The Fuzzy DEA-Based Manufacturing Service Efficiency Evaluation and Ranking Approach for a Parallel Two-Stage Structure of a Complex Product System on the Example of Solid Waste Recycling

Abstract

:1. Introduction

2. Research Status

2.1. Data Envelopment Analysis

2.2. Solid Waste Recycling

3. Basic Definitions

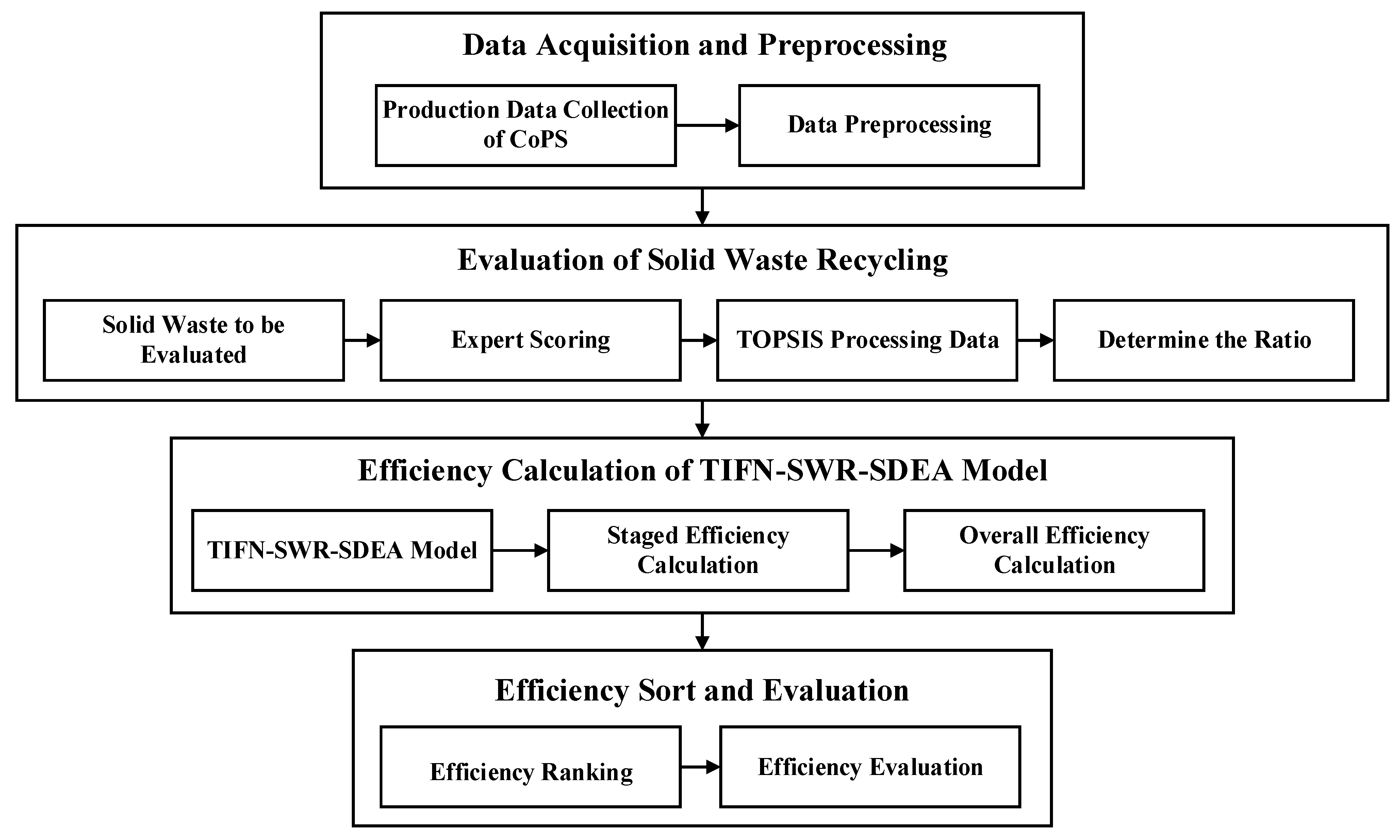

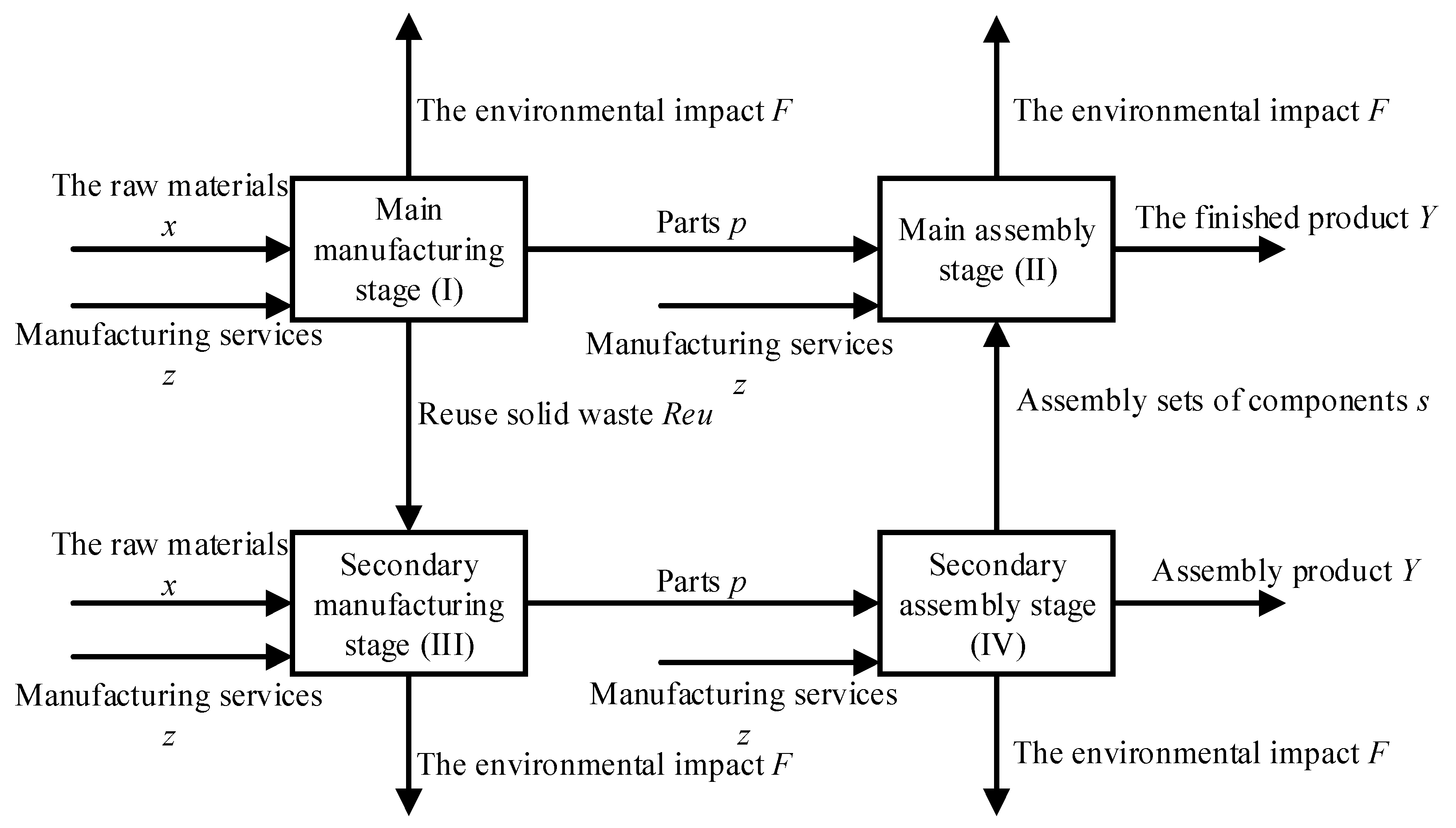

4. Mathematical Modeling

4.1. Problem Description

4.2. Solid Waste Recycling Evaluation

| Algorithm 1: selection of the reuse solid waste |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

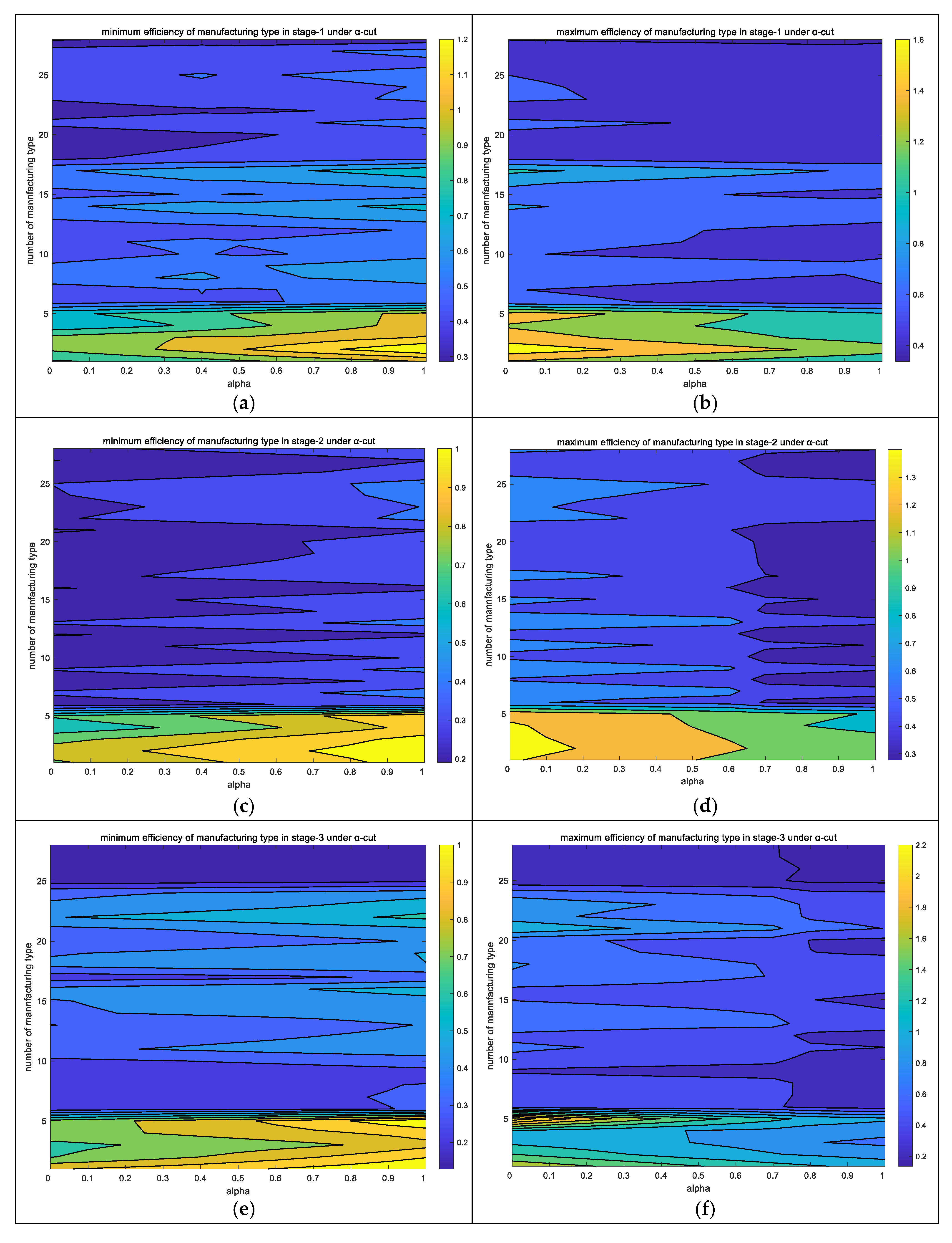

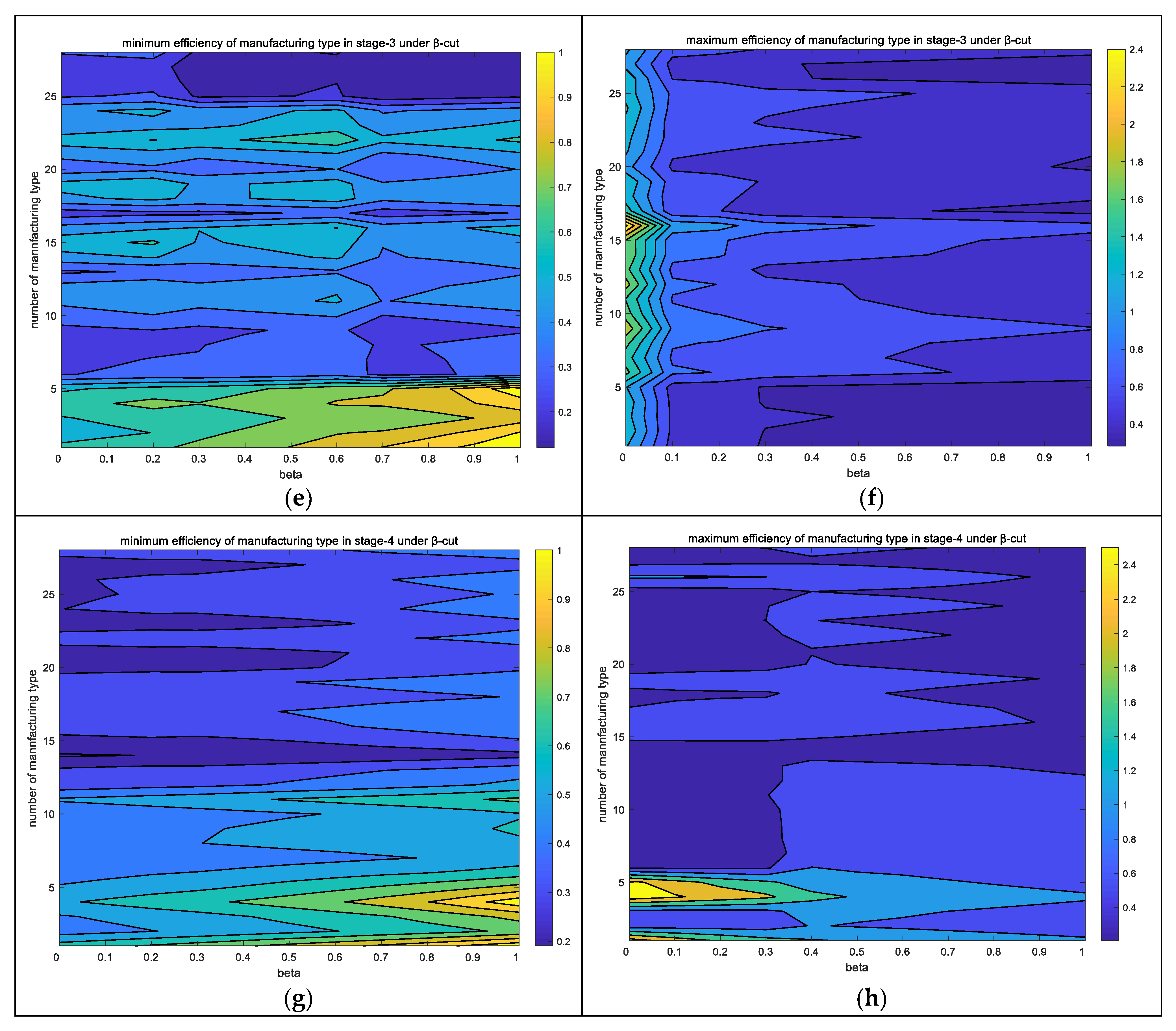

4.3. Calculation of Parallel Manufacturing Service Efficiency

| Algorithm 2: stage of main manufacturing of DEA efficiency measurement under α-cut |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Algorithm 3: Calculating minimum efficiency of the model under α-cut |

