Integrated Optimization of Production Scheduling and Haulage Route Planning in Open-Pit Mines

Abstract

:1. Introduction

1.1. Literature Review

1.2. Main Contributions

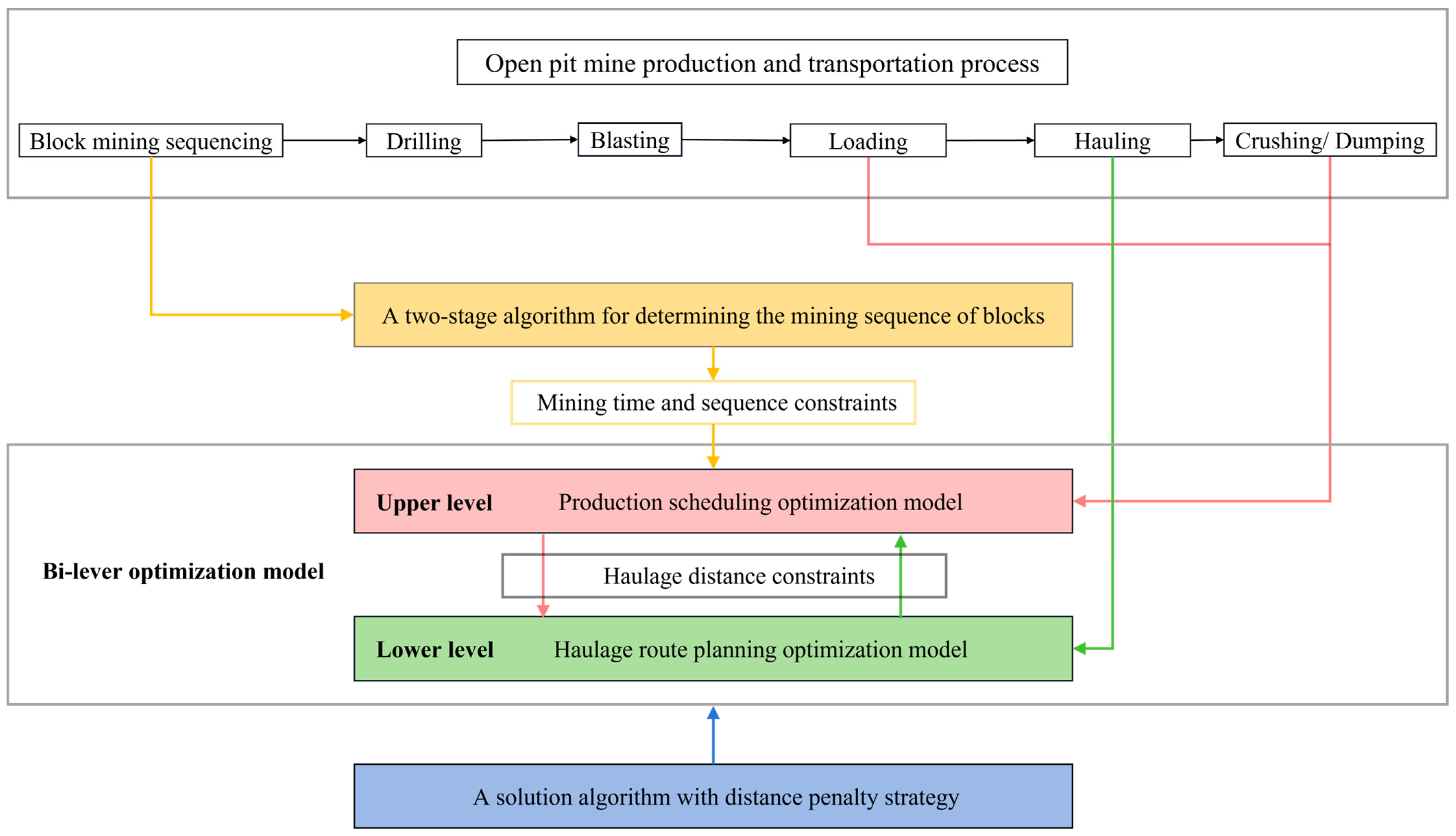

