Differential Flatness-Based Cascade Energy/Current Control of Battery/Supercapacitor Hybrid Source for Modern e–Vehicle Applications

Abstract

:1. Introduction

2. Hybrid Power Source

2.1. Power Converter Structure

2.2. Power Plant Modeling

3. Control Structure and Control Laws

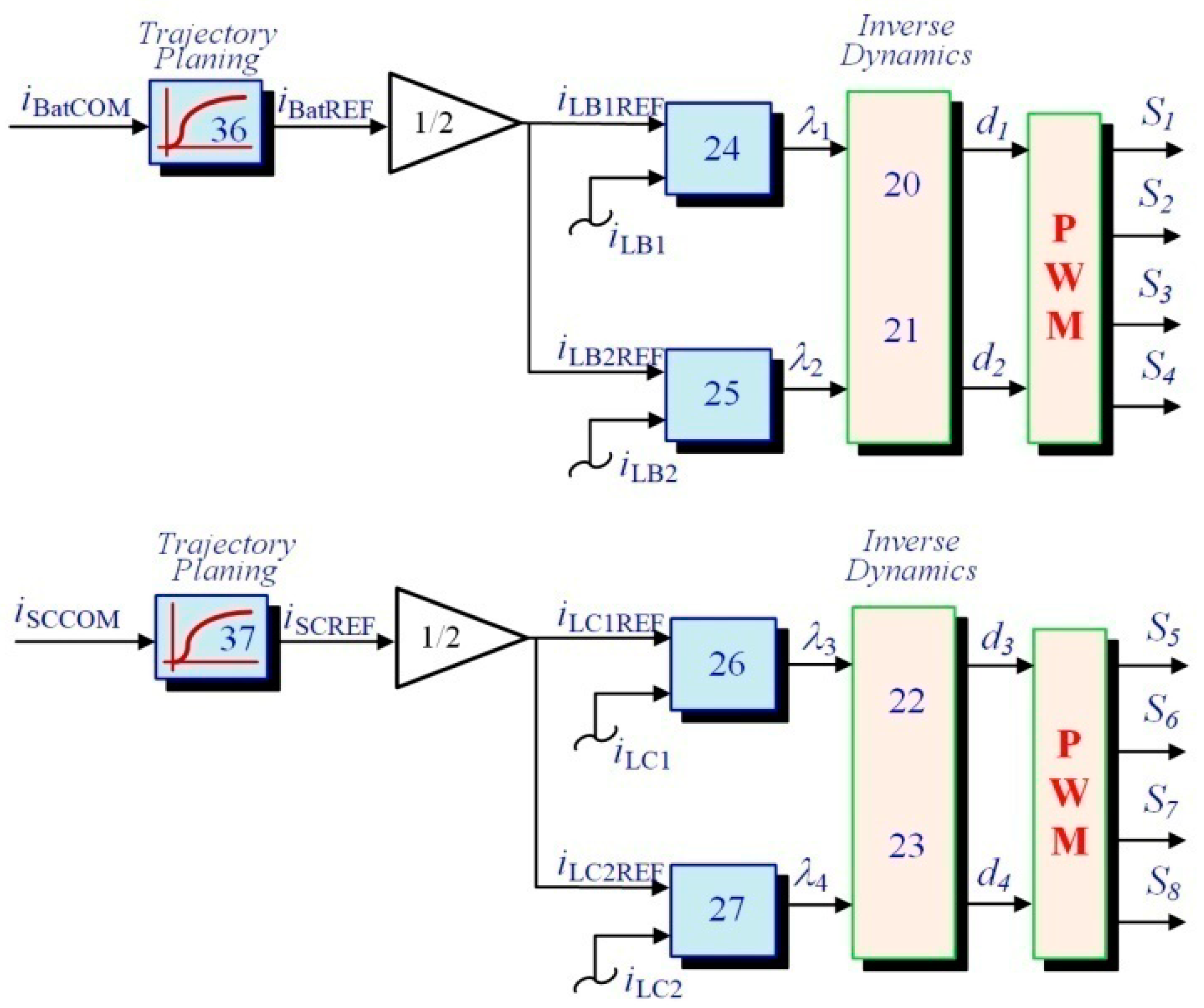

3.1. Inner Current Regulations

3.2. Outer Energy Controls

4. Performance Validation

4.1. Test Bench Setup and Flatness Control Parameters

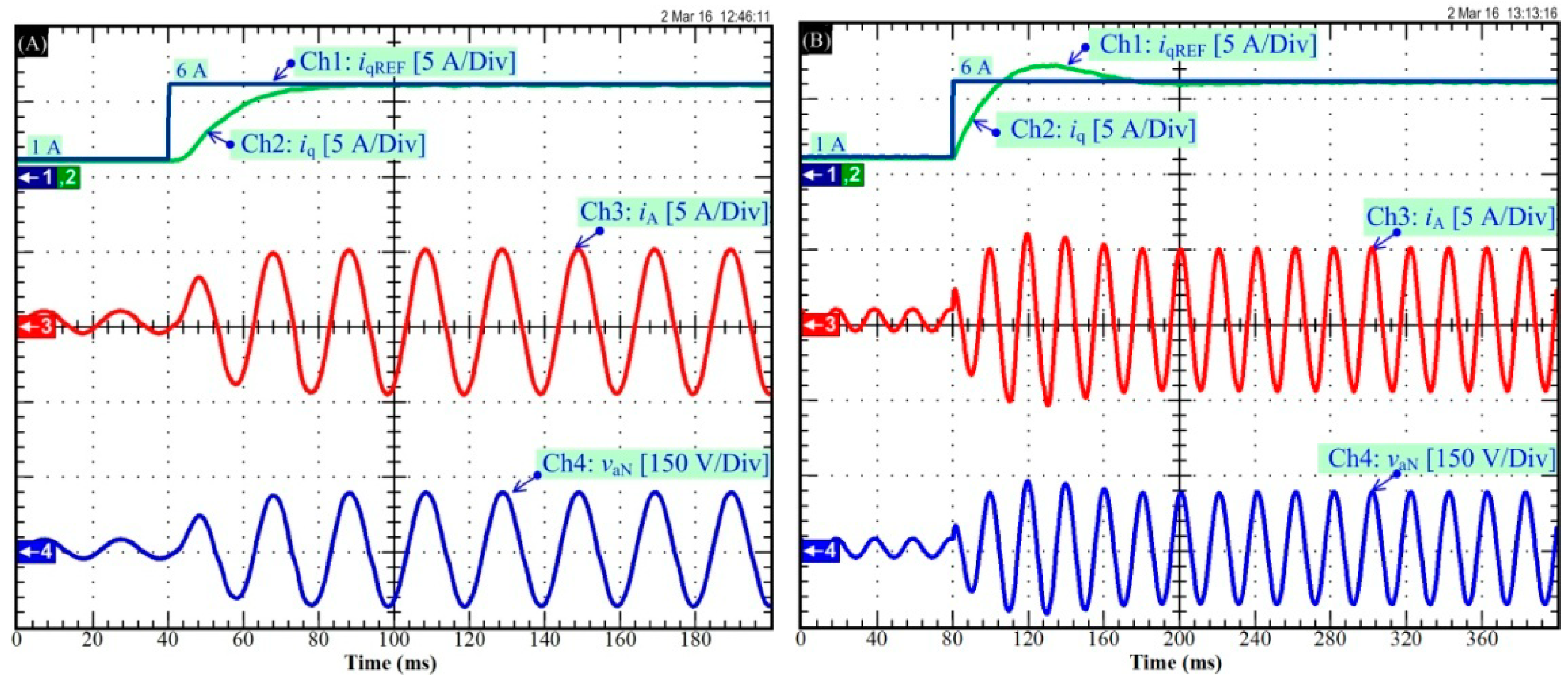

- Ch1: the battery current set-point iBatREF at +20 A (battery discharging mode);

- Ch2: the measured battery current iBat;

- Ch3: the 1st inductor current iLB1;

- Ch4: the 2nd inductor current iLB2.

- Ch1: the SC current set-point iSCREF;

- Ch2: the measured SC current iSC;

- Ch3: the 1st inductor current iLC1;

- Ch4: the 2nd inductor current iLC2.

- Ch1: the battery reference iBatREF;

- Ch2: the measured input battery current iBat;

- Ch3: the 1st inductor current iLB1;

- Ch4: the 2nd inductor current iLB2.

- Ch1: the SC current reference iSCREF;

- Ch2: the measured SC current iSC;

- Ch3: the 1st inductor current iLC1;

- Ch4: the 2nd inductor current iLC2.