|

|

|

|

|

|

|

|

|

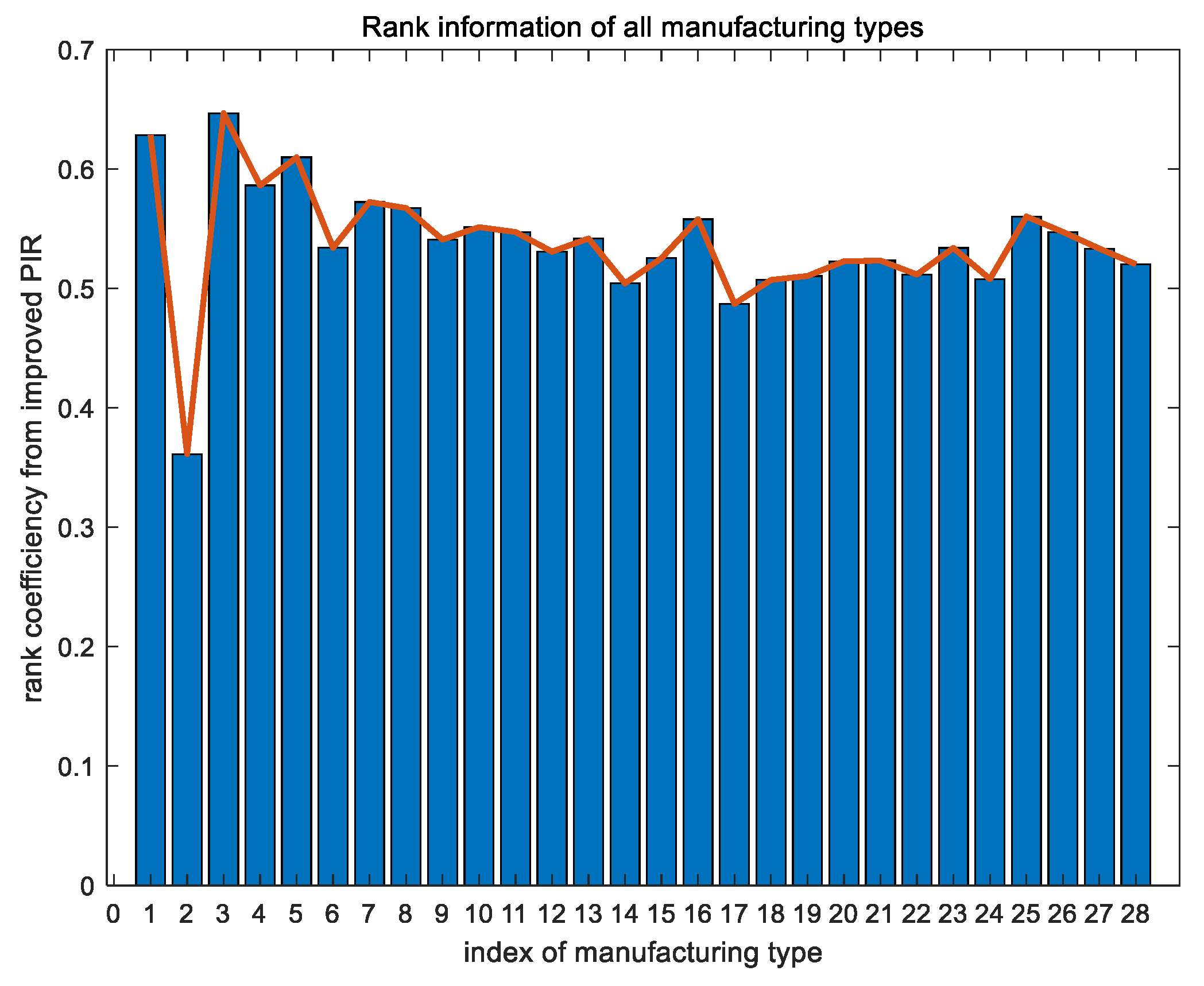

4.4. Efficiency Ranking

5. Empirical Research and Analysis

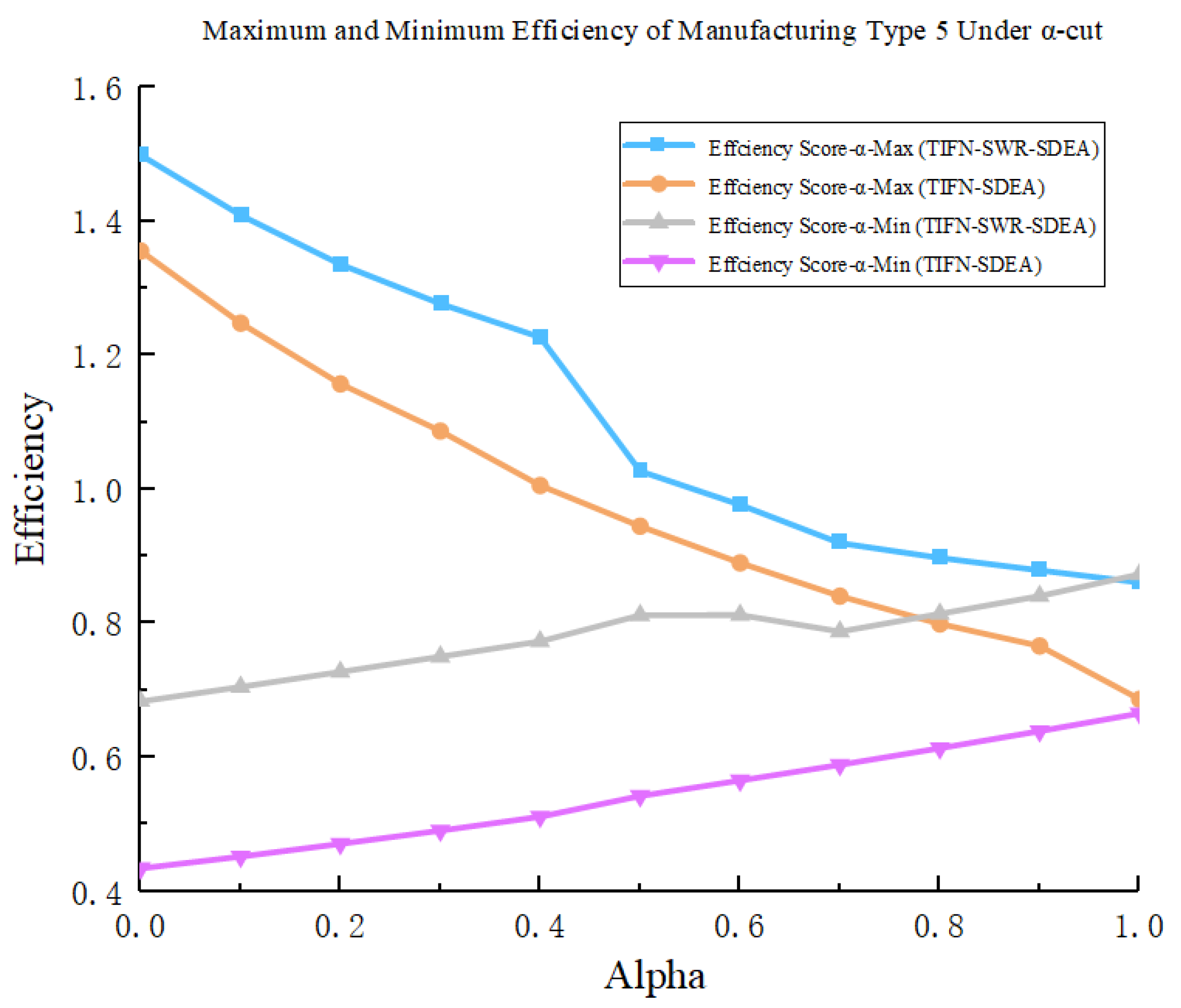

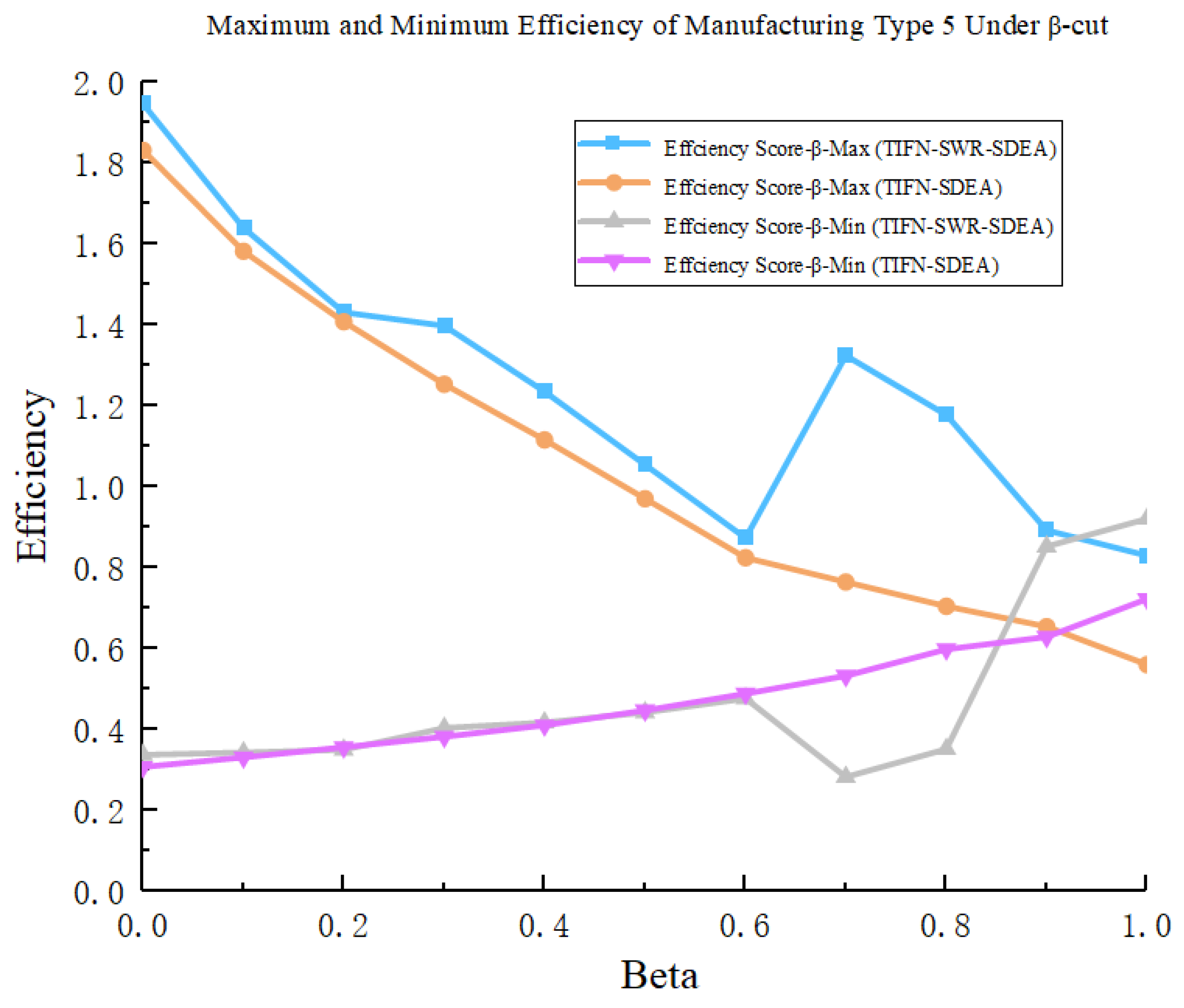

5.1. Comparison of Algorithms

5.2. Analysis and Discussion

5.3. Improvement Recommendations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Production Process Data of Complex Product Systems—The Core Component Processing Stage

| Serial Number | Raw Materials (t) | Manufacturing Services | Industrial Added Value (Ten Thousand Yuan) | Environmental Impact | Available Solid Waste (t) | ||||

| Energy Consumption (kW·h) | Technical Staff | Manufacture Service Factor | Solid Waste (t) | Average Noise (dB) | Carbon Emission (kg) | ||||

| 1 | (558.62, 600.00, 638.10; 436.68, 600.00, 759.22) | (1054.40, 1100.00, 1168.40; 875.90, 1100.00, 1290.59) | (18, 20, 23; 12, 20, 26) | (0.54, 0.60, 0.71; 0.53, 0.60, 0.72) | (748.75, 800.00, 831.78; 653.31, 800.00, 840.18) | (58.60, 60.00, 64.37; 55.99, 60.00, 65.20) | (62.36, 65.00, 68.60; 58.86, 65.00, 70.38) | (793.60, 831.49, 912.93; 665.08, 831.49, 1035.25) | (14.47, 15.00, 15.85; 14.06, 15.00, 16.41) |

| 2 | (593.91, 640.48, 652.50; 496.15, 640.48, 819.16) | (949.28, 1030.86, 1087.85; 808.53, 1030.86, 1252.95) | (15, 18, 22; 13, 18, 27) | (0.61, 0.66, 0.76; 0.55, 0.66, 0.81) | (658.46, 730.54, 801.43; 624.81, 730.54, 770.92) | (62.70, 65.00, 68.84; 59.73, 65.00, 71.05) | (66.36, 67.83, 73.26; 63.21, 67.83, 74.15) | (760.41, 779.22, 846.44; 588.84, 779.22, 931.75) | (18.32, 19.18, 20.58; 17.43, 19.18, 21.05) |

| 3 | (539.36, 560.49, 605.71; 447.83, 560.49, 669.69) | (918.33, 990.63, 992.38; 751.99, 990.63, 1232.81) | (19, 23, 27; 18, 23, 31) | (0.56, 0.60, 0.71; 0.53, 0.60, 0.75) | (747.64, 818.57, 840.74; 700.85, 818.57, 867.55) | (61.50, 63.86, 68.24; 57.67, 63.86, 69.90) | (62.14, 64.82, 68.92; 60.97, 64.82, 70.73) | (698.09, 748.82, 815.72; 576.33, 748.82, 890.66) | (15.29, 16.09, 17.00; 14.53, 16.09, 17.66) |

| 4 | (624.32, 636.24, 693.59; 464.45, 636.24, 775.18) | (1015.50, 1082.26, 1109.36; 848.87, 1082.26, 1259.85) | (15, 17, 22; 11, 17, 24) | (0.62, 0.66, 0.76; 0.53, 0.66, 0.84) | (712.36, 787.74, 846.77; 634.97, 787.74, 805.06) | (61.89, 63.56, 68.43; 57.53, 63.56, 68.80) | (66.50, 68.79, 73.53; 63.41, 68.79, 75.03) | (802.14, 818.08, 849.63; 653.06, 818.08, 970.16) | (14.48, 15.01, 16.06; 13.92, 15.01, 16.38) |

| 5 | (569.76, 617.54, 673.64; 492.57, 617.54, 733.12) | (1133.50, 1150.46, 1215.01; 880.58, 1150.46, 1376.74) | (16, 17, 18; 9, 17, 27) | (0.61, 0.65, 0.77; 0.56, 0.65, 0.83) | (728.03, 787.74, 852.94; 648.50, 787.74, 847.93) | (59.10, 62.18, 66.38; 58.31, 62.18, 67.89) | (57.96, 60.23, 64.65; 55.68, 60.23, 65.11) | (812.12, 869.64, 869.79; 685.39, 869.64, 1042.57) | (14.99, 15.53, 16.52; 14.15, 15.53, 17.06) |

| 6 | (881.10, 900.00, 969.23; 700.10, 900.00, 1124.77) | (3183.74, 3300.00, 3441.52; 2496.22, 3300.00, 3838.92) | (39, 40, 41; 33, 40, 47) | (0.64, 0.70, 0.81; 0.60, 0.70, 0.85) | (1036.26, 1100.00, 1209.78; 939.08, 1100.00, 1112.64) | (47.94, 50.00, 52.69; 46.38, 50.00, 54.69) | (75.20, 78.00, 83.14; 73.62, 78.00, 85.07) | (2316.08, 2494.47, 2620.66; 1933.06, 2494.47, 3097.97) | (33.94, 35.00, 37.35; 32.24, 35.00, 37.94) |

| 7 | (906.61, 970.39, 977.13; 713.46, 970.39, 1201.86) | (3039.59, 3040.11, 3269.90; 2330.11, 3040.11, 3550.42) | (40, 41, 43; 33, 41, 49) | (0.72, 0.76, 0.89; 0.64, 0.76, 0.93) | (1073.94, 1157.23, 1214.81; 1004.98, 1157.23, 1245.07) | (50.79, 52.41, 56.20; 49.26, 52.41, 56.71) | (67.69, 70.74, 76.12; 65.13, 70.74, 77.31) | (2163.59, 2298.02, 2362.45; 1726.91, 2298.02, 2704.68) | (31.84, 33.25, 35.15; 30.43, 33.25, 36.56) |

