Position Tracking of an Underwater Robot Based on Floating-Downing PI Control

Abstract

:1. Introduction

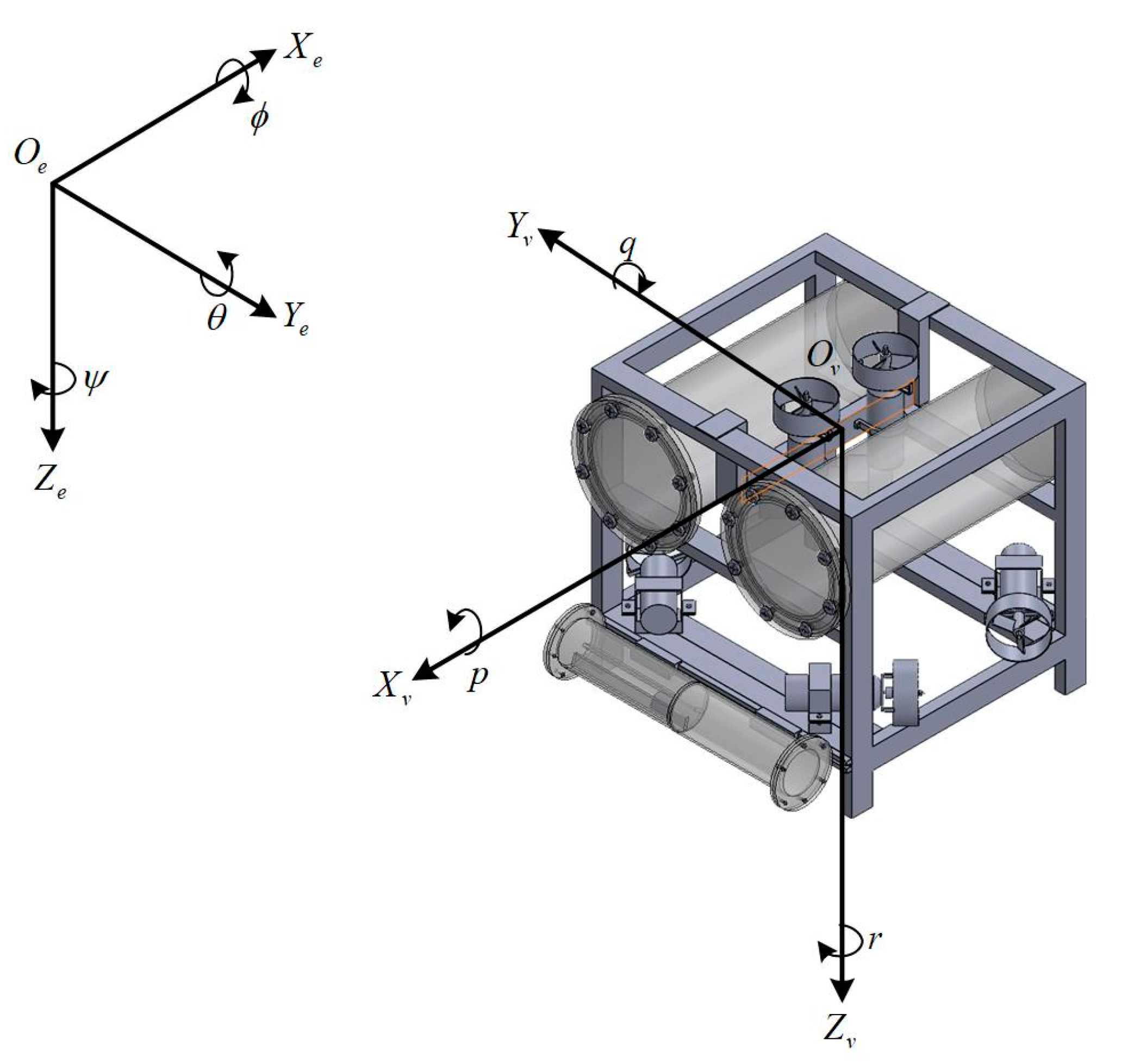

2. Motion and Dynamic Model of ROV

3. System Design and Hardware Architecture

4. The Proposed Control Method

5. Experimental Results

5.1. Experiment 1: Station-Keeping Test and Evaluation

5.2. Experiment 2: Trajectory Tracking Test and Evaluation

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, J.H.; Yoo, S.J. Adaptive Event-Triggered Control Strategy for Ensuring Predefined Three-Dimensional Tracking Performance of Uncertain Nonlinear Underactuated Underwater Vehicles. Mathematics 2021, 9, 137. [Google Scholar] [CrossRef]