4.2. Hybrid Power Plant Load Cycles

4.3. Comparison of the Performances Compared to the Previous Works

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tu, H.; Feng, H.; Srdic, S.; Lukic, S. Extreme fast charging of electric vehicles: A technology overview. IEEE Trans. Transp. Electrif. 2019, 5, 861–878. [Google Scholar] [CrossRef]

- Skouras, T.A.; Gkonis, P.K.; Ilias, C.N.; Trakadas, P.T.; Tsampasis, E.G.; Zahariadis, T.V. Electrical Vehicles: Current State of the Art, Future Challenges, and Perspectives. Clean Technol. 2020, 2, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.; Li, Z.; Wang, X.; Li, C. Technology development of electric vehicles: A review. Energies 2020, 13, 90. [Google Scholar] [CrossRef] [Green Version]

- Hoai, H.-K.; Chen, S.-C.; Than, H. Realization of the sensorless permanent magnet synchronous motor drive control system with an intelligent controller. Electronics 2020, 9, 365. [Google Scholar] [CrossRef] [Green Version]

- De Santis, M.; Agnelli, S.; Patanè, F.; Giannini, O.; Bella, G. Experimental study for the assessment of the measurement uncertainty associated with electric powertrain efficiency using the back-to-back direct method. Energies 2018, 11, 3536. [Google Scholar] [CrossRef] [Green Version]

- Sikkabut, S.; Mungporn, P.; Ekkaravarodome, C.; Bizon, N.; Tricoli, P.; Nahid-Mobarakeh, B.; Pierfederici, S.; Davat, B.; Thounthong, P. Control of high-energy high-power densities storage devices by li-ion battery and supercapacitor for fuel cell/photovoltaic hybrid power plant for autonomous system applications. IEEE Trans. Ind. Appl. 2016, 52, 4395–4407. [Google Scholar] [CrossRef] [Green Version]

- Mutarraf, M.U.; Terriche, Y.; Niazi, K.A.K.; Vasquez, J.C.; Guerrero, J.M. Energy storage systems for shipboard microgrids—A review. Energies 2018, 11, 3492. [Google Scholar] [CrossRef] [Green Version]

- Manandhar, U.; Wang, B.; Zhang, X.; Beng, G.H.; Liu, Y.; Ukil, A. Joint control of three-level DC–DC converter interfaced hybrid energy storage system in DC microgrids. IEEE Trans. Energy Convers. 2019, 34, 2248–2257. [Google Scholar] [CrossRef]

- Mukherjee, N.; Strickland, D. Control of cascaded DC–DC converter-based hybrid battery energy storage systems—part I: Stability issue. IEEE Trans. Ind. Electron. 2016, 63, 2340–2349. [Google Scholar] [CrossRef]

- Roche, M.; Shabbir, W.; Evangelou, S.A. Voltage control for enhanced power electronic efficiency in series hybrid electric vehicles. IEEE Trans. Veh. Technol. 2017, 66, 3645–3658. [Google Scholar] [CrossRef]

- Vargas, U.; Lazaroiu, G.C.; Tironi, E.; Ramirez, A. Harmonic modeling and simulation of a stand-alone photovoltaic-battery-supercapacitor hybrid system. Int. J. Electr. Power Energy Syst. 2019, 105, 70–78. [Google Scholar] [CrossRef]

- Hu, J.; Shan, Y.; Xu, Y.; Guerrero, J.M. A coordinated control of hybrid ac/dc microgrids with PV-wind-battery under variable generation and load conditions. Int. J. Electr. Power Energy Syst. 2019, 104, 583–592. [Google Scholar] [CrossRef] [Green Version]

- Marzougui, H.; Kadri, A.; Martin, J.; Amari, M.; Pierfederici, S.; Bacha, F. Implementation of energy management strategy of hybrid power source for electrical vehicle. Energy Convers. Manag. 2019, 195, 830–843. [Google Scholar] [CrossRef]

- Song, Z.; Hou, J.; Hofmann, H.; Li, J.; Ouyang, M. Sliding-mode and Lyapunov function-based control for battery/supercapacitor hybrid energy storage system used in electric vehicles. Energy 2017, 122, 601–612. [Google Scholar] [CrossRef]

- Zhang, L.; Ye, X.; Xia, X.; Barzegar, F. A real-time energy management and speed controller for an electric vehicle powered by a hybrid energy storage system. IEEE Trans. Ind. Inform. 2020. [Google Scholar] [CrossRef]

