Main Technical and Economic Guidelines to Implement Wind/Solar-Powered Reverse-Osmosis Desalination Systems

Abstract

:1. Introduction

2. Preliminary Sizing and Appropriate Range of the RO Nominal Capacity

2.1. Generalities

2.2. Off-Grid PV-Driven Reverse-Osmosis Desalination Systems

2.3. Wind-Driven Reverse-Osmosis Desalination Systems

- The identification of recommendations for wind-driven desalination systems [34].

- The identification of the RO operation oscillations under variable frequencies of the isolated grid due to the low wind speed conditions: pressure (59–61 bar), water conductivity (900–925 µS/cm), and product flow (890–980 L/h; 89–98% of the nominal point) [35].

- Stability in power balance under low-wind conditions [36].

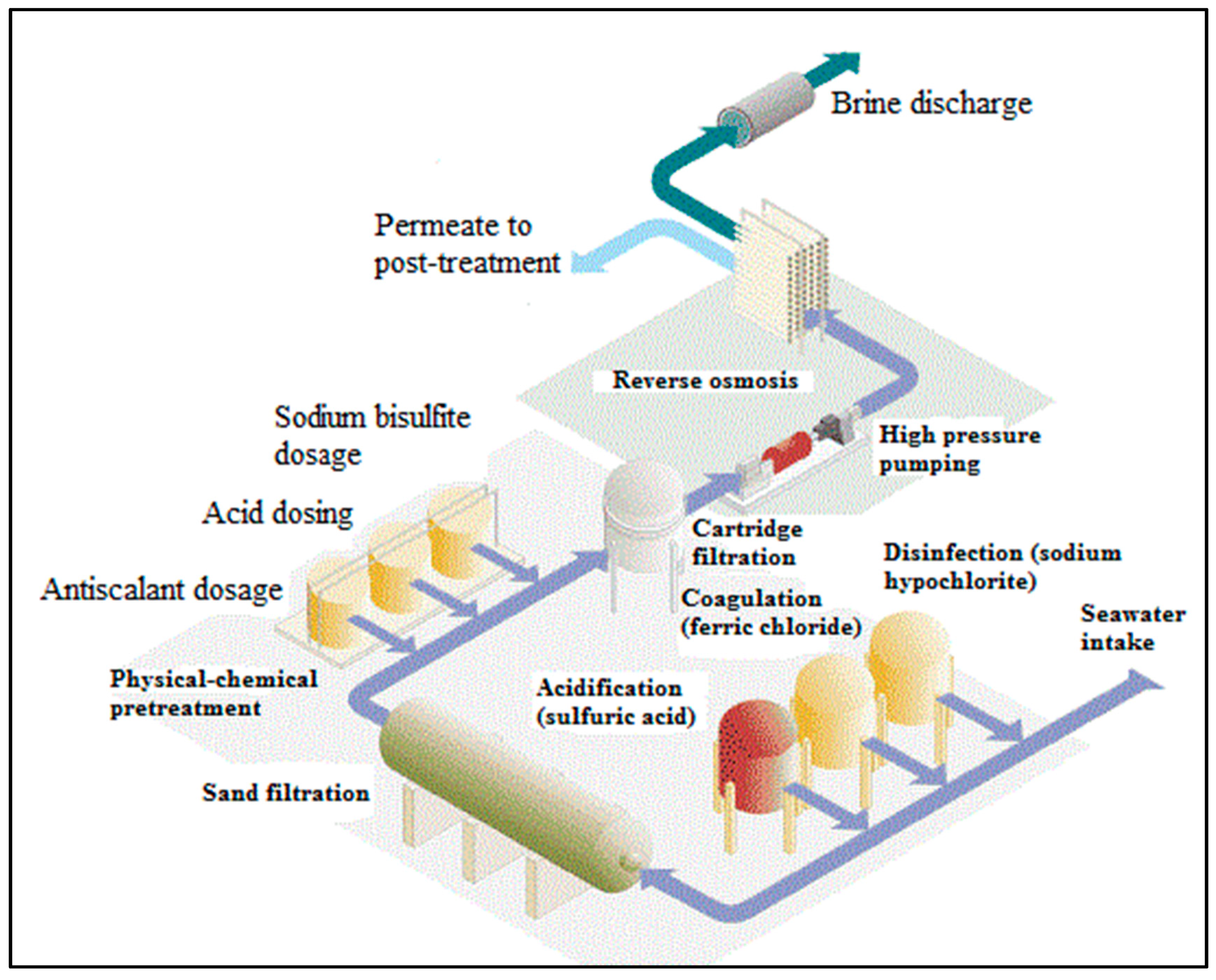

3. Appropriate Pre-Treatment

3.1. General Recommendations

- A direct raw water intake from the sea should be avoided in order to prevent the introduction of organic matter and suspended solids. The recommended solution for the medium and low scale is to dig a coastal well, thereby using the ground as a natural pre-filter.

- Chemical product requirements should be limited insofar as possible, in order to reduce the external dependence, as RE-driven autonomous systems are normally located in remote areas.

- We should select a medium–low RO recovery ratio in the design in order to reduce the pre-treatment requirements, selecting a value below the results from simulations: 75–80% for brackish water (the normal recovery is 85–90%), and 35–40% for seawater (the usual recovery is 43–45%).