- Duan, K.; Fong, S.; Chen, C.L.P. Multilayer Neural Networks-Based Control of Underwater Vehicles with Uncertain Dynamics and Disturbances. Nonlinear Dyn. 2020, 100, 3555–3573. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, M.; Xu, J. Robust. Adaptive Sliding Mode Control of Underactuated Autonomous Underwater Vehicles with Uncertain Dynamics. Ocean Eng. 2019, 173, 802–809. [Google Scholar] [CrossRef]

- Ghafoor, H.; Noh, Y. An Overview of Next-Generation Underwater Target Detection and Tracking: An Integrated Underwater Architecture. IEEE Access 2019, 7, 98841–98853. [Google Scholar] [CrossRef]

- Sahoo, A.; Dwivedy, S.K.; Robi, P. Advancements in the Field of Autonomous Underwater Vehicle. Ocean Eng. 2019, 181, 145–160. [Google Scholar] [CrossRef]

- Yuan, C.; Licht, S.; He, H. Formation Learning Control of Multiple Autonomous Underwater Vehicles with Heterogeneous Nonlinear Uncertain Dynamics. IEEE Trans. Cyber. 2018, 47, 2168–2267. [Google Scholar] [CrossRef] [PubMed]

- Pinheiro, B.C.; Moreno, U.F.; Sousa, J.T.B.; Rodriguez, O.C. Kernel-function-based Models for Acoustic Localization of Underwater Vehicles. IEEE J. Ocean. Eng. 2017, 42, 603–618. [Google Scholar] [CrossRef]

- Smallwood, D.A.; Whitcomb, L.L. Model-Based Dynamic Positioning of Underwater Robotic Vehicles: Theory and Experiment. IEEE J. Ocean. Eng. 2004, 29, 169–186. [Google Scholar] [CrossRef]

- Hsu, L.; Costa, R.R.; Lizarralde, F.; Da Cunha, J.P.V.S. Dynamic Positioning of Remotely Operated Underwater Vehicles. IEEE Robot Autom. Mag. 2000, 7, 21–31. [Google Scholar] [CrossRef]

- Lygouras, J.N. DC Thruster Controller Implementation with Integral Anti-wind up Compensator for Underwater ROV. J. Intell. Robot Syst. 1999, 25, 79–94. [Google Scholar] [CrossRef]

- Koh, T.H.; Lau, M.W.S.; Seet, G.; Low, A. A Control Module Scheme for an Underactuated Underwater Robotic Vehicle. J. Intell. Robot Syst. 2006, 46, 43–58. [Google Scholar] [CrossRef]

- Makavita, C.D.; Jayasinghe, S.G.; Nguyen, H.D.; Ranmuthugala, D. Experimental Study of a Command Governor Adaptive Depth Controller for an Unmanned Underwater Vehicle. Appl. Ocean. Res. 2019, 86, 62–71. [Google Scholar] [CrossRef]

- Tanakitkorn1a, K.; Wilsona, P.A.; Turnocka, S.R.; Phillipsb, A.B. Depth Control for an Over-Actuated, Hover-Capable Autonomous Underwater Vehicle with Experimental Verification. Machines 2017, 41, 67–81. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Liu, K.; Li, Y.; Ren, S. Dynamic Sliding Mode Control Based on Multi-model Switching Laws for the Depth Control of an Autonomous Underwater Vehicle. Int. J. Adv. Robot. Syst. 2015, 12, 142. [Google Scholar] [CrossRef] [Green Version]

- Nag, A.; Patel, S.S.; Akbar, S.A. Fuzzy Logic Based Depth Control of an Autonomous Underwater Vehicle. In Proceedings of the 2013 International Mutli-Conference on Automation, Computing, Communication, Control and Compressed Sensing (iMac4s), Kottayam, India, 22–23 March 2013; pp. 22–23. [Google Scholar]

- Pu, Y.C.; Kuo, C.L.; Chen, J.L.; Lin, C.H.; Yan, J.J. Bilateral Propellers Dynamic Control for an Underwater Operated Vehicle Using a Self-Synchronization Practical Tracking Controller. Ocean Eng. 2018, 150, 318–326. [Google Scholar] [CrossRef]

- Haibao, J.; Dezhi, H.; Han, L.; Jiuzhang, H.; Wenjing, N. Time Synchronized Velocity Error for Trajectory Compression. Comput. Model. Eng. Sci. 2022, 130, 1193–1219. [Google Scholar]