| 8 | (888.38, 984.22, 1023.65; 780.64, 984.22, 1174.08) | (2940.28, 3011.81, 3247.64; 2356.57, 3011.81, 3599.13) | (40, 44, 48; 37, 44, 50) | (0.72, 0.76, 0.86; 0.63, 0.76, 0.98) | (1067.69, 1172.68, 1276.57; 1017.31, 1172.68, 1223.43) | (48.12, 49.66, 52.35; 46.76, 49.66, 53.80) | (74.90, 78.41, 82.67; 74.48, 78.41, 86.16) | (2111.32, 2276.63, 2369.84; 1750.88, 2276.63, 2834.28) | (36.17, 37.94, 40.71; 35.39, 37.94, 41.19) |

| 9 | (921.07, 981.63, 1064.33; 780.73, 981.63, 1177.52) | (3734.77, 3739.58, 3772.97; 2983.21, 3739.58, 4432.96) | (31, 35, 39; 29, 35, 41) | (0.67, 0.72, 0.84; 0.63, 0.72, 0.89) | (999.65, 1082.38, 1109.18; 892.11, 1082.38, 1135.22) | (49.60, 52.05, 55.95; 47.26, 52.05, 56.79) | (82.57, 85.67, 91.35; 77.57, 85.67, 93.96) | (2730.46, 2826.75, 2856.52; 2208.78, 2826.75, 3276.92) | (40.18, 41.80, 43.95; 38.28, 41.80, 45.72) |

| 10 | (814.52, 899.26, 981.40; 648.79, 899.26, 1119.42) | (3116.38, 3254.09, 3527.87; 2495.83, 3254.09, 3820.65) | (40, 44, 49; 37, 44, 50) | (0.74, 0.78, 0.91; 0.66, 0.78, 0.96) | (1027.47, 1096.77, 1194.50; 933.03, 1096.77, 1161.50) | (45.01, 47.05, 49.94; 43.79, 47.05, 51.18) | (78.13, 79.98, 85.29; 73.71, 79.98, 87.86) | (2402.05, 2459.76, 2504.30; 1882.33, 2459.76, 2981.80) | (28.45, 29.11, 30.95; 27.35, 29.11, 31.85) |

| 11 | (701.67, 750.00, 822.25; 586.59, 750.00, 881.53) | (2381.40, 2500.00, 2643.42; 1903.19, 2500.00, 2925.60) | (31, 35, 38; 30, 35, 45) | (0.61, 0.65, 0.75; 0.54, 0.65, 0.83) | (948.91, 1000.00, 1063.06; 824.36, 1000.00, 1064.00) | (52.39, 55.00, 58.00; 50.16, 55.00, 60.14) | (66.68, 70.00, 74.78; 63.55, 70.00, 77.00) | (1757.14, 1889.75, 1945.99; 1436.11, 1889.75, 2298.27) | (24.46, 25.00, 26.89; 22.87, 25.00, 27.20) |

| 12 | (698.89, 735.17, 767.25; 570.07, 735.17, 856.65) | (2426.31, 2626.87, 2878.73; 2087.19, 2626.87, 3022.33) | (28, 31, 36; 21, 31, 38) | (0.58, 0.62, 0.72; 0.54, 0.62, 0.78) | (925.29, 989.31, 1080.14; 838.35, 989.31, 1015.84) | (65.73, 68.86, 72.98; 65.23, 68.86, 74.69) | (48.24, 50.65, 53.43; 45.94, 50.65, 55.60) | (1866.35, 1985.65, 2136.41; 1562.34, 1985.65, 2390.35) | (25.55, 26.29, 27.90; 24.21, 26.29, 28.67) |

| 13 | (652.99, 677.06, 737.81; 527.85, 677.06, 810.18) | (2595.32, 2803.76, 2829.10; 2142.06, 2803.76, 3391.80) | (28, 32, 33; 23, 32, 39) | (0.61, 0.66, 0.76; 0.55, 0.66, 0.79) | (991.91, 1088.73, 1138.83; 899.85, 1088.73, 1114.31) | (62.63, 64.32, 68.35; 60.90, 64.32, 70.44) | (47.62, 49.48, 52.86; 45.20, 49.48, 53.87) | (1955.59, 2119.36, 2156.81; 1614.46, 2119.36, 2560.24) | (30.10, 31.13, 33.32; 28.67, 31.13, 33.72) |

| 14 | (677.57, 682.20, 733.61; 504.72, 682.20, 814.34) | (2699.52, 2745.99, 2971.54; 2104.93, 2745.99, 3312.66) | (36, 38, 39; 29, 38, 45) | (0.60, 0.64, 0.75; 0.56, 0.64, 0.81) | (1052.24, 1151.61, 1189.55; 949.61, 1151.61, 1207.42) | (54.00, 55.25, 58.50; 49.73, 55.25, 59.70) | (34.66, 36.15, 38.67; 33.92, 36.15, 39.29) | (2049.79, 2075.69, 2211.05; 1608.66, 2075.69, 2422.60) | (23.64, 24.85, 26.34; 22.47, 24.85, 27.09) |

| 15 | (746.82, 752.17, 765.56; 559.80, 752.17, 888.31) | (2610.63, 2726.96, 2774.51; 2078.92, 2726.96, 3227.90) | (34, 37, 40; 31, 37, 44) | (0.57, 0.62, 0.69; 0.52, 0.62, 0.79) | (980.70, 1054.53, 1150.52; 848.50, 1054.53, 1082.27) | (52.56, 55.11, 58.35; 51.47, 55.11, 59.60) | (49.86, 52.08, 55.74; 48.18, 52.08, 57.10) | (1886.73, 2061.31, 2097.16; 1617.17, 2061.31, 2447.81) | (21.06, 22.03, 23.64; 20.43, 22.03, 23.85) |

| 16 | (778.85, 814.22, 885.73; 606.76, 814.22, 950.83) | (2403.59, 2621.69, 2781.97; 1974.46, 2621.69, 3101.84) | (32, 36, 38; 30, 36, 46) | (0.55, 0.59, 0.69; 0.52, 0.59, 0.71) | (953.96, 1016.27, 1069.87; 843.54, 1016.27, 1028.61) | (65.91, 68.02, 72.84; 63.47, 68.02, 74.06) | (40.62, 42.41, 45.40; 39.82, 42.41, 46.58) | (1892.63, 1981.74, 1990.38; 1521.67, 1981.74, 2428.63) | (29.65, 31.21, 32.87; 28.24, 31.21, 34.28) |

| 17 | (696.37, 740.11, 790.59; 565.59, 740.11, 925.12) | (2541.98, 2681.21, 2772.35; 2055.18, 2681.21, 3301.61) | (27, 31, 33; 26, 31, 41) | (0.57, 0.62, 0.74; 0.50, 0.62, 0.75) | (1157.57, 1266.35, 1370.23; 1051.06, 1266.35, 1382.32) | (58.41, 60.72, 64.84; 55.61, 60.72, 66.33) | (46.82, 47.88, 50.79; 44.12, 47.88, 52.31) | (1964.56, 2026.72, 2055.31; 1523.15, 2026.72, 2449.09) | (30.98, 31.86, 34.01; 29.46, 31.86, 34.90) |

| 18 | (661.35, 687.00, 740.05; 502.48, 687.00, 860.25) | (2686.27, 2835.72, 3039.37; 2134.64, 2835.72, 3415.82) | (35, 39, 40; 31, 39, 48) | (0.68, 0.74, 0.87; 0.62, 0.74, 0.91) | (939.38, 991.44, 1048.94; 845.38, 991.44, 1025.79) | (59.19, 61.39, 65.25; 56.35, 61.39, 66.39) | (46.61, 48.09, 51.93; 44.22, 48.09, 52.82) | (1965.31, 2143.52, 2299.99; 1705.17, 2143.52, 2511.20) | (19.45, 20.33, 21.71; 18.32, 20.33, 22.36) |

| 19 | (614.13, 656.34, 710.40; 523.03, 656.34, 774.56) | (2995.65, 3106.46, 3194.34; 2472.00, 3106.46, 3797.94) | (30, 34, 36; 26, 34, 40) | (0.85, 0.92, 1.09; 0.80, 0.92, 1.14) | (907.34, 989.11, 1040.73; 819.45, 989.11, 1024.26) | (69.61, 71.90, 76.99; 66.39, 71.90, 79.01) | (55.15, 56.82, 60.22; 51.98, 56.82, 61.44) | (2270.50, 2348.17, 2441.90; 1767.24, 2348.17, 2705.49) | (19.85, 20.46, 22.03; 18.84, 20.46, 22.48) |

| 20 | (616.06, 672.62, 730.33; 537.34, 672.62, 828.65) | (2981.63, 3244.14, 3442.43; 2537.09, 3244.14, 4019.82) | (36, 39, 43; 34, 39, 46) | (0.75, 0.80, 0.96; 0.71, 0.80, 1.02) | (935.50, 1013.26, 1093.88; 858.87, 1013.26, 1042.09) | (71.53, 74.20, 78.09; 70.34, 74.20, 80.90) | (55.47, 57.67, 60.58; 53.27, 57.67, 63.30) | (2435.87, 2452.24, 2620.79; 1880.84, 2452.24, 2838.03) | (23.60, 24.59, 26.35; 22.29, 24.59, 26.92) |

| 21 | (650.17, 687.48, 751.03; 516.16, 687.48, 790.63) | (2933.98, 3068.72, 3123.75; 2306.11, 3068.72, 3802.28) | (38, 40, 45; 34, 40, 46) | (0.69, 0.76, 0.84; 0.62, 0.76, 0.96) | (1145.00, 1209.84, 1236.00; 1050.20, 1209.84, 1330.01) | (71.29, 73.11, 78.06; 66.78, 73.11, 80.31) | (51.25, 53.01, 57.24; 48.31, 53.01, 57.35) | (2089.00, 2319.65, 2368.91; 1804.04, 2319.65, 2704.73) | (21.76, 22.54, 24.25; 20.54, 22.54, 24.50) |

| 22 | (727.99, 729.02, 796.33; 545.09, 729.02, 912.77) | (2958.15, 2966.13, 2985.41; 2356.16, 2966.13, 3629.84) | (39, 41, 44; 31, 41, 49) | (0.86, 0.92, 1.06; 0.78, 0.92, 1.19) | (956.31, 1024.42, 1063.40; 874.08, 1024.42, 1069.76) | (72.41, 74.31, 79.85; 68.22, 74.31, 81.63) | (50.90, 52.59, 55.35; 48.63, 52.59, 56.90) | (2156.99, 2242.10, 2457.22; 1747.28, 2242.10, 2583.06) | (20.00, 20.82, 22.46; 19.18, 20.82, 22.50) |

| 23 | (570.40, 625.41, 678.86; 487.64, 625.41, 724.33) | (2631.72, 2883.06, 3163.12; 2259.96, 2883.06, 3472.61) | (40, 44, 46; 35, 44, 53) | (0.72, 0.77, 0.88; 0.67, 0.77, 0.98) | (961.80, 1015.06, 1061.43; 862.87, 1015.06, 1070.30) | (63.39, 65.07, 69.50; 60.59, 65.07, 70.49) | (49.22, 51.39, 54.90; 48.22, 51.39, 55.88) | (2021.99, 2179.30, 2361.65; 1666.87, 2179.30, 2507.80) | (23.96, 24.64, 26.03; 22.63, 24.64, 26.95) |

| 24 | (632.80, 691.55, 719.23; 534.62, 691.55, 795.42) | (2424.47, 2572.19, 2699.64; 2007.57, 2572.19, 2971.70) | (41, 44, 47; 39, 44, 54) | (0.72, 0.76, 0.86; 0.64, 0.76, 0.96) | (998.38, 1053.21, 1101.30; 910.51, 1053.21, 1081.51) | (66.85, 68.39, 72.38; 63.38, 68.39, 73.93) | (54.62, 56.78, 60.63; 51.88, 56.78, 61.67) | (1773.93, 1944.31, 1982.74; 1486.37, 1944.31, 2330.17) | (21.10, 21.95, 23.46; 19.91, 21.95, 24.03) |

| 25 | (1125.80, 1178.62, 1193.76; 909.66, 1178.62, 1502.35) | (2535.39, 2676.51, 2878.52; 2029.04, 2676.51, 3328.28) | (40, 43, 45; 36, 43, 52) | (0.79, 0.85, 0.98; 0.73, 0.85, 1.03) | (1036.86, 1139.36, 1190.26; 941.31, 1139.36, 1203.20) | (65.24, 66.77, 70.68; 62.01, 66.77, 72.61) | (72.25, 75.22, 78.99; 69.43, 75.22, 82.00) | (1908.54, 2023.18, 2163.82; 1521.51, 2023.18, 2494.89) | (32.26, 33.46, 35.44; 30.69, 33.46, 36.69) |

| 26 | (1059.71, 1071.85, 1122.41; 839.50, 1071.85, 1285.21) | (2876.42, 3061.25, 3110.64; 2322.88, 3061.25, 3666.78) | (40, 41, 43; 33, 41, 47) | (0.86, 0.94, 1.05; 0.83, 0.94, 1.19) | (1084.92, 1168.27, 1198.53; 959.54, 1168.27, 1191.97) | (61.60, 64.14, 68.85; 58.53, 64.14, 69.44) | (68.46, 71.79, 75.42; 65.68, 71.79, 78.87) | (2187.99, 2314.00, 2489.34; 1775.89, 2314.00, 2797.96) | (32.01, 33.35, 35.26; 31.42, 33.35, 36.22) |

| 27 | (973.99, 1041.22, 1052.11; 790.14, 1041.22, 1314.51) | (2552.06, 2801.18, 3000.02; 2146.62, 2801.18, 3250.68) | (38, 41, 44; 35, 41, 48) | (0.82, 0.88, 0.98; 0.72, 0.88, 1.14) | (998.38, 1094.99, 1127.33; 918.85, 1094.99, 1189.65) | (60.17, 63.13, 67.70; 58.42, 63.13, 68.50) | (63.70, 66.44, 70.84; 61.18, 66.44, 72.54) | (2046.15, 2117.41, 2259.87; 1647.85, 2117.41, 2614.79) | (31.75, 32.41, 34.25; 29.81, 32.41, 35.02) |

| 28 | (796.29, 851.92, 858.72; 668.56, 851.92, 1069.18) | (3803.00, 4009.98, 4291.79; 3166.47, 4009.98, 4771.12) | (43, 44, 49; 35, 44, 53) | (0.80, 0.86, 0.96; 0.75, 0.86, 1.11) | (934.88, 1022.64, 1122.74; 823.29, 1022.64, 1073.49) | (66.07, 68.08, 73.19; 62.59, 68.08, 74.48) | (73.51, 76.20, 80.56; 68.83, 76.20, 82.30) | (2818.08, 3031.15, 3200.43; 2288.42, 3031.15, 3665.62) | (27.03, 28.13, 29.70; 25.45, 28.13, 30.72) |