2. Methodology

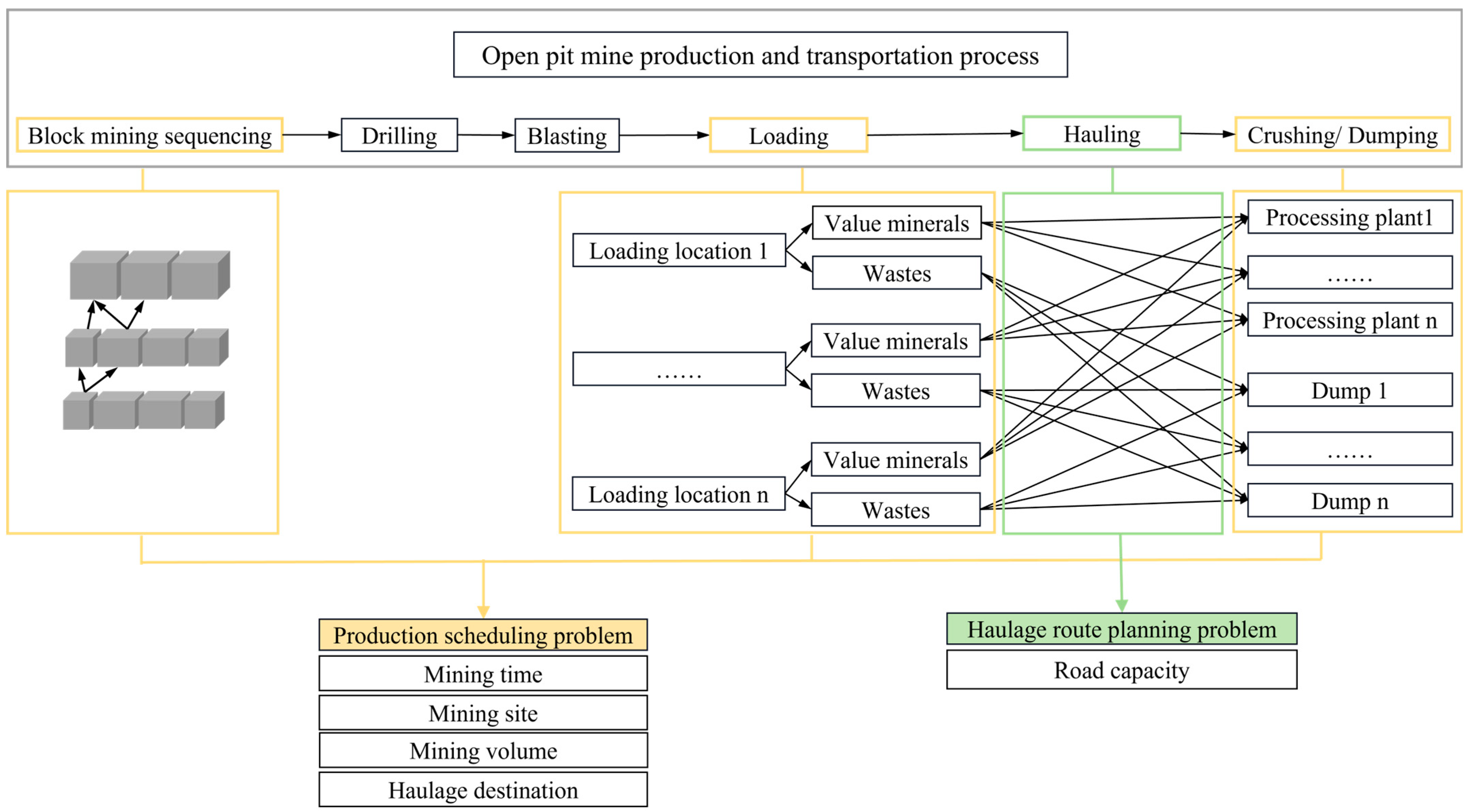

2.1. Problem Description

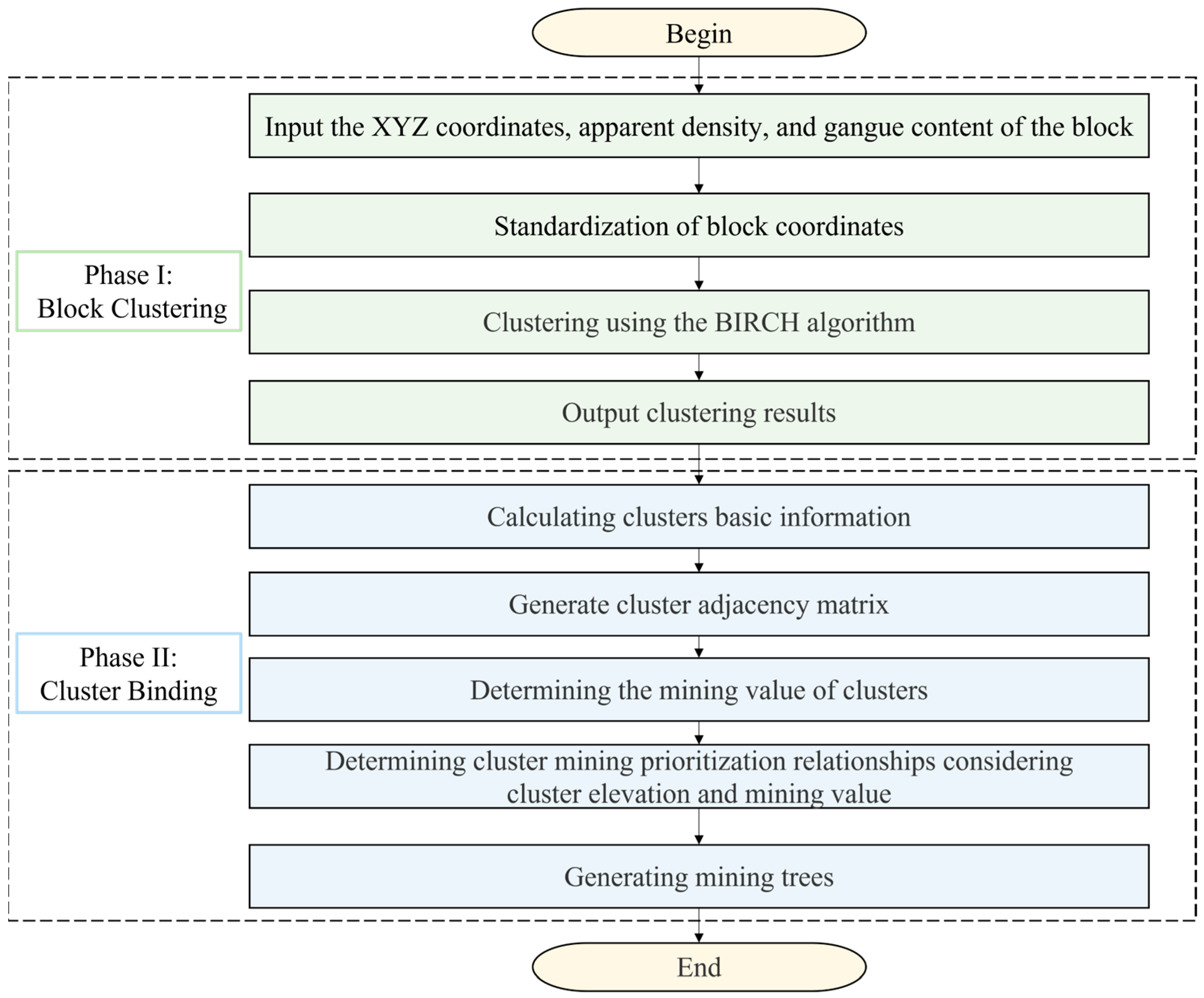

2.2. Block Mining Sequence

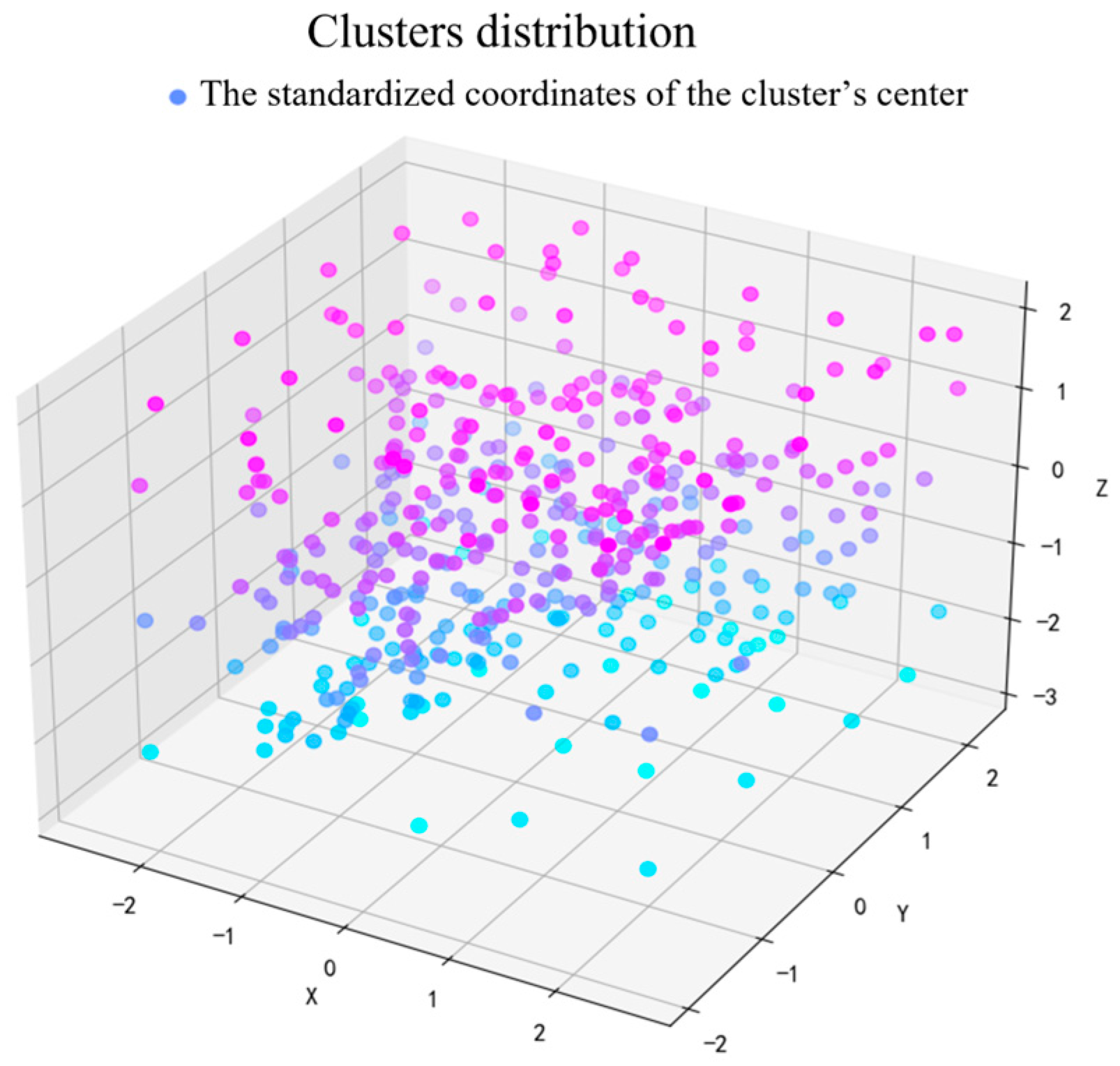

- (1)