3.2. Physical Pre-Treatment

3.3. Chemical Pre-Treatment

4. Brine Energy Recovery

5. Energy Storage Systems

6. Recommendations for Autonomous RE Desalination Plants in Remote Locations

6.1. Information to Be Gathered on Local Conditions

6.2. General Concept of the Design

- (a)

- Indications regarding the O&M team include preliminary steps along the commissioning and first weeks of operation will require an active implication of external installers, including the comprehensive training of the local team who will progressively assume the O&M tasks. The simpler the operation and understanding of the system (being user friendly), the longer the successful operation the installation will have.

- (b)

- Indications regarding the equipment include the inclusion of spare parts for the main components and the most common hydraulic and electric elements, as well as the use of tough and high-quality materials.

6.3. Operation and Maintenance

7. Wind-PV (Hybrid) Systems

8. Economics

8.1. Generalities

- The low nominal capacity of the desalination plant and the associated economic scale factor, particularly in PV-driven RO installations.

- The additional investment for all of the components of the stand-alone generation system.

8.2. CAPEX Review

8.3. Calculation of the Desalinated Water Costs

- The size of the facility;

- The local wind/solar resources;

- The quality and salinity of the raw water;

- The factors associated with the location: transport, the proximity to a place with spare parts and a consumables supply, and the availability of skilled operators for corrective maintenance, among others).

8.4. Optimization of the Water Cost

9. Future Perspectives

9.1. Technical Keys

- The reduction of energy consumption: There is a progressive upgrading process in energy saving and its associated exceptional results (below 2 kWh/m3) using ultra-low-energy membrane elements, high-performance pumps, a salinity gradient, and very efficient energy recovery systems. The lower the energy demand, the greater the operation time for the same available energy; this progression will open an interesting path to optimize RE-powered RO desalination [61,63].

- The performance of RO operations: The latest tendencies in membrane technologies (intermediate stages, a higher size of modules, advances in nano- and ultra-filtration as pre-treatment options) could lead to a higher performance of RO operations, reducing the specific energy consumption space requirements and maintenance costs, and increasing the product water quality and the lifespan of membrane elements and installations;

- The latest advances in wind energy involve an increment in the unitary power, improvements in the output power control power, advance monitoring, and preventive maintenance.

- There are indications to improve the design, durability and quality of components and reduction of O&M costs by minimizing the time to repair and reinstall failed equipment, along with preventive maintenance schedules, particularly regarding inverters, a key component which is responsible for up to 36% of the energy loss and 43–70% of PV power plant service requests [66].

- The use of hybrid generation systems: The preferable option is mainly, but not only, based on PV and wind power. The incorporation of wind energy balances the lack of solar power during low solar radiation and nighttime periods, extending the available energy, and thus the operation time and associated water production [60,64,67,68].

- The latest advances in control systems involve the incorporation of genetic algorithms [68], the forecast of wind and solar resources, and the use of machine learning techniques [68,69,70,71,72,73,74] to predict the performance and to control the autonomous RO units, allowing more accurate and efficient operation.

- Integration into micro-grids: The simultaneous supply of water and electricity by RO plants coupled to hybrid micro-grids in isolated places that can both cover the demands and extend the penetration of RE sources [77]. Furthermore, the inclusion of a RO unit, as a controllable load, in a micro-grid will contribute to a more stable supply.

9.2. Economic Keys

- The capex of RE technologies has been decreasing over the past few years; it is expected to reach a value of EUR 1 per installed watt (referred to the whole PV system) within a few years [58].

- There is a rising market and new commercial opportunities derived from the climate crisis, and indications from the IPCC to reduce greenhouse effect emissions.

- The volatility of oil prices, the increasing difficulty to discover new reserves, and uncertain future prices could lead to a crisis as soon as oil demand overcome the offer.

- The future water crisis derived from climate change, particularly relevant in countries with historical water shortage, will increase the demand for autonomous and RE-driven desalination systems.

- Very attractive water costs can be expected, considering the recent lowest water levelized tariffs in on-grid SWRO plants: about USD 0.3 per cubic meter (Hassyan plant) [79]. This is possible thanks to the high capacity of the plant (more than 450,000 m3/d), the use of low-cost energy and the selection of the most efficient and reliable technologies.

9.3. Other Aspects

- Social component: There is a specific necessity for autonomous water supply in developing regions associated with cooperation projects, wherein the social issues must be specifically considered from the beginning of the project [51]. The long-term success of the system will strongly depend on the following social aspects:

- The analysis of the social reality of the beneficiary community in order to adapt the project to the local conditions and incorporate their participation and commitment.

- The involvement of local authorities to give them a relevant role in the decisions and, ideally, to achieve a contribution to cover either part of the initial investment and/or the assumption of the O&M expenses.

- The appropriate selection of people to be trained to assume the management and maintenance tasks of the system.

- Environmental component: The integration of RE resources, such as wind and/or solar energy, in the operation of RO plants curbs (or at least, highly reduces) CO2 emissions associated with conventional on-grid RO plants. Nonetheless, brine discharge must be assessed and considered, particularly in inland locations; evaporation ponds, the blending with raw water for appropriate dilution and later disposal, or even the watering of crops adapted to high-salinity water, could be adopted as actions to curb or restrict the environmental impact of brine discharge [51].

- Political component: Decision makers, who are normally the key group amongst the stakeholders to start a project, suffer from an important lack of information on and knowledge of these technologies. Therefore, dissemination activities and introductory training courses are essential items for the creation of the necessary awareness. A complete vision of the barriers and suggested proposals is given in [80].