Appendix B. Production Process Data of Complex Product Systems—The Core Component Assembly Stage

| Serial Number | Industrial Added Value (Ten Thousand Yuan) | Manufacturing Services | Finished Product Value (Ten Thousand Yuan) | Environmental Impact | ||||

| Energy Consumption (kW·h) | Technical Staff | Manufacture Service Factor | Solid Waste (t) | Average Noise (dB) | Carbon Emission (kg) | |||

| 1 | (748.75, 800.00, 831.78; 653.31, 800.00, 840.18) | (2947.53, 3000.00, 3101.82; 2293.01, 3000.00, 3625.10) | (15, 15, 17; 13, 15, 18) | (0.66, 0.70, 0.80; 0.59, 0.70, 0.89) | (1362.99, 1500.00, 1618.84; 1209.92, 1500.00, 2435.26) | (34.02, 35.00, 37.78; 33.01, 35.00, 37.53) | (33.56, 35.00, 37.14; 32.01, 35.00, 38.34) | (2079.12, 2267.70, 2307.77; 1804.57, 2267.70, 2797.87) |

| 2 | (658.46, 730.54, 801.43; 624.81, 730.54, 770.92) | (2704.13, 2769.19, 2850.82; 2083.62, 2769.19, 3192.39) | (12, 13, 13; 10, 13, 16) | (0.63, 0.69, 0.79; 0.60, 0.69, 0.87) | (1255.66, 1355.23, 1523.76; 1096.44, 1355.23, 2190.91) | (34.61, 36.05, 38.20; 34.12, 36.05, 38.82) | (31.34, 32.84, 35.45; 29.86, 32.84, 36.10) | (2012.66, 2093.23, 2179.46; 1665.13, 2093.23, 2485.11) |

| 3 | (747.64, 818.57, 840.74; 700.85, 818.57, 867.55) | (2669.74, 2906.31, 3058.66; 2227.25, 2906.31, 3381.00) | (14, 14, 16; 13, 14, 17) | (0.63, 0.68, 0.80; 0.59, 0.68, 0.88) | (1344.15, 1434.50, 1606.58; 1156.53, 1434.50, 2350.77) | (36.36, 37.34, 40.16; 35.19, 37.34, 39.62) | (31.95, 32.99, 35.02; 30.26, 32.99, 35.97) | (2172.64, 2196.88, 2318.74; 1692.24, 2196.88, 2629.77) |

| 4 | (712.36, 787.74, 846.77; 634.97, 787.74, 805.06) | (2974.76, 3295.22, 3323.86; 2612.70, 3295.22, 3893.91) | (14, 16, 19; 13, 16, 19) | (0.57, 0.63, 0.74; 0.55, 0.63, 0.76) | (1317.81, 1450.25, 1552.01; 1249.62, 1450.25, 2374.04) | (32.40, 33.93, 36.27; 30.86, 33.93, 37.12) | (31.43, 32.12, 34.55; 29.40, 32.12, 35.16) | (2336.70, 2490.86, 2615.66; 1960.32, 2490.86, 2919.40) |

| 5 | (728.03, 787.74, 852.94; 648.50, 787.74, 847.93) | (3233.28, 3579.40, 3844.00; 2718.19, 3579.40, 4336.52) | (15, 16, 16; 13, 16, 20) | (0.67, 0.71, 0.85; 0.58, 0.71, 0.89) | (1468.56, 1605.15, 1799.34; 1363.75, 1605.15, 2611.26) | (31.19, 31.97, 33.88; 29.05, 31.97, 34.79) | (31.04, 32.55, 34.66; 29.41, 32.55, 35.53) | (2521.40, 2705.67, 2838.34; 2057.01, 2705.67, 3230.04) |

| 6 | (1036.26, 1100.00, 1209.78; 939.08, 1100.00, 1112.64) | (8517.19, 9000.00, 9234.65; 7016.10, 9000.00, 10780.22) | (25, 25, 25; 24, 25, 29) | (0.66, 0.73, 0.81; 0.61, 0.73, 0.93) | (1864.27, 2000.00, 2285.67; 1634.31, 2000.00, 3243.44) | (43.40, 45.00, 48.08; 40.96, 45.00, 49.23) | (43.46, 45.00, 48.17; 40.87, 45.00, 49.07) | (6765.59, 6803.10, 6855.24; 5112.82, 6803.10, 7951.83) |

| 7 | (1073.94, 1157.23, 1214.81; 1004.98, 1157.23, 1245.07) | (8512.52, 8869.43, 9120.81; 6811.02, 8869.43, 10539.28) | (22, 24, 24; 21, 24, 28) | (0.72, 0.77, 0.92; 0.62, 0.77, 0.99) | (2549.98, 2724.09, 2873.14; 2336.76, 2724.09, 4376.16) | (48.21, 49.54, 52.25; 46.33, 49.54, 53.52) | (32.99, 34.00, 36.48; 32.13, 34.00, 37.12) | (6227.10, 6704.40, 6791.83; 5188.73, 6704.40, 7794.22) |

| 8 | (1067.69, 1172.68, 1276.57; 1017.31, 1172.68, 1223.43) | (9106.28, 9435.02, 10268.15; 7149.82, 9435.02, 11778.45) | (26, 27, 29; 26, 27, 31) | (0.72, 0.78, 0.90; 0.62, 0.78, 1.01) | (1991.78, 2192.81, 2352.42; 1876.79, 2192.81, 3533.17) | (44.07, 45.67, 49.21; 41.16, 45.67, 50.19) | (33.23, 34.50, 36.47; 31.49, 34.50, 37.62) | (6603.59, 7131.93, 7499.29; 5648.20, 7131.93, 8578.27) |

| 9 | (999.65, 1082.38, 1109.18; 892.11, 1082.38, 1135.22) | (8562.86, 9097.54, 9639.11; 7133.61, 9097.54, 11101.20) | (24, 24, 26; 22, 24, 26) | (0.72, 0.79, 0.91; 0.67, 0.79, 1.01) | (2447.17, 2690.81, 3082.17; 2230.33, 2690.81, 4367.68) | (43.33, 45.42, 47.99; 40.91, 45.42, 49.88) | (36.61, 37.65, 39.83; 34.14, 37.65, 41.17) | (6757.16, 6876.83, 7267.24; 5469.50, 6876.83, 7989.01) |

| 10 | (1027.47, 1096.77, 1194.50; 933.03, 1096.77, 1161.50) | (10212.61, 10402.3, 10857.38; 7832.36, 10402.3, 12342.91) | (27, 27, 29; 24, 27, 29) | (0.71, 0.78, 0.89; 0.67, 0.78, 0.99) | (1956.62, 2120.04, 2373.26; 1835.20, 2120.04, 3412.17) | (45.65, 47.15, 50.78; 42.45, 47.15, 51.86) | (33.06, 34.51, 37.11; 31.89, 34.51, 37.79) | (7564.91, 7863.10, 8179.65; 6019.73, 7863.10, 9688.34) |

| 11 | (948.91, 1000.00, 1063.06; 824.36, 1000.00, 1064.00) | (6108.82, 6600.00, 7094.00; 4977.42, 6600.00, 7758.83) | (23, 23, 25; 20, 23, 26) | (0.65, 0.70, 0.80; 0.61, 0.70, 0.85) | (1457.43, 1600.00, 1839.28; 1340.99, 1600.00, 2593.41) | (40.73, 42.00, 44.60; 38.85, 42.00, 44.98) | (40.68, 42.00, 45.20; 39.58, 42.00, 45.58) | (4701.48, 4988.94, 5284.29; 3769.90, 4988.94, 5870.63) |

| 12 | (925.29, 989.31, 1080.14; 838.35, 989.31, 1015.84) | (7375.86, 8082.27, 8443.32; 6099.13, 8082.27, 9991.70) | (21, 23, 25; 21, 23, 25) | (0.71, 0.76, 0.84; 0.61, 0.76, 0.97) | (1495.92, 1609.34, 1848.94; 1361.14, 1609.34, 2613.53) | (50.43, 52.83, 55.55; 49.63, 52.83, 57.60) | (32.77, 33.79, 36.37; 31.64, 33.79, 37.09) | (5722.93, 6109.38, 6519.71; 4717.38, 6109.38, 7210.20) |

| 13 | (991.91, 1088.73, 1138.83; 899.85, 1088.73, 1114.31) | (6053.49, 6393.90, 6513.58; 4977.01, 6393.90, 7724.09) | (21, 22, 23; 21, 22, 25) | (0.54, 0.56, 0.62; 0.49, 0.56, 0.70) | (1467.52, 1619.14, 1724.78; 1347.14, 1619.14, 2640.59) | (42.94, 44.18, 46.95; 40.67, 44.18, 48.37) | (53.18, 54.55, 58.01; 49.17, 54.55, 59.71) | (4734.64, 4833.15, 4918.04; 3678.19, 4833.15, 5682.09) |

| 14 | (1052.24, 1151.61, 1189.55; 949.61, 1151.61, 1207.42) | (8075.81, 8177.05, 8614.71; 6526.78, 8177.05, 9576.08) | (20, 21, 23; 20, 21, 24) | (0.65, 0.71, 0.79; 0.61, 0.71, 0.90) | (1401.80, 1553.14, 1774.67; 1276.49, 1553.14, 2533.21) | (34.98, 36.10, 38.22; 33.26, 36.10, 38.80) | (47.42, 49.65, 53.00; 45.18, 49.65, 53.77) | (6071.40, 6181.03, 6522.00; 4938.13, 6181.03, 7703.22) |

| 15 | (980.70, 1054.53, 1150.52; 848.50, 1054.53, 1082.27) | (7350.14, 7622.06, 7836.95; 5982.49, 7622.06, 9215.51) | (22, 22, 24; 20, 22, 25) | (0.68, 0.74, 0.87; 0.65, 0.74, 0.96) | (1504.27, 1667.27, 1899.77; 1429.06, 1667.27, 2691.18) | (40.33, 41.58, 43.86; 38.09, 41.58, 44.28) | (49.20, 50.90, 54.45; 48.10, 50.90, 55.68) | (5501.10, 5761.52, 5774.58; 4487.48, 5761.52, 6709.78) |

| 16 | (953.96, 1016.27, 1069.87; 843.54, 1016.27, 1028.61) | (8175.25, 8249.94, 8847.99; 6522.74, 8249.94, 10231.00) | (21, 22, 22; 19, 22, 25) | (0.74, 0.81, 0.90; 0.68, 0.81, 1.03) | (1442.48, 1572.30, 1745.18; 1375.12, 1572.30, 2520.60) | (43.32, 44.80, 47.61; 40.85, 44.80, 47.89) | (47.35, 49.18, 51.95; 46.51, 49.18, 53.18) | (5788.97, 6236.13, 6663.06; 4966.23, 6236.13, 7669.01) |

| 17 | (1157.57, 1266.35, 1370.23; 1051.06, 1266.35, 1382.32) | (6290.49, 6423.52, 6968.45; 4993.36, 6423.52, 7626.47) | (22, 22, 22; 21, 22, 24) | (0.57, 0.63, 0.72; 0.54, 0.63, 0.76) | (1445.65, 1526.61, 1609.62; 1236.59, 1526.61, 2450.90) | (52.07, 53.42, 56.86; 48.61, 53.42, 57.25) | (48.89, 50.34, 52.89; 46.07, 50.34, 54.99) | (4690.05, 4855.54, 4961.75; 3829.64, 4855.54, 6040.43) |

| 18 | (939.38, 991.44, 1048.94; 845.38, 991.44, 1025.79) | (6579.32, 6930.27, 7611.70; 5424.00, 6930.27, 8413.16) | (25, 25, 28; 23, 25, 29) | (0.72, 0.79, 0.93; 0.64, 0.79, 0.98) | (1516.58, 1634.17, 1732.84; 1354.82, 1634.17, 2628.01) | (41.18, 42.10, 45.10; 38.93, 42.10, 44.99) | (34.72, 36.19, 38.93; 32.57, 36.19, 39.39) | (5212.42, 5238.59, 5304.48; 4161.73, 5238.59, 6456.76) |

| 19 | (907.34, 989.11, 1040.73; 819.45, 989.11, 1024.26) | (7826.74, 8121.47, 8931.78; 6273.56, 8121.47, 9639.48) | (23, 23, 26; 22, 23, 27) | (0.78, 0.82, 0.98; 0.69, 0.82, 1.06) | (1822.07, 1931.62, 2104.65; 1672.60, 1931.62, 3119.23) | (42.91, 44.53, 48.00; 40.58, 44.53, 47.94) | (34.51, 35.93, 38.41; 32.83, 35.93, 38.97) | (6071.85, 6139.02, 6705.63; 4894.72, 6139.02, 7372.78) |

| 20 | (935.50, 1013.26, 1093.88; 858.87, 1013.26, 1042.09) | (7011.85, 7195.46, 7390.68; 5615.38, 7195.46, 8899.83) | (27, 29, 29; 27, 29, 31) | (0.84, 0.92, 1.01; 0.80, 0.92, 1.11) | (1566.51, 1696.32, 1864.46; 1386.12, 1696.32, 2776.46) | (46.13, 47.25, 50.14; 44.26, 47.25, 51.67) | (44.13, 45.18, 47.82; 41.84, 45.18, 48.93) | (5195.66, 5439.05, 5529.09; 4088.64, 5439.05, 6467.07) |

| 21 | (1145.00, 1209.84, 1236.00; 1050.20, 1209.84, 1330.01) | (7943.09, 8320.72, 9017.47; 6261.52, 8320.72, 9672.80) | (23, 25, 27; 22, 25, 29) | (0.83, 0.88, 1.04; 0.74, 0.88, 1.12) | (1657.56, 1783.95, 1960.14; 1472.72, 1783.95, 2882.23) | (42.45, 44.21, 47.12; 40.76, 44.21, 47.11) | (43.75, 44.98, 47.32; 40.90, 44.98, 49.26) | (6258.77, 6289.63, 6918.03; 4877.13, 6289.63, 7458.85) |

| 22 | (956.31, 1024.42, 1063.40; 874.08, 1024.42, 1069.76) | (6187.22, 6611.63, 6889.26; 5241.19, 6611.63, 7966.68) | (23, 23, 24; 22, 23, 26) | (0.86, 0.92, 1.07; 0.81, 0.92, 1.10) | (1829.49, 1935.26, 2100.04; 1653.08, 1935.26, 3161.18) | (48.88, 50.74, 54.15; 48.16, 50.74, 54.16) | (41.46, 42.55, 45.85; 38.42, 42.55, 46.05) | (4626.04, 4997.73, 5316.53; 3838.55, 4997.73, 6141.81) |

| 23 | (961.80, 1015.06, 1061.43; 862.87, 1015.06, 1070.30) | (6648.25, 7215.42, 7845.68; 5687.49, 7215.42, 8628.35) | (22, 24, 28; 21, 24, 28) | (0.92, 0.98, 1.17; 0.81, 0.98, 1.22) | (1879.80, 1983.45, 2226.51; 1683.22, 1983.45, 3240.29) | (41.90, 43.37, 45.57; 40.21, 43.37, 46.18) | (38.27, 39.75, 42.73; 35.89, 39.75, 43.53) | (4967.36, 5454.13, 5836.11; 4355.55, 5454.13, 6385.58) |

| 24 | (998.38, 1053.21, 1101.30; 910.51, 1053.21, 1081.51) | (6228.73, 6816.99, 7442.10; 5409.77, 6816.99, 7922.51) | (29, 29, 32; 28, 29, 32) | (0.84, 0.90, 1.07; 0.74, 0.90, 1.08) | (1842.37, 1994.62, 2098.08; 1739.34, 1994.62, 3213.91) | (41.62, 43.07, 45.40; 40.11, 43.07, 46.55) | (40.89, 42.24, 45.43; 38.79, 42.24, 46.30) | (4637.85, 5152.96, 5429.76; 4097.56, 5152.96, 6317.58) |

| 25 | (1036.86, 1139.36, 1190.26; 941.31, 1139.36, 1203.20) | (7206.28, 7347.20, 7633.62; 5720.36, 7347.20, 8505.00) | (28, 28, 31; 25, 28, 31) | (0.86, 0.93, 1.06; 0.75, 0.93, 1.19) | (2285.90, 2477.53, 2710.04; 2176.67, 2477.53, 4048.14) | (56.71, 58.99, 62.71; 55.65, 58.99, 63.09) | (63.54, 65.72, 69.14; 59.69, 65.72, 71.67) | (5518.09, 5553.75, 5774.59; 4380.16, 5553.75, 6485.90) |

| 26 | (1084.92, 1168.27, 1198.53; 959.54, 1168.27, 1191.97) | (8382.29, 8717.13, 9185.15; 6763.39, 8717.13, 10304.35) | (29, 31, 33; 29, 31, 33) | (0.77, 0.84, 0.95; 0.69, 0.84, 1.01) | (2056.86, 2199.38, 2404.42; 1875.50, 2199.38, 3530.22) | (44.40, 45.57, 48.28; 42.45, 45.57, 49.83) | (55.53, 57.61, 60.62; 54.65, 57.61, 62.37) | (6180.84, 6589.28, 7079.72; 4946.51, 6589.28, 7707.93) |

| 27 | (998.38, 1094.99, 1127.33; 918.85, 1094.99, 1189.65) | (9543.78, 9555.49, 10053.31; 7556.74, 9555.49, 11421.33) | (30, 31, 33; 30, 31, 35) | (0.84, 0.93, 1.03; 0.74, 0.93, 1.14) | (1962.25, 2091.19, 2323.43; 1728.89, 2091.19, 3417.98) | (43.35, 44.76, 48.08; 41.69, 44.76, 48.46) | (52.32, 53.78, 57.50; 50.91, 53.78, 58.24) | (6601.53, 7222.99, 7573.96; 5537.09, 7222.99, 8452.29) |

| 28 | (934.88, 1022.64, 1122.74; 823.29, 1022.64, 1073.49) | (6311.42, 6861.57, 7334.20; 5414.73, 6861.57, 8151.33) | (27, 28, 28; 27, 28, 32) | (0.86, 0.91, 1.05; 0.75, 0.91, 1.18) | (1823.15, 2025.71, 2178.16; 1727.82, 2025.71, 3279.00) | (59.63, 62.49, 66.89; 57.35, 62.49, 66.74) | (50.61, 51.91, 55.41; 48.39, 51.91, 56.23) | (5138.80, 5186.66, 5203.06; 4108.26, 5186.66, 6157.43) |

