [CrossRef]

- Lin, C.-C.; Deng, D.-J.; Chen, Z.-Y.; Chen, K.-C. Key Design of Driving Industry 4.0: Joint Energy-Efficient Deployment and Scheduling in Group-Based Industrial Wireless Sensor Networks. IEEE Commun. Mag. 2016, 54, 46–52. [Google Scholar] [CrossRef]

- Laskurain-Iturbe, I.; Arana-Landín, G.; Landeta-Manzano, B.; Uriarte-Gallastegi, N. Exploring the Influence of Industry 4.0 Technologies on the Circular Economy. J. Clean. Prod. 2021, 321, 128944. [Google Scholar] [CrossRef]

- Gromova, E.A.; Koneva, N.S.; Titova, E.V. Legal Barriers to the Implementation of Digital Industry (Industry 4.0) Components and Ways to Overcome Them. J. World Intellect. Prop. 2022, 25, 186–205. [Google Scholar] [CrossRef]

- Habrat, D. Legal Challenges of Digitalization and Automation in the Context of Industry 4.0. Procedia Manuf. 2020, 51, 938–942. [Google Scholar] [CrossRef]

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Koiwanit, J. Analysis of Environmental Impacts of Drone Delivery on an Online Shopping System. Adv. Clim. Chang. Res. 2018, 9, 201–207. [Google Scholar] [CrossRef]

- Hübner, A.; Wollenburg, J.; Holzapfel, A. Retail Logistics in the Transition from Multi-Channel to Omni-Channel. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 562–583. [Google Scholar] [CrossRef]

- Pavlić, H.S.; Zaninović, P.A. Perspectives of Blockchain Technology for Sustainable Supply Chains. In Integration of Information Flow for Greening Supply Chain Management; Kolinski, A., Dujak, D., Golinska-Dawson, P., Eds.; EcoProduction: Paris, France, 2019; pp. 77–92. [Google Scholar]

| I Group of Keywords | II Group of Keywords | III Group of Keywords | IV Group of Keywords | V Group of Keywords |

|---|---|---|---|---|

| last mile, last-mile, last miles, final mile, home, parcel, B2C, door, customer | definition, concept, review | delivery, logistic, logistics, transport, storage, warehouse, loading, package, inventory, order | technology, new technologies, 4.0, industry 4.0, smart, names of technologies and corresponding abbreviations (Internet of things, IoT, automated guided vehicles, etc.) | selection, choice, evaluation, ranking, multi-criteria decision-making, MCDM, multiple-criteria decision analysis, MCDA, names of MCDM methods and corresponding abbreviations (analytic hierarchy process, AHP, Promethee, etc.) |

| Method(s) | Field of Application | Differences | Source |

|---|---|---|---|

| AHP | Selection of last-mile logistics center location | PC method; the paper does not deal with technologies but with the problem of locating the place of delivery | [23] |

| Fuzzy AHP, fuzzy measurement of alternatives and ranking according to compromise solution (MARCOS) | Logistics service provider evaluation | PC and DB methods; the paper does not deal with technologies but with the evaluation of providers | [24] |

| Fuzzy Delphi, fuzzy FARE, fuzzy VIKOR | Evaluation of sustainable delivery solution | S, DB, and O methods; the paper deals with concepts based on several I4.0 technologies | [25] |

| AHP, TOPSIS | Evaluation of sustainable delivery solution | PC and DB methods; less comprehensiveness of alternatives; taking into account the views of different stakeholders | [4] |

| SWOT (strengths, weaknesses, opportunities, and threats) analysis, 2-tuple VIKOR, AHP | Evaluation of smart solutions and strategies | PC and DB methods; less comprehensiveness of alternatives and criteria | [5] |

| Interval-valued inferential fuzzy TOPSIS | Evaluation of delivery drone types | DB method; the paper deals with the selection of the type of one I4.0 technology | [26] |

| Spherical fuzzy MARCOS | Evaluation of drone-based delivery concepts | DB method; the paper deals with concepts based on one I4.0 technology | [27] |

| Fuzzy Delphi ANP | Analysis of barriers to the use of drones in delivery | PC and S methods; the paper deals with barriers to the application of an I4.0 technology | [28] |

| Fuzzy AHP, fuzzy TOPSIS | Evaluation of delivery methods | PC and DB methods; the paper is not concerned with technologies but with delivery methods | [54] |

| Multi-criteria decision analysis (MCDA) | Evaluation of transport technologies | Less comprehensiveness of alternatives and criteria; Taking into account the views of different stakeholders | [6] |