10. Conclusions

- The high importance of the appropriate identification of the local characteristics in order to carry out a tailor-made design and a correct O&M plan. This is particularly critical when the system is installed in developing countries.

- The suitable selection of high-quality materials and main components.

- The inclusion of an energy recovery unit for seawater, and an energy storage system.

- The use of a beach well as the feed water intake for SWRO is much more favorable.

- Wherever there is the simultaneous availability of relevant solar and wind resources, it makes sense to consider hybrid systems.

- The consideration of an integral concept of the project to include all of the elements associated with the cost.

- The latest advances in membranes and generation technologies have produced more efficient and economical products, leading to more competitive costs. The set of recommendations presented in this document may also be considered as a basic set of ideas to reduce water costs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baalousha, H. Desalination status in the Gaza Strip and its environmental impact. Desalination 2006, 196, 1–12. [Google Scholar] [CrossRef]

- El Sheikh, R.; Ahmed, M.; Hamdan, S. Strategy of water desalination in the Gaza Strip. Desalination 2003, 156, 39–42. [Google Scholar] [CrossRef]

- Mogheir, Y.; Foul, A.A.; Abuhabib, A.; Mohammad, A. Assessment of large scale brackish water desalination plants in the Gaza Strip. Desalination 2013, 314, 96–100. [Google Scholar] [CrossRef]

- Subiela, V.J.; De La Fuente, J.A.; Piernavieja, G.; Peñate, B. Canary Islands Institute of Technology (ITC) experiences in desalination with renewable energies (1996–2008). Desalin. Water Treat. 2009, 7, 220–235. [Google Scholar] [CrossRef]

- Gómez-Gotor, A.; Del Río-Gamero, B.; Prado, I.P.; Casañas, A. The history of desalination in the Canary Islands. Desalination 2018, 428, 86–107. [Google Scholar] [CrossRef]

- Prieto-Prado, I.; Del Río-Gamero, B.; Gómez-Gotor, A.; Pérez-Báez, S. Water and energy self-supply in isolated areas through renewable energies using hydrogen and water as a double storage system. Desalination 2018, 430, 1–14. [Google Scholar] [CrossRef]

- Charoset, C. A review of membrane processes and renewable energies for desalination. Desalination 2009, 245, 214–231. [Google Scholar] [CrossRef]

- Ghermandi, A.; Messalem, R. Solar-driven desalination with reverse osmosis: The state of the art. Desalin. Water Treat. 2009, 7, 285–296. [Google Scholar] [CrossRef] [Green Version]

- Subiela, V.; Peñate, B.; Castellano, F.; Rodríguez, F. Solar PV powered RO systems. In Renewable Energy Applications for Freshwater Production; CRC Press/Francis&Taylor Group: Boca Raton, FL, USA, 2012; Volume 8, pp. 135–160. [Google Scholar]

- Partners of the Project. Prodes Project. Available online: http://www.prodes-project.org/ (accessed on 14 May 2018).

- Boesch, W.W. World’s first solar powered reverse osmosis desalination plant. Desalination 1982, 41, 233–237. [Google Scholar] [CrossRef]

- García-Rodríguez, L. Renewable energy applications in desalination: State of the art. Sol. Energy 2003, 75, 381–393. [Google Scholar] [CrossRef]

- Tzen, E.; Morris, R. Renewable energy sources for desalination. Sol. Energy 2003, 75, 375–379. [Google Scholar] [CrossRef]

- Tzen, E.; Theofilloyianakos, D.; Kologios, Z. Autonomous reverse osmosis units driven by RE sources experiences and lessons learned. Desalination 2008, 221, 29–36. [Google Scholar] [CrossRef]

- Carvalho, P.C.M.; Carvalho, L.A.D.; Filho, J.J.H.; Oliveira, R.S.H. Feasibility study of photovoltaic powered reverse osmosis and pumping plant configurations. IET Renew. Power Gener. 2013, 7, 134–143. [Google Scholar] [CrossRef]

- Davis, L.W. The Economic Cost of Global Fuel Subsidies. National Bureau of Economic Research, 2013. Available online: http://www.nber.org/papers/w19736 (accessed on 21 March 2022).

- Fthenakis, V.; Atia, A.A.; Morin, O.; Bkayrat, R.; Sinha, P. New prospects for PV powered water desalination plants: Case studies in Saudi Arabia. Prog. Photovolt. Res. Appl. 2016, 24, 543–550. [Google Scholar] [CrossRef]

- Shatat, M.; Worall, M.; Riffat, S. Opportunities for solar water desalination worldwide: Review. Sustain. Cities Soc. 2013, 9, 67–80. [Google Scholar] [CrossRef]

- Goetzberger, A.; Hebling, C.; Schock, H.-W. Photovoltaic materials, history, status and outlook. Mater. Sci. Eng. R Rep. 2003, 40, 1–46. [Google Scholar] [CrossRef]

- Solarbuzz. Price Survey. Available online: http://www.solarbuzz.com (accessed on 12 July 2008).