- Block clustering

- (2)

- Cluster binding

| Algorithm 1. Two-stage algorithm for determining the mining sequence of blocks. | |

| 1 | # Phase I: Block Clustering |

| 2 | Input: the XYZ coordinates, apparent density, and gangue content of the block |

| 3 | Standardization of block coordinates |

| 4 | clustering using the BIRCH algorithm |

| 5 | return cluster results and central coordinates of clusters |

| 6 | end |

| 7 | # Phase II: Cluster Binding |

| 8 | Input: cluster results, central coordinates of clusters, and block XYZ coordinate lengths |

| 9 | calculating cluster boundaries, mass, and valuable mineral content |

| 10 | generate cluster adjacency matrix |

| 11 | identifying clusters with positive valuable mineral content and establishing node set |

| 12 | calculating the mining value of clusters within the node set |

| 13 | calculating the level of clusters based on elevation |

| 14 | calculating the mining sequence of clusters within the node set |

| 15 | to record occurrences of clusters |

| 16 | for each cluster within the node set: |

| 17 | |

| 18 | : |

| 19 | to empty |

| 20 | continue |

| 21 | |

| 22 | > 0: |

| 23 | |

| 24 | |

| 25 | |

| 26 | is reset to an empty set |

| 27 | : |

| 28 | |

| 29 | |

| 30 | |

| 31 | return the mining tree |

| 32 | end |

2.3. Production Scheduling Optimization Model

- (1)

- Unloading location selection constraints

- (2)

- Mining complete constraints

- (3)

- Mining time and sequence constraints

- (4)

- Mining capacity constraints

- (5)

- Processing plant value mineral requirement

- (6)

- Value mineral content constraints

- (7)

- Processing capacity constraints

- (8)

- Haulage distance constraints

- (9)

- Variable constraints

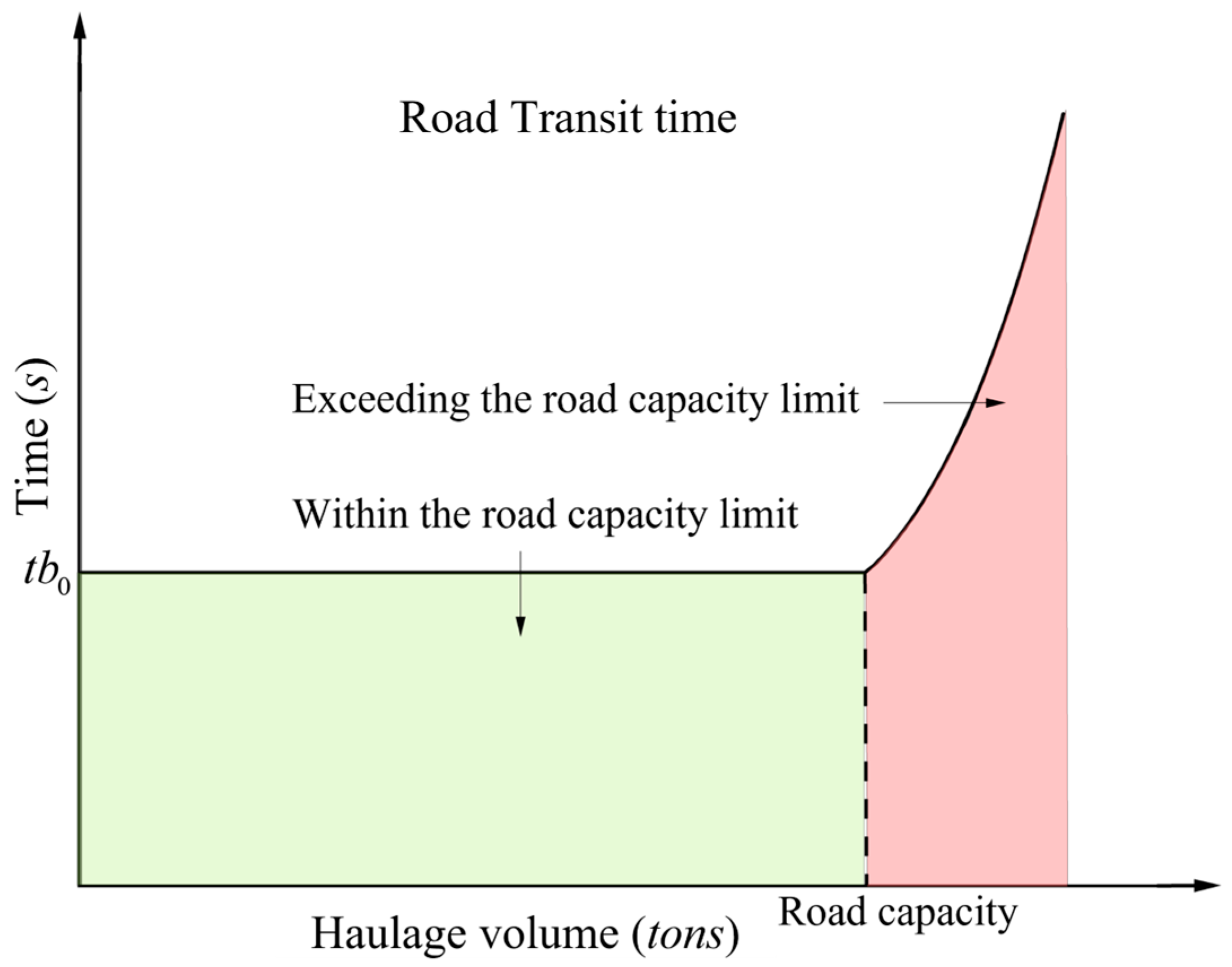

2.4. Haulage Route Planning Optimization Model

- (1)

- Network flow conservation constraints

- (2)

- Road capacity constraints

- (3)