| Fuzzy ANP, fuzzy ADAM | Evaluation of I4.0 technologies for LML | PC and G methods; greater comprehensiveness of alternatives and criteria | This study |

| Linguistic Term | Abbreviation | Fuzzy Scale |

|---|---|---|

| “None” | “N” | (1, 1, 2) |

| “Very low” | “VL” | (1, 2, 3) |

| “Low” | “L” | (2, 3, 4) |

| “Fairly low” | “FL” | (3, 4, 5) |

| “Medium” | “M” | (4, 5, 6) |

| “Fairly high” | “FH” | (5, 6, 7) |

| “High” | “H” | (6, 7, 8) |

| “Very high” | “VH” | (7, 8, 9) |

| “Extremely high” | “EH” | (8, 9, 10) |

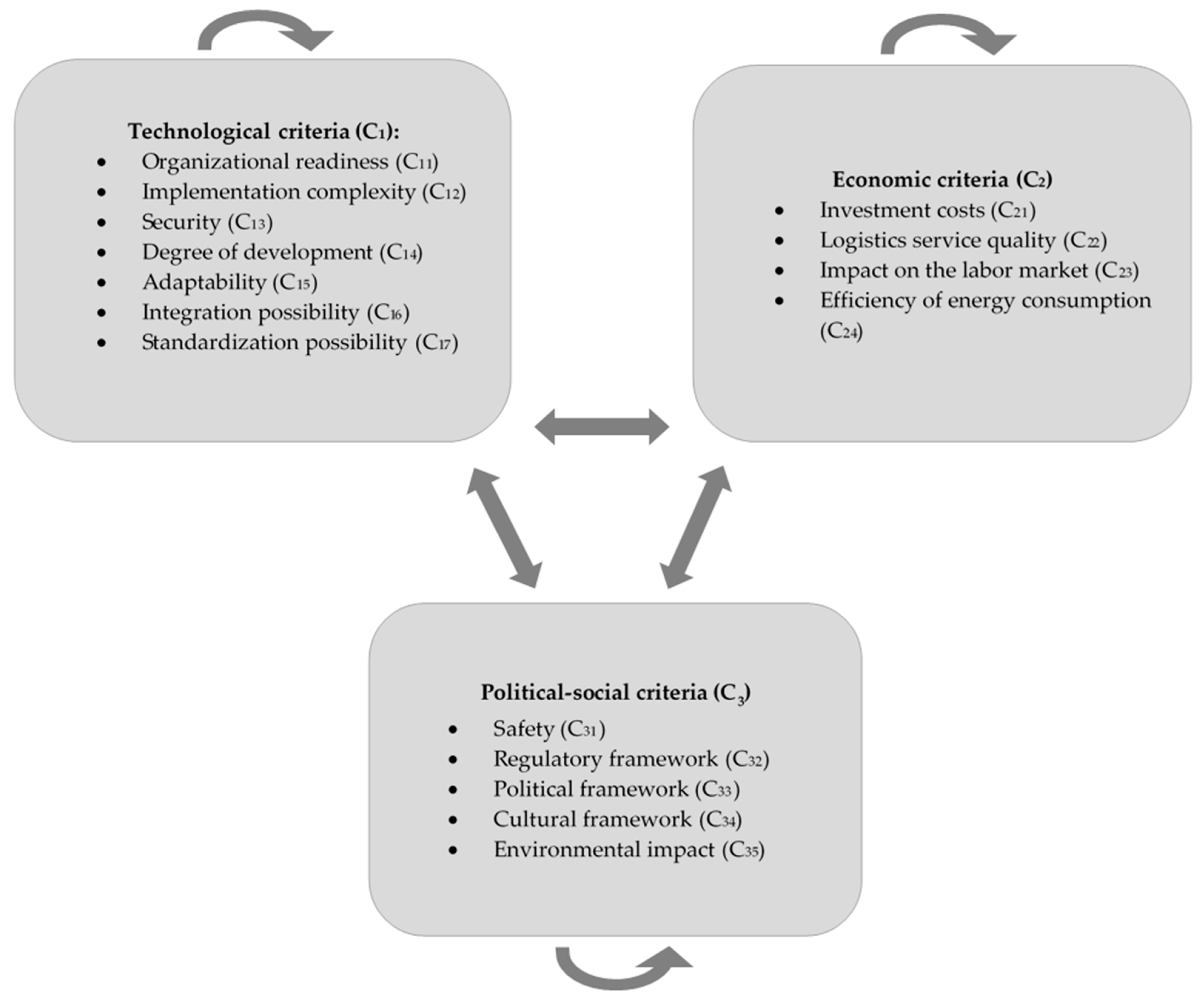

| Technological Criteria (C1) | Description | Source(s) |

| Organizational readiness (C11) | The number of changes within the organization implies procedures, employees, etc., required to realize the full potential of the technology | [32,101,102,103] |