- Thomson, M.; Infield, D. A photovoltaic-powered seawater reverse-osmosis system without batteries. Desalination 2003, 153, 1–8. [Google Scholar] [CrossRef]

- Shalaby, S.M. Reverse osmosis desalination powered by photovoltaic and solar Rankine cycle power systems: A review. Renew. Sustain. Energy Rev. 2017, 73, 789–797. [Google Scholar] [CrossRef]

- Bundschuh, J.; Kaczmarczyk, M.; Ghaffour, N.; Tomaszewska, B. State-of-the-art of renewable energy sources used in water desalination: Present and future prospects. Desalination 2021, 508, 115035. [Google Scholar] [CrossRef]

- Ahmed, F.E.; Hashaikeh, R.; Hilal, N. Solar powered desalination—Technology, energy and future outlook. Desalination 2019, 453, 54–76. [Google Scholar] [CrossRef] [Green Version]

- Raval, H.D.; Maiti, S. A Novel Photovoltaic Powered Reverse Osmosis with Improved Productivity of Reverse Osmosis and Photovoltaic Panel. J. Membr. Sci. Res 2015, 1, 113–117. [Google Scholar]

- Raval, H.D.; Maiti, S. Ultra-low energy reverse osmosis with thermal energy recovery from photovoltaic panel cooling and TFC RO membrane modification. Desalin. Water Treat. 2014, 57, 1–10. [Google Scholar] [CrossRef]

- Ghafoor, A.; Munir, A.; Ahmed, T.; Nauman, M.; Amjad, W. Investigation of hybrid solar-driven desalination system employing reverse osmosis process. Desalin. Water Treat. 2020, 178, 32–40. [Google Scholar] [CrossRef]

- Subiela, V.J.; Peñate, B.; García-Rodríguez, L. Design recommendations and cost assessment for non-stop off-grid plants of seawater desalination based on PV-driven with wind/diesel energy backup. Desalin. Water Treat. 2020, 181, 80–100. [Google Scholar] [CrossRef]

- Water Technology. Available online: https://www.water-technology.net/projects/israel/ (accessed on 14 May 2018).

- Peñate, B.; Subiela, V.; Melián, G.; de la Fuente, J. Energy recovery devices for reverse osmosis low water production capacity desalination plants (<100 m3/d). In Proceedings of the EuroMed 2010 EDS Conference “Desalination for Clean Water & Energy”, Tel Aviv, Israel, 3–7 October 2010. [Google Scholar]

- SMA. SMA Website. Available online: www.sma.de/en (accessed on 14 May 2018).

- Peñate, B.; Castellano, F.; Bello, A.; García-Rodríguez, L. Assessment of a stand-alone gradual capacity reverse osmosis desalination plant to adapt to wind power availability: A case study. Energy 2011, 36, 4372–4384. [Google Scholar] [CrossRef]

- Koohi-Kamali, S.; Tyagi, V.; Rahim, N.; Panwar, N.L.; Mokhlis, H. Emergence of energy storage technologies as the solution for reliable operation of smart power systems: A review. Renew. Sustain. Energy Rev. 2013, 25, 135–165. [Google Scholar] [CrossRef]

- Subiela, V.J.; Carta, J.A.; González, J. The SDAWES project: Lessons learnt from an innovative project. Desalination 2004, 168, 39–47. [Google Scholar] [CrossRef]

- Carta, J.; González, J.; Subiela, V. Operational analysis of an innovative wind powered reverse osmosis system installed in the Canary Islands. Sol. Energy 2003, 75, 153–168. [Google Scholar] [CrossRef]

- Carta, J.; González, J.; Subiela, V. The SDAWES project: An ambitious R&D prototype for wind-powered desalination. Desalination 2004, 161, 33–48. [Google Scholar] [CrossRef]

- UFTEC Partners. UFTEC Website. EC European Commission, Life Programme. Available online: http://www.life-uftec.eu (accessed on 23 May 2018).

- Knops, F.; Kahne, E.; Román, A.; Rubio, M. Technological Innovations in Pretreatment with membranes. In III International Desalination Seminar; ALADYR: Antofagasta City, Chile, 2012. [Google Scholar]

- Available online: http://novena.asambleamurcia.es/sites/external/murcia_agua/cap15.2.htm (accessed on 15 March 2022).

- Danfoss. Danfoss Website. Available online: www.danfoss.com (accessed on 10 May 2018).

- KSB. SALINO Pressure Center. Available online: https://www.ksb.com/salino-en/downloads (accessed on 10 May 2018).

- SPECTRA Watermakers. Available online: www.spectrawatermakers.com (accessed on 10 May 2018).

- Energy Recovery. Available online: www.energyrecovery.com (accessed on 10 May 2018).

- Peñate, B.; de la Fuente, J.; Barreto, M. Operation of the RO Kinetic® energy recovery system: Description and real experiences. Desalination 2010, 252, 179–185. [Google Scholar] [CrossRef]

- Stover, R.L.; Efraty, N. Low-Energy Consumption with Closed-Circuit Desalination. IDA J. Desalin. Water Reuse 2012, 4, 12–19. [Google Scholar] [CrossRef]

- Gorona del Viento. Available online: www.goronadelviento.es (accessed on 23 May 2018).