- Variable constraints

| Algorithm 2. Updating haulage tasks | |

| 1 | |

| 2 | for each loading location of the set of loading locations : |

| 3 | for each unloading location in the set of unloading locations : |

| 4 | for each mining time in the set of mining times : |

| 5 | : |

| 6 | if the cluster can be unloaded at |

| 7 | determining the proportion of clusters to be hauled |

| 8 | |

| 9 | If the mining haulage ratio ≠ 0 and the loading location ≠ 0: |

| 10 | determine the haulage volume |

| 11 | add temporary haulage task |

| 12 | forming a set of haulage tasks |

| 13 | return the set of haulage tasks |

| 14 | end |

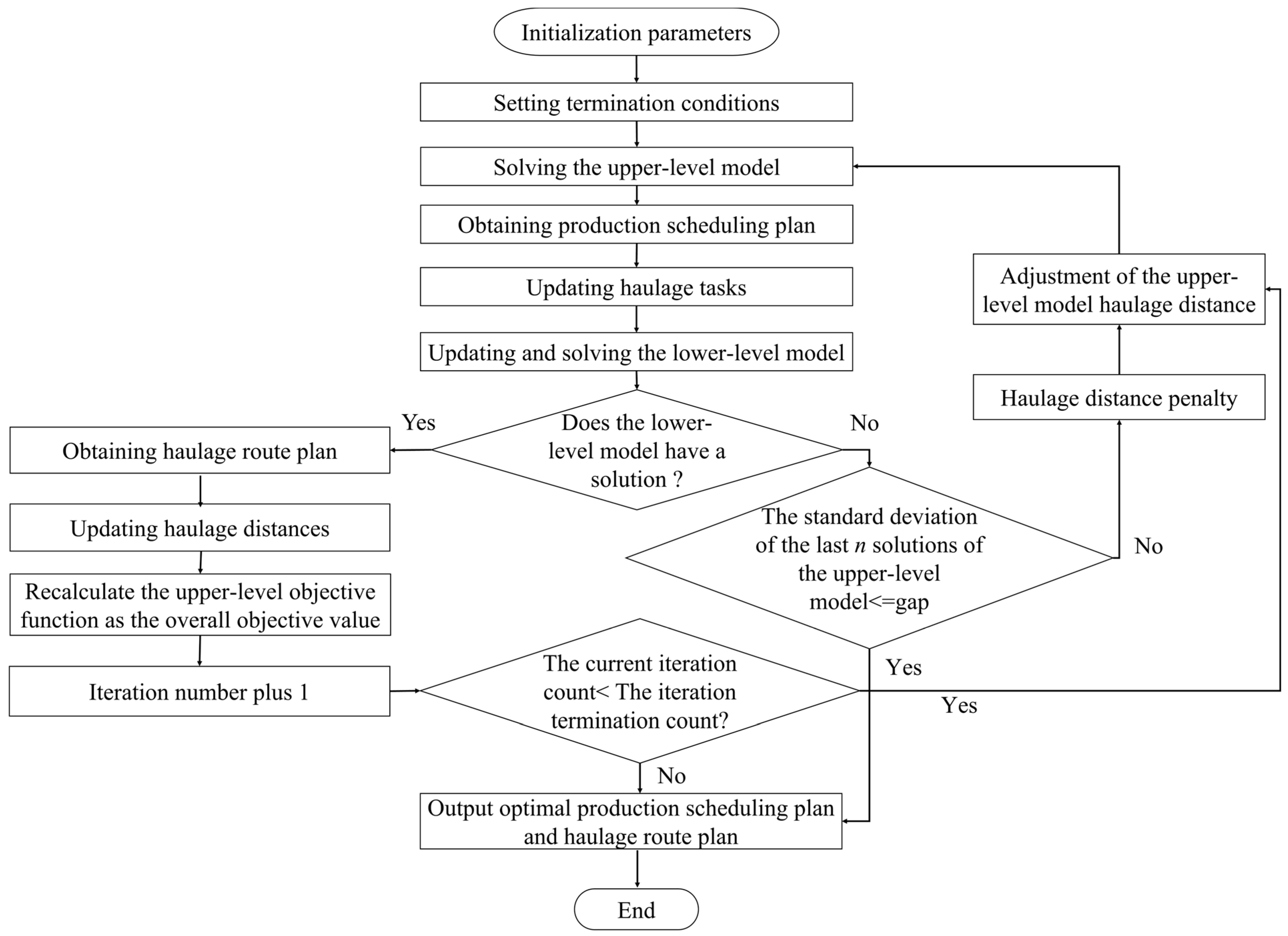

3. Solution Algorithm

| Algorithm 3. Updating haulage distances | |

| 1 | |

| 2 | for each haulage task in the set of haulage tasks : |

| 3 | for haulage task |

| 4 | for each road segment in the road network segment set : |

| 5 | calculating the total haulage distance for the haulage task |

| 6 | |

| 7 | updating haulage distance |

| 8 | return haulage distances |

| 9 | end |

4. Case Study

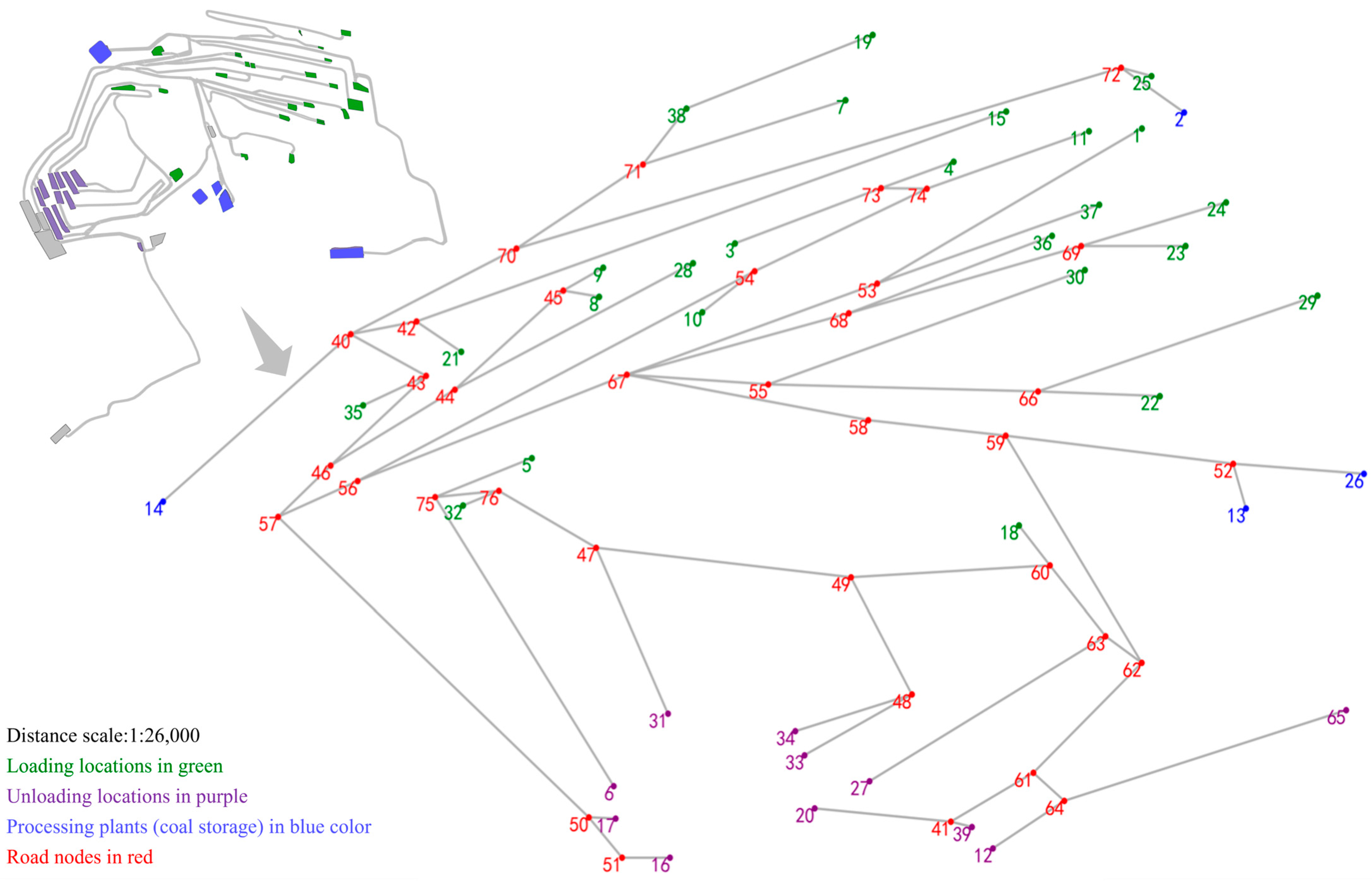

4.1. Data Description

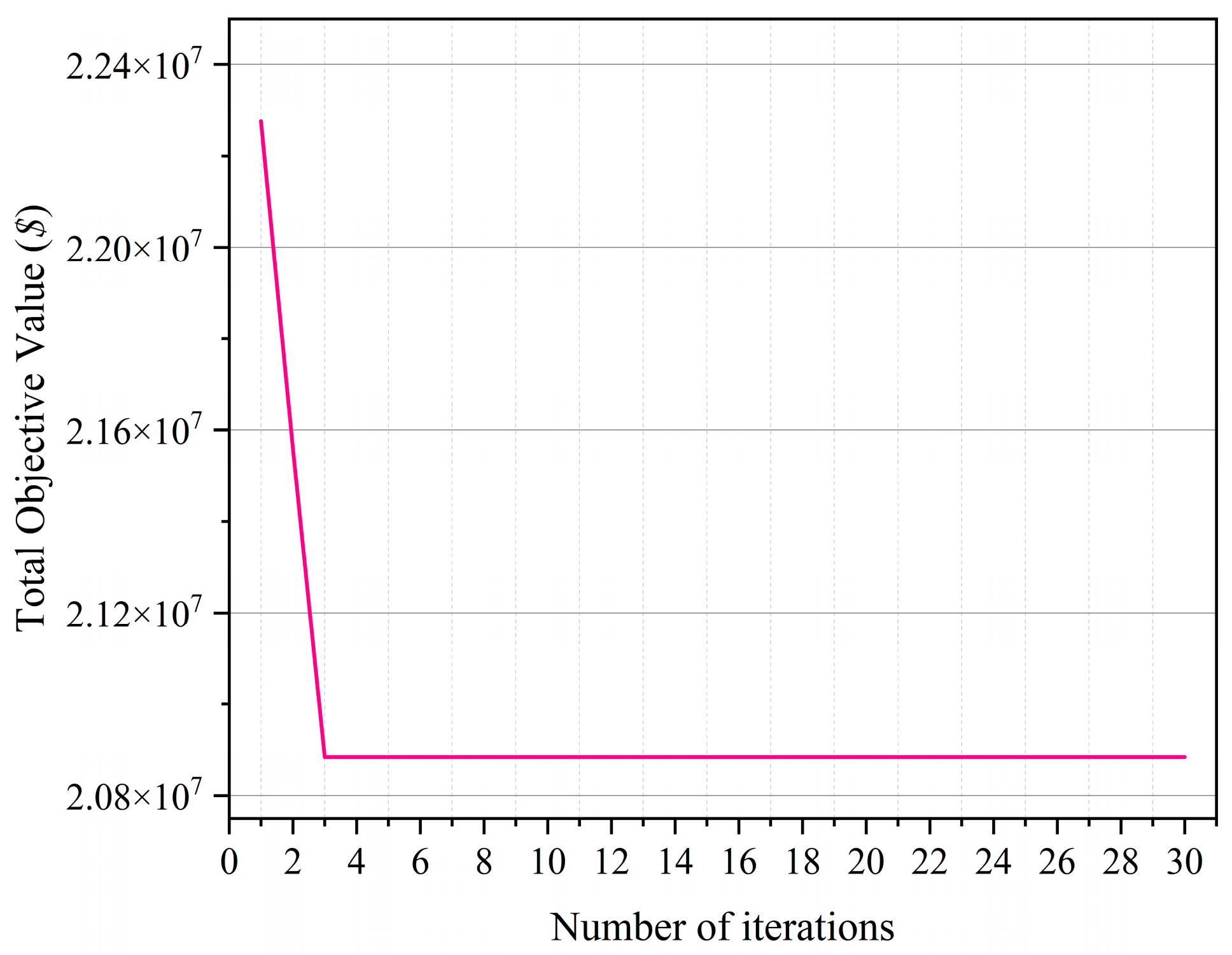

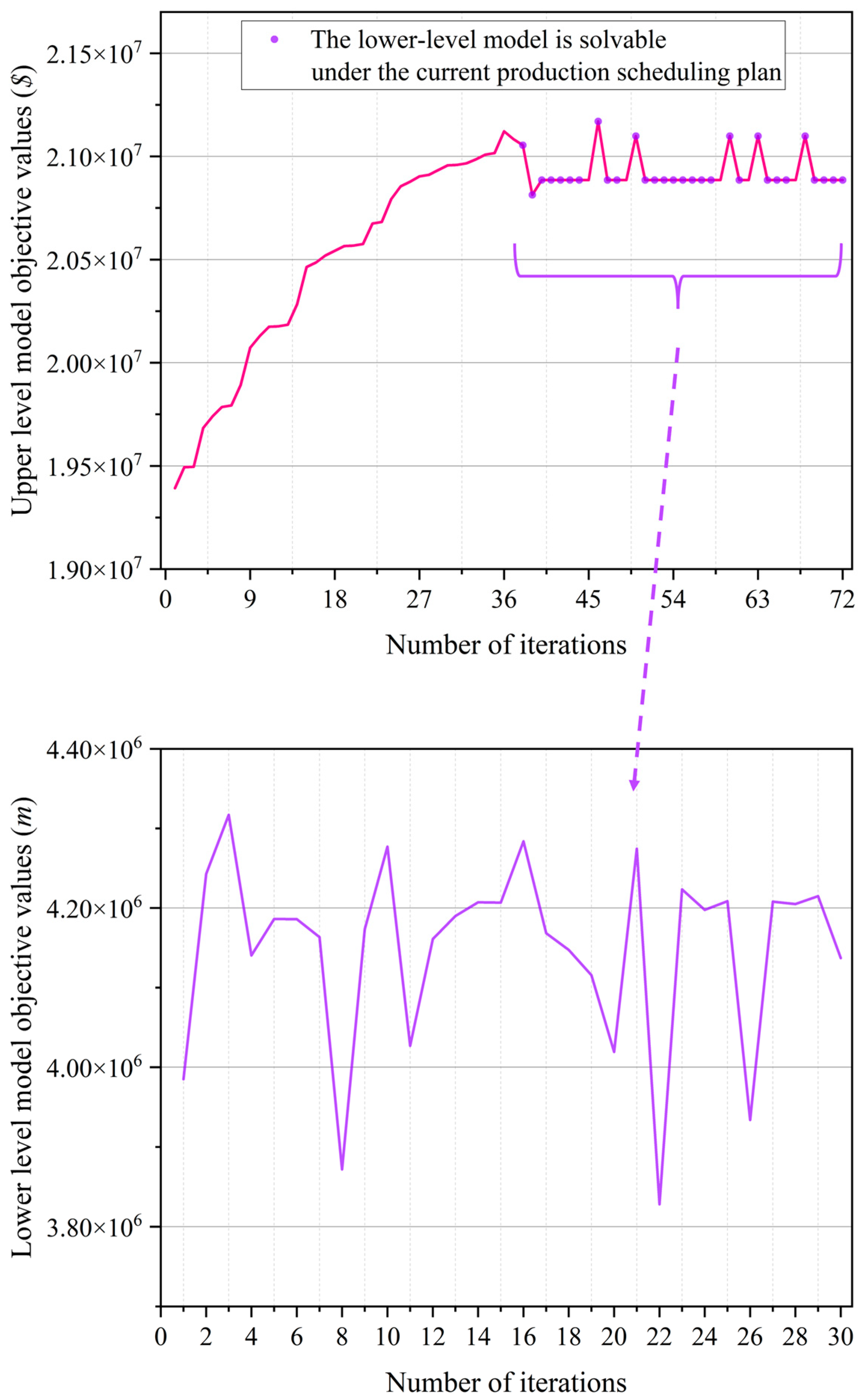

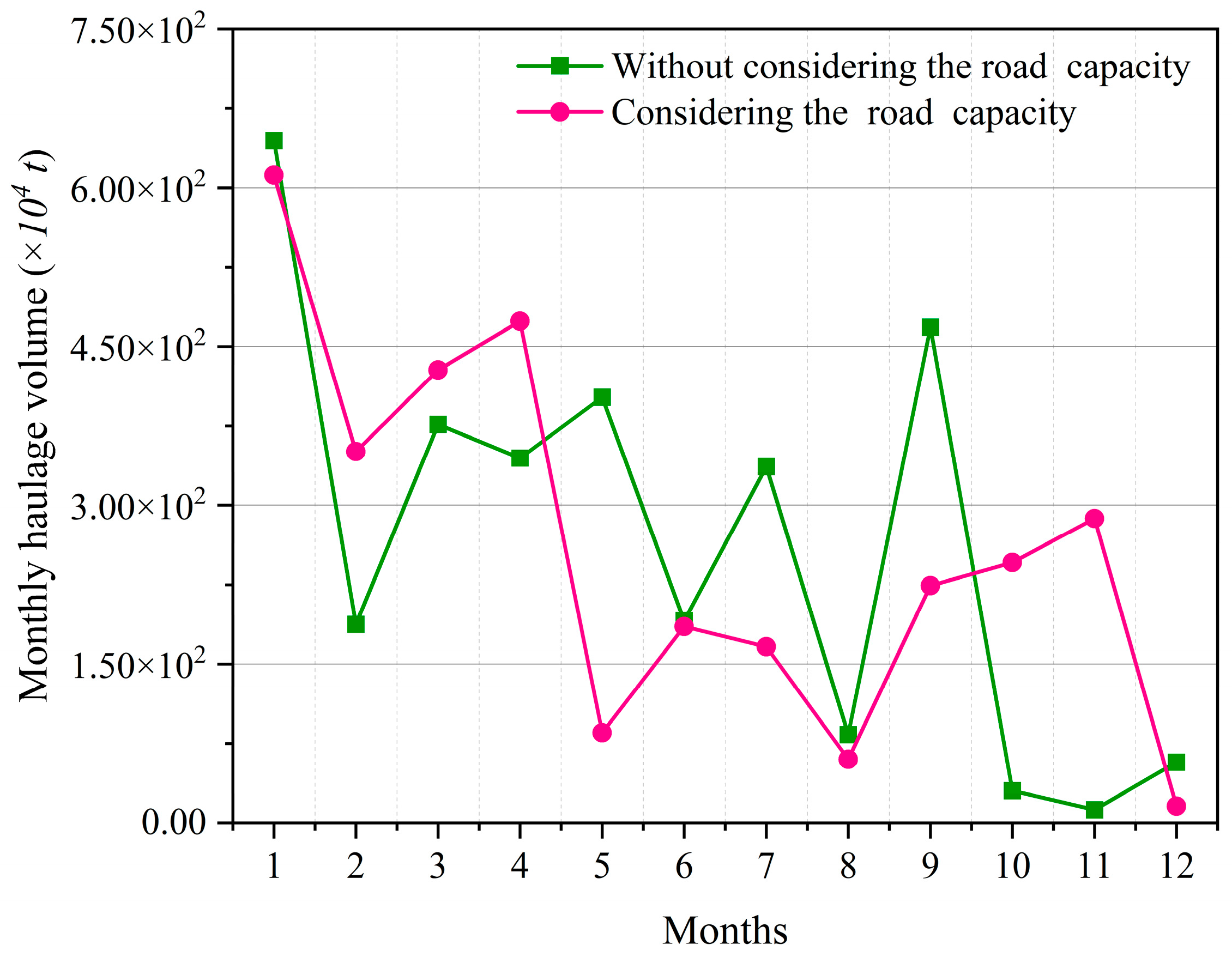