Appendix C. Production Process Data of Complex Product Systems—The Supporting Component Processing Stage

| Serial Number | Raw Materials (t) | Manufacturing Services | Industrial Added Value (Ten Thousand Yuan) | Environmental Impact | ||||

| Energy Consumption (kW·h) | Technical Staff | Manufacture Service Factor | Solid Waste (t) | Average Noise (dB) | Carbon Emission (kg) | |||

| 1 | (54.99, 60.00, 64.47; 47.67, 60.00, 69.99) | (2804.27, 3000.00, 3143.09; 2281.43, 3000.00, 3522.63) | (11, 14, 18; 5, 14, 20) | (0.62, 0.65, 0.68; 0.57, 0.65, 0.72) | (469.47, 500.00, 538.13; 423.31, 500.00, 555.31) | (47.01, 48.00, 51.79; 45.01, 48.00, 51.96) | (48.42, 50.00, 53.53; 47.07, 50.00, 54.05) | (2178.61, 2267.70, 2380.76; 1802.07, 2267.70, 2832.23) |

| 2 | (49.33, 54.70, 57.06; 42.77, 54.70, 67.32) | (2916.00, 3203.96, 3491.35; 2412.85, 3203.96, 3857.94) | (10, 12, 13; 4, 12, 21) | (0.60, 0.63, 0.69; 0.55, 0.63, 0.73) | (474.62, 525.70, 549.02; 455.05, 525.70, 597.74) | (48.41, 49.56, 52.81; 46.86, 49.56, 53.77) | (44.58, 46.04, 49.48; 41.68, 46.04, 49.95) | (2416.93, 2421.87, 2490.23; 1844.40, 2421.87, 2809.83) |

| 3 | (57.29, 58.54, 60.15; 46.51, 58.54, 69.39) | (3748.97, 3892.80, 4057.64; 2959.74, 3892.80, 4721.85) | (14, 15, 18; 7, 15, 24) | (0.62, 0.67, 0.72; 0.57, 0.67, 0.76) | (480.42, 521.55, 556.36; 428.19, 521.55, 586.08) | (43.88, 45.76, 48.85; 42.61, 45.76, 49.44) | (47.48, 48.58, 51.67; 45.01, 48.58, 52.96) | (2794.18, 2942.56, 2947.34; 2303.30, 2942.56, 3648.94) |

| 4 | (63.53, 64.41, 69.16; 50.59, 64.41, 75.23) | (3586.44, 3587.64, 3600.87; 2723.08, 3587.64, 4303.80) | (17, 19, 20; 10, 19, 26) | (0.61, 0.64, 0.67; 0.54, 0.64, 0.72) | (466.45, 516.67, 543.77; 449.56, 516.67, 588.00) | (49.13, 51.14, 55.17; 46.78, 51.14, 56.16) | (44.42, 46.21, 48.76; 43.41, 46.21, 50.37) | (2477.56, 2711.90, 2838.29; 2153.22, 2711.90, 3216.25) |

| 5 | (62.81, 63.43, 66.41; 49.67, 63.43, 74.63) | (3328.00, 3348.81, 3634.80; 2676.89, 3348.81, 3975.89) | (5, 9, 10; 0, 9, 15) | (0.57, 0.63, 0.68; 0.54, 0.63, 0.71) | (426.51, 466.97, 475.31; 401.54, 466.97, 530.58) | (43.79, 45.30, 47.98; 42.60, 45.30, 48.95) | (49.07, 51.05, 54.36; 47.65, 51.05, 55.98) | (2423.88, 2531.37, 2553.85; 2008.34, 2531.37, 3146.99) |

| 6 | (78.67, 80.00, 87.91; 62.69, 80.00, 93.09) | (8110.33, 9000.00, 9054.99; 7064.94, 9000.00, 11096.13) | (28, 30, 33; 21, 30, 36) | (0.60, 0.66, 0.71; 0.54, 0.66, 0.74) | (602.08, 660.00, 704.53; 564.68, 660.00, 741.44) | (33.28, 35.00, 36.95; 32.03, 35.00, 38.46) | (62.01, 65.00, 68.96; 61.31, 65.00, 71.48) | (6567.50, 6803.10, 6817.33; 5291.96, 6803.10, 7886.94) |

| 7 | (70.88, 78.09, 84.67; 61.42, 78.09, 97.42) | (7719.76, 8431.67, 8739.15; 6454.08, 8431.67, 9998.99) | (24, 25, 29; 18, 25, 31) | (0.62, 0.66, 0.71; 0.57, 0.66, 0.76) | (587.72, 628.46, 673.13; 505.07, 628.46, 693.76) | (33.98, 35.19, 37.10; 31.98, 35.19, 38.26) | (70.83, 73.79, 78.44; 69.61, 73.79, 79.88) | (5838.60, 6373.50, 6425.81; 4782.19, 6373.50, 7565.81) |

| 8 | (69.18, 76.21, 82.19; 55.41, 76.21, 94.41) | (7662.81, 8351.40, 9038.61; 6601.93, 8351.40, 9798.91) | (29, 30, 33; 23, 30, 36) | (0.60, 0.66, 0.70; 0.55, 0.66, 0.73) | (626.06, 665.05, 697.05; 537.53, 665.05, 741.60) | (34.76, 35.99, 38.55; 32.67, 35.99, 39.22) | (72.85, 74.68, 79.66; 67.46, 74.68, 80.77) | (6190.93, 6312.82, 6790.88; 5000.03, 6312.82, 7470.37) |

| 9 | (76.62, 80.86, 83.52; 62.75, 80.86, 97.00) | (10482.37, 11620.79, 12492.18; 8849.07, 11620.79, 14395.17) | (30, 32, 35; 25, 32, 41) | (0.59, 0.63, 0.67; 0.50, 0.63, 0.71) | (666.48, 722.50, 761.42; 590.73, 722.50, 810.06) | (32.69, 33.37, 35.15; 30.46, 33.37, 36.53) | (66.30, 69.01, 73.63; 63.16, 69.01, 75.63) | (8005.37, 8784.15, 9434.23; 6634.40, 8784.15, 10813.34) |

| 10 | (72.53, 75.02, 81.12; 55.90, 75.02, 91.80) | (7712.73, 8505.36, 9030.93; 6750.89, 8505.36, 10340.56) | (24, 27, 30; 21, 27, 35) | (0.59, 0.63, 0.69; 0.52, 0.63, 0.71) | (574.50, 628.67, 662.99; 542.58, 628.67, 719.88) | (33.49, 34.43, 36.71; 31.06, 34.43, 37.75) | (71.74, 73.28, 77.52; 67.85, 73.28, 79.32) | (5988.34, 6429.20, 6477.07; 4974.85, 6429.20, 7975.70) |

| 11 | (71.72, 75.00, 78.43; 54.35, 75.00, 97.13) | (6318.46, 6500.00, 7072.97; 5144.07, 6500.00, 8065.90) | (24, 25, 29; 18, 25, 30) | (0.56, 0.60, 0.64; 0.53, 0.60, 0.68) | (569.53, 600.00, 653.86; 501.15, 600.00, 681.74) | (34.23, 35.00, 36.93; 31.60, 35.00, 37.97) | (63.85, 66.92, 71.42; 62.27, 66.92, 73.54) | (4703.34, 4913.35, 5242.61; 3693.24, 4913.35, 6016.73) |

| 12 | (70.85, 73.57, 75.59; 53.03, 73.57, 90.51) | (7738.93, 7986.32, 8607.86; 6070.98, 7986.32, 9597.17) | (21, 24, 25; 19, 24, 29) | (0.56, 0.59, 0.64; 0.50, 0.59, 0.67) | (626.33, 695.40, 761.94; 582.26, 695.40, 773.26) | (38.90, 40.61, 43.23; 36.89, 40.61, 44.34) | (60.56, 62.07, 66.62; 57.70, 62.07, 67.66) | (5868.96, 6036.86, 6630.24; 4763.82, 6036.86, 7103.81) |

| 13 | (76.87, 81.32, 84.79; 62.98, 81.32, 100.31) | (6329.40, 6580.84, 6752.07; 5013.98, 6580.84, 8110.38) | (17, 20, 23; 10, 20, 29) | (0.45, 0.50, 0.54; 0.43, 0.50, 0.56) | (489.61, 537.85, 563.82; 468.40, 537.85, 606.46) | (35.70, 36.79, 39.09; 33.33, 36.79, 40.42) | (62.93, 65.97, 70.19; 61.88, 65.97, 71.52) | (4641.24, 4974.45, 5355.59; 3931.54, 4974.45, 6193.89) |

| 14 | (73.17, 78.49, 83.70; 57.17, 78.49, 90.70) | (6960.58, 7469.03, 7625.11; 5973.77, 7469.03, 9056.98) | (21, 23, 27; 13, 23, 33) | (0.58, 0.62, 0.66; 0.51, 0.62, 0.69) | (619.81, 667.42, 682.44; 560.31, 667.42, 745.27) | (35.24, 36.28, 38.80; 32.68, 36.28, 39.38) | (63.59, 65.01, 69.65; 59.96, 65.01, 70.65) | (5261.76, 5645.84, 5991.81; 4358.04, 5645.84, 7015.01) |

| 15 | (63.78, 70.04, 76.55; 51.07, 70.04, 89.78) | (7677.18, 8064.05, 8867.16; 6126.54, 8064.05, 9636.78) | (19, 20, 22; 15, 20, 26) | (0.52, 0.57, 0.61; 0.47, 0.57, 0.66) | (584.09, 620.65, 669.94; 524.75, 620.65, 682.95) | (30.85, 31.70, 33.29; 29.73, 31.70, 34.58) | (56.99, 58.44, 61.59; 55.32, 58.44, 63.24) | (6051.98, 6095.61, 6441.49; 4646.29, 6095.61, 7156.59) |

| 16 | (74.40, 80.81, 86.13; 62.02, 80.81, 96.29) | (7223.81, 7428.96, 7806.27; 5873.55, 7428.96, 8759.73) | (22, 23, 24; 16, 23, 33) | (0.46, 0.50, 0.52; 0.40, 0.50, 0.56) | (675.42, 715.00, 755.17; 584.31, 715.00, 820.17) | (30.16, 30.85, 33.27; 28.18, 30.85, 33.89) | (57.32, 59.10, 62.11; 54.46, 59.10, 64.93) | (5088.70, 5615.55, 5998.64; 4232.09, 5615.55, 6888.11) |

| 17 | (76.06, 81.65, 87.30; 64.10, 81.65, 95.18) | (7244.71, 7839.00, 8005.91; 5957.54, 7839.00, 9567.24) | (27, 29, 32; 22, 29, 36) | (0.54, 0.57, 0.61; 0.51, 0.57, 0.65) | (519.58, 552.63, 601.98; 464.77, 552.63, 627.10) | (43.03, 44.86, 47.24; 41.14, 44.86, 48.99) | (71.39, 73.69, 77.62; 68.71, 73.69, 80.83) | (5635.02, 5925.50, 6095.06; 4659.84, 5925.50, 7231.24) |

| 18 | (75.44, 78.70, 80.52; 56.76, 78.70, 91.59) | (5666.49, 5924.47, 6004.42; 4624.69, 5924.47, 7135.08) | (19, 20, 22; 15, 20, 28) | (0.56, 0.62, 0.67; 0.51, 0.62, 0.70) | (448.26, 483.38, 526.73; 409.50, 483.38, 538.69) | (30.61, 32.02, 34.24; 29.16, 32.02, 34.96) | (65.45, 67.95, 72.73; 61.80, 67.95, 73.97) | (4446.52, 4478.31, 4723.69; 3363.09, 4478.31, 5366.19) |

| 19 | (71.37, 77.66, 81.86; 62.07, 77.66, 97.87) | (6540.82, 7112.01, 7411.63; 5368.11, 7112.01, 8472.76) | (12, 16, 18; 8, 16, 23) | (0.61, 0.66, 0.69; 0.55, 0.66, 0.75) | (512.26, 561.05, 570.85; 480.81, 561.05, 621.17) | (34.48, 35.61, 37.64; 32.45, 35.61, 39.09) | (79.52, 81.96, 87.95; 76.06, 81.96, 89.16) | (5373.59, 5375.97, 5424.61; 4280.11, 5375.97, 6461.07) |

| 20 | (80.19, 82.25, 84.92; 65.04, 82.25, 100.19) | (6736.81, 7265.64, 7714.03; 5462.35, 7265.64, 8779.76) | (12, 16, 17; 8, 16, 24) | (0.70, 0.76, 0.83; 0.64, 0.76, 0.85) | (459.60, 502.84, 521.89; 423.45, 502.84, 560.36) | (34.88, 36.55, 38.80; 33.59, 36.55, 40.12) | (81.24, 84.48, 88.87; 77.91, 84.48, 92.92) | (5242.16, 5492.10, 5577.15; 4278.94, 5492.10, 6820.62) |

| 21 | (74.20, 80.45, 83.75; 61.76, 80.45, 101.40) | (6105.05, 6265.37, 6382.39; 4816.23, 6265.37, 7744.32) | (13, 15, 17; 5, 15, 21) | (0.63, 0.68, 0.73; 0.55, 0.68, 0.77) | (456.63, 490.97, 534.06; 429.86, 490.97, 553.12) | (32.69, 33.97, 36.55; 30.59, 33.97, 37.35) | (66.91, 69.38, 73.03; 65.43, 69.38, 76.12) | (4471.25, 4736.00, 5070.21; 3744.96, 4736.00, 5569.51) |

| 22 | (81.63, 83.46, 89.50; 64.05, 83.46, 102.43) | (4932.41, 5360.89, 5458.22; 4091.33, 5360.89, 6526.19) | (14, 16, 19; 10, 16, 26) | (0.67, 0.74, 0.80; 0.61, 0.74, 0.84) | (498.11, 548.59, 575.50; 476.54, 548.59, 626.35) | (31.35, 32.01, 33.77; 28.96, 32.01, 35.01) | (73.31, 76.98, 81.89; 71.74, 76.98, 84.55) | (3887.59, 4052.30, 4299.33; 3156.31, 4052.30, 4974.12) |

| 23 | (79.89, 86.51, 87.33; 62.37, 86.51, 111.44) | (5193.52, 5572.32, 5990.07; 4180.49, 5572.32, 6584.60) | (20, 22, 25; 14, 22, 28) | (0.60, 0.66, 0.71; 0.58, 0.66, 0.76) | (522.26, 575.15, 596.38; 489.47, 575.15, 643.49) | (35.03, 36.19, 38.15; 34.20, 36.19, 39.10) | (72.98, 74.83, 80.27; 68.33, 74.83, 80.89) | (4140.97, 4212.12, 4255.76; 3326.40, 4212.12, 5223.21) |

| 24 | (73.14, 73.17, 78.04; 56.80, 73.17, 90.29) | (6731.04, 6833.61, 6942.47; 5371.10, 6833.61, 8105.85) | (20, 21, 24; 14, 21, 26) | (0.56, 0.62, 0.66; 0.52, 0.62, 0.69) | (488.30, 533.26, 541.90; 464.54, 533.26, 607.57) | (31.35, 32.09, 34.55; 29.95, 32.09, 34.91) | (76.36, 80.36, 86.78; 74.59, 80.36, 87.20) | (4918.58, 5165.53, 5505.12; 3933.34, 5165.53, 6248.48) |

| 25 | (151.70, 160.17, 161.29; 126.72, 160.17, 197.73) | (18402.47, 20146.82, 20685.69; 25528.64, 20146.82, 23559.46) | (18, 19, 23; 13, 19, 28) | (0.60, 0.64, 0.70; 0.56, 0.64, 0.73) | (540.88, 592.52, 644.48; 492.17, 592.52, 659.93) | (30.95, 32.07, 34.37; 30.09, 32.07, 34.65) | (102.74, 105.33, 113.63; 99.03, 105.33, 115.81) | (14638.62, 15228.98, 16103.04; 11536.35, 15228.98, 17801.42) |

| 26 | (140.54, 152.70, 159.26; 119.35, 152.70, 197.83) | (16667.25, 17801.09, 18472.16; 13649.85, 17801.09, 21971.62) | (15, 16, 17; 8, 16, 26) | (0.58, 0.63, 0.67; 0.50, 0.63, 0.70) | (505.07, 560.40, 605.02; 487.82, 560.40, 616.68) | (48.33, 49.96, 53.68; 45.55, 49.96, 54.50) | (86.15, 88.17, 94.36; 82.31, 88.17, 95.97) | (12557.12, 13455.84, 13829.82; 10732.80, 13455.84, 15751.97) |

| 27 | (156.30, 158.56, 166.98; 119.24, 158.56, 195.10) | (16704.01, 18202.94, 18355.40; 13664.60, 18202.94, 22555.83) | (14, 18, 22; 11, 18, 23) | (0.67, 0.72, 0.79; 0.58, 0.72, 0.80) | (468.40, 497.07, 514.37; 429.51, 497.07, 570.78) | (43.18, 44.89, 47.23; 42.62, 44.89, 48.56) | (114.35, 117.18, 123.41; 105.56, 117.18, 128.45) | (12919.22, 13759.61, 14210.30; 10756.84, 13759.61, 16691.68) |

| 28 | (128.77, 130.14, 130.43; 102.92, 130.14, 163.95) | (19024.08, 19621.13, 19752.61; 15545.15, 19621.13, 23563.44) | (17, 19, 23; 14, 19, 27) | (0.61, 0.65, 0.71; 0.53, 0.65, 0.73) | (476.52, 520.81, 553.40; 424.58, 520.81, 574.09) | (30.99, 31.88, 34.36; 30.28, 31.88, 34.65) | (91.41, 94.64, 100.06; 89.53, 94.64, 103.23) | (13499.19, 14831.61, 16269.87; 11309.59, 14831.61, 18268.97) |