- Peñate, B.; Subiela, V.J.; Vega, F.; Castellano, F.; Domínguez, F.J.; Millán, V. Uninterrupted eight-year operation of the autonomous solar photovoltaic reverse osmosis system in Ksar Ghilène (Tunisia). Desalin. Water Treat. 2015, 55, 3141–3148. [Google Scholar] [CrossRef]

- Thomson, M.; Infield, D. Laboratory demonstration of a photovoltaic-powered seawater reverse-osmosis system without batteries. Desalination 2005, 183, 105–111. [Google Scholar] [CrossRef]

- Miranda, M.S.; Infield, D. A wind-powered seawater reverse-osmosis system without batteries. Desalination 2003, 153, 9–16. [Google Scholar] [CrossRef]

- Subiela, V.J.; Banat, F. Region identification and site selection. In ADIRA Handbook, A Guide to Autonomous Desalination System Concepts; Seval Sözen, S.T., Ed.; European Union: Brussels, Belgium, 2007; Chapter 2. [Google Scholar]

- Subiela, V.J.; Peñate, B. Autonomous Desalination and Cooperation. The Experience in Morocco Within the ADIRA Project. In Black Sea Energy Resource Development and Hydrogen Energy Problems; Springer: Berlin/Heidelberg, Germany, 2011; pp. 319–337. [Google Scholar]

- Tzen, E. Successful Desalination RES Plants Worldwide (Seminar of the ADU-RES Project). Hammamet (Tunisia). 2005. Available online: http://www.adu-res.org/pdf/CRES.pdf (accessed on 7 May 2018).

- Water Department, ITC, Canary Islands Institute of Technology. Data from Purchased Equipment for R&D Projects on Wind/PV Powered Seawater Reverse Osmosis Desalination; ITC: Gran Canaria Island, Spain, 2007. [Google Scholar]

- Water Department, ITC, Canary Islands Institute of Technology. Own Data from Purchased Systems Installed in Morocco (ADIRA Project, MEDA Water Programme, EC); ITC: Gran Canaria Island, Spain, 2007. [Google Scholar]

- ATERSA. ATERSA Shop. Available online: https://atersa.shop/ (accessed on 21 June 2018).

- Caldera, U.; Bogdanov, D.; Breyer, C. Desalination Costs Using Renewable Energy Technologies. In Renewable Energy Powered Desalination Handbook; Elsevier: Amsterdam, The Netherlands, 2018; pp. 287–329. [Google Scholar]

- Ghaffour, N.; Venkat Reddy, K. The True Cost of Water Desalination: Review and Evaluation. In Proceedings of the IDA World Congress, Dubai, United Arab Emirates, 7–12 November 2009. [Google Scholar]

- IRENA. IRENA Publications. Available online: http://www.irena.org/publications/2015/Dec/Renewable-Desalination-Technology-Options-for-Islands (accessed on 20 May 2018).

- Koklas, P.A.; Papathanassiou, S.A. Component sizing for an autonomous wind-driven desalination plant. Renew. Energy 2006, 31, 2122–2139. [Google Scholar] [CrossRef]

- Wu, B.; Maleki, A.; Pourfayaz, F.; Rosen, M.A. Optimal design of stand-alone reverse osmosis desalination driven by a photovoltaic and diesel generator hybrid system. Sol. Energy 2018, 163, 91–103. [Google Scholar] [CrossRef]

- Lior, N.; Kim, D. Quantitative sustainability analysis of water desalination—A didactic example for reverse osmosis. Desalination 2018, 431, 157–170. [Google Scholar] [CrossRef]

- Juma bin Jarsh Al Falasi, M. Water-Energy Nexus in Abu Dhabi: An Opportunity to Accelerate the Transition to a Green Economy; IDA Global Connections Summer: Topsfield, MA, USA, 2021. [Google Scholar]

- Touati, K.; Salamanca, J.; Tadeo, F.; Elfil, H. Energy recovery from two-stage SWRO plant using PRO without external freshwater feed stream: Theoretical analysis. Renew. Energy 2017, 105, 84–95. [Google Scholar] [CrossRef]

- Zarzo, D.; Prats, D. Desalination and energy consumption. What can we expect in the near future? Desalination 2018, 427, 1–9. [Google Scholar] [CrossRef]

- Maleki, A.; Pourfayaz, F.; Ahmadi, M.H. Design of a cost-effective wind/photovoltaic/hydrogen energy system for supplying a desalination unit by a heuristic approach. Sol. Energy 2016, 139, 666–675. [Google Scholar] [CrossRef]

- Karavas, C.-S.; Arvanitis, K.G.; Kyriakarakos, G.; Piromalis, D.D.; Papadakis, G. A novel autonomous PV powered desalination system based on a DC micro grid concept incorporating short-term energy storage. Sol. Energy 2018, 159, 947–961. [Google Scholar] [CrossRef]

- Hacke, P.; Lokanath, S.; Williams, P.; Vasan, A.; Sochor, P.; TamizhMani, G.; Shinohara, H.; Kurtz, S. A status review of photovoltaic power conversion equipment reliability, safety, and quality assurance protocols. Renew. Sustain. Energy Rev. 2018, 82, 1097–1112. [Google Scholar] [CrossRef]

- Bourouni, K.; Ben M’Barek, T.; Al Taee, A. Design and optimization of desalination reverse osmosis plants driven by renewable energies using genetic algorithms. Renew. Energy 2011, 36, 936–950. [Google Scholar] [CrossRef]

- Gupta, R.; Kumar, R.; Bansal, A.K. BBO-based small autonomous hybrid power system optimization incorporating wind speed and solar radiation forecasting. Renew. Sustain. Energy Rev. 2015, 41, 1366–1375. [Google Scholar] [CrossRef]

- Yang, D.; Kleissl, J.; Gueymard, C.; Pedro, H.T.; Coimbra, C.F. History and trends in solar irradiance and PV power forecasting: A preliminary assessment and review using text mining. Sol. Energy 2018, 168, 60–101. [Google Scholar] [CrossRef]