- Fliess, M.; Lévine, J.; Martin, P.; Rouchon, P. Flatness and defect of nonlinear systems: Introductory theory and examples. Int. J. Control 1995, 61, 1327–1361. [Google Scholar] [CrossRef] [Green Version]

- Mungporn, P.; Thounthong, P.; Sikkabut, S.; Yodwong, B.; Chunkag, V.; Kumam, P.; Bizon, N.; Nahid-Mobarakeh, B.; Pierfederici, S. Dynamics improvement of 3-phase inverter with output LC-filter by using differential flatness based control for grid connected applications. In Proceedings of the IEEE 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016; pp. 1–6. [Google Scholar]

- Poonnoy, N.; Mungporn, P.; Thounthong, P.; Sikkabut, S.; Yodwong, B.; Boonseng, A.; Ekkaravarodome, C.; Kumam, P.; Bizon, N.; Nahid-Mobarakeh, B.; et al. Differential flatness based control of 3-phase AC/DC converter. In Proceedings of the IEEE 2017 European Conference on Electrical Engineering and Computer Science (EECS), Bern, Switzerland, 17–19 November 2017; pp. 136–141. [Google Scholar]

- Thounthong, P.; Sikkabut, S.; Poonnoy, N.; Mungporn, P.; Yodwong, B.; Kumam, P.; Bizon, N.; Nahid-Mobarakeh, B.; Pierfederici, S. Nonlinear differential flatness-based speed/torque control with state-observers of permanent magnet synchronous motor drives. IEEE Trans. Ind. Appl. 2018, 54, 2874–2884. [Google Scholar] [CrossRef]

- Mehrasa, M.; Pouresmaeil, E.; Taheri, S.; Vechiu, I.; Catalão, J.P.S. Novel control strategy for modular multilevel converters based on differential flatness theory. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 888–897. [Google Scholar] [CrossRef] [Green Version]

- Huangfu, Y.; Li, Q.; Xu, L.; Ma, R.; Gao, F. Extended state observer based flatness control for fuel cell output series interleaved boost converter. IEEE Trans. Ind. Appl. 2019, 55, 6427–6437. [Google Scholar] [CrossRef]

- Sriprang, S.; Nahid-Mobarakeh, B.; Pierfederici, S.; Takorabet, N.; Bizon, N.; Kumam, P.; Mungporn, P.; Thounthong, P. Robust flatness control with extended Luenberger observer for PMSM drive. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Bangkok, Thailand, 6–9 June 2018; pp. 1–8. [Google Scholar]

- Sriprang, S.; Nahid-Mobarakeh, B.; Takorabet, N.; Pierfederici, S.; Bizon, N.; Kuman, P.; Thounthong, P. Permanent magnet synchronous motor dynamic modeling with state observer-based parameter estimation for AC servomotor drive application. Appl. Sci. Eng. Prog. 2019, 12, 286–297. [Google Scholar] [CrossRef]

- Ma, R.; Xu, L.; Xie, R.; Zhao, D.; Huangfu, Y.; Gao, F. Advanced robustness control of DC–DC converter for proton exchange membrane fuel cell applications. IEEE Trans. Ind. Appl. 2019, 55, 6389–6400. [Google Scholar] [CrossRef]

- Mungporn, P.; Thounthong, P.; Sikkabut, S.; Yodwong, B.; Ekkaravarodome, C.; Kumam, P.; Junkhiaw, S.T.; Bizon, N.; Nahid-Mobarakeh, B.; Pierfederici, S. Differential flatness-based control of current/voltage stabilization for a single-phase PFC with multiphase interleaved boost converters. In Proceedings of the 2017 IEEE European Conference on Electrical Engineering and Computer Science (EECS 2017), Bern, Switzerland, 17–19 November 2017; pp. 124–130. [Google Scholar] [CrossRef]

- Thammasiriroj, W.; Chunkag, V.; Phattanasak, M.; Pierfederici, S.; Davat, B.; Thounthong, P. Nonlinear model based single-loop control of interleaved converters for a hybrid source system. ECTI Trans. Electr. Eng. Electron. Commun. 2017, 15, 19–31. [Google Scholar]