4.2. Results Analysis and Discussion

4.2.1. Comparison of the Optimized Results

| Segment Exceeding road Capacity | The Haulage Volume (×104 t) | Transit Time (s) | Transit Time Considering Road Capacity (s) | Extra Time (s) |

| (67, 58) | 414.86 | 59.33 | 70.53 | 11.20 |

| (58, 59) | 414.86 | 28.47 | 33.84 | 5.37 |

| (59, 52) | 414.86 | 47.84 | 56.87 | 9.03 |

| (57, 50) | 386.70 | 213.06 | 243.42 | 30.36 |

| (50, 17) | 386.70 | 5.63 | 6.43 | 0.80 |

| Total | 2017.98 | 354.33 | 411.09 | 56.76 |

4.2.2. Impact of the Distance Penalty Strategy

4.2.3. Haulage Routes

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Espinoza, D.; Goycoolea, M.; Moreno, E.; Newman, A. MineLib: A Library of Open Pit Mining Problems. Ann. Oper. Res. 2013, 206, 93–114. [Google Scholar] [CrossRef]

- Das, R.; Topal, E.; Mardaneh, E. A Review of Open Pit Mine and Waste Dump Schedule Planning. Resour. Policy 2023, 85, 104064. [Google Scholar] [CrossRef]

- Chicoisne, R.; Espinoza, D.; Goycoolea, M.; Moreno, E.; Rubio, E. A New Algorithm for the Open-Pit Mine Production Scheduling Problem. Oper. Res. 2012, 60, 517–528. [Google Scholar] [CrossRef]

- Xu, X.; Gu, X.; Wang, Q.; Zhao, Y.; Kong, W.; Zhu, Z.; Wang, F. Enumeration Optimization of Open Pit Production Scheduling Based on Mobile Capacity Search Domain. Sci. Rep. 2023, 13, 91. [Google Scholar] [CrossRef]