- Liu, H.; Mi, X.; Li, Y. Smart deep learning based wind speed prediction model using wavelet packet decomposition, convo-lutional neural network and convolutional long short term memory network. Energy Convers. Manag. 2018, 166, 120–131. [Google Scholar] [CrossRef]

- Sharma, A.; Kakkar, A. Forecasting daily global solar irradiance generation using machine learning. Renew. Sustain. Energy Rev. 2018, 82, 2254–2269. [Google Scholar] [CrossRef]

- Cabrera, P.; Carta, J.A.; González, J.; Melián, G. Artificial neural networks applied to manage the variable operation of a simple seawater reverse osmosis plant. Desalination 2017, 416, 140–156. [Google Scholar] [CrossRef]

- Cabrera, P.; Carta, J.A.; González, J.; Melián, G. Wind-driven SWRO desalination prototype with and without batteries: A performance simulation using machine learning models. Desalination 2018, 435, 77–96. [Google Scholar] [CrossRef]

- Little, M.; Thomson, M.; Infield, D. Electrical integration of renewable energy into stand-alone power supplies incorporating hydrogen storage. Int. J. Hydrogen Energy 2007, 32, 1582–1588. [Google Scholar] [CrossRef]

- Siddiqui, O.; Dincer, I. Examination of a new solar-based integrated system for desalination, electricity generation and hydrogen production. Sol. Energy 2018, 163, 224–234. [Google Scholar] [CrossRef]

- Astolfi, M.; Mazzola, S.; Silva, P.; Macchi, E. A synergic integration of desalination and solar energy systems in stand-alone microgrids. Desalination 2017, 419, 169–180. [Google Scholar] [CrossRef]

- Abunayyan, M. The Elements Needed to Achieve Lower Desalination Tariffs; IDA Global Connections Summer: Topsfield, MA, USA, 2021. [Google Scholar]

- Technical Review Middle East. DEWA Receives Record Low Tariff Hassyan Sea Water RO Plant. Available online: https://www.technicalreviewmiddleeast.com/power-a-water/water-a-environment/dewa-receives-record-low-tariff-hassyan-sea-water-ro-plant (accessed on 15 March 2022).

- PRODES Partners. Roadmap. Available online: http://www.prodes-project.org/fileadmin/Files/ProDes_Road_map_on_line_version.pdf (accessed on 14 May 2018).

| Country | Year | Feed Water | Permeate Production [m3/d] |

|---|---|---|---|

| Australia | 2011 | BW | 4.8 |

| USA | 2012 | BW | 75 |

| Egypt | 2012 | BW | 5 |

| Jordan | 2012 | BW | 5.7 |

| Jordan | 2012 | BW | 5.7 |

| Tunisia | 2013 | BW | 1800 |

| Qatar | 2013 | SW | 12,000 |

| Vanuatu | 2013 | SW | 96 |

| Vanuatu | 2013 | SW | 96 |

| Mexico | 2014 | BW | 840 |

| Mexico | 2014 | BW | 48 |

| Brazil | 2014 | BW | 3600 |

| UAE | 2015 | SW | 200 |

| India | 2015 | BW | 1.04 |

| India | 2015 | BW | 1.068 |

| India | 2015 | BW | 1.68 |

| India | 2015 | SW | 0.64 |

| Qatar | 2015 | BW | 100 |

| Malaysia | 2016 | BW | 5.1 |

| Jordan | 2016 | BW | 13–63 |

| Turkey | 2017 | SW | 24 |

| Cape Verde | 2021 | SW | 120 |

| Type of Feed Water & Associated Power Demand for a Nominal Flow of 1 m3/h | Energy Storage to Cover One Day Operation (8 h) Without Solar Energy | PV Field to Feed the Energy Storage (70% of Efficiency and 5 Peak Solar Hours) | Inverter Power (Internal Efficiency: 0.9) |

|---|---|---|---|

| Seawater (SW), 4 kW (3 kW for RO—with ERD—and 1 kW for the feed water pump) | 667 Ah (4000 W × 8 h/48 V) | 9.1 kWp (4 kW/0.7 × 8 h = 45.7 kWh; 45.7 kWh/5 h) | 4.4 kW (4 kW/0.9) |

| Brackish Water (BW), 2–2.5 kW | 334 Ah | 4.5 kWp | 2.2 kW |

| Power | Reference | Associated RO Capacity |

|---|---|---|

| 24 kW | 3 phase off-grid system [31] | 5.7 m3/h (SW) 11.36 m3/h (BW) |

| Treatment | Objective | Possible Compounds | Recommended Dosing |

|---|---|---|---|

| Chlorination | Biocide to avoid fouling | NaClO or Ca(ClO)2 or Cl2O | Depending on the type of raw water and the physical pre-treatment |

| Acidification | pH adjustment to prevent scaling and enhance the biocide activity | H2SO4, HNO3, or HCl | The required for a pH of 5.5–6 |

| Anti-scaling dosing | Avoid the solid deposits of low solubility salts (BaSO4, CaSO4, SrF2, among others) | Na hexametaphosphate, among many other compounds | Depending on the concentration of the low solubility salts and the recovery ratio |

| De-chlorination | Avoid damage to the membranes due to the presence of free chlorine | Either active carbon filter or sodium meta-bisulphite dosing | Dosing is regulated by measuring the residual free chlorine or REDOX |

| Flocculation | Increase the retention of particles in case of high levels of suspended solids | FeCl3 or Al2(SO4)3 | Optimal dosing adjusted experimentally until reaching the appropriate turbidity |