Appendix D. Production Process Data of Complex Product Systems—The Assembly Stage of Supporting Components

| Serial Number | Industrial Added Value (Ten Thousand Yuan) | Manufacturing Services | Finished Product Value (Ten Thousand Yuan) | Environmental Impact | Supporting Components for Assembly (t) | ||||

| Energy Consumption (kW·h) | Technical Staff | Manufacture Service Factor | Solid Waste (t) | Average Noise (dB) | Carbon Emission (kg) | ||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | (469.47, 500.00, 538.13; 423.31, 500.00, 555.31) | (1842.50, 2000.00, 2189.51; 1567.00, 2000.00, 2447.79) | (4, 5, 6; 2, 5, 8) | (0.71, 0.75, 0.77; 0.66, 0.75, 0.85) | (401.65, 432.00, 466.29; 346.66, 432.00, 452.10) | (19.01, 20.00, 21.28; 18.61, 20.00, 21.93) | (48.67, 50.00, 53.26; 46.51, 50.00, 54.43) | (1457.64, 1511.80, 1648.01; 1172.96, 1511.80, 1855.35) | (43.48, 45.00, 47.28; 42.63, 45.00, 48.68) |

| 2 | (474.62, 525.70, 549.02; 455.05, 525.70, 597.74) | (2260.32, 2322.78, 2355.29; 1760.06, 2322.78, 2852.35) | (5, 7, 9; 4, 7, 11) | (0.68, 0.75, 0.84; 0.65, 0.75, 0.85) | (385.62, 416.45, 449.05; 346.14, 416.45, 423.51) | (20.83, 21.44, 23.08; 20.23, 21.44, 23.34) | (49.91, 52.51, 56.00; 48.62, 52.51, 56.94) | (1665.93, 1755.79, 1827.82; 1368.66, 1755.79, 2092.56) | (39.84, 41.02, 43.22; 38.59, 41.02, 44.99) |

| 3 | (480.42, 521.55, 556.36; 428.19, 521.55, 586.08) | (1965.93, 2121.82, 2134.04; 1635.85, 2121.82, 2503.95) | (4, 6, 9; 4, 6, 10) | (0.77, 0.82, 0.87; 0.70, 0.82, 0.93) | (378.44, 416.04, 439.69; 352.22, 416.04, 446.00) | (19.69, 20.72, 22.20; 19.20, 20.72, 22.62) | (49.42, 51.46, 54.81; 47.35, 51.46, 56.08) | (1445.44, 1603.89, 1712.37; 1245.25, 1603.89, 1995.86) | (37.81, 39.39, 41.90; 36.90, 39.39, 42.96) |

| 4 | (466.45, 516.67, 543.77; 449.56, 516.67, 588.00) | (1868.12, 2067.97, 2125.89; 1627.74, 2067.97, 2388.60) | (2, 4, 4; 2, 4, 7) | (0.73, 0.78, 0.84; 0.64, 0.78, 0.89) | (384.42, 418.85, 446.90; 338.63, 418.85, 467.66) | (20.40, 21.11, 22.66; 19.84, 21.11, 23.07) | (43.70, 45.04, 47.61; 41.39, 45.04, 49.34) | (1559.51, 1563.18, 1605.11; 1184.05, 1563.18, 1803.70) | (38.78, 40.54, 43.69; 37.33, 40.54, 44.37) |

| 5 | (426.51, 466.97, 475.31; 401.54, 466.97, 530.58) | (2058.56, 2081.25, 2145.60; 1623.29, 2081.25, 2481.91) | (5, 5, 7; 2, 5, 9) | (0.75, 0.81, 0.83; 0.68, 0.81, 0.91) | (359.80, 391.37, 414.74; 325.05, 391.37, 439.74) | (20.67, 21.71, 23.14; 20.29, 21.71, 23.66) | (45.19, 46.47, 49.81; 43.55, 46.47, 50.72) | (1481.09, 1573.22, 1703.62; 1183.60, 1573.22, 1850.37) | (39.47, 41.35, 43.78; 39.27, 41.35, 45.39) |

| 6 | (602.08, 660.00, 704.53; 564.68, 660.00, 741.44) | (2495.99, 2500.00, 2596.04; 1958.18, 2500.00, 3059.71) | (15, 15, 16; 12, 15, 19) | (0.72, 0.79, 0.85; 0.64, 0.79, 0.89) | (651.87, 689.00, 741.18; 582.00, 689.00, 768.70) | (24.49, 25.00, 26.32; 22.77, 25.00, 27.43) | (61.79, 65.00, 69.46; 61.32, 65.00, 70.69) | (1745.23, 1889.75, 2038.93; 1441.38, 1889.75, 2318.25) | (57.25, 60.00, 64.02; 54.14, 60.00, 64.84) |

| 7 | (587.72, 628.46, 673.13; 505.07, 628.46, 693.76) | (2433.34, 2620.47, 2663.29; 2084.97, 2620.47, 3272.52) | (16, 17, 17; 16, 17, 20) | (0.71, 0.76, 0.80; 0.64, 0.76, 0.86) | (590.49, 632.71, 681.95; 518.72, 632.71, 704.83) | (25.33, 26.27, 28.36; 24.70, 26.27, 28.68) | (63.59, 65.39, 68.80; 60.50, 65.39, 71.23) | (1806.08, 1980.82, 2000.51; 1512.14, 1980.82, 2412.48) | (68.94, 71.58, 76.11; 66.73, 71.58, 77.69) |

| 8 | (626.06, 665.05, 697.05; 537.53, 665.05, 741.60) | (2440.63, 2704.84, 2852.28; 2115.32, 2704.84, 3221.11) | (13, 16, 19; 13, 16, 19) | (0.78, 0.85, 0.92; 0.74, 0.85, 0.95) | (543.68, 573.39, 603.65; 461.64, 573.39, 640.30) | (24.48, 25.20, 27.13; 22.97, 25.20, 27.70) | (67.81, 70.86, 76.35; 67.13, 70.86, 77.30) | (1940.15, 2044.59, 2080.93; 1548.78, 2044.59, 2455.70) | (72.19, 75.80, 79.89; 69.97, 75.80, 83.14) |

| 9 | (666.48, 722.50, 761.42; 590.73, 722.50, 810.06) | (2638.48, 2756.38, 2983.24; 2122.47, 2756.38, 3363.44) | (13, 13, 14; 12, 13, 15) | (0.76, 0.80, 0.88; 0.68, 0.80, 0.92) | (530.41, 564.89, 598.16; 476.66, 564.89, 604.77) | (24.53, 25.48, 27.04; 23.62, 25.48, 27.86) | (69.58, 72.63, 77.86; 67.37, 72.63, 79.27) | (1941.59, 2083.55, 2230.80; 1596.49, 2083.55, 2509.07) | (69.83, 71.66, 77.10; 65.08, 71.66, 78.11) |

| 10 | (574.50, 628.67, 662.99; 542.58, 628.67, 719.88) | (2371.66, 2549.52, 2668.76; 1949.18, 2549.52, 3005.13) | (12, 13, 14; 10, 13, 17) | (0.79, 0.85, 0.86; 0.69, 0.85, 0.98) | (441.54, 465.40, 490.24; 380.07, 465.40, 482.78) | (22.52, 23.01, 24.45; 20.92, 23.01, 25.08) | (68.63, 70.42, 75.87; 66.62, 70.42, 76.46) | (1738.65, 1927.18, 2015.39; 1481.74, 1927.18, 2369.82) | (60.00, 62.80, 66.39; 56.54, 62.80, 68.01) |

| 11 | (569.53, 600.00, 653.86; 501.15, 600.00, 681.74) | (2724.16, 3000.00, 3268.96; 2387.06, 3000.00, 3562.28) | (9, 10, 12; 8, 10, 12) | (0.66, 0.70, 0.70; 0.61, 0.70, 0.79) | (450.22, 500.00, 533.76; 403.11, 500.00, 553.83) | (21.41, 22.00, 23.10; 20.13, 22.00, 24.01) | (52.36, 55.00, 58.10; 51.84, 55.00, 60.01) | (2174.85, 2267.70, 2430.50; 1761.32, 2267.70, 2647.20) | (53.32, 55.00, 58.79; 50.25, 55.00, 60.20) |

| 12 | (626.33, 695.40, 761.94; 582.26, 695.40, 773.26) | (3429.60, 3498.19, 3642.89; 2792.99, 3498.19, 4254.95) | (9, 10, 14; 9, 10, 14) | (0.81, 0.86, 0.87; 0.74, 0.86, 0.98) | (625.01, 682.91, 721.83; 568.23, 682.91, 717.05) | (32.73, 34.22, 36.10; 30.88, 34.22, 37.52) | (66.49, 69.85, 74.06; 66.03, 69.85, 75.65) | (2508.58, 2644.28, 2664.42; 2105.10, 2644.28, 3236.97) | (64.76, 66.16, 69.78; 59.99, 66.16, 72.68) |

| 13 | (489.61, 537.85, 563.82; 468.40, 537.85, 606.46) | (2905.11, 3194.80, 3202.58; 2475.80, 3194.80, 3857.93) | (10, 11, 11; 9, 11, 14) | (0.69, 0.75, 0.83; 0.66, 0.75, 0.85) | (646.03, 711.48, 753.86; 587.85, 711.48, 725.33) | (40.52, 42.57, 45.17; 40.37, 42.57, 46.79) | (43.94, 46.02, 49.62; 41.68, 46.02, 49.86) | (2270.61, 2414.95, 2576.03; 1906.36, 2414.95, 2991.60) | (51.95, 53.04, 55.74; 48.71, 53.04, 57.91) |

| 14 | (619.81, 667.42, 682.44; 560.31, 667.42, 745.27) | (3023.26, 3251.42, 3327.00; 2578.78, 3251.42, 3814.43) | (11, 13, 14; 11, 13, 17) | (0.74, 0.78, 0.78; 0.68, 0.78, 0.89) | (424.64, 455.07, 484.48; 377.44, 455.07, 468.90) | (44.26, 45.74, 48.07; 42.84, 45.74, 50.19) | (57.14, 59.30, 63.16; 54.47, 59.30, 64.49) | (2454.10, 2457.75, 2560.44; 1959.66, 2457.75, 2916.49) | (51.25, 52.91, 57.07; 48.84, 52.91, 57.79) |

| 15 | (584.09, 620.65, 669.94; 524.75, 620.65, 682.95) | (3106.04, 3272.78, 3305.69; 2616.32, 3272.78, 3786.76) | (7, 8, 9; 5, 8, 11) | (0.61, 0.66, 0.67; 0.55, 0.66, 0.76) | (515.16, 558.04, 587.29; 448.07, 558.04, 608.51) | (43.96, 45.48, 48.20; 42.21, 45.48, 49.34) | (42.87, 44.54, 46.93; 40.87, 44.54, 48.45) | (2308.19, 2473.90, 2568.66; 1973.03, 2473.90, 2907.73) | (51.07, 52.63, 55.33; 48.39, 52.63, 57.60) |

| 16 | (675.42, 715.00, 755.17; 584.31, 715.00, 820.17) | (3040.49, 3082.08, 3223.19; 2384.56, 3082.08, 3743.65) | (10, 10, 12; 7, 10, 13) | (0.61, 0.68, 0.70; 0.57, 0.68, 0.77) | (599.37, 640.22, 674.42; 529.00, 640.22, 703.61) | (36.89, 38.17, 40.08; 36.03, 38.17, 41.76) | (48.37, 49.61, 53.38; 45.77, 49.61, 54.25) | (2291.89, 2329.74, 2562.50; 1751.21, 2329.74, 2761.33) | (61.46, 63.78, 67.99; 58.54, 63.78, 69.42) |

| 17 | (519.58, 552.63, 601.98; 464.77, 552.63, 627.10) | (3304.11, 3362.11, 3499.96; 2666.83, 3362.11, 3886.99) | (7, 8, 10; 6, 8, 11) | (0.64, 0.68, 0.73; 0.58, 0.68, 0.77) | (540.40, 587.22, 634.01; 485.41, 587.22, 608.90) | (38.37, 40.11, 43.22; 37.91, 40.11, 44.04) | (54.96, 57.81, 61.27; 54.84, 57.81, 62.62) | (2381.45, 2541.42, 2543.63; 2023.55, 2541.42, 2947.02) | (65.33, 68.74, 74.06; 63.57, 68.74, 75.52) |

| 18 | (448.26, 483.38, 526.73; 409.50, 483.38, 538.69) | (3001.62, 3291.89, 3361.45; 2469.12, 3291.89, 3828.16) | (8, 10, 11; 7, 10, 12) | (0.83, 0.91, 0.97; 0.80, 0.91, 1.03) | (502.41, 545.39, 586.45; 450.24, 545.39, 599.05) | (41.81, 43.80, 46.46; 40.19, 43.80, 47.77) | (48.21, 50.60, 54.64; 47.14, 50.60, 54.93) | (2259.91, 2488.34, 2492.17; 1930.02, 2488.34, 3044.45) | (67.94, 69.98, 74.29; 65.62, 69.98, 76.81) |

| 19 | (512.26, 561.05, 570.85; 480.81, 561.05, 621.17) | (3197.18, 3502.87, 3603.31; 2700.58, 3502.87, 4190.83) | (6, 8, 11; 6, 8, 11) | (0.99, 1.10, 1.12; 0.96, 1.10, 1.23) | (576.72, 618.05, 662.02; 515.98, 618.05, 671.15) | (43.04, 44.55, 48.03; 41.76, 44.55, 48.44) | (48.93, 50.19, 53.61; 45.25, 50.19, 54.99) | (2536.21, 2647.82, 2830.49; 2091.24, 2647.82, 3077.78) | (77.87, 80.47, 85.86; 72.91, 80.47, 88.18) |

| 20 | (459.60, 502.84, 521.89; 423.45, 502.84, 560.36) | (3372.92, 3395.09, 3553.36; 2638.94, 3395.09, 4142.53) | (11, 12, 12; 10, 12, 16) | (0.99, 1.04, 1.07; 0.90, 1.04, 1.18) | (661.05, 717.57, 764.42; 577.65, 717.57, 777.55) | (47.76, 49.80, 52.49; 45.40, 49.80, 53.95) | (60.64, 62.98, 67.10; 58.77, 62.98, 69.26) | (2379.52, 2566.35, 2757.87; 2005.02, 2566.35, 3206.49) | (74.14, 77.69, 82.84; 72.34, 77.69, 84.74) |

| 21 | (456.63, 490.97, 534.06; 429.86, 490.97, 553.12) | (3318.97, 3490.68, 3760.02; 2623.95, 3490.68, 4290.91) | (8, 10, 11; 8, 10, 13) | (1.01, 1.12, 1.23; 0.97, 1.12, 1.27) | (610.55, 676.59, 730.03; 574.13, 676.59, 703.65) | (50.82, 52.22, 56.21; 47.08, 52.22, 56.70) | (58.86, 60.70, 63.85; 54.74, 60.70, 66.40) | (2616.62, 2638.60, 2872.60; 2011.18, 2638.60, 3113.83) | (72.07, 74.47, 79.52; 68.47, 74.47, 81.47) |