- Bougrine, M.; Benalia, A.; Delaleau, E.; Benbouzid, M. Minimum time current controller design for two-interleaved bidirectional converter: Application to hybrid fuel cell/supercapacitor vehicles. Int. J. Hydrogen Energy 2018, 43, 11593–11605. [Google Scholar] [CrossRef]

- Erickson, R.; Maksimović, D. Fundamentals of Power Electronics, 2nd ed.; Kluwer Academic: New York, NY, USA, 2004. [Google Scholar]

- Sriprang, S.; Nahid-Mobarakeh, B.; Pierfederici, S.; Takorabet, N.; Bizon, N.; Kumam, P.; Mungporn, P.; Thounthong, P. Robust flatness-based control with state observer-based parameter estimation for PMSM drive. In Proceedings of the 2018 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles and International Transportation Electrification Conference (ESARS-ITEC 2018), Nottingham, UK, 7–9 November 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Cordero, A.; Maimó, J.G.; Torregrosa, J.R.; Vassileva, M.P. Iterative methods with memory for solving systems of nonlinear equations using a second order approximation. Mathematics 2019, 7, 1069. [Google Scholar] [CrossRef] [Green Version]

- Thammasiriroj, W.; Chunkag, V.; Phattanasak, M.; Pierfederici, S.; Davat, B.; Thounthong, P. Simplified single-loop full-flatness control of a hybrid power plant. In Proceedings of the 2016 IEEE SICE International Symposium on Control Systems (ISCS 2016), Nagoya, Japan, 7–10 March 2016. [Google Scholar] [CrossRef]

- Thounthong, P.; Raël, S.; Davat, B. Control strategy of fuel cell/supercapacitors hybrid power sources for electric vehicle. J. Power Sources 2006, 158, 806–814. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Rated DC grid voltage, vBus | 310 V |

| Nominal battery voltage, vBat | 120 V |

| Nominal SC voltage, vSC | 140 V |

| Inductor LB1 = LB2 = LC1 = LC2 | 200 μH |

| Equivalent serial resistances RLB1 = RLB2 = RLC1 = RLC2 | 0.06 Ω |

| Total DC Bus Capacitors | 2000 μF, 900 V |

| Power MOSFETs Switching Frequency, fS | 25 kHz |

| Parameters | Value |

|---|---|

| ζ1 = ζ2 = ζ3 = ζ4 | 0.7 |

| ωn1 = ωn2 = ωn3 = ωn4 | 8000 |

| Ki11 =Ki21 = Ki31 = Ki41 | 11,200 |

| Ki12 = Ki22 = Ki32 = Ki42 | 64,000,000 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| vBusREF | 310 V | pSCMax | +3600 W |

| ζ5 | 0.7 | pSCMin | −3600 W |

| ωn5 | 80 rad·s−1 | vSCMax | 160 V |

| Kv1 | 112 | VSCMin | 70 V |

| Kv2 | 6400 | iSCRated | 30 A |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| vSCREF | 140 V | PBatMax | +2100 W |

| CSC | 6 F | PBatMin | 0 W |

| ζ6 | 1 | IBatMax | +18 A |

| ωn6 | 0.8 rad·s−1 | IBatMin | 0 A |

| Kv3 | 0.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yodwong, B.; Thounthong, P.; Guilbert, D.; Bizon, N. Differential Flatness-Based Cascade Energy/Current Control of Battery/Supercapacitor Hybrid Source for Modern e–Vehicle Applications. Mathematics 2020, 8, 704. https://doi.org/10.3390/math8050704

Yodwong B, Thounthong P, Guilbert D, Bizon N. Differential Flatness-Based Cascade Energy/Current Control of Battery/Supercapacitor Hybrid Source for Modern e–Vehicle Applications. Mathematics. 2020; 8(5):704. https://doi.org/10.3390/math8050704

Chicago/Turabian StyleYodwong, Burin, Phatiphat Thounthong, Damien Guilbert, and Nicu Bizon. 2020. "Differential Flatness-Based Cascade Energy/Current Control of Battery/Supercapacitor Hybrid Source for Modern e–Vehicle Applications" Mathematics 8, no. 5: 704. https://doi.org/10.3390/math8050704

APA StyleYodwong, B., Thounthong, P., Guilbert, D., & Bizon, N. (2020). Differential Flatness-Based Cascade Energy/Current Control of Battery/Supercapacitor Hybrid Source for Modern e–Vehicle Applications. Mathematics, 8(5), 704. https://doi.org/10.3390/math8050704