| Manufacturer/Model | Brine Flow [m3/h] | Efficiency (%) | Reference | SEC * (kWh/m3) |

|---|---|---|---|---|

| Danfoss i-Save | 7–52 (several models) | Up to 93–95 | [40] | n.a. |

| KSB/4 in 1 system | 12.6 | n.a. | [41] | n.a. |

| Danfoss (APP-APM, Axial Piston Pump-Motor) | 3.1 | n.a. | [30] | 2.16 |

| Clarck pump | 24 L/h (product flow) | n.a. | [42] | 3.6 |

| ERI | 45–68 | 96.1–97.8 | [43] | 2.35 |

| RO Kinetic | 8 and 40 | Close to 98 | [44] | 2–2.5 |

| Raw Water and Energy Data | |||

|---|---|---|---|

| Physical Properties | Chemical Properties | RE Resources | Water Demand |

|

|

|

|

| Other Data | |||

| Geographic information | State of possible existent infrastructure of water & energy supply | Economic data | Social data |

|

|

|

|

| Indication | Possible Causes | Recommended Actions |

|---|---|---|

| 1. Increase of the specific energy consumption | i. Loss of efficiency in pumps ii. Reduction in product flow iii. Reduction in inlet pressure iv. Increase in pressure drop through the membranes (fouling or scaling) | i. Check the internal components of the pump (impeller, bearings, fan) to find friction points and/or overheating ii. See indication 3 iii. Check pressure drop in filters and clean or replace filtering material iv. Chemical cleaning or replacement of affected modules |

| 2. Increase of the product water conductivity | v. Malfunction in membrane elements vi. Possible brine leakage inside the pressure vessels | v. Replacement of damaged elements vi. Check the internal connections between elements for possible damage in O rings. |

| 3. Reduction of the product flow | vii. Insufficient feed flow viii. Insufficient inlet pressure to membranes ix. Product flow to brine current | vii. Check feed pump, pressure drop in filters, or level of raw water well viii. Check the high-pressure pump |

| Component | Problem | Solution |

|---|---|---|

| Synchronous machine coupled to the flywheel | Difficult starting of the stand-alone grid under low wind conditions. Insufficient power in specific moments (under a high decrease of wind speed). Overheating and excessive friction losses. | Inclusion of a variable speed starting-up motor to initiate the movement. Proposed replacement of the installed flywheel by a friction-less (vacuum operation) high-speed flywheel. Selection of tough and efficient mechanical supports and bearings. |

| Wind generator | Corrosion on the outside metal components. Failure in the blade motors due to the continuous regulation of the pitch angle to control the output power. | Selection of specific high quality materials. Consider extra motors as spare parts. Improvements on the control software to minimize the stress on the blade motors. |

| Feed water system | Variations in the feed water pressure due to the variable connection of the different RO units. | Extend the operation range of feed pressure to the RO units. |

| RO plants | Sudden reduction of operation pressure after stops. | Proposed installation of an automatic needle valve for appropriate pressure control. |

| Control system | Malfunction in control PC due to the simultaneous monitoring and control software in the same hardware. | Suggested use of specific control and monitoring software in different hardware. |

| Component | Problem | Solution |

|---|---|---|

| PV field | Corrosion on metallic surfaces. Solar tracking systems were damaged due to wind load. | Proposed use of other materials for structures. Installation of plastic walls as windbreakers. |

| Batteries | Failure of module. | Replacement by a new module; meanwhile, operation without the damaged module was temporally implemented but at lower DC voltage (updating of control and converters setup was required). |

| Converters | High local temperature (50 °C) in Tunisia. | Construction of a partially buried building to use the soil as natural thermal isolation. |

| RO plants | High temperature of raw water (>35 °C) in Tunisia Reduction in the water quality and quantity in comparison with the nominal values after 8 years of operation Water production is higher than demand. | Installation of a feed water tank before the RO membranes to store feed water and slightly reduce the temperature. Proposed increase of the frequency of chemical cleanings. Proposed use of water surplus by sending water to nearby communities, services or for watering. Another option would be to use part of the electricity to power other loads, such as lighting. |

| Control system | Start/stop sequences of RO unit and batteries operation are not optimal. | New control software setup is recommended. |

| Pros | Cons |

|---|---|

| More power at all times, i.e., more energy per day. | Not all locations are appropriate, since simultaneous availability of solar and wind resources are required. |

| More operation time, i.e., more water production. | Two types of generation systems with very different variability in power production, maintenance requirements and operation performance. |

| Probable reduction in water cost, in comparison with a system based on only one RE source. | More complex control & monitoring systems to check the power balance and reach a stable operation. |

| Location | PV Power | Wind Power | RO Capacity | Batteries Storage | Reference |

|---|---|---|---|---|---|

| CRES facilities CRES (Lavrio, Greece) | 3.96 kWp | 900 W | 130 L/h | 1800 Ah/100 h | [52] |

| ITC facilities ITC (Pozo Izquierdo, Gran Canaria, Spain) | 600 Wp | 890 W | 154 L/h | 868 Ah/100 h | [4] |

| Component | Nominal Size | Specific Cost (€) | Reference Year | Location | Ref. |

|---|---|---|---|---|---|

| Flywheel and synchronous machine | 100 kVA | 224 €/kVA | 1997 | Gran Canaria Island, Spain | [53] |

| Wind farm (only the wind generators) | 2 × 230 kW | 828 €/kW | 1999 | Gran Canaria Island, Spain | [53] |