- Tabesh, M.; Moradi Afrapoli, A.; Askari-Nasab, H. A Two-Stage Simultaneous Optimization of NPV and Throughput in Production Planning of Open Pit Mines. Resour. Policy 2023, 80, 103167. [Google Scholar] [CrossRef]

- Elsayed, S.; Sarker, R.; Essam, D.; Coello Coello, C.A. Evolutionary Approach for Large-Scale Mine Scheduling. Inf. Sci. 2020, 523, 77–90. [Google Scholar] [CrossRef]

- Fu, Z.; Asad, M.W.A.; Topal, E. A New Model for Open-Pit Production and Waste-Dump Scheduling. Eng. Optim. 2019, 51, 718–732. [Google Scholar] [CrossRef]

- Ma, X.; Zhong, H.; Li, Y.; Ma, J.; Cui, Z.; Wang, Y. Forecasting Transportation Network Speed Using Deep Capsule Networks With Nested LSTM Models. IEEE Trans. Intell. Transp. Syst. 2021, 22, 4813–4824. [Google Scholar] [CrossRef]

- Yan, H.; Ma, X.; Pu, Z. Learning Dynamic and Hierarchical Traffic Spatiotemporal Features With Transformer. IEEE Trans. Intell. Transp. Syst. 2022, 23, 22386–22399. [Google Scholar] [CrossRef]

- Liu, X.; Cathy Liu, X.; Liu, Z.; Shi, R.; Ma, X. A Solar-Powered Bus Charging Infrastructure Location Problem under Charging Service Degradation. Transp. Res. D Transp. Environ. 2023, 119, 103770. [Google Scholar] [CrossRef]