| Implementation complexity (C12) | The amount of effort required to implement the technology implies workforce training, software, hardware, and supporting systems | [32] |

| Security (C13) | Implies the vulnerability of technology to unauthorized download, misuse, or deletion of data | [32,101] |

| Degree of development (C14) | The degree of technology development, the activities for which it is applied, and the methods of application | [32] |

| Adaptability (C15) | Ability to modify and/or improve technology to adapt to changes in the business environment | [3,104] |

| Integration possibility (C16) | Compatibility and likelihood of joint application with other technologies and concepts | [32,101,104] |

| Standardization possibility (C17) | Possibility of standardization of technological aspects, such as processes, procedures, equipment, etc. | [32,103] |

| Economic criteria (C2) | Description | Source (s) |

| Investment costs (C21) | Costs of equipment, software, worker training, technology development, and implementation | [32,103,105,106] |

| Logistics service quality (C22) | Reliability, speed, user needs understanding, flexibility, availability, accuracy, visibility, traceability, real-time monitoring, sustainability, etc. | [32,102,103] |

| Impact on the labor market (C23) | Effect on increasing or decreasing the number of jobs or their transformation | [32] |

| Efficiency of energy consumption (C24) | Degree of efficiency of use and protection of limited energy resources | [32,105] |

| Political–social criteria (C3) | Description | Source (s) |

| Safety (C31) | Impact on the safety of the environment, population, ecosystem, facilities, workforce, etc. | [6,32] |

| Regulatory framework (C32) | Favorability of legal conditions at different levels | [6,32,101,103] |

| Political framework (C33) | Favorability of political conditions at different levels, influence of political entities, degree of political will | [32] |

| Cultural framework (C34) | Favorability of cultural conditions, degree of acceptance of innovations | [32,102,103] |

| Environmental impact (C35) | Effects on the environment in terms of greenhouse gases, noise, vibrations, particulate emissions, waste generation, space occupation, etc. | [6,32,101] |

| Sector | Number of Experts | Years of Experience |

|---|---|---|

| Last-mile logistics/City logistics | 4 | <5 |

| 6 | 5–15 | |

| 5 | >15 | |

| Industry 4.0 | 4 | <5 |

| 7 | 5–15 | |

| 4 | >15 |

| Last-Mile Logistics/City Logistics | |||||||||||||||

| E11 | E14 | E4 | E13 | E3 | E6 | E7 | E12 | E2 | E4 | E5 | E8 | E10 | E1 | E9 | mean |

| (4, 5, 6) | (4, 5, 6) | (5, 6, 7) | (5, 6, 7) | (6, 7, 8) | (6, 7, 8) | (6, 7, 8) | (7, 8, 9) | (7, 8, 9) | (7, 8, 9) | (7, 8, 9) | (7, 8, 9) | (7, 8, 9) | (8, 9, 10) | (8, 9, 10) | (6.27, 7.27, 8.27) |

| “M” | “M” | “FH” | “FH” | “FH” | “H” | “H” | “VH” | “VH” | “VH” | “VH” | “VH” | “VH” | “EH” | “EH” | “H” |

| Industry 4.0 | |||||||||||||||

| E17 | E22 | E16 | E20 | E25 | E28 | E15 | E18 | E19 | E21 | E23 | E24 | E30 | E26 | E29 | mean |

| (3, 4, 5) | (3, 4, 5) | (4, 5, 6) | (4, 5, 6) | (4, 5, 6) | (4, 5, 6) | (5, 6, 7) | (5, 6, 7) | (6, 7, 8) | (6, 7, 8) | (7, 8, 9) | (7, 8, 9) | (7, 8, 9) | (8, 9, 10) | (8, 9, 10) | (5.40, 6.40, 7.40) |