- Felipe, J.T.; Gerardo, V.G.; Carlos, D.G.; Ricardo, Z.-Y.; Mario, A.G.; Adolfo, R.L. Synchronization of Robot Manipulators Actuated by Induction Motors with Velocity Estimator. Comput. Model. Eng. Sci. 2019, 121, 609–630. [Google Scholar]

- Thiago, A.M.E.; Pericles, R.B. Iterative Procedure for Tuning Decentralized PID Controllers. IFAC-Pap. 2015, 48, 1180–1185. [Google Scholar]

- Miranda, M.F.; Vamvoudakis, K.G. Online optimal auto-tuning of PID controllers for tracking in a special class of linear systems. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016. [Google Scholar] [CrossRef]

- Korani, W.M.; Dorrah, H.T.; Emara, H.M. Bacterial Foraging Oriented by Particle Swarm Optimization Strategy for PID Tuning. In Proceedings of the 10th Annual Conference Companion on Genetic and Evolutionary Computation (CIRA), Daejeon, Korea, 15–18 December 2009. [Google Scholar] [CrossRef] [Green Version]

- Bazanella, A.S.; Pereira, L.F.A.; Parraga, A. A New Method for PID Tuning Including Plants Without Ultimate Frequency. IEEE Trans. Control Syst. Technol. 2017, 25, 637–644. [Google Scholar] [CrossRef]

- Fossen, T.I. Handbook of Marine Craft Hydrodynamics and Motion Control; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Fossen, T.I. Guidance and Control of Ocean Vehicles; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 1994. [Google Scholar]

- Fossen, T.I. Marine Control Systems: Guidance, Navigation and Control of Ships, Rigs and Underwater Vehicles, Marine Cybernetics; Marine Cybernetics: Trondheim, Norway, 2002; ISBN 82-92356-00-2. [Google Scholar]

- Ziegler, J.G.; Nichols, N.B. Optimum settings for automatic controllers. Trans. ASME 1942, 64, 759–768. [Google Scholar] [CrossRef] [Green Version]

| Item | Specification | Item | Specification |

|---|---|---|---|

| Motor type | DC brushless motor | Maximum thrust | 6.5 kg |

| Operating voltage | DC 24 V | Net weight | 0.85 kg |

| Rated current | 15 A | Control signal | PWM signal |

| Maximum current | 16 A (instantaneous) | Signal pulse width | 1000 μs (maximum value at reverse rotation) 1500 μs (start/stop) 2000 μs (maximum value at forward rotation) |

| Rated power | 250 W | ||

| Maximum speed | 4000 rpm/min | ||

| Operating depth | 300 m | Signal frequency | 50 Hz, constant frequency, variable duty cycle |

| Voltage Output | 0.5–4.5 V |

| Accuracy | ±1% |

| Operating Pressure | 15 PSI (103.42 pa) |

| Voltage Input | 5V |

| Operating Temp | −40∼105 °C |

| Literature | Control Method | Parameter Tuning Method | System Plant | Test Signal | Controller Parameters |

|---|---|---|---|---|---|

| [19] | PID control | Gershgorin bands and equivalent open-loop process | Model | Step function | Kp = 3.94 Ki = 1.77 Kp = 0.91 Tf = 0.1 |

| [20] | PID control | Reinforcement learning algorithm | Model | Step function | Kp = 525.2879 Ki = 201.5363 Kp = 44.1397 |

| [21] | PID control | Bacterial foraging oriented by particle swarm optimization | Model | Step function | Kp = 1.17 Ki = 0.83 Kp = 1.26 |

| [22] | IP and PID control | Extended forced oscillation | Model | Step function | Kp = 1.43 Ti = 4.71 |

| Proposed Method | Switch PI controller with BBC control | Ziegler–Nichols | Modeless | Step function and sinusoidal wave | Floating: Kp = 48 Ki = 0.015 Diving: Kp = 45 Ki = 0.013 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, C.-L.; Pu, Y.-C.; Chen, Q.-A. Position Tracking of an Underwater Robot Based on Floating-Downing PI Control. Processes 2022, 10, 2346. https://doi.org/10.3390/pr10112346

Kuo C-L, Pu Y-C, Chen Q-A. Position Tracking of an Underwater Robot Based on Floating-Downing PI Control. Processes. 2022; 10(11):2346. https://doi.org/10.3390/pr10112346

Chicago/Turabian StyleKuo, Chao-Lin, Yu-Chi Pu, and Qi-An Chen. 2022. "Position Tracking of an Underwater Robot Based on Floating-Downing PI Control" Processes 10, no. 11: 2346. https://doi.org/10.3390/pr10112346