- Bakhtavar, E.; Mahmoudi, H. Development of a Scenario-Based Robust Model for the Optimal Truck-Shovel Allocation in Open-Pit Mining. Comput. Oper. Res. 2020, 115, 104539. [Google Scholar] [CrossRef]

- Zhang, L.; Shan, W.; Zhou, B.; Yu, B. A Dynamic Dispatching Problem for Autonomous Mine Trucks in Open-Pit Mines Considering Endogenous Congestion. Transp. Res. Part. C Emerg. Technol. 2023, 150, 104080. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, A.; Ai, Y.; Tian, B.; Chen, L. Real-Time Scheduling of Autonomous Mining Trucks via Flow Allocation-Accelerated Tabu Search. IEEE Trans. Intell. Veh. 2022, 7, 466–479. [Google Scholar] [CrossRef]

- Liu, X.; Qu, X.; Ma, X. Optimizing Electric Bus Charging Infrastructure Considering Power Matching and Seasonality. Transp. Res. D Transp. Environ. 2021, 100, 103057. [Google Scholar] [CrossRef]

- Samavati, M.; Essam, D.; Nehring, M.; Sarker, R. A Local Branching Heuristic for the Open Pit Mine Production Scheduling Problem. Eur. J. Oper. Res. 2017, 257, 261–271. [Google Scholar] [CrossRef]

- Moreno, E.; Rezakhah, M.; Newman, A.; Ferreira, F. Linear Models for Stockpiling in Open-Pit Mine Production Scheduling Problems. Eur. J. Oper. Res. 2017, 260, 212–221. [Google Scholar] [CrossRef]

- Epstein, R.; Goic, M.; Weintraub, A.; Catalán, J.; Santibáñez, P.; Urrutia, R.; Cancino, R.; Gaete, S.; Aguayo, A.; Caro, F. Optimizing Long-Term Production Plans in Underground and Open-Pit Copper Mines. Oper. Res. 2012, 60, 4–17. [Google Scholar] [CrossRef]

- Jélvez, E.; Morales, N.; Nancel-Penard, P.; Peypouquet, J.; Reyes, P. Aggregation Heuristic for the Open-Pit Block Scheduling Problem. Eur. J. Oper. Res. 2016, 249, 1169–1177. [Google Scholar] [CrossRef]

- Boland, N.; Dumitrescu, I.; Froyland, G.; Gleixner, A.M. LP-Based Disaggregation Approaches to Solving the Open Pit Mining Production Scheduling Problem with Block Processing Selectivity. Comput. Oper. Res. 2009, 36, 1064–1089. [Google Scholar] [CrossRef]

- Alipour, A.; Khodaiari, A.A.; Jafari, A.; Tavakkoli-Moghaddam, R. An Integrated Approach to Open-Pit Mines Production Scheduling. Resour. Policy 2022, 75, 102459. [Google Scholar] [CrossRef]

- Paithankar, A.; Chatterjee, S. Open Pit Mine Production Schedule Optimization Using a Hybrid of Maximum-Flow and Genetic Algorithms. Appl. Soft Comput. J. 2019, 81, 105507. [Google Scholar] [CrossRef]

- Gilani, S.O.; Sattarvand, J.; Hajihassani, M.; Abdullah, S.S. A Stochastic Particle Swarm Based Model for Long Term Production Planning of Open Pit Mines Considering the Geological Uncertainty. Resour. Policy 2020, 68, 101738. [Google Scholar] [CrossRef]

- Choi, Y.; Park, H.D.; Sunwoo, C.; Clarke, K.C. Multi-Criteria Evaluation and Least-Cost Path Analysis for Optimal Haulage Routing of Dump Trucks in Large Scale Open-Pit Mines. Int. J. Geogr. Inf. Sci. 2009, 23, 1541–1567. [Google Scholar] [CrossRef]

- Choi, Y.; Nieto, A. Optimal Haulage Routing of Off-Road Dump Trucks in Construction and Mining Sites Using Google Earth and a Modified Least-Cost Path Algorithm. Autom. Constr. 2011, 20, 982–997. [Google Scholar] [CrossRef]

- Li, X.; Gu, Q.; Ruan, S.; Feng, Z. Optimal Transportation Path Planning of Truck in Open-Pit Mine under Dynamic Energy Consumption. J. China Coal Soc. 2021, 46, 590–600. [Google Scholar] [CrossRef]

- Ramazan, S. The New Fundamental Tree Algorithm for Production Scheduling of Open Pit Mines. Eur. J. Oper. Res. 2006, 177, 1153–1166. [Google Scholar] [CrossRef]

- Lang, A.; Schubert, E. BETULA: Fast Clustering of Large Data with Improved BIRCH CF-Trees. Inf. Syst. 2022, 108, 101918. [Google Scholar] [CrossRef]

- Lorbeer, B.; Kosareva, A.; Deva, B.; Softić, D.; Ruppel, P.; Küpper, A. Variations on the Clustering Algorithm BIRCH. Big Data Res. 2018, 11, 44–53. [Google Scholar] [CrossRef]

- Zhou, J.; Love, P.E.D.; Teo, K.L.; Luo, H. An Exact Penalty Function Method for Optimising QAP Formulation in Facility Layout Problem. Int. J. Prod. Res. 2017, 55, 2913–2929. [Google Scholar] [CrossRef]

- Wang, Y.; Assogba, K.; Fan, J.; Xu, M.; Liu, Y.; Wang, H. Multi-Depot Green Vehicle Routing Problem with Shared Transportation Resource: Integration of Time-Dependent Speed and Piecewise Penalty Cost. J. Clean. Prod. 2019, 232, 12–29. [Google Scholar] [CrossRef]

- Liu, X.; Liu, X.; Zhang, X.; Zhou, Y.; Chen, J.; Ma, X. Optimal Location Planning of Electric Bus Charging Stations with Integrated Photovoltaic and Energy Storage System. Comput.-Aided Civil. Infrastruct. Eng. 2023, 38, 1424–1446. [Google Scholar] [CrossRef]

- Zhang, T.; Ramakrishnan, R.; Livny, M. BIRCH: A New Data Clustering Algorithm and Its Applications; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1997; Volume 1. [Google Scholar]

- Das, R.; Topal, E.; Mardaneh, E. Concurrent Optimisation of Open Pit Ore and Waste Movement with Optimal Haul Road Selection. Resour. Policy 2024, 91, 104834. [Google Scholar] [CrossRef]

- Sun, X.; Zhao, S.; Liu, H.; Zhang, H. Equilibrium Distribution Model of Traffic Flow on Road Network for Traffic Flow of Open Pit. J. China Coal Soc. 2017, 42, 1607–1613. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, N.; Xiang, L.; Wang, C. Abnormal Cascading Dynamics Based on the Perspective of Road Impedance. Phys. A Stat. Mech. Its Appl. 2023, 627, 129128. [Google Scholar] [CrossRef]