| “FL” | “FL” | “M” | “M” | “M” | “M” | “FH” | “H” | “H” | “H” | “VH” | “VH” | “VH” | “EH” | “EH” | “FH” |

| Technological Criteria | Economic Criteria | |||||||||||

| C11 | C12 | C13 | C14 | C15 | C16 | C17 | C21 | C22 | C23 | C24 | ||

| C11 | “N” | “L” | “FL” | “M” | “H” | “H” | C21 | “L” | “M” | “FH” | ||

| C12 | “L” | “FL” | “M” | “H” | “H” | C22 | “FL” | “FH” | ||||

| C13 | “L” | “FL” | “FH” | “FH” | C23 | “VL” | ||||||

| C14 | “L” | “FL” | “FL” | C24 | ||||||||

| C15 | “VL” | “VL” | ||||||||||

| C16 | “N” | |||||||||||

| C17 | ||||||||||||

| Political and Social Criteria | Criteria Groups | |||||||||||

| C31 | C32 | C33 | C34 | C35 | C1 | C2 | C3 | |||||

| C31 | “N” | “FL” | “M” | “H” | C1 | “L” | “FL” | |||||

| C32 | “L” | “FL” | “FH” | C2 | “VL” | |||||||

| C33 | “FL” | “M” | C3 | |||||||||

| C34 | “FL” | |||||||||||

| C35 | ||||||||||||

| C11 | C12 | C13 | C14 | C15 | C16 | C17 | C21 | C22 | C23 | C24 | C31 | C32 | C33 | C34 | C35 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | “FL” | “FL” | “VH” | “L” | “VH” | “H” | “M” | “FL” | “VH” | “FL” | “EH” | “H” | “FH” | “FH” | “M” | “H” |

| A2 | “M” | “H” | “FH” | “FH” | “EH” | “VH” | “FH” | “FL” | “EH” | “M” | “H” | “FH” | “M” | “H” | “M” | “FH” |

| A3 | “M” | “H” | “M” | “H” | “EH” | “EH” | “VH” | “FL” | “EH” | “H” | “VH” | “M” | “FL” | “FH” | “M” | “H” |

| A4 | “M” | “FL” | “M” | “H” | “FH” | “VH” | “FH” | “M” | “H” | “M” | “FH” | “M” | “FL” | “FH” | “M” | “M” |

| A5 | “H” | “H” | “M” | “H” | “EH” | “VH” | “VH” | “H” | “FH” | “VH” | “FH” | “FH” | “M” | “H” | “VH” | “VH” |

| A6 | “FH” | “VH” | “H” | “FH” | “VH” | “H” | “FH” | “H” | “EH” | “VH” | “FH” | “VH” | “H” | “H” | “VH” | “VH” |

| A7 | “H” | “H” | “H” | “VH” | “EH” | “EH” | “H” | “H” | “FH” | “FL” | “FH” | “H” | “EH” | “VH” | “EH” | “EH” |

| A8 | “H” | “FL” | “FH” | “EH” | “VH” | “EH” | “VH” | “FH” | “VH” | “FH” | “EH” | “H” | “L” | “FH” | “H” | “VH” |

| A9 | “VH” | “M” | “M” | “VH” | “EH” | “VH” | “H” | “H” | “H” | “H” | “H” | “VH” | “FH” | “EH” | “VH” | “VH” |

| Alternatives | Volume | Rank |

|---|---|---|

| A1 | 0.026570 | 7 |

| A2 | 0.026451 | 8 |

| A3 | 0.027665 | 6 |

| A4 | 0.021221 | 9 |

| A5 | 0.032206 | 4 |

| A6 | 0.033538 | 3 |

| A7 | 0.037400 | 1 |

| A8 | 0.031686 | 5 |

| A9 | 0.035496 | 2 |

| C11 | C12 | C13 | C14 | C15 | C16 | C17 | C21 | C22 | C23 | C24 | C31 | C32 | C33 | C34 | C35 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sc. 0 | 0.13 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 1 | 0.13 | 0.144 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 2 | 0.13 | 0.096 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 3 | 0.13 | 0.048 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 4 | 0.13 | 0 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 5 | 0.098 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 6 | 0.065 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 7 | 0.033 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 8 | 0 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 9 | 0.13 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.08 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 10 | 0.13 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.053 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 11 | 0.13 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0.027 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 12 | 0.13 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.103 | 0.047 | 0.031 | 0.015 | 0 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 13 | 0.13 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.077 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 14 | 0.13 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.052 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 15 | 0.13 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0.026 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 16 | 0.13 | 0.192 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0 | 0.047 | 0.031 | 0.015 | 0.106 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 17 | 0 | 0 | 0.07 | 0.061 | 0.016 | 0.009 | 0.01 | 0 | 0.047 | 0.031 | 0.015 | 0 | 0.067 | 0.043 | 0.082 | 0.016 |