| 22 | (498.11, 548.59, 575.50; 476.54, 548.59, 626.35) | (3468.80, 3602.55, 3901.66; 2865.83, 3602.55, 4226.72) | (11, 12, 14; 9, 12, 15) | (0.86, 0.92, 0.99; 0.78, 0.92, 1.03) | (722.10, 784.30, 828.60; 631.01, 784.30, 863.05) | (43.71, 44.87, 47.32; 41.29, 44.87, 49.33) | (52.47, 54.48, 57.34; 50.78, 54.48, 59.58) | (2546.37, 2723.16, 2970.79; 2147.81, 2723.16, 3154.55) | (83.53, 85.79, 91.62; 81.46, 85.79, 93.31) |

| 23 | (522.26, 575.15, 596.38; 489.47, 575.15, 643.49) | (3639.29, 3851.95, 3945.23; 3009.00, 3851.95, 4806.20) | (9, 9, 11; 8, 9, 12) | (0.94, 1.00, 1.02; 0.87, 1.00, 1.14) | (712.27, 783.82, 837.70; 632.28, 783.82, 873.32) | (51.35, 52.75, 56.11; 49.78, 52.75, 56.98) | (58.42, 60.68, 64.63; 55.22, 60.68, 65.74) | (2672.70, 2911.69, 3044.14; 2286.25, 2911.69, 3606.41) | (66.59, 69.48, 74.17; 64.81, 69.48, 75.54) |

| 24 | (488.30, 533.26, 541.90; 464.54, 533.26, 607.57) | (3198.99, 3473.19, 3804.26; 2765.64, 3473.19, 4314.16) | (9, 10, 11; 9, 10, 12) | (0.89, 0.96, 0.97; 0.78, 0.96, 1.11) | (749.55, 816.57, 873.43; 670.14, 816.57, 862.17) | (45.46, 46.74, 49.68; 42.32, 46.74, 51.06) | (51.78, 54.09, 56.92; 50.96, 54.09, 59.25) | (2572.92, 2625.39, 2692.99; 2010.35, 2625.39, 3129.63) | (69.21, 72.69, 76.90; 67.01, 72.69, 79.10) |

| 25 | (540.88, 592.52, 644.48; 492.17, 592.52, 659.93) | (5063.60, 5446.62, 5585.51; 4127.39, 5446.62, 6392.35) | (12, 12, 13; 11, 12, 15) | (1.04, 1.13, 1.26; 0.96, 1.13, 1.28) | (923.17, 979.25, 1057.51; 804.86, 979.25, 1042.43) | (47.16, 49.54, 52.27; 45.43, 49.54, 54.41) | (71.13, 73.49, 78.26; 68.05, 73.49, 79.91) | (3859.89, 4117.10, 4119.80; 3225.97, 4117.10, 4977.09) | (90.94, 93.51, 98.24; 87.54, 93.51, 101.01) |

| 26 | (505.07, 560.40, 605.02; 487.82, 560.40, 616.68) | (4511.81, 4824.96, 5113.90; 3636.56, 4824.96, 5572.80) | (8, 9, 9; 6, 9, 11) | (0.88, 0.94, 0.94; 0.81, 0.94, 1.06) | (1009.21, 1078.89, 1135.93; 912.97, 1078.89, 1085.66) | (61.09, 62.51, 67.35; 58.07, 62.51, 67.82) | (78.41, 81.28, 86.43; 76.40, 81.28, 89.19) | (3574.15, 3647.19, 3963.75; 2815.71, 3647.19, 4383.99) | (108.77, 111.93, 118.09; 102.05, 111.93, 121.25) |

| 27 | (468.40, 497.07, 514.37; 429.51, 497.07, 570.78) | (4171.52, 4207.95, 4359.60; 3323.04, 4207.95, 5209.21) | (11, 12, 12; 11, 12, 15) | (1.05, 1.12, 1.22; 0.97, 1.12, 1.26) | (712.08, 769.74, 829.39; 647.19, 769.74, 785.59) | (66.38, 68.10, 72.91; 64.36, 68.10, 74.46) | (77.12, 79.68, 85.47; 73.60, 79.68, 87.60) | (2934.89, 3180.79, 3428.98; 2472.76, 3180.79, 3671.67) | (110.68, 113.99, 120.91; 106.45, 113.99, 124.81) |

| 28 | (476.52, 520.81, 553.40; 424.58, 520.81, 574.09) | (4361.31, 4743.83, 4768.99; 3761.15, 4743.83, 5681.57) | (10, 11, 11; 9, 11, 15) | (0.96, 1.03, 1.12; 0.88, 1.03, 1.17) | (995.86, 1052.40, 1129.03; 848.24, 1052.40, 1204.17) | (54.20, 57.03, 61.06; 52.92, 57.03, 62.21) | (61.62, 64.48, 67.75; 60.72, 64.48, 70.60) | (3511.57, 3585.86, 3612.39; 2798.33, 3585.86, 4294.37) | (108.32, 111.16, 117.92; 100.81, 111.16, 122.12) |

References

- Zhou, J.; Zhu, J.; Wang, H. Strategic cooperation with capital-constrained supplier and downstream competition in complex product systems. Comput. Ind. Eng. 2020, 139, 106139. [Google Scholar] [CrossRef]

- Du, B.; Tan, T.; Guo, J.; Li, Y.; Guo, S. Energy-cost-aware resource-constrained project scheduling for complex product system with activity splitting and recombining. Expert Syst. Appl. 2021, 173, 114754. [Google Scholar] [CrossRef]

- Wang, X.; Orelaja, O.A.; Ibrahim, D.S.; Ogbonna, S.M. Evaluation of noise risk level and its consequences on technical operators of tobacco processing equipment in a cigarette producing company in Nigeria. Sci. Afr. 2020, 8, e00344. [Google Scholar] [CrossRef]

- Ding, T.; Wu, H.; Jia, J.; Wei, Y.; Liang, L. Regional assessment of water-energy nexus in China’s industrial sector: An interactive meta-frontier DEA approach. J. Clean. Prod. 2020, 244, 118797. [Google Scholar] [CrossRef]

- Wang, M.; Huang, Y.; Li, D. Assessing the performance of industrial water resource utilization systems in China based on a two-stage DEA approach with game cross efficiency. J. Clean. Prod. 2021, 312, 127722. [Google Scholar] [CrossRef]

- Guo, K.; Cao, Y.; Wang, Z.; Li, Z. Urban and industrial environmental pollution control in China: An analysis of capital input, efficiency and influencing factors. J. Environ. Manag. 2022, 316, 115198. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, J.; Choi, G. A two-stage eco-efficiency evaluation of China’s industrial sectors: A dynamic network data envelopment analysis (DNDEA) approach. Process Saf. Environ. Prot. 2021, 148, 879–892. [Google Scholar] [CrossRef]

- Zhang, X.; Ming, X.; Liu, Z.; Qu, Y.; Yin, D. General reference model and overall frameworks for green manufacturing. J. Clean. Prod. 2019, 237, 117757. [Google Scholar] [CrossRef]

- Hole, G.; Hole, A.S. Recycling as the way to greener production: A mini review. J. Clean. Prod. 2019, 212, 910–915. [Google Scholar] [CrossRef]

- Nandy, S.; Fortunato, E.; Martins, R. Green economy and waste management: An inevitable plan for materials science. Prog. Nat. Sci. Mater. Int. 2022, 32, 1–9. [Google Scholar] [CrossRef]

- Zhang, L.; Du, X.; Chiu, Y.-H.; Pang, Q.; Wang, X.; Yu, Q. Measuring industrial operational efficiency and factor analysis: A dynamic series-parallel recycling DEA model. Sci. Total Environ. 2022, 851 Pt 1, 158084. [Google Scholar] [CrossRef]

- Zhang, L.; Zhuang, Y.; Chiu, Y.-H.; Pang, Q.; Chen, Z.; Shi, Z. Measuring urban integrated water use efficiency and spatial migration path in China: A dynamic two-stage recycling model within the directional distance function. J. Environ. Manag. 2021, 298, 113379. [Google Scholar] [CrossRef]

- Chu, J.; Wu, J.; Chu, C.; Liu, M. A new DEA common-weight multi-criteria decision-making approach for technology selection. Int. J. Prod. Res. 2020, 58, 3686–3700. [Google Scholar] [CrossRef]

- Sun, J.; Li, G.; Wang, Z. Technology heterogeneity and efficiency of China’s circular economic systems: A game meta-frontier DEA approach. Resour. Conserv. Recycl. 2019, 146, 337–347. [Google Scholar] [CrossRef]

- Ding, L.-L.; Lei, L.; Wang, L.; Zhang, L.-F. Assessing industrial circular economy performance and its dynamic evolution: An extended Malmquist index based on cooperative game network DEA. Sci. Total Environ. 2020, 731, 139001. [Google Scholar] [CrossRef]

- Kao, C. Efficiency decomposition for parallel production systems. J. Oper. Res. Soc. 2017, 63, 64–71. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, Z.; Chai, J.; Yao, L.; Wang, S.; Lev, B. Efficiency evaluation for banking systems under uncertainty: A multi-period three-stage DEA model. Omega 2019, 85, 68–82. [Google Scholar] [CrossRef]

- Leng, J.; Zhang, H.; Yan, D.; Liu, Q.; Chen, X.; Zhang, D. Digital twin-driven manufacturing cyber-physical system for parallel controlling of smart workshop. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1155–1166. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, X.; Wang, L. Smart manufacturing process and system automation—A critical review of the standards and envisioned scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Zhang, K.; Wan, M.; Qu, T.; Jiang, H.; Li, P.; Chen, Z.; Xiang, J.; He, X.; Li, C.; Huang, G.Q. Production service system enabled by cloud-based smart resource hierarchy for a highly dynamic synchronized production process. Adv. Eng. Inform. 2019, 42, 100995. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, L.; Li, X.; Pang, S. A multi-attribute personalized recommendation method for manufacturing service composition with combining collaborative filtering and genetic algorithm. J. Manuf. Syst. 2021, 58, 348–364. [Google Scholar] [CrossRef]

- Guo, S.; Gao, Y.; Guo, J.; Yang, Z.; Du, B.; Li, Y. A multi-stage group decision making for strategic supplier selection based on prospect theory with interval-valued q-rung orthopair fuzzy linguistic sets. J. Intell. Fuzzy Syst. 2021, 40, 9855–9871. [Google Scholar] [CrossRef]

- Xu, M.; Liu, S.; Xu, Z.; Zhou, W. DEA Evaluation Method Based on Interval Intuitionistic Bayesian Network and Its Application in Enterprise Logistics. IEEE Access 2019, 7, 98277–98289. [Google Scholar] [CrossRef]

- Arya, A.; Yadav, S.P. Development of intuitionistic fuzzy data envelopment analysis models and intuitionistic fuzzy input–output targets. Soft Comput. 2018, 23, 8975–8993. [Google Scholar] [CrossRef]

- Deng, X.; Fang, W. A novel mean-variance-maverick DEA prospect cross-efficiency approach for fuzzy portfolio selection. J. Intell. Fuzzy Syst. 2019, 37, 8113–8130. [Google Scholar] [CrossRef]

- Tavassoli, M.; Saen, R.F.; Zanjirani, D.M. Assessing sustainability of suppliers: A novel stochastic-fuzzy DEA model. Sustain. Prod. Consum. 2020, 21, 78–91. [Google Scholar] [CrossRef]

- Aparicio, J.; Kapelko, M.; Ortiz, L. Enhancing the measurement of firm inefficiency accounting for corporate social responsibility: A dynamic data envelopment analysis fuzzy approach. Eur. J. Oper. Res. 2022. [CrossRef]

- Singh, N.; Pant, M. Efficiency assessment of Indian paper mills through fuzzy DEA. Mater. Manuf. Processes 2020, 35, 725–736. [Google Scholar] [CrossRef]

- Farrell, M.J. The Measurement of Productive Efficiency. J. R. Stat. Society. Ser. A (Gen.) 1957, 120, 253–290. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision-making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Lee, H.S.; Choi, Y. Environmental performance evaluation of the Korean manufacturing industry based on sequential DEA. Sustainability 2019, 11, 874. [Google Scholar] [CrossRef] [Green Version]

- Ostovan, S.; Mozaffari, M.R.; Jamshidi, A.; Gerami, J. Evaluation of Two-Stage Networks Based on Average Efficiency Using DEA and DEA-R with Fuzzy Data. Int. J. Fuzzy Syst. 2020, 22, 1665–1678. [Google Scholar] [CrossRef]

- Guo, C.; Shureshjani, R.A.; Foroughi, A.A.; Zhu, J. Decomposition weights and overall efficiency in two-stage additive network DEA. Eur. J. Oper. Res. 2017, 257, 896–906. [Google Scholar] [CrossRef]

- Broekel, T.; Rogge, N.; Brenner, T. The innovation efficiency of German regions—A shared-input DEA approach. Rev. Reg. Res. 2018, 38, 77–109. [Google Scholar] [CrossRef] [Green Version]

- Fukuyama, H.; Matousek, R.; Tzeremes, N.G. A Nerlovian cost inefficiency two-stage DEA model for modeling banks’ production process: Evidence from the Turkish banking system. Omega 2020, 95, 102198. [Google Scholar] [CrossRef]

- Shamohammadi, M.; Oh, D.-H. Measuring the efficiency changes of private universities of Korea: A two-stage network data envelopment analysis. Technol. Forecast. Soc. Chang. 2019, 148, 119730. [Google Scholar] [CrossRef]

- Ameri, Z.; Sana, S.S.; Sheikh, R. Self-assessment of parallel network systems with intuitionistic fuzzy data: A case study. Soft Comput. 2019, 23, 12821–12832. [Google Scholar] [CrossRef]

- Chen, X.; Liu, X.; Gong, Z.; Xie, J. Three-stage super-efficiency DEA models based on the cooperative game and its application on the R&D green innovation of the Chinese high-tech industry. Comput. Ind. Eng. 2021, 156, 107234. [Google Scholar]

- Shuai, S.; Fan, Z. Modeling the role of environmental regulations in regional green economy efficiency of China: Empirical evidence from super efficiency DEA-Tobit model. J. Environ. Manag. 2020, 261, 110227. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, Z.; Yao, L.; Tu, Y.; Lev, B.; Pedrycz, W. A novel Data Envelopment Analysis model for evaluating industrial production and environmental management system. J. Clean. Prod. 2018, 170, 773–788. [Google Scholar] [CrossRef]

- Ahmadvand, S.; Pishvaee, M.S. An efficient method for kidney allocation problem: A credibility-based fuzzy common weights data envelopment analysis approach. Health Care Manag. Sci. 2018, 21, 587–603. [Google Scholar] [CrossRef] [PubMed]

- Arya, A.; Yadav, S.P. Performance Efficiency of Public Health Sector Using Intuitionistic Fuzzy DEA. Int. J. Uncertain. Fuzziness Knowl. Based Syst. 2020, 28, 289–315. [Google Scholar] [CrossRef]

- Chien, L.; Chi, S. An integrated data envelopment approach for evaluating the meat companies efficiency. Agric. Econ. 2019, 65, 470–480. [Google Scholar] [CrossRef]

- Soltani, M.R.; Edalatpanah, S.A.; Sobhani, F.M.; Najafi, S.E. A Novel Two-Stage DEA Model in Fuzzy Environment: Application to Industrial Workshops Performance Measurement. Int. J. Comput. Intell. Syst. 2020, 13, 1134–1152. [Google Scholar] [CrossRef]

- Singh, S. Intuitionistic fuzzy DEA/AR and its application to flexible manufacturing systems. RAIRO-Oper. Res. 2018, 52, 241–257. [Google Scholar] [CrossRef] [Green Version]

- Arya, A.; Singh, S. Development of two-stage parallel-series system with fuzzy data: A fuzzy DEA approach. Soft Comput. 2020, 25, 3225–3245. [Google Scholar] [CrossRef]

- Davoudabadi, R.; Mousavi, S.M.; Mohagheghi, V. A new decision model based on DEA and simulation to evaluate renewable energy projects under interval-valued intuitionistic fuzzy uncertainty. Renew. Energy 2021, 164, 1588–1601. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, F. Does increasing investment in research and development promote economic growth decoupling from carbon emission growth? An empirical analysis of BRICS countries. J. Clean. Prod. 2020, 252, 119853. [Google Scholar] [CrossRef]