- Chen, J.; Mei, Z.; Wang, W. Road Resistance Model under Mixed Traffic Flow Conditions with Curb Parking. China Civil. Eng. J. 2009, 40, 95–100. [Google Scholar]

| Notation | Definition |

|---|---|

| Subscripts and sets | |

| Mining time (month) | |

| Loading location | |

| Unloading location | |

| Clusters | |

| Mining time set | |

| Loading location set | |

| Unloading location set | |

| Unloading location alternative set of clusters | |

| Processing plant set | |

| Cluster set | |

| Prioritized mining cluster set for cluster | |

| Input variable | |

| The weight of the cluster (×104 t) | |

| The weight of value minerals contained in clusters (×104 t) | |

| The elevation difference between loading location and unloading location (m) | |

| Binary variable, if cluster is loaded at loading location | |

| Binary variable, if unloading location | |

| Binary variable, if cluster can be unloaded at unloading location | |

| The processing capacity at unloading location (×104 t/month) | |

| The minimum amount of value mineral required for the processing plant (×104 t) | |

| The mining capacity at loading location (×104 t/month) | |

| Haulage cost ($/104 t/m) | |

| Unit material haulage change unit elevation cost ($/104 t/m) | |

| Intermediate variable | |

| Distance between loading and unloading locations (m) | |

| Decision variables | |

| Binary variable, if the cluster is mined in period | |

| The proportion of mined clusters hauled to unloading location in period |

| Notation | Definition |

|---|---|

| Subscripts and sets | |

| Road nodes | |

| Haulage tasks | |

| The set of haulage tasks in period | |

| The set of road segments | |

| The set of road nodes | |

| Input variables | |

| Loading/unloading location for haulage task | |

| Haulage volume for haulage task (×104 t) | |

| Maximum road capacity of segment (×104 t/month) | |

| Length of road segment (m) | |

| Decision variable | |

| Haulage volume for haulage task on road segment (×104 t) |

| Location Type | Set of IDs |

| Loading | 1 3 4 5 7 8 9 10 11 18 19 22 23 24 28 32 35 36 37 38 |

| Unloading | 2 6 12 13 14 16 17 20 26 27 31 33 34 39 65 |

| Processing plant | 2 13 14 26 |

| Loading Location ID | Total Mining Volume (×104 t) | Coal Volume (×104 t) | Processing Plant ID | Coal Volume Requirements (×104 t) |

| 1 | 991.38 | 110.24 | 2 | 70 |

| 3 | 421.22 | 39.59 | 13 | 120 |

| 4 | 196.31 | 19.42 | 14 | 50 |

| 5 | 342.50 | 25.42 | 26 | 180 |

| 7 | 118.39 | 25.53 | - | - |

| 8 | 84.63 | 10.74 | - | - |

| 9 | 53.27 | 16.49 | - | - |

| 10 | 32.31 | 7.55 | - | - |

| 11 | 30.95 | 25.72 | - | - |

| 18 | 51.73 | 36.80 | - | - |

| 19 | 24.95 | 21.57 | - | - |

| 22 | 83.64 | 55.21 | - | - |

| 23 | 31.42 | 26.20 | - | - |

| 24 | 188.94 | 39.63 | - | - |

| 28 | 45.63 | 3.00 | - | - |

| 32 | 80.47 | 70.16 | - | - |

| 35 | 91.24 | 74.15 | - | - |

| 36 | 129.86 | 120.45 | - | - |

| 37 | 126.63 | 105.60 | - | - |

| 38 | 9.18 | 4.35 | - | - |

| Route ID | Route | Route ID | Route |

| 1 | [1, 53, 67, 56, 57, 50, 17] | 21 | [19, 38, 71, 70, 72, 2] |

| 2 | [1, 53, 67, 58, 59, 52, 26] | 22 | [19, 38, 71, 70, 40, 43, 46, 57, 50, 17] |

| 3 | [3, 73, 74, 54, 56, 67, 58, 59, 52, 13] | 23 | [22, 66, 55, 67, 58, 59, 52, 13] |

| 4 | [3, 73, 74, 54, 56, 57, 50, 17] | 24 | [22, 66, 55, 67, 56, 57, 50, 17] |

| 5 | [3, 73, 74, 54, 56, 67, 58, 59, 52, 26] | 25 | [23, 69, 68, 67, 58, 59, 52, 13] |

| 6 | [4, 73, 74, 54, 56, 57, 50, 17] | 26 | [23, 69, 68, 67, 56, 57, 50, 17] |

| 7 | [4, 73, 74, 54, 56, 67, 58, 59, 52, 26] | 27 | [24, 69, 68, 67, 58, 59, 52, 13] |

| 8 | [5, 75, 76, 47, 49, 60, 63, 27] | 28 | [24, 69, 68, 67, 56, 57, 50, 17] |

| 9 | [7, 71, 70, 72, 2] | 29 | [28, 44, 46, 43, 40, 14] |

| 10 | [7, 71, 70, 40, 43, 46, 57, 50, 17] | 30 | [28, 44, 46, 57, 50, 17] |

| 11 | [8, 45, 44, 46, 43, 40, 70, 72, 2] | 31 | [32, 76, 47, 31] |

| 12 | [8, 45, 44, 46, 43, 40, 14] | 32 | [35, 43, 40, 14] |

| 13 | [8, 45, 44, 46, 57, 50, 17] | 33 | [35, 43, 46, 57, 50, 17] |

| 14 | [9, 45, 44, 46, 43, 40, 70, 72, 2] | 34 | [36, 68, 67, 58, 59, 62, 61, 64, 12] |

| 15 | [9, 45, 44, 46, 57, 50, 17] | 35 | [36, 68, 67, 56, 57, 46, 43, 40, 14] |

| 16 | [10, 54, 56, 67, 58, 59, 52, 13] | 36 | [37, 53, 67, 58, 59, 52, 13] |

| 17 | [10, 54, 56, 57, 50, 17] | 37 | [37, 53, 67, 56, 57, 50, 17] |

| 18 | [11, 74, 54, 56, 57, 50, 17] | 38 | [38, 71, 70, 72, 2] |

| 19 | [11, 74, 54, 56, 67, 58, 59, 52, 26] | 39 | [38, 71, 70, 40, 43, 46, 57, 50, 17] |

| 20 | [18, 60, 49, 48, 33] | - | - |

| Staged Optimization Approach | Integrated Optimization Approach | Improvement | |

| Total objective value (USD) | 23,221,832.77 | 20,885,328.25 | −10.06% |

| The number of segments exceeding road capacity | 5 | 0 | −5 |

| Segment Exceeding road Capacity | The Haulage Volume (×104 t) | Transit Time (s) | Transit Time Considering Road Capacity (s) | Extra Time (s) |

|---|---|---|---|---|

| (67, 58) | 414.86 | 59.33 | 70.53 | 11.20 |

| (58, 59) | 414.86 | 28.47 | 33.84 | 5.37 |

| (59, 52) | 414.86 | 47.84 | 56.87 | 9.03 |

| (57, 50) | 386.70 | 213.06 | 243.42 | 30.36 |

| (50, 17) | 386.70 | 5.63 | 6.43 | 0.80 |

| Total | 2017.98 | 354.33 | 411.09 | 56.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, C.; Chen, G.; Lu, H.; Zhang, Q.; Liu, Z.; Bian, J. Integrated Optimization of Production Scheduling and Haulage Route Planning in Open-Pit Mines. Mathematics 2024, 12, 2070. https://doi.org/10.3390/math12132070

Xu C, Chen G, Lu H, Zhang Q, Liu Z, Bian J. Integrated Optimization of Production Scheduling and Haulage Route Planning in Open-Pit Mines. Mathematics. 2024; 12(13):2070. https://doi.org/10.3390/math12132070

Chicago/Turabian StyleXu, Changyou, Gang Chen, Huabo Lu, Qiuxia Zhang, Zhengke Liu, and Jing Bian. 2024. "Integrated Optimization of Production Scheduling and Haulage Route Planning in Open-Pit Mines" Mathematics 12, no. 13: 2070. https://doi.org/10.3390/math12132070

APA StyleXu, C., Chen, G., Lu, H., Zhang, Q., Liu, Z., & Bian, J. (2024). Integrated Optimization of Production Scheduling and Haulage Route Planning in Open-Pit Mines. Mathematics, 12(13), 2070. https://doi.org/10.3390/math12132070