| Sc. 18 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 | 0.063 |

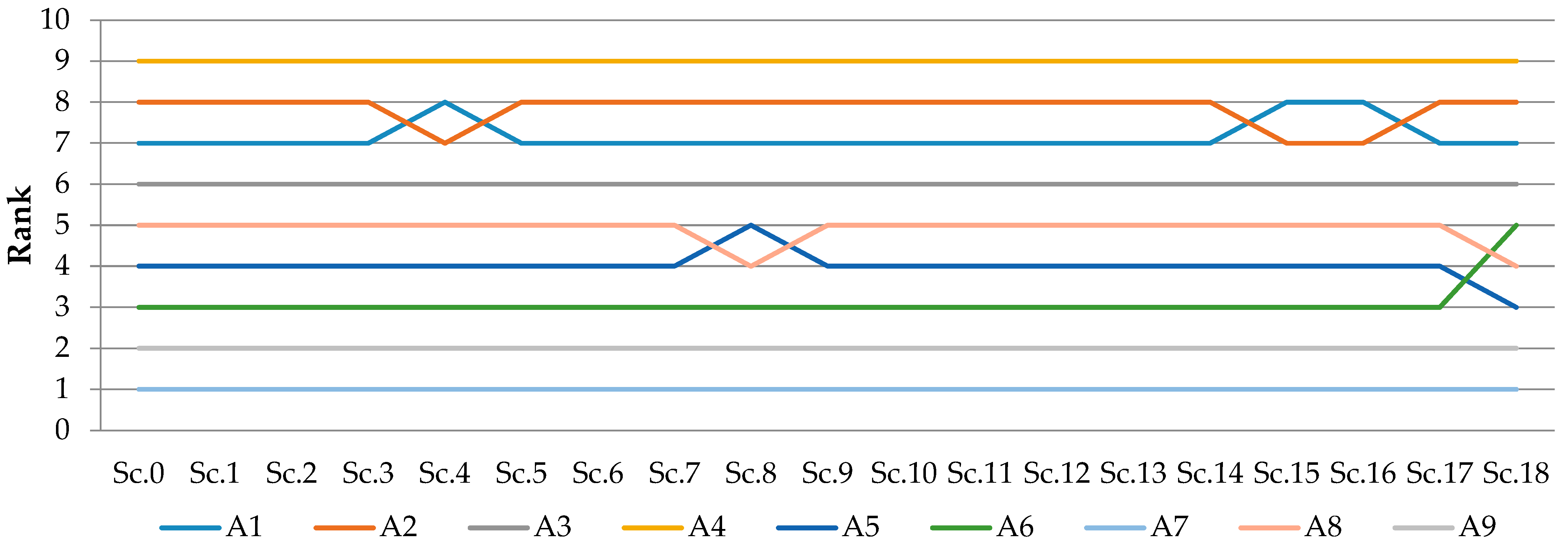

| Sc. | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 7 | 7 | 7 | 7 | 8 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 8 | 8 | 7 | 7 |

| A2 | 8 | 8 | 8 | 8 | 7 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 7 | 7 | 8 | 8 |

| A3 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| A4 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 |

| A5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 3 |

| A6 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 5 |

| A7 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| A8 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 4 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 4 |

| A9 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Veljović, M.; Tadić, S.; Krstić, M. Last Word in Last-Mile Logistics: A Novel Hybrid Multi-Criteria Decision-Making Model for Ranking Industry 4.0 Technologies. Mathematics 2024, 12, 2010. https://doi.org/10.3390/math12132010

Veljović M, Tadić S, Krstić M. Last Word in Last-Mile Logistics: A Novel Hybrid Multi-Criteria Decision-Making Model for Ranking Industry 4.0 Technologies. Mathematics. 2024; 12(13):2010. https://doi.org/10.3390/math12132010

Chicago/Turabian StyleVeljović, Miloš, Snežana Tadić, and Mladen Krstić. 2024. "Last Word in Last-Mile Logistics: A Novel Hybrid Multi-Criteria Decision-Making Model for Ranking Industry 4.0 Technologies" Mathematics 12, no. 13: 2010. https://doi.org/10.3390/math12132010

APA StyleVeljović, M., Tadić, S., & Krstić, M. (2024). Last Word in Last-Mile Logistics: A Novel Hybrid Multi-Criteria Decision-Making Model for Ranking Industry 4.0 Technologies. Mathematics, 12(13), 2010. https://doi.org/10.3390/math12132010