| RO plant SW (1 m3/h) | 30 m3/d | 1200 €/installed daily m3 | 2007 | Gran Canaria Island, Spain | [53] |

| Complete PV-RO system | 50 m3/d | 5230 €/installed daily m3 | 2007 | Ksar Ghilène, (Tunisia) | [9] |

| Off-grid inverter | 4 kW | 433 €/kW (nominal power) | 2008 | Sidi Ifni, (Morocco) | [54] |

| Batteries & associated charge controllers | 650 Ah | 6.6 €/Ah | 2008 | Sidi Ifni, (Morocco) | [54] |

| RO plant of brackish water (BW) | 24 m3/d | 1045 €/installed daily m3) | 2008 | Sidi Ifni, (Morocco) | [54] |

| PV system (modules, batteries, converters, cabling, structure) | 4 kWp | 5 €/Wp | 2008 | Sidi Ifni, (Morocco) | [54] |

| Complete PV-RO system | 3 × 24 m3/d + 12 m3/d | 4250 €/installed daily m3 | 2008 | Four villages in Morocco (Provinces of Essaouira and Tiznit) | [9] |

| Small wind generator | 4–20 kW | 2.3–6.2 €/W (nominal power) | 2012 | Public data prices | [53] |

| Solar kit for off-grid supply | 5 kWp | 2.16 €/Wp | 2018 | Public data prices | [55] |

| Maintenanceless gel batteries | 41–200 Ah C100 | 1.6–2 €/Ah | 2018 | Public data prices | [55] |

| Off-grid inverter | 8 kW | 404 €/kW (nominal power) | 2018 | Public data prices | [55] |

| Investment Costs | Operation Costs | Incomes |

|---|---|---|

|

|

|

| Type of Plant | RE Power (kW) | Water Production | Total Water Cost | Place | Commissioning Year (Estimation) | Ref. |

|---|---|---|---|---|---|---|

| PV-SWRO | 100 | 5 m3/h | 6 €/m3 | Lampedusa (Italy) | 1990 | [57] |

| Wind-PV SWRO | 0.6 (Wind) + 3.5 (PV) | 125 L/h | 7.53 €/m3 | Maagan (Israel) | 1999 | [57] |

| PV-BWRO | 1.1 | 250 L/h | 10.32 €/m3 | Ceara, Brazil | 2000 | [57] |

| PV-SWRO | 4.8 | 400 L/h | 9 €/m3 | Pozo Izquierdo, Gran Canaria (Spain) | 2000 | [57] |

| Wind-SWRO | 2.5 | 500 L/h | 1.78 €/m3 | R&D test Loughboroug University (UK) | 2003 | [57] |

| Wind-SWRO | 15 | 800 L/h | 3–5 €/m3 | Pozo Izquierdo, Gran Canaria Island (Spain) | 2004 | [57] |

| PV-BWRO | 10.5 | February: 3.3–8.3 m3/d August: 6.6–12.8 m3/d | 3 €/m3 | Ksar Ghilène (Tunisia) | 2006 | [47] |

| PV-BWRO (4 units) | 2.5–4 | 3–6 m3/d | 5.45 €/m3 (average value) | 4 villages in Morocco | 2008 | [51] |

| PV-SWRO | 2.4 | 3–5 m3/d | 2 UK pounds/m3 | Case study for Eritrea | n.a. | [48] |

| PV-SWRO | 243 | 250 m3/d | 2.2–3.2 USD/m3 | Theoretical study | n.a. | [58] |

| Wind-SWRO | n.a. | 250 m3/d | 3–4 US$/m3 (case of 2000 full load hours/year) | Theoretical study | n.a. | [58] |

| 60Wind-SWRO | 15 | 10.5 m3/d (anual average) | 3.8 €/m3 | Theoretical study | n.a. | [59] |

| PV-Diesel SWRO | 12 (Diesel) + 18 (PV) | 10 m3/d | 1.6–2.4 USD/m3 | Theoretical study | n.a. | [60] |

| Wind-PV SWRO | Several | Several | 1–2 €/m3 | Forecast study for 2030 | n.a. | [56] |

| Generation System | RO Plant | Energy Storage System |

|---|---|---|

|

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subiela-Ortín, V.J.; Peñate-Suárez, B.; de la Fuente-Bencomo, J.A. Main Technical and Economic Guidelines to Implement Wind/Solar-Powered Reverse-Osmosis Desalination Systems. Processes 2022, 10, 653. https://doi.org/10.3390/pr10040653

Subiela-Ortín VJ, Peñate-Suárez B, de la Fuente-Bencomo JA. Main Technical and Economic Guidelines to Implement Wind/Solar-Powered Reverse-Osmosis Desalination Systems. Processes. 2022; 10(4):653. https://doi.org/10.3390/pr10040653

Chicago/Turabian StyleSubiela-Ortín, Vicente J., Baltasar Peñate-Suárez, and Juan A. de la Fuente-Bencomo. 2022. "Main Technical and Economic Guidelines to Implement Wind/Solar-Powered Reverse-Osmosis Desalination Systems" Processes 10, no. 4: 653. https://doi.org/10.3390/pr10040653

APA StyleSubiela-Ortín, V. J., Peñate-Suárez, B., & de la Fuente-Bencomo, J. A. (2022). Main Technical and Economic Guidelines to Implement Wind/Solar-Powered Reverse-Osmosis Desalination Systems. Processes, 10(4), 653. https://doi.org/10.3390/pr10040653