- Murrell, J.; Kehoe, D.; Aysola, M.; Jing, D.; Punreddy, S.; Verma, A.; Mann, K.; Lawson, T.; Rook, M. Single use expansion and harvest of adult stem cells supports large scale manufacturing. Cytotherapy 2014, 16, S73. [Google Scholar] [CrossRef]

- Willmann, J.; Stocker, D.; Dörsam, E. Characteristics and evaluation criteria of substrate-based manufacturing. Is roll-to-roll the best solution for printed electronics? Org. Electron. 2014, 15, 1631–1640. [Google Scholar] [CrossRef] [Green Version]

- Amaral, M.C.D.; Zonatti, W.F.; Silva, K.L.D.; Karam Junior, D.; Amato Neto, J.; Baruque-Ramos, J. Industrial textile recycling and reuse in Brazil: Case study and considerations concerning the circular economy. Gestão Produção 2018, 25, 431–443. [Google Scholar] [CrossRef]

- Ali, A.K.; Wang, Y.; Alvarado, J.L. Facilitating industrial symbiosis to achieve circular economy using value-added by design: A case study in transforming the automobile industry sheet metal waste-flow into Voronoi facade systems. J. Clean. Prod. 2019, 234, 1033–1044. [Google Scholar] [CrossRef]

- Paulillo, A.; Striolo, A.; Lettieri, P. Data on the environmental impacts of the Hellisheiethi geothermal plant and on the carbon intensity of geothermal energy and other energy technologies. Data Brief 2019, 27, 104771. [Google Scholar] [CrossRef]

- Wen, Y. Combined material recycling study with aesthetic of entropy and place making. Sci. World J. 2015, 2015, 208342. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, Z.; Tian, G.; Fathollahi-Fard, A.M.; Hao, N.; Li, Z.; Wang, W.; Tan, J. A Novel Hybrid Fuzzy Grey TOPSIS Method: Supplier Evaluation of a Collaborative Manufacturing Enterprise. Appl. Sci. 2019, 9, 3770. [Google Scholar] [CrossRef] [Green Version]

- Rani, P.; Mishra, A.R.; Mardani, A.; Cavallaro, F.; Alrasheedi, M.; Alrashidi, A. A novel approach to extended fuzzy TOPSIS based on new divergence measures for renewable energy sources selection. J. Clean. Prod. 2020, 257, 120352. [Google Scholar] [CrossRef]

- Arya, A.; Yadav, S.P. Development of intuitionistic fuzzy super-efficiency slack based measure with an application to health sector. Comput. Ind. Eng. 2018, 115, 368–380. [Google Scholar] [CrossRef]

| Set and Indices | Description |

|---|---|

| Indices | |

| Index of raw materials, where b = 1, 2, …, B. | |

| Index of environment influence, where = 1, 2, …, I. | |

| Index of manufacturing services, where h = 1, 2, …, H. | |

| Index of part products, where n = 1, 2, …, N. | |

| Index of reused solid wastes, where k = 1, 2, …, K. | |

| Index of end products, where a = 1, 2, …, A. | |

| Index of supporting products, where d = 1, 2, …, D. | |

| Index of evaluated manufacturing types, where j = 1, 2, …, | |

| Index of manufacturing types being evaluated. | |

| Paremeters | |

| Number of raw materials. | |

| Number of environment influences. | |

| Number of manufacturing services. | |

| Number of part products. | |

| Number of reused solid wastes. | |

| Number of end products. | |

| Number of supporting products. | |

| Number of evaluated manufacturing types. | |

| Minimum efficiency evaluation. | |

| Maximum efficiency evaluation. | |

| The min/max efficiencies | |

| The minimum efficiency of evaluated manufacturing type in DMU 1 under | |

| The maximum efficiency of evaluated manufacturing type in DMU 1 under | |

| The minimum efficiency of evaluated manufacturing type in DMU 1 under | |

| The maximum efficiency of evaluated manufacturing type in DMU 1 under | |

| The weights of each variate (inputs, outputs, and intermediates) | |

| The weight of part product n of evaluated manufacturing type in minimum efficiency evaluation DMU 1. | |

| The weight of reuse solid waste k of evaluated manufacturing type in minimum efficiency evaluation DMU 1. | |

| The weight of environmental influence 1i of evaluated manufacturing type in minimum efficiency evaluation DMU 1 (superscript number 1 means the index of DMUs and subscript number 1 denotes the index of environment influence). | |

| The weight of raw material 1b of evaluated manufacturing type in minimum efficiency evaluation (superscript number 1 means the index of DMUs). | |

| The weight of manufacturing service 1h of evaluated manufacturing type in minimum efficiency evaluation DMU 1 (superscript number 1 means the index of DMUs and subscript number 1 denotes the index of manufacturing services). | |

| The weight of part product 1n of evaluated manufacturing type in minimum efficiency evaluation DMU 1 (superscript number 1 means the index of DMUs and subscript number 1 denotes the index of part products). | |

| The weight of reused solid waste 1k of evaluated manufacturing type in minimum efficiency evaluation DMU 1 (superscript number 1 means the index of DMUs and subscript number 1 denotes the index of reuse solid waste). | |

| The weight of end product 1a of evaluated manufacturing type in minimum efficiency evaluation DMU 1 (subscript number 1 denotes the index of end products). | |

| The weight of supporting product 1d of evaluated manufacturing type in minimum efficiency evaluation DMU 1 (subscript number 1 denotes the index of supporting products). | |

| The intuitionistic fuzzy numbers of each variate | |

| The intuitionistic fuzzy number medium m of part product p1n of evaluated manufacturing type jo in DMU 1(subscript number 1 denotes the index of DMUs and superscript l means the low value of membership degree in the intuitionistic fuzzy number). | |

| The intuitionistic fuzzy number medium m of reuse solid waste Reu1k of evaluated manufacturing type in DMU 1 (subscript number 1 denotes the index of DMUs, where superscript l means the low value of membership degree in the intuitionistic fuzzy number). | |

| The intuitionistic fuzzy number medium m of environment influence of evaluated manufacturing type in DMU 1 (subscript number 1 denotes the index of DMUs, where superscript l means the low value of membership degree in the intuitionistic fuzzy number and superscript number 1 means the first environment influence). | |

| The intuitionistic fuzzy number medium m of raw materials x1b of evaluated manufacturing type in DMU 1 (subscript number 1 denotes the index of DMUs, where superscript l means the low value of membership degree in the intuitionistic fuzzy number). | |

| The intuitionistic fuzzy number medium m of manufacturing service of evaluated manufacturing type in DMU 1 (subscript number 1 denotes the index of DMUs, where superscript l means the low value of membership degree in the intuitionistic fuzzy number and superscript number 1 means the first manufacturing service). | |

| The intuitionistic fuzzy number medium m of end product of evaluated manufacturing type in DMU 1 (subscript number 1 denotes the index of DMUs, where superscript l means the low value of membership degree in the intuitionistic fuzzy number). | |

| The intuitionistic fuzzy number medium m of supporting product s1d of evaluated manufacturing type in DMU 1 (subscript number 1 denotes the index of DMUs, where superscript l means the low value of membership degree in the intuitionistic fuzzy number). | |

| T1 | T2 | … | Tc | … | TC | |

|---|---|---|---|---|---|---|

| A1 | [u11,v11] | [u12,v12] | … | [u1c,v1c] | … | [u1C,v1C] |

| A2 | [u21,v21] | [u22,v22] | … | [u2c,v2c] | … | [u2C,v2C] |

| … | … | … | … | … | … | … |

| Ad | [ud1,vd1] | [ud2,vd2] | … | [udc,vdc] | … | [udC,vdC] |

| … | … | … | … | … | … | … |

| AD | [uD1,vD1] | [uD2,vD2] | … | [uDc,vDc] | … | [uDC,vDC] |

| Final Score (Percentile) | Solid Waste Recycling Ratio (%) |

|---|---|

| >90 | 20 |

| 85–90 | 15 |

| 80–85 | 10 |

| 70–80 | 5 |

| 60–70 | 2.5 |

| <60 | 0 |

| Stages of Efficiency Calculation | Group | α/β Value | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | ||

| ES-α-max | 5 | 1.3554 | 1.2479 | 1.1571 | 1.0870 | 1.0058 | 0.9451 | 0.8902 | 0.8408 | 0.7993 | 0.7664 | 0.6870 |

| 14 | 0.4787 | 0.4568 | 0.4366 | 0.4206 | 0.3977 | 0.3833 | 0.3702 | 0.3581 | 0.3477 | 0.3396 | 0.3034 | |

| … | 27 | 0.3358 | 0.3281 | 0.3207 | 0.3168 | 0.3053 | 0.2981 | 0.2914 | 0.2849 | 0.2787 | 0.2728 | 0.2574 |

| ES-α-min | 5 | 0.4345 | 0.4523 | 0.4714 | 0.4911 | 0.5117 | 0.5428 | 0.5656 | 0.5892 | 0.6138 | 0.6392 | 0.6660 |

| 14 | 0.2111 | 0.2178 | 0.2247 | 0.2317 | 0.2386 | 0.2479 | 0.2575 | 0.2675 | 0.2779 | 0.2890 | 0.3010 | |

| 27 | 0.1625 | 0.1678 | 0.1733 | 0.1787 | 0.1841 | 0.1897 | 0.1953 | 0.2011 | 0.2070 | 0.2130 | 0.2192 | |

| ES-β-max | 5 | 1.8312 | 1.5816 | 1.4073 | 1.2527 | 1.1152 | 0.9698 | 0.8240 | 0.7639 | 0.7040 | 0.6535 | 0.5599 |

| 14 | 0.5497 | 0.3924 | 0.3815 | 0.3577 | 0.3641 | 0.3633 | 0.3601 | 0.3556 | 0.3470 | 0.3391 | 0.3108 | |

| 27 | 0.3962 | 0.3086 | 0.3066 | 0.2944 | 0.2975 | 0.2985 | 0.2999 | 0.3052 | 0.3035 | 0.3031 | 0.2780 | |

| ES-β-min | 5 | 0.3070 | 0.3304 | 0.3552 | 0.3816 | 0.4098 | 0.4464 | 0.4877 | 0.5321 | 0.5976 | 0.6281 | 0.7219 |

| 14 | 0.2018 | 0.2155 | 0.2297 | 0.2446 | 0.2601 | 0.2772 | 0.2857 | 0.2997 | 0.3226 | 0.2728 | 0.2925 | |

| 27 | 0.1145 | 0.1244 | 0.1350 | 0.1467 | 0.1594 | 0.1733 | 0.1871 | 0.2050 | 0.2223 | 0.2198 | 0.2379 | |

| Stages of Efficiency Calculation | Group | α/β Value | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | ||

| ES-α-max | 5 | 1.4984 | 1.4090 | 1.3355 | 1.2767 | 1.2269 | 1.0272 | 0.9768 | 0.9199 | 0.8977 | 0.8792 | 0.8610 |

| 14 | 0.4224 | 0.4112 | 0.4007 | 0.3910 | 0.3816 | 0.3727 | 0.3642 | 0.3516 | 0.3324 | 0.3254 | 0.3222 | |

| … | 27 | 0.5199 | 0.5107 | 0.5018 | 0.4931 | 0.4846 | 0.4762 | 0.4680 | 0.4592 | 0.4528 | 0.4452 | 0.4754 |

| ES-α-min | 5 | 0.6834 | 0.7054 | 0.7277 | 0.7503 | 0.7732 | 0.8123 | 0.8124 | 0.7879 | 0.8143 | 0.8408 | 0.8732 |

| 14 | 0.2783 | 0.2836 | 0.2891 | 0.2947 | 0.3005 | 0.3041 | 0.3307 | 0.3355 | 0.3407 | 0.3268 | 0.3348 | |

| 27 | 0.3949 | 0.4040 | 0.4134 | 0.4230 | 0.4313 | 0.4224 | 0.4434 | 0.4512 | 0.4591 | 0.4618 | 0.4700 | |

| ES-β-max | 5 | 1.9462 | 1.6394 | 1.4305 | 1.3970 | 1.2346 | 1.0536 | 0.8727 | 1.3239 | 1.1772 | 0.8919 | 0.8293 |

| 14 | 0.3732 | 0.3179 | 0.3220 | 0.3188 | 0.4000 | 0.3885 | 0.3809 | 0.3646 | 0.3477 | 0.3396 | 0.3299 | |

| 27 | 0.5050 | 0.4983 | 0.5002 | 0.4984 | 0.4995 | 0.5099 | 0.5213 | 0.5031 | 0.4819 | 0.4612 | 0.4782 | |

| ES-β-min | 5 | 0.3366 | 0.3422 | 0.3494 | 0.4032 | 0.4163 | 0.4414 | 0.4757 | 0.2818 | 0.3511 | 0.8516 | 0.9202 |

| 14 | 0.2459 | 0.2549 | 0.2643 | 0.2554 | 0.2679 | 0.2783 | 0.2860 | 0.2869 | 0.2984 | 0.3262 | 0.3424 | |

| 27 | 0.2495 | 0.2532 | 0.2611 | 0.2644 | 0.2743 | 0.2842 | 0.3060 | 0.3258 | 0.4269 | 0.4480 | 0.4714 | |

| Manufacturing Service Number | Ordinal Value of α-Cut | Ordinal Value of β-Cut | Composite Index Value |

|---|---|---|---|

| 1 | 0.344783 | 0.408454 | 0.376618 |

| 2 | 0.390017 | 0.002107 | 0.195009 |

| 3 | 0.323078 | 0.443562 | 0.383320 |

| 4 | 0.347644 | 0.328882 | 0.338263 |

| 5 | 0.317286 | 0.366529 | 0.341907 |

| 6 | 0.126470 | 0.497043 | 0.311757 |

| 7 | 0.147169 | 0.532083 | 0.339626 |

| 8 | 0.158444 | 0.512760 | 0.335602 |

| 9 | 0.164630 | 0.461933 | 0.313281 |

| 10 | 0.159867 | 0.501913 | 0.330890 |

| 11 | 0.194604 | 0.460244 | 0.327424 |

| 12 | 0.114222 | 0.476064 | 0.295143 |

| 13 | 0.159769 | 0.449626 | 0.304698 |

| 14 | 0.038109 | 0.551814 | 0.294962 |

| 15 | 0.093113 | 0.524391 | 0.308752 |

| 16 | 0.173379 | 0.478117 | 0.325748 |

| 17 | 0.107488 | 0.455521 | 0.281504 |

| 18 | 0.076223 | 0.511835 | 0.294029 |

| 19 | 0.100922 | 0.488530 | 0.294726 |

| 20 | 0.072969 | 0.536875 | 0.304922 |

| 21 | 0.078057 | 0.530198 | 0.304128 |

| 22 | 0.083389 | 0.510815 | 0.297102 |

| 23 | 0.113729 | 0.502834 | 0.308282 |

| 24 | 0.105322 | 0.486918 | 0.296120 |

| 25 | 0.102970 | 0.548566 | 0.325768 |

| 26 | 0.070054 | 0.560510 | 0.315282 |

| 27 | 0.080475 | 0.538604 | 0.309539 |

| 28 | 0.042303 | 0.566550 | 0.304426 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Guo, S.; Tang, H.; Tan, T.; Du, B.; Huang, L. The Fuzzy DEA-Based Manufacturing Service Efficiency Evaluation and Ranking Approach for a Parallel Two-Stage Structure of a Complex Product System on the Example of Solid Waste Recycling. Processes 2022, 10, 2322. https://doi.org/10.3390/pr10112322

Yang Z, Guo S, Tang H, Tan T, Du B, Huang L. The Fuzzy DEA-Based Manufacturing Service Efficiency Evaluation and Ranking Approach for a Parallel Two-Stage Structure of a Complex Product System on the Example of Solid Waste Recycling. Processes. 2022; 10(11):2322. https://doi.org/10.3390/pr10112322

Chicago/Turabian StyleYang, Zhijie, Shunsheng Guo, Hongtao Tang, Tian Tan, Baigang Du, and Lang Huang. 2022. "The Fuzzy DEA-Based Manufacturing Service Efficiency Evaluation and Ranking Approach for a Parallel Two-Stage Structure of a Complex Product System on the Example of Solid Waste Recycling" Processes 10, no. 11: 2322. https://doi.org/10.3390/